Page 1

FormNo.3392-628RevA

T42404-WheelDrive5-Plex

MowerTractionUnit

ModelNo.02750—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-628*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

Thismachineisaride-on,cutterhead-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedforcutting

grassonparks,sportselds,caravanparks,cemeteriesand

commercialgrounds.Itisnotdesignedforcuttingbrushor

foragriculturaluse.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyforproductandaccessory

information,helpndingadealer,ortoregisteryour

productatToroCommercialProductsServiceDepartment

Spellbrook,Bishop’sStortford,CM234BU ,England,

+44(0)1279603019,Email:uk.service@toro.com.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareona

platemountedontheleftsideoftheframeunderthefoot

rest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUK

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................13

BrakingSystem...................................................14

WarningSystems................................................18

IndicatorLights..................................................19

Specications........................................................20

Attachments/Accessories........................................20

Operation....................................................................21

ThinkSafetyFirst...................................................21

CheckingtheEngine-OilLevel.................................21

AddingFuel...........................................................21

UsingtheOperatorPlatformLatching

Mechanism........................................................22

UnderstandingtheOperatorPresence

Controls............................................................23

StartingandStoppingtheEngine..............................24

AdjustingtheHeight-of-Cut....................................25

ControllingthePositionofanIndividualCutting

Unit..................................................................25

DualLiftCongurationControl...............................25

EngagingtheCuttingUnitDrive..............................26

UsingtheWeight-Transfer/Traction

Assistance..........................................................26

FoldingtheROPS..................................................26

JackingPoints........................................................27

ClearingtheCuttingCylinders..................................27

OperatingTips......................................................28

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

DailyMaintenanceChecklist....................................30

Pre-Maintenance...................................................31

ServiceIntervalChart.............................................32

Lubrication...............................................................33

GreasingtheBearings,Bushings,andPivots...............33

EngineMaintenance..................................................34

CheckingtheEngineOverheatWarning

System..............................................................34

ServicingtheAirCleaner.........................................34

CheckingtheEngine-OilLevel.................................34

ChangingtheEngineOilandFilter...........................35

FuelSystemMaintenance...........................................36

DrainingtheFuelTank...........................................36

CheckingtheFuelLinesandConnections..................36

ReplacingtheFuelFilterCanister..............................36

BleedingtheFuelSystem.........................................36

BleedingAirfromtheFuelInjectors..........................37

ElectricalSystemMaintenance....................................37

ServicingtheBattery...............................................37

DriveSystemMaintenance.........................................38

ChangingtheTransmission-OilFilter........................38

CheckingtheRearWheelAlignment.........................38

CheckingtheTirePressure......................................39

CheckingtheTorqueoftheWheelNuts.....................39

CoolingSystemMaintenance......................................39

CheckingtheCoolingSystem...................................39

RemovingDebrisfromtheCoolingSystem................40

BrakeMaintenance....................................................40

TowingtheMachine...............................................40

RecommissioningtheMachineafterTowing...............41

BeltMaintenance......................................................42

CheckingtheConditionandTensionofthe

AlternatorBelt...................................................42

ControlsSystemMaintenance.....................................42

CheckingtheForward/ReverseTravelPedal

Action...............................................................42

CheckingtheOperator-PresenceSeatSwitch..............42

CheckingtheCutterDriveInterlockSwitch................42

CheckingtheParkingBrakeInterlockSwitch..............42

CheckingtheTransmissionNeutralInterlock

Switch...............................................................43

CheckingtheDiverterValves...................................43

HydraulicSystemMaintenance....................................43

ServicingtheHydraulicSystem.................................43

CheckingtheHydraulicFluid...................................44

ChangingtheHydraulicOilReturnFilter...................45

CheckingtheHydraulicOilOverheatWarning

System..............................................................45

CheckingtheHydraulicLinesandHoses....................45

CuttingUnitMaintenance...........................................46

Storage........................................................................46

PreparingtheTractionUnitforStorage.....................46

PreparingtheEngineforStorage..............................46

Troubleshooting...........................................................47

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithEN

ISO5395:2013.

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

SafeOperatingPractices

•Replacedamagedorwornsilencers/mufers.

•Onlyuseaccessoriesandattachmentsapprovedbythe

manufacturer.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemachine.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleanddamageto

property.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,hardhat,safetyglasses,and

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,engagetheparking

brake,disengagethecuttingunitdrivesystemandensure

thattheforward/reversespeedcontrolsareinthe

NEUTRALposition.

•Donotuseonaslopeofmorethan16degrees.Care

shouldbetakenwhenusingthemachineonanyslope

wheregroundconditionsaresuchthattheremaybea

riskofthemachinerollingover.Therequirementsof

Directive2009/104/EC,‘UseofWorkEquipmentby

WorkersatWork,’shouldbeconsidered.

•Rememberthatthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.Toguard

againstoverturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Machinespeedsshouldbekeptlowonslopesand

duringtightturns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Donotturnsharply.

–Usecarewhenreversing.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Donottamperwithordisablethesafetysystems.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besure

thatallinterlocksareattached,adjustedproperly ,and

functioningproperly.

4

Page 5

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethedrivetothecuttingunits;

–liftthecuttingunitstothetransportpositionand

securelylockthesafetylatchesoralternativelylower

thecuttingunitstotheground;

–Ensurethetransmissionisinneutralandengagethe

parkingbrake;

–stoptheengineandremovethekey.

•Whentransportingthemachine:

–disengagethedrivetothecuttingunits;

–raisethecuttingunitstothetransportposition;

–engagethetransportlatchesandsafetylockingrings.

–stoptheengineandremovethekey.

•Whendrivingthemachinebetweenworksitesitis

importanttoensurethatthecuttingunitscannotbe

inadvertentlyloweredandstarted:

–disengagethedrivetothecuttingunits;

–raisethecuttingunitstothetransportposition;

–engagethetransportlatchesandsafetylockingrings.

•Stoptheengineanddisengagedrivetothecuttingunits:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemachine;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemachinefordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthecylinders/cutting

unitsiftheyarenotmowing.

•Donotoperatethemachinewhiletired,ill,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelisammableandthevapors

areexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.DonotweartheseatbeltwhentheROPSis

foldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

5

Page 6

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-cuttingunitmachines,takecare

asrotatingonecylinder/cuttingunitcancauseother

cylinders/cuttingunitstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/cuttingunits.W ear

glovesandusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedinthesafetystandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesisadvisableandrequiredbysome

localordinancesandinsuranceregulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raiseandlatchthecuttingunitswhendrivingfromone

workareatoanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

6

Page 7

MaintenanceandStorage

•Beforeservicingormakingadjustments,stoptheengine

andremovetheignitionkey.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheckall

nuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

VibrationLevel

Hand-Arm

Measuredvibrationlevel=0.5m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.1m/s

UncertaintyValue(K)=0.1m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

2

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasameasuredsoundpowerlevelof105dB(A),

whichincludesanUncertaintyValueof2dB(A).

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof86

dB(A),whichincludesanUncertaintyValue(K)of2dB(A).

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

70-13-072

1.Jackingpoint

70-13-077

1.Warning—stoptheengineandremovetheignitionkey

beforereleasingoroperatingsafetylatches.

924868

1.Dieselfuel

1.Tippinghazard—donotoperatethemachineunlessthe

platformiscorrectlyseatedandthelatchislockedinplace.

70–13–078

950832

1.Tirepressure

950889

1.Warning—hotsurfaces.

8

Page 9

953829

1.Crushinghazard,cuttingunit—alwayslowerthecutting

unitsbeforegoingnearthem.

1.Differentiallock

2.Pushdowntoengagethe

differentiallock.

3.Releasetodisengagethe

differentiallock.

953876

4.Reverse

speed—directionalcontrol

5.Forward

speed—directionalcontrol

1.Forwardspeed

2.Fast

953877

3.Slow

9

Page 10

111-3901

1.Transmissionoil—readtheOperator'sManualformore

information.

111-3902

1.Warning—cuttinghazardofhand,fan.

2.Hotsurfaces—readtheOperator'sManualformore

information.

994912

1.Engagetheparkingbrake.

2.Disengagetheparking

brake.

3.Fast9.Ignitionswitch

4.Slow

5.Raise/lowertheleftcutting

unit.

6.Raise/lowerthecenter

cuttingunit.

7.Raise/lowertheright

cuttingunit.

8.Horn

10.Engagethereel.

11.Disengagethereel.

12.Engagebacklapping.

111-0773

1.Warning—crushingofngers,forceappliedfromside.

10

Page 11

953812

1.Fuellevel5.Aircleaner

2.Engineoil

3.Tires

4.Fasteners

6.Cutterheads

7.Cleanandinspectthe

machine.

8.Wheelnuttorque—front,

200N-m(147ft-lb);rear,54

N-m(40ft-lb)

9.Seatswitch13.Coolantlevel—30-40mm

10.Hoselines

11.Hydraulicoil

12.Radiator/screens

(1-1.5in)

14.Greasepoints

11

Page 12

111-8098

1.Tippinghazard—driveslowlywhenturningorgoingupslopes.

2.TIppinghazard—onlydriveupslopesthatarebetween0and

18degrees;donotdriveupslopesthataregreaterthan18

degrees.

3.Tippinghazard—wearaseatbeltwhentheROPSisup;do

notwearaseatbeltwhentheROPSisdown.

