Page 1

Part No. 111-1033 Rev A

Reelmaster 3220-D and 3240-D

Code: 650D-Serial No. from 270000001

Code: 651D-Serial No. from 270000001

Operator’s Manual

Original Instructions (EN)

Page 2

Page 3

ATTENTION

THIS SYMBOL MEANS

BE ALERT!

YOUR SAFETY IS INVOLVED

READ THIS MANUAL BEFORE USING THE REELMASTER®® 3220-D OR 3240-D.

IT IS ESSENTIAL THAT OPERATORS STUDY IT FOR THEIR OWN SAFETY.

ALL OPERATORS SHOULD SEEK AND OBTAIN PROFESSIONAL AND

PRACTICAL INSTRUCTIONS ON THE SAFE USE OF THE MOWER. THESE

SERVICES ARE AVAILABLE THROUGH TORO APPROVED COMMERCIAL DEALERS.

Page 4

111-1033TH051006

CONTENTS

CONTENTS

SAFETY PRECAUTIONS.

Training.

Preparation.

Operation.

Handling and storage of fluids.

Maintenance and storage.

Decals.

EC CONFORMITY INFORMATION.

Noise levels / Vibration Levels.

EC Declaration of Conformity.

INTRODUCTION.

SPECIFICATIONS.

Engine.

Transmission system.

Cutterhead drive system.

Cutterhead lift system and steering.

Hydraulic system.

Vehicle specifications.

Operator controls.

Instrumentation.

Weight and dimensions.

Recommended lubricants and hydraulic fluids.

Cutterheads.

OPERATING THE MOWER.

Safety Notice

Operator presence controls.

Identification of controls.

Braking system.

Throttle control.

Travel.

Transport latches.

Differential lock.

Speed Control Pedal.

Operator platform latching mechanism.

Adjustable Steering Column.

Operator Seat.

Folding the R.O.P.S

Warning systems.

Audible warning horn.

Ignition key.

Engine pre-heat indicator light.

Fuel level gauge.

Page No.

1.6 - 1.14

1.6

1.6 - 1.7

1.7 - 1.9

1.10

1.11

1.12 - 1.14

1.15 - 1.16

1.15

1.16

1.17

1.18 - 1.24

1.18

1.19

1.19

1.20

1.20

1.21

1.22

1.22

1.23

1.23

1.24

1.25 - 1.42

1.25

1.25

1.26

1.27

1.27

1.27

1.28

1.28

1.28

1.29

1.30

1.31

1.32 - 1.33

1.34

1.34

1.35

1.35

1.35

1.4

1.4

Page 5

111-1033TH051006

CONTENTS

CONTENTS Continued.

Hourmeter.

Transmission neutral indicator light.

Cutterdeck drive switch indicator light.

Parking brake indicator light.

Hydraulic return filter indicator light.

Hydraulic transmission filter indicator light.

Cutterhead position control.

Cutterhead drive engagement.

Weight transfer/traction assistance.

Starting the engine.

Stopping the engine.

Unblocking Cutting Cylinders

Centre Cutterhead Height of Cut Correction Adjustment

General operating hints.

Cutterhead general information.

MK3 200mm Fixed Cutterhead.

MK3 254mm Fixed Cutterhead.

MK3 200mm Floating Cutterhead.

MAINTENANCE.

Maintenance

Engine.

Running in period.

Running in period - at first 50 hours.

Daily and before use.

Every 50 hours.

Every 250 hours.

Every 500 hours.

Cutterhead cylinder to bottom blade adjustment.

Cutterhead backlapping.

Cutterhead grinding.

Cutterhead bottom blade replacement.

Raising the mower off the ground.

Towing the mower.

GRASS CUTTING FAULTS.

TROUBLE SHOOTING.

ELECTRICAL CIRCUIT DIAGRAM .

HYDRAULIC CIRCUIT DIAGRAMS.

WARRANTY.

NOTES.

CUSTOMER INFORMATION.

Page No.

1.35

1.36

1.36

1.36

1.36

1.36

1.37

1.37

1.38

1.38 - 1.39

1.39

1.40

1.40

1.41

1.42

1.43

1.43

1.44

1.45 - 1.64

1.45 - 1.46

1.47

1.47

1.47 - 1.48

1.49 - 1.52

1.53 - 1.54

1.55

1.56 - 1.58

1.59

1.60

1.61

1.61

1.62

1.63 - 1.64

1.65 - 1.67

1.68 - 1.74

1.75 - 1.78

1.79 - 1.83

1.84

1.85

1.86

1.5

1.5

Page 6

111-1033TH051006

SAFETY PRECAUTIONS

TRAINING

Read the instructions carefully. Be familiar with the controls and the proper use of the equipment. Learn

how to stop the mower quickly in an emergency.

Never allow children or people unfamiliar with these instructions to use the mower. Local regulations

may restrict the age of the operator.

Never mow while people, especially children, or pets are nearby.

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or

their property.

Do not carry passengers.

All drivers should seek and obtain professional and practical instruction. Such instruction should emphasise:

The need for care and concentration when working with this machine.

The need to slow down when making tight turning manoeuvres. Failure to take adequate care can affect

stability leading to loss of control of the machine particularly when operating in transport mode.

Control of a ride-on-machine sliding on a slope will not be regained by application of the brake.

The main reasons for loss of control are:

- Insufficient wheel grip.

- Being driven too fast.

- Inadequate braking.

- The type of machine is unsuitable for the task.

- Lack of awareness of the effect of ground conditions, especially slopes.

- Incorrect load distribution.

PREPARATION

Check that the machine complies with all applicable regulations, including those in force when used on

the public highway.

While mowing, always wear substantial footwear and long trousers. Do not operate the equipment when

barefoot or wearing open sandals. Eye protection should be worn.

Thoroughly inspect the area where the equipment is to be used and remove all objects which can be

thrown by the machine.

Never operate the machine without first checking that the operator platform latching mechanism is fully

engaged and in good working order, refer - ‘OPERATOR PLATFORM LATCHING MECHANISM’.

READ THIS MANUAL BEFORE USING THE REELMASTER®® 3220-D OR 3240-D , IT IS

ESSENTIAL THAT OPERATORS STUDY IT FOR THEIR OWN SAFETY.

THE FOLLOWING PRECAUTIONS MUST BE TAKEN TO HELP PREVENT ACCIDENTS.

A CAREFUL OPERATOR WHO USES COMMON SENSE IS THE SAFEST OPERATOR.

-

-

-

1.6

1.6

Page 7

111-1033TH051006

SAFETY PRECAUTIONS

PREPARATION Continued.

Ensure that the cutterheads are fully raised with the latches and safety locks engaged in position before

transporting the mower.

Replace faulty silencers.

Check the condition of the tyres and ensure that they are inflated to the correct pressures, refer -

SPECIFICATIONS.

This is particularly important if the machine is to be taken on the public highway.

Check that the mower is in good working order, paying particular attention to the brakes and steering.

Also ensure that the forward/reverse speed control pedals move freely to neutral when released.

Before use, always visually inspect to see that the blades, blade bolts and cutting cylinders are not worn

or damaged. Replace worn or damaged components.

Check the mower hydraulic system, particularly the hydraulic hoses, fittings and hose supports. Worn,

crushed or damaged hoses can burst, with risks to health and damage to the machine and surrounding

turf areas.

After refuelling and adding oil to the hydraulic oil tank ensure that the caps are replaced securely.

Check that all linkages, connections and pivot nuts are secure and that wheel nuts are torqued correctly,

refer - SPECIFICATIONS.

Before operating the machine ensure that there are no foreign objects or liquids on the platform or pedals - ALWAYS KEEP THE OPERATOR PLATFORM CLEAN/CLEAR.

Always make sure that the folding R.O.P.S is secured in its vertical operating postion before use.

OPERATION

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect.

Mow only in daylight or in good artificial light.

Before attempting to start the engine, engage the parking brake, disengage the cutterhead drive system

and ensure that the forward/reverse speed controls are in the neutral position.

Never operate the machine without first checking that the operator platform latching mechanism is fully

engaged and in good working order, refer - OPERATOR PLATFORM LATCHING MECHANISM.

Stored energy devices are charged when the outer wing units are in transport position. Always operate

the relevant lift controls to provide hydraulic support for the wing units suspensions before attempting

to release the transport latches.

1.7

1.7

Page 8

111-1033TH051006

1.8

1.8

SAFETY PRECAUTIONS

SLOPES

Do not use on a slope of more than 16 degrees. Care should be taken when using the mower on any slope

where ground conditions are such that there may be a risk of the mower rolling over. The requirements

of SI 1998 No. 2306 “Provision and Use of Work Equipment Regulations” should be considered.

