Page 1

FormNo.3412-393RevA

TimeCutter

®

SS5000Riding

Mower

ModelNo.74731—SerialNo.400000000andUp

ModelNo.74775—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3412-393*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

GrossHorsepower

Thegrossornethorsepowerofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewiththe

SocietyofAutomotiveEngineers(SAE)J1940.Ascongured

tomeetsafety,emission,andoperatingrequirements,

theactualenginetorqueonthisclassofmowerwillbe

signicantlylower.

Gotowww .Toro.comtoviewspecicationsonyourmower

model.

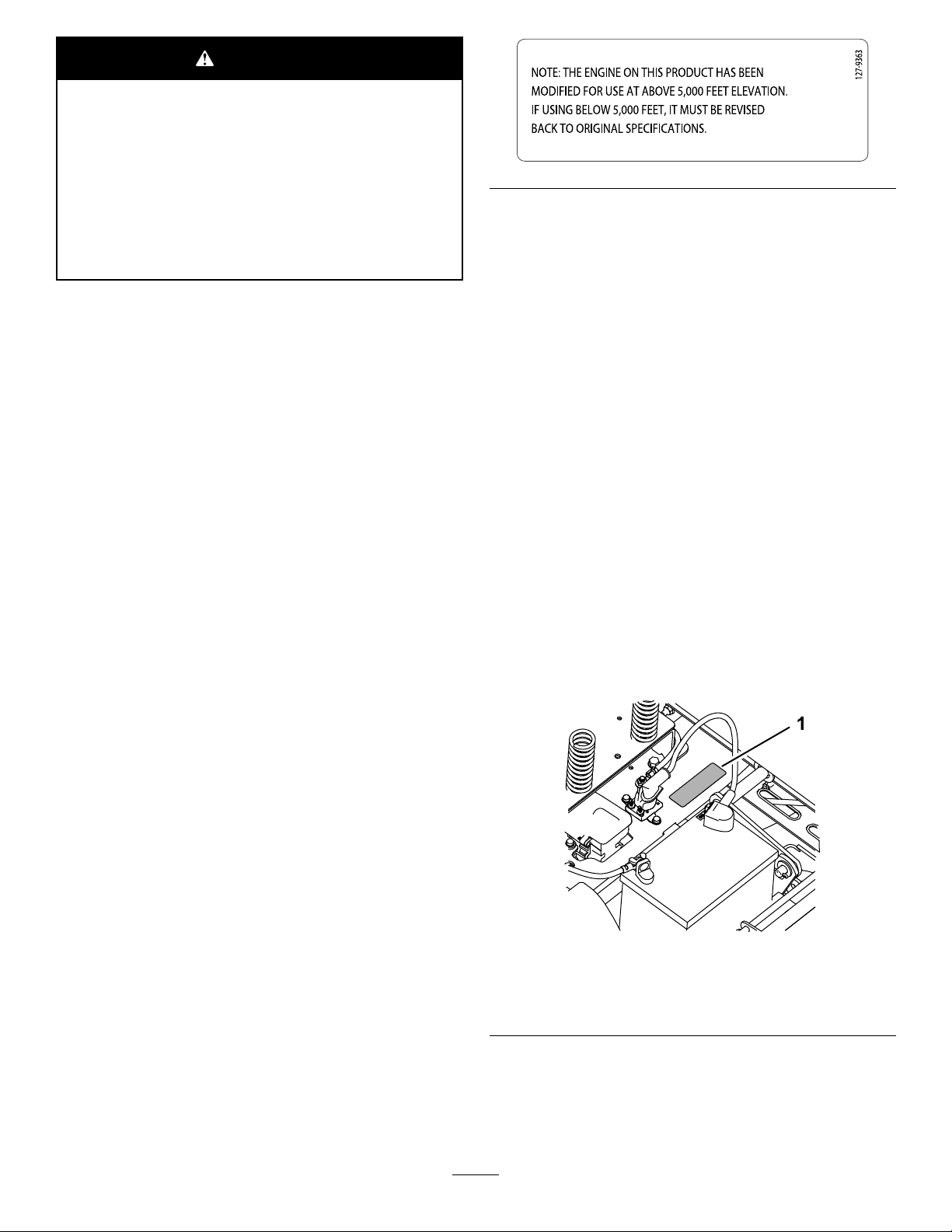

Important:IfyouareusingamachinewithaT oro

engineabove1500m(5,000ft)foracontinuousperiod,

ensurethattheHighAltitudeKithasbeeninstalledso

thattheenginemeetsCARB/EPAemissionregulations.

TheHighAltitudeKitincreasesengineperformance

whilepreventingspark-plugfouling,hardstarting,and

increasedemissions.Onceyouhaveinstalledthekit,

attachthehigh-altitudelabelnexttotheserialdecal

onthemachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocateadealer

convenienttoyou,accessourwebsiteatwww .Toro.com

orcontactourToroCustomerCareDepartmentatthe

number(s)listedinyourEmissionControlWarranty

Statement.

Removethekitfromtheengineandrestoretheengine

toitsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperateanengine

thathasbeenconvertedforhigh-altitudeuseatlower

altitudes;otherwise,youcouldoverheatanddamage

theengine.

Ifyouareunsurewhetherornotyourmachinehasbeen

convertedforhigh-altitudeuse,lookforthefollowing

label.

decal127-9363

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g188142

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

ProductOverview.........................................................11

Controls...............................................................11

BeforeOperation......................................................13

BeforeOperationSafety..........................................13

RecommendedFuel................................................13

UsingStabilizer/Conditioner...................................14

FillingtheFuelTank...............................................14

g000502

CheckingtheEngine-OilLevel.................................14

BreakinginaNewMachine......................................14

ThinkSafetyFirst...................................................14

UsingtheSafety-InterlockSystem.............................15

PositioningtheSeat................................................16

AdjustingtheMotion-ControlLevers........................16

DuringOperation.....................................................17

DuringOperationSafety.........................................17

OperatingtheMowerBlade-ControlSwitch

(PTO)...............................................................18

OperatingtheThrottle............................................18

OperatingtheChoke...............................................18

OperatingtheIgnitionSwitch..................................19

StartingandShuttingOfftheEngine.........................19

UsingtheMotion-ControlLevers.............................20

DrivingtheMachine...............................................20

StoppingtheMachine.............................................21

AdjustingtheHeightofCut.....................................22

AdjustingtheAnti-ScalpRollers...............................22

UsingtheSideDischarge.........................................23

OperatingTips......................................................23

AfterOperation........................................................24

AfterOperationSafety............................................24

PushingtheMachinebyHand..................................24

TransportingtheMachine........................................25

LoadingtheMachine..............................................25

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

Pre-MaintenanceProcedures......................................28

MaintenanceandStorage.........................................28

RaisingtheSeat......................................................28

Lubrication...............................................................29

GreasingtheBearings.............................................29

EngineMaintenance..................................................29

EngineSafety.........................................................29

ServicingtheAirCleaner.........................................29

ServicingtheEngineOil..........................................30

ServicingtheSparkPlug..........................................33

CleaningtheCoolingSystem....................................34

FuelSystemMaintenance...........................................34

ReplacingtheIn-LineFuelFilter...............................34

ElectricalSystemMaintenance....................................35

ElectricalSystemSafety...........................................35

ServicingtheBattery...............................................35

ServicingtheFuses.................................................36

3

Page 4

DriveSystemMaintenance.........................................37

CheckingtheTirePressure......................................37

ReleasingtheElectricBrake.....................................38

MowerMaintenance...................................................38

ServicingtheCuttingBlades.....................................38

LevelingtheMowerDeck........................................40

RemovingtheMowerDeck.....................................42

ReplacingtheGrassDeector..................................43

MowerBeltMaintenance............................................45

InspectingtheBelts................................................45

ReplacingtheMower-DeckBelt...............................45

Cleaning...................................................................46

WashingtheUndersideoftheMower........................46

Storage........................................................................47

