Page 1

FormNo.3393-645RevC

g027913

TimeCutter

®

SW3200Riding

Mower

ModelNo.74670—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3393-645*C

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

G014523

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

GrossHorsepower

Thegrossornethorsepowerofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewiththe

SocietyofAutomotiveEngineers(SAE)J1940.Ascongured

tomeetsafety ,,andoperatingrequirements,theactualengine

torqueonthisclassofmowerwillbesignicantlylower.

Gotowww .Toro.comtoviewspecicationsonyourmower

model.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

Introduction

Thismachineisaride-on,rotary-bladeintendedtobeused

byhomeownersinresidentialapplications.Itisprimarily

designedforcuttinggrassonwell-maintainedlawns.Itisnot

designedforcuttingbrush,mowinggrassandothergrowth

alongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

Model74670...........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................13

Controls...............................................................13

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngine-oilLevel..................................16

BreakinginaNewMachine......................................16

ThinkSafetyFirst...................................................17

StartingtheEngine.................................................19

OperatingtheParkingBrake(SmartPark

OperatingtheBlades...............................................19

StoppingtheEngine...............................................20

DrivingtheMachine...............................................20

StoppingtheMachine.............................................20

MowinginReverse.................................................21

AdjustingtheHeight-of-Cut....................................21

PositioningtheSeat................................................22

PositioningtheSteeringWheel.................................22

PushingtheMachinebyHand..................................22

ConvertingtoSideDischarge...................................23

TransportingtheMachine........................................24

LoadingtheMachine..............................................24

OperatingTips......................................................26

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

PremaintenanceProcedures........................................27

RaisingtheSeat......................................................27

ReleasingtheMower-DeckCurtain...........................28

RaisingtheFrontoftheMachine..............................28

Lubrication...............................................................28

GreasingtheBearings.............................................28

EngineMaintenance..................................................29

ServicingtheAirCleaner.........................................29

ServicingtheEngineOil..........................................30

ServicingtheSparkPlug..........................................33

CleaningtheBlowerHousing...................................34

FuelSystemMaintenance...........................................34

ReplacingtheIn-lineFuelFilter................................34

ElectricalSystemMaintenance....................................35

ChargingtheBattery...............................................35

ServicingtheFuses.................................................36

DriveSystemMaintenance.........................................37

CheckingtheTirePressure......................................37

ReleasingtheElectricBrake.....................................37

MowerMaintenance...................................................38

ServicingtheCuttingBlades.....................................38

LevelingtheMowerDeck........................................41

RemovingtheMowerDeck.....................................43

ServicingtheMowerBelt.........................................44

InstallingtheMowerDeck.......................................44

ReplacingtheGrassDeector..................................45

™

)................19

Cleaning...................................................................46

CleaningUndertheFrontoftheMachine...................46

WashingtheUndersideoftheMower........................46

Storage........................................................................47

CleaningandStoringtheMachine.............................47

Troubleshooting...........................................................48

Schematics...................................................................50

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperlyusingormaintainingthismowercanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructions.

Torodesignedandtestedthismowerforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety ,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthemowerreadand

understandthecontentsofthismanualbeforethe

engineiseverstarted.Payparticularattentiontothe

safetyalertsymbol(Figure2)whichmeansCaution,

Warning,orDanger—“personalsafetyinstruction.”

Readandunderstandtheinstructionbecauseithasto

dowithsafety.Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,

substantial,slip-resistantfootwear,longpants,gloves,and

hearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’ sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

4

Page 5

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow .

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownthemachinebeforemakingturnsanduse

extracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatingthemachine

inreverse.

•Donotjerkthesteeringwheel;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan15degrees.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

•Donotcarryequipmentonthemachine.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly.Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

6

Page 7

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Checkthebrakeoperationfrequently.Adjustandservice

thebrakeasrequired.

Model74670

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof87

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand/ArmVibration

Measuredvibrationlevelforlefthand=1.7m/s

Measuredvibrationlevelforrighthand=1.8m/s

UncertaintyValue(K)=0.9m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

WholeBodyVibration

Measuredvibrationlevel=0.51m/s

UncertaintyValue(K)=0.26m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013(RidingandStand-ons).