ProductOverview

4.Warning—readtheOperator'sManual;removethekeyfrom

theignitionandreadtheOperator'sManualbeforeservicing

orperformingmaintenance.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

Figure2

1.Frontcuttingunits4.Enginehood

2.Steeringwheel

3.Operator'sseat

12

5.Rearcuttingunit

Page 13

Controls

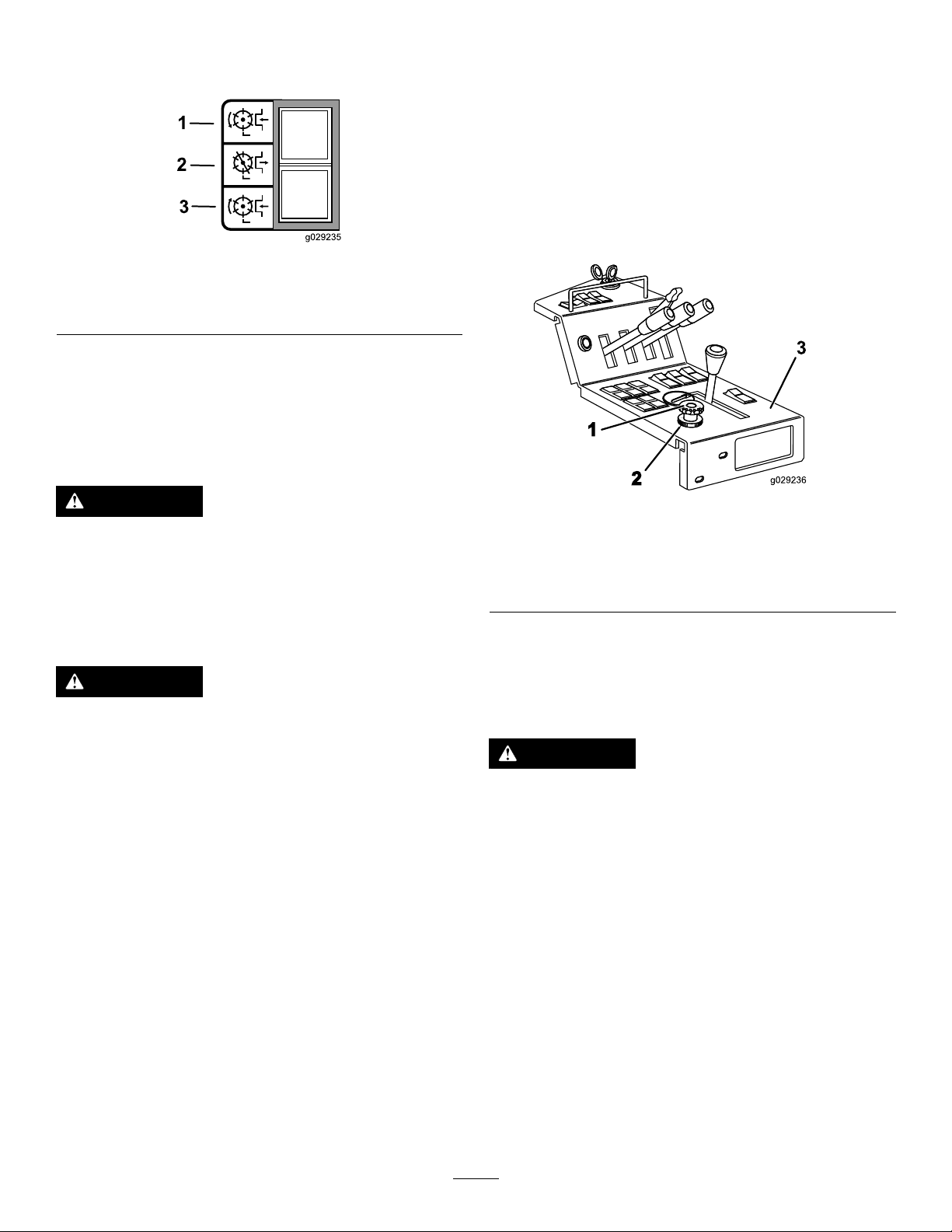

ControlPanelComponents

1.Throttle-controllever

2.Cutting-unit-positionlever

3.Parking-brakelever9.Hazard-warningswitch

4.Work/Transportmode

switch

5.Weight-transfercontrol

6.Duallift-conguration

switch

7.Lightingswitch(supplied

withlightingkit)

8.Warning-beaconswitch

(suppliedwithbeaconkit)

(suppliedwithlightingkit)

10.Engine

temperature-warning

indicator

11.Transmission-temperature

indicator

12.Oil-pressureindicator

Figure3

13.Hourmeter

14.Transmission-neutral

indicator

15.Parking-brakeindicator21.Direction-indicatorswitch

16.Cutting-unitdrive-off

indicator

17.Glow-plugindicator23.Cutting-unitdriveswitch

18.Battery-warningindicator24.Ignitionkey

19.Transmission-oillter

indicator

20.Hornbutton

(suppliedwithlightingkit)

22.Dipbeam/mainbeam

lightswitch(suppliedwith

lightingkit)

13

Page 14

1.Left,frontcutting-unit

transportlatch

2.Reverse-travelpedal

3.Forward-travelpedal

4.Right,frontcutting-unit

transportlatch

5.Rightwing-unittransport

latch

Figure4

6.Forwardtravelspeed

backstoplever

7.Leftwing-unittransport

latch

8.Centercutting-unit

transportlatch

9.Differentiallockpedal

intotheneutralposition.Servicebrakingiseffectiveonthe

frontwheelsonly.

WARNING

Theservicebrakingsystemisnotabletoholdthe

moweratastandstill.Alwaysensuretheparking

brakeisengagedtoparkthemoweratastandstill.

EmergencyBrake

Intheeventofservicebrakefailure,turntheignitionoffto

bringthemowertoastandstill.

WARNING

Takecarewhenusingtheemergencybraking.

Remainseatedandholdontothesteeringwheel

topreventejectionfromthemowercausedbythe

frontwheelbrakesbeingappliedsuddenlywhen

traveling.

ThrottleControl

Operatethethrottlecontrolinaforwarddirectiontoincrease

theenginespeed.Operatethethrottlecontrolinarearward

directiontoreduceenginespeed(Figure3).

Note:Theenginespeeddictatesthespeedoftheother

functions,i.e.travel,cuttingcylinderrotationspeedand

cuttingunitliftspeed.

BrakingSystem

ParkingBrake

Movetheparkingbrakeswitchtotherearwardpositionby

pressingthesmallerlockingbuttonandmovingtheswitch

forwardtoengagetheparkingbrake(Figure3).

Note:Donotoperatethemachinewiththeparkingbrake

engagedanddonotengagetheparkingbrakewhilethe

machineismoving.

Thislightilluminateswhentheparkingbrakeisengagedand

theignitionkeyisturnedtopositionI.

WARNING

Theparkingbrakeoperatesonthefrontwheels

only.Donotparkthemachineonaslope.

ServiceBrake

Servicebrakingisachievedbythehydraulictransmission

system.Whentheforwardorreversetravelpedalsare

releasedortheenginespeedreduced,servicebraking

becomeseffectiveandtravelspeedisautomaticallyreduced.

Toincreasethebrakingeffect,pushthetransmissionpedal

TravelPedals

Forwardtravel:Presstheforwardtravelpedaltoincrease

forwardtravelspeed.Releasethepedaltoreducespeed

(Figure4).

Reversetravel:Pressthereversetravelpedaltoincrease

reversetravelspeed.Releasethepedaltoreducespeed

(Figure4).

Stop(Neutral):Releasetheforwardorreversetravelpedal.

Work/TransportMode

SelectWORKmodewhenoperatingthemachineinpoor

tractionconditionswhenyouneedmaximumtractive

performance(Figure3).SelectingWORKmodewillenable

theuseofthedifferentiallock.

SelectTRANSPORTmodewhenoperatingthemachineingood

tractioncondition(i.e.,whentravelingonpublichighwayor

mowinglarge,level,openareas).SelectingTRANSPORTmode

intheseconditionswillreducetransmissionsystemwearand

tear.

Note:Thedifferentiallockisnotavailableforusewhenthe

TRANSPORTmodeisselected.

14

Page 15

TransportLatches

G014548

CuttingUnitDriveSwitch

Alwaysraisethecuttingunitstothetransportpositionand

securewiththetransportlatchesandsafetylockswhen

travelingbetweenworkareas(Figure5).

Figure5

AlwaysputthecuttingunitdriveswitchintheOFFposition

whentravelingbetweenworkareas.

AdjustableSteeringColumn

WARNING

Neveroperatethemachinewithoutrstchecking

thatthesteeringcolumnadjustermechanismis

ingoodworkingorderandthat,onceadjusted

andlocked,thesteeringwheelremainssecurelyin

position.

Onlyadjustthesteeringwheelandsteeringcolumnwhenthe

machineisatastandstillwiththeparkingbrakeengaged.

Toadjusttheangleofthesteeringwheel,movethelever

down,adjusttheangle,andreleasethelever(Figure6).

Toadjusttheheightofthesteeringcolumn,movethelever

up,adjusttheheight,andreleasethelever(Figure6).

DifferentialLock

WARNING

Donotengagethedifferentiallockathighspeed.

Theturningcirclewillincreasewiththedifferential

lockengaged.

Engagethedifferentiallocktoincreasetractiveeffort.Only

engagethedifferentiallockatslowspeeds(Figure4).Itwill

operatewhilethemachineismovingforwardandreverse.

Toengagethedifferentiallock,pressthedifferential

lockpedal.Todisengagethedifferentiallock,releasethe

differentiallockpedal.

Note:ThedifferentiallockiseffectiveonlywhenWORK

isselected.

ForwardTravelSpeedBackstopLever

Usethebackstoplevertolimitthemovementoftheforward

pedalforaccurateforwardtravelspeedandtolimittheclip

raterequired(Figure4).

1.Adjusttheangleofthe

steeringwheel.

2.Adjusttheheightofthe

steeringcolumn.

Figure6

3.Lever

Movetheleverforwardtoincreasethetravelspeedsetting

andrearwardtodecreaseit.

Note:Thisisnotacruise-controldevice.Releasingthe

forwardtravelpedalwillallowittoreturntoneutral.

