Page 1

FormNo.3408-598RevA

g027913

TimeCutter

®

SW3200Riding

Mower

ModelNo.74780—SerialNo.400000000andUp

ModelNo.74781—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3408-598*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

GrossHorsepower

g188142

Figure1

Undertheseat

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

Thegrossornethorsepowerofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewiththe

SocietyofAutomotiveEngineers(SAE)J1940.Ascongured

tomeetsafety,emission,andoperatingrequirements,

theactualenginetorqueonthisclassofmowerwillbe

signicantlylower.

Gotowww .Toro.comtoviewspecicationsonyourmower

model.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

ProductOverview.........................................................10

Controls...............................................................10

BeforeOperation......................................................12

BeforeOperationSafety..........................................12

RecommendedFuel................................................12

UsingStabilizer/Conditioner...................................12

FillingtheFuelTank...............................................13

CheckingtheEngine-OilLevel.................................13

BreakinginaNewMachine......................................13

ThinkSafetyFirst...................................................13

UsingtheSafety-InterlockSystem.............................15

PositioningtheSeat................................................16

PositioningtheSteeringWheel.................................16

DuringOperation.....................................................16

DuringOperationSafety.........................................16

OperatingtheSmartPark

OperatingtheMowerBlade-ControlSwitch

(PTO)...............................................................17

OperatingtheThrottle............................................18

OperatingtheIgnitionSwitch..................................18

StartingandShuttingOfftheEngine.........................19

DrivingtheMachine...............................................19

StoppingtheMachine.............................................20

MowinginReverse.................................................20

AdjustingtheHeightofCut.....................................20

UsingtheGrassDeector.......................................21

OperatingTips......................................................21

AfterOperation........................................................22

AfterOperationSafety............................................22

PushingtheMachinebyHand..................................22

TransportingtheMachine........................................23

LoadingtheMachine..............................................23

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

Pre-MaintenanceProcedures......................................25

MaintenanceandStorage.........................................25

RaisingtheSeat......................................................26

RaisingtheFrontoftheMachine..............................26

Lubrication...............................................................27

GreasingtheBearings.............................................27

EngineMaintenance..................................................27

EngineSafety.........................................................27

ServicingtheAirCleaner.........................................27

ServicingtheEngineOil..........................................28

ServicingtheSparkPlug..........................................31

CleaningtheBlowerHousing...................................31

FuelSystemMaintenance...........................................32

ReplacingtheIn-LineFuelFilter...............................32

ElectricalSystemMaintenance....................................33

ElectricalSystemSafety...........................................33

ChargingtheBattery...............................................33

ServicingtheFuses.................................................34

™

ParkingBrake..................17

DriveSystemMaintenance.........................................35

CheckingtheTirePressure......................................35

ReleasingtheElectricBrake.....................................35

MowerMaintenance...................................................36

ServicingtheCuttingBlades.....................................36

LevelingtheMowerDeck........................................38

RemovingtheMowerDeck.....................................39

InstallingtheMowerDeck.......................................40

ReplacingtheGrassDeector..................................40

MowerBeltMaintenance............................................41

InspectingtheBelts................................................41

ReplacingtheMowerBelt........................................41

Cleaning...................................................................42

CleaningundertheFrontoftheMachine...................42

WashingtheUndersideoftheMower........................42

Storage........................................................................43