CleaningandStorage..............................................47

Troubleshooting...........................................................48

Schematics...................................................................50

Safety

ThismachinehasbeendesignedinaccordancewithANSI

B71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

Page 5

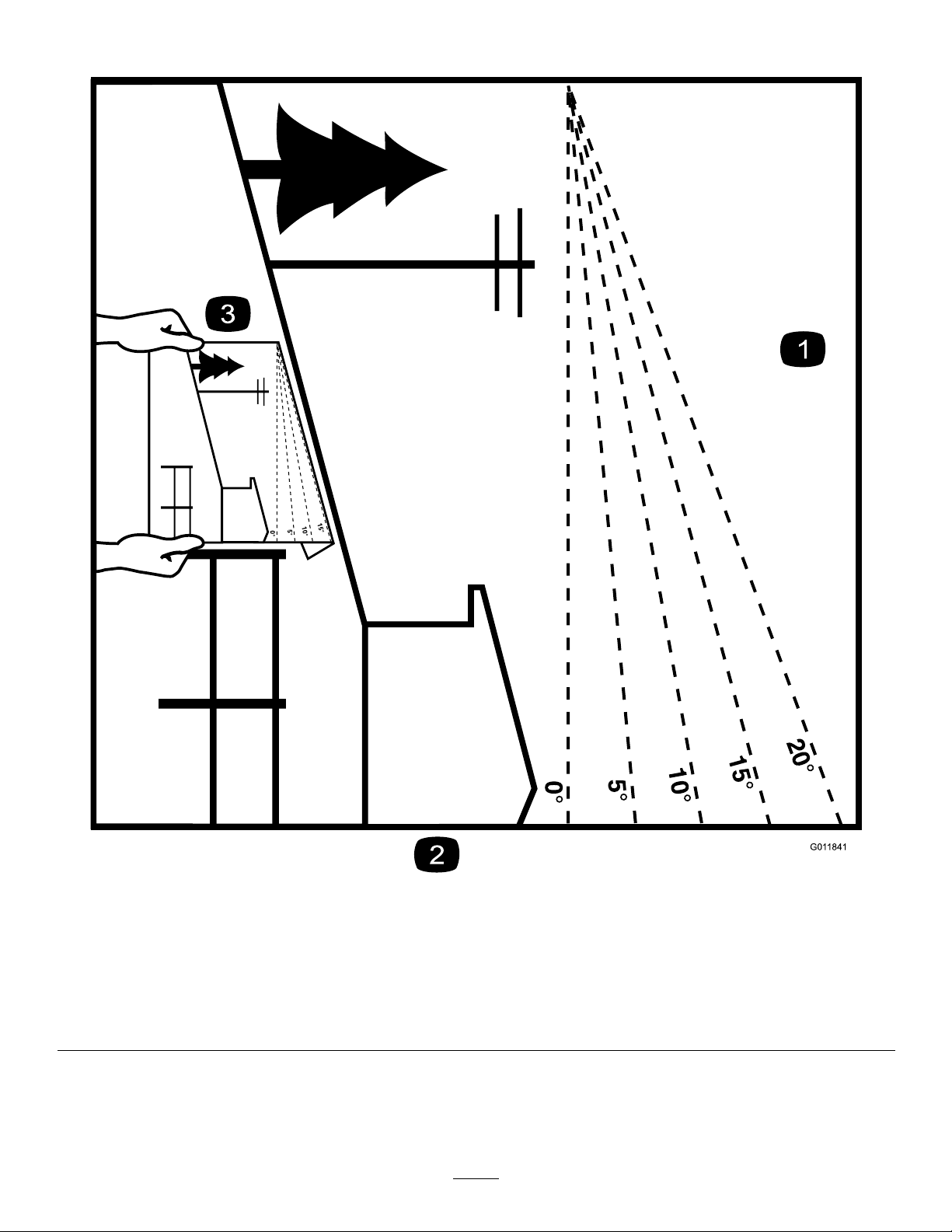

SlopeIndicator

G011841

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

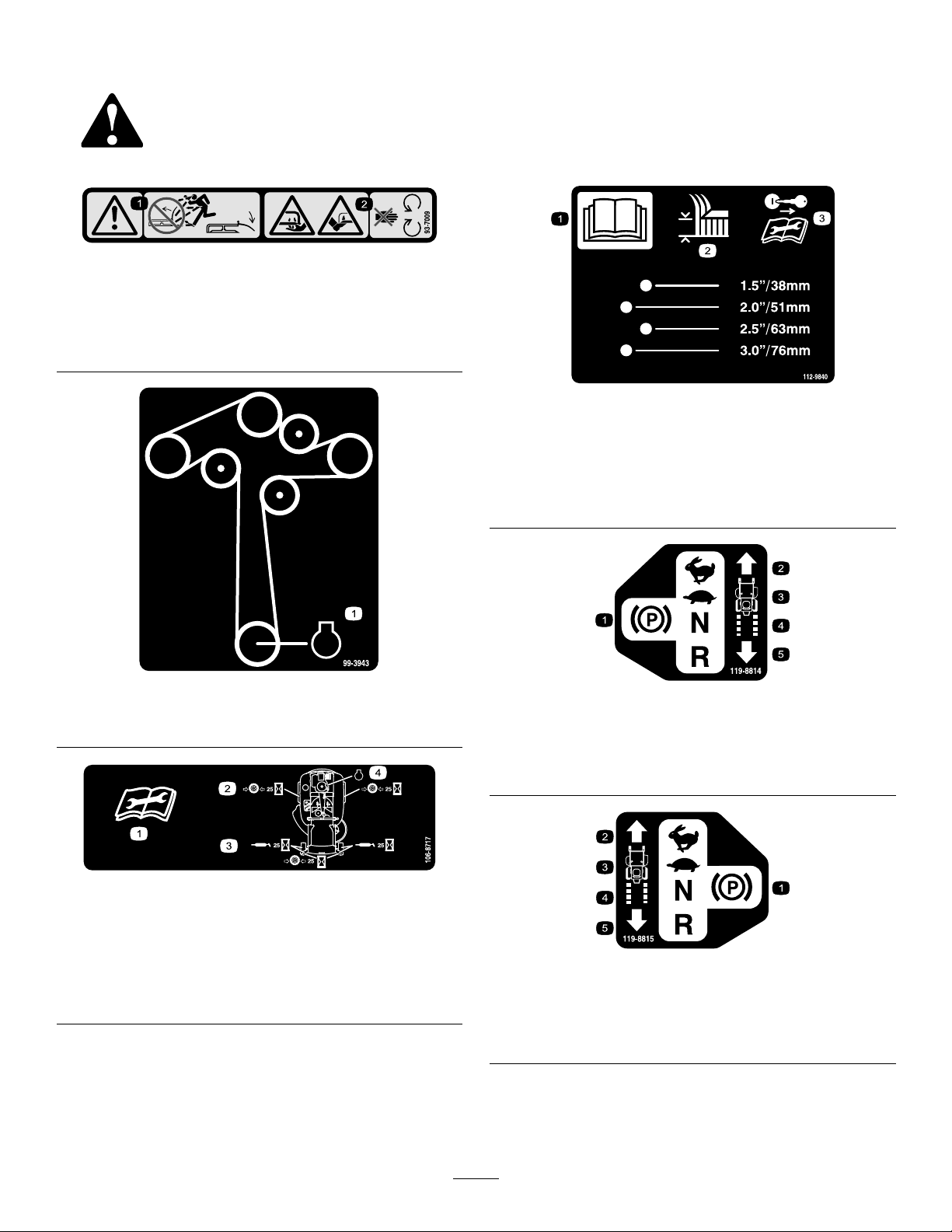

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

decal93-7009

decal112-9840

112-9840

1.ReadtheOperator's

Manual.