Stability angles given are maximum figures for a machine equipped with a R.O.P.S and are for guidance

only. Particular conditions such as wet grass or uneven ground may not permit safe operation on the

slope limits stated.

Remember there is no such thing as a "safe" slope. Travel on grass slopes requires particular care. To

guard against overturning or loss of traction when travelling or mowing on a slope:

- Exercise extreme care when changing direction on a slope.

- Do not stop or start suddenly.

- Engage drive slowly.

- Keep machine speed low.

- Avoid tight turns.

- Stay alert for humps, hollows and other hidden hazards.

- Keep away from sharp inclines and steep drops.

- A thorough risk assessment should be carried out by a competent

person before travelling or mowing on a slope.

Never park on a slope.

OPERATION Continued.

3DA176

16 Degree slope

Ground level

Page 9

111-1033TH051006

SAFETY PRECAUTIONS

OPERATION Continued.

Watch out for traffic when crossing or near roadways.

Use extreme caution when reversing.

Disengage the cutterhead drive system before crossing surfaces other than grass.

When using the machine, never direct discharge of material towards bystanders or allow anyone near

the machine while in operation.

Never operate the mower with defective guards, shields or without safety protective devices in place

and in good working order.

Do not change the engine governor settings or overspeed the engine. Operating an engine at excessive

speed may increase the risk of personal injury.

Before leaving the operator's position:

- Disengage the drive to the cutterheads.

- Lift cutterheads to the transport position and securely lock the safety latches

or alternatively lower cutterheads to the ground.

- Ensure the transmission is in neutral and engage the parking brake.

- Stop the engine and remove the ignition key.

Engage the parking brake, disengage the drive to the cutterheads, stop the engine and remove ignition key :

- Before releasing blockages.

- Before checking, cleaning or working on the mower.

- After striking a foreign object. Inspect the mower for damage and make

repairs before restarting and operating the equipment.

- If the machine starts to vibrate abnormally ( check immediately ).

- Before refuelling.

- Before making cutterhead adjustments.

Disengage the drive to the cutterheads when transporting or not in use.

Reduce the throttle setting during engine run - out.

Never work on the mower when the engine is running.

Always keep feet and hands well away from the cutting cylinders when making adjustments.

Never operate the mower without first checking that the operator platform is securely latched.

Always wear the seat belt when the folding R.O.P.S is in its vertical operating position.

Never wear the seat belt when the folding R.O.P.S is NOT in its vertical operating position.

Pay particular attention when operating due to the additional weight towards the front of the machine.

1.9

1.9

Page 10

111-1033TH051006

SAFETY PRECAUTIONS

HANDLING AND STORAGE OF FLUIDS

Hydraulic Oil

- Avoid contact with eyes and prolonged contact with skin.

- Protective goggles should be worn when pouring.

- Use of gloves or barrier cream is recommended.

- Wash hands thoroughly after contact.

- Store under cover, away from heat and sources of ignition.

Diesel Oil

- Avoid skin and eye contact.

- Wear impervious gloves when regular contact is likely and goggles when there is risk of splashing.

- Wash hands thoroughly after contact.

- Store in a cool dry well ventilated place away from heat and sources of ignition, in vessels specifically designed for storing fuel oils.

Lubricating Oil

- Avoid skin and eye contact.

- Wear impervious gloves when regular contact is likely and goggles when there is risk of splashing.

- Wash hands thoroughly after contact.

- Store in a cool dry well ventilated place away from heat and sources of ignition.

Anti- Freeze

- Keep away from heat, sparks, and flames.

- Avoid skin and eye contact and breathing vapours.

- Store in a closed container in a cool dry well ventilated area.

1.10

1.10

Page 11

111-1033TH051006

SAFETY PRECAUTIONS

MAINTENANCE AND STORAGE

Take care when rotating a cutting cylinder as this can cause other cylinders to rotate.

When the machine is to be parked, stored or left unattended, lift the cutterheads to the transport position

and engage the safety locks or lower the cutterheads to the ground.

Keep all nuts, bolts, and screws tight to be sure the equipment is in safe working condition.

Allow the engine to cool before storing in any enclosure.

To reduce the risk of fire, keep the engine, silencer, fuel tank and battery compartment free of grass, leaves

or excessive grease.

Frequently check fuel lines and fittings for cracks or leaks and replace if necessary.

Replace worn or damaged parts for safety.

Ensure that all safety decals are properly secured and in good condition.

If the fuel tank has to be drained, this should be done outdoors.

Be careful during adjustment of the machine to prevent entrapment of the fingers between moving blades

and fixed parts of the machine.

Never attempt to disconnect any part of the hydraulic system before de-pressurisation. This may be

achieved by lowering all cutterheads to the ground, stopping the engine and removing the ignition key.

Avoid skin or eye contact with hydraulic or diesel fluids. Wear protective clothing.

Leaking fluids under pressure can penetrate the skin or eyes, causing serious injury.

Always use a piece of cardboard or paper when searching for leaks.

Health and Safety at Work Act:

In accordance with section 6 of the Health and Safety at Work Act 1974, the Reelmaster®® 3220-D and

3240-D Mowers have been designed and constructed so that, in so far as is reasonably practical, they will

not endanger the safety and health of those working with them. This is, however, subject to the machine

being properly used and maintained according to the conditions stated in this manual and elsewhere,

which have been found necessary as a result of the research and testing of The Toro Company.