CleaningandStorage..............................................43

Troubleshooting...........................................................45

Schematics...................................................................47

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithANSI

B71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

Page 5

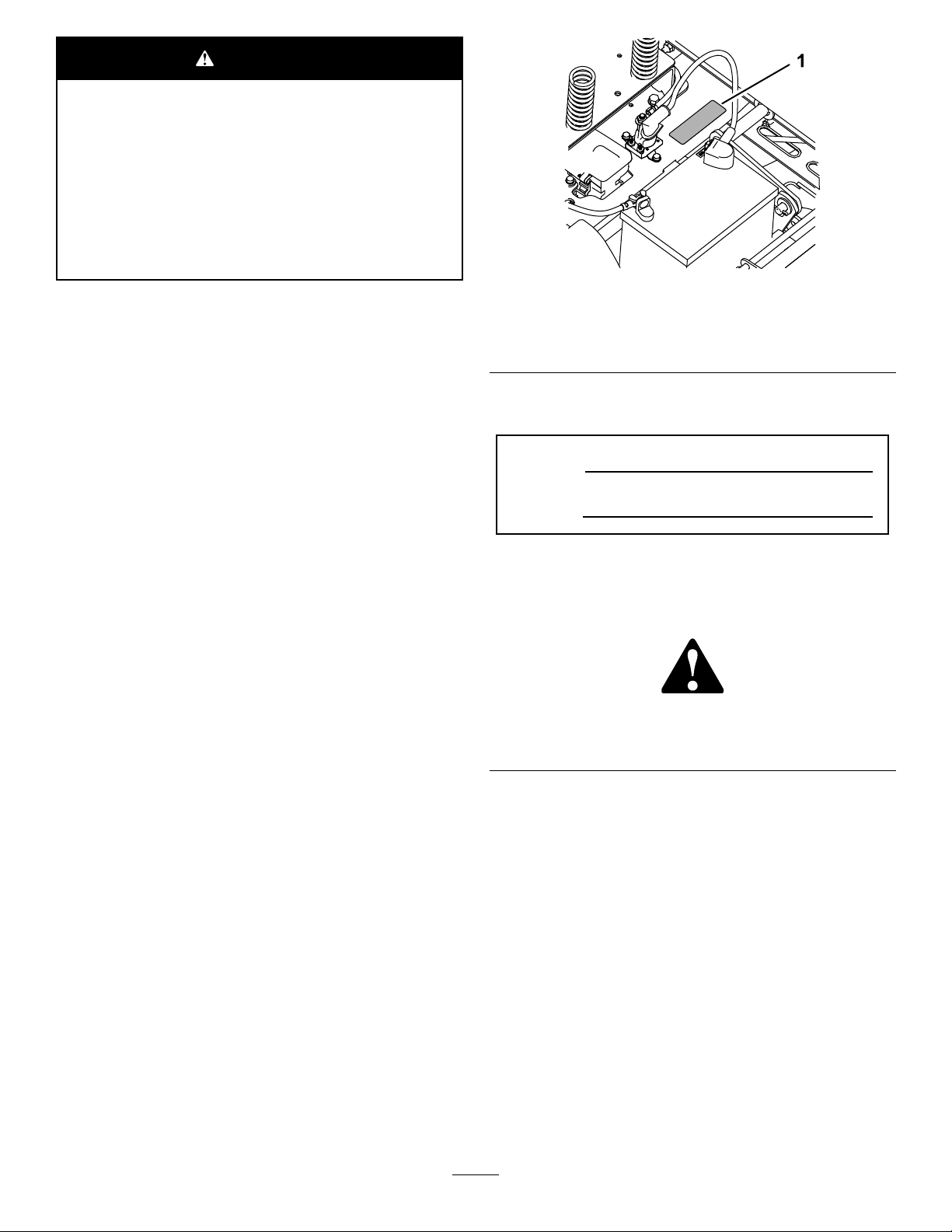

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

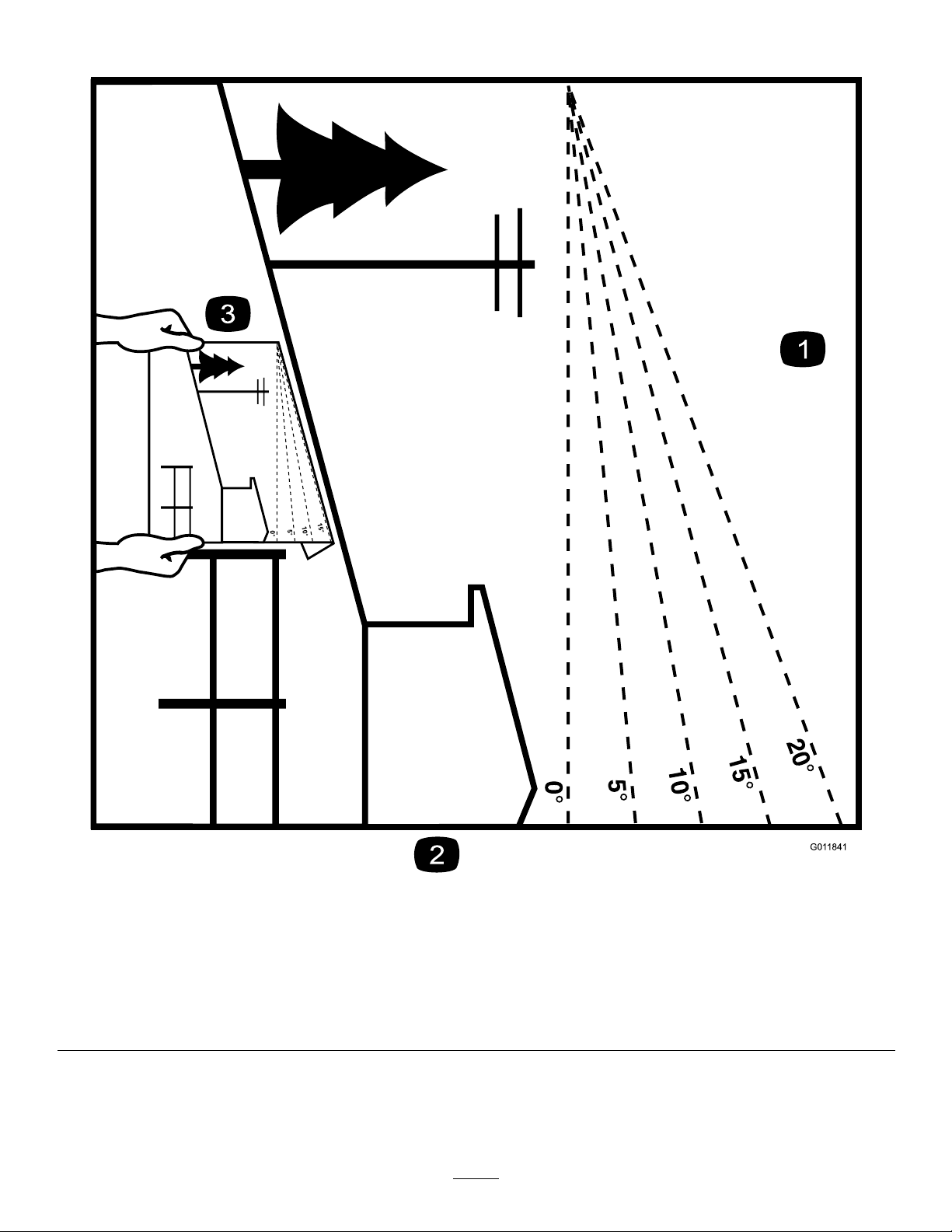

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

106-8717

decal93-7009

decal106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decal119-8871

119-8871

1.Height-of-cut

decaloemmarkt

1.Bypassleverpositionfor

pushingthemachine

6

decal121-2989b

121-2989

2.Bypassleverpositionfor

operatingthemachine

Page 7

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

6.Keepbystandersasafe

7.Weareyeprotection;

smoking

3.Causticliquid/chemical

8.Batteryacidcancause

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

10.Containslead;donot

Manual.

distanceawayfromthe

battery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

131-3621

1.Crushing/dismembermenthazardofbystanders—keep

bystandersawayfromthemachine;donotstartthe

machinewithbystandersnearby.

131-3665

1.Bladespinning

2.Reverse

3.ReadtheOperator's

Manual.

decal131-3621b

decal131-3665

decal131-3620

131-3620

1.Pedalposition—forward

2.Pedalposition—neutral

3.Pedalposition—reverse

decal131-3955

131-3955

1.On2.Off

7

Page 8

decal132-0872

132-0872

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

decal132-6863

132-6863

decal121-0771

121-0771

1.Choke4.Slow

2.Fast

3.Continuousvariablesetting

5.Powertake-off(PTO),Bladecontrolswitch

8

Page 9

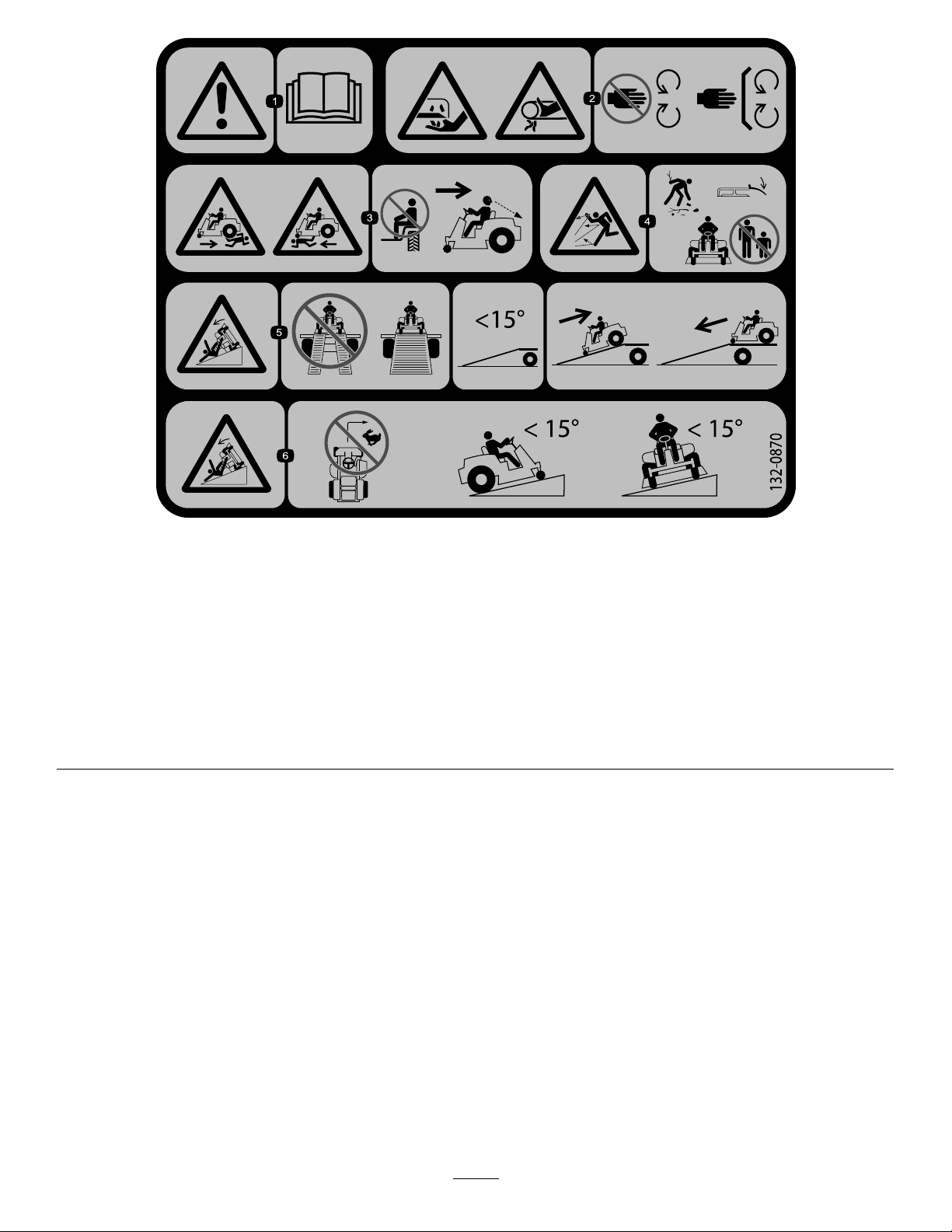

decal132-0870

132-0870

1.Warning—readtheOperator'sManual.

2.Cuttinghazardofhand,mowerblade;

pinchinghazardofhand,belt—keep

handsandfeetawayfrommoving

parts;keepallguardsandshieldsin

place.

3.Bodilyharmhazard—noriders;look

behindyouwhenmowinginreverse.

4.Thrownobjecthazard—keep

bystandersawayfromthemachine;

removedebrisfromtheareabefore

mowing;keepthedeectorshield

down.

5.Ramptippinghazard—whenloading

ontoatrailer,donotusedualramps;

onlyuseasinglerampwideenough

forthemachineandthathasanincline

lessthan15degrees;backupthe

ramp(inreverse)anddriveforwardoff

theramp.

6.Tippinghazardonslopes—donot

makesharp,quickturns;donotuse

slopesgreaterthan15degrees.

