Page 1

TFS Series, Toro Flow Sensor

Installation Instructions

Overview

The Toro fl ow sensors provide an accurate fl ow measurements by generating a frequency signal (pulses per second)

that is proportional to the fl ow rate. The Toro fl ow sensors are designed for below grade applications for irrigation

monitoring where the fl ow rates are between 0.5–30 ft/sec and temperatures are below 180º Fahrenheit. The

To ro fl ow sensors are supplied with two single conductor, 18 AWG solid copper wire leads with U.L. Style 116666

direct burial insulation. An internal preamplifi er allows the pulse signal to travel up to 2000’ without further signal

amplifi cation.

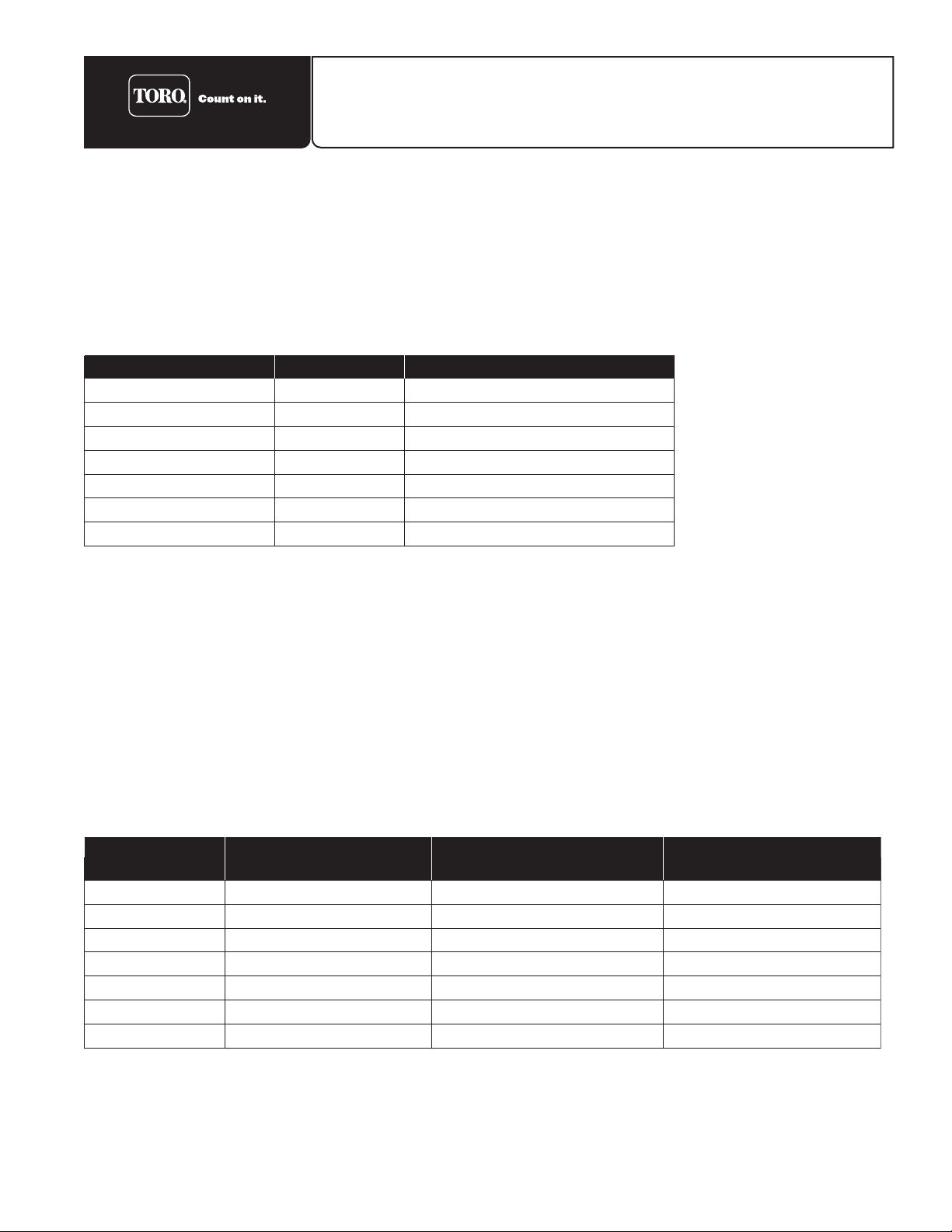

Models

Model Number Size Description

TFS-050 1/2” Flow Sensor, 1/2”, Plastic Tee

TFS-075 3/4” Flow Sensor, 3/4”, Plastic Tee

TFS-100 1” Flow Sensor, 1”, Plastic Tee

TFS-150 1.5” Flow Sensor, 1.5”, Plastic Tee

TFS-200 2” Flow Sensor, 2”, Plastic Tee

TFS-300 3” Flow Sensor, 3”, Plastic Tee

TFS-400 4” Flow Sensor, 4”, Plastic Tee

Controller Compatibility

The Toro fl ow sensors are compatible with the following controllers:

• Toro TMC-424 • Toro Intelli-SenseTM TIS-360/480

• Toro SentinelTM • Toro SitePro

• Irritrol MC-E • Any controller compatible with Frequency output fl ow sensor

(Pulse per Second proportional to fl ow velocity)

®

Sizing

The following table indicates the suggested fl ow range of the Toro fl ow sensors. Although the sensors will operate

above and below the indicated fl ow rates, following the suggested range will ensure the best performance from the

fl ow sensor. Sensors should be sized according to fl ow rates rather than pipe size.

Model Number

TFS-050 1.2 – 12

TFS-075 2.7 – 28

TFS-100 5 – 50

TFS-150 5 – 100

TFS-200 10 – 200

TFS-300 20 – 300

TFS-400 40 – 500

Suggested Operating

Range (Gallons / Minute)

Suggested Operating

Range (Liters / Second)

0.1 – 0.8 0.3 – 2.7

0.2 – 1.8 0.6 – 6.4

0.3 – 3.2 1.1 – 11.4

0.3 – 6.3

0.6 – 12.6

1.3 – 18.9

2.5 – 31.5

Suggested Operating

Range (Cubic Meters / Hour)

