Page 1

T7 SERIES ROTORS

The 1” inlet Toro® T7 Series rotor is built rugged to withstand the performance and durability requirements

of municipal/government, sports fields and large commercial settings. Driven by customer feedback, the T7

Series rotor has been designed and tested to ensure consistent performance and features a full 5” pop-up

height, a visual top-of-rotor arc adjustment dial, and Smart Arc™ Memory that resets the rotor’s arc should it

be changed due to vandalism or inexperienced users. Further enhancing its versatility, the T7 Series is also

available in Low Flow models for smaller radius, lower flow applications, such as baseball infields.

FEATURES & BENEFITS

Visual Arc Indication

Arc setting indicator on top of the rotor allows for easy wet or dry

adjustments from 45°-360°.

High Eciency Nozzles

Single port design ensures water is evenly distributed across

the pattern without putting too much water near the head, which

prevents seed from washing away.

Euent

Vandal and Abuse Resistance

Smart Arc™ memory safely returns sprinkler to previously set arc

if vandalized. An integrated slip clutch prevents the breaking and

stripping of gears.

Design Solutions and Safety

Standard check valve prevents low head drainage, and a minimal

2.2” exposed rubber cover diameter reduces the potential for

injuries on play areas.

Options

Available

SST Riser

Options

Available

Durability

Heavy-duty retract spring and wiper seal reduce the occurrence

of stick-ups and seal leakage, while a water-lubricated gear drive

contributes to long-term consistent performance.

Page 2

Additional Features

Standard reversible Check-O-Matic seal

Variable reversing stator

Included nozzle trees:

Low flow nozzles (2, 3, 4.5, 6, 7.5, and 9 gpm)

Standard nozzles (7, 9, 12, 16, 20, 24, and 27 gpm)