1.11

1.11

Page 12

111-1033TH051006

SAFETY PRECAUTIONS

DECALS

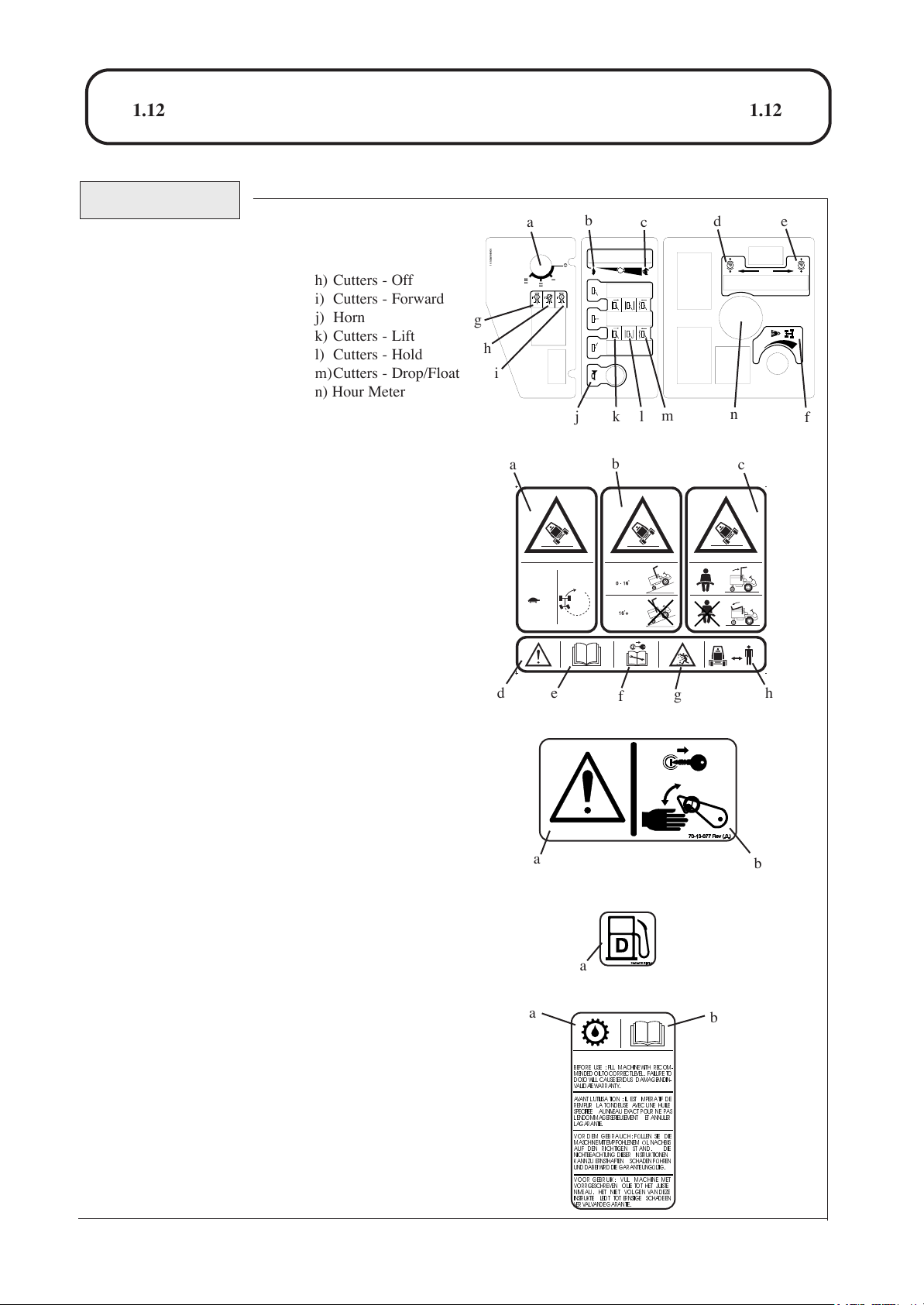

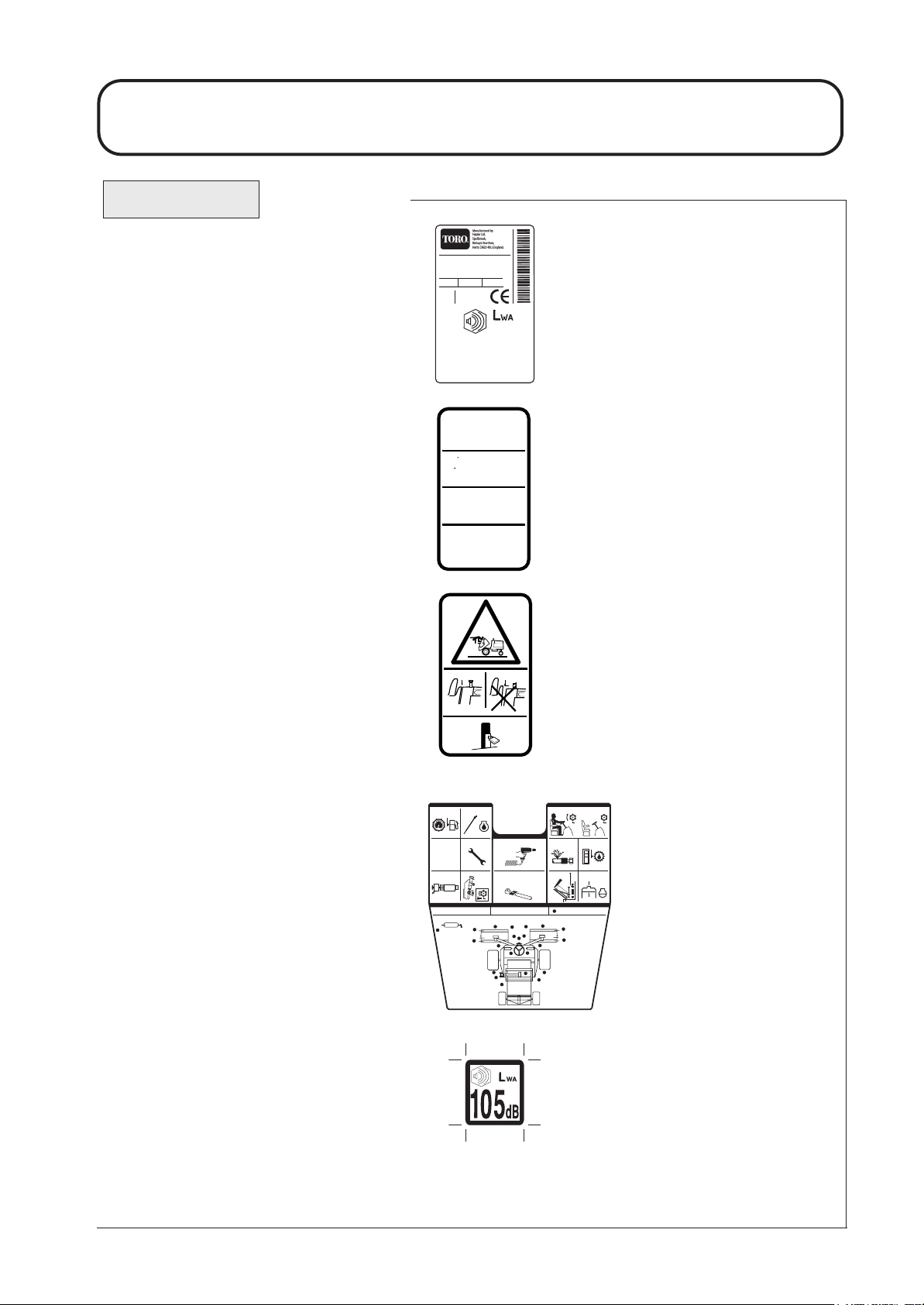

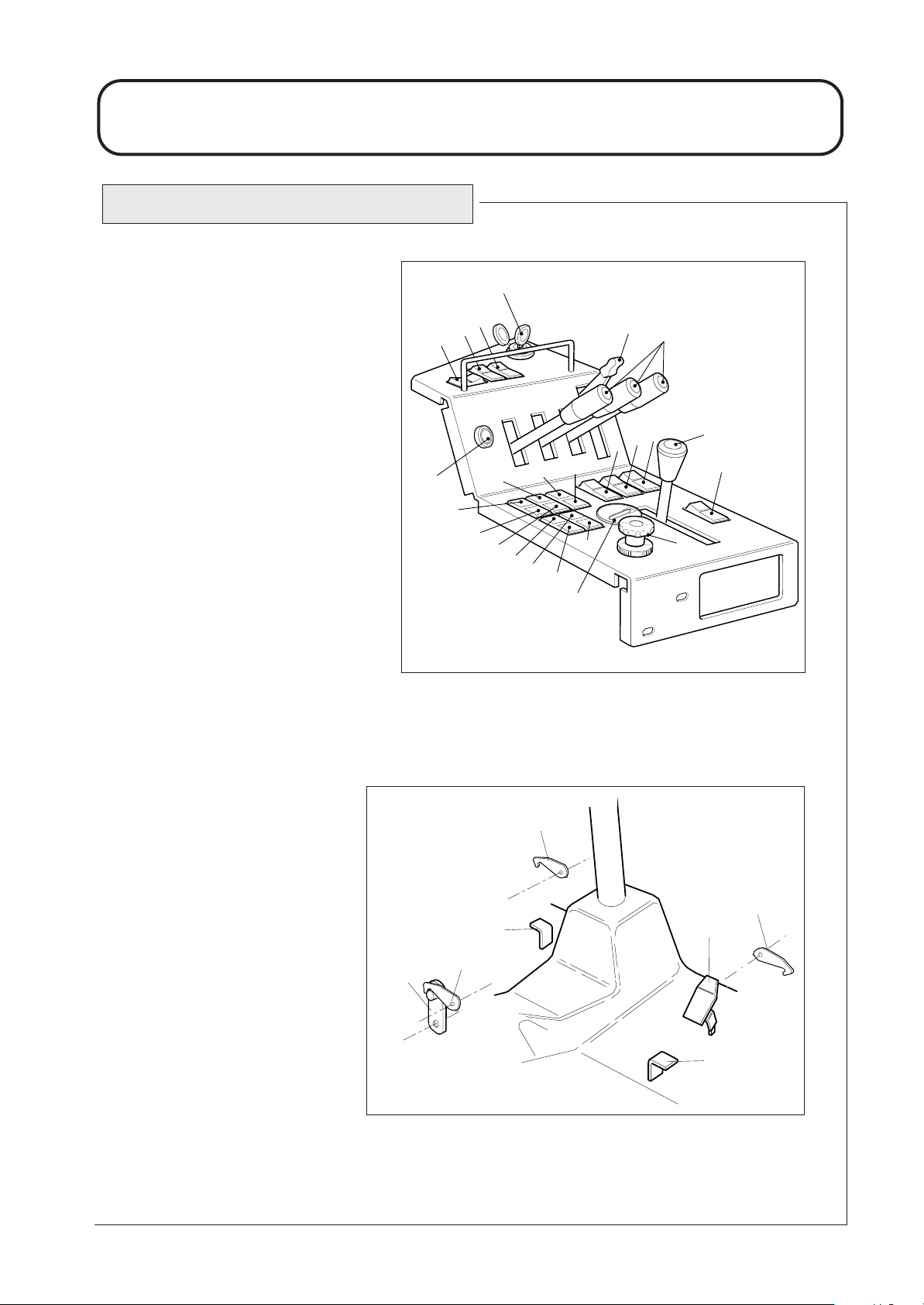

Decal - Control Panel Part No: 924898 (A)

Location: Control Panel.

a) Ignition Switch

b) Engine Speed - Slow

c) Engine Speed - Fast

d) Parking Brake - Engage

e) Parking Brake - Disengage

f) Weight Transfer - Control

g) Cutters - Reverse

Decal - Inclines Part No: 111-0936 (A)

Location: Centre Platform.

a) Warning - Travel slowly when turning and on slopes

b) Warning - Maximum Slope without ROPS

c) Warning - Seat belt must be worn with a ROPS fitted.

d) Caution

e) Read Operators Manual

f) Stop engine/Remove ignition key before servicing or

maintenance

g) Beware of flying objects

h) Keep Bystanders Clear

Decal - Danger Latch Part No: 70-13-077

Location: LH / RH / Centre Arms

a) Caution

b) Stop engine/Remove ignition key before releasing or

operating safety latches.