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

2.Heightofcut

decal99-3943

99-3943

1.Engine

1.Parkingposition4.Neutral

119-8814

decal119-8814

2.Fast5.Reverse

3.Slow

decal106-8717

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

decal119-8815

119-8815

1.Parkingposition4.Neutral

2.Fast5.Reverse

3.Slow

6

Page 7

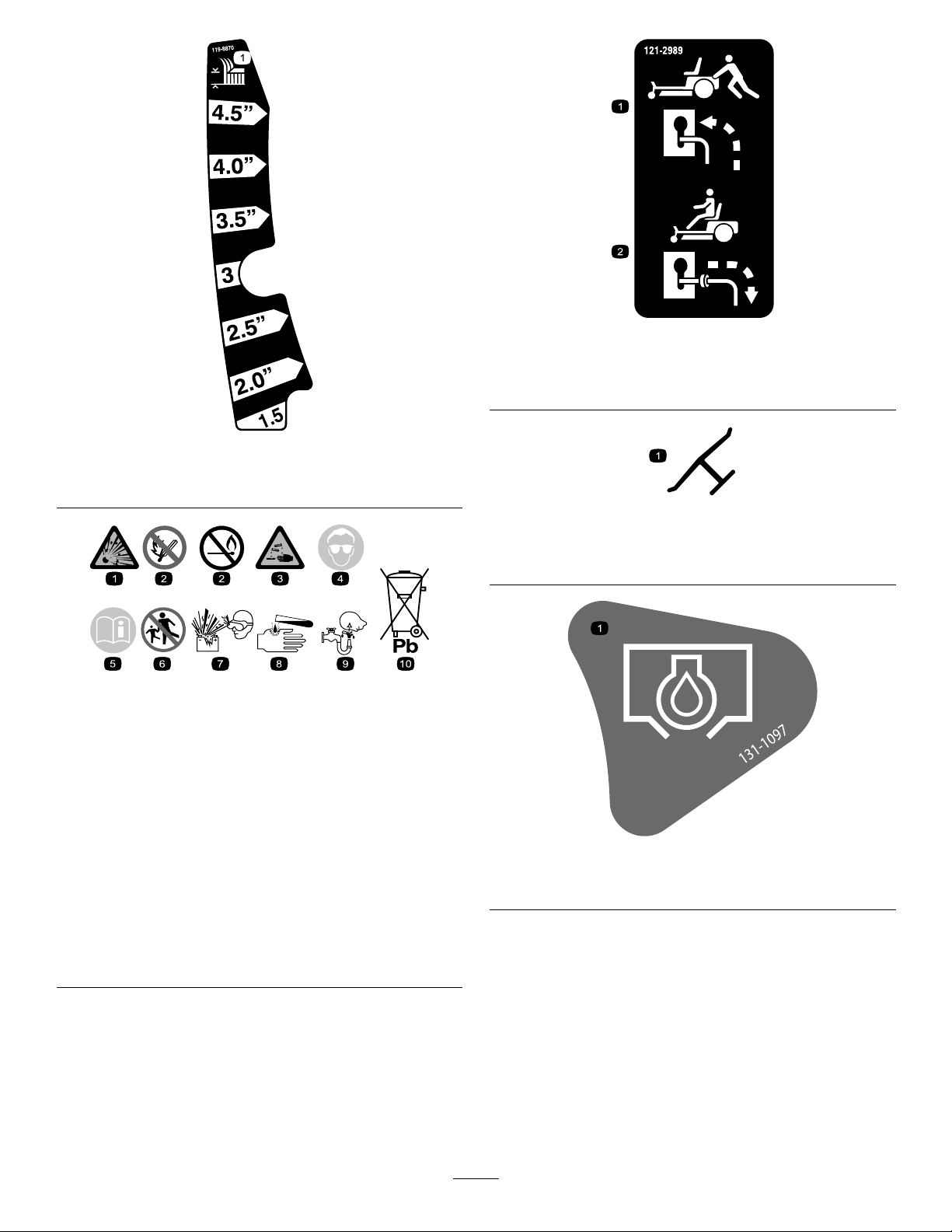

decal121-2989b

121-2989

119-8870

1.Heightofcut

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

1.Bypassleverpositionfor

pushingthemachine

decal119-8870

2.Bypassleverpositionfor

operatingthemachine

decaloemmarkt

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decalbatterysymbols

decal131-1097

131-1097

1.Oildrain

7

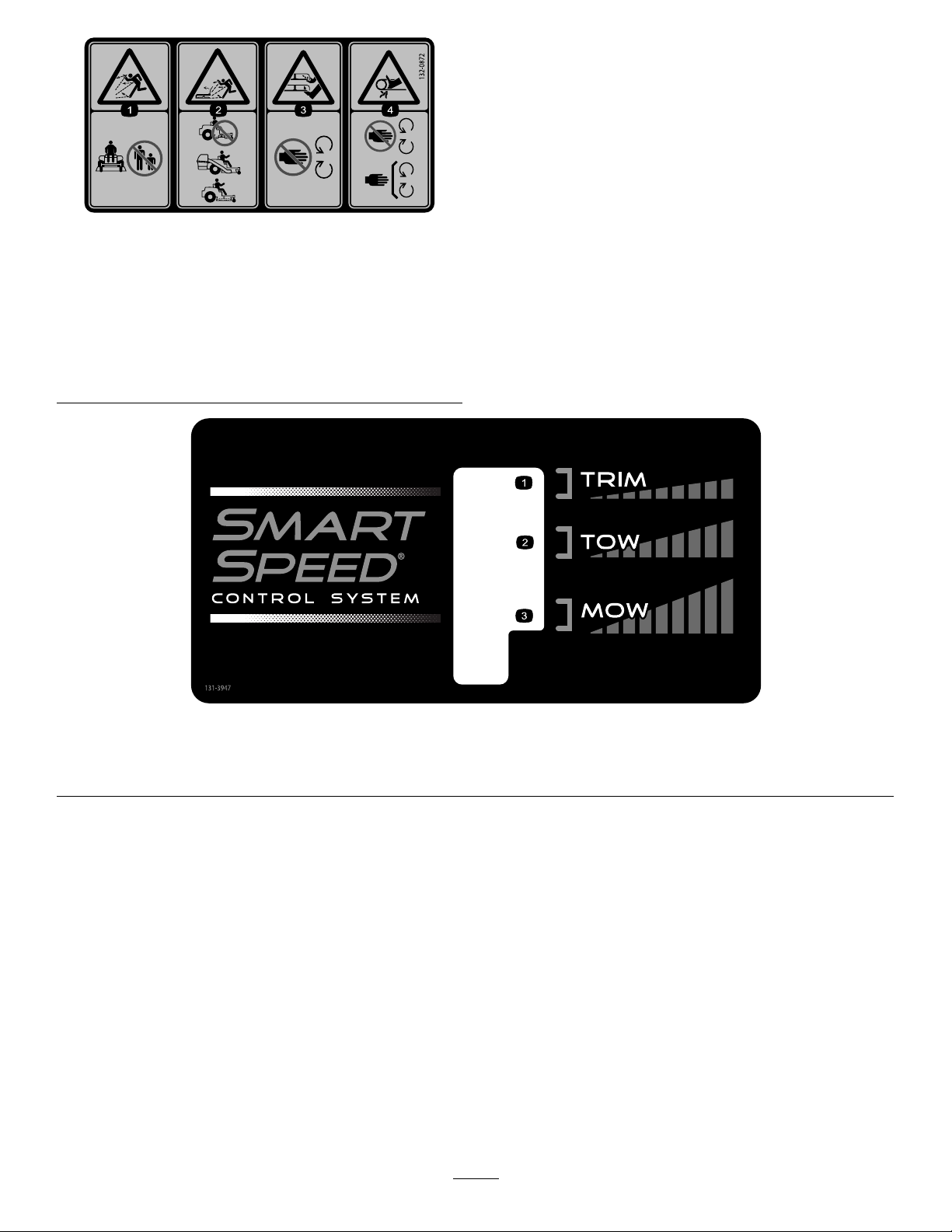

Page 8

decal132-0872

132-0872

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

decal131-3947

131-3947

1.Trim—slow

3.Mow—fast

2.Tow—medium

8

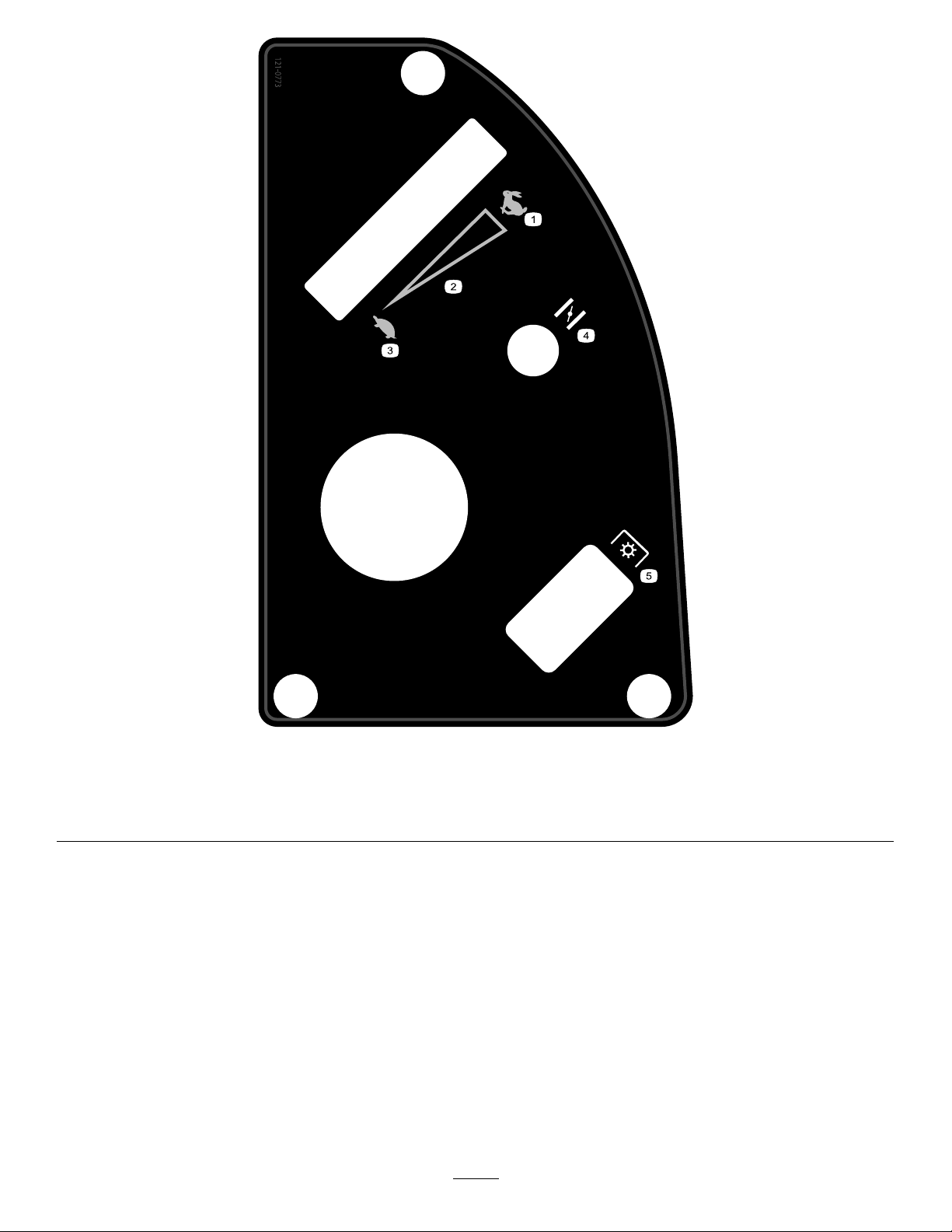

Page 9

decal121-0773

121-0773

1.Fast

4.Choke

2.Continuous-variablesetting5.Powertakeoff(PTO),blade-controlswitch

3.Slow

9

Page 10

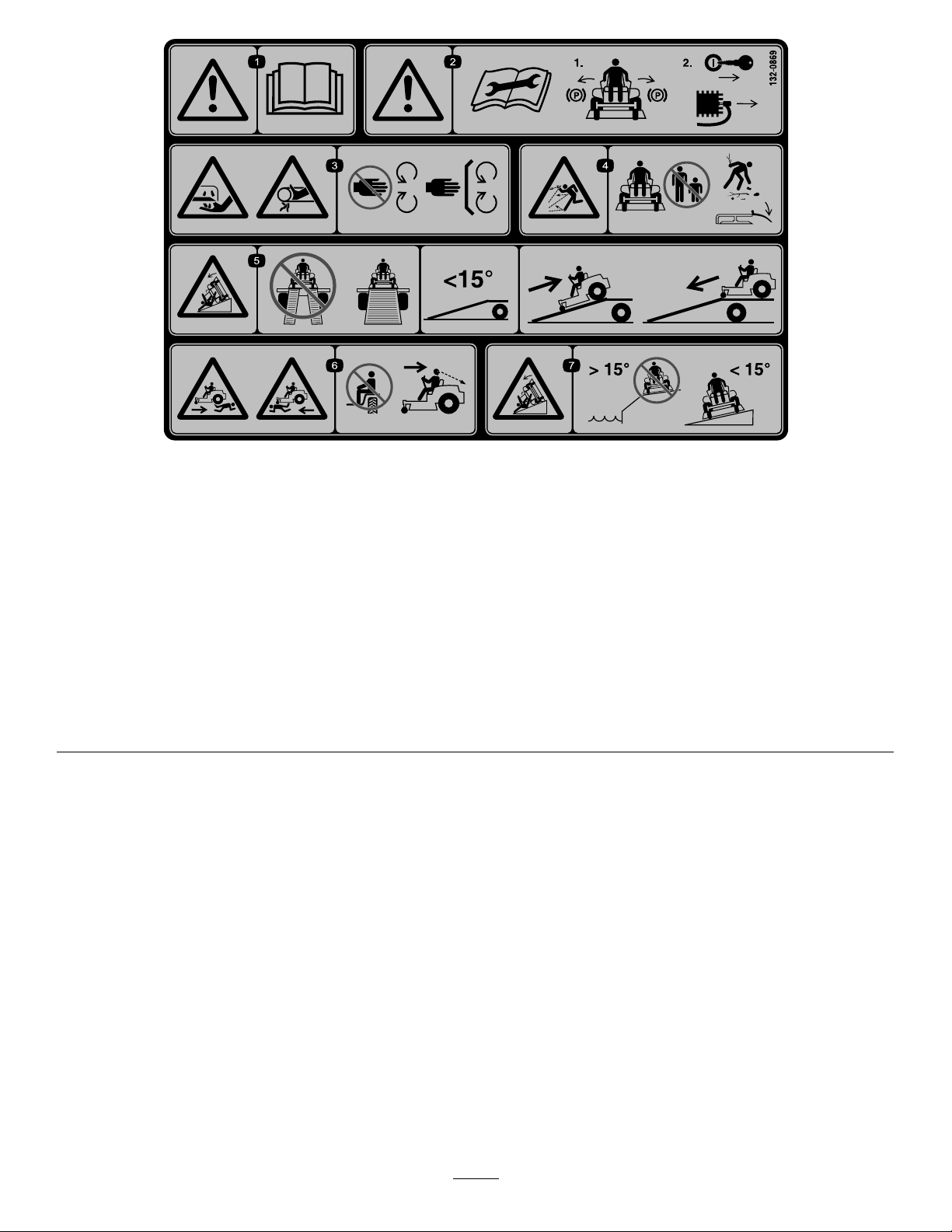

decal132-0869

132-0869

1.Warning—readthe

Operator'sManual.

2.Warning—beforeservicing,

engagetheparkingbrake,

removethekeyandthe

