Toro TimeCutter HD MyRide 48in, TimeCutter HD MyRide 54in, 75213, TimeCutter HD MyRide 60in, 75212 Operator's Manual

Page 1

FormNo.3415-511RevA

TimeCutter

®

HDMyRide48in,

54in,and60inRidingMower

ModelNo.75211—SerialNo.400000000andUp

ModelNo.75212—SerialNo.400000000andUp

ModelNo.75213—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3415-511*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

GrossHorsepower

Thegrossornethorsepowerofthisenginewas

laboratoryratedbytheenginemanufacturerin

accordancewiththeSocietyofAutomotiveEngineers

(SAE)J1940.Asconguredtomeetsafety,emission,

andoperatingrequirements,theactualenginetorque

onthisclassofmowerwillbesignicantlylower.

Gotowww.T oro.comtoviewspecicationsonyour

mowermodel.

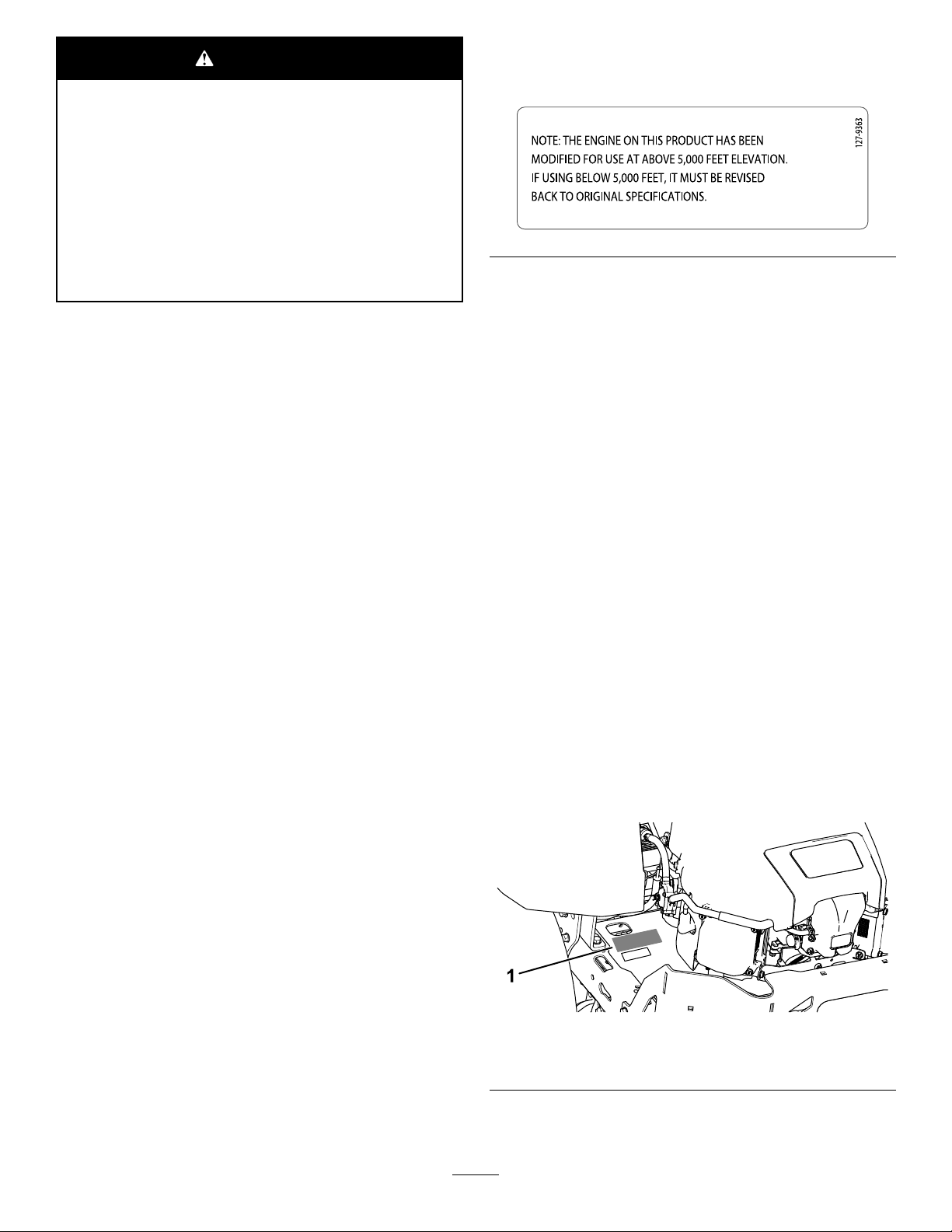

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EP A

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachine

hasbeenconvertedforhigh-altitudeuse,lookfor

thefollowinglabel.

decal127-9363

Introduction

Thisrotary-blade,ridinglawnmowerisintended

tobeusedbyresidentialhomeownersorhired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g188704

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-AlertSymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview....................................................11