Decal - Diesel Part No: 70-13-07

Location: Fuel Tank

a) Diesel fuel only

Decal - Transmission Oil Part No: 70-13-071

Location: Oil Filler Bracket Mounted Behind Fuel tank.

a) Transmission Oil

b) Read and understand the Operators Manual.

IMPOR T ANT / WICHTIG / BELANGRIJK

BEFORE USE : FILL MACHINEWITH RECOM-

MENDED OILTO CORRECTLEVEL. FAILURE TO

DOSOWILL CAUSE SERIOUS DAMAGE AND IN-

VALIDATE WARRANTY .

AVANT L'UTILISA TION : IL EST IMPERATIF DE

REMPLIR LA TONDEUSE AVEC UNE HUILE

SPECIFIEE AUNIVEAU EXACT POUR NE PAS

L'ENDOMMAGER SERIEUSEMENT ET ANNULER

LAGARANTIE.

VOR DEM GEBRAUCH: F ÜLLEN SIE DIE

MASCHINE MITEMPFOHLENEM ÖL NACH,BIS

AUF DEN RICHTIGEN ST AND. DIE

NICHTBEACHTUNG DIESER INSTRUKTIONEN

KANN ZU ERNSTHAFTEN SCHADEN F ÜHREN

UNDDABEI WIRD DIE GARANTIE UNGÜLTIG.

VOOR GEBRUIK: VUL MACHINE MET

VORRGESCHREVEN OLIE TOT HET JUISTE

NIVEAU. HET NIET VOLGEN VAN DEZE

INSTRUKTIE LEIDT TOT ERNSTIGE SCHADE EN

VER VA LVANDE GARANTIE.

1.12

1.12

a

b

c

d

e

f

g

h

i

jkl

m

h) Cutters - Off

i) Cutters - Forward

j) Horn

k) Cutters - Lift

l) Cutters - Hold

m)Cutters - Drop/Float

n) Hour Meter

a

b

c

de

f

g

h

a

b

a

a

b

n

924898(REV. 0 )

III

O

I

II

P

P

kg

111-0936 (A)

Page 13

111-1033TH051006

SAFETY PRECAUTIONS

DECALS Continued.

HEIZKORPERDECKELENTFERNEN ERST WENN DER MOTORKUHLIST.

ONLY REMOVE RADIATORCAP WHEN ENGINE IS COOL.

VERWIJDERDE RADIATORDOPPASNADAT DE MOTORISAFGEKOELD.

IL FAUTTOUJOURSATTENDRE LE REFROIDISSEMENTDUMOTEUR

AVANTDE RETIRER LE BOUCHONDU RADIATEUR.

70-13-073 REV (.0.)

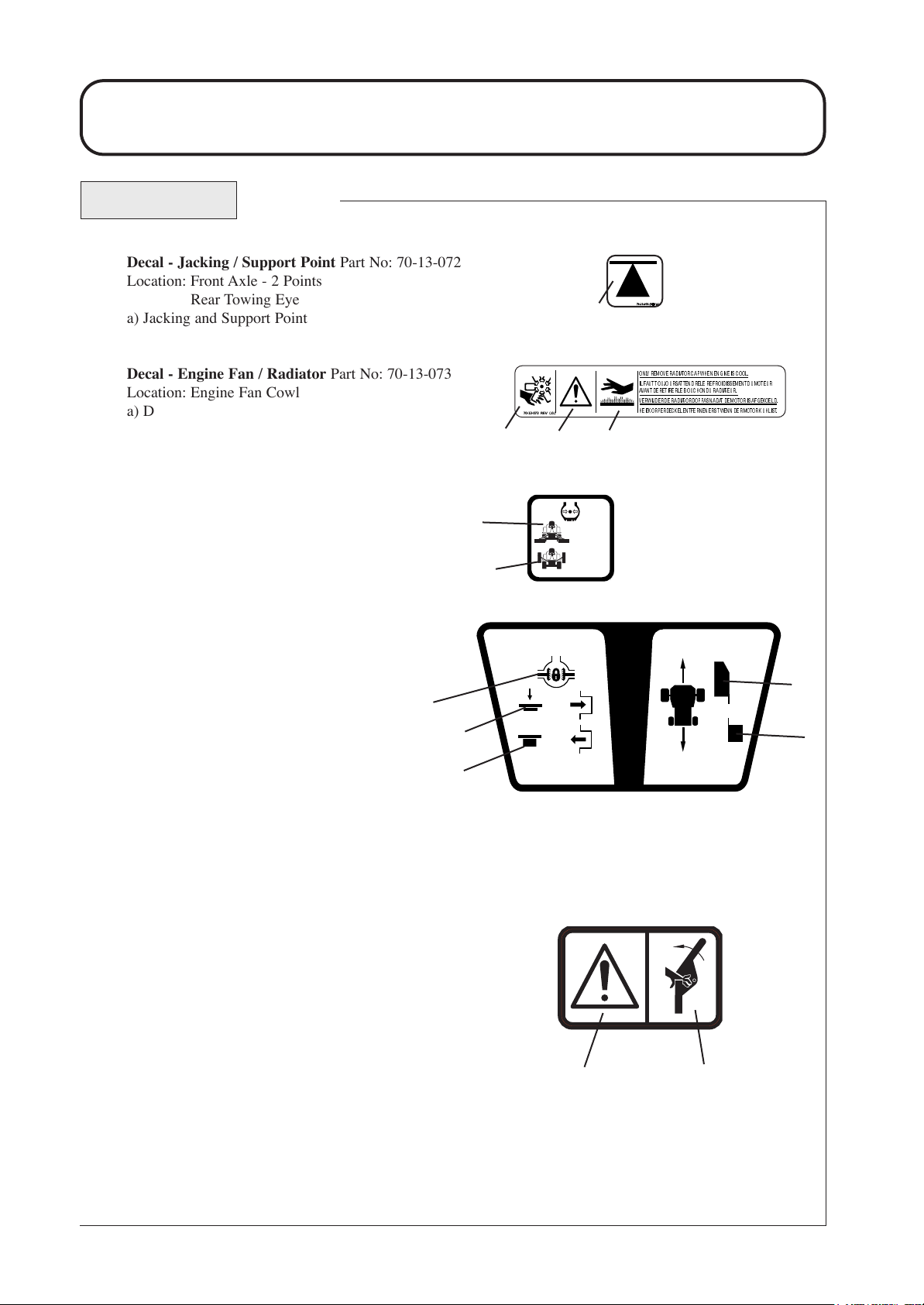

Decal - Jacking / Support Point Part No: 70-13-072

Location: Front Axle - 2 Points

Rear Towing Eye

a) Jacking and Support Point

Decal - Engine Fan / Radiator Part No: 70-13-073

Location: Engine Fan Cowl

a) Danger of Severing Fingers

b) Caution

c) Warning - Hot Surfaces

Decal - Tyre Pressure Part No. 950832 (2)

Location: LH/RH Chassis - 4 Places

a) Mowing

b) Road Travel

Decal - Diff Lock / Control Pedal Part No: 924812

Location: Centre Platform.

a) Differential Lock

b) Depress to engage Diff-lock

c) Release to Dis-engage Diff-lock

d) Forward Speed & Directional Control

e) Reverse Speed & Directional Control

Decal - Warning Crush Hazard

Part No. 111-0773(A)

A = Safety Alert - Be aware to the possibility of injury

B = Crushing of fingers. Force applied from side.

950832 Rev.2

0.7 BAR

10 PSI

1.4 BAR

20 PSI

1.13

1.13

a

a

b

c

a

b

924812 REV.(0)

a

b

c

d

e

a

b

111-0773 Rev A

Page 14

111-1033TH051006

SAFETY PRECAUTIONS

DECALS Continued.

Decal - Serial Number

Location: Rear Bulkhead

Decal - Prevent Platform

Damage

Part No. 924828

Location : Platform, Seatwell.

Decal - Warning Platform Latch

Part No. 924868

Location: Next to Platform Latch

Warning - Prevent Accidents: Ensure platform is correctly seated and the latch is

fully locked before operating the machine.

Decal - Maintenance

Part No. 924882 (2)

Location: Underside of Engine Cover next

to Latch.

Decal - Noise

Part No. 922854

Location: Base of Seat on GRP

1.14

1.14

RM3240-D REELMASTER

:2800 kW:26.1

RPM

kg:1025

Code Serial No:

650D

270000001

105

PREVENT PLATFORM DAMAGE !