sparkplugconnection.

3.Cuttinghazardofhand,

mowerblade;pinching

hazardofhand,belt—keep

handsandfeetawayfrom

movingparts;keepall

guardsandshieldsinplace.

4.Thrownobject

hazard—keepbystanders

awayfromthemachine;

removedebrisfromthe

areabeforemowing;keep

thedeectorshielddown.

5.Ramptipping

hazard—whenloading

ontoatrailer,donotuse

dualramps;onlyusea

singlerampwideenough

forthemachineandthat

hasaninclinelessthan

15degrees;backupthe

ramp(inreverse)anddrive

forwardofftheramp.

6.Bodilyharmhazard—no

riders;lookbehindyou

whenmowinginreverse.

7.Tippinghazardon

slopes—donotuseon

slopesnearopenwater;do

notuseonslopesgreater

than15degrees.

10

Page 11

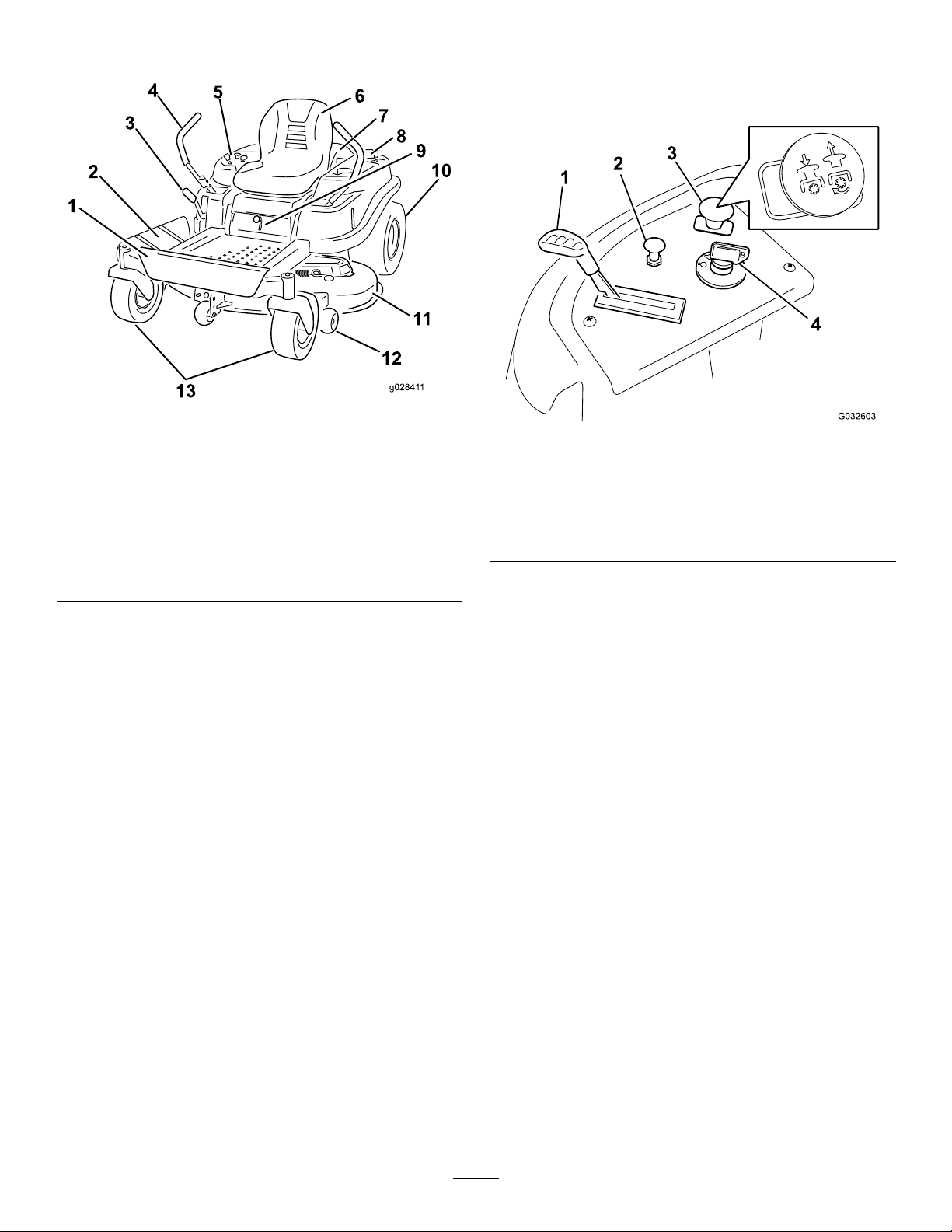

ProductOverview

Figure5

1.Footrest

2.Deector9.SmartSpeed™lever

3.Height-of-cutlever

4.Motion-controllever11.Mowerdeck

5.Controlpanel

6.Operatorseat

7.Engine

8.Gas-tankcap

10.Reardrivewheel

12.Anti-scalproller

13.Frontcasterwheel

Controls

BecomefamiliarwithallofthecontrolsinFigure5and

Figure6beforeyoustarttheengineandoperatethemachine.

g028411

g032603

Figure6

Controlpanel

1.Throttle3.Blade-controlswitch

2.Choke

(powertakeoff)

4.Ignitionswitch

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3positions:

START,RUN,andOFF.