9

Page 10

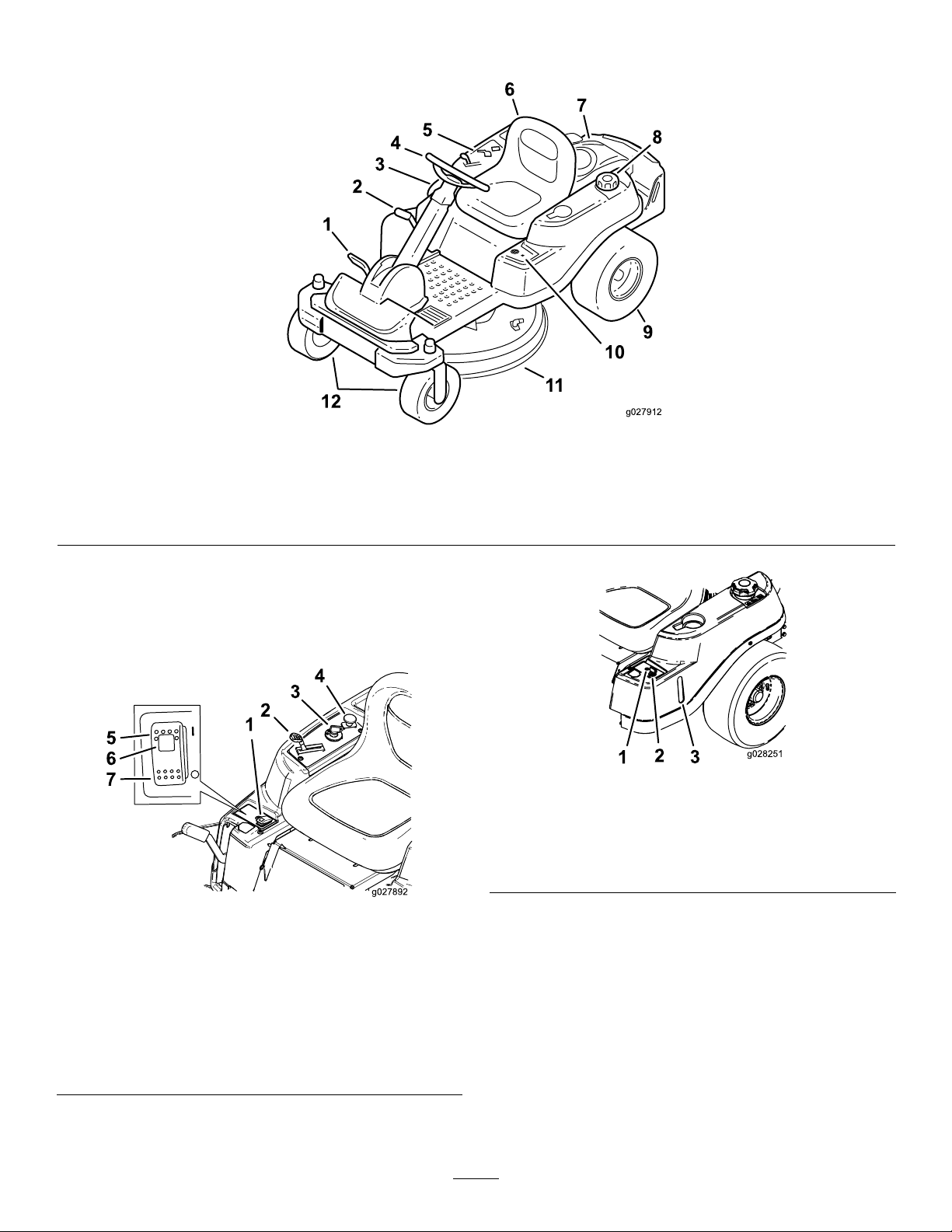

ProductOverview

g027912

1

2

4

5

6

7

8

9

11

12

10

3

5

6

7

g027892

1.Traction-controlpedal

2.Height-of-cutlever5.Controlpanel

3.SmartPark

™

switch6.Operatorseat

4.Steeringwheel

Figure4

7.Engine

8.Fuel-tankcap11.Mowerdeck

9.Reardrivewheel12.Frontcasterwheels

10.KeyChoice

g027912

®

control

Controls

BecomefamiliarwithallcontrolsinFigure4,Figure5,and

Figure6beforeyoustarttheengineandoperatethemachine.

g028251

Figure6

1.Operating–in–Reverse

warninglight

2.KeyChoicekey(bluein

color)

Figure5

1.SmartPark™switch5.Parkingbrake—On

2.Throttle/Chokecontrol

3.Ignitionswitch

4.Blade-controlswitch

(powertake-off)

ControlPanel

6.Parkingbrakeindicator

light

7.Parkingbrake—Off

g027892

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3positions:

START,RUN,andOFF.

3.Fuel-presencewindow

10

Page 11

Throttle/ChokeControl

Attachments/Accessories

Thethrottleandchokecontrolsarecombinedinto1control

lever.Thethrottlecontrolstheenginespeedandhasa

continuous-variablesettingfromSLOWtoFAST.Engagethe

chokebymovingtheleverpasttheFASTsettinguntilitstops

(Figure5).

Blade-ControlSwitch(PowerTakeoff)

Theblade-controlswitch(PTO)engagesanddisengages

powertothemowerblades(Figure5).

Fuel-PresenceWindow

Thefuelwindow ,locatedontheleftsideofthemachine,can

beusedtoverifythepresenceoffuelinthetank(Figure6).

Height-of-CutLever

Usetheheight-of-cutlevertolowerandraisethedeckfrom

theseatedposition.Movingtheleverup(towardyou)raises

thedeckfromthegroundandmovingtheleverdown(away

fromyou)lowersthedecktowardtheground.Adjustthe

height-of-cutonlywhilethemachineisnotmoving(Figure

19).

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

KeyChoice

Thisswitchallowsyoutomowinreversewhenitisactivated.

Toactivateit,turntheswitchtotheONpositionandrelease

itafterthePTOisengaged.Todeactivateit,disengagethe

powertakeoff(PTO)(Figure6).

®

Switch

Operating-in-ReverseWarningLight

TheOperating-in-Reversewarninglightilluminates

wheneveryouusetheKeyChoicekeytodeactivatethe

operating-in-reverseinterlock.Itisareminderthatthe

interlocksystemisdeactivated.Thelightgoesoutwhenever

youdisengagethePTOorshutofftheengine.Whenthelight

ison,lookbehindyouanduseextracautionwhenbackingup.

SmartPark

Theparkingbrakeisactivatedelectronically.

Engagetheparkingbrakeby1ofthefollowingactions:

•PressingtheSmartPark

(Figure5).

•Theparkingbrakeengagesautomaticallywhenyouleave

theseatandthetractioncontrolpedalisintheNEUTRAL

position.

•Theparkingbrakeautomaticallyengages5to6seconds

aftertheignitionswitchisturnedtotheOFFposition(if

itisnotalreadyengaged).

™

Switch

™

switchtotheONposition

Todisengagetheparkingbrake,presstheSmartParkswitch

totheOFFpositionwiththekeyintheRUNposition.

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutofftheengine

quickly.

•Checkthatoperator-presencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operatethemachineunlesstheyarefunctioningproperly.

•Beforemowing,alwaysinspectthemachinetoensurethat

theblades,bladebolts,andcuttingassembliesareingood

workingcondition.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelvaporsareammableand

explosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefueltank

whiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

theground,awayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerand

refuelitwhileitisontheground.Ifthisisnotpossible,

thenrefuelfromaportablecontainerratherthana

fuel-dispensernozzle.

•Donotoperatethemachinewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

•Storefuelinanapprovedcontainerandkeepitoutofthe

reachofchildren.Neverbuymorethana30-daysupply

offuel.

•Donotllthefueltankcompletelyfull.Addfueltothe

fueltankuntilthelevelis6to13mm(1/4to1/2inch)

belowthebottomofthellerneck.Thisemptyspacein

thetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfueltank

opening.