1.1 – 22.7

2.3 – 45.4

4.5 – 68.1

9.1 – 113.6

Page 2

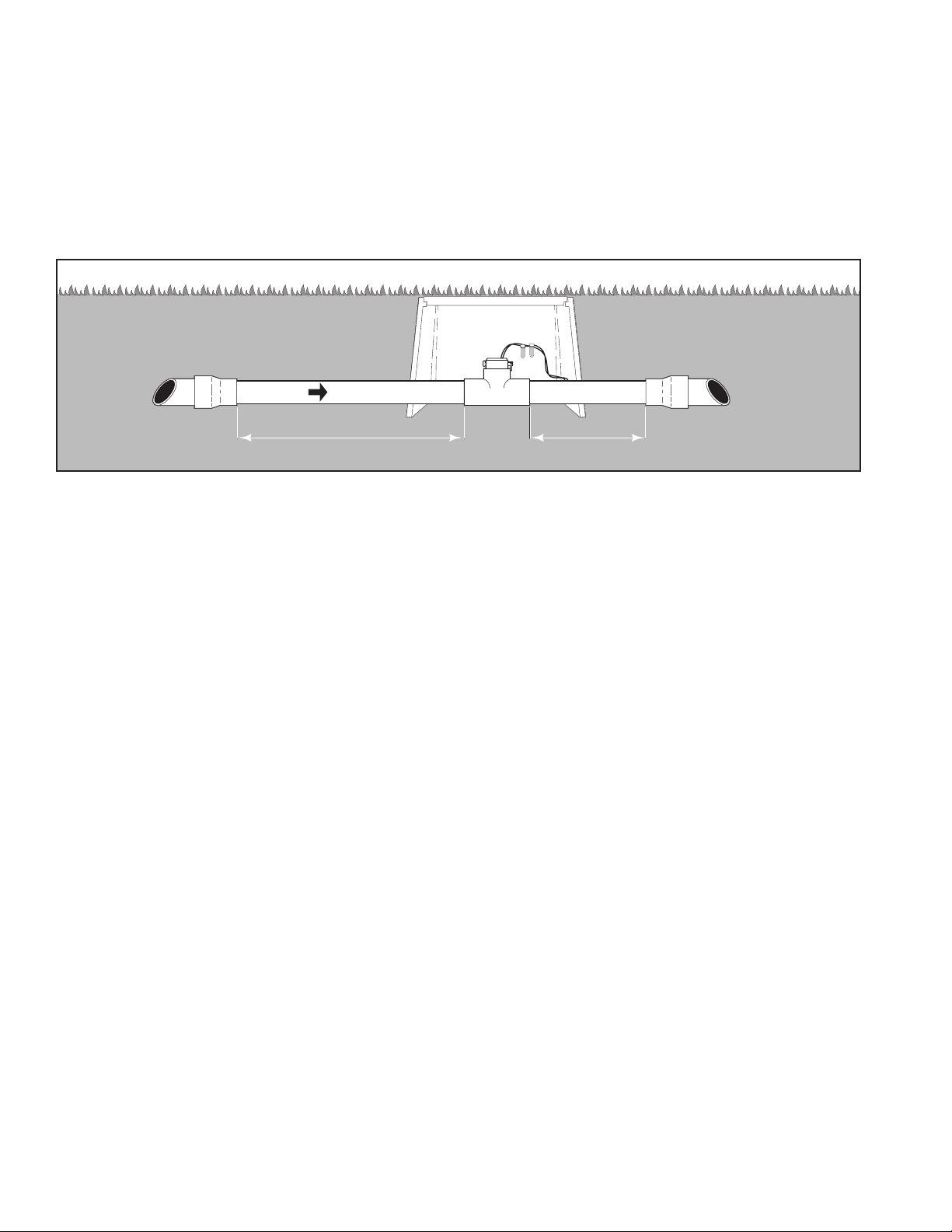

Flow Sensor to Pipeline Installation

The accuracy of the fl ow sensor’s measurement is highly dependent on proper sensor location within the piping

system. Irregular fl ow velocity caused by valves, fi ttings, pipe bends, etc. can lead to inaccurate fl ow rate

measurements even though local fl ow velocity measurements may be accurate. A sensor located in the pipe

where it can be affected by air bubbles, fl oating debris, or sediment may not achieve full accuracy and could be

damaged. The Toro fl ow sensors are designed to operate reliably even under adverse conditions but following

recommendations will ensure maximum system accuracy.

Select a location along the pipe system that is 10 times the pipe diameter upstream and 5 times the pipe diameter

downstream to minimize fl ow disturbance. Pipe bends, valves, pipe fi ttings, pipe enlargements and reductions

should not be present within this pipe length.

Flow

10 X Pipe Diameter 5 X Pipe Diameter

Note: For 1.5” and larger fl ow sensors, install according to the fl ow direction shown by the arrow on the tee. For 1.0”

and smaller fl ow sensors, installation is not dependent on fl ow direction.

Flow Sensor to Pipeline Installation

Step 1 - Remove the sensor from the tee.

a. For 1.5” and larger Sensors: Pull the clevis pin that retains the fl ow sensor to the tee,

then carefully remove it from the tee.

b. For 1.0” and smaller Sensors: Unscrew the sensor cap from the tee by turning it counterclockwise.

Carefully pull the sensor out from the tee.

Step 2 - Properly clean the pipe ends and tee socket.

Step 3 - Use solvent cement to secure the pipes to the tee.

Step 4 - Reinstall the sensor to the tee as follows:

a. For 1.5” and larger Sensors:

i. Align the fl ow arrow on top of the sensor housing to the direction of the fl ow.

ii. Carefully press the sensor straight into the tee.

iii. Install the clevis pin through the tee and sensor.

iiii. Install the cotter ring into the clevis pin.

b. For 1.0” and smaller Sensors:

i. Carefully line up the guide pin on the sensor to the slot on the tee.

ii. Carefully press the sensor straight into the tee.

iii. Screw the sensor cap fi rmly onto the tee.

Note: Hand tighten the sensor only.