ChokeControl

Usethechoketostartacoldengine.Pullthechokeknob

uptoengageit.Pushthechokeknobdowntodisengage

it(Figure7).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFASTposition

(Figure7).

Blade-ControlSwitch(PowerTakeoff)

Theblade-controlswitch,representedbyapower-takeoff

(PTO)symbol,engagesanddisengagespowertothemower

blades(Figure6).

11

Page 12

Motion-ControlLevers

G014521

1

Height-of-CutLever

Usethemotion-controlleverstodrivethemachineforward,

reverse,andturneitherdirection.

ParkPosition

Movethemotion-controlleversoutwardfromthecenterto

thePARKpositionwhenexitingthemachine(Figure20).

Alwayspositionthemotion-controlleversintothePARK

positionwhenyoustopthemachineorleaveitunattended.

SmartSpeed™ControlSystemLever

TheSmartSpeed™Control-Systemlever,locatedbelowthe

operatingposition,givesyouachoicetodrivethemachineat

3speedranges—trim,tow ,andmow(Figure23).

Fuel-PresenceWindow

Youcanusethefuelwindow ,locatedontheleftsideofthe

machine,toverifythepresenceoffuelinthetank(Figure7).

Usetheheight-of-cutlevertolowerandraisethedeckfrom

theseatedposition.Movingtheleverup(towardyou)raises

thedeckfromthegroundandmovingtheleverdown(away

fromyou)lowersthedecktowardtheground.Adjustthe

height-of-cutonlywhilethemachineisnotmoving(Figure

24).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

g014521

Figure7

1.Fuel-presencewindow

12

Page 13

Operation

thenrefuelfromaportablecontainerratherthana

fuel-dispensernozzle.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operatethemachineunlesstheyarefunctioningproperly.

•Beforemowing,alwaysinspectthemachinetoensurethat

theblades,bladebolts,andcuttingassembliesareingood

workingcondition.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelvaporsareammableand

explosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefueltank

whiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

•Donotoperatethemachinewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

•Storefuelinanapprovedcontainerandkeepitoutofthe

reachofchildren.Neverbuymorethana30-daysupply

offuel.

•Donotllthefueltankcompletelyfull.Addfueltothe

fueltankuntilthelevelis6to13mm(1/4to1/2inch)

belowthebottomofthellerneck.Thisemptyspacein

thetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandgastank

opening.

–Avoidcontactwithskin;washoffspillswithsoapand

water.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

•Donotllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

theground,awayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerand

refuelitwhileitisontheground.Ifthisisnotpossible,

13

Page 14

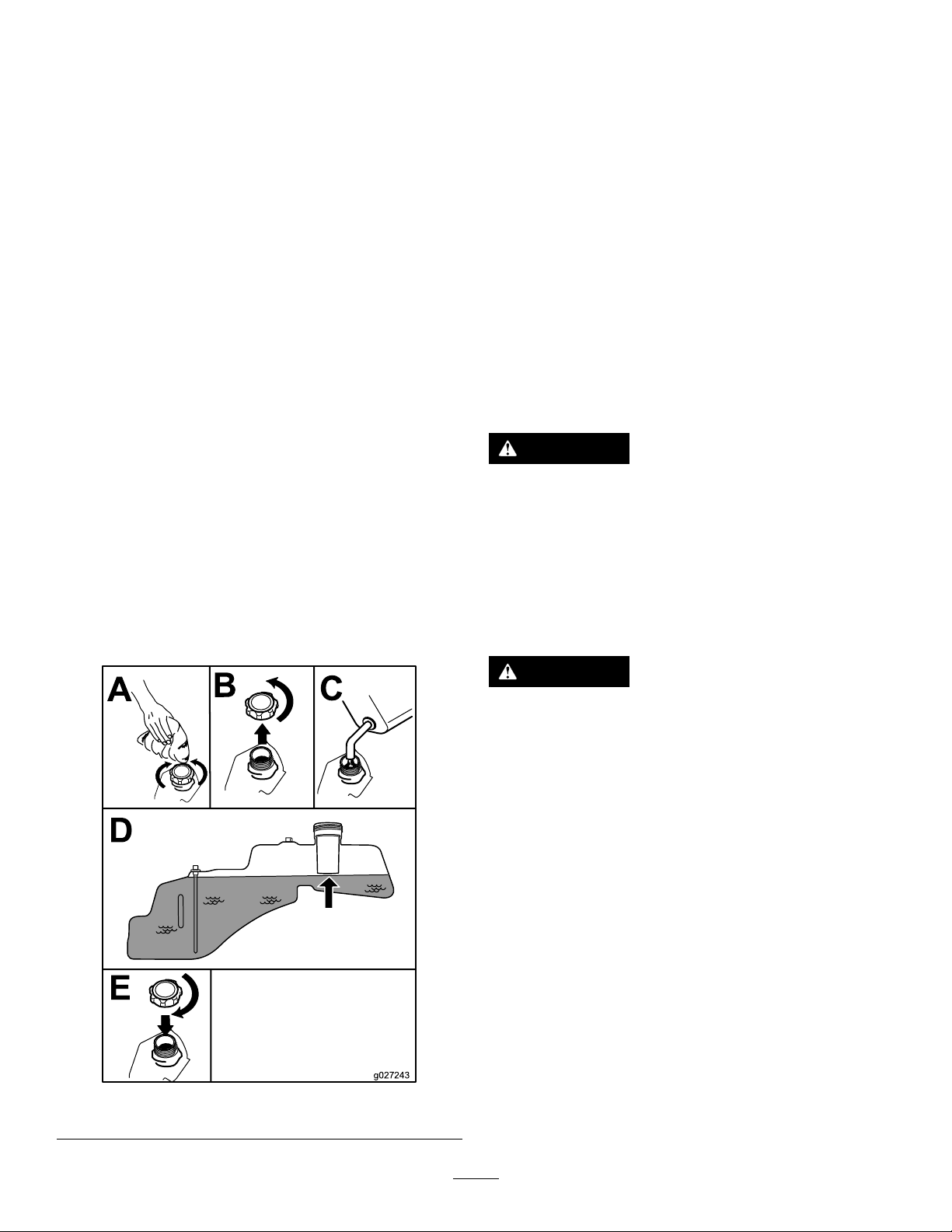

UsingStabilizer/Conditioner

g027243

A

B

E

D

C

CheckingtheEngine-OilLevel

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless(drain

thefueltankwhenstoringthemachineformorethan

90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.T ominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shutofftheengineandengagetheparkingbrake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck(Figure

8).

Note:Donotllthefueltankcompletelyfull.The

emptyspaceinthetankallowsthefueltoexpand.

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page30).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

g027243

Figure8

14

Page 15

G009027

1

2

UsingtheSafety-Interlock System

WARNING

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Figure9

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

g000513

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshutoffthe

enginewheneverthecontrolleversareoutofthePARK

positionandyourisefromtheseat.

TestingtheSafety-InterlockSystem

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sitontheseat,movethemotion-controlleversinthe

PARKposition,andmovetheblade-controlswitchto

theONposition.Trystartingtheengine;theengine

shouldnotcrank.

2.Sitontheseatandmovetheblade-controlswitchto

theOFFposition.Moveeithermotion-controlleverto

thecenter,unlockedposition.Trystartingtheengine;

theengineshouldnotcrank.Repeatwiththeother

motion-controllever.

g009027

Figure10

1.Weareyeprotection.2.Wearhearingprotection.

3.Sitontheseat,movetheblade-controlswitchtothe

OFFposition,andlockthemotion-controlleversin

thePARKposition.Starttheengine.Whiletheengine

isrunning,engagetheblade-controlswitch,andrise

slightlyfromtheseat;theengineshouldshutoff.

4.Sitontheseat,movetheblade-controlswitchtothe

OFFposition,andlockthemotion-controlleversinthe

PARKposition.Starttheengine.Whiletheengineis

running,movethemotion-controlleverstothecenter,

unlockedposition,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshouldshutoff.