2

2

2

2

7

Page 8

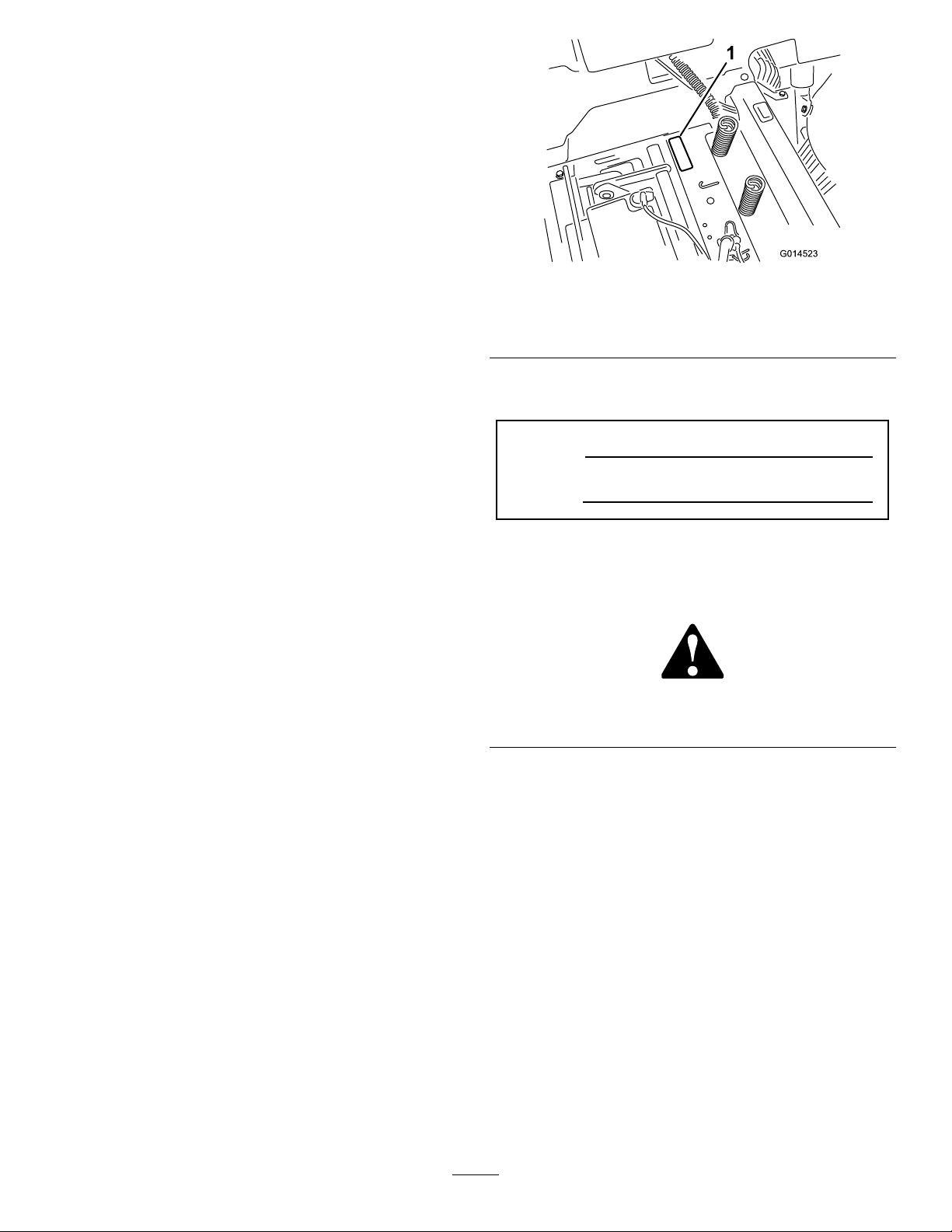

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

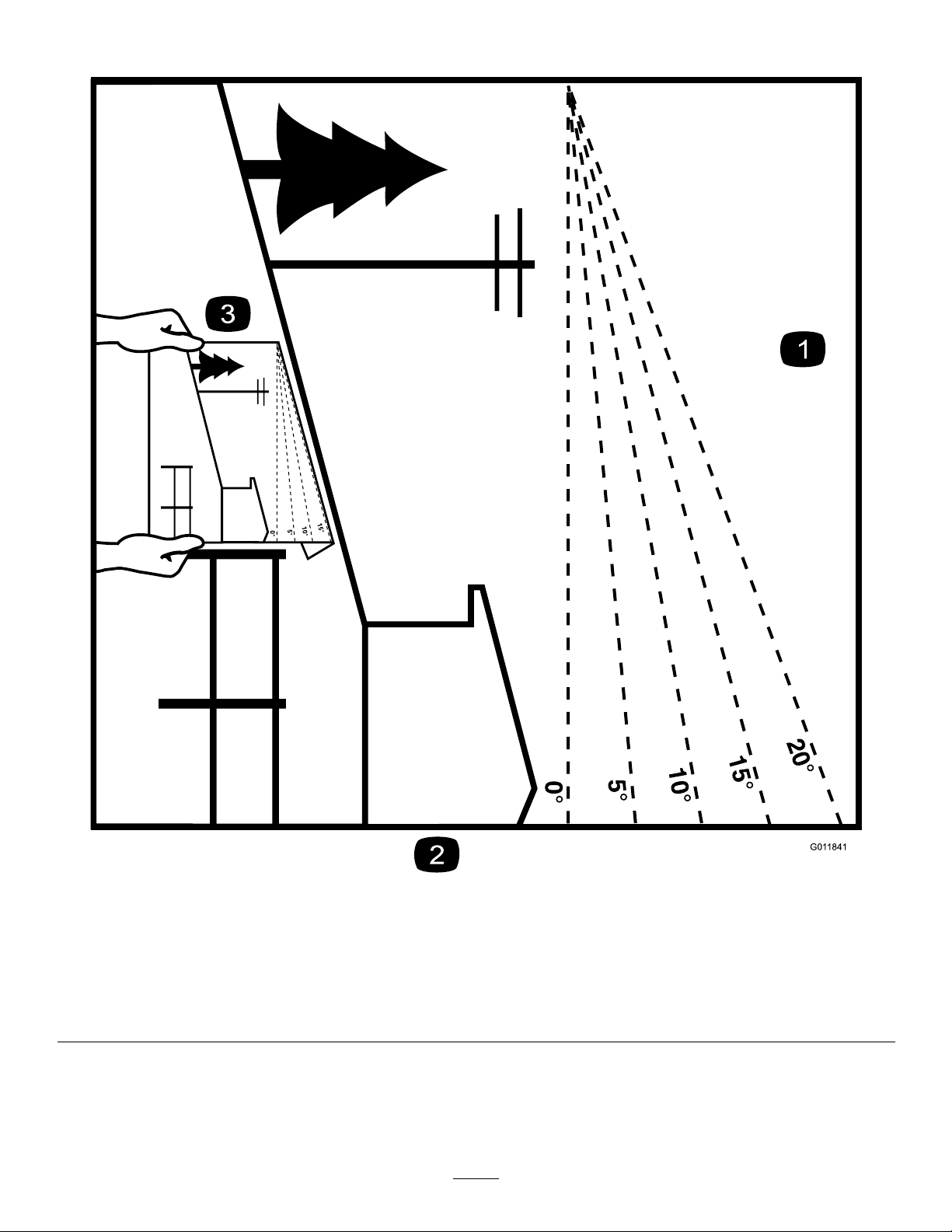

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

120-5469

1.Height-of-cut

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

1.Bypassleverpositionfor

pushingthemachine

9

121-2989

2.Bypassleverpositionfor

operatingthemachine

Page 10

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

131-3665

1.Bladespinning

2.Reverse

3.ReadtheOperator's

Manual.

131-3620

1.Pedalposition—forward

2.Pedalposition—neutral

3.Pedalposition—reverse

131-3955

1.On2.Off

131-4036

131-3621

1.Crushing/dismembermenthazardofbystanders—keep

bystandersawayfromthemachine;donotstartthe

machinewithbystandersnearby.

1.Maximumdrawbarpull80

lbs(36kg)

2.ReadtheOperator's

Manual.