Slip clutch

Locking cap screw

Adjustment/pull up tool included

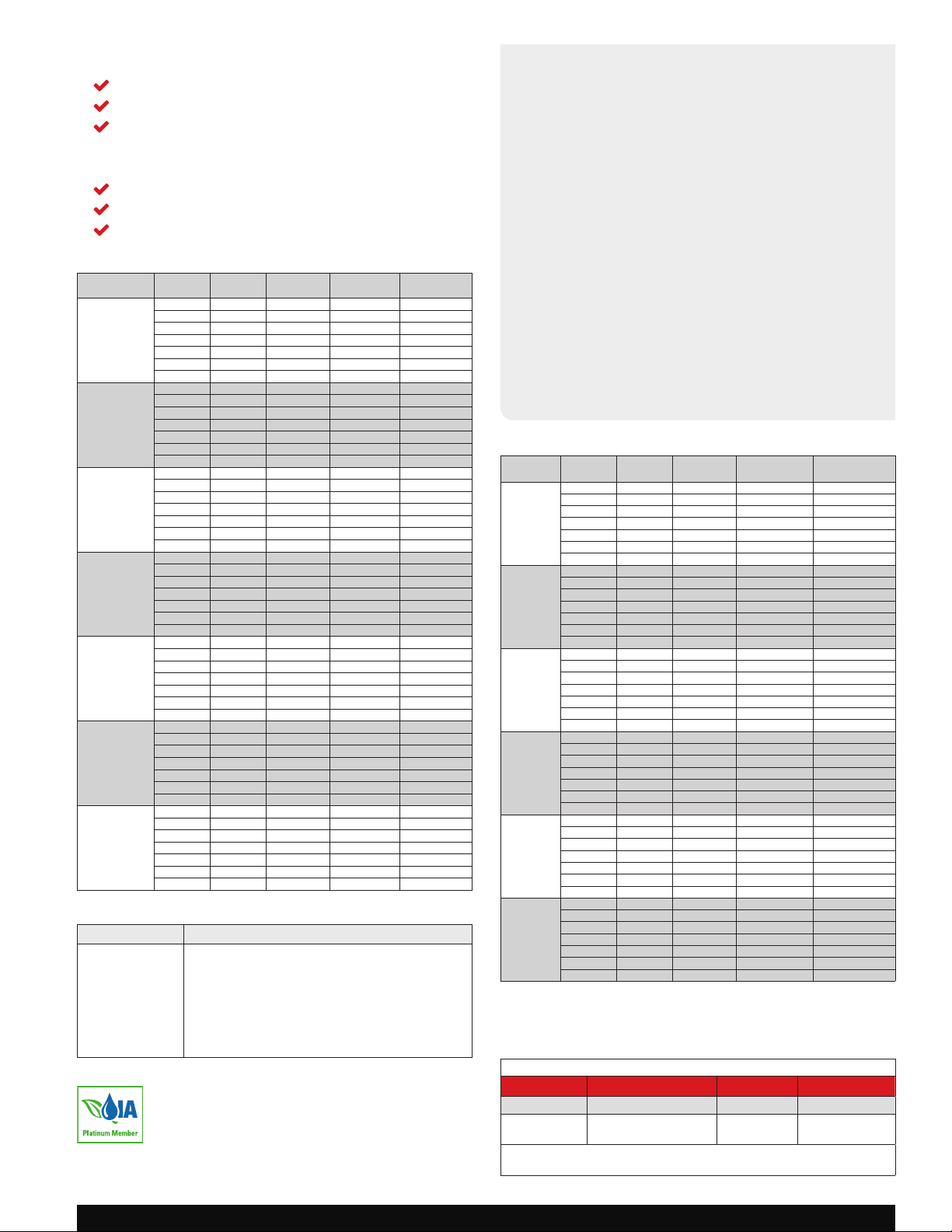

NOZZLE PERFORMANCE DATA-HIGH FLOW MODELS

Nozzle psi Radius (ft) gpm

40 46 6.6 0.72 0.62

50 47 7.4 0.75 0.65

7.0

9.0

12. 0*

16. 0

20.0

24.0

27. 0

60 48 8.1 0.78 0.68

70 49 8.8 0.82 0.71

80 51 9. 4 0.83 0.72

90 52 10. 3 0.85 0.73

100 54 10.7 0.83 0.72

40 47 7.4 0.76 0.66

50 50 8.3 0.73 0.64

60 51 8 .7 0 .76 0.66

70 52 9. 4 0.81 0.70

80 54 9.9 0.80 0. 69

90 55 10.9 0.82 0.71

100 56 11. 5 0.84 0.7 3

40 50 9.5 0.89 0.7 7

50 51 11. 6 0.9 0 0 .78

60 53 12.7 0.91 0 .79

70 54 13. 8 0.96 0.83

80 55 14.7 0 .99 0.86

90 56 15.6 1. 02 0.88

100 57 16. 5 1.04 0 .90

40 53 13. 0 1.06 0.92

50 56 15 .1 1.06 0.92

60 58 16. 2 1. 04 0.90

70 59 17.5 1.09 0 .95

80 61 18. 8 1.10 0.95

90 62 20.0 1.14 0.98

100 63 21.1 1.17 1.01

40 53 16. 0 1.28 1.10

50 58 17. 5 1. 22 1.0 5

60 60 19.5 1. 21 1.0 5

70 61 20.6 1.2 6 1.09

80 65 22.2 1.19 1.03

90 66 23.6 1. 23 1.06

100 67 24. 8 1.25 1. 09

40 52 15.8 1.27 1.10

50 60 17. 5 1.09 0.9 5

60 63 19.3 1.11 0.96

70 65 20.7 1.14 0.99

80 67 22.3 1.15 1.00

90 68 23.8 1. 20 1.0 4

100 71 25.3 1.16 1.01

40 55 18. 7 1. 42 1. 23

50 65 23.4 1.16 1.0 0

60 71 23.6 1.0 5 0.91

70 72 25.8 1.10 0.95

80 73 2 7.4 1.14 0.99

90 74 2 9.1 1.18 1.02

100 75 30.6 1.21 1. 05

T7 ROTOR MODEL LIST

Model Description

T7P-02

T7P-02E

T7P-02L

T7P-02LE

T7PSS- 02

T7PSS-02E

T7PSS-02L

T7PSS-02LE

1” Ro to r

1” Rotor, Effluent r ubber cover

1” Rotor, Low Flow

1” Rotor, Low Flow, Effluent rubber cover

1” Stainless Steel Rotor

1” Stainless Steel Rotor, Effluent rubber cover

1” Stainless Steel Rotor, Low Flow

1” Stainless Steel Rotor, Low Flow, Effluent rubber cover

www.toro.com

The Toro Company • Irrigation Division • 5825 Jasmine

St. Riverside, CA • 92504 • 877-345-8676

Specifications subject to change without notice. For more

information, contact your local Toro distributor. ©2015 The Toro

Company. All rights reserved. P/N 15-1099-IRC

Precip. Rate

(in/hr) ▲

Precip. Rate

(in/hr) ■

SPECIFICATIONS

Operational

• Radius capability: Low flow models—39’-56’