Controls............................................................11

BeforeOperation.................................................13

BeforeOperationSafety...................................13

RecommendedFuel.........................................13

UsingStabilizer/Conditioner.............................14

FillingtheFuelTank..........................................14

CheckingtheEngine-OilLevel..........................14

BreakinginaNewMachine..............................14

ThinkSafetyFirst..............................................15

UsingtheSafety-InterlockSystem....................15

PositioningtheSeat..........................................16

AdjustingtheMyRide™Suspension

System..........................................................17

AdjustingtheMotion-ControlLevers.................18

DuringOperation.................................................18

DuringOperationSafety...................................18

OperatingtheParkingBrake.............................20

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................20

OperatingtheThrottle.......................................21

OperatingtheChoke.........................................21

OperatingtheIgnitionSwitch............................21

StartingandShuttingOfftheEngine.................22

UsingtheMotion-ControlLevers.......................22

DrivingtheMachine..........................................23

UsingtheSmartSpeed

TM

Control

System..........................................................24

StoppingtheMachine.......................................24

UsingtheSideDischarge.................................25

AdjustingtheHeightofCut...............................26

AdjustingtheAnti-ScalpRollers........................27

UsingAttachmentsandAccessories.................27

OperatingTips.................................................28

AfterOperation....................................................29

AfterOperationSafety......................................29

PushingtheMachinebyHand..........................29

TransportingtheMachine.................................30

LoadingtheMachine........................................30

Maintenance...........................................................32

g000502

RecommendedMaintenanceSchedule(s)...........32

Pre-MaintenanceProcedures..............................33

MaintenanceandStorageSafety......................33

EngineMaintenance...........................................34

EngineSafety...................................................34

ServicingtheAirCleaner..................................34

ServicingtheEngineOil....................................35

ServicingtheSparkPlug...................................37

CleaningtheCoolingSystem............................38

FuelSystemMaintenance...................................39

ReplacingtheIn-LineFuelFilter.......................39

ElectricalSystemMaintenance...........................40

ElectricalSystemSafety...................................40

ServicingtheBattery.........................................40

ServicingtheFuses..........................................42

DriveSystemMaintenance..................................42

CheckingtheTirePressure...............................42

MowerMaintenance.............................................43

ServicingtheCuttingBlades.............................43

LevelingtheMowerDeck..................................46

RemovingtheMowerDeck...............................47

InstallingtheMowerDeck.................................48

ReplacingtheGrassDeector..........................49

MowerBeltMaintenance......................................50

InspectingtheBelts..........................................50

ReplacingtheMowerBelt.................................50

Cleaning..............................................................51

WashingtheUndersideoftheMower................51

CleaningtheSuspensionSystem.....................51

DisposingofWaste...........................................51

Storage...................................................................52

CleaningandStorage.......................................52

Troubleshooting......................................................53

Schematics.............................................................55

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

4

Page 5

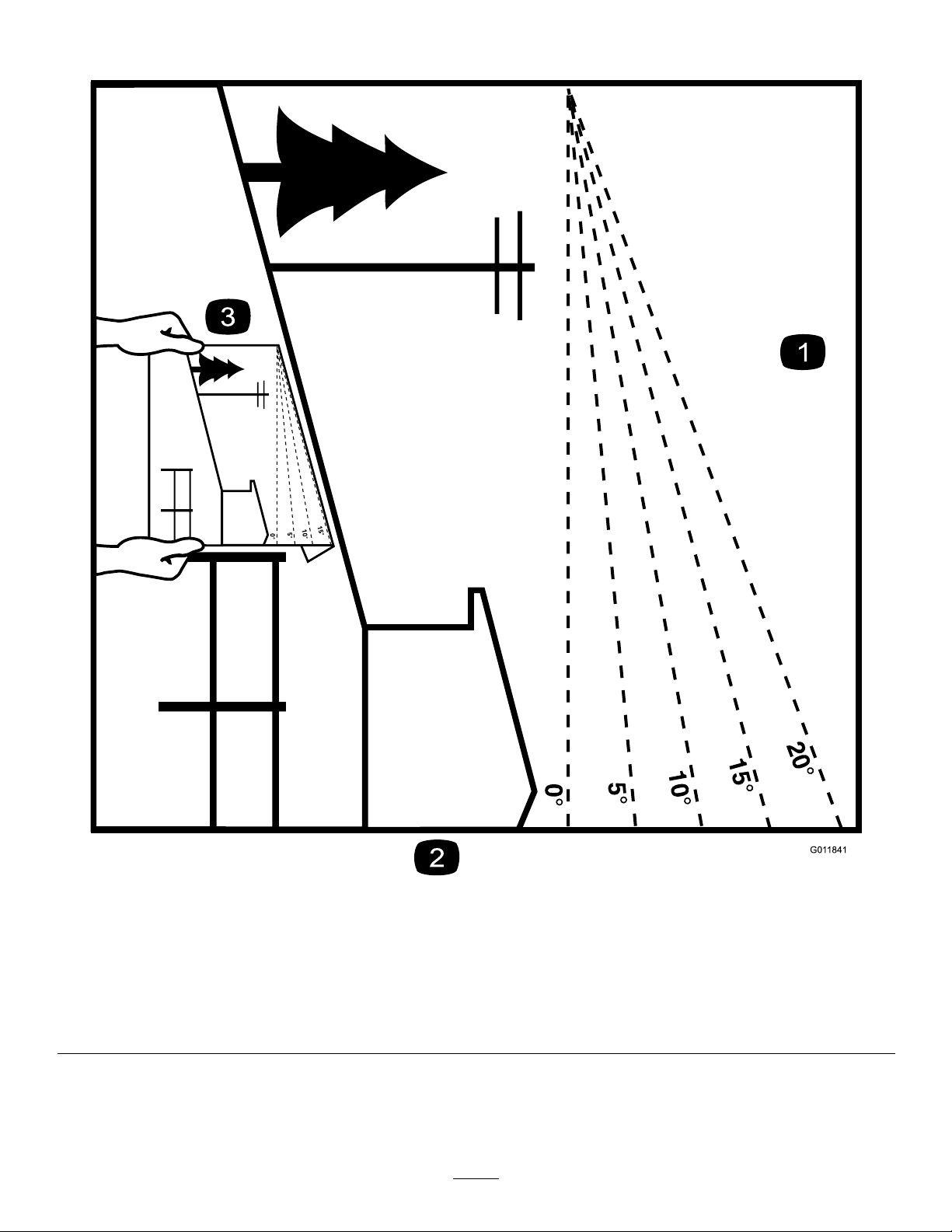

SlopeIndicator

G011841

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

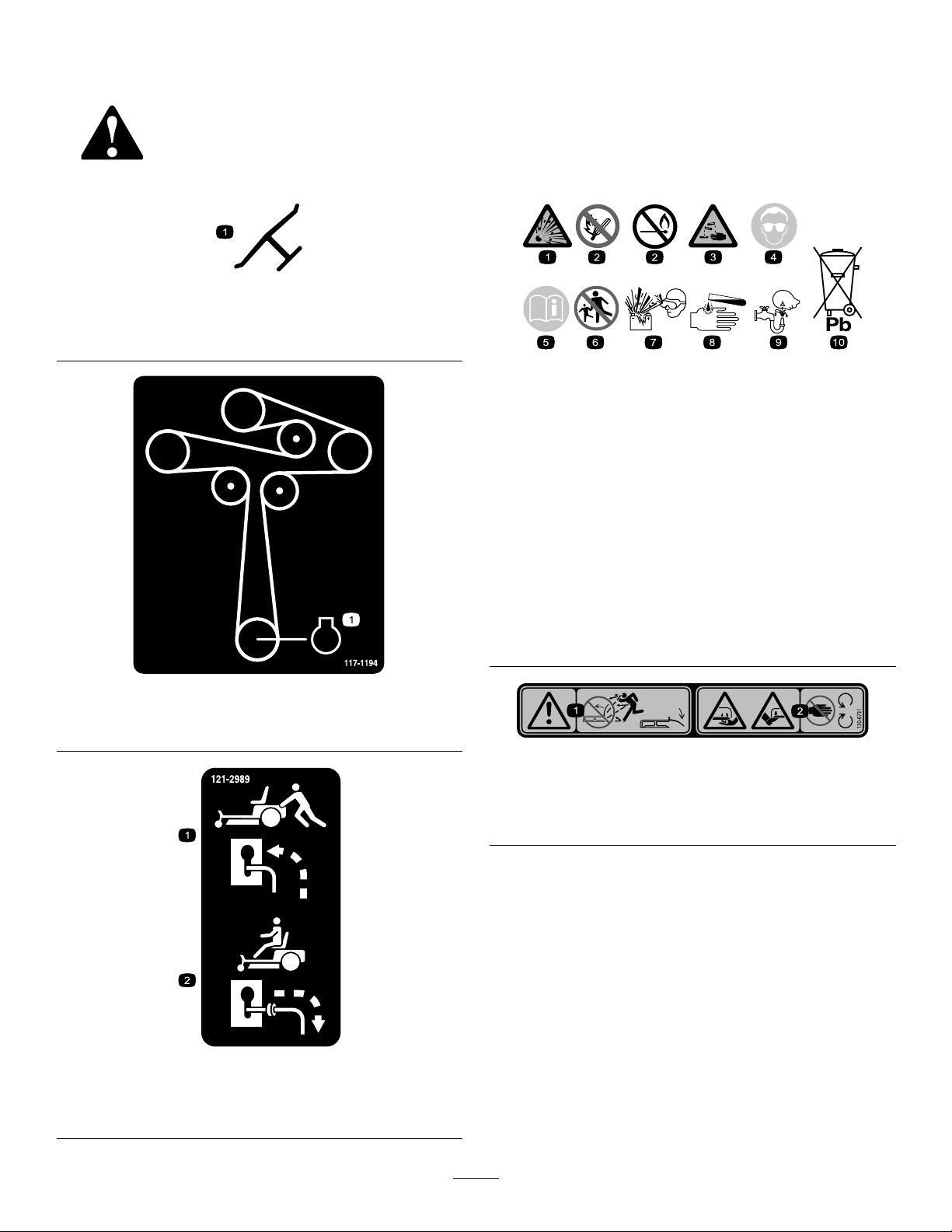

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decaloemmarkt

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

decal117-1 194

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

117-1194

1.Engine

decal130-0731

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

1.Bypassleverpositionfor

pushingthemachine

decal121-2989b

121-2989

2.Bypassleverpositionfor

operatingthemachine

6

Page 7

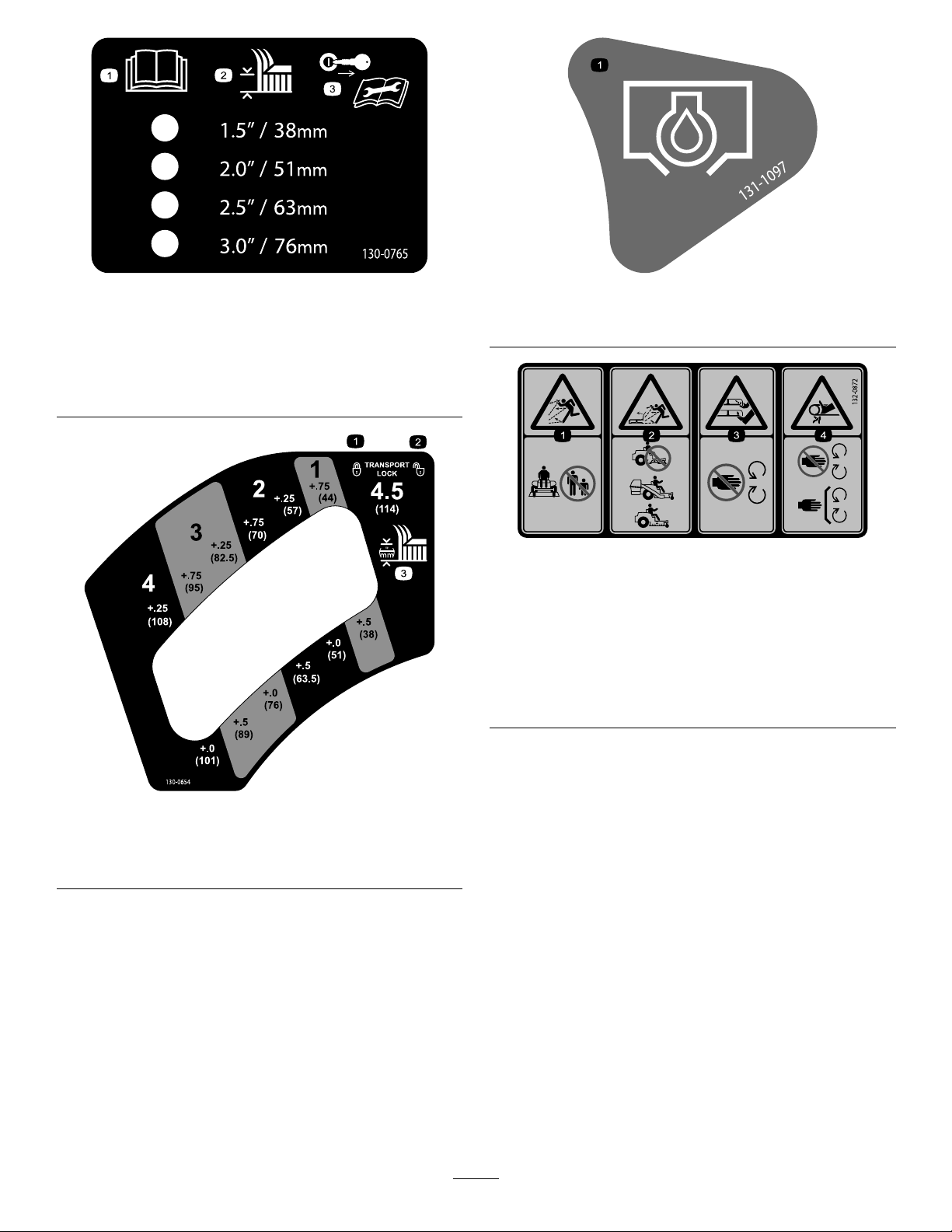

decal130-0765

130-0765

131-1097

decal131-1097

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

performingmaintenance.