132-6863

10

Page 11

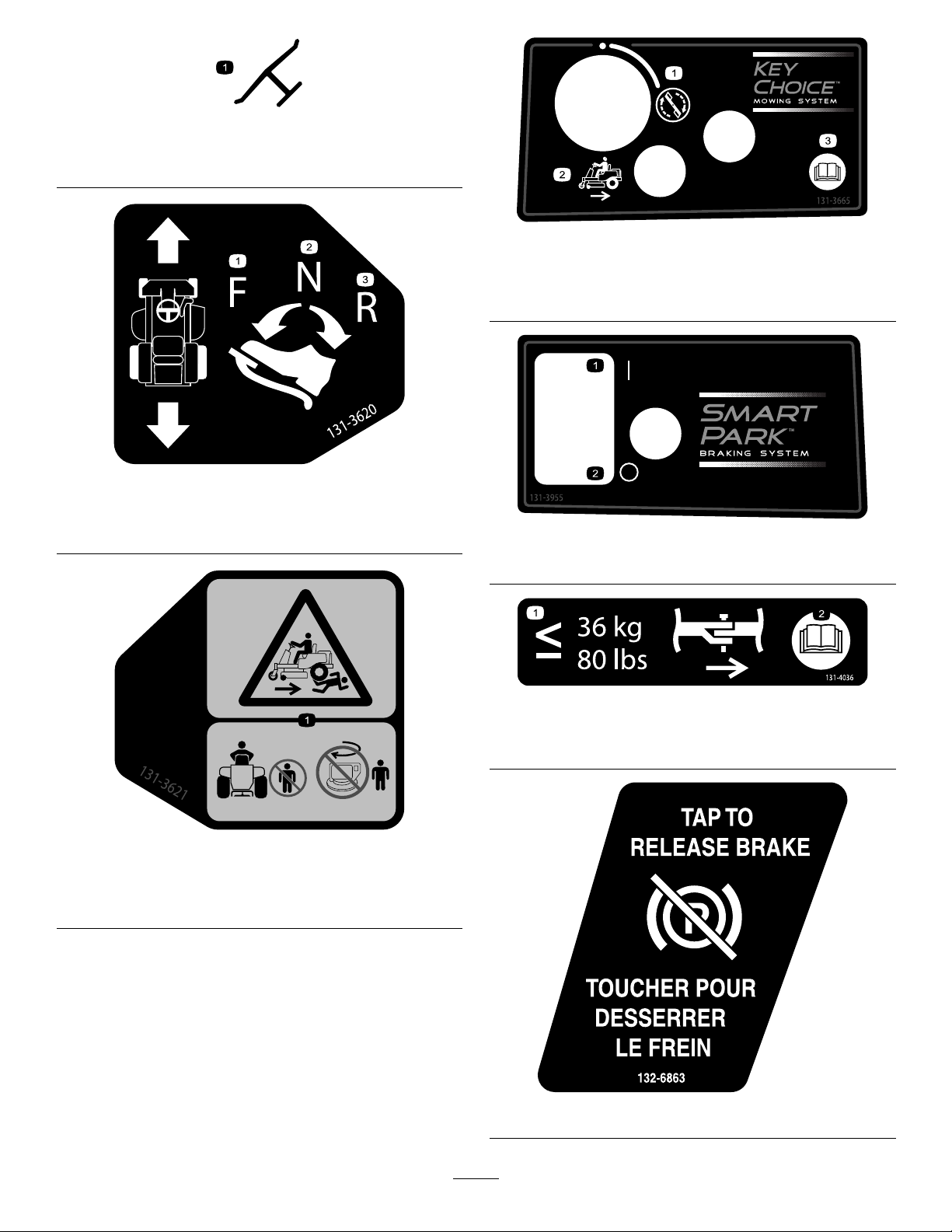

132-0870

1.Warning—readtheOperator'sManual.

2.Cuttinghazardofhand,mowerblade;

pinchinghazardofhand,belt—keep

handsandfeetawayfrommoving

parts;keepallguardsandshieldsin

place.

3.Bodilyharmhazard—noriders;look

behindyouwhenmowinginreverse.

4.Thrownobjecthazard—keep

bystandersawayfromthemachine;

removedebrisfromtheareabefore

mowing;keepthedeectorshield

down.

5.Ramptippinghazard—whenloading

ontoatrailer,donotusedualramps;

onlyuseasinglerampwideenough

forthemachineandthathasanincline

lessthan15degrees;backupthe

ramp(inreverse)anddriveforwardoff

theramp.

6.Tippinghazardonslopes—donot

makesharp,quickturns;donotuse

slopesgreaterthan15degrees.