15

Page 16

OperatorSeat

1

G016377

1

2

G016378

WARNING

Neveroperatethemachinewithoutrstchecking

thattheoperatorseatmechanismsareingood

workingorderandthat,onceadjustedandlocked,

theseatremainssecurelyinposition.

Onlyadjusttheseatmechanismswhenthemachine

isatastandstillwiththeparkingbrakeengaged.

•Fore/AftAdjustment:Movetheleverupwardtoadjust

thefore/aftpositionoftheseat.Releasethelevertolock

theseatinposition(Figure7).

•Operatorweightadjustment:Rotatethehandle

clockwisetoincreasesuspensionstiffnessand

counter-clockwisetodecrease.Thedialindicateswhen

theoptimumsuspensionadjustmenthasbeenset

accordingtooperatorweight(Figure8).

Figure8

1.Lever2.Dial

Figure7

1.Lever

16

Page 17

•Heightadjustment:Manuallylifttheseatfor

G016379

1

G016380

incrementalheightadjustment.T olower,lifttheseat

beyonditshighestsetting,thenallowittodroptothe

lowestsetting(Figure9).

•Backrestadjustment:Pullthehandleoutwardtoadjust

theseatbackrestangle.Releasethehandletolocktheseat

backrestinposition.

Figure9

Figure10

1.Handle

17

Page 18

WarningSystems

AudibleWarningHorn

Engine-CoolantOverheatingWarning

Theengine-coolantwarninglight(Figure11)illuminatesand

thehornsoundsiftheenginecoolantoverheats.

Figure11

HydraulicOilOverheatingWarningLight

Thehydraulic-oilwarninglight(Figure12)illuminatesandthe

hornsoundswhenthehydraulicoilinthereservoirexceeds

95°C(203°F).

Figure12

PresstheHORNbutton(Figure15)toprovideanaudible

warning.

Important:Thehornautomaticallysoundswhen

anenginecoolantorhydraulicoiloverheatcondition

occurs.Stoptheengineimmediatelyandxthemachine

beforestarting.

Figure15

IgnitionKey

Theignitionkeypositionsareasfollows:

0=Engineoff

I=Enginerun/auxiliaryon

II=Enginepre-heat

III=Enginestart

LowBatteryChargeWarningLight

Thebattery-chargewarninglight(Figure13)illuminateswhen

thebatterychargeislow.

Figure13

LowEngine-OilPressureWarningLight

Theengine-oilpressurewarninglight(Figure14)illuminates

whentheoilpressureistoolow.

Figure16

WARNING

Alwaysremovetheignitionkeywhenthemachine

isnotinuse.

Important:Alwaysinstalltheprotectivecapwhenthe

ignitionkeyisremovedtopreventingressofdirtand

moisturedamagingthemechanism.

Figure14

18

Page 19

FuelGauge

G014558

FUEL

E

F

Cutting-Unit-Drive-SwitchIndicatorLight

Thefuelgaugeshowstheamountoffuelinthetank(Figure

17).

Figure17

HourMeter

Thehourmetershowsthetotalhoursthatthemachinehas

beenoperated(Figure3).

IndicatorLights

EnginePre-HeatIndicatorLight

TurntheignitionkeytopositionII.Theenginepreheat

indicatorlightwillilluminate(Figure18)andheattheglow

plugs.

Important:Attemptingtostartacoldenginebefore

usingthepre-heatcancauseunnecessaryweartothe

battery.

Thecutting-unit-drive-switchindicatorlight(Figure20)

illuminateswhenthecuttingunitdriveswitchisintheOFF

positionandtheignitionkeyisturnedtopositionI.

Figure20

Parking-Brake-IndicatorLight

Theparking-brake-indicatorlight(Figure21)illuminates

whentheparkingbrakeisengagedandtheignitionkeyis

turnedtopositionI.

Figure21

Hydraulic-Transmission-Filter-IndicatorLight

Thehydraulic-transmission-lter-indicatorlight(Figure22)

illuminateswhenthetransmissionlterelementisblocked.

Note:Theenginemustberunningfortheindicatorlightto

illuminate.Theindicatorlightmayilluminatebrieywhen

thehydraulicoiliscold.

Figure18

Transmission-Neutral-IndicatorLight

Thetransmission-neutral-indicatorlight(Figure19)

illuminateswhenthetravelcontrolpedalisintheNEUTRAL

positionandtheignitionkeyisturnedtopositionI.

Note:Theparkingbrakemustbeengagedforthe

transmissionneutralindicatorlighttoilluminate.

Figure19

Figure22

19

Page 20

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Specication

TransportWidth

Widthofcut3460mm(136.2inches)

Length

Height

Weight(with2-postROPS,8-inch/6-blade

cuttingunits,anduids)

Engine

Fueltankcapacity

Travelspeed

Recommendedmaximummowingspeed

Hydraulicsystemcapacity

2385mm(94.0inches)withROPSintheverticaloperatingposition

Kubota35.3kw(47.3hp)@2800rpmDIN70020V2203diesel4cylindersinline

1775mm(70.0inches)withROPSfolded

Model02750

1890mm(74.5inches)

2930mm(115.0inches)

1870kg(4123lb)

70L(18.5USgallons)

0to24km/h(0to15mph)

11km/h(6.85mph)

77L(20.3USgallons)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesare

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributor.

20

Page 21

Operation

G009027

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Long-termexposuretovibrationwhileoperating

themachinemaycausesomenumbnessinthe

handsandwrists.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Lowerthecuttingunitstotheground,setthe

parkingbrake,andremovethekeyfromtheignition

switchbeforeservicingormakingadjustmentsto

themachine.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Wearglovesthatdampenthevibrationwhenever

youoperatethemachineforanextendedperiodof

time.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure23

1.Wearsafetyglasses.

2.Wearhearingprotection.

CheckingtheEngine-OilLevel

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.RefertoCheckingtheEngine-OilLevel(page34).

AddingFuel

Useonlyclean,freshdieselfuelwithlow(<500ppm)orultra

low(<15ppm)sulfurcontent.Theminimumcetanerating

shouldbe40.Purchasefuelinquantitiesthatcanbeused

within180daystoensurefuelfreshness.

Readandfollowtherolloverprotectioninstructions

Fueltankcapacity:70L(18.5USgallons)

andwarnings.

Usesummer-gradedieselfuel(No.2-D)attemperatures

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan18degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

CAUTION

Thismachineproducessoundlevelsthatcancause

above-7°C(20°F)andwinter-grade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.

Usingsummer-gradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Usingwinter-gradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

21

Page 22

WARNING

DANGER

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis1inch(25mm)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundthefuel-tankcap.

3.Removethecapfromthefueltank.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfuel-tankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

UsingtheOperatorPlatform LatchingMechanism

WARNING

Neveroperatethemachinewithoutrstchecking

thattheoperatorplatformlatchingmechanismis

fullyengagedandingoodworkingorder.

ReleasingthePlatform

1.Ensurethatthefront2cuttingunitsareloweredto

theground.

2.Releaseandremovethetooltrayfromtheleftsideof

theplatform(Figure24).

3.Releasethepadlocksecuringthelockinglatchhandle

withthekeyprovided.

22

Page 23

4.Movethelockinglatchhandletowardthefrontofthe

machineuntilthelatchhooksclearthelockingbarand

raisetheplatform(Figure24).

UnderstandingtheOperator PresenceControls

Note:Thegasspringwillprovideassistance.

Figure24

1.Towardfrontofthe

machine

2.Lockinglatchhandle4.Tooltray

3.Towardrearofmachine

Note:Theenginestopsiftheoperatorleavestheseat

withoutengagingtheparkingbrake.

EngineStartLockout:Theenginecanonlybestarted

whentheforward/reversetravelpedalisintheNEUTRAL

position,thecuttingunitdriveswitchisintheOFFposition

andtheparkingbrakeisengaged.Whenthesecircumstances

aresatised,switchesareactivated,permittingtheengineto

bestarted.

EngineRunInterlock:Afterstartingtheengine,youmust

beseatedbeforereleasingtheparkingbrakefortheengineto

continuetorun.

CuttingCylinderDriveLockout:Thedrivetothecutting

cylindersisonlypossiblewhenyouareseated.Ifyouraise

offtheseatforaperiodofmorethan1second,aswitch

activatesandthedrivetothecuttingcylindersautomatically

disengages.Toengagedrivetothecuttingcylinders,return

totheseat,thenoperatethecuttingunitdriveswitchtothe

OFFpositionbeforemovingitbacktotheONposition.If

youriseofftheseatforabriefmomentduringnormalwork,

drivetothecuttingcylindersisnotaffected.

Theenginecanonlybestartedwiththecutting-unitdrive

switchintheOFFposition.

WARNING

SecuringthePlatform

1.Lowertheplatformcarefully .

Note:Thegasspringwillprovideassistance.

2.Movethelockinglatchhandletowardthefrontof

themachineastheplatformnearsthefullylowered

position(Figure24).

Note:Thiswillensurethatthelatchhooksclearthe

lockingbar.

3.Fullylowertheplatformandmovethelockinglatch

handletowardtherearofthemachineuntilthelatch

hooksfullyengagethelockingbar(Figure24).

4.Installthepadlocktosecurethelockinglatchhandle

inplace.

Donotoperatetheturfmachineiftheoperator

presencecontrolsaremalfunctioninginanyway .

Al w ays

replacedamagedorwornpartsandcheck

thattheyfunctioncorrectlybeforeoperatingthe

machine.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

23

Page 24

StartingandStoppingthe

G014563

Engine

Important:Y oumustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengineforthe

rsttime,theenginehasstoppedduetolackoffuel,or

youhaveperformedmaintenanceonthefuelsystem;

refertoBleedingtheFuelSystem(page36).