ENGAGE PARKING BRAKE AND

DROP CUTTERHEADS BEFORE

RAISING/LOWERING PLATFORM.

POUR EVITER DES DOMMAGES

METTRE LE FREIN DE PARKING ET POSER

LES TETES DE COUPES AVANT DE

BOUGER LA PLATE-FORME.

..

SCHADEN VERMEIDEN

FESTSETZEN UND DIE SCHNEIDEINHEITEN

HERUNTERLASSEN BEVOR DIE SITZPLATTFORM GEKIPPT WIRD.

VOORKOM BESCHADIGING!

MACHINE OP HANDREM EN LAAT DE

KOOIEN ZAKKEN, VOORDAT HET

BEDIENINGS PLATFORM NAAR VOREN

GEKANTELD OF TERUG GEPLAATST

WORDT.

dB

- PARKBREMSE

ZET

924828 REV.0.

924868 REV .0

2005

,

DAILY MAINTENANCE DAILY MAINTENANCE

FUEL LEVEL

ENGINE OIL

FUEL

EF

D

TYRES

FASTENERS

AIR CLEANER

DAILY 50 HOURS (WEEKLY)DAILY (IF FITTED)

50 HOURS MAINTENANCE

CLEAN AND INSPECT THE MACHINE.

WHEEL NUT TORQUE

FRONT: 200Nm

REAR: 54Nm

GREASE POINTS

SEAT SWITCH

HOSE LINES HYDRAULIC OIL

RADIATOR/

SCREENS

924882(Rev 1)

COOLANT LEVELCUTTERHEADS

30 - 40mm

Page 15

111-1033TH051006

EC CONFORMITY INFORMATION

NOISE LEVELS

Operators Daily Personal Noise Exposure: The Toro Company has no

control over site conditions, duration of use, state of maintenance or

adjustment of the mower. All of these factors will affect the operator's

daily personal noise exposure level - L

EP,d

Under typical working conditions operators could be exposed to a daily

personal noise exposure level in excess of 85 dB (A) L

EP,d

Sound pressure level:

The sound pressure level at the operator's position is 84 dB (A)

measured in accordance with European Standard EN836.

Sound power level:

The guaranteed sound power level is 105 dB(A) measured in accordance

with EC Directive 2000/14/EC.

If hearing protection is required, ear protectors with good attenuation in

the 63 - 8000 Hz frequency range should be used.

Employers of personnel using this machine are advised to read the 'Noise

at Work Regulations' as the operator's daily personal exposure level could

be above the 'First Action Level'.

1.15

1.15

Wear Hearing

Protection

VIBRATION LEVELS

Operators Daily Personal Vibration Exposure: HAYTER LIMITED have

no control over site conditions, duration of use, state of maintenance or adjustment of the mover. All of these factors will affect the operator’s daily

personal vibration exposure level.

Under certain working conditions the operator may be exposed to vibration

levels above those stated.

RM3240-D REELMASTER

:2800 kW:26.1

RPM

kg:1025

Code Serial No:

650D

270000001

2005

105

dB

Page 16

111-1033TH051006

EC CONFORMITY INFORMATION

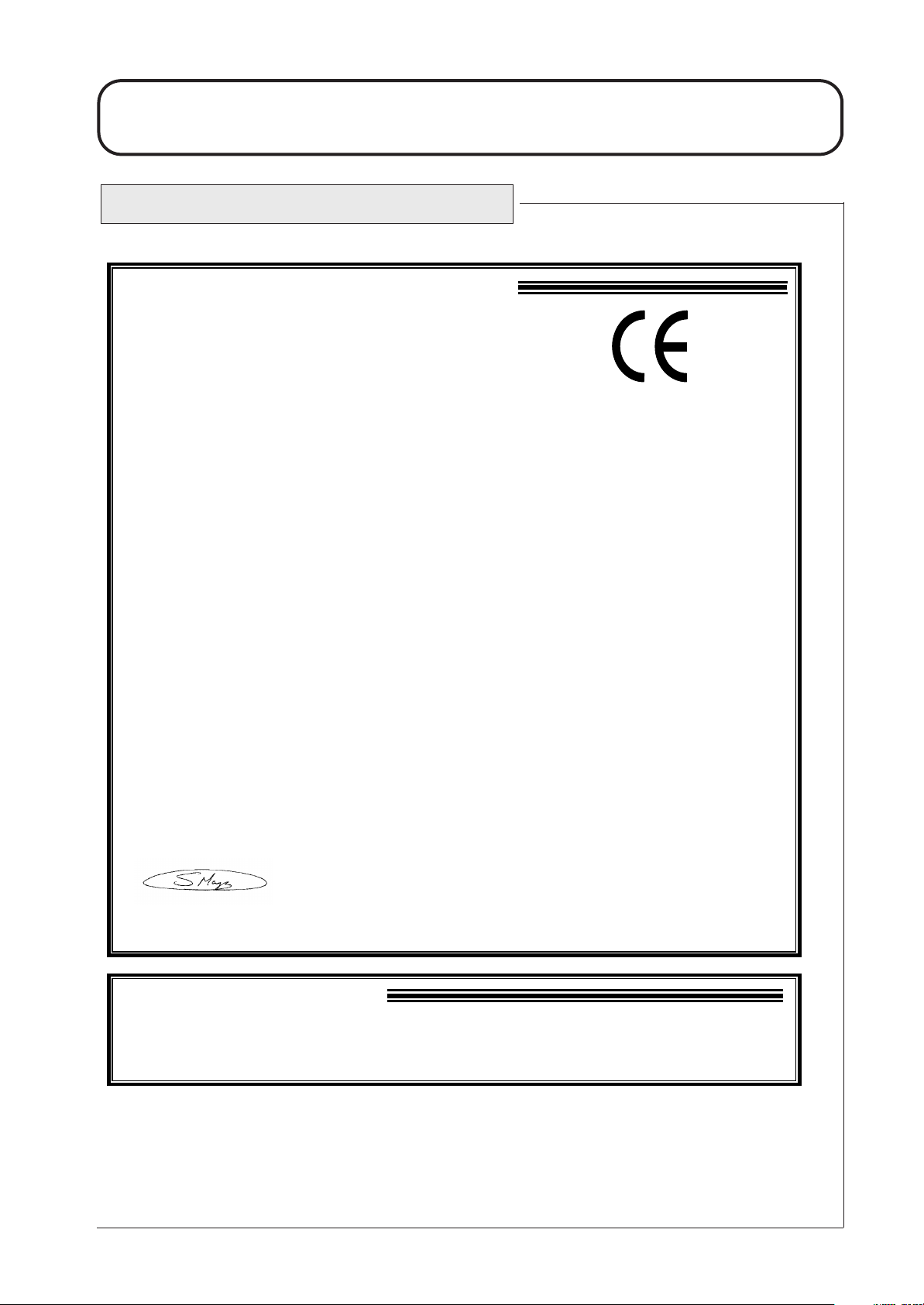

EC DECLARATION OF CONFORMITY

1.16

1.16

101dB(A)

105dB(A)

EC DECLARATION OF CONFORMITY

Manufact ured for The Toro Company

By: HAYTE R LIMITED,

Spellbrook, Bishop’s Stortford, Herts. CM23 4BU. ENGLAND

declare tha t the lawnmow er :

Model name:

Type:

Model No:

Cutting width:

Speed of rotation of the cu tting

device:

Engine manufacturer:

Speedofrotationofengine:

Complies with the provisions of Directive: 98/37/EC Essentia l Health & Safety Requirements Relating to the Design &

Construction of Machinery and Safety Components, as amended and the regulations transposed into national law.

RM3220-D

Ride-on Cylinder

CODE 650D

212cm

1050 rpm

Kubota

2850 rpm

RM3240-D

Ride-on Cylinder

CODE 651D

212cm

1050 rpm

Kubota

2850 rpm

Also Directive 79/622/EEC Roll Over Protection Structures, as amended and the regulation s transposed into national law.

Also Directive 89/336/EEC Electromagnetic Compatibili ty, as amended and the regulations transposed into national law.

Also Directi ve 2000/14/EC Noise emission in the enviro nm ent by equipment for use outdoors and the regulations transposed into

national law.

Procedure applied for the conformity assessment: ANNEX VI, procedure 1.