1.Oildrain

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

decal132-0872

132-0872

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

decal130-0654

130-0654

1.Transport—lock

2.Transport—unlock

3.Heightofcut

7

Page 8

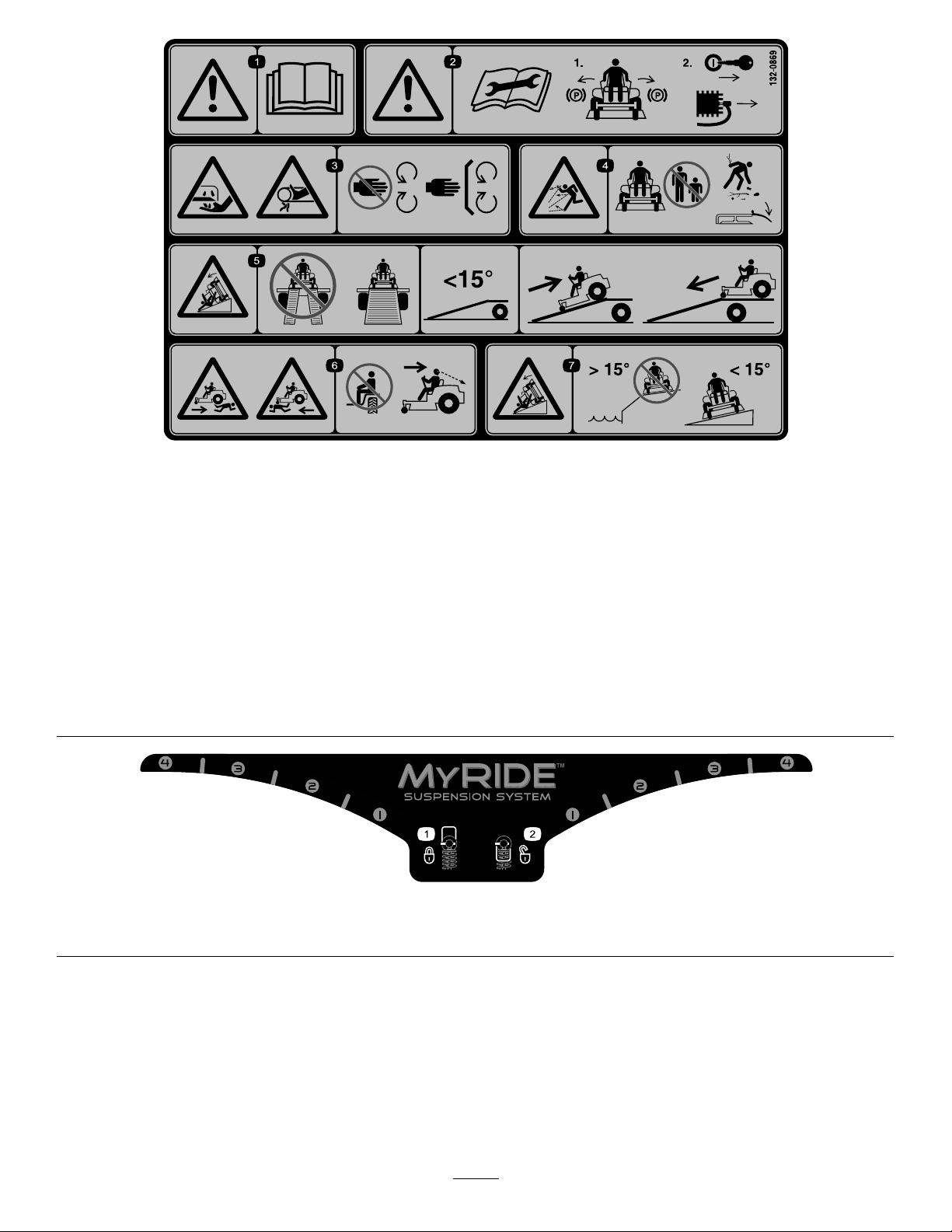

decal132-0869

132-0869

1.Warning—readtheOperator'sManual.

2.Warning—readtheinstructionsbeforeservicingorperforming

5.Ramphazard—Whenloadingontoatrailer,donotusesplit

6.Crushing/dismembermenthazardofbystanders,inreverse

maintenance;movethemotion-controlleverstothepark

(brake)position,removetheignitionkey,anddisconnectthe

spark-plugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

7.Tippinghazard—donotusethemachineneardrop-offswith

hazard,belt—stayawayfrommovingpartsandkeepall

guardsandshieldsinplace.

4.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine,pickupdebrisbeforeoperating,and

keepthedeectorinplace.

133-5198

1.Camlock2.Camunlock

ramps.Onlyuseafull-widthrampwideenoughforthe

machine.Rampanglewiththegroundshouldbelessthan15

degrees.Backuptherampanddriveforwardofftheramp.

andforward—donotcarrypassengers,lookbehindanddown

whenreversing.

slopesgreaterthan15degreesornearwater;onlyuseon

slopeslessthan15degrees.

decal133-5198

8

Page 9

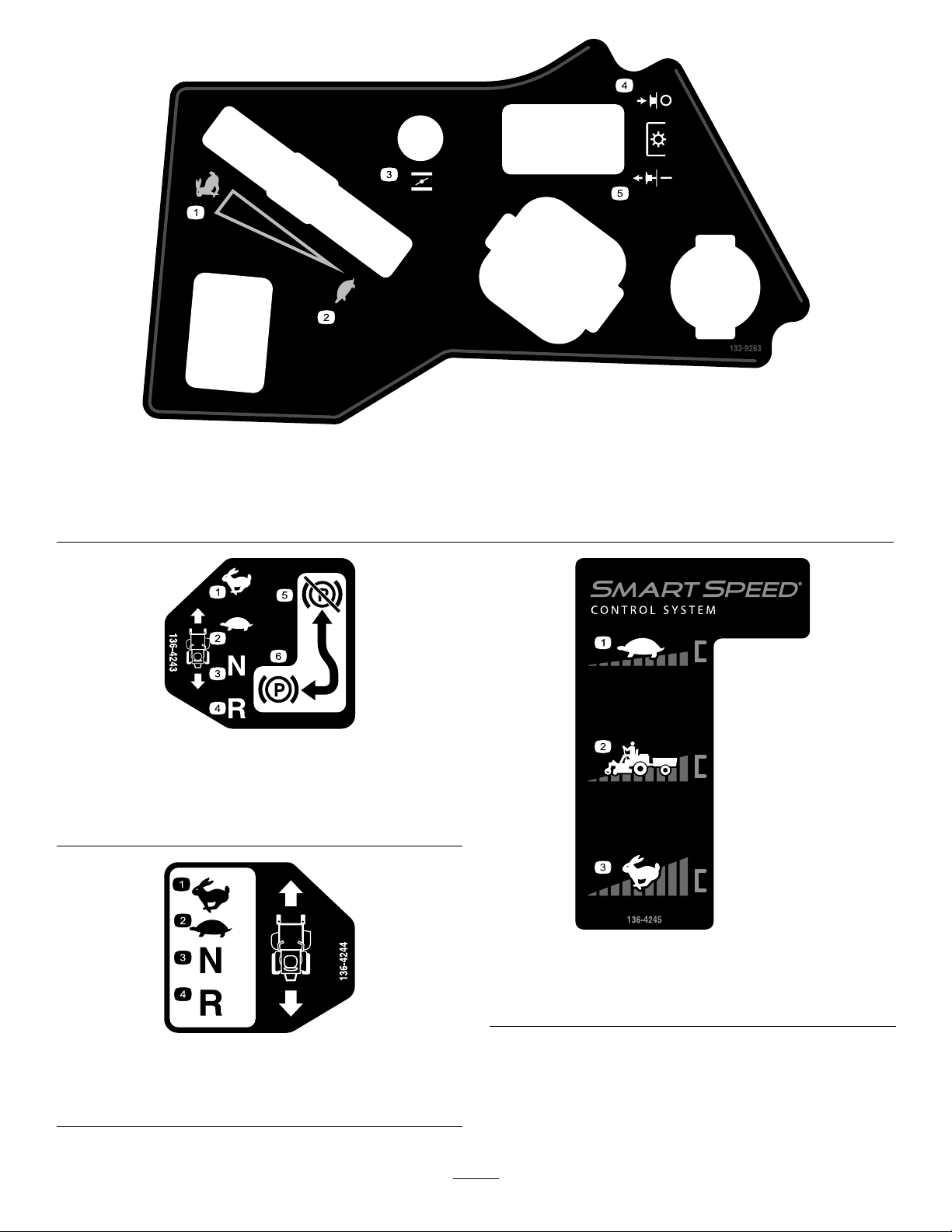

decal133-9263

133-9263

1.Fast

2.Slow5.PTOengage

3.Choke

decal136-4243

136-4243

1.Fast4.Reverse

2.Slow

3.Neutral6.Parkingbrakeengaged

5.Parkingbrakedisengaged

4.PTOdisengage

136-4244

1.Fast3.Neutral

2.Slow

decal136-4245

136-4245

1.Slow

2.Transport

decal136-4244

4.Reverse

3.Fast

9

Page 10

decal136-5596

136-5596

1.Checkthetirepressure

every25operatinghours.