StartingaWarmEngine

1.Sitontheseat,keepyourfootoffthetractionpedal

sothatitisinNEUTRAL,ensurethecuttingunitdrive

switchisoff,engagetheparkingbrakeandsetthe

throttletothe70percentfullthrottle.

2.TurntheignitionkeytotheignitiononpositionIand

checkthattheengineoilpressureandbatterycharge

warninglightsilluminate.

WARNING

Operatingthemachineinanunsafemannercould

resultinpersonalinjury.

Beforestartingtheengine,ensurethatthefollowing

conditionsaremet:

•YouhavereadandunderstoodtheSafety(page

4)sectioninthismanual.

•Theareaisclearofbystanders.

•Thecuttingunitisdisengaged.

•Theparkingbrakeisset.

•ThetravelcontrolpedalsareinNEUTRAL.

Important:Thismachineisttedwithanenginestart

lockout;refertoUnderstandingtheOperatorPresence

Controls(page23).

StartingaColdEngine

1.Sitontheseat,keepyourfootoffthetractionpedals

sothatitisinNEUTRAL,ensurethecuttingunitdrive

switchisoff,engagetheparkingbrakeandsetthe

throttletothe70percentfull-throttleposition.

2.TurntheignitionkeytotheignitiononpositionIand

checkthattheengineoilpressureandbatterycharge

warninglightsilluminate.

3.TurntheignitionkeytothestartpositionIIIandhold

tocranktheengine.

Note:Cranktheenginefornolongerthan15seconds.

ReleasetheignitionkeybacktopositionIwhenthe

enginestarts.

4.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MoveallcontrolstoNEUTRAL,settheparkingbrake,

movethethrottletothelowidlepositionandallowthe

enginetoreachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafullload

operation.Failuretodosomayleadtotroubleon

aturbo-chargedengine.

2.Lettheengineidlefor5minutes.

3.Turntheignitionkeytoposition0.

Iftheenginefailstostopwhentheignitionkeyis

turnedto0,operatetheenginestopleverinforward

direction(Figure25).

WARNING

Keephandsclearofmovingobjectsandhot

enginepartswhiletheengineisrunning.

3.TurntheignitionkeytothepreheatpositionIIsothat

thepre-heatindicatorlightison(Figure18).Holdit

for5secondstoheattheglowplugs.

4.Afterpreheatingtheglowplugs,turnkeytothestart

positionIIIandholdtocranktheengine.

Cranktheenginefornolongerthan15seconds.

ReleasetheignitionkeybacktopositionIwhenthe

enginestarts.

5.Runtheengineatlowidlespeeduntilitwarmsup.

Important:Whentheengineisoperatingallwarning

lightsshouldbeoff.Ifawarninglightilluminates,stop

theengineimmediatelyandxtheissuebeforestarting

theengine.

Figure25

24

Page 25

AdjustingtheHeight-of-Cut

DualLiftCongurationControl

RefertoyourcuttingunitsOperator’sManualtoadjustthe

height-of-cut.

ControllingthePositionofan IndividualCuttingUnit

Thecuttingunitsmayberaisedorloweredindependently

usingthebankof3lift-controllevers.

1.Tolowerthecuttingunits,operatethelift-control

leversinadownwarddirectionandrelease(Figure26).

Note:Thecylinderdrivewillengagewhenthecutting

unitsareapproximately300mm(11.8inches)above

groundlevel.Thecuttingunitsarenowin‘oat’mode

andwillfollowthegroundcontours.

Important:Thelift-controlleversmustbelocked

inposition1whilemoving .Donotmowwiththe

liftcontrolleversinposition2.

Thedualliftcongurationcontrolfunctionenablesthelift

controlstobeusedinthefollowingways(Figure27):

Figure27

1.5-gangmode

2.3/5-gangmode5.Rightliftlever

3.Leftliftlever

4.Centerliftlever

Figure26

1.Position1—down/oat4.Leftliftlever

2.Position2—neutral

3.Position3—raise

Note:Theliftleverswillcontroldifferentcutting

unitsdependingontheliftcongurationmode;refer

toDualLiftCongurationControl(page25).

2.Toraisethecuttingunits,operatethelift-controllevers

inanupwarddirectionandholdinposition3.

Note:IfthecuttingunitdriveswitchisintheON

position,thecylinderdrivewilldisengagewhenthe

cuttingunitsareapproximately300mm(11.8inches)

abovegroundlevel.

3.Releasethelift-controlswitcheswhenthecuttingunits

areattherequiredheight.

Note:Thecontrolswitcheswillautomaticallyreturn

toposition2andthearmsarehydraulicallylockedinto

position.

5.Centerliftlever

6.Rightliftlever

5-gangmode:

•Theleftliftlevercontrolstheleftwingcuttingunit.

•Thecenterliftlevercontrolstheleftfront,center,and

rightfrontcuttingunits.

•Therightliftlevercontrolstherightwingcuttingunit.

3/5-gangmode:

•Theleftliftlevercontrolstheleftwingandleftfront

cuttingunits.

•Thecenterliftlevercontrolsthecentercuttingunit.

•Therightliftlevercontrolstherightwingandrightfront

cuttingunits.

3/5-gangmodewithleftandrightwingcuttingunits

lockedintransportposition:

•Theleftliftlevercontrolstheleftfrontcuttingunit.

•Thecenterliftlevercontrolsthecentercuttingunit.

•Therightliftlevercontrolstherightfrontcuttingunit.

25

Page 26

EngagingtheCuttingUnit Drive

Figure28

1.Forward3.Reverse

2.Off

Youcanengagethecuttingunitdriveonlywhenyouareseated

correctly,refertoUnderstandingtheOperatorPresence

Controls(page23).

Forwardrotationcuttingunitdriveengagement:Press

thetopofthecuttingunitdriveswitchtotheFORWARD

position.

Toengageweighttransfer:Youcanvarytheamountof

weighttransfertosuitoperatingconditionsbyrotatingthe

weighttransferhandwheelasfollows:

1.Releasethevalvelocknut1/2turnanti-clockwiseand

hold.

2.Rotatethevalvehandwheel.

•Anti-clockwisetoreduceweighttransfer.

•Clockwisetoincreaseweighttransfer.

3.Tightenthenut.

WARNING

Onlyoperatetheforwardcuttingunitrotation,

oncethereelshavecompletelystopped,otherwise

machinedamagecouldoccur.

Reverserotationcuttingunitdriveengagement:Press

thebottomofthecuttingunitdriveswitchtotheREVERSE

position.

WARNING

Onlyoperatethereversecuttingunitrotation,once

reelshavecompletelystopped,otherwisemachine

damagecouldoccur.

Allcuttingunitdrivesdisengagement:Settheswitchto

themiddleposition.

Tolowerthecuttingunit:Operatethelift-controllever

inadownwarddirection.Thecylinderwilldrivewhenthe

cuttingunitsareapproximately300mm(11.8inches)above

groundlevel.

Usingthe Weight-Transfer/Traction Assistance

Avariablehydraulicweighttransfersystemisprovidedfor

improvingtiregripwiththegrasssurface-tractionassistance.

Hydraulicpressureinthecuttingunitsliftsystemprovidesa

liftingforcewhichreducesthecuttingunits’weightonthe

groundandtransferstheweightasadownwardforceontothe

tiresofthemachine.Thisactionisknownasweighttransfer.

Figure29

1.Weight-transferwheel3.Controlpanel

2.Lockwheel

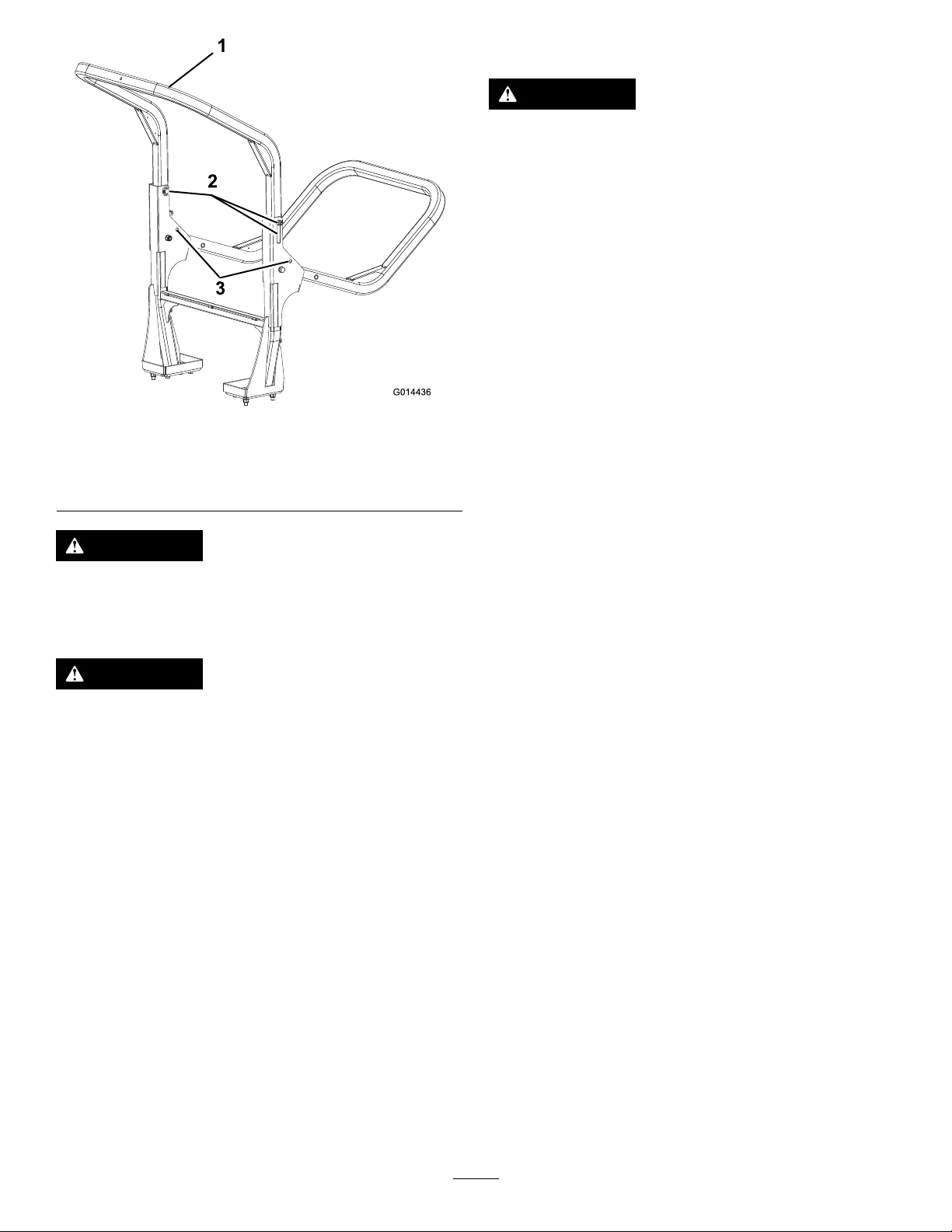

FoldingtheROPS

Theupperframemaybefoldeddowntoallowaccessinto

areasofrestrictedheight.