–Avoidcontactwithskin;washoffspillswithsoapand

water.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless(drain

thefueltankwhenstoringthemachineformorethan

90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

12

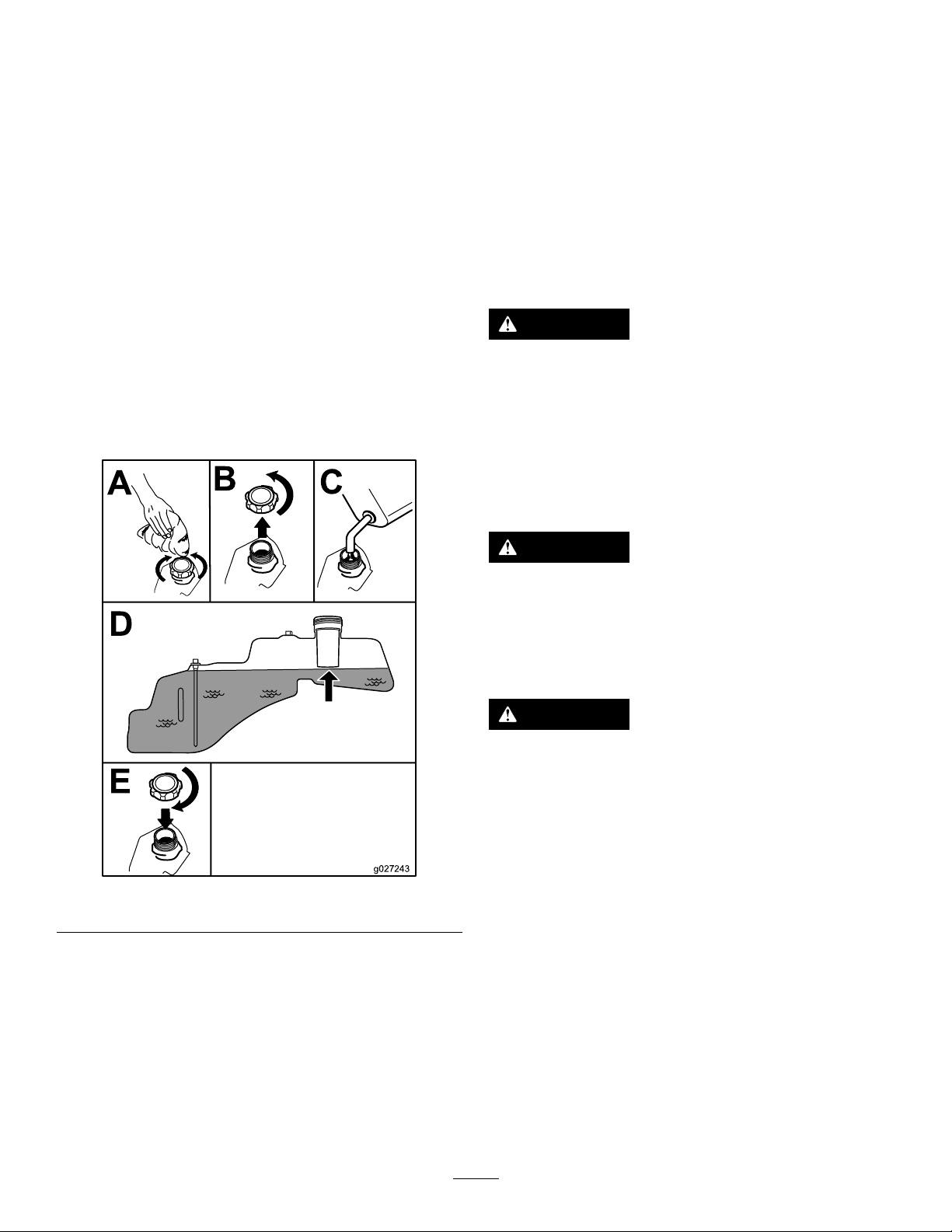

Page 13

Important:Donotusefueladditivescontaining

g027243

A

B

E

D

C

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.T ominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

ThinkSafetyFirst

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shutofftheengineandengagetheparkingbrake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck(Figure

7).

Note:Donotllthefueltankcompletelyfull.The

emptyspaceinthetankallowsthefueltoexpand.

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

Figure7

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page28).

DANGER

Operatingthemachinewhiletherollbarisdown

mayleadtoseriousinjuryordeathintheeventofa

rollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

g027243

13

Page 14

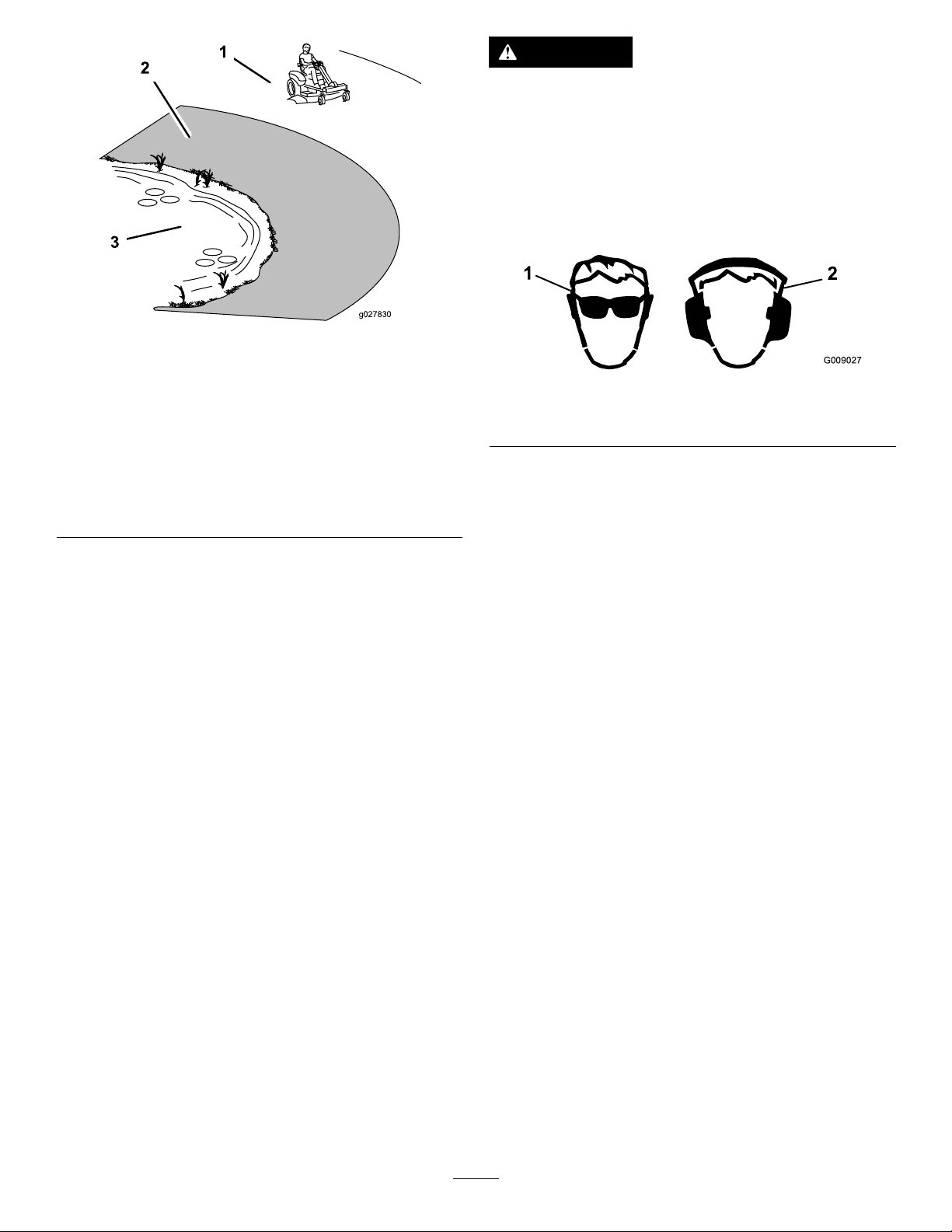

g027830

Figure8

G009027

1

2

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

g027830

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

3.Water

g009027

Figure9

1.Weareyeprotection.2.Wearhearingprotection.

14

Page 15

UsingtheSafety-Interlock System

TestingtheSafety-InterlockSystem

1.Sitintheseatwiththeengineoffandensurethatthe

PTOswitchisintheOFFposition.

WARNING

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

daily,andreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedforthefollowing:

•Topreventtheenginefromstartingunlessthetraction

pedalisintheNEUTRALposition.

•Toautomaticallyensurethattheparkingbrakeisengaged

andthePTOisoffwhenstartingthemachine.

•Toshutofftheenginewheneverthetractionpedalisnot

intheNEUTRALpositionandyourisefromtheseat.

•Toautomaticallyengagetheparkingbrakeanddisengage

thePTO ,whenyouriseoutoftheseatwiththetraction

pedalintheNEUTRALposition.