2.Engineoil

4.Checkthetirepressure

every25operatinghours.

5.ReadtheOperator's

Manualbeforeperforming

maintenance.

3.Checkthetirepressure

every25operatinghours.

136-9186

1.ReadtheOperator'sManualbeforeaddingweighttothe

bucket.

decal136-9186

10

Page 11

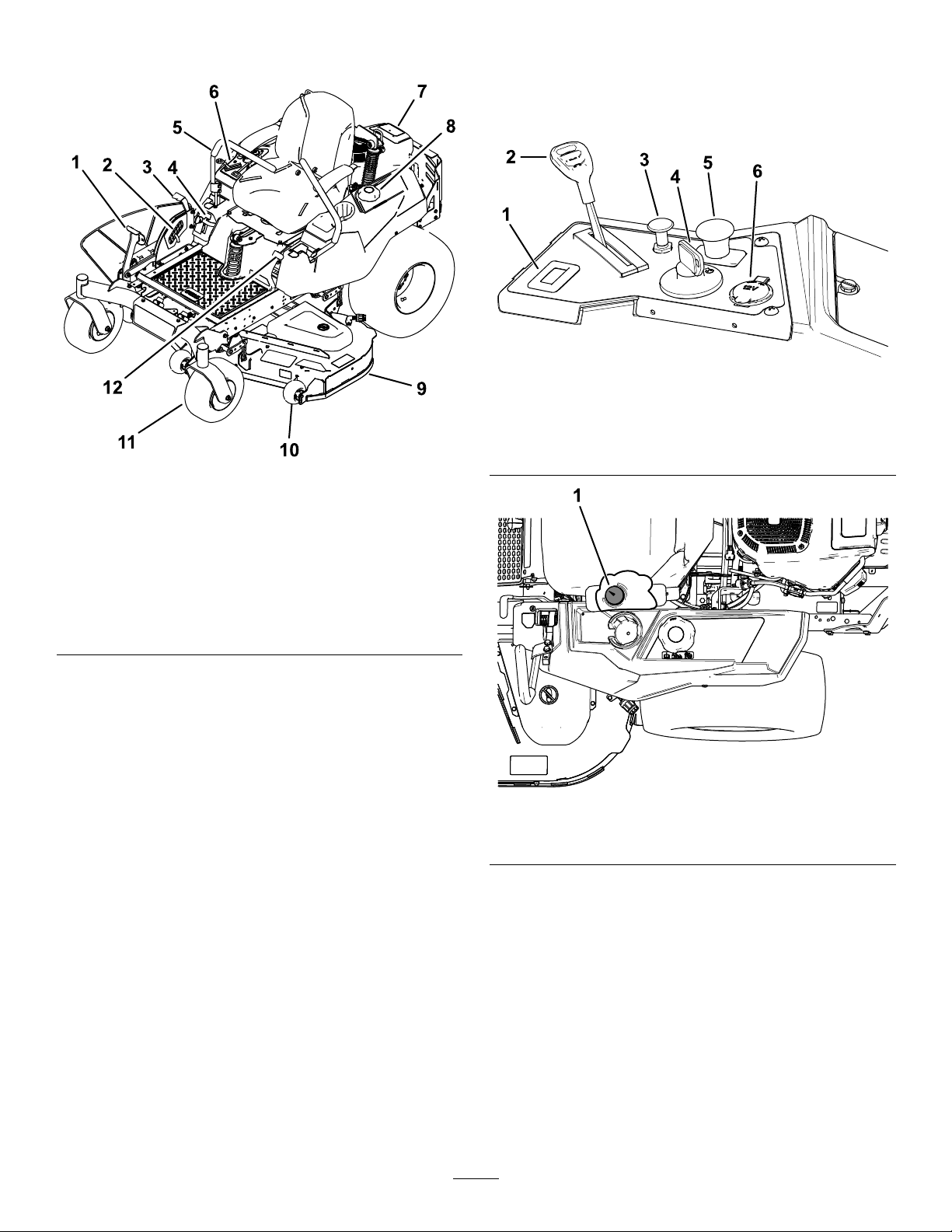

ProductOverview

Controls

BecomefamiliarwithallcontrolsinFigure6and

Figure7beforeyoustarttheengineandoperatethe

machine.

g188738

Figure6

1.Hourmeter4.Ignitionswitch

2.Throttlecontrol

3.Chokecontrol

g195717

Figure5

5.PTOswitch

6.12Vpowerpoint

1.Deck-liftpedal

2.Height-of-cutpin

3.Height-of-cut

lever/transportlock

4.SmartSpeed™lever

5.Motion-controllever

6.Controls

7.Engine

8.Fuelcap

9.Mowerdeck

10.Anti-scalproller

11.Casterwheel

12.Parking-brakelever

g188776

Figure7

1.Fuelgauge

FuelGauge

Thefuelgaugedisplaystheamountoffuelinthetank

(Figure7).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

11

Page 12

ChokeControl

12VPowerPoint

Usethechokecontroltostartacoldengine.Pullthe

chokecontroluptoengageit.Pushdownonthe

chokecontroltodisengageit.

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

Motion-ControlLevers

Themotion-controlleversarespeed-sensitivecontrols

ofindependentwheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltothe

amounttheleverismoved.Movethecontrollevers

outwardfromthecentertotheNEUTRAL-LOCKposition

andexitthemachine(Figure5).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Usethepowerpointtopower12Vaccessories

(Figure6).

Important:Whennotusingthe12Vpowerpoint,

inserttherubberplugtopreventdamagetothe

powerpoint.

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3

positions:ST ART,RUN,andOFF.

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch(PTO)engagesand

disengagespowertothemowerblades(Figure6).

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Onlyadjust

theheightofcutwhilemachineisnotmoving(Figure

5).

Theparking-brakeleverislocatedonleftsideof

theconsole(Figure5).Thebrakeleverengagesa

parkingbrakeonthedrivewheels.

Toengagetheparkingbrake,pulluptheleveruntilit

latchesintothedetentslot.

Todisengagetheparkingbrake,pulltheleveroutof

thedetentslotandtowardyou,thenpushitdown.

FootPedalDeck-LiftSystem

Thefootpedaldeck-liftsystemallowsyoutolower

andraisethedeckfromtheseatedposition.Y ou

canusethefootpedaltoliftthedeckbrieytoavoid

obstaclesorlockthedeckinthehighestheightofcut

ortransportposition(Figure5).

SmartSpeed™ControlSystem

Lever

TheSmartSpeed™Control-Systemlever,located

belowtheoperatingposition,givesyouachoiceto

drivethemachineat3speedranges—trim,tow,and

mow(Figure27).