Notified Body: Sound Research Laboratories Ltd. Holbrook House, Lit tle Waldingfield,

Sudbury , Suffolk. CO10 0TH. ENGLAND

Notified body identification No: 1088

Measured sound power level :

Guaranteed sound power level:

Complies with harmonized standards: EN 292, EN 836 and EN ISO 14982

Signed

S.A Maryniak

(Technical Director)

101dB(A)

105dB(A)

Date: 15.12.05

Declaration done and technical do cumentation k ept at:

HAYTER LIMITED

Spellbrook, Bishop’s Stortford,

Herts. CM23 4BU ENGLAND

VIBRATION INFORMATION

The vibration level at the operator contact positions, measured in accordance with European Standard EN 836

CODE 650D Steering Whee l Does not exceed 2.5ms-2Seat Does not exceed 0.5ms

CODE 651D Steering Whee l Does not exceed 2.5ms-2Seat Does not exceed 0.5ms

-2

-2

Page 17

111-1033TH051006

INTRODUCTION

The Toro Reelmaster® 3220-D is a diesel engine powered self propelled machine with hydraulic systems for ground drive, cutterhead drives and steering. The machine operates in two wheel drive.

The 3240-D machine also is a diesel engine powered self propelled machine and operates in two wheel

drive with automatic four wheel drive on demand. A differential lock function may be selected. The

transmission system is converted automatically to engage drive to all 4 wheels when the machine speed

decreases as a result of front wheel traction slip. 2WD is automatically re-engaged when traction slip is

reduced.

The Toro Reelmaster® 3220-D and 3240-D are precision built machines designed solely for cutting grass

and similar low lying ground vegetation within the limitations stated in this manual. Use in any other

way is considered as contrary to the intended use. Compliance with and strict adherence to the conditions of operation, service and repair as specified in this Operators Manual also constitute essential elements of the intended use. The way in which these machines are operated and maintained will have a

profound effect on its performance and reliability.

This manual contains advice on the Toro Reelmaster® 3220-D and 3240-D which should be operated, serviced and repaired only by persons who are familiar with their particular characteristics and who are

acquainted with the relevant safety procedures.

The safety precautions listed herein and all other generally recognised regulations on safety and all road

traffic regulations must be observed at all times.

Any arbitrary modifications carried out to these machines may relieve The Toro Company of liability for

any resulting damage or injury.

In the pursuit of continuous product development The Toro Company reserves the right to alter specifications without notice.

Cutterhead Variants: The Toro Reelmaster® 3220-D and 3240-D can be fitted with a range of cutterhead configurations and optional extras:

Optional Extras:

Beacon Kit - Amber flashing warning light.

Lighting Kit - Complies with EC traffic regulations.

R.O.P.S. Cab - Full weather protection and roll - over protection.

Note: with a R.O.P.S. Cab fitted stability angle will decrease on both the RM3220-D and

RM3240-D, due to the higher centre of gravity of the machine.

When fitting optional extra kits to the mower be sure to fix the serial number decal supplied with the

kit to the rear bulkhead underneath the engine cover. This will help the Toro spare parts department to

supply the correct spare parts throughout the service life of the mower.

Left and Right: Throughout this manual the terms 'Left' and 'Right' refer to the machine when looking

in the direction of forward travel.

Fixed

Heads

Cutterhead

Number of bladesCylinder diameter

MK3 Cutterhead

200mm (8")

4, 6, 8, 10.

✔

✔

Floating Heads with smooth

or grooved front rollers

254mm (10")

4, 6

✔

INTRODUCTION

1.17

1.17

Page 18

111-1033TH051006

SPECIFICATIONS

ALL FIGURES ARE NOMINALLY QUOTED AT THE RATED ENGINE SPEED OF 2800 RPM

UNLESS OTHERWISE STATED.

ENGINE

Type:

Power Rating:

Capacity:

Air Cleaner:

Cooling System:

Battery:

Alternator:

Starter:

Cold Starting:

Idle Speed:

Fuel Type:

IMPORTANT: PREVENT DAMAGE - for further information regarding the engine, refer to ENGINE MANUAL .

SPECIFICATIONS

3240-D

Kubota V1505 -BB.

4 Cylinders in line.

26.1 kw (35hp) @ 2800 RPM.

DIN 70020.

1498 cc (91.4 cu in).

Clean air drawn through screened air

intake in-front of radiator via a cyclonic

air cleaner with built in pre-cleaner.

Water-Cooled.

12V. 480 Amps S.A.E.

40 Amps.

1.2 KW (1.6 hp) Electric.

Glow Plug.

1250(+50) R.P.M.

Diesel.

1.18

1.18

3220-D

Kubota V1305 -E.

4 Cylinders in line.

24.0 kw (31.1hp) @ 2800 RPM.

DIN 70020.

1335 cc (81.5 cu in).

Clean air drawn through screened air

intake in-front of radiator via a

cyclonic air cleaner with built in

pre-cleaner.

Water-Cooled.

12V. 480 Amps S.A.E.

40 Amps.

1.2 KW (1.6 hp) Electric.

Glow Plug.

1250 (+50) R.P.M

Diesel.

Page 19

111-1033TH051006

SPECIFICATIONS

TRANSMISSION SYSTEM

Drive Type:

Pump:

Wheel Motors:

Differential Lock:

Drive:

Relief Valve Setting:

CUTTERHEAD DRIVE SYSTEM

Drive Type:

Pump:

Delivery Rate:

Cutterhead Motors:

Control:

Relief Valve Setting:

Hydraulic.

Variable displacement hydraulic piston pump with integral charge

pump and pedal control.

Front Axle - Radial piston, fixed displacement, with integral disc

brake (pressure released).

3240-D Only: Rear Axle - Gear motor, fixed displacement.

Electro - hydraulic control valve with pedal control.

2WD (front axle) with differential lock (selectable).

3240-D Only: Automatic 4WD on demand (forward & reverse).

3220-D: Main service relief 250 bar (3265 psi) differential.

3240-D: Main service relief 300 bar (4350 psi) differential.

Charge pressure relief 18.5 bar (268 psi) differential.

Hydraulic.

Hydraulic gear type.

31 Litres per minute (8.2 UK gallons per minute).

Hydraulic gear type, reversible, pressure balanced with integral

differential pressure sensing relief check valve. Direct drive.

Electro-hydraulic.

Automatic diverter valve safety cut-off.

250 bar (3625 psi) differential.

1.19

1.19

Page 20

111-1033TH051006

SPECIFICATIONS

CUTTERHEAD LIFT SYSTEM AND STEERING

Drive Type:

Pump:

Delivery Rate:

Steering:

Cutterhead Lift Control:

Relief Valve:

Weight Transfer:

HYDRAULIC SYSTEM

Hydraulic Oil Type:

Capacity:

Cooling:

Suction Line Filtration:

Return line Filtration:

Transmission Filtration:

Maximum Oil Contamination Level:

Maximum Oil Temperature:

Hydraulic.

Hydraulic gear pump with integral relief valve.

11 Litres per minute (2.9 UK gallons per minute).

Power beyond hydrostatic steering valve with priority flow to

steering and auxiliary flow to cutterhead lift system. Manual

emergency steering.

Mechanical-hydraulic.

105 bar (1522 psi).

Variable hydraulic applied weight transfer acting on all

cutterheads.

Refer - RECOMMENDED LUBRICANTS

AND HYDRAULIC FLUIDS.

40 Litres (8.8 UK gallons).

Forced air finned tube oil cooler.

125 micron no bypass mesh filter.

10 micron with 2 bar (29 psi) bypass check valve.

10 micron no bypass pressure filter.

ISO Code 18/13 or better (ISO 4406)

1300 - 2500 Particles/ml<15μ

40 - 80 Particles/ml>15μ

95

0

C (2030F)

1.20

1.20

Page 21

111-1033TH051006

SPECIFICATIONS

Wheel Nut Torque Setting: Front axle 200Nm (148 Ibf.ft).

Rear axle 54Nm (40 Ibf.ft).

Service Brakes: Closed loop hydrostatic service braking operating on drive wheels only.

Parking Brake: Lever operated oil immersed disc brakes on front wheels only. Pressurised hydraulic oil

release with mechanical override for emergency towing purposes.

Ground Clearance: 180mm(7.1") at 13mm(.5") cut height and with cutterheads raised.

Steering: Hydrostatic rear wheel steering, emergency manual steering.

Features: Tilting operator platform.

Lockable engine cover.

Adjustable suspension seat with folding arms.

Adjustable steering column.

Cutterhead parking latches with safety locks.

Backlapping facility.

Differential lock ( selectable ).

Engine coolant and hydraulic oil overheat audible warning (horn).

Variable cutterhead weight transfer/traction assistance.

2WD (3240-D Only: 4WD on demand (forward & reverse)).

Hydraulic oil filter blocked telltales on control panel.

Safety Features: Neutral start interlock on transmission pump, parking brake and

cutterhead drive switch.

Operator presence control (seat switch).