WARNING

Whiletheupperframeisfoldeddownitdoesnot

provideanyprotectionintheeventofaroll-overand

shouldnotbeconsideredasaRollOverProtective

Structure.

1.Applytheparkingbrakeandswitchofftheengine.

2.Supporttheweightoftheupperframewhileremoving

thehandnuts,washersandretainingboltsfromthe

pivotbrackets(Figure30).

3.Carefullylowertheframedownwarduntilitrestson

thestops.

4.Inserttheretainingboltsinthelowerholesandfully

tightenthehandnutstosupporttheupperframein

itsloweredposition.

5.Toraisetheframe,followtheseinstructionsinreverse

order.

26

Page 27

3

2

1

G014436

ClearingtheCuttingCylinders

WARNING

Neverattempttorotatethecuttingcylindersby

hand.

•Theremaybesomeresidualpressureinthe

hydraulicsystemwhichcouldcauseinjury

throughsuddenmovementofthecylinder(s)

whentheblockageisreleased.

•Alwayswearprotectiveglovesanduseasuitable

strongwoodeninstrument.

•Ensurethatthewoodeninstrumentwillt

betweenthebladesandthroughthecylinder

andislongenoughtoprovidesufcientleverage

toreleasetheblockage.

Figure30

1.Upperframe

2.Handnuts,washersand

retainingbolts

3.Lowerholes

WARNING

Whenintheraisedposition,bothretainingbolt

assembliesmustbeinstalledandfullytightenedto

ensurefullrolloverprotection.

WARNING

Becarefulloweringandraisingtheupperframeto

prevententrapmentofngersbetweenxedpart

andpivotpartofthestructure.

•Keepallnuts,boltsandscrewscorrectlytorquedensure

thattheequipmentisinsafeworkingcondition.

•Replacewornordamagedpartsforsafety.

•Ensurethattheseatbeltandmountingsareinsafe

workingorder.

•Weartheseatbeltwhentheupperframeisraisedandno

seatbeltwhentherollbarislowered.

1.Stopthemachineonlevelground.

2.Applytheparkingbrakeanddisengagealldrives.

3.Lowerthecuttingunitstothegroundorsecurelylock

inthedesignatedtransportpositions.

4.Stoptheengineandremovetheignitionkeytoisolate

allpowersourcesandcheckthattheyarestopped.

5.Releaseallstoredenergydevices.

6.Checkthatallmovingpartsarestationary.

7.Usingasuitablestrongwoodeninstrument,remove

theblockage.Makesurethatthewoodeninstrumentis

properlysupportedinthecylinderandavoidtheuseof

excessiveforcetopreventdamage.

8.Ensurethatthewoodeninstrumentisremovedfrom

thecuttingcylinderbeforerestartingthepowersource.

9.Repairoradjustthecylinderifrequired.

Important:Theupperframeisanintegralandeffective

safetydevice.Keeptheupperframeintheraised

positionwhenoperatingthemachine.Lowertheupper

frametemporarilyonlywhenabsolutelynecessary.

JackingPoints

Note:Usejackstandstosupportthemachinewhenrequired.

•Front—underthefrontarmmount.

•Rear—rearstrappinghook.

27

Page 28

OperatingTips

BecomingFamiliarwiththeMachine

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandstoptheengine.Operateinforwardand

reverse.Lowerandraisethecuttingunitsandengageand

disengagethecuttingunits.Whenyoufeelfamiliarwiththe

machine,practiceoperatingupanddownslopesatdifferent

speeds.

UnderstandingtheWarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

MowingGrass

Therotationalspeedofthecuttingcylindersshouldalways

bekeptashighaspossibleinordertomaintainthehighest

qualityofcut.Thisinturnrequiresthattheenginespeed

bekeptashighaspossible.

WARNING

Takecarewhentravelingoverobstaclessuchas

roadsidecurbs.Alwaystravelatslowspeedover

obstaclestopreventdamagetothetires,wheels,

andsteeringsystem.Ensurethatthetiresare

inatedtotherecommendedpressures.

OperatingtheMachineonSlopes

Useextracarewhenoperatingthemachineonslopes.Drive

slowlyandavoidsharpturnsonslopestopreventrollovers.

Lowerthecuttingunitsforsteeringcontrolwhengoing

downhill.

UsingtheRearRollerScrapers

Itisgenerallywisetoremoverearrollerscraperswhere

conditionsallow ,asoptimumgrassdischargeisachieved

withoutthem.Installthescraperswhenconditionsaresuch

thatmudandgrassstarttobuildupontherollers.When

installingthescraperwires,ensurethattheyarecorrectly

tensioned.

Cuttingperformanceisbestwhencuttingagainstthelieof

thegrass.Inordertotakeadvantageofthisfact,theoperator

shouldattempttoalternatethedirectionofmowingbetween

cuts.

Takecarenottoleaveuncutstripsofgrassattheoverlap

pointsbetweenadjacentcuttingunitsbyavoidingtightturns.

MaximizingtheQualityofCut

Thequalityofcutwilldeteriorateiftheforwardspeedis

excessive.Alwaysbalancethequalityofcutwiththeworkrate

requiredandsettheforwardspeedaccordingly.

MaximizingEngineEfciency

Donotlettheenginelabor.Ifyounoticethattheengine

startstolabor,reducetheforwardspeedorincreasethe

heightofcut.Checkthatthecuttingcylindersarenotin

heavycontactwiththeirbottomblades.

DrivingtheMachineinTransportMode

Alwaysdisengagethecuttingunitdrivewhentravelingacross

un-grassedareas.Grasswilllubricatethecuttingedgeswhilst

mowing.Excessiveheatwillbuildupifthecuttingcylinders

arerunwhennotmowingandthiswillcauserapidwearto

takeplace.Forthisreasonitisalsowisetoreducecutting

speedwhenmowinglightlygrassedareasorwhenthegrassis

dry.Becarefulwhendrivingbetweenobjectssothatyoudo

notaccidentallydamagethemachineorthecuttingunits.