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

12

Page 13

Operation

containersontheground,awayfromyourvehicle

beforelling.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

13

Page 14

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless

(drainthefueltankwhenstoringthemachinefor

morethan90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

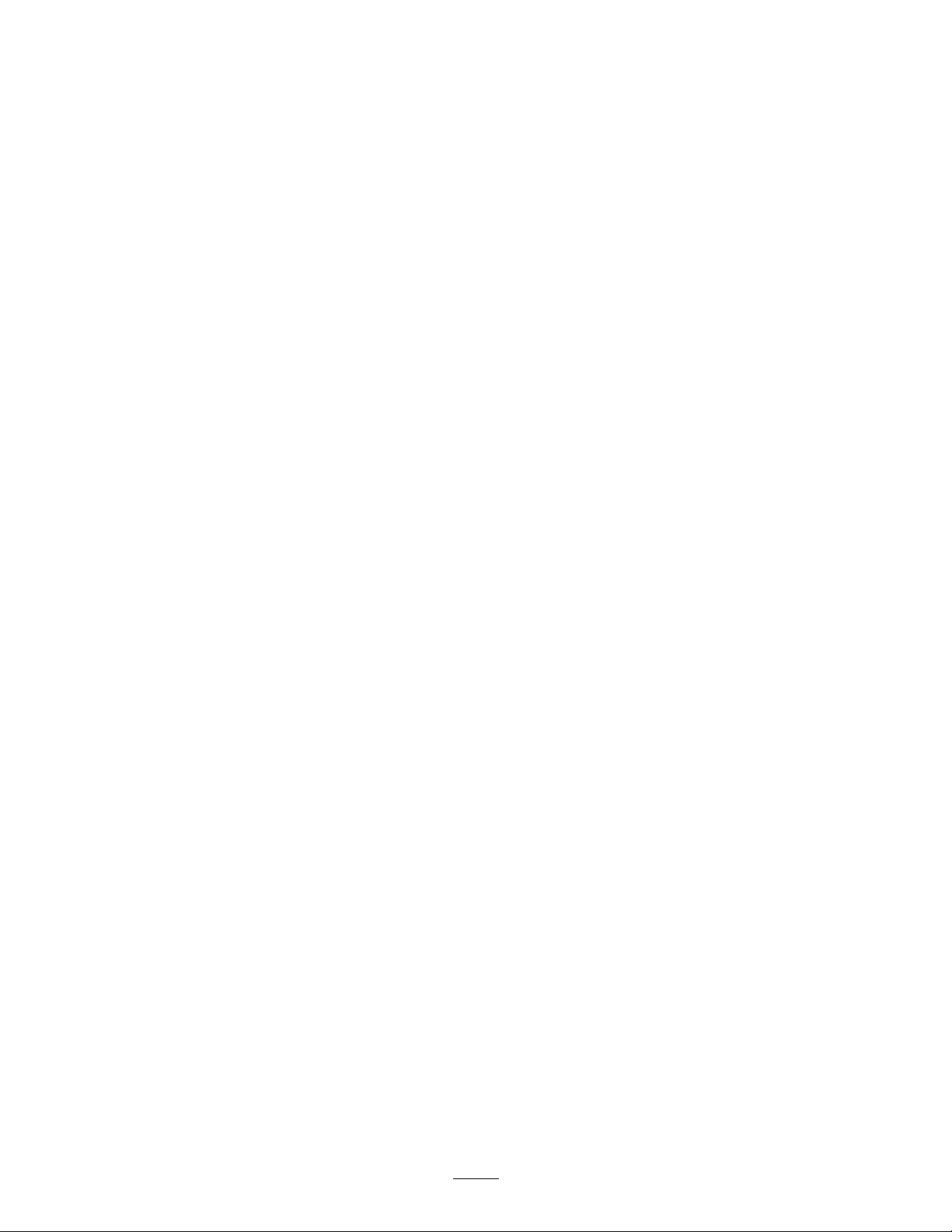

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltankuntilthefuelgaugereadsatthe

fullmark(Figure8).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

g197123

Figure8

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page14).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

14

Page 15

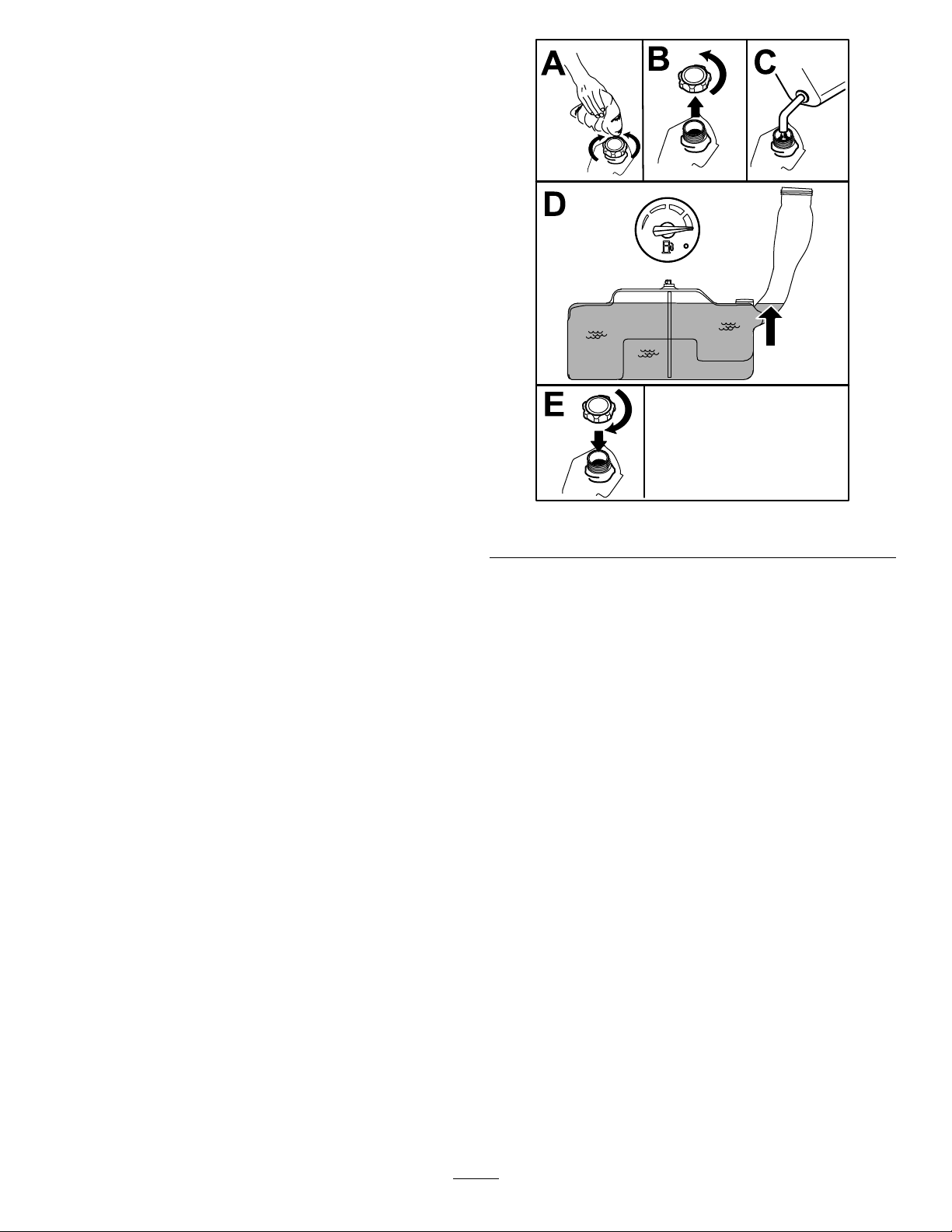

ThinkSafetyFirst

G009027

1

2

CAUTION

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,

feet,andhead.

g009027

Figure10

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheSafety-Interlock

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

Figure9

3.Water

System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

g000513

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

•Theparkingbrakeisengaged.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewheneverthecontrolleversareoutof

theNEUTRAL-LOCKpositionandyourisefromtheseat.

15

Page 16

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotcrank.

2.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controllever(out

oftheNEUTRAL-LOCKposition).Trystartingthe

engine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

theNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,releasetheparking

brake,engagetheblade-controlswitch(PTO),

andriseslightlyfromtheseat;theengineshould

shutoff.

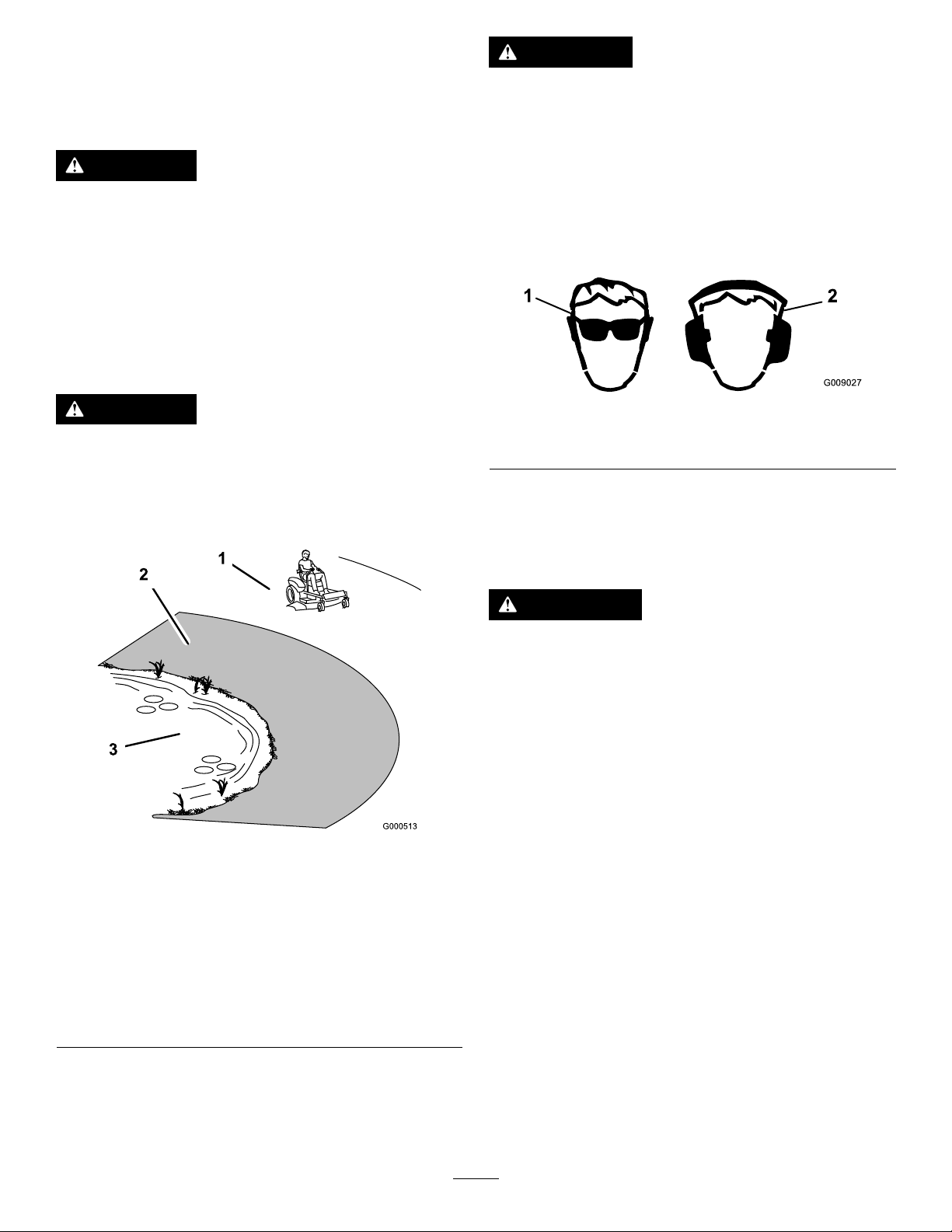

PositioningtheSeat

Theseatmovesforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

Toadjust,movetheleversidewaystounlocktheseat

(Figure11).

g027632

Figure11

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

toNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,centereither

motion-controlleverandmoveitforwardor

reverse;theengineshouldshutoff.Repeatfor

othermotion-controllever.