2 Post folding R.O.P.S designed and tested to European Directive 79/622/EEC.

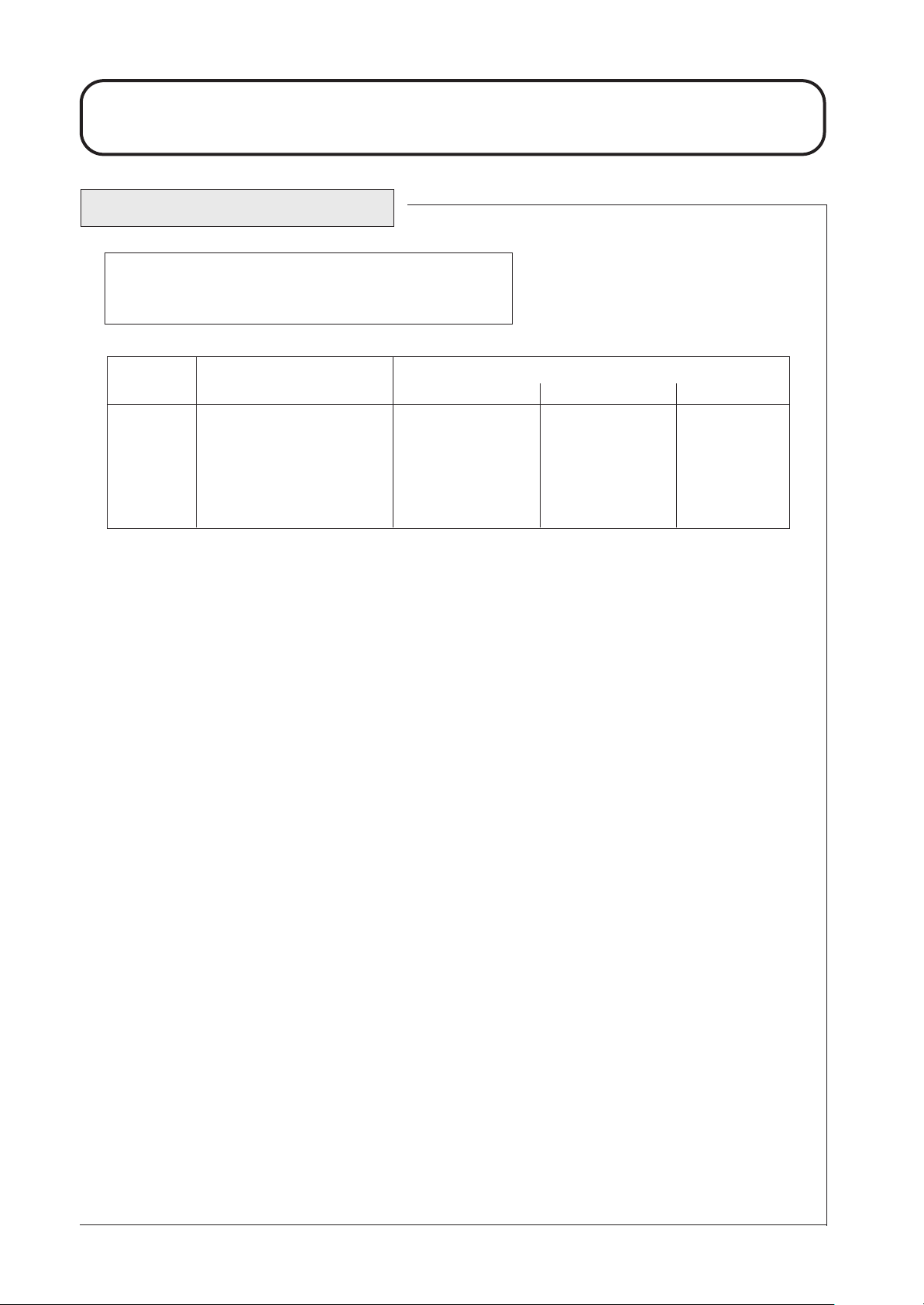

VEHICLE SPECIFICATIONS

Travel Speed:

0-22 km/hr (0-14 mph) forward.

0-11 km/hr (0-7 mph) reverse.

Tyre s Tyre Type

Front axle

Rear axle

0.7 bar

(10 psi )

0.7 bar

(10 psi).

1.4 bar

(20 psi)

1.4 bar

(20 psi)

Recommended Tyre Pressures

Turf Conditions

Max Pressure

Road Conditions

26 x 12 - 12 4 ply

Trelleborg turf pattern.

18 x 9.5 - 8 6 ply

Dico turf pattern.

1.7 bar

(25 psi)

1.7 bar

(25 psi)

1.21

1.21

Page 22

111-1033TH051006

SPECIFICATIONS

Automotive padded steering wheel.

Electrical switch (forward - off - reverse).

Hand operated lever.

Hand operated lever.

Forward and reverse foot pedal.

Key start, shut - off and engine preheat.

Foot pedal.

Hand operated lever.

Button switch.

Hand wheel.

Engine oil pressure.

Battery charge.

Engine coolant temperature.

Hydraulic transmission oil temperature.

Digital hour meter.

Fuel level.

Hydraulic oil level sight glass.

Engine pre-heat.

Hydraulic return filter blocked.

Hydraulic transmission filter blocked.

Cutterhead drive switch off.

Parking brake engaged.

Transmission neutral.

Steering:

Cylinder Drive:

Engine Speed:

Parking Brake:

Forward and Reverse:

Ignition:

Differential Lock:

Cutterhead Position:

Horn:

Weight Transfer:

OPERATOR CONTROLS

INSTRUMENTATION

Warning Lights:

Gauges:

Indicator Lights:

1.22

1.22

Page 23

1.23

SPECIFICATIONS

WEIGHT AND DIMENSIONS

1.23

Wheel Base:

Working Width:

Cutting Width:

Transport Width:

Overall Length:

Overall Height:

Working Weight:

1440 mm (56.7").

2300 mm (90.6").

2120 mm (83.5").

1575 mm (58") at 13mm (.5") height of cut.

2690 mm (106").

1770 mm (69.7") with R.O.P.S folded.

2424 mm (95.4") with R.O.P.S in its vertical operating position.

Including 2 post R.O.P.S, 8 inch 6 blade cutterheads and full tank of

fuel. It excludes the operator and any other options.

1266 kg (2791 Ib) LT322 only

1317 kg (2903 Ib) LT324 only

RECOMMENDED LUBRICANTS AND HYDRAULIC FLUIDS

Grease Points: A good quality medium grease.

Engine: Refer - ENGINE OPERATORS MANUAL.

Hydraulic System:

Ambient Temperature Range

O

0 - 30 C (32 - 86 F)

I S O viscosity grade

46 hydraulic oil.

O

15 - 40 C (59 - 104 F)

O

I S O viscosity grade

68 hydraulic oil.

Should you be in any doubt please contact your Toro dealer. Using incorrect grades will cause

premature wear of hydraulic components and invalidate warranty.

O

111-1033TH051006

Page 24

111-1033TH051006

SPECIFICATIONS

CUTTERHEADS

Cutting Width:

Cylinder Diameter:

Cylinder Speed:

Height of Cut:

Number of Blades:

Smooth Rear Roller:

Smooth Front Roller:

Grooved Front Roller:

Configuration:

MK3 200mm Cutterhead

762 mm (30").

200 mm (8").

1050 rpm approx.

12mm(.5") - 80mm (3").

4, 6, 8, 10

Standard.

Optional.

Optional.

Fixed / Floating.

MK3 254mm Cutterhead

762 mm (30").

254 mm (10").

1050 rpm approx.

12 - 80 mm.

4, 6

Standard.

-

-

Fixed

1.24

1.24

Page 25

111-1033TH051006

OPERATING THE MOWER

OPERATOR PRESENCE CONTROLS

Cutting Cylinder Drive Lockout: Drive to the cutting cylinders is only possible when the operator is

seated. If the operator raises off the seat for a period of more than one second, a switch is activated and

drive to the cutting cylinders is automatically disengaged. To re-engage drive to the cutting cylinders, the

operator must return to the seat, then operate the cutterhead drive switch to the ‘OFF’ position before

moving it back to the ‘ON’ position. If the operator rises off the seat for a brief moment during normal

work, drive to the cutting cylinders is not affected.

The engine can only be started with the cutterhead drive switch in the ‘OFF’ position.

Engine Start Lockout: The engine can only be started when the forward/reverse travel pedal is released

to the 'NEUTRAL' position, the cutterhead drive switch is in the ‘OFF’ position and the parking brake is

engaged. When these circumstances are satisfied, switches are activated permitting the engine to be started.

Engine Run Interlock: Once the engine is started the operator must be seated before the parking brake is

released for the engine to continue to run.

Note: The engine will cut out if the operator leaves the seat without engaging the parking brake.

WARNING: PREVENT ACCIDENTS - Do not operate the Reelmaster®® mower if the operator

presence controls are defective in any way. ALWAYS replace faulty parts and check that they function correctly before operating the mower.