15

Page 16

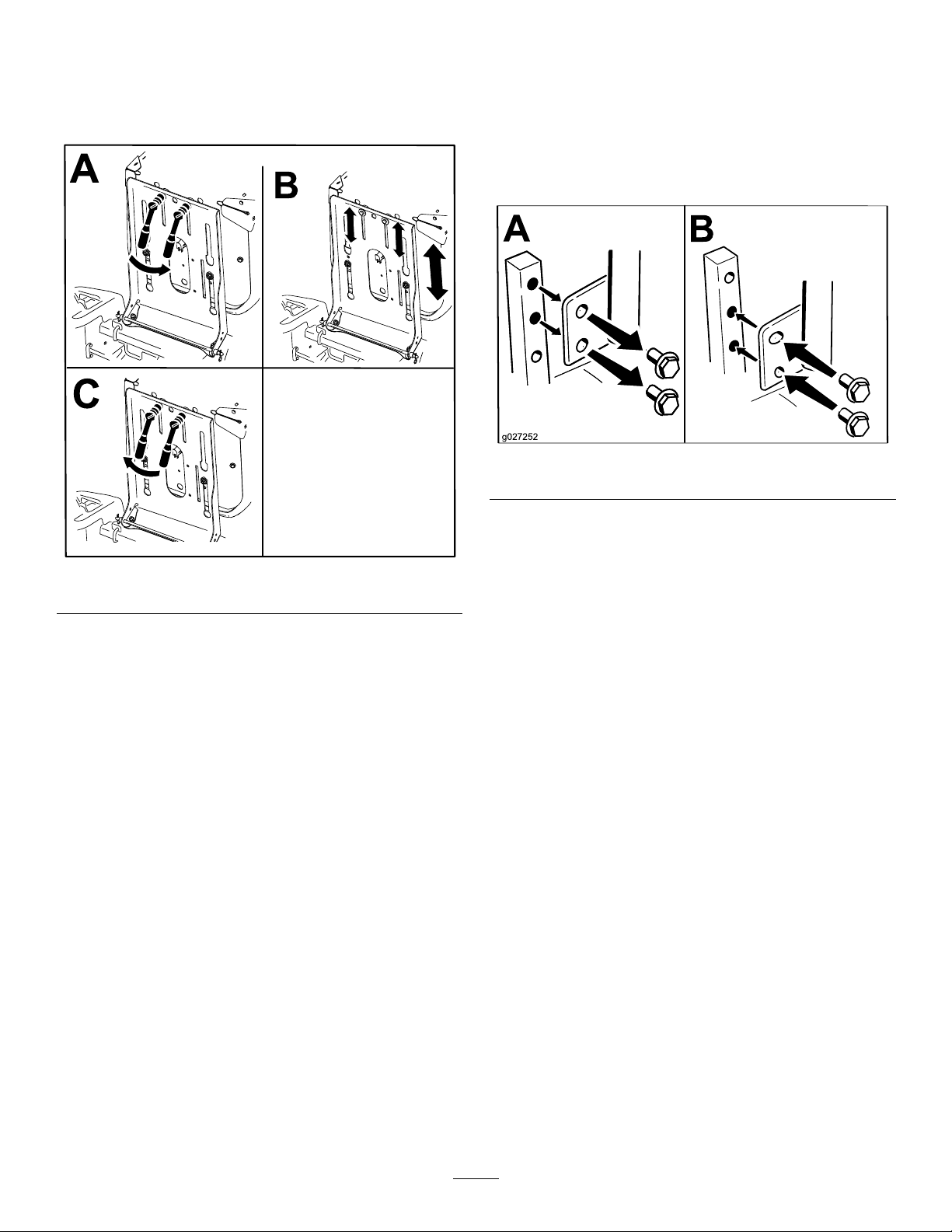

PositioningtheSeat

g027252

B

A

AdjustingtheMotion-Control

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable(Figure11).

Levers

AdjustingtheHeight

Youcanadjustthemotion-controllevershigherorlowerfor

maximumcomfort(Figure12).

g027252

Figure12

Figure11

AdjustingtheTilt

g188217

Youcanadjustthemotion-controlleversforwardorrearward

foryourcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorrearward(Figure12).

3.Tightenbothboltstosecurethecontrolleverinthe

newposition.

4.Repeattheadjustmentfortheothercontrollever.

16

Page 17

DuringOperation

DuringOperationSafety

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

GeneralSafety

•Theowner/operatorcanpreventandisresponsiblefor

accidentsthatmaycausepersonalinjuryorproperty

damage.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachineduring

operation.

•Operatethemachineonlyingoodvisibilitytoavoidholes

orhiddenhazards.

•Avoidmowingonwetgrass.Reducedtractioncould

causethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparkingbrake

isengaged,andyouareintheoperatingpositionbefore

youstarttheengine.

•Keepyourhandsandfeetawayfromthecuttingunits.

Keepclearofthedischargeopeningatalltimes.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistheriskof

lightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeedthe

engine.

•UseaccessoriesandattachmentsapprovedbyToroonly.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelupanddownonhillsides.Turfconditionscan

affectthestabilityofthemachine.

•Avoidturningthemachineonslopes.Ifyoumustturnthe

machine,turnitslowlyandgraduallydownhill,ifpossible.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscureyourvision.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgegivesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshutoffthe

enginebeforeadjustingtheheightofcut(unlessyoucan

adjustitfromtheoperatingposition).

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(includingtoempty

thecatchersortounclogthechute),dothefollowing:

–Stopthemachineonlevelground.

17

Page 18

OperatingtheMower

G008945

G009174

G008959

1

2

OperatingtheThrottle

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

Figure13

Note:AlwaysengagethebladeswiththethrottleintheFAST

position(Figure14).

YoucanmovethethrottlecontrolbetweentheFASTand

SLOWpositions(Figure16).

AlwaysusetheFASTpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

g187517

g008945

Figure16

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pullupthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure17).

Note:Ensurethatyoufullyengagethechoke.You

mayneedtoholdtheknobupwhenyouusethe

ignitionswitch.

3.Pushdownthechoketodisengagethechokeafterthe

enginehasstarted(Figure17).

g187516

Figure14

DisengagingtheBlade-ControlSwitch

(PTO)

g009174

Figure15

Figure17

g008959

1.Onposition2.Offposition

18

Page 19

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g027581

B

C

D

E

A

G

F

1.TurntheignitionkeytotheSTARTposition(Figure18).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failureto

followtheseinstructionscanburnoutthestarter

motor.

Note:Youmayneedmultipleattemptstostartthe

enginewhenyoustartitthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure18

g008947

2.TurntheignitionkeytotheSTOPpositiontoshutoff

theengine.

StartingandShuttingOffthe Engine

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformorethan

5secondsatatime.Engagingthestartermotorfor

morethan5secondscandamagethestartermotor.If

theenginefailstostart,wait10secondsbeforeoperating

theenginestarteragain.

g027581

Figure19

ShuttingOfftheEngine

1.Disengagethebladesbymovingtheblade-control

switchtotheOFFposition(Figure17).

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytotheOFFpositionandremove

thekey.

19

Page 20

UsingtheMotion-Control

G008952

G008953

Levers

DrivingForward

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotion-controllevers

forward(Figure21).

Figure20

1.Motion-control

lever—PARKposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingtheMachine

Thedrivewheelsturnindependently,poweredbyhydraulic

motorsoneachaxle.Youcanturn1sideinreversewhileyou

turntheotherforward,causingthemachinetospinrather

thanturn.Thisgreatlyimprovesthemachinemaneuverability

butmayrequiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatein

thefullthrottlepositionwhenmowing.

g008952

Figure21

g004532

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure22).

WARNING

Themachinecanspinveryrapidly.Y oumaylose

controlofthemachineandcausepersonalinjuryor

damagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

g008953

Figure22

20

Page 21

UsingtheSmartSpeed

TM

Control

System

TheSmartSpeed

operatingposition(Figure23),givestheoperatorachoice

todrivethemachineat3groundspeedranges—trim,tow ,

andmow .

1.Smart-speedlever

TM

Control-Systemlever,locatedbelowthe

Figure23

Tow

Thisisthemediumspeed.Thesuggestedusesforthisspeed

areasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Normalmowing

•Transportingthemachine

StoppingtheMachine

Tostopthemachine,movethemotion-controlleversto

g027625

NEUTRALandoutwardtothePARKposition,disengagethe

blade-controlswitch,ensurethatthethrottleisintheFAST

position,andturntheignitionkeytoOFF.Removethekey

fromtheignitionswitch.

Tochangespeeds,dothefollowing:

1.Movethemotion-controlleverstoneutralandoutward

tothePARKposition.

2.Disengagetheblade-controlswitch.

3.Adjustthelevertothedesiredposition.

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,andthe

heightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtothePARKposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Trim

Thisisthelowestspeed.Thesuggestedusesforthisspeed

areasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

21

Page 22

AdjustingtheHeightofCut

G010233

1

2

3

4

AdjustingtheAnti-Scalp

Note:Thetransportpositionisthehighestheight-of-cut

positionat115mm(4-1/2inches)asshowninFigure24.

Rollers

Wheneveryouchangetheheightofcut,adjusttheheight

oftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssotherollersdonottouch

thegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Ensurethattheparkingbrakeisengaged,shutoffthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollers(Figure25)tomatchthe

closestheight-of-cutposition.

g010233

Figure25

1.Anti-scalproller3.Flangenut

g027504

Figure24

2.Bolt4.Holespacing

22

Page 23

UsingtheSideDischarge

MowingatCorrectIntervals

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,ora

completegrass-catcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovetheblade-controlswitch

(PTO)totheOFFposition,rotatetheignition

keytotheOFFposition,andremovethekey.

•Makesurethatthegrassdeectorisinthedown

position.

Grassgrowsatdifferentratesatdifferenttimesoftheyear.