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

NEUTRAL-LOCKposition.Trystartingtheengine;

theengineshouldnotcrank.

16

Page 17

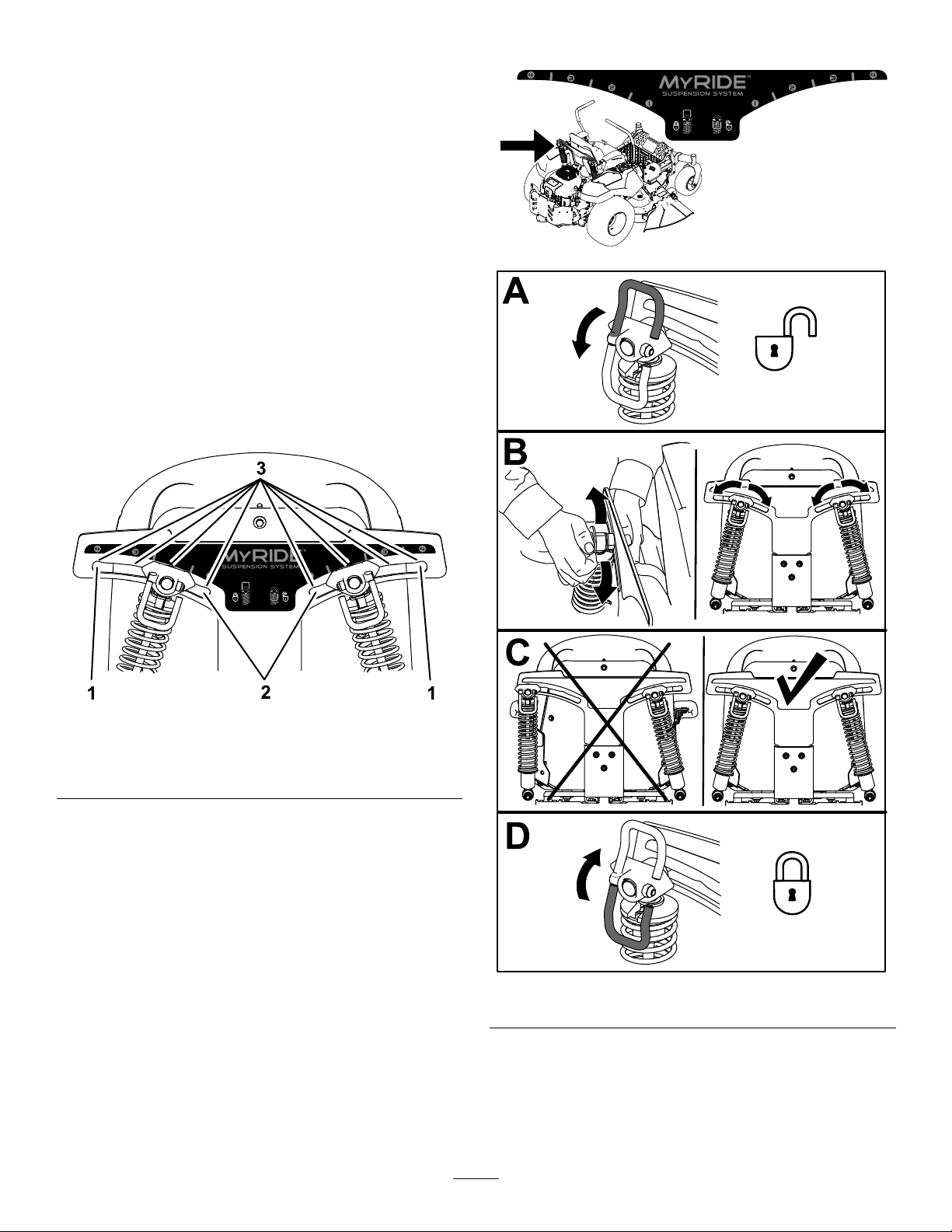

AdjustingtheMyRide™ SuspensionSystem

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Adjustingtherear

2-shockassembliesistheeasiestandquickest

adjustmentforchangingthesuspensionsystem.

Positionthesuspensionsystemwhereyouaremost

comfortable.

Adjusttherear-shockassemblies(Figure13).

AdjustingtheRear-Shock

Assemblies

Theslotsfortherear-shockassemblieshave

detentpositionsforreference.Youcanpositionthe

rear-shockassembliesanywhereintheslot,notjust

inthedetentpositions.

Thefollowinggraphicshowsthepositionforasoftor

rmrideandthedifferentdetentpositions(Figure12).

g195746

Figure12

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

g195744

g195745

Figure13

17

Page 18

g027252

B

A

Adjustingthe Motion-ControlLevers

AdjustingtheHeight

Youcanadjustthemotion-controllevershigheror

lowerformaximumcomfort(Figure14).

Figure14

AdjustingtheTilt

Youcanadjustthemotion-controlleversforwardor

rearwardforyourcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrol-armshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforwardorrearward(Figure14).

3.Tightenbothboltstosecurethecontrolleverin

thenewposition.

4.Repeattheadjustmentfortheothercontrollever.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;and

hearingprotection.Tiebacklonghairanddonot

wearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

g027252

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

18

Page 19

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly.

SlopeSafety

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecavesin.Establisha

safetyareabetweenthemachineandanyhazard

(2machinewidths).

•A2-postROPS(RolloverProtectionSystem)is

availableforthemachineasanaccessory.A

ROPSisrecommendedifyouwillbemowingnext

todrop-offs,nearwater,oronsteepbankswhich

couldresultinarollover.ContactanAuthorized

ServiceDealerformoredetails.TheCalifornia

CodeofRegulationsrequiresROPS(ifavailable)

onallmowersusedcommerciallyeffectiveMarch

1,201 1.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

sloperequiresextracaution.

•Operatethemachineatalowerspeedwhenyou

areonaslope.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.T allgrasscanhideobstacles.

•Choosealowgroundspeedsoyouwillnothave

tostoporshiftwhileonaslope.

•Arollovercanoccurbeforethetireslosetraction.

•Avoidoperatingthemachineonwetgrass.Tires

maylosetraction;regardlessifthebrakesare

availableandfunctioning.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

19

Page 20

OperatingtheParking

G008945

G009174

OperatingtheMower

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

Toengagetheparkingbrake,pulluptheparking

brakeuntilitlatchesintothedetentslot(Figure15).

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control

Switch(PTO)

g008945

Figure17

Note:Alwaysengagethebladeswiththethrottlein

theFASTposition(Figure18).

Figure15

1.Pulluptheparkingbrake.

DisengagingtheParkingBrake

Todisengagetheparkingbrake,pulltheleveroutof

thedetentslotandtowardyou,thenpushitdown

(Figure16).

Figure16

1.Pushtheparkingbrake

outofthedetentslotand

towardyou.

2.Pushtheparkingbrake

down.

g188778

g187516

Figure18

DisengagingtheBlade-Control

Switch(PTO)

g188777

g009174

Figure19

20

Page 21

OperatingtheThrottle

G008959

1

2

START

RUN

STOP

G008947

OperatingtheIgnition

YoucanmovethethrottlecontrolbetweentheFAST

andSLOWpositions(Figure20).

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

Figure20

OperatingtheChoke

Usethechoketostartacoldengine.

Switch

1.TurntheignitionkeytotheSTARTposition

(Figure22).

Note:Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostart,allowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Y oumayneedmultipleattemptstostart

theenginewhenyoustartitthersttimeafter

thefuelsystemhasbeenwithoutfuelcompletely.

g187517

1.Iftheengineiscold,usethechoketostartthe

engine.

Figure22

g008947

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure21).

3.Pushdownonthechoketodisengagethechoke

2.Turntheignitionkeytoshutofftheengine.

aftertheenginehasstarted(Figure21).

g008959

Figure21

1.ONposition2.OFFposition

21

Page 22

StartingandShuttingOff

UsingtheMotion-Control

theEngine

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

Levers

Figure23

ShuttingOfftheEngine

1.Disengagethebladesbymovingthe

blade-controlswitchtotheOFFposition(Figure

21).

g004532

Figure24

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

g189354

4.Backward

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytotheOFFpositionand

removethekey.

22

Page 23

DrivingtheMachine

G008952

DrivingForward

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Themachinecanspinveryrapidly ,which

maycauseyoutolosecontrolofmachine,

resultinginpersonalinjuryordamageto

machine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Note:Theenginestopswhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostop,pullthemotion-controlleverstotheNEUTRAL

position.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page20).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure25).

Figure25

g008952

23

Page 24

DrivingBackward

G008953

3.Adjustthelevertothedesiredposition.

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure26).