11

Page 12

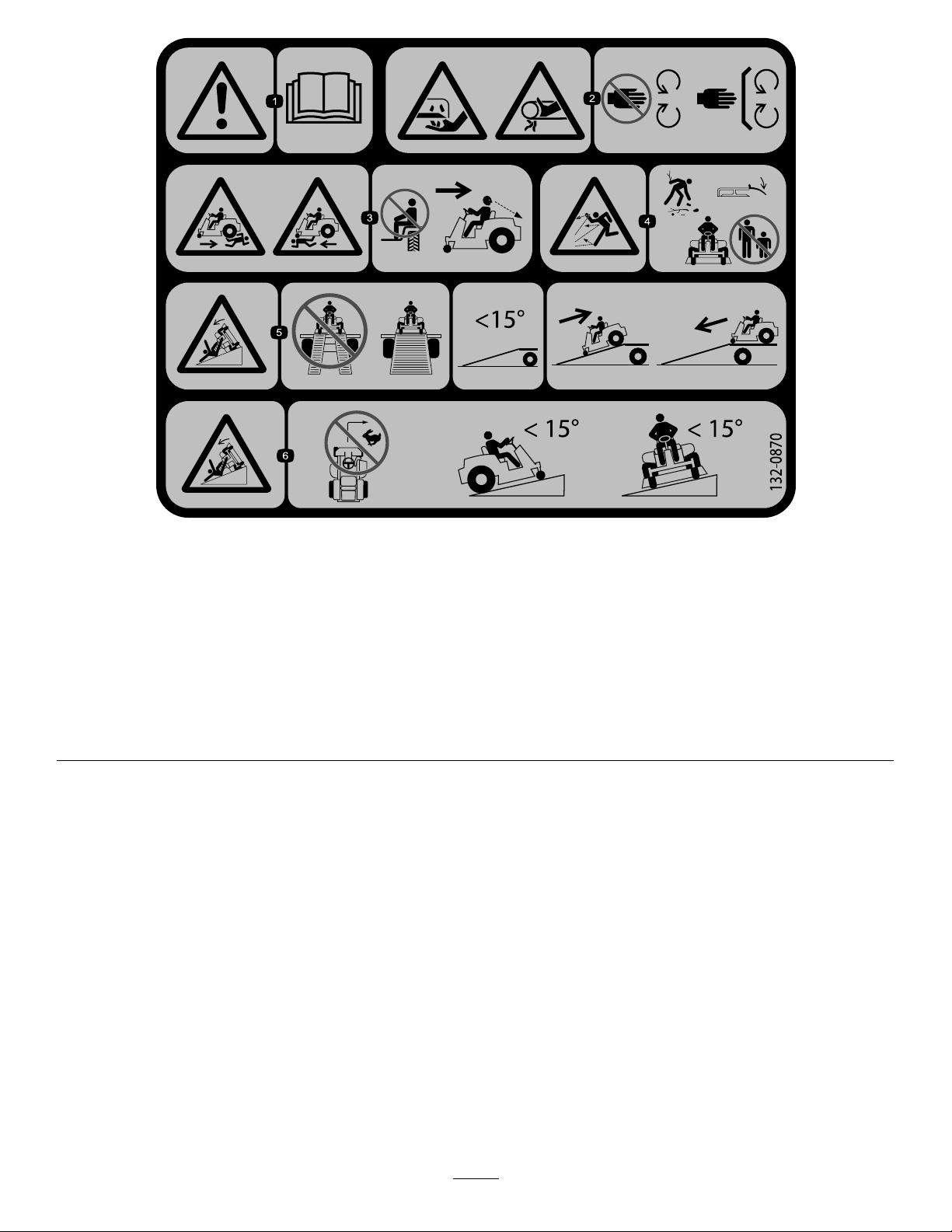

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

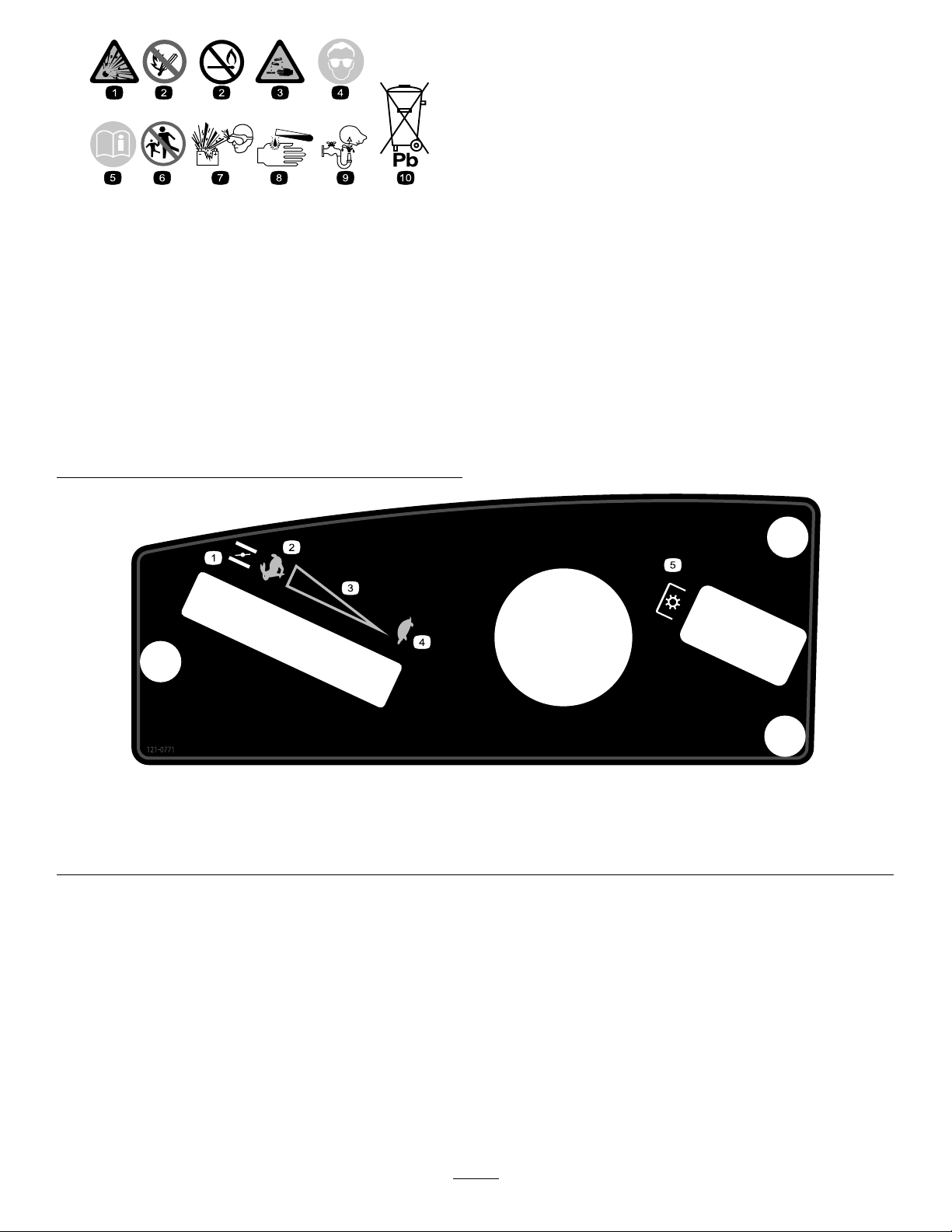

121-0771

1.Choke4.Slow

2.Fast

3.Continuousvariablesetting

12

5.Powertake-off(PTO),Bladecontrolswitch

Page 13

ProductOverview

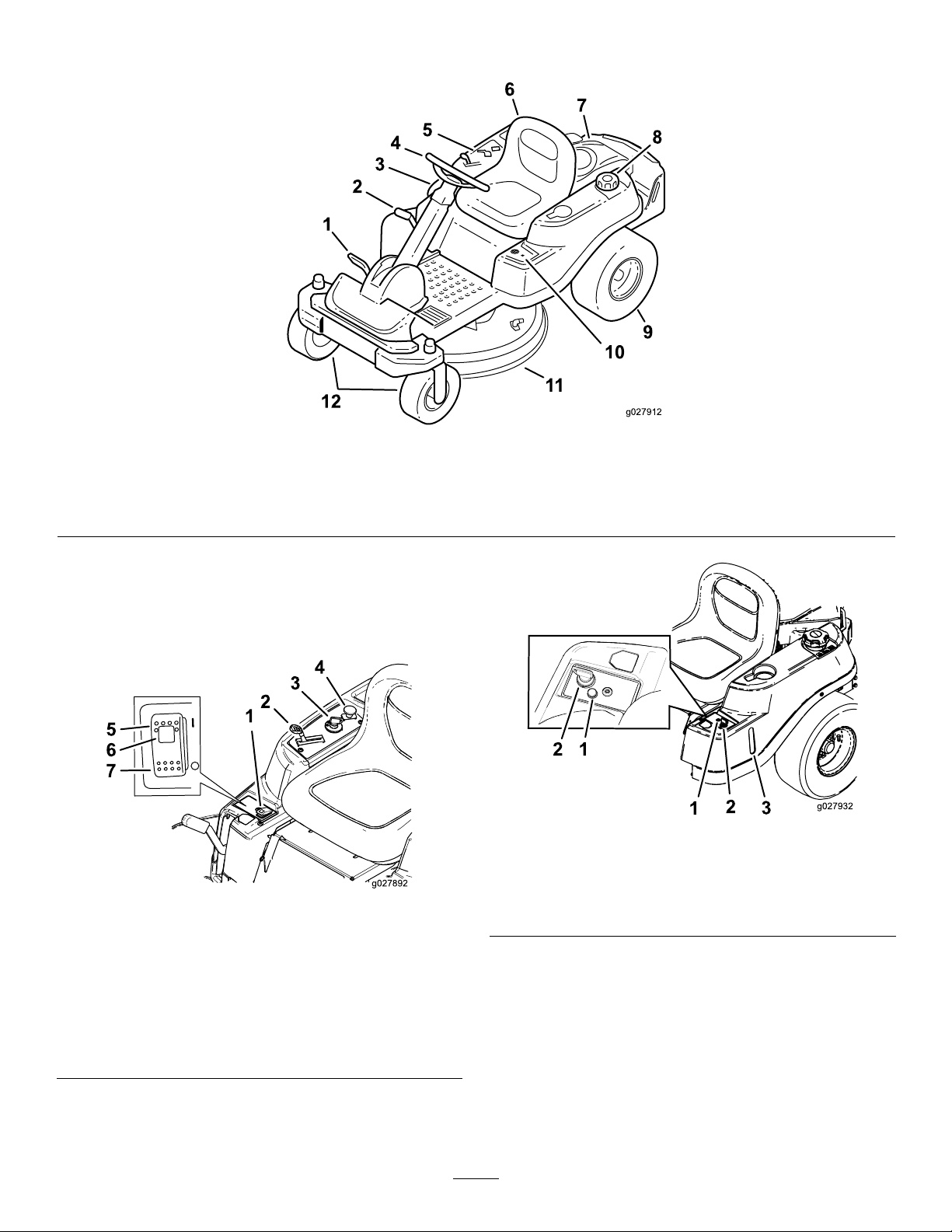

g027912

1

2

4

5

6

7

8

9

11

12

10

3

5

6

7

g027892

1.Traction-controlpedal

2.Height-of-cutlever5.Controlpanel

3.SmartPark

™

switch6.Operatorseat

4.Steeringwheel

Figure4

7.Engine

8.Fuel-tankcap11.Mowerdeck

9.Reardrivewheel12.Frontcasterwheels

10.KeyChoice

®

control

Controls

BecomefamiliarwithallcontrolsinFigure4andFigure5

beforeyoustarttheengineandoperatethemachine.

Figure6

1.Operating–in–Reverse

warninglight

1.Parkingbrakeswitch

2.Throttle/Choke

3.Ignitionswitch

4.Blade-controlswitch

Figure5

ControlPanel

(powertake-off)

5.Parkingbrake—On

6.Parkingbrakeindicator

light

7.Parkingbrake—Off

2.KeyChoicekey(bluein

color)

IgnitionSwitch

Theignitionswitchhas3positions—OFF,RUNandSTART.

ThekeywillturntoSTARTandmovebacktoRUNupon

release.TurningthekeytotheOFFpositionwillstopthe

engine;however,alwaysremovethekeywhenleavingthe

machinetopreventsomeonefromaccidentallystartingthe

engine(Figure5).

3.Fuel-presencewindow

13

Page 14

Throttle/ChokeControl

Thethrottleandchokearecombinedintoonecontrollever.