•Toshutofftheenginewhenevertheparkingbrakeisnot

engagedandyourisefromtheseat.

2.TurntheignitionkeytotheSTARTposition;thestarter

shouldcrank.Donotstartorshutofftheengineprior

tostep3.

3.TurnthekeytotheONpositionandpushtheSmart

ParkswitchtotheOFFposition.Thebrakeshould

disengageandthebrakelightshouldturnoff.

4.Withthebrakedisengagedandtractionpedalinthe

NEUTRALposition,turntheignitionswitchtothe

STARTposition.Thebrakeshouldautomatically

engage,theengineshouldcrank,andthebrakelight

shouldturnon.

5.WiththeengineoffandthekeyintheONposition,

engagethePTObypullinguptheblade-controlswitch;

youshouldheartheclutchengage.

6.Ensurethatthetractionpedalisinneutralandturn

theignitionswitchtotheSTARTposition.ThePTO

shoulddisengageandtheengineshouldcrankandstart

withoutthebladesmoving.

7.Withtheenginerunning,risefromtheseat.Theengine

shouldremainrunningandthebrakelightshouldbe

on.

8.Returntotheseatanddisengagetheparkingbrakeby

pushingtheSmartParkswitchtotheOFFposition.

Theengineshouldcontinuetorun.

9.Risefromtheseatagain.Thebrakeshould

automaticallyengageandtheengineshouldcontinue

torun.

10.Returntotheseatandengagethebladesbypullingup

theblade-controlswitch.

11.Risefromtheseat.Thebladesshoulddisengageand

theengineshouldcontinuetorun.

12.Returntotheseatandpulluptheblade-controlswitch.

Thebladesshouldengage.Disengagethebladesby

pushingdowntheblade-controlswitch.

13.Pulluptheblade-controlswitchtoengagetheblades.

MovethetractionpedaltotheREVERSEposition.The

bladesshoulddisengage.Movethetractionpedalto

theNEUTRALposition.

14.Pulluptheblade-controlswitchtoengagetheblades.

TurntheKeyChoiceswitchtotheONposition

andreleaseit.Theoperating-in-reverselightshould

illuminate.

15.MovethetractionpedaltotheREVERSEposition.

Thebladesshouldremainengaged.Pushthe

blade-controlswitchintodisengagetheblades.The

operating-in-reverselightshouldturnoff.Movethe

tractionpedaltotheNEUTRALposition.

16.Ifnotengaged,pushtheSmarkParkswitchtotheON

positionandlightlytapthetractionpedalintheeither

15

Page 16

theFORWARDorREVERSEposition.Thebrakeshould

g027249

B

C

A

g027751

B

A

disengageandthebrakelightshouldturnoff.

Note:Tapthepedal,donotfullyengagethepedalas

thatcausesthebrakesystemtobindandnotrelease.

17.Withthebrakereleased,engagethetractionpedal

slightlyandrisefromtheseat.Theengineshouldshut

off.

18.Returntotheseatandturntheignitionkeytothe

OFFposition.Afterseveralseconds,thebrakesystem

shouldengage.

Note:WiththekeyintheOFFposition,thebrakelight

doesnotilluminate.

PositioningtheSeat

PositioningtheSteeringWheel

Thesteeringwheelhas3positionsforoperationand1full-up

position.Usethefull-uppositionforsteppingonandoff

themachineandgettingoutoftheseat.Whenoperatingthe

machine,positionthesteeringwheelwhereyouhavethebest

controlofthemachineandaremostcomfortable.

1.Pressyourfootontothesteering-columnreleaselever.

2.Positionthesteeringwheeltothedesiredposition

(Figure11).

Figure10

g027751

Figure11

DuringOperation

DuringOperationSafety

GeneralSafety

g027249

•Theowner/operatorcanpreventandisresponsiblefor

accidentsthatmaycausepersonalinjuryorproperty

damage.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachineduring

operation.

•Operatethemachineonlyingoodvisibilitytoavoidholes

orhiddenhazards.

•Avoidmowingonwetgrass.Reducedtractioncould

causethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparkingbrake

isengaged,andyouareintheoperatingpositionbefore

youstarttheengine.

16

Page 17

•Keepyourhandsandfeetawayfromthecuttingunits.

G008945

Keepclearofthedischargeopeningatalltimes.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

OperatingtheSmartPark

ParkingBrake

Theparkingbrakeisactivatedelectronically.

™

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscureyourvision.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgegivesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshutoffthe

enginebeforeadjustingtheheightofcut(unlessyoucan

adjustitfromtheoperatingposition).

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(includingtoempty

thecatchersortounclogthechute),dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

Engagetheparkingbrakeby1ofthefollowingactions:

•PressingtheSmartPark

(Figure5).

™

switchtotheONposition

•Theparkingbrakeengagesautomaticallywhenthe

operatorleavestheseatandthetractioncontrolpedalis

intheNEUTRALposition.

•Theparkingbrakeautomaticallyengages5to6seconds

aftertheignitionswitchisturnedtotheOFFposition(if

itisnotalreadyengaged).

Disengagetheparkingbrakeby1ofthefollowingactions:

•Tapthetraction-controlpedalforwardorreverse.

•PressingthebrakeswitchtotheOFFposition(Figure5).

OperatingtheMower Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistheriskof

lightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeedthe

engine.

•UseaccessoriesandattachmentsapprovedbyToroonly.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelupanddownonhillsides.Turfconditionscan

affectthestabilityofthemachine.

•Avoidturningthemachineonslopes.Ifyoumustturnthe

machine,turnitslowlyandgraduallydownhill,ifpossible.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

g008945

Figure12

Note:AlwaysengagethebladeswiththethrottleintheFAST

position(Figure13).

17

Page 18

Figure13

G009174

START

RUN

STOP

G008947

DisengagingtheBlade-ControlSwitch

(PTO)

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheSTARTposition(Figure16).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failureto

followtheseinstructionscanburnoutthestarter

motor.

Note:Youmayneedmultipleattemptstostartthe

g186693

enginewhenyoustartitthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

g008947

Figure16

Figure14

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweentheFASTand

SLOWpositions(Figure15).

AlwaysusetheFASTpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

Figure15

g009174

2.TurntheignitionkeytotheSTOPpositiontoshutoff

theengine.

g187361

18

Page 19

StartingandShuttingOffthe

g027899

B

C

D

E

A

F

DrivingtheMachine

Engine

StartingtheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformorethan

5secondsatatime.Engagingthestartermotorfor

morethan5secondscandamagethestartermotor.If

theenginefailstostart,wait10secondsbeforeoperating

theenginestarteragain.

Thismachinehasthecharacteristicsofbothagardentractor

andazero-turnmachine.Likeagardentractor,themachine

hasafootpedalthatcontrolstheforwardandreversemotion

alongwiththespeed,andithasasteeringwheelthatcontrols

thedirectionandtheturningradius.Likeazero-turnmachine,

thereardrivewheelsoperateindependentlyofeachother,

enablingyoutomakesharpturnsandtoturnindifferent

directionsquickly.Thesecharacteristicsvastlyimprovethe

maneuverabilityofthemachine,buttheymayalsorequire

youtopracticedrivingifyouareunfamiliarwiththistypeof

machine.

WARNING

Themachinecanspinveryrapidly.Y oumaylose

controlofthemachineandcausepersonalinjuryor

damagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placingthethrottlecontrol

intheFASTpositioncanbebestforperformance.Formost

applications,operatingintheFULL-THROTTLEpositionis

desirable.

Figure17

ShuttingOfftheEngine

1.Disengagethebladesbymovingtheblade-control

switchtotheOFFposition(Figure17).

2.MovethethrottlelevertotheFASTposition.

3.TurntheignitionkeytotheOFFpositionandremove

thekey.

DrivingForwardorBackward

1.MovethethrottletotheFASTposition.

2.Releasetheparkingbrake.

3.Placeyourfootontothetraction-controlpedaland

slowlypressthetopofthepedaltogoforward,or

pressonthebottomofthepedaltomovebackward

(Figure18).

Note:Thefartheryoumovethepedalineither

g027899

direction,thefasterthemachinemovesinthat

direction.

g027750

Figure18

1.Forward3.Backward

2.Traction-controlpedal

4.Toslowdown,releasethepressureonthe

traction-controlpedal.