28

Page 29

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

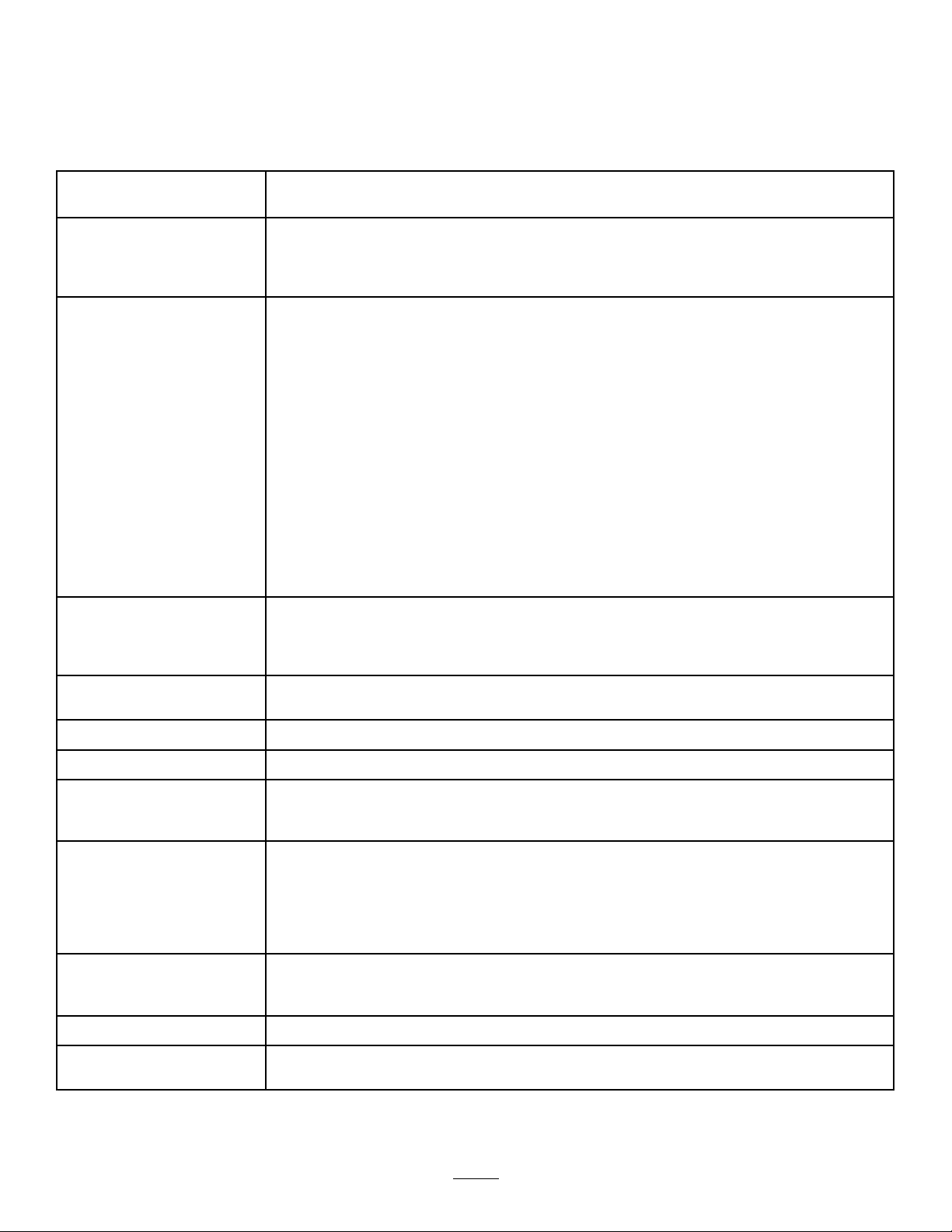

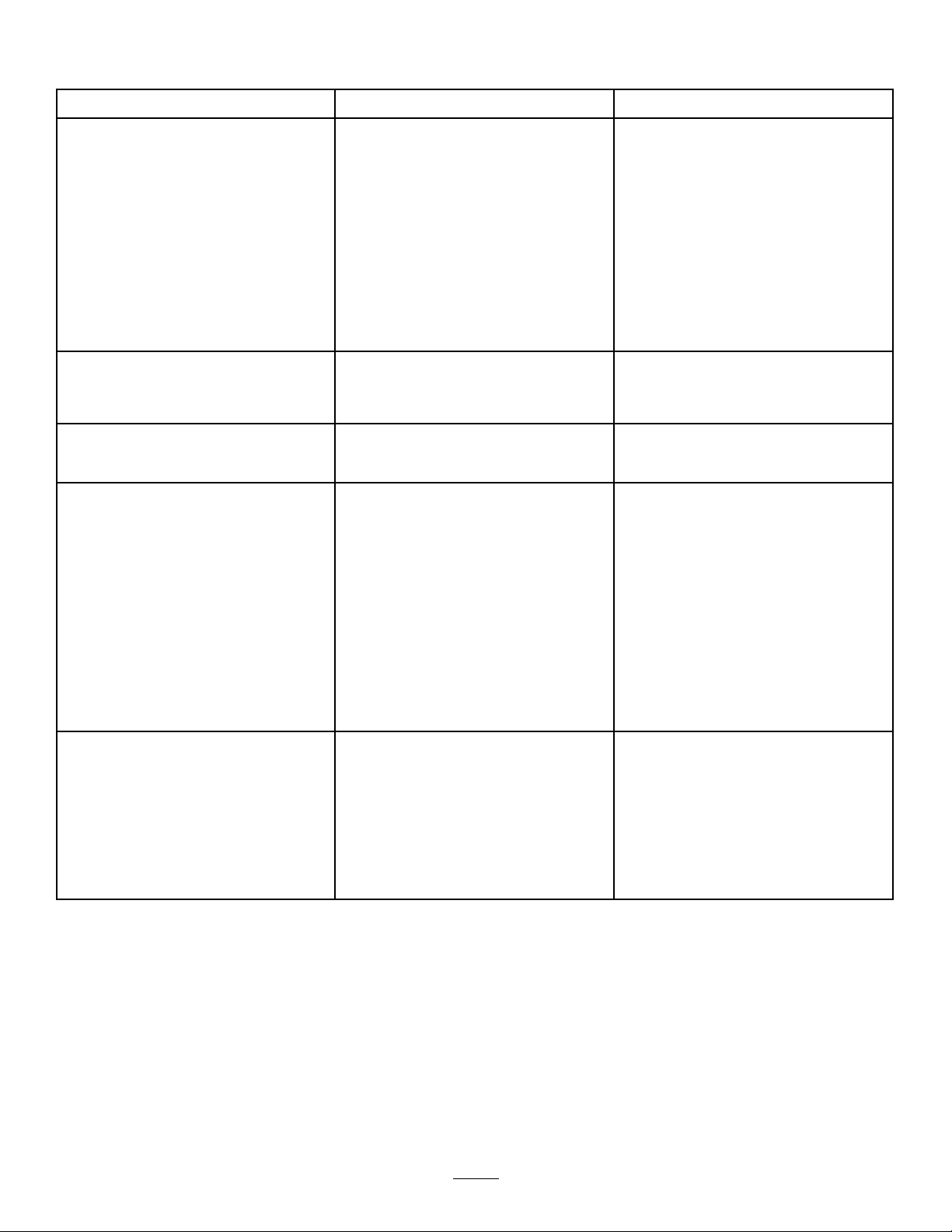

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Changetheengineoilandlter.

•Changethetransmission-oillter.

•Changethehydraulicreturnlter.

•Checktheenginespeed(idleandfullthrottle).

•Checkthetirepressure.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Checktheair-lter-blockageindicator.

•Checktheengine-oillevel.

•Checkthetirepressure.

•Torquethewheellugnuts.

•Checkthelevelofthecoolantinthecoolingsystem.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthesafetyinterlocksystem.

•Checkthehydraulicuidlevel.

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Checkthefastenersofthemachine.

•Checkthecuttingunits.

•Checktheforward/reversetravelpedalaction.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

Every100hours

Every150hours

Every200hours

Every400hours

Every500hours

Every800hours

Beforestorage

Every2years

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

•Servicetheaircleaner.(Morefrequentlyinextremelydirtyordustyconditions)

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Checktheenginespeed(idleandfullthrottle).

•Checkengineoverheatwarningsystem.

•Changethetransmission-oillter.

•Checktherearwheelalignment.

•ServicetheHydraulicSystem

•Changethehydraulicreturnlter.

•Checkhydraulicoiloverheatwarningsystem

•Drainandcleanthefueltank.

•Flushandreplacethecoolingsystemuid.

•Adjusttheenginevalves(refertotheengineoperator’smanual).

•Drainandcleanthefueltank.

•Replaceallmovinghoses.

•Replacethetransmissioncable.

29

Page 30

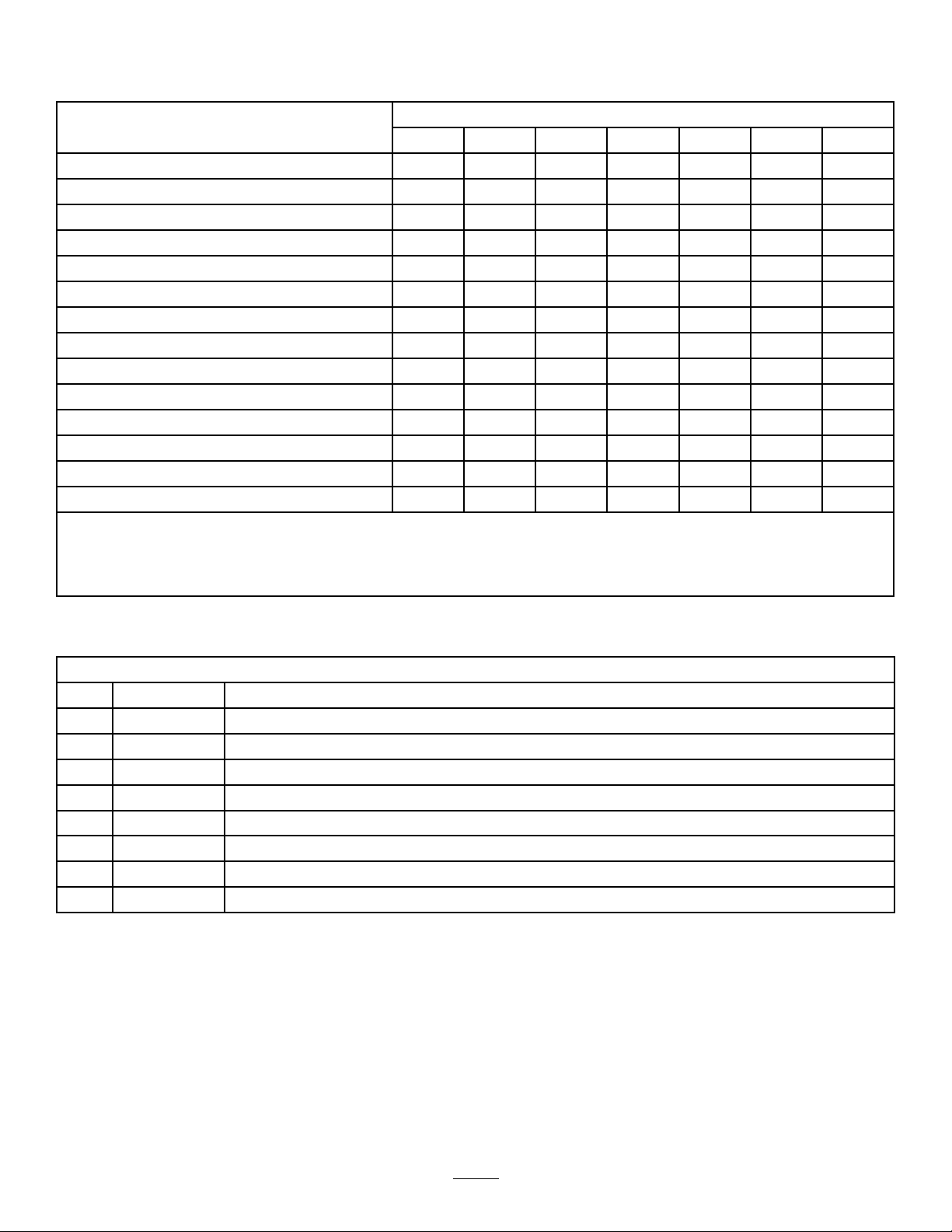

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

Information

30

Page 31

Pre-Maintenance

Beforeperforminganymaintenanceensurethattheengineisswitchedtooffandtheignitionkeyisremoved,theparking

brakeisset,thereisnopressureinthehydraulicsystem,thecuttingunitsareonthegroundandthesafetyprecautionsin

thismanualhavebeenreadandunderstood.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Important:Regularmaintenanceisessentialforthecontinuedsafeoperationofthemachine.Correctservicingwill

prolongtheworkinglifeofthemachineandsafeguardtheWarranty.AlwaysusegenuineT oroservicepartsasthese

wareaccuratelymatchedtotherequiredduty.Theuseofnon-genuinepartsmayresultinpersonalinjuryordeath.