Figure26

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,

andtheheightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

TransportX

TrimTowMow

X

X

Trim

Thisisthelowestspeed.Thesuggestedusesforthis

speedareasfollows:

•Parking

g008953

•Heavy,wetgrassmowingconditions

•Training

UsingtheSmartSpeed

ControlSystem

TheSmartSpeed

therightoftheoperatingposition(Figure27),gives

youachoicetodrivethemachineat3groundspeed

ranges—trim,tow,andmow.

1.Smart-speedlever

Tochangespeeds,dothefollowing:

TM

Control-Systemlever,locatedto

Figure27

Tow

TM

Thisisthemediumspeed.Thesuggestedusesfor

thisspeedareasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthis

speedareasfollows:

•Normalmowing

•Transportingthemachine

StoppingtheMachine

Tostopthemachine,movethetraction-controllevers

toneutral,andthenmovethemtothelockedposition,

disengagetheblade-controlswitch(PTO),andturn

g197125

theignitionkeytotheOFFposition.

Engagetheparkingbrakewhenyouleavethe

machine;refertoEngagingtheParkingBrake(page

20).Remembertoremovethekeyfromtheignition

switch.

1.Movethemotion-controlleverstoneutraland

outwardtotheNEUTRAL-LOCKposition.

2.Disengagetheblade-controlswitch.

24

Page 25

CAUTION

UsingtheSideDischarge

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatetheignitionkeytotheOFF

position,andremovethekey.

•Makesurethatthegrassdeectorisinthe

downposition.

25

Page 26

AdjustingtheHeightofCut

g024409

Themachineisequippedwithafootpedaldeck-lift

system.Youcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthe

highestheightofcutortransportposition.Youcan

usetheheight-of-cutleverwiththefootpedaltolock

thedeckinaspeciccuttingheight.

UsingtheFootPedalDeck-Lift

System

•Pressthedeck-liftpedaldowntoraisethedeck;

continuetopressthepedaluntilthedecklocksin

thetransportposition(Figure28).

•Pushonthedeck-liftpedalwithyourfootandpull

thetransportlockhandlerearwardtodisengage

thetransportlock(Figure28).

3.Selectaholeintheheight-of-cutsystem

correspondingtothedesiredheightofcutand

insertthepin(Figure29).

4.Pushonthedeck-liftpedalwithyourfootand

pullthehandlerearwardtodisengagethe

transportlock(Figure28).

5.Lowerthedeckslowlyuntilthelevermakes

contactwiththepin.

Figure28

TransportLockPosition

AdjustingtheHeightofCut

Youcanadjusttheheightofcutfrom38to114mm

(1-1/2to4-1/2inches)in6mm(1/4inch)increments

byrelocatingtheheight-of-cutpinintodifferenthole

locations.

g188850

Figure29

1.Deck-liftpedal

2.Handle

g024409

3.Pin

4.Height-of-cutpositions

1.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktothetransport-lock

position(alsothe114mm(4-1/2inches)cutting

heightposition)asshowninFigure29.

2.T oadjust,removethepinfromtheheight-of-cut

bracket(Figure29).

26

Page 27

AdjustingtheAnti-Scalp

g029955

UsingAttachmentsand

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

30.

Accessories

UseonlyToroapprovedattachmentsandaccessories.

Ifyouattachabuckettotheengineguard,useanylon

straptosecureit.

Important:Thebucketweightimpactsthe

stabilityofthemachine.Ifyouarecarryingmore

thantheweightlistedinthetablebelowina

bucketattachedtotheengineguard,youmust

equipyourmachinewiththeBucket-SupportKit.

ContactyourauthorizedToroservicedealer.

ModelMaximumweightperbucket

48-inchdeck

54-inchdeck

60-inchdeck

withouttheBucket-Support

Kit

1.1kg(2.5lb)

1.1kg(2.5lb)

4.5kg(10lb)

Figure30

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

g029955

27

Page 28

OperatingTips

UsingtheFastThrottleSetting

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

inuncutgrass.Alwaystrytohave1sideofthemower

freefromuncutgrass,whichallowsairtobedrawn

intothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

thepastisgenerallythebestonetouse.Whencutting

grasslongerthan15cm(6inches)tall,youmaywant

tocutthelawntwicetoensureanacceptablequality

ofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.T omaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

28

Page 29

AfterOperation

PushingtheMachineby Hand

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

Important:Alwayspushthemachinebyhand.Do

nottowthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,and

topushthemachine,theignitionkeymustbeinthe

RUNposition.Thebatteryneedstobechargedand

functioningfortheelectricbraketobedisengaged.

PushingtheMachine

1.Parkthemachineonalevelsurface,and

disengagetheblade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,

andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversforwardthroughthekey

holeanddowntolocktheminplace(Figure31).

Note:Dothisforeachlever.

5.Disengagetheparkingbrake.

Note:Donotstartthemachine.

1.Bypasslever

2.Leverpositionforpushing

29

g188854

Figure31

3.Leverpositionfor

operatingthemachine

themachine

Page 30

OperatingtheMachine

LoadingtheMachine

Movethebypassleversrearwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure31.

Note:Dothisforeachlever.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampanddriveitforward

downtheramp(Figure33).

Figure33

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure34).

•Useextremecautionwhenoperatinga

machineonaramp.

g027995

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthe

brake,andclosethefuelvalve.

5.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumper(Figure32).

Figure32

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast

4timesaslongastheheightofthetrailer

ortruckbedtotheground.Thisensures

thattherampangledoesnotexceed15

degreesonatground.

•Backuprampsanddriveforwarddown

ramps.

g027708

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

30

Page 31

g027996

5

1

2

6

Figure34

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

31

Page 32

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,loose,ordamagedparts.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Cleantheair-cleanerfoamelement(moreoftenindusty ,dirtyconditions).

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Replacetheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Servicetheair-cleanerpaperelement(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenindusty,dirtyconditions).

•Changetheoillter(moreoftenindusty,dirtyconditions).

•Checkthesparkplug(s).

•Checkthein-linefuellter.

•Replacetheair-cleanerpaperelement(moreoftenindusty,dirtyconditions).

•Replacethesparkplug(s).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

Beforestorage

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyouperformanymaintenance.

32

Page 33

Pre-Maintenance

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

Procedures

MaintenanceandStorage Safety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesor

drainthefuelindoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingcondition

andallhardwaretightened,especiallythe

blade-attachmentbolts.Replaceallwornor

damageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

33

Page 34

EngineMaintenance

g027800

g027801

g027802

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothing,and

otherbodypartsawaythemuferandother

hotsurfaces.

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy.

g027800

RemovingtheElements

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch(PTO).

2.Engagetheparkingbrake,shutofftheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Cleanaroundtheair-cleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.

4.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(Figure35).

g027801

Figure35

5.Removethefoamelementfromthepaper

element(Figure36).

g027802

Figure36

ServicingtheFoamElement

ServiceInterval:Every25hours/Monthly(whichever

comesrst)—Cleantheair-cleaner

foamelement(moreoftenindusty,

dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—Replacetheair-cleanerfoamelement

(moreoftenindusty,dirtyconditions).

Washthefoamelementwithwaterandreplacethe

foamelementifitisdamaged.

34

Page 35

ServicingthePaperElement

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Servicetheair-cleaner

paperelement(moreoftenindusty,

dirtyconditions).

Every200hours/Every2years(whichever

comesrst)—Replacetheair-cleanerpaper

element(moreoftenindusty,dirtyconditions).

1.Lightlytaptheelementonaatsurfaceto

removedustanddirt.

2.Inspecttheelementfortears,anoilylm,and

damagetotheseal.

Important:Donotcleanthepaperelement

withpressurizedairorliquids,suchas

solvent,gasoline,orkerosene.Replacethe

paperelementifitisdamagedorcannotbe

cleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,shutofftheengine,

engageparkingbrake,andremovethekey.

2.Makesurethattheengineisshutoff,level,and

iscool,sothattheoilhashadtimetodraininto

thesump.

3.T okeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure38).

4.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

CrankcaseCapacity:withlter—2.4L(2.5USqt)

Viscosity:Seethetablebelow.

Figure37

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

g029683

g193541

Figure38

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothing,and

otherbodypartsawaythemuferandother

hotsurfaces.

35

Page 36

ChangingtheEngineOilandOil

g027799

A

B

C

D

E

F

G

H

g029570

Filter

ServiceInterval:Aftertherst5hours/Afterthe

rstmonth(whichevercomes

rst)—Changetheengineoil.

Every100hours/Y early(whichevercomes

rst)—Changetheengineoil(moreoftenin

dusty,dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—Changetheoillter(moreoftenindusty,

dirtyconditions).

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachineonalevelsurfacetoensure

thattheoildrainscompletely.

2.DisengagethePTOandensurethattheparking

brakeisengaged.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheengineoil.

g027799

g029570

Figure39

36

Page 37

5.Changetheengine-oillter(Figure40).

B

A

C D

E

F

3/4

g027477

Note:Ensurethattheoil-ltergaskettouches

theengineandthenturnthelteranextra3/4

turn.

g193530

Figure41

6.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

41).

Figure40

ServicingtheSparkPlug

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthespark

plug(s).

g027477

Every200hours/Every2years(whichever

comesrst)—Replacethesparkplug(s).

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.Useaspark-plugwrenchforremovingand

installingthesparkplug(s)andagappingtool/feeler

gaugetocheckandadjusttheairgap.Installanew

sparkplug(s)ifnecessary.