Thethrottlecontrolstheenginespeedandithasacontinuous

variablesettingfromSlowtoFast.Engagethechokeby

movingtheleverpasttheFastsettinguntilitstops(Figure5).

Blade-ControlSwitch(PowerTake-off)

Theblade-controlswitch,(PTO),engagesanddisengages

powertothemowerblades(Figure5).

Fuel-PresenceWindow

Thefuelwindowlocatedontheleft-handsideofthemachine,

canbeusedtoverifythepresenceofgasolineinthetank

(Figure6).

Height-of-CutLever

Theheight-of-cutleverallowsyoutolowerandraisethedeck

fromtheseatedposition.Whenyouraisethelever(toward

you),thedeckisraisedfromtheground,andwhenyou

lowerit(awayfromyou),itlowerstotheground.Adjustthe

height-of-cutonlywhilethemachineisnotmoving(Figure

14).

KeyChoice

Thisswitchallowsyoutomowinreversewhenitisactivated.

Toactivateit,turntheswitchtoonandreleaseitafterthe

PTOisengaged.T odeactivateit,disengagethepower

take-off(PTO)(Figure6).

®

Switch

Operating–in–ReverseWarningLight

TheOperating–in–Reversewarninglightwillilluminate

whenevertheKeyChoicekeyisusedtodeactivatethe

operating–in–reverseinterlock.Itisareminderthatthe

interlocksystemisdeactivated.Thelightgoesoutwhenever

thePTOisdisengagedortheengineisshutoff.Whenthe

lightison,lookbehindanduseextracautionwhenbacking.

SmartPark

Theparkingbrakeisactivatedelectronically.

Engagetheparkingbrakebyoneofthefollowingactions:

•PressingtheSmartPark

(Figure5).

•Theparkingbrakeengagesautomaticallywhenthe

operatorleavestheseatandthetractioncontrolpedal

isinneutralposition.

•Theparkingbrakeautomaticallyengages5to6seconds

aftertheignitionswitchisturnedtotheOFFposition(if

notalreadyengaged).

™

Switch

™

switchtotheONposition

Todisengagetheparkingbrake,presstheSmartparkswitch

totheOFFpositionwiththekeyintheRUNposition.

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

15

Page 16

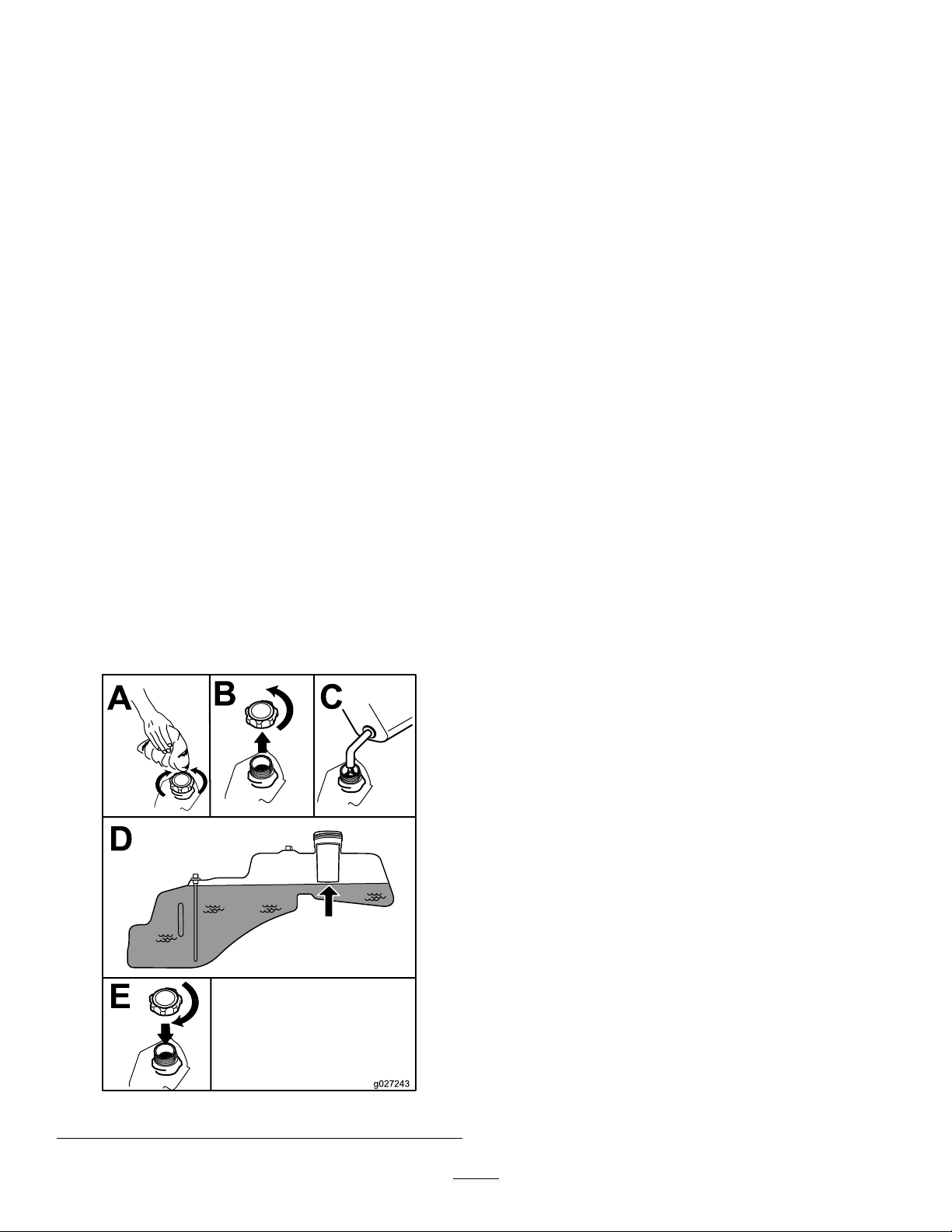

UsingStabilizer/Conditioner

g027243

A

B

E

D

C

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

FillingtheFuelTank

Note:Ensurethattheengineisshutoffandthemotion

controlsareintheparkedposition.

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page30).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

Note:Youcanusethefuelwindowtoverifythepresenceof

gasolinebeforellingthetank(Figure7).

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakage,damagetotheengine,ordamagetothe

emissionssystem.

Figure7

16

Page 17

ThinkSafetyFirst

g027830

G009027

1

2

CAUTION

OperatingSafety

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily ,pets,orbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducethespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure9

1.Wearsafetyglasses

2.Wearhearingprotection

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Figure8

1.Safezone—usethe

TimeCutterhere

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

3.Water

17

Page 18

UnderstandingtheSafety-Interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedforthefollowing:

•Topreventtheenginefromstartingunlessthetraction

pedalisintheneutralposition.

•Toautomaticallyensurethattheparkingbrakeisengaged

andthePTOisoffwhenstarting.

Note:Theengineshouldremainrunning.

9.Returntotheseat,disengagetheparkingbrakeby

pushingtheSmartParkswitchtotheOFFposition.

Note:Theengineshouldremainrunning.

10.Raisefromtheseat.

Note:Thebrakeshouldautomaticallyengageandthe

engineshouldremainrunning.

11.Returntotheseat,engagethebladesbypullingupon

theblade-controlswitch.

12.Raisefromtheseat.