Dirtandcontaminationaretheenemiesofanyhydraulicsystem.Whencarryingoutmaintenanceproceduresonthehydraulic

systemalwaysensurethattheworkareaandthecomponentsarethoroughlycleanbefore,duringandafterretting.Ensurethat

allopenhydrauliclinesandports,etc.arepluggedduringmaintenanceprocedures.

Therecommendedserviceintervalsarebasedonnormaloperatingconditions.Severeorunusualconditionswillnecessitate

shorterserviceintervals.

Alwaysgreasethepivotpointsimmediatelyafterpressurewashingorsteamcleaning.

WARNING

Theengine,transmissionoilandhydraulicsystemswillbehotaftermachineuse.Allowthesystemstocool

beforeworkingonthemachine,particularlybeforeworkingontheengineorwhenchangingoiloroillters.

31

Page 32

ServiceIntervalChart

Figure31

32

Page 33

Lubrication

bearingsandbushingsimmediatelyaftereverywashing,

regardlessoftheintervallisted.

GreasingtheBearings, Bushings,andPivots

ServiceInterval:Beforeeachuseordaily

Every50hours

Lubricateallgreasettingsforthebearingsandbushings

withNo.2general-purpose,lithium-basedgrease.Lubricate

Replaceanydamagedgreasettings.

Greaseallcuttingunitgreasepointsandinjectsufcient

greasesuchthatyoucanseecleangreaseescapingfromthe

rollerendcaps.Thisprovidesvisibleevidencethattheroller

sealshavebeenpurgedofgrassanddebrisandwillensures

maximumworkinglife.

Thegrease-ttinglocationsandquantitiesareasfollows:

Figure32

1.–Greasedaily3.–Greaseevery50hours(weekly)

2.

–Greasedaily(iftted)

33

Page 34

EngineMaintenance

1

G014437

CheckingtheEngineOverheat WarningSystem

ServiceInterval:Every500hours

Figure33

1.Temperatureswitch

1.TurntheignitionkeytotheignitiononpositionI.

2.Disconnecttheblack/purplewireterminalfromthe

enginetemperatureswitch.

3.Touchthemetalterminalofthiswireontoasuitable

earthpoint,ensuringthatthemetalsurfacesmake

goodcontact.

Thehornwillsoundandtheenginecoolanttemperature

warninglightwillilluminatetoconrmcorrectoperation.

Ifthesystemisfaulty ,makerepairsbeforeoperatingthe

machine.

ServicingtheAirCleaner

Figure34

1.Aircleanerbody3.Rubberoutletvalve

2.Aircleanercover

3.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,clean

anddry)tohelpremovelargeaccumulationsofdebris

packedbetweentheoutsideofthelterandthe

canister.Avoidusinghighpressureairwhichcould

forcedirtthroughthelterintotheintaketract.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

4.Removeandreplacetheprimarylter.

Cleaningoftheusedelementisnotrecommendeddue

tothepossibilityofdamagetotheltermedia.Inspect

thenewlterforshippingdamage,checkingthesealing

endofthelterandthebody .Donotuseadamaged

element.Insertthenewlterbyapplyingpressureto

theouterrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenterofthe

lter.

5.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

6.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5o’clock

to7o’clockwhenviewedfromtheend.

ServiceInterval:Every200hours(Morefrequentlyin

extremelydirtyordustyconditions)

Beforeeachuseordaily

Checktheaircleanerbodyfordamagewhichcouldcausean

airleak.Replaceifdamaged.Checkthewholeintakesystem

forleaks,damageorloosehoseclamps.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Crankcasecapacityisapproximately7.6L(8qt)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher

Changingtheairlterbeforeitisnecessaryonlyincreasesthe

chanceofdirtenteringtheenginewhenthelterisremoved.

•Preferredoil:SAE15W-40(above32°C(0°F))

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Important:Besurethecoverisseatedcorrectlyand

sealswiththeaircleanerbody .

1.Opentheenginecover.

2.Releasethelatchessecuringtheaircleanercovertothe

aircleanerbody(Figure34).

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W -40or10W-30viscosity .

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrake,andremovethekeyfromthe

ignitionswitch.

2.Releasetheenginecoverlatchandopenthehood.

34

Page 35

3.Removethedipstick,wipeitclean,andinstallit(Figure

G012280

1

G012281

1

G012305

1

G012306

1

35).

Figure35

1.Dipstick

4.Removedipstickandcheckoillevelondipstick.

TheoillevelshouldbeuptotheFULLmark.

ChangingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethedrainplug(Figure37)andlettheoilow

intoadrainpan.

5.IftheoillevelisbelowtheFULLmark,removethell

cap(Figure36)andaddoiluntillevelreachestheFULL

markondipstick.

Important:Donotoverll.

Figure36

1.Oilllcap

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultofover

llingorunderllingtheengineoil.

6.Installtheoilllcap.

7.Closeenginecoverandsecurewiththelatches.

Figure37

1.Oildrainplug

2.Whentheoilstops,installthedrainplug.

3.Removetheoillter(Figure38).

Figure38

1.Oillter

4.Applyalightcoatofcleanoiltothenewlterseal.

5.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

Important:Donotovertightenthelter.

6.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page34).

35

Page 36

FuelSystem

BleedingtheFuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inches)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

Youmustbleedthefuelsystembeforestartingtheengine

afteranyofthefollowingsituations:

•Initialstartupofanewmachine

•Enginehasceasedrunningduetolackoffuel

•Maintenancehasbeenperformeduponfuelsystem

components(i.e.,replacedlter,servicedseparator,etc.)

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inches)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystembecomes

contaminatedorifthemachineistobestoredforanextended

period.Usecleanfueltoushoutthetank.

CheckingtheFuelLinesand Connections

ServiceInterval:Every400hours/Yearly(whichevercomes

rst)

Checkthefuellinesandconnections.Inspectthemfor

deterioration,damage,orlooseconnections.

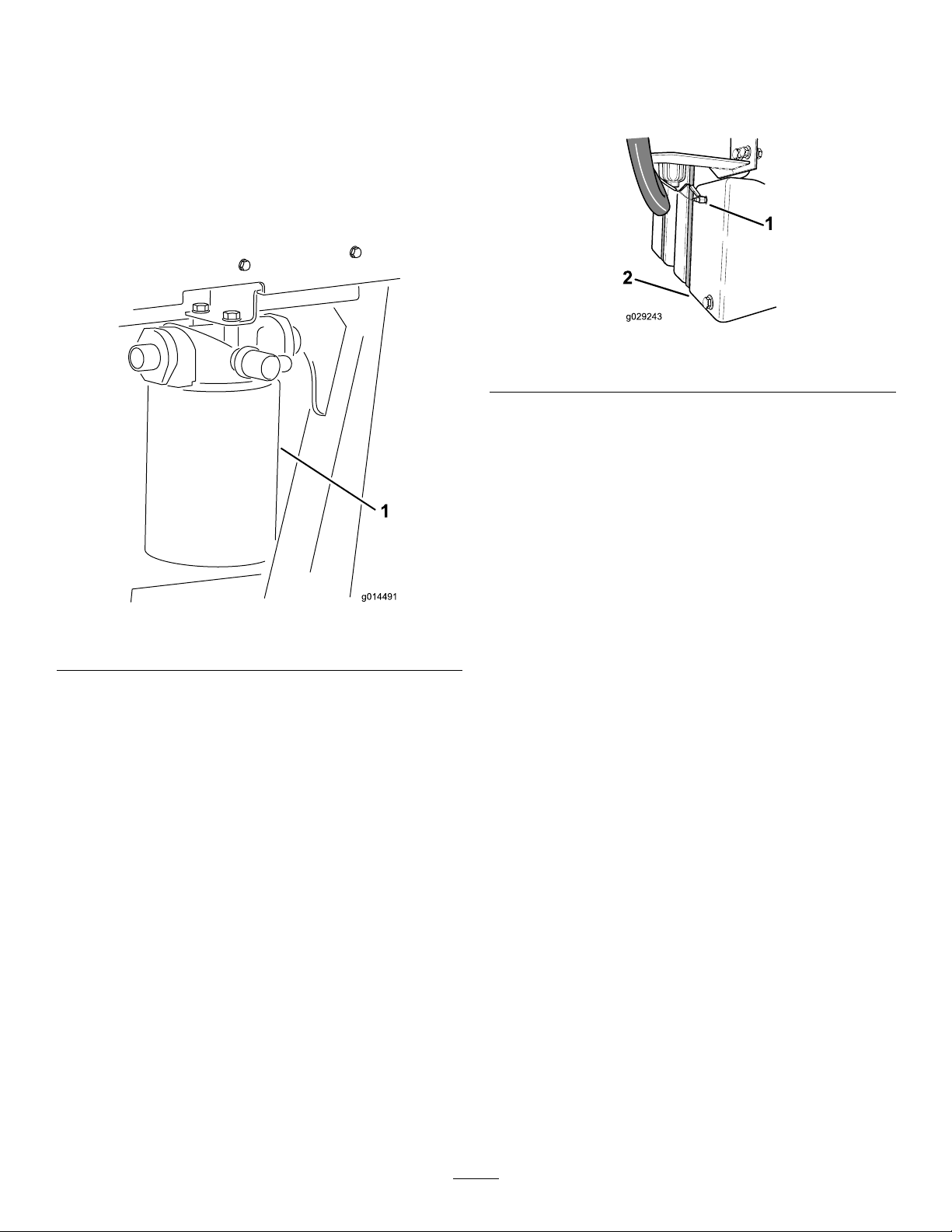

ReplacingtheFuelFilter Canister

ServiceInterval:Every400hours

1.Cleantheareawheretheltercanistermounts.