Standard models—46’-75’

• Flow rates: Low flow models—1.7-12.8 gpm

Standard models—6.6-30.6 gpm

• Operating pressure range: 40-100 psi

• Recommended operating pressure: 60-70 psi

• Inlet size: 1” female NPT

• Nozzle trajector y: 25°

• Arc adjustment: 45°-360° (unidirectional at 360°)

Dimensions

• Pop-up height (measured from top of cap to nozzle): 5”

• Body height: 8.8”

• Body diameter: 2.7”

• Rubber cover diameter: 2.2”

Available Options

• Stainless Steel riser

• Effluent Lavender rubber cover

Warranty

• Five years

NOZZLE PERFORMANCE DATA-LOW FLOW MODELS

Nozzle psi Radius (ft) gpm

40 39 1.7 0.25 0.22

50 39 2.0 0.29 0.25

2.0

3.0*

4.5

6.0

7.5

9.0

†

When the spr inkler is adjusted to 360 °, it will be uni- directional in that d irectio n of rotation

60 40 2.2 0.30 0.26

70 40 2.4 0.33 0.28

80 40 2.6 0.35 0.31

90 41 2.7 0.36 0.31

100 41 2.9 0.38 0.33

40 39 2.4 0.36 0.31

50 40 2.8 0.39 0.33

60 41 3 .1 0. 41 0.36

70 41 3.4 0.45 0.39

80 42 3.6 0.46 0.40

90 42 3 .9 0. 47 0 .41

100 43 4.1 0.49 0.42

40 38 4 .1 0.63 0.54

50 41 4.7 0.62 0.53

60 41 5.2 0.68 0.59

70 42 5.7 0.71 0.62

80 42 6 .1 0.77 0.66

90 43 6.5 0.78 0.68

100 43 6.9 0.83 0.72

40 43 5.0 0.59 0.51

50 46 5.7 0.59 0. 51

60 48 6.3 0. 61 0.52

70 49 7.0 0.65 0.57

80 49 7.4 0.68 0.59

90 50 7. 9 0.70 0 .61

100 50 8.4 0.74 0.64

40 44 5.8 0.66 0.58

50 46 6.7 0.70 0.60

60 48 7. 4 0.71 0.62

70 49 8.0 0.7 5 0.65

80 50 8.8 0.78 0 .67

90 50 9. 5 0.84 0.73

100 52 10. 0 0.81 0.70

40 45 7. 4 0.81 0.70

50 49 8.5 0.78 0.68

60 51 9.4 0.80 0.70

70 53 10. 4 0.83 0.72

80 55 11.3 0.83 0.72

90 55 12.0 0.89 0.77

100 56 12. 8 0.90 0.78

(clockwis e or counter clockwise) a t the moment when the sp rinkler was changed to 360 °

Precip. Rate

(in/hr) ▲

* Pre-ins talled nozzle. Data base d on 180°.

Specifying Information—T7 Series

T7PXX- 02XX

Description Optional Thread Optional

T7P XX 02 XX

T7 Series Rotor SS-Stainless Steel Riser NPT Thread E—Effluent

Example: A low flow T7 Series rotor with a Stainless Steel riser and Effluent rubber

cover would be specified as: T7PSS-02LE

Precip. Rate

(in/hr) ■

L—Low Flow

Loading...

Loading...