Note:Thebladesshoulddisengageandtheengine

shouldremainrunning.

13.Returntotheseat,andpullthebladecontrolswitchup.

Note:Thebladesshouldengage.

14.Pushdownontheblade-controlswitch.

•Tostoptheenginewheneverthetractionpedalisnotin

theneutralpositionandyourisefromtheseat.

•Toautomaticallyengagetheparkingbrakeanddisengage

thePTO ,whenyouriseoutoftheseatwiththetraction

pedalintheneutralposition.

•Tostoptheenginewhenevertheparkingbrakeisnot

engagedandyourisefromtheseat.

TestingtheSafety-interlockSystem

1.Whilesittingontheseat,movetheblade-control

switchtoOFF.

2.TurntheignitionkeytotheSTARTposition.

Note:Thestartershouldcrank.

3.PushtheSmartParkswitchtotheOFFposition.

Note:Thebrakeshoulddisengage,andthebrakelight

shouldturnoff.

4.Withbrakedisengagedandtractionpedalinneutral,

turntheignitionswitchtotheSTARTposition.

Note:Thebrakeshouldautomaticallyengage,the

engineshouldcrank,andthebrakelightwillturnon.

5.EngagethePTObypullingupontheblade-control

switch.

6.Ensurethetractionpedalisinneutralandturnignition

switchtotheSTARTposition.

Note:ThePTOshoulddisengageandtheengine

shouldcrank.

7.Ensurethetractioncontrolpedalisintheneutral

positionandstarttheengine.

Note:Thebladesshoulddisengage.

15.Engagethebladesbypullingupontheblade-control

switch.

16.Movetractionpedaltoreverse.

Note:Thebladesshoulddisengage.

17.Engagethebladesbypullingupontheblade-control

switch.

18.TurntheKeyChoiceswitchtoONandrelease.

Note:Theoperatinginreverselightshouldilluminate.

19.Movethetractionpedaltoreverse.

Note:Thebladesshouldremainengaged.

20.PushthePTOswitchtotheOFFposition.

Note:Thebladesshouldturnoffandthereverse

warninglightshouldturnoff.

21.EngagetheparkingbrakebypushingSmartParkswitch

totheONposition.

Note:Thebrakeshouldengageandthebrakelight

shouldbeon.

22.Pushandreleasethetractionpedalineithertheforward

orreversedirection.

Note:Thebrakeshoulddisengageandthebrakelight

shouldturnoff.

23.Raisefromtheseat,andpushthetractionpedalto

eithertheforwardorreversedirection.

Note:Theengineshouldkill.

8.Raisefromtheseat.

18

Page 19

StartingtheEngine

g027899

B

C

D

E

A

F

g027901

g027247

Note:Itmaybenecessarytoholdtheleveragainstthestop,

intheCHOKEposition,whiletryingtostarttheengine.

•Tapthetraction-controlpedalforwardorreverse.

•PressingthebrakeswitchtotheOFFposition(Figure5).

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformorethan

5secondsatatime.Engagingthestartermotorfor

morethan5secondscandamagethestartermotor.If

theenginefailstostart,wait10secondsbeforeoperating

theenginestarteragain.

OperatingtheBlades

Theblade-controlswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades.Thisswitchcontrolspowertoanyattachmentsthat

drawpowerfromtheengine,includingthemowerdeckand

cuttingblades.

EngagingtheBlades

Important:Donotengagethebladeswhenparkedin

tallgrass.Beltorclutchdamagecanoccur.

Note:Alwaysengagethebladeswiththethrottleinthe

FASTposition.

Figure10

OperatingtheParkingBrake

™

)

™

switchtotheONposition

(SmartPark

Theparkingbrakeisactivatedelectronically.

Engagetheparkingbrakebyoneofthefollowingactions:

•PressingtheSmartPark

(Figure5).

•Theparkingbrakeengagesautomaticallywhenthe

operatorleavestheseatandthetractioncontrolpedalis

intheneutralposition.

•Theparkingbrakeautomaticallyengages5to6seconds

aftertheignitionswitchisturnedtotheOFFposition(if

notalreadyengaged).

Disengagetheparkingbrakebyoneofthefollowingactions:

Figure11

DisengagingtheBlades

Figure12

1.Controlpanel2.Blade-controlswitch—Off

19

Page 20

StoppingtheEngine

1.Disengagethebladesbypushingtheblade-control

switchtoOFF(Figure12).

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytoOFFandremovethekey .

DrivingtheMachine

Thismachinehasthecharacteristicsofbothagardentractor

andazero-turnmachine.Likeagardentractor,themachine

hasafootpedalthatcontrolstheforwardandreversemotion

alongwiththespeed,andithasasteeringwheelthatcontrols

thedirectionandtheturningradius.Likeazero-turnmachine,

thereardrivewheelsoperateindependentlyofeachother,

enablingyoutomakesharpturnsandtoturnindifferent

directionsquickly.Thesecharacteristicsvastlyimprovethe

maneuverabilityofthemachine,buttheymayalsorequire

youtopracticedrivingifyouareunfamiliarwiththistypeof

machine.

WARNING

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofthemachineandcausepersonal

injuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFASTpositioncanbebestforperformance.Formost

applications,operatinginthefull-throttlepositionisdesirable.

Figure13

1.Forward3.Backward

2.Traction-controlpedal

4.Toslowdown,releasethepressureonthe

traction-controlpedal.

StoppingtheMachine

Tostopthemachine,releasethetraction-controlpedal,

disengagetheblade-controlswitch,ensurethethrottleisin

theFASTposition,settheparkingbrakeandturntheignition

keytoOFF.

Note:Remembertoremovethekeyfromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

DrivingForwardorBackward

1.MovethethrottletotheFASTposition.

2.Releasetheparkingbrake.RefertoOperatingthe

ParkingBrake(SmartPark

3.Placeyourfootontothetraction-controlpedaland

slowlypressthetopofthepedaltogoforward,or

pressonthebottomofthepedaltomovebackward

(Figure13).

Note:Thefartheryoumovethepedalineither

direction,thefasterthemachinewillmoveinthat

direction.

™

)(page19).

20

Page 21

MowinginReverse

AdjustingtheHeight-of-Cut

Themachinehasaninterlockfeaturethatpreventsthemower

deckfrommowingwhilethemachineistravelinginreverse.

IfyoushiftintoreversewiththePTOengaged,thePTO

willstop.Ifyouneedtomowwhileinreversegear,youcan

temporarilydeactivatethisinterlock.

Note:Donotmowwhilebackingupunlessitisabsolutely

necessary.

DANGER

Achildorbystandercouldbebackedoverbya

ridingmowerwithbladesengagedandcause

seriouspersonalinjuryordeath.

•Donotmowinreverseunlessabsolutely

necessary.

•Alwayslookbackwardanddownbeforebacking

up.

•UsetheKeyChoiceswitchonlyifyouarecertain

nochildrenorotherbystanderswillappearin

themowingarea.

•AlwaysremoveboththeignitionandKeyChoice

keysandputtheminasafeplaceoutofthe

reachofchildrenorunauthorizeduserswhen

leavingtheunitunattended.

Note:Thetransportpositionisthehighestheight-of-cut

positionorcuttingheight115mm(4.5inches)asshownin

Figure14.

Ifyouarecertainthatyoucansafelymoworoperatean

attachmentinreverse,completethefollowingprocedure:

1.InserttheKeyChoicekeyintotheKeyChoiceswitch

(Figure6).