2.Removetheltercanisterandcleanthemounting

surface.

3.Lubricatethegasketontheltercanisterwithcleanoil.

4.Installthenewltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitanadditional

1/2turn.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

1.Parkthemachineonalevelsurfaceandensurethatthe

fueltankisatleasthalffull.

2.Openthehood.

3.TurnthekeyintheignitionswitchtotheONposition

andcranktheengine.

Note:Themechanicalpumpwillsuckfueloutofthe

tank,llthefuellterandfuelhoseandforcetheair

intotheengine.Thiscouldtakesometimetofully

purgealltheairoutofthesystemandtheenginemight

reerraticallyuntilallairispurgedout.Whenallairis

purgedandtheengineisrunningsmoothly ,itshouldbe

runforafewminutestoensurethatitisfullypurged.

36

Page 37

BleedingAirfromtheFuel

G012307

1

Injectors

Note:Onlyusethisprocedureifthefuelsystemhasbeen

purgedofairthroughnormalprimingproceduresandthe

enginewillnotstart;refertoBleedingtheFuelSystem(page

36).

1.LoosenthepipeconnectiontotheNo.1nozzleand

holderassembly(Figure39).

Figure39

1.Fuelinjectors

ElectricalSystem

Maintenance

Important:Beforeweldingonthemachine,disconnect

bothcablesfromthebatteryandtheterminalconnector

fromthealternatortopreventdamagetotheelectrical

system.

ServicingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

2.MovethrottletotheFASTposition.

3.TurnthekeyinthekeyswitchtotheSTARTposition

andwatchthefuelowaroundtheconnector.

Note:Theenginewillcrank.

4.Whenyouobserveasolidowoffuel,turnthekey

totheOFFposition.

5.Tightenthepipeconnectorsecurely.

6.Repeatsteps1through5ontheremainingnozzles.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfromit.

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metaltractorcomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

37

Page 38

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Always

cablebeforedisconnectingthepositive(red)

cable.

•Always

beforeconnectingthenegative(black)cable.

Checkthebatteryconditionweeklyorafterevery50hours

ofoperation.Keeptheterminalsandtheentirebatterycase

cleanbecauseadirtybatterywilldischargeslowly .Toclean

thebattery,washtheentirecasewithasolutionofbaking

sodaandwater.Rinseitwithclearwater.Coatthebattery

postsandcableconnectorswithGrafo112X(skin-over)

grease(ToroPartNo.505-47)orpetroleumjellytoprevent

corrosion.

disconnect

connect

thenegative(black)battery

thepositive(red)batterycable

DriveSystem

Maintenance

Changingthe Transmission-OilFilter

ServiceInterval:Aftertherst50hours

Every500hours

1.Unscrewandremovethebottomofthetransmission-oil

lterhousing.

2.Withdrawthelterelementanddiscardit.

3.Retanewlterelement.

4.Installthehousing.

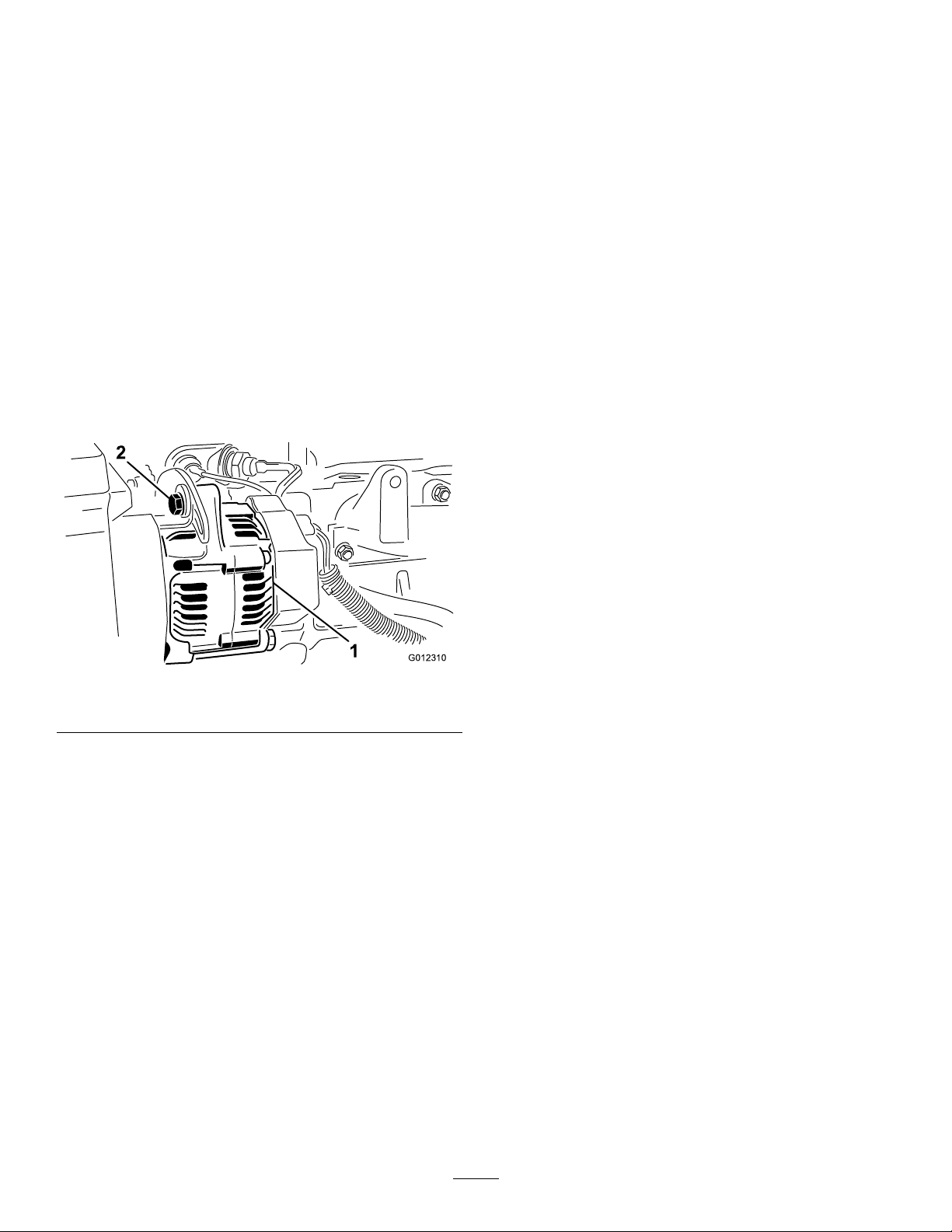

Figure40

1.Transmission-oillter

2.Centercuttingunit

3.Hydraulic-oiltank

CheckingtheRearWheel Alignment

ServiceInterval:Every500hours

Topreventexcessivetirewearandensuresafemachine

operation,therearwheelsmustbecorrectlyalignedto3to

8mm(0.12to0.31inches).

1.Settherearwheelsinthestraightaheadposition.

2.Measureandcomparethedistancebetweenthefront

sidewallsandtherearsidewallsatthewheelcenter

height(Figure41).

Note:Thedistancebetweenthefrontsidewallsmust

beset3to8mm(0.12to0.31inches)lessthanthe

distancebetweentherearsidewalls.

38

Page 39

2

4

1

G014442

3

x + 3 - 8mm

x

Figure41

1.Wheelcenterheight

2.Tire4.Track-rodassembly

3.Directionofforwardtravel

CoolingSystem

Maintenance

Capacityofthecoolingsystemis14L(3.7USgallons).

Alwaysprotectthecoolingsystemwitha50/50solutionof

waterandethyleneglycolanti-freeze.Donotusewateronly

inthecoolingsystem.

•Afterevery100operatinghours,tightenhoseconnections.

Replaceanydeterioratedhoses.

•Afterevery800operatinghours,drainandushthe

coolingsystem.Addanti-freeze.

3.Toadjustthealignmentoftherearwheels,backoffthe

leftandrightlocknutsonthetrackrodassembly.

Note:Theleftlocknutisaleftthread.

4.Rotatethetrackrodtoachievethecorrectdistanceas

describedaboveandtightenthelocknutssecurely.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checktheairpressureinthefrontandreartires.Refertothe

chartbelowforthecorrectpressure.

Important:Maintaincorrecttirepressureinalltiresto

ensurecorrectcontactwiththeturf.

TiresTireTypeRecommendedTirePressures

FrontAxle26x12-

12,4ply

RearAxle20x10-

8,4ply

Conditions

0.7bar(10

0.7bar(10

Turf

psi)

psi)

Road

Conditions

1.4bar(20

psi)

1.4bar(20

psi)

Maximum

Pressure

1.7bar(25

psi)

1.7bar(25

psi)

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Capacityofsystemis14L(3.7USgallons).

1.Carefullyremovetheradiatorcapandexpansiontank

cap(Figure42).

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

2.Checklevelofcoolantinradiatorwhenthecoolantis

cold.Radiatorshouldbelledtothetopoftheller