19

Page 20

StoppingtheMachine

Toshutoffthemachine,releasethetraction-controlpedal,

disengagetheblade-controlswitch,ensurethatthethrottle

isintheF ASTposition,engagetheparkingbrake,andturn

theignitionkeytooff.

Note:Remembertoremovethekeyfromtheignitionswitch.

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileitis

unattended.

AlwaysremoveboththeignitionandKeyChoice

keysandengagetheparkingbrakewhenleavingthe

machineunattended,evenifjustforafewminutes.

MowinginReverse

Themachinehasaninterlockfeaturethatpreventsthemower

deckfrommowingwhilethemachineistravelinginreverse.

IfyoushiftintoreversewiththePTOengaged,thePTO

stops.Ifyouneedtomowwhileinreversegear,youcan

temporarilydeactivatethisinterlock.

4.Performthemowing.

5.Whennishedmowing,removetheKeyChoicekey

(Figure6).

Note:Onceyoudeactivatetheinterlock,itstaysin

thismode—withyourmowerbladeorPTOpowered

attachmentoperatingwheneveryoubackup—andthe

consolelightstaysonuntilyoueitherdisengagethe

PTOorshutofftheengine.

AdjustingtheHeightofCut

Note:Thetransportpositionisthehighestheight-of-cut

positionorcuttingheightat115mm(4-1/2inches)asshown

inFigure19.

Heightofcutiscontrolledbytheleverlocatedtotherightof

theoperatingposition(Figure19).

Note:Donotmowwhilebackingupunlessitisnecessary.

DANGER

Achildorbystandercouldbebackedoverbya

ridingmowerwithbladesengagedandcause

seriouspersonalinjuryordeath.

•Donotmowinreverseunlessabsolutely

necessary.

•Alwayslookbackwardanddownbeforebacking

up.

•UsetheKeyChoiceswitchonlyifyouarecertain

nochildrenorotherbystanderswillappearin

themowingarea.

•AlwaysremoveboththeignitionandKeyChoice

keysandputtheminasafeplaceoutofthe

reachofchildrenorunauthorizeduserswhen

leavingthemachineunattended.

Ifyouarecertainthatyoucansafelymoworoperatean

attachmentinreverse,completethefollowingprocedure:

g028025

Figure19

1.InserttheKeyChoicekeyintotheKeyChoiceswitch

(Figure6).

2.EngagethePTO .

3.TurntheKeyChoicekeyclockwiseuntilitstopsand

releaseit.

Note:Aredlightilluminatingontheconsoleindicates

thattheinterlockhasbeendeactivated.

20

Page 21

UsingtheGrassDeector

OperatingTips

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriscausesinjuryordeath.

•Neverremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovetheblade-controlswitch

totheOFFpositionandrotatetheignitionkey

toOFFposition.Alsoremovethekeyandpull

thewireoffthesparkplug(s).

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesoftheyear.

Tomaintainthesamecuttingheight,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight,thenmowagain2days

lateratalowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheighttoavoid

scalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

21

Page 22

KeepingtheUndersideoftheMower

g017303

1 2

3

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AfterOperation

AfterOperationSafety

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausedamagemayoccur.

Thismachinehasanelectric-brakemechanism,andtopush

themachine,theignitionkeymustbeintheRUNposition.

Thebatteryneedstobechargedandfunctioningforthe

electricbraketobedisengaged.

PushingtheMachine

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversontheframeonbothsidesof

theengine.

4.Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplace(Figure20).

Note:Dothisforeachlever.

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,mufers,

andenginecompartmenttohelppreventres.Cleanup

oilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

5.Turntheignitionkeyonanddisengagetheparking

brake.

Note:Donotstartthemachine.

Figure20

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

3.Leverpositionforpushing

themachine

g017303

6.Whennished,ensurethatthekeyhasbeenreturnedto

theSTOPpositiontoavoiddrainingthebatterycharge.

Note:Ifthemachinefailstomove,theelectricbrakemay

stillbeengaged.Youcanreleasetheelectricbrakemanuallyif

necessary;refertoReleasingtheElectricBrake(page35).

22

Page 23

OperatingtheMachine

LoadingtheMachine

Movethebypassleversrearwardthroughthekeyholeand

downtolocktheminplaceasshowninFigure20.

Note:Dothisforeachlever.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,engagetheparking

brake,andclosethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure21).

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuptherampand

driveforwarddowntheramp(Figure22).

Figure22

1.Backthemachineupthe

ramp.

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

2.Drivethemachineforward

downtheramp.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath(Figure23).

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

g028294

Figure21

•Ensurethatthelengthoframpisatleast4times

aslongastheheightofthetrailerortruckbed

totheground.Thisensuresthattherampangle

doesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

g027708

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

23

Page 24

g027996

5

1

2

6

Figure23

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Cleanandchecktheaircleanerfoamelement.

•Checktheengine-oillevel.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Checkandcleanthefrontofthemachine.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Replacetheaircleanerpaperelement.

•Checkthesparkplug.

•Changetheengineoil(changeitmoreoftenunderaheavyloadorinhigh

temperatures).

•Changetheengine-oillter.

•Replacethesparkplug.

•Cleantheblowerhousing(moreoftenunderextremelydusty,dirtyconditions).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectbatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Pre-Maintenance

Procedures

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesordrain

thefuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

MaintenanceandStorage

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Connectthe

positiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthicklypaddedgloves,andusecautionwhen

25

Page 26

servicingthem.Onlyreplaceblades;donotstraighten

orweldthem.

•Keepyourhandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened,especiallytheblade-attachmentbolts.Replace

allwornordamageddecals.

•Neverinterferewiththeintendedfunctionofasafety

deviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.Adjustand

serviceasrequired.

RaisingtheSeat

Ensurethattheparkingbrakeisengagedandlifttheseat

forward.

Youcanaccessfollowingcomponentsbyraisingtheseat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts

•Fuellter

•Batteryandbatterycables

RaisingtheFrontofthe Machine

Ifyouneedtoraisethefrontofthemachine,usethevery

frontedgeasshowninFigure24.

Important:Topreventdamagetothesteering

mechanism,ensurethattheveryfrontedgeofthe

machineisusedforjackingpoints.

g028320

Figure24

26

Page 27

Lubrication

g020242

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Ensurethattheparkingbrakeisengaged,shutoffthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Cleanthegreasettings(Figure25andFigure26)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theaircleanerfoamelement.

Every50hours—Replacetheaircleanerpaper

element.

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch(PTO),engagetheparkingbrake,

shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position..

Figure25

1.Frontcastertire

Figure26

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

4.Connectagreaseguntoeachtting(Figure25and

Figure26).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

3.Greaseevery25operating

hours

4.Engine

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

g027752

decal106-8717

3.Removetheair-cleanercoverbyunscrewingthe2

knobs(Figure27).

g020242

Figure27

1.Air-cleanercover2.Knobs

4.Carefullyremovethefoamandpaperlterelements

fromtheair-cleanerhousing(Figure28).