2.EngagethePTO .

3.TurntheKeyChoicekeyclockwiseuntilitstopsand

releaseit.

Note:Aredlightilluminatesontheconsoletoserve

asareminderthattheinterlockhasbeendeactivated.

4.Performthemowing.

5.Whennishedmowing,removetheKeyChoicekey

(Figure6).

Note:Onceyoudeactivatetheinterlock,itstaysin

thismode—withyourmowerbladeorPTOpowered

attachmentoperatingwheneveryoubackup—andthe

consolelightstaysonuntilyoueitherdisengagethe

PTOorturnofftheengine.

Figure14

21

Page 22

PositioningtheSeat

g027249

B

C

A

g027751

B

A

g017303

1 2

3

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,theignitionkeyneedstobeintheRUNposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengage.

PushingtheMachine

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure17).

Figure15

PositioningtheSteeringWheel

Thesteeringwheelhas3positionsforoperationandone,

full-upposition.Usethefull-uppositionforsteppingonand

offthemachineandgettingoutoftheseat.Whenoperating

themachine,positionthesteeringwheelwhereyouhavethe

bestcontrolofthemachineandaremostcomfortable.

1.Pressyourfootontothesteering-columnreleaselever.

2.Positionthesteeringwheeltothedesiredposition

(Figure16).

Note:Ensurethisisdoneforeachlever.

5.Turntheignitionkeyonanddisengagetheparking

brake.

Note:Donotstartthemachine.

Note:Themachineisnowabletobepushedbyhand.

Figure17

Figure16

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeenreturnedto

theSTOPpositiontoavoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Ifnecessary,theelectricbrakecanbereleased

manually;refertoReleasingtheElectricBrake(page37).

22

3.Leverpositionforpushing

themachine

Page 23

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure17.

Note:Ensurethisisdoneforeachlever.

ConvertingtoSideDischarge

Thismowerdeckhastheoptiontobeoperatedinthe

side-dischargemode.Removethedischargecoverfor

operatingintheside-dischargemode.

RemovingtheDischargeCoverforSide

Discharge

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Removethewingnutandboltsecuringthecoverin

place(Figure18).

InstallingtheDischargeCoverfor

Mulching

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Liftthegrassdeectorandplacethedischargecover

overtheopeningontothelowerlipofthemowerand

slideitintothefronthinge(Figure18).

4.Slidethehingepinthroughthehinge(Figure18).

5.Securethedischargecovertothemowerwiththewing

nut(Figure18).

6.Lowerthegrassdeectoroverthedischargeopening.

Note:Retainallofthepartsforfutureuse.

Figure18

1.Grassdeector

2.Dischargecover5.Wingnut

3.Lowerlip

4.Hingepin

4.Removethehingepinsecuringthecovertothedeck

(Figure18).

5.Liftthecoveroutandawayfromthedeck.

6.Lowerthegrassdeectoroverthedischargeopening.

Important:Ensurethatthemowerhasahinged

grassdeectorthatdispersesclippingstotheside

anddowntowardtheturf,whileinsidedischarge

mode.

23

Page 24

TransportingtheMachine

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure19).

Note:Avoidthesteeringcomponentswhentying

downthemachineatthefrontcasterwheels.

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuprampsand

driveforwarddownramps(Figure20).

Figure20

1.Backupramps

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure21).Onat

ground,thisrequiresaramptobeatleastfourtimes(4X)as

longastheheightofthetrailerortruckbedtotheground.A

steeperanglemaycausemowercomponentstogetcaughtas

theunitmovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

loadingonornearaslope,positionthetrailerortrucksothat

itisonthedownsideoftheslopeandtherampextendsup

theslope.Thiswillminimizetherampangle.

2.Driveforwarddownramps

Figure19

24

Page 25

WARNING

g027996

5

1

2

6

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethelengthoframpisatleastfourtimes

(4X)aslongastheheightofthetrailerortruck

bedtotheground.Thiswillensurethatramp

angledoesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

Figure21

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

25

Page 26

OperatingTips

UsingtheFastThrottleSetting

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,andmowmoreoften

inearlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Stopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Cleanandchecktheaircleanerfoamelement.

•Checktheengineoillevel.

•Checktheairintakeandcoolingareas,andcleanasnecessary.

•Checkthecuttingblades.

•Inspectthegrassdeectorfordamage.

•Checkandcleanthefrontofthemachine.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Checktirepressure.

•Checkthebeltsforwear/cracks.

•Replacetheaircleanerpaperelement.

•Checkthesparkplug.

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhigh

temperatures).

•Changetheengine-oillter.

•Replacethesparkplug.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Premaintenance

Procedures

RaisingtheSeat

Makesurethattheparkingbrakeisengaged,andlifttheseat

forward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

27

Page 28

ReleasingtheMower-Deck Curtain

Lubrication

Loosenthe2bottomboltsofthecurtaintogainaccesstothe

topofthemowerdeck(Figure22).

Figure22

1.Bottombolt2.Mower-deckcurtain

RaisingtheFrontofthe Machine

Ifthefrontofthemachineneedstoberaised,usethevery

frontedgeasshowinFigure23.

GreasingtheBearings

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2generalpurpose,lithium-basegrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure24andFigure25)with

arag.

Note:Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

Important:Topreventdamagetothesteering

mechanism,ensuretheveryfrontedgeofthemachine

isusedforjackingpoints.

Figure23

Figure24

1.Frontcastertire

Figure25

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

4.Connectagreaseguntoeachtting(Figure24and

Figure25).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

3.Greaseevery25operating

hours

4.Engine

28

Page 29

EngineMaintenance

g020242

g020243

3

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theaircleanerfoamelement.

Every50hours—Replacetheaircleanerpaper

element.

Note:Servicetheaircleanermorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Disengagetheblade-controlswitch(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Removetheair-cleanercoverbyunscrewingthe2

knobs(Figure26).

Figure26

Figure27

1.Foamelement2.Paperelement

6.Separatethefoamandpaperelements.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

4.Installthefoamelementontoacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,andblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

1.Air-cleanercover2.Knobs

5.Carefullyremovethefoamandpaperlterelements

fromtheair-cleanerhousing(Figure27).

Important:Donotcleanthepaperelementwith

liquids,suchassolvents,gasoline,orkerosene.

Replacethepaperelementifitisdamagedor

cannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofalldirt,dust,

anddebris.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure27).

2.Installthefoamandpaperlterontotheair-cleaner

housing.

3.Installtheair-cleanercover,andtightenthe2knobs

(Figure26).

29

Page 30

ServicingtheEngineOil

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

B

A

C

D

E

G029368

F

G H

I J K

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher)

CrankcaseCapacity:1.0L(34oz)whenyoudonotchange

thelter;1.05L(36oz)whenyouchangethelter.

Viscosity:Seethetablebelow.

Figure28

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoiland

runtheengine;enginedamagemayresult.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade-controlswitch(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Checktheengine-oillevel(Figure29).

Figure29

30

Page 31

ChangingtheEngineOilandFilter

B

A

C

E F

D

G

H

g029369

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenunderaheavy

loadorinhightemperatures).

Every100hours

Note:Changetheengine-oilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Parkthemachine,sothattherightsideisslightly

lowerthantheleftside,toensurethattheoildrains

completely.

2.Disengagetheblade-controlswitch(PTO).

3.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

4.Draintheoilfromtheengine.