Tomaintainthesamecuttingheight,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight,thenmowagain2days

lateratalowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheighttoavoid

scalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

23

Page 24

AfterOperation

g017303

1 2

3

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,mufers,

andenginecompartmenttohelppreventres.Cleanup

oilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.

Note:Donotstartthemachine.

Note:Youcannowpushthemachinebyhand.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagetothehydraulicdrive

systemmayoccur.

Thismachinehasanelectric-brakemechanism.Topushthe

machine,turntheignitionkeytotheRUNposition.The

batterymustbechargedandfunctioningtodisengagethe

electricbrake.

PushingtheMachine

Figure26

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,turnthekeytotheSTOPpositionto

avoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrake

maystillbeengaged.Youcanreleasetheelectricbrakeif

necessary;refertoReleasingtheElectricBrake(page38).

3.Leverpositionforpushing

themachine

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure26.

Note:Dothisforeachlever.

g017303

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure26).

Note:Dothisforeachlever.

5.Movethemotion-controlleversinwardtothe

NEUTRALpositionandturntheignitionkeytothe

RUNposition.

24

Page 25

TransportingtheMachine

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure27).

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuptherampand

driveforwarddowntheramp(Figure28).

Figure28

1.Backthemachineupthe

ramp.

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

2.Drivethemachineforward

downtheramp.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath(Figure29).

•Useextremecautionwhenoperatingamachine

onaramp.

g027995

Figure27

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

g027708

•Ensurethatthelengthoframpisatleast4times

aslongastheheightofthetrailerortruckbed

totheground.Thisensuresthattherampangle

doesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

25

Page 26

g027996

5

1

2

6

Figure29

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,loose,ordamagedparts.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Greasealllubricationpoints.

•Cleantheair-cleanerfoamelement(moreoftenindusty ,dirtyconditions).

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Replacetheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Servicetheair-cleanerpaperelement(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenindusty,dirtyconditions).

•Changetheoillter(moreoftenindusty,dirtyconditions).

•Checkthesparkplug(s).

•Checkthein-linefuellter.

•Replacetheair-cleanerpaperelement(moreoftenindusty,dirtyconditions).

•Replacethesparkplug(s).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

Beforestorage

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyouperformanymaintenance.

27

Page 28

Pre-Maintenance

RaisingtheSeat

Procedures

MaintenanceandStorage

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesordrain

thefuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

Makesurethatthemotion-controlleversarelockedinthe

PARKposition.Lifttheseatforward.

Youcanaccessthefollowingcomponentsbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Connectthe

positiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthicklypaddedgloves,andusecautionwhen

servicingthem.Onlyreplaceblades;donotstraighten

orweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened,especiallytheblade-attachmentbolts.Replace

allwornordamageddecals.

•Neverinterferewiththeintendedfunctionofasafety

deviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.Adjustand

serviceasrequired.

28

Page 29

Lubrication

g027800

g027801

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure30andFigure31)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElements

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch(PTO).

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanaroundtheair-cleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Liftthecoverandrotatetheair-cleanerassemblyout

oftheengine(Figure32).

Figure30

1.Frontcastertire

Figure31

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance.

2.Checkthetirepressure

every25operatinghours.

3.Greaseevery25operating

hours.

4.Engine

4.Connectagreaseguntoeachtting(Figure30and

Figure31).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

g032432

g027800

decal106-8717

g027801

Figure32

29

Page 30

5.Removethefoamelementfromthepaperelement

g027802

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

(Figure33).

Figure33

ServicingtheFoamElement

ServiceInterval:Every25hours/Monthly(whichever

comesrst)—Cleantheair-cleanerfoam

element(moreoftenindusty,dirty

conditions).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orSL)

CrankcaseCapacity:withlter—2.4L(2.5USqt)

Viscosity:Seethetablebelow.

g027802

g029683

Figure34

Every100hours/Yearly(whichevercomes

rst)—Replacetheair-cleanerfoamelement(more

oftenindusty,dirtyconditions).

Washthefoamelementwithwaterandreplacethefoam

elementifitisdamaged.

ServicingthePaperElement

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Servicetheair-cleanerpaper

element(moreoftenindusty,dirty

conditions).

Every200hours/Every2years(whichevercomes

rst)—Replacetheair-cleanerpaperelement(more

oftenindusty,dirtyconditions).

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchassolvent,

gasoline,orkerosene.Replacethepaperelement

ifitisdamagedorcannotbecleanedthoroughly .

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmaydamage

theengine.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,shutofftheengine,engage

parkingbrake,andremovethekey.

2.Makesurethattheengineisshutoff,level,andiscool,

sothattheoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoil-llcapanddipstickbefore

removingit(Figure35).

4.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

30

Page 31

B

A

C

D

E

G029368

F

G H

I J K

ChangingtheEngineOilandOilFilter

ServiceInterval:Aftertherst5hours/Aftertherst

month(whichevercomesrst)—Change

theengineoil.

Every100hours/Yearly(whichevercomes

rst)—Changetheengineoil(moreoftenindusty,

dirtyconditions).

Every100hours/Yearly(whichevercomes

rst)—Changetheoillter(moreoftenindusty,dirty

conditions).

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachineonalevelsurfacetoensurethatthe

oildrainscompletely.

2.DisengagethePTOandensurethattheparkingbrake

isengaged.

3.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Draintheengineoil.

g029368

Figure35

31

Page 32

g027799

A

B

C

D

E

F

G

H

g029570

5.Changetheengine-oillter(Figure37).

B

A

C D

E

F

3/4

g027477

Note:Ensurethattheoil-ltergaskettouchesthe

engineandthenturnthelteranextra3/4turn.

g027799

g027477

Figure37

6.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure38).

Figure36

g029570

32

Page 33

B

A

C

D

E

F

g027484

Figure38

B

A

g027478

B

A

g027479

RemovingtheSparkPlug

1.DisengagethePTOandmovethemotion-control

leverstothePARKposition.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

g027478

Figure39

Note:Duetothedeeprecessaroundthesparkplug,

blowingoutthecavitywithcompressedairisthemost

g027484

effectivemethodforcleaning.Thesparkplugismost

accessiblewhentheblowerhousingisremovedfor

cleaning.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Checkthesparkplug(s).

Every200hours/Every2years(whichevercomes

rst)—Replacethesparkplug(s).

Makesurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.Use

aspark-plugwrenchforremovingandinstallingthespark

plug(s)andagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplug(s)ifnecessary.

Type:Champion

Airgap:0.76mm(0.03inch)

®

RN9YCorNGK

®

BPR6ES

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.76mm(0.03inch).

g027479

Figure40

33

Page 34

InstallingtheSparkPlug

B

A

25-30 N-m

18.5-22.1 ft-lb

g027960

C

D

Tightenthesparkplug(s)to25to30N∙m(18.5to22.1ft-lb).

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyou,others,andcandamageproperty.

•Performanyfuel-relatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstayaway

fromanopenameorwhereasparkmayignite

thefuelfumes.

Figure41

CleaningtheCoolingSystem

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagetheblade-controlswitchandmovethe

motion-controlleverstothePARKposition.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.Topreventdebrisenteringtheairintake,installtheair

ltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

7.Removetheairlterandinstalltheengineshroud.

g027960

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Checkthein-linefuellter.

Every200hours/Every2years(whichevercomes

rst)—Replacethein-linefuellter.

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Ensurethatthebrakeisengaged,shutofftheengine,

removethekey ,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

8.Installtheairlter.

34

Page 35

g027939

ElectricalSystem

Maintenance

ElectricalSystemSafety

g027939

•Disconnectthebatterybeforerepairingthemachine.

Disconnectthenegativeterminalrstandthepositive

last.Connectthepositiveterminalrstandthenegative

last.

•Chargethebatteryinanopen,well-ventilatedarea,away

fromsparksandames.Unplugthechargerbefore

connectingordisconnectingthebattery.Wearprotective

clothinganduseinsulatedtools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure42

ServicingtheBattery

RemovingtheBattery

WARNING

g033082

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure43).

Note:Retainallfasteners.

35

Page 36

WARNING

G005072

1

2

3

4

5

6

7

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

6.Disconnectthepositive(red)cablefromthebattery

post(Figure43).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure43),andliftthe

batteryfromthebatterytray .

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectthebatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page35).

2.Chargethebatteryforaminimumof1hourat6to

10A.

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure44).

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

g000538

Figure44

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure43).

2.Usingthefastenerspreviouslyremoved,installthe

positive(red)batterycabletothepositive(+)battery

terminal.

3.Usingthefastenerspreviouslyremoved,installthe

negativebatterycabletothenegative(-)battery

g005072

Figure43

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

terminal.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure43).

6.Lowertheseat.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

1.Removethescrewssecuringthecontrolpaneltothe

machine.

36

Page 37

Note:Retainallfasteners.

30

25

30

25

G014921

2

1

2.Liftthecontrolpaneuptoaccessthemainwireharness

andfuseblock(Figure45).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure45).

Figure45

1.Main(30A)2.Chargecircuit(25A)

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure46).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

g014921

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

g000554

Figure46

1.Valvestem

37

Page 38

ReleasingtheElectricBrake

Youcanmanuallyreleasetheelectricbrakebyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergized,the

brakeresets.