27

Page 28

g020243

3

InstallingtheFoamandPaperElements

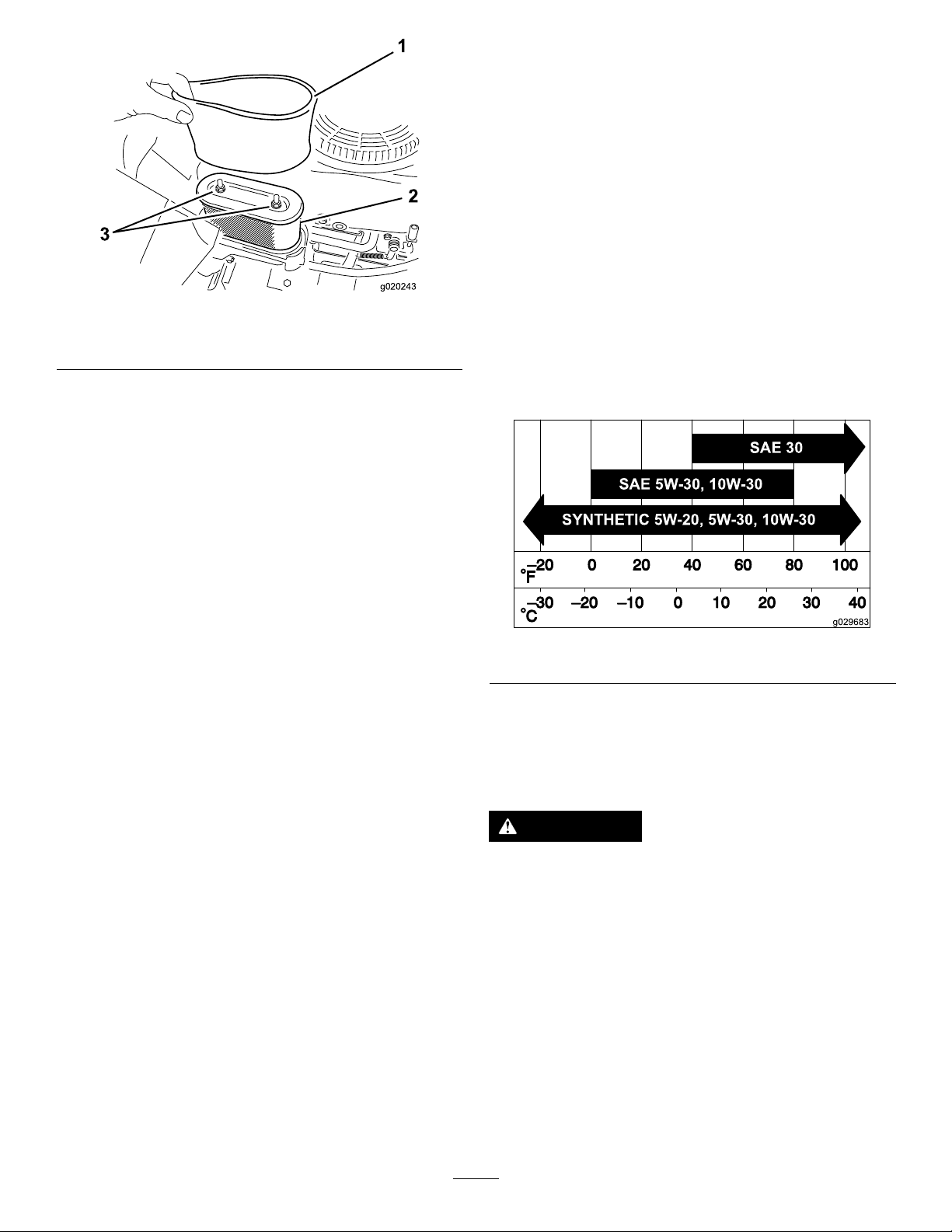

SAE 5W -30, 10W -30

SAE 30

SYNTHETIC 5W -20, 5W -30, 10W -30

g029683

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure28).

2.Installthefoamandpaperlterontotheair-cleaner

housing.

3.Installtheair-cleanercover,andtightenthe2knobs

(Figure27).

Figure28

1.Foamelement2.Paperelement

5.Separatethefoamandpaperelements.

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarmwater.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifitistorn

orworn.

4.Installthefoamelementontoacleanpaperelement.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,andblow

itoutfromtheinsidewithcompressedairtoremove

dustanddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totherubberseal.

Important:Donotcleanthepaperelementwith

liquids,suchassolvents,gasoline,orkerosene.

Replacethepaperelementifitisdamagedor

cannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofalldirt,dust,

anddebris.

g020243

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher)

CrankcaseCapacity:withlter—1.4L(1.5USqt)

Viscosity:Seethetablebelow.

g029683

Figure29

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil,

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLowmark,becausetheengine

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,shutofftheengine,engagethe

parkingbrake,andremovethekey.

2.Makesurethattheengineisstopped,level,andiscool,

sotheoilhashadtimetodrainintothesump.

28

Page 29

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

B

A

C

D

E

G029368

F

G H

I J K

B

A

C

E F

D

G

H

g029369

cleantheareaaroundtheoil-llcapanddipstickbefore

removingit(Figure30).

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenunderaheavy

loadorinhightemperatures).

Every100hours

g029368

Figure30

g029369

Figure31

5.Changetheengine-oillter.

Note:Changetheengine-oilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Parkthemachine,sothattherightsideisslightly

lowerthantheleftside,toensurethattheoildrains

completely.

2.DisengagethePTOandengagetheparkingbrake.

3.Shutofftheengine,waitforallmovingpartstostop,

andremovethekeybeforeleavingtheoperating

position.

4.Draintheoilfromtheengine.

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenturnthelteranextra3/4turn.

29

Page 30

B

A

C D

E

F

3/4

g027477

Figure32

B

A

C

D

E

F

g027484

6.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure33).

g027484

Figure33

g027477

30

Page 31

ServicingtheSparkPlug

B

A

g027478

B

A

g027479

InstallingtheSparkPlug

ServiceInterval:Every50hours—Checkthesparkplug.

Every100hours—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtoolorfeelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:Champion

BCPR6ES

AirGap:0.76mm(0.03inch)

®

RC12YC,Autolite

®

3924,orNGK

®

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

3.Removethesparkplug(Figure34).

Tightenthesparkplugto20N∙m(15ft-lb).

g027480

Figure36

Figure34

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

CleaningtheBlowerHousing

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

g027478

Toensurepropercooling,makesurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Cleanthecoolingnsandexternalsurfacesasnecessary.

Makesurethatthecoolingshroudsareinstalled.Torquethe

blowerhousingscrewsto7.5N·m(5.5ft-lb).

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,causesenginedamagedue

tooverheating.

g027479

Figure35

31

Page 32

FuelSystem

g027506

Maintenance

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyou,others,andcandamageproperty.

•Performanyfuel-relatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstayaway

fromanopenameorwhereasparkmayignite

thefuelfumes.

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours—Replacethein-linefuel

lter.

g027506

Neverinstalladirtylterifitisremovedfromthefuelline.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

g033082

Figure37

32

Page 33

ElectricalSystem

G005072

1

2

3

4

5

6

7

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthemachine.

Disconnectthenegativeterminalrstandthepositive

last.Connectthepositiveterminalrstandthenegative

last.

•Chargethebatteryinanopen,well-ventilatedarea,away

fromsparksandames.Unplugthechargerbefore

connectingordisconnectingthebattery.Wearprotective

clothinganduseinsulatedtools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post(Figure38).Retainallfasteners.

6.Removethebatteryhold-downandliftthebattery

fromthebatterytray(Figure38).

ChargingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcablefromthe

batterypost(Figure38).Retainallfasteners.

g005072

Figure38

1.Battery5.Negativebatterypost

2.Positivebatterypost6.Wingnut,washer,andbolt

3.Bolt,washer,andnut7.Batteryhold-down

4.T erminalboot

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebatteryand

disconnectbatterycables.

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page33).

2.Chargethebatteryforaminimumof1hourat6to

10A.

Important:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure39).

33

Page 34

ServicingtheFuses

30

25

30

25

G014540

2

1

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

Figure39

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure38).

2.Installthepositive(red)batterycabletothepositive(+)

batteryterminalusingthefastenersremovedpreviously.

3.Installthenegativebatterycabletothenegative(-)

batteryterminalusingthefastenersremovedpreviously.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure38).

6.Lowertheseat.

g000538

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwireharness

andfuseblock(Figure40).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure40).

g014540

Figure40

1.Main(30A)2.Chargecircuit(25A)

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

34

Page 35

DriveSystem

Maintenance

ReleasingtheElectricBrake

Youcanmanuallyreleasetheelectricbrakebyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergized,the

brakeresets.

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure41).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

g000554

Figure41

1.Valvestem

1.TurntheignitionkeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected(Figure42).

3.Rotatetheshaftforwardtoreleasethebrake.

g027911

Figure42

1.Brake-linkarmontheelectricbrakecontrolmodule

2.Left,reartire

35

Page 36

MowerMaintenance

G014972

1

2

3

G014973

1

2

3

ServicingtheCuttingBlades

Toensureasuperiorqualityofcut,keepthebladessharp.For

convenientsharpeningandreplacement,keepextrablades

onhand.

BladeSafety

Awornordamagedbladecanbreak,andapieceoftheblade

couldbethrowntowardyouorbystanders,resultinginserious

personalinjuryordeath.Tryingtorepairadamagedblade

mayresultindiscontinuedsafetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthebladesor

weargloves,andusecautionwhenservicingtheblades.

Onlyreplaceorsharpentheblades;neverstraightenor

weldthem.

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position.

2.Whilewearingthicklypaddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure44).

•Onmulti-bladedmachines,takecareasrotating1blade

cancauseotherbladestorotate.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,engagetheparkingbrake,shutoffthe

engine,andremovethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure43).