Figure30

31

Page 32

5.Removetheengine-oillter(Figure31)

B

A

C D

E

F

3/4

g027477

B

A

C

D

E

F

g027484

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenturnthelteranextra3/4turn.

6.Slowlypourapproximately80%ofthespecied

amountofoilintothellhole(Figure32).

7.Checktheoillevel;refertoFigure32.

Figure32

Figure31

32

Page 33

ServicingtheSparkPlug

B

A

g027478

B

A

g027479

B

A

15 ft-lb

20 N-m

g027480

C

D

CheckingtheSparkPlug

ServiceInterval:Every50hours—Checkthesparkplug.

Every100hours—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtoolorfeelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:ChampionRC12YC,Autolite3924,NGKBCPR6ES

orequivalent

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethemotion

controlsoutwardtothePARKposition,stoptheengine,

andremovethekey.

2.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

3.Removethesparkplug(Figure33).

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

Figure34

InstallingtheSparkPlug

Tightenthesparkplugto20N-m(15ft-lb).

Figure33

Figure35

33

Page 34

CleaningtheBlowerHousing

g027506

B

A

C

D

g029685

FuelSystem

Toensurepropercooling,makesurethegrassscreen,cooling

ns,andotherexternalsurfacesoftheenginearekeptclean

atalltimes.

Annuallyorevery100hoursofoperation(moreoftenunder

extremelydusty,dirtyconditions),removetheblowerhousing

andanyothercoolingshrouds.Cleanthecoolingnsand

externalsurfacesasnecessary.Makesurethecoolingshrouds

areinstalledafternishingthemaintenance.Torquethe

blower-housingscrewsto7.5N-m(5.5ft-lb).

Important:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,and/orcooling

shroudsremoved,willcauseenginedamagedueto

overheating.

Maintenance

ReplacingtheIn-lineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter.

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

Figure36

34

Page 35

ElectricalSystem

G005072

1

2

3

4

5

6

7

Maintenance

Batteryposts,terminals,andrelatedaccessoriescontain

leadandleadcompounds,chemicalsknowntotheState

ofCaliforniatocausecancerandreproductiveharm.

Washhandsafterhandling.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure37).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure37),andliftthe

batteryfromthebatterytray .

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery.

Figure37

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.T erminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure37).

Note:Retainallfasteners.

35

Page 36

ChargingtheBattery

30

25

30

25

G014540

2

1

ServicingtheFuses

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page35).

2.Chargethebatteryforaminimumof1hourat6to

10amps.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure38).

Figure38

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(Figure39).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure39).

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure37).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure37).

6.Lowertheseat.

Figure39

1.Main—30amp

2.Chargecircuit—25amp

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

36

Page 37

DriveSystem

Maintenance

ReleasingtheElectricBrake

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergizedthebrakewill

reset.

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure40).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto89.6kPa(13psi).

Figure40

1.Valvestem

Toreleasethebrake:

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftswherethebrake-linkarmsare

connectedonbothsidesoftheelectricbrake(Figure

41).

3.Rotatetheshaftsforwardtoreleasethebrakes.

Figure41

1.Rotatebrake-linkarmforwardontheelectric-brake-control

module

2.Leftreartire

37

Page 38

MowerMaintenance

G009679

1

2

3

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily—Checkthe

cuttingblades.

1.Inspectthecuttingedges(Figure42).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page40).

2.Inspecttheblades,especiallythecurvedarea(Figure

42).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(item3inFigure42),immediately

installanewblade.

Figure42

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,stoptheengine,andremovethekey.

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure43).

Figure43

1.Deck3.Blade

2.Spindlehousing

38

Page 39

3.Measurefromthetipofthebladetotheatsurface

G009680

1

2

3

G009681

1

2

3

G009680

1

2

3

(Figure44).

Figure44

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenthebladeandthesurface(A)

4.Rotatethesameblade180degrees,sothattheopposing

cuttingedgeisnowinthesameposition(Figure45).

5.Measurefromthetipofthebladetotheatsurface

(Figure46).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

Figure46

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page40)and

InstallingtheBlades(page40).

Figure45

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

Note:Ifabentbladeisreplacedwithanewone,

andthedimensionobtainedcontinuestoexceed

3mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

Repeatthisprocedureoneachblade.

39

Page 40

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.T oensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

Figure49

1.Blade2.Balancer

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,thecurvedwasher,theblade

stiffener,andthebladefromthespindleshaft(Figure

47).

Figure47

1.Sailareaoftheblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener

SharpeningtheBlades

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure47).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthebladestiffener,thecurvedwasher(cupped

sidetowardtheblade),andthebladebolt(Figure47).

3.Torquethebladeboltto47to88N-m(35to65ft-lb).

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure48).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure48

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure49).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure48).

40

Page 41

LevelingtheMowerDeck

G014630

1

2

3

4

4

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

toCheckingforBentBlades(page38)beforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Alltiresmustbeproperlyinated;refertoCheckingthe

TirePressure(page37).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatetheblade(s)sothattheyareallsideto

side(Figure50.

Note:Rotatetherearnutclockwisetoraisethemower

deck;rotatetherearnutcounter-clockwisetolower

themowerdeck.

Figure51

1.Hangerbracket3.Rearnut

2.Sidelockingnut

9.Checktheside-to-sideadjustmentsagain.Repeatthis

procedureuntilthemeasurementsarecorrect.

10.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page42).

Figure50

1.Bladesidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

5.Measurebetweentheoutsidecuttingedgesandthe

3.Outsidecuttingedges

bladetotheatsurface

here

atsurface(Figure50.Ifbothmeasurementsarenot

within5mm(3/16inch),anadjustmentisrequired;

continuewiththisprocedure.

6.Movetotheleftsideofthemachine.

7.Loosenthesidelockingnut.

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearnut.(Figure51).

41

Page 42

AdjustingtheFront-to-RearBlade

G014631

1

2

2

G014634

1

2

3

Slope

Checkthefront-to-rearbladeslopeanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevel

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page41).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure52.

Figure53

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Toraisethefrontofthemower,tightentheadjustment

nut.

Figure52

Mowerdeckswith1blade

1.Bladefronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure52).

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure53).

8.Tolowerthefrontofthemower,loosentheadjustment

nut.

9.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure52).

10.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain;refertoLeveling

fromSidetoSide(page41).

42

Page 43

RemovingtheMowerDeck

G014635

1

2

3

G015338

2

2

3

1

2

2

3

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpincotterfromthefrontsupportrod,

andremovetherodfromthedeckbracket(Figure

54).Carefullylowerthefrontofthemowerdeckto

theground.

5.Liftthemowerdeckandhangerbracketsclearofthe

rearliftrod,andlowerthemowercarefullytothe

ground(Figure55).

Figure55

Figure54

1.Frontsupportrod3.Deckbracket

2.Lockingnut

1.Mowerdeck

2.Hangerbracket

3.Rearliftrod

6.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

7.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

43

Page 44

ServicingtheMowerBelt

G015129

1

2

3

4

5

4

6

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsfor

wear/cracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Settheparkingbrake,stoptheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutatthelowestcuttingposition(38

mm(1-1/2inches)).

Figure56

Mowerdeckswith1blade

4.Usingaspring-removaltool(Toropartno.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulley,androllthebeltoffofthe

pulleys(Figure56.

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

1.Idlerpulley

2.Mowerbelt5.Enginepulley