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected(Figure47).

MowerMaintenance

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.For

convenientsharpeningandreplacement,keepextrablades

onhand.

BladeSafety

3.Rotatetheshaftforwardtoreleasethebrake.

Figure47

1.Brake-linkarmontheelectricbrakecontrolmodule

2.Left,reartire

Awornordamagedbladecanbreak,andapieceoftheblade

couldbethrownatyouorbystanders,resultinginserious

personalinjuryordeath.Tryingtorepairadamagedblade

mayresultindiscontinuedsafetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthebladesor

weargloves,andusecautionwhenservicingtheblades.

Onlyreplaceorsharpentheblades;neverstraightenor

weldthem.

•Onmulti-bladedmachines,takecareasrotating1blade

cancauseotherbladestorotate.

BeforeInspectingorServicingthe

g027911

Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andmovethe

motion-controlleversoutwardtothePARKposition.

2.Shutofftheengine,removethekey,anddisconnectthe

spark-plugwiresfromthesparkplugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure48).

2.Iftheedgesarenotsharporhavenicks,removeand

sharpentheblade;refertoSharpeningtheBlades(page

40).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforminginthis

area,immediatelyinstallanewblade(Figure48).

Figure48

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

38

g006530

Page 39

CheckingforBentBlades

G014972

1

2

3

G014973

1

2

3

G014974

1

2

3

G014973

1

2

3

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure49).

Figure49

1.Deck3.Blade

2.Spindlehousing

g014974

Figure51

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure52).

Note:Thevarianceshouldbenomorethan3mm

g014972

(1/8inch).

3.Measurefromthetipofthebladetotheatsurface

(Figure50).

Figure50

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition(Figure51).

g014973

Figure52

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

g014973

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page40)and

InstallingtheBlades(page40).

Note:Ifabentbladeisreplacedwithanew

blade,andthedimensionobtainedcontinuesto

exceed3mm(1/8inch),thebladespindlecould

bebent.ContactanAuthorizedToroDealerfor

service.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

6.Repeatthisprocedureoneachblade.

39

Page 40

RemovingtheBlades

G027833

Thebladesmustbereplacedifasolidobjectishit,iftheblade

isoutofbalance,orifthebladeisbent.Forbestperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

g000553

Figure55

1.Blade2.Balancer

1.Holdthebladeendusingaragorthicklypaddedglove.

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure53).

Figure53

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure53).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthecurvedwasher(cuppedsidetowardthe

blade)andthebladebolt(Figure53).

3.Torquethebladeboltto47to88N∙m(35to65ft-lb).

LevelingtheMowerDeck

g027833

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

totheCheckingforBentBlades(page39)beforecontinuing.

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure54).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure54

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure55).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure54).

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Alltiresmustbeproperlyinated;refertoCheckingthe

TirePressure(page37).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

g000552

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

4.Carefullyrotatethebladessothattheyareallsideto

side(Figure56).

40

Page 41

G005278

1

2

2

3

3

4

4

Figure56

G009659

1

2

3

2

3

1.Bladessidetoside

2.Sailareaofblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure56).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuewith

thisprocedure.

6.Movetotheleftsideofthemachine.

7.Loosenthesidelockingnut.

9.Checktheside-to-sideadjustmentsagain.Repeatthis

procedureuntilthemeasurementsarecorrect.

10.Continuelevelingthemowerdeckbycheckingthe

front-to-rearbladeslope;refertoAdjustingthe

Front-to-RearBladeSlope(page41).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

g005278

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutlevertomiddleposition.

Note:Checkandadjusttheside-to-sidebladelevel

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page40).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure58).

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearnut(Figure57).

Note:Rotatetherearnutclockwisetoraisethemower

deck;rotatetherearnutcounter-clockwisetolowerthe

mowerdeck.(Figure57).

g009659

Figure58

1.Bladesfronttorear3.Measurefromthetipofthe

2.Outsidecuttingedges

bladetotheatsurface

here.

5.Measurefromthetipofthefrontbladetotheat

surface,andthetipoftherearbladetotheatsurface

(Figure58).

g027588

Figure57

1.Hangerbracket3.Rearnut

2.Sidelockingnut

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure59).

41

Page 42

G014634

1

2

3

Figure59

G014635

1

2

3

1.Adjustingrod3.Locknut

2.Adjustingblock

7.Toraisethefrontofthemower,tightentheadjustment

nut.

RemovingtheMowerDeck

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpin-cotterpinfromthefrontsupport

rod,andremovetherodfromthedeckbracket(Figure

60).

g014634

8.Tolowerthefrontofthemower,loosentheadjustment

nut.

9.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure58).

10.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain,refertoLeveling

fromSidetoSide(page40).

g014635

Figure60

1.Frontsupportrod3.Deckbracket

2.Lockingnut

5.Carefullylowerthefrontofthemowerdecktothe

ground.

6.Liftthemowerdeckandhangerbracketsclearof

therearliftrodandlowerthemowercarefullytothe

ground(Figure61).

42

Page 43

2

2

3

G005077

1

2

2

3

Figure61

G005192

1

2

3

4

5

6

7

g005077

Figure62

g005192

1.Mowerdeck

2.Hangerbracket

3.Rearliftrod

7.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

8.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

ReplacingtheGrassDeector

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

Inspectthegrassdeectorfordamagebeforeeachuse.

Replaceanydamagedpartsbeforeuse.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsatyouorbystanders,

resultinginseriousinjury.Also,contactwiththe

bladecouldoccur.Neveroperatethemachine

withoutthegrassdeector,thedischargecover,or

thegrass-collectionsysteminplace.

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

5.Spring

2.Slidetherodoutoftheshortstandoff,spring,andthe

grassdeector(Figure62).

3.Removethedamagedorworngrassdeector.

4.Replacethegrassdeector(Figure62).

5.Slidetherod(straightend),throughthe

rear-grass-deectorbracket.

6.Placethespringontherod,withtheendwiresdown

andbetweenthegrass-deectorbrackets.

7.Sliderodthroughthesecondgrass-deectorbracket

(Figure62).

8.Inserttherodatthefrontofthegrassdeectorinto

theshortstandoffonthedeck.

9.Securetherearendoftherodintothemowerwitha

nut(3/8inch)asshowninFigure62.

Important:Thegrassdeectormustbespring

loadedandinthedownposition.Liftthedeector

uptotestthatitsnapstothefullydownposition.

Neveroperatethemachinewithoutthegrass

deector,thedischargecover,orthegrass-collection

systeminplace.

SSMachinesOnly

1.Removethenut(3/8inch)fromtherodunderthe

mower(Figure62).

MXMachinesOnly

Inspectthegrassdeectorfordamagebeforeeachuse.

Replaceanydamagedpartsbeforeuse.

1.Disengagethespringfromthenotchinthedeector

bracketandslidetherodoutoftheweldeddeck

brackets,spring,anddischargedeector(Figure63).

43

Page 44

g017617

1

3

2

4

5

g017618

1

3

4

2

Figure64

g017618

Figure63

1.Rod4.Deckbrackets

2.Spring5.Springinstalledoverthe

3.Deector

2.Removethedamagedorworndischargedeector.

rod

3.Positionthenewdischargedeectorwiththebracket

endsbetweentheweldedbracketsonthedeckas

showninFigure64.

4.Installthespringontothestraightendoftherod.

5.Positionthespringontherodasshowninsothe

shorterspringendiscomingfromundertherodbefore

thebendandgoingovertherodasitreturnsfromthe

bend.

1.Rodandspringassembly

installed

2.Loopendofthespring

installedintothenotchin

thedeectorbracket

3.Rod,shortend,moved

behindmowerbracket

4.Shortend,retainedby

mowerbracket.

7.Securetherodandspringassemblybytwistingitsothe

shortendoftherodisplacedbehindthefrontbracket

weldedtothedeck(Figure64).

g017617

Important:Thegrassdeectormustbespring

loadedinthedownposition.Liftthedeectorup

totestthatitsnapstothefulldownposition.

6.Lifttheloopendofthespringandplaceitintothe

notchonthedeectorbracket(Figure64).

44

Page 45

MowerBeltMaintenance

G014931

1

2

3

3

4

5

6

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsforwear

orcracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMower-Deck Belt

Thesignsofawornbeltincludesquealingwhilethebeltis

rotating,bladesslippingwhilecuttinggrass,andfrayededges,

burnmarks,andcracksonthebelt.Replacethemowerbeltif

anyoftheseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothePARK

position,shutofftheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

Figure66

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

4.Spring

g014931

3.Settheheight-of-cutatthelowestcuttingpositionof

38mm(1-1/2inches).

4.Removethepulleycovers(Figure65).

Figure65

1.Cover2.Screw

5.Usingaspring-removaltool(ToroPartNo.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulley ,androllthebeltoffthe

pulleys(Figure66).

6.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure66).

7.Usingaspring-removaltool,installtheidlerspringover

thedeckhook,andplacetensionontheidlerpulley

andmowerbelt(Figure66).

8.Installthepulleycovers(Figure65).

g032555

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

45

Page 46

Cleaning