2.Iftheedgesarenotsharporhavenicks,removeand

sharpentheblade;refertoSharpeningtheBlades(page

37).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforminginthis

area,immediatelyinstallanewblade(Figure43).

g014972

Figure44

1.Deck3.Blade

2.Spindlehousing

3.Measurefromthetipofthebladetotheatsurface

(Figure45).

g014973

Figure45

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition(Figure46).

g006530

Figure43

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

36

Page 37

G014974

1

2

3

Figure46

G014973

1

2

3

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

RemovingtheBlades

Replacethebladesiftheyhitasolidobject,orifthebladeis

outofbalanceorbent.

1.Holdthebladeendusingaragorthicklypaddedglove.

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure48).

g014974

5.Measurefromthetipofthebladetotheatsurface

(Figure47).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

Figure47

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page37)and

InstallingtheBlades(page38).

Note:Ifabentbladeisreplacedwithanew

blade,andthedimensionobtainedcontinuesto

exceed3mm(1/8inch),thebladespindlecould

bebent.ContactanAuthorizedToroDealerfor

service.

g000551

Figure48

1.Sailareaoftheblade

2.Blade

3.Curvedwasher

4.Bladebolt

5.Bladestiffener

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure49).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

g014973

g000552

Figure49

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure50).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure49).

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

6.Repeatthisprocedureoneachblade.

g000553

Figure50

1.Blade2.Balancer

37

Page 38

3.Repeatthisprocedureuntilthebladeisbalanced.

G014630

1

2

3

4

4

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure48).

Important:Thecurvedpartoftheblademust

pointupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthecurvedwasher(cuppedsidetowardthe

blade)andthebladebolt(Figure48).

3.Torquethebladeboltto47to88N∙m(35to65ft-lb).

LevelingtheMowerDeck

g014630

Figure51

Checktoensurethatthemowerdeckislevelanytimeyou

installthemowerorwhenyouseeanunevencutonyour

lawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced;refer

toCheckingforBentBlades(page36)beforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;refertoChecking

theTirePressure(page35).

LevelingfromSidetoSide

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

1.Bladesidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface

here

5.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure51.

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuewith

thisprocedure.

6.Movetotheleftsideofthemachine.

7.Loosenthesidelockingnut.

8.Raiseorlowertheleftsideofthemowerdeckby

rotatingtherearnut(Figure52).

Note:Rotatetherearnutclockwisetoraisethemower

deck;rotatetherearnutcounter-clockwisetolower

themowerdeck.

3.Settheheight-of-cutlevertothemiddleposition.

4.Carefullyrotatethebladesothatitissidetoside

(Figure51.

g027588

Figure52

1.Hangerbracket3.Rearnut

2.Sidelockingnut

38

Page 39

9.Checktheside-to-sideadjustmentsagain.Repeatthis

G014631

1

2

2

G014634

1

2

3

procedureuntilthemeasurementsarecorrect.

10.Continuelevelingthedeckbycheckingthefront-to-rear

bladeslope;refertoAdjustingtheFront-to-RearBlade

Slope(page39).

AdjustingtheFront-to-RearBlade

Slope

Checkthefront-to-rearbladeslopeanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Settheheight-of-cutlevertomiddleposition.

g014634

Figure54

1.Adjustingrod3.Locknut

2.Adjustingblock

Note:Checkandadjusttheside-to-sidebladelevel

ifyouhavenotcheckedthesetting;refertoLeveling

fromSidetoSide(page38).

4.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure53.

Figure53

Mowerdeckswith1blade

1.Bladefronttorear

2.Measurefromthetipofthebladetotheatsurfacehere.

5.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure53).

7.Toraisethefrontofthemower,tightentheadjustment

nut.

8.Tolowerthefrontofthemower,loosentheadjustment

nut.

9.Afteradjustment,checkthefront-to-rearslopeagain,

continueadjustingthenutuntilthefrontbladetipis

1.6to7.9mm(1/16to5/16inch)lowerthantherear

bladetip(Figure53).

10.Whenthefront-to-rearbladeslopeiscorrectcheckthe

side-to-sidelevelofthemoweragain;refertoLeveling

fromSidetoSide(page38).

RemovingtheMowerDeck

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

g014631

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Lowertheheight-of-cutlevertothelowestposition.

4.Removethehairpincotterfromthefrontsupportrod

andremovetherodfromthedeckbracket(Figure

55).Carefullylowerthefrontofthemowerdeckto

theground.

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,adjustthe

frontlocknut.

6.Toadjustthefront-to-rearbladeslope,rotatethe

adjustmentnutinthefrontofthemower(Figure54).

39

Page 40

G014635

1

2

3

Figure55

G015338

2

2

3

1

2

2

3

1.Frontsupportrod3.Deckbracket

2.Lockingnut

InstallingtheMowerDeck

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowestposition.

5.Lifttherearofthemowerdeckandguidethehanger

bracketsovertherearliftrod(Figure56).

6.Attachthefrontsupportrodtothemowerdeckwith

theclevispinandhairpincotter(Figure55).

7.Installthemowerbeltontotheenginepulley;referto

ReplacingtheMowerBelt(page41).

ReplacingtheGrassDeector

g014635

ServiceInterval:Beforeeachuseordaily—Inspectthegrass

deectorfordamage.

WARNING

5.Usingthemower-deckhandles,liftthemowerdeck

andhangerbracketsclearoftherearliftrodandlower

themowercarefullytotheground(Figure56).

Figure56

1.Mowerdeck

2.Hangerbracket

3.Rearliftrod

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.Never

operatethemachinewithoutthegrassdeector,

thedischargecover,orthegrass-collectionsystem

inplace.

Neveroperatethemachinewithoutthegrass

deector,thedischargecover,orthegrass-collection

systeminplace.

1.Removethenut(3/8inch)fromtherodunderthe

mower(Figure57).

g015338

6.Slidethemowerdeckrearwardtoremovethemower

beltfromtheenginepulley.

7.Slidethemowerdeckoutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

40

Page 41

G014636

1

2

3

4

5

6

7

Figure57

1.Mowerdeck

2.Grassdeector6.Nut(3/8inch)

3.Grass-deectorbracket7.Shortstandoff

4.Rod

2.Slidetherodoutoftheshortstand-off,spring,and

grassdeector(Figure57).

3.Removethedamagedorworngrassdeector.

4.Replacethegrassdeector(Figure57).

5.Slidetherod,straightend,throughthereargrass

deectorbracket.

5.Spring

MowerBeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebeltsforwear

orcracks.

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

g014636

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Settheheightofcutatthelowestcuttingpositionof

38mm(1-1/2inches).

4.Usingaspring-removaltool(ToroPartNo.92-5771),

removetheidlerspringfromthedeckhooktoremove

tensionontheidlerpulley,androllthebeltoffofthe

pulleys(Figure58).

6.Placethespringontherod,withendwiresdown,and

betweenthegrassdeectorbrackets.

WARNING

Thespringisundertensionwheninstalled

7.Slidetherodthroughthesecondgrass-deector

bracket(Figure57).

8.Inserttherodatthefrontofthegrassdeectorinto

theshortstandoffonthedeck.

9.Securetherearendoftherodintothemowerwitha

nut(3/8inch)asshowninFigure57.

Important:Thegrassdeectormustbe

spring-loadedinthedownposition.Liftthe

deectoruptotestthatitsnapsintothefull-down

position.

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

41

Page 42

G015129

1

2

3

4

5

4

6

Figure58

Mowerdeckswith1blade

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

4.Spring

Cleaning

CleaningundertheFrontof theMachine

ServiceInterval:Aftereachuse—Checkandcleanthefront

ofthemachine.

Removedebrisunderthefrontofthemachinewith

compressedairorbyhandwithabrush(Figure59).

Note:Donotusewatertocleanunderthefrontofthe

machine,thiscancausebuildupofdebris.

g015129

g028248

Figure59

WashingtheUndersideofthe

5.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure58).

6.Usingaspring-removaltool(ToroPartNo.92-5771),

installtheidlerspringoverthedeckhookandplacing

tensionontheidlerpulleyandthemowerbelt(Figure

58).

Mower

ServiceInterval:Aftereachuse—Cleanthemower-deck

housing.

Important:Y oucanwashthemachinewithamild

detergentandwater.Donotpressurewashthemachine.