Type:Champion

Airgap:0.76mm(0.03inch)

®

RN9YCorNGK

®

BPR6ES

RemovingtheSparkPlug

1.DisengagethePTOandensurethattheparking

brakeisengaged.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

37

Page 38

B

A

g027478

Figure42

B

A

g027479

B

A

25-30 N-m

18.5-22.1 ft-lb

g027960

C

D

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isthemosteffectivemethodforcleaning.The

sparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

CheckingtheSparkPlug

InstallingtheSparkPlug

Tightenthesparkplug(s)to25to30N∙m(18.5to

22.1ft-lb).

g027478

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.76mm(0.03inch).

Figure43

g027960

Figure44

CleaningtheCooling System

Cleantheairintakescreenfromgrassanddebris

beforeeachuse.

1.Disengagetheblade-controlswitchandapply

theparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g027479

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.T opreventdebrisenteringtheairintake,install

theairltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

7.Removetheairlterandinstalltheengine

shroud.

8.Installtheairlter.

38

Page 39

FuelSystem

g027939

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyou,others,and

candamageproperty.

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanyfuelthat

spills.

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

ReplacingtheIn-LineFuel Filter

g027939

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthein-linefuel

lter.

Every200hours/Every2years(whichever

comesrst)—Replacethein-linefuellter.

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Ensurethatthebrakeisengaged,shutoffthe

engine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperating

position.

g033082

Figure45

39

Page 40

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

g190587

Figure46

1.Batterycover2.Fasteners

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

ServicingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure47).

Note:Retainallfasteners.

WARNING

Incorrectbattery-cableroutingcould

damagethemachineandcablescausing

sparks.Sparkscancausethebattery

gassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

5.Slidetherubbercoverupthepositive(red)

cable.

6.Disconnectthepositive(red)cablefromthe

batterypost(Figure47).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure47),and

liftthebatteryfromthebatterytray.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Ensurethattheparkingbrakeisengaged,

shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthe2fastenersonthebatterycover

counterclockwise1/4turn,andremovethe

batterycover(Figure46).

40

Page 41

Figure47

1.Battery

2.Negative(–)batterypost

3.Bolt,washer ,andnutfor

thenegative(–)battery

post

4.Bolt,washer ,andnutfor

thepositive(+)battery

post

5.Positive(+)batterypost

6.Terminalboot

7.Batteryhold-down

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectthebatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page40).

g000538

Figure48

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

g188903

InstallingtheBattery

1.Positionthebatteryinthetray(Figure47).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

47).

6.Installthebatterycoverbypushingdownand

tighteningthe2fastenersclockwise(Figure46).

2.Chargethebatteryforaminimumof1hourat

6to10A.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure48).

41

Page 42

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(15A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

ToreplacetheMain(15A)fuse,reachintothe

openinginthesideoftheconsole,pulloutthefuse,

andinstallanew15Afuse(Figure49).

Figure49

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure51).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethefrontcasterwheeltiresto103kPa(15psi).

Inatethereardrivewheeltiresto90kPa(13psi).

g190588

1.Main(15A)2.Consoleopening

ToreplacetheChargeCircuit(25A)fuse,locatethe

fusetotheleftofbattery,pulloutthefuse,andinstall

anew25Afuse(Figure50).

Figure50

1.Chargecircuit(25A)

g000554

Figure51

1.Valvestem

g190589

42

Page 43

MowerMaintenance

G014972

1

2

3

ServicingtheCutting Blades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,

keepextrabladesonhand.

g006530

Figure52

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.Tryingto

repairadamagedblademayresultindiscontinued

safetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

BeforeInspectingorServicingthe

Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighest

height-of-cutposition.

2.Whilewearingthicklypaddedgloves,orother

adequatehandprotection,slowlyrotatethe

bladetobemeasureintoapositionthatallows

effectivemeasurementofthedistancebetween

thecuttingedgeandthelevelsurfacethe

machineison(Figure53).

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure52).

2.Iftheedgesarenotsharporhavenicks,remove

andsharpentheblade;refertoSharpeningthe

Blades(page45).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforming

inthisarea,immediatelyinstallanewblade

(Figure52).

g014972

Figure53

1.Deck3.Blade

2.Spindlehousing

3.Measurefromthetipofthebladetotheat

surface(Figure54).

43

Page 44

G014973

1

2

3

Figure54

G014974

1

2

3

G014973

1

2

3

g014973

g014973

Figure56

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothat

theopposingcuttingedgeisnowinthesame

position(Figure55).

Figure55

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page45)andInstallingtheBlades(page

45).

Note:Ifabentbladeisreplacedwitha

newblade,andthedimensionobtained

continuestoexceed3mm(1/8inch),the

bladespindlecouldbebent.Contactan

AuthorizedT oroDealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

g014974

6.Repeatthisprocedureoneachblade.

5.Measurefromthetipofthebladetotheat

surface(Figure56).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

44

Page 45

RemovingtheBlades

1

2

3

4

G010341

Thebladesmustbereplacedifasolidobjectishit,if

thebladeisoutofbalance,orifthebladeisbent.For

bestperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

1.Holdthebladeendusingaragorthicklypadded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure57).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure58).

g000553

Figure59

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeis

balanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

57).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

Figure57

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure58).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

2.Installthecurvedwasher(cuppedsidetoward

theblade)andthebladebolt(Figure57).

3.T orquethebladeboltto135to150N∙m(100

to110ft-lb).

g010341

g004536

Figure60

1.Sailareaoftheblade3.Curvedwasher

g000552

Figure58

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure59).

2.Blade4.Bladebolt

45

Page 46

LevelingtheMowerDeck

Ensurethatthemowerdeckislevelanytimeyou

installthemowerdeckorwhenyouseeanuneven

cutonyourlawn.

Checkthemowerdeckforbentbladespriorto

leveling;removeandreplaceanybentblades;referto

CheckingforBentBlades(page43)beforecontinuing.

Levelthemowerdeckside-to-sidebeforeadjusting

thefront-to-rearslope.

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;referto

CheckingtheTirePressure(page42).

CheckingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

7.9mm(5/16inch)lowerthantherearofthemower,

adjustthebladelevelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,engagetheparking

brake,shutofftheengine,removethekey ,and

waitforallmovingpartstostopbeforeleaving

theoperatingposition.

3.Carefullyrotatethebladessotheyarefacing

fronttorear(Figure62).

CheckingtheSide-to-SideLevel

Themowerbladesmustbelevelfromsidetoside.

Checktheside-to-sidelevelanytimeyouinstallthe

mowerorwhenyouseeanunevencutonyourlawn.

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,

removethekey,engagetheparkingbrake,and

waitforallmovingpartstostopbeforeleaving

theoperatingposition.

3.Carefullyrotatethebladessidetoside.

4.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure61).

Note:Ifbothmeasurementsarenotwithin5

mm(3/16inch),anadjustmentisrequired;refer

toLevelingtheMowerDeck(page47).

4.Measurefromthetipofthefrontbladetothe

atsurfaceandthetipoftherearbladetothe

atsurface(Figure62).

Note:Ifthefrontbladetipisnot1.6to7.9mm

(1/16to5/16inch)lowerthantherearbladetip,

continuetotheLevelingtheMowerDeck(page

47)procedure.

g007199

Figure62

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here.

2.Outsidecuttingedges

1.Bladessidetoside

2.Outsidecuttingedges

g007202

Figure61

3.Measurefromthetipofthe

bladetotheatsurface

here.

46

Page 47

LevelingtheMowerDeck

1.Settheanti-scalprollerstothetopholesor

removethemcompletelyforthisprocedure;refer

toAdjustingtheAnti-ScalpRollers(page27).

2.Settheheight-of-cutlevertothe76mm(3inch)

position;refertoAdjustingtheHeightofCut

(page26).

3.Place2blockseachhavingathicknessof6.6

cm(2-5/8inches)undereachsideofthefront

edgeofthedeck,butnotundertheanti-scalp

rollerbrackets(Figure63).

4.Place2blockseachhavingathicknessof7.3

cm(2-7/8inches)undertherearedgeofthe

cuttingdeckskirt;1oneachsideofthecutting

deck(Figure63).

g024313

Figure64

Figure63

1.Woodblock—6.6cm

(2-5/8inches)thick

2.Woodblock—7.3cm

(2-7/8inches)thick

3.Frontedge

5.Loosentheadjustmentboltsonall4cornersso

thatthedeckissittingsecurelyonall4blocks

(Figure64).

1.Deck-liftarm

2.Chain

3.Hook

4.Adjustmentbolt

6.Ensurethatthereistensiononall4chains

(Figure64).

7.Tightenthe4adjustmentbolts(Figure64).

8.Ensurethattheblockstsnuglyunderthedeck

g024428

skirtandthatallboltsaretight.

9.Verifythatthedeckislevelbycheckingthe

side-to-sidelevelandfront-to-rearbladeslope;

repeatthedecklevelingprocedureifnecessary.

RemovingtheMowerDeck

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controllevers

outwardtotheNEUTRAL-LOCKposition,engagethe

parkingbrake,shutofftheengine,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

Lowerthemowertothelowestheightofcut.Select1

ofthefollowingproceduresdependingonthemower

decksizeinstalledtocompletetheremoval.

PreparingtoRemovetheMower

Deck

1.Lowerthemowertothe76mm(3inches)

height-of-cutposition.

2.Removethemowerbeltfromtheenginepulley;