Step 5 - Complete the wiring connections.

Page 3

Cable Installation

Step 1 - Use a twisted pair cable suitable for direct burial

to connect the sensor to the controller. Multi-pair

telecommunication cable or direct burial cables may

be used. Shielded cable is recommended. Connect

the cable wires to the sensor wires.

Step 2 - Waterproof the splices. Two part epoxy

waterproofi ng kits or waterproof wire connectors

are recommended.

Step 3 - Route the cable from the sensor to the controller.

The cable may be extended up to 2000’ if using a

2-conductor shielded 18 AWG or larger stranded

copper wire with appropriate ratings. Be sure to

leave enough fl exibility in the cable for future sensor

servicing.

Step 4 - When connecting to a Toro controller, connect the red wire to “IN”, “SIGNAL” or “(+)” terminal and the black

wire to “GND”, “SIGNAL”, “(–)” or “COM” terminal.

Example: Sensor

Connection to TMC-424

Red Wire

connect to

Controller

Sensor (+)

TSM-4F

Module

Black Wire

connect to

Controller

Sensor (–)

Calibration Tables

For controllers displaying Flow Rate (GPM, etc.), the Toro fl ow sensor use a unique K and Offset numbers for

calibration. The Calibration Table below provides the calibration data for each of the Toro fl ow sensors when installed

in SCH 40 piping.

Model Number Size Description

TFS-050 1/2” Flow Sensor, 1/2”, Plastic Tee

TFS-075 3/4” Flow Sensor, 3/4”, Plastic Tee

TFS-100 1” Flow Sensor, 1”, Plastic Tee

TFS-150 1.5” Flow Sensor, 1.5”, Plastic Tee

TFS-200 2” Flow Sensor, 2”, Plastic Tee

TFS-300 3” Flow Sensor, 3”, Plastic Tee

TFS-400 4”

K Value

0.07800

0.15630

0.26112

1.69900

2.84290

8.30900

13.74283

Offset

0.9

0.9

1.2

-0.31600

0.14350

0.22700

0.23707Flow Sensor, 4”, Plastic Tee

Troubleshooting

Step 1 - If the voltage at the sensor input is less than 7 VDC during “NO Flow” situation, disconnect the sensor

from the sensor terminals. Re-measure the voltage at the sensor terminals. The voltage reading should

be between 8–20 VDC. If the voltage at the sensor terminals is still below 7 VDC, the controller may be

the cause of the problem (hardware or fi rmware). If the proper voltage is present at the sensor terminals,

proceed to Step 2.

Step 2 - If you suspect that the sensor is defective, test the controller’s circuitry by connecting a wire to one of the

sensor terminal. Use the other end of the wire to short the other sensor terminal repeatedly to simulate

a fl ow signal. Depending on the controller, you night be required to continue this for a few seconds

for the controller to register a reading. If the display do not show a fl ow reading, it indicates a problem

with the controller. If the controller does register a fl ow reading, then the defect might be between the

communication cable and the sensor. Proceed to Step 3.

Step 3 - Test the cable for continuity. Disconnect the splices from the sensor and connect the cable wires together.

Take the cable wires at the controller side and test for continuity. Use a volt meter with a continuity tester. If

the volt meter indicates good continuation in the cable, then the cable is not defective, continue to Step 4.

If the cable indicates no continuation, then a break in the circuit is present within the cable. If there are any

splices in the cable, check and re-secure it. Check the cable’s continuity again. Replace the cable if you still

detect a continuity break.

Step 4 - Drain the pipe line and verify that the pressure is relieved. Remove the sensor from the tee (See Flow

Sensor to Pipeline Installation, Step 1). If the sensor has been disconnected from the controller,

reconnect it to test. Spin the impeller by hand. If the controller detects a fl ow and the impeller spins freely,

then the fl ow rate may have been below our design minimum or the pipeline system is full of air pockets. If

the sensor fails to send a fl ow signal when the impeller is spinning, then the sensor is defective. Replace the

sensor.

Page 4

© 2007 The Toro Company • Irrigation Division • www.toro.com Part Number 373-0429 Rev. A

Loading...

Loading...