SAFETY NOTICE

WARNING: PREVENT ACCIDENTS - Before operating the mower it is essential that;

- The operator reads and understands this manual.

- The operator platform latching mechanism is fully engaged and in good working order, refer Operator Platform Latching Mechanism.

- The daily maintenance checks have been properly carried out and the mower is in good working

order.

- The operator should wear safety clothing and eye protection. Failure to do so could result in risk to

health and safety.

- The area where the equipment is to be used is inspected and all objects which may be thrown by the

machine are removed.

Operate safely on slopes;

It is essential to follow safe working practices when working on slopes. In order to avoid potentially

hazardous situations, it is essential that the operator understands and observes the relevant safety

precautions listed in this manual, refer - ‘SAFETY PRECAUTIONS’.

This machine is fitted with a R.O.P.S as standard to increase operator safety in the event of the

machine rolling over.

The R.O.P.S frame may be folded down to allow access into area of restricted height.

While the R.O.P.S is folded down it does not provide any protection in the event of a roll over and

should not be considered as a Roll Over Protective structure.

1.25

1.25

Page 26

111-1033TH051006

OPERATING THE MOWER

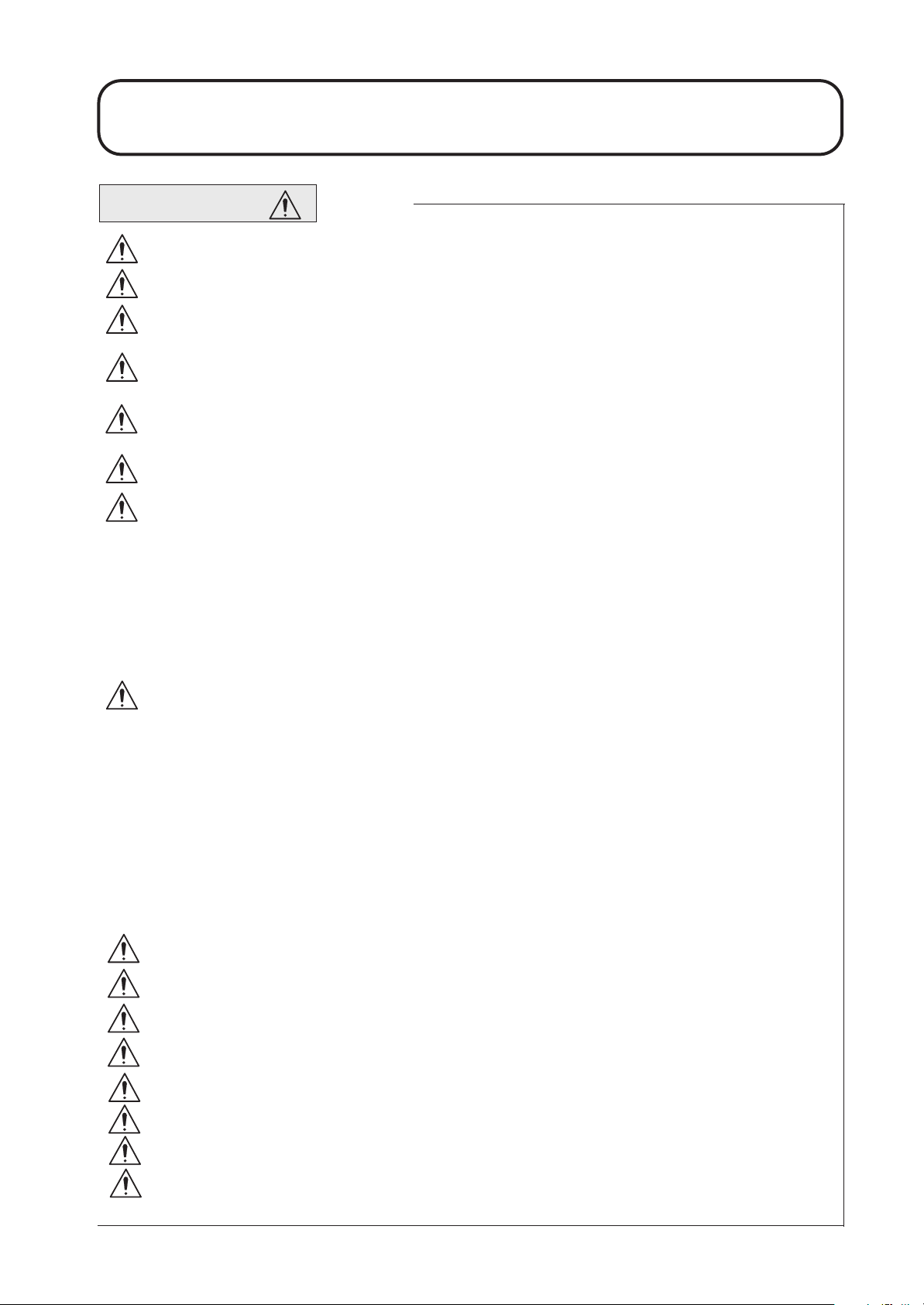

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

Parking brake lever.

Lighting switch

(supplied with lighting kit).

Warning beacon switch

(supplied with beacon kit).

Hazard warning switch

(supplied with lighting kit).

Cutterhead position controls.

Throttle control lever.

Ignition key.

Cutterhead drive switch.

Dip beam / main beam light switch

(supplied with lighting kit).

Direction indicator switch

(supplied with lighting kit).

Horn button.

Transmission oil filter indicator.

Oil pressure indicator.

Transmission temperature indicator.

Return oil filter indicator.

Battery warning indicator.

Engine temperature warning

indicator.

Glow plug indicator.

Cutterhead drive off indicator.

Parking brake indicator.

Transmission neutral indicator.

Weight transfer control.

Wash / wipe switch

(supplied with cab kit).

Hour Meter

Left hand cutterhead safety latch.

Right hand cutterhead safety latch.

Centre cutterhead transport latch.

Reverse travel pedal.

Forward travel pedal.

Differential lock pedal.

Centre cutterhead safety latch.

4A924A02 (1)

1

2

5

6

10

9

4

7

8

11

14

13

12

15

16

18

19

20

21

17

22

3

23

24

HOURS

QUARTZ

CURTIS

1

10

1D924S04A (1)

31

27

25

29

26

28

30

IDENTIFICATION OF CONTROLS

1.26

1.26

Page 27

111-1033TH051006

OPERATING THE MOWER

BRAKING SYSTEM

Parking brake : Move the parking brake lever to its rear position to engage the

parking brake. Do not operate the mower with the parking brake engaged.

WARNING : PREVENT ACCIDENTS - The parking brake operates on the front wheels only. Do not

park the mower on a slope.

Service brakes : Service braking is achieved by the hydraulic transmission system. When the forward or

reverse travel pedals are released or the engine speed reduced, service braking becomes effective and travel speed is automatically reduced. To increase the braking effect, push the transmission pedal into the neutral position. Service braking is effective on the front wheels only.

WARNING : PREVENT ACCIDENTS - The service braking system will not hold the mower at a standstill. ALWAYS ensure the parking brake is engaged to park the mower at a standstill.

Emergency braking : In the event of service brake failure, turn the ignition off to bring the mower to a

standstill.

WARNING: PREVENT ACCIDENTS - Take care when using the emergency braking. Remain

seated and hold on to the steering wheel to prevent ejection from the mower caused by the front

wheel brakes being applied suddenly when travelling.

THROTTLE CONTROL

Operate the throttle control in a forward direction to increase the engine speed.

Operate the throttle control in a rearward direction to reduce engine speed.

Note that the engine speed dictates the speed of the other functions, i.e. travel, cutting cylinder, position controls.

TRAVEL

Forward travel: Depress the forward travel pedal to increase forward travel

speed. Release the pedal to reduce speed.

Reverse travel: Depress the reverse travel pedal to increase reverse travel speed.

Release the pedal to reduce speed.

Stop (Neutral): Release the forward or reverse travel pedal.

1.27

1.27

Parking brake engaged

SlowFast

Engine Speed

P

Page 28

111-1033TH051006

OPERATING THE MOWER

DIFFERENTIAL LOCK

WARNING : PREVENT ACCIDENTS - Do not engage the

differential lock at high speed. The turning circle will increase with

the differential lock engaged.

The differential lock operates in both ‘forwards’ and ‘reverse’ and can be

engaged whilst the mower is travelling slowly. Engage the

differential lock to prevent excessive wheel spin when the drive wheels

lose traction. Engine power demand increases when the differential lock

is engaged. Prevent excessive power requirements by operating with

differential lock at SLOW speed.

Engaging differential lock: Depress the differential lock pedal.

Disengaging differential lock: Release the differential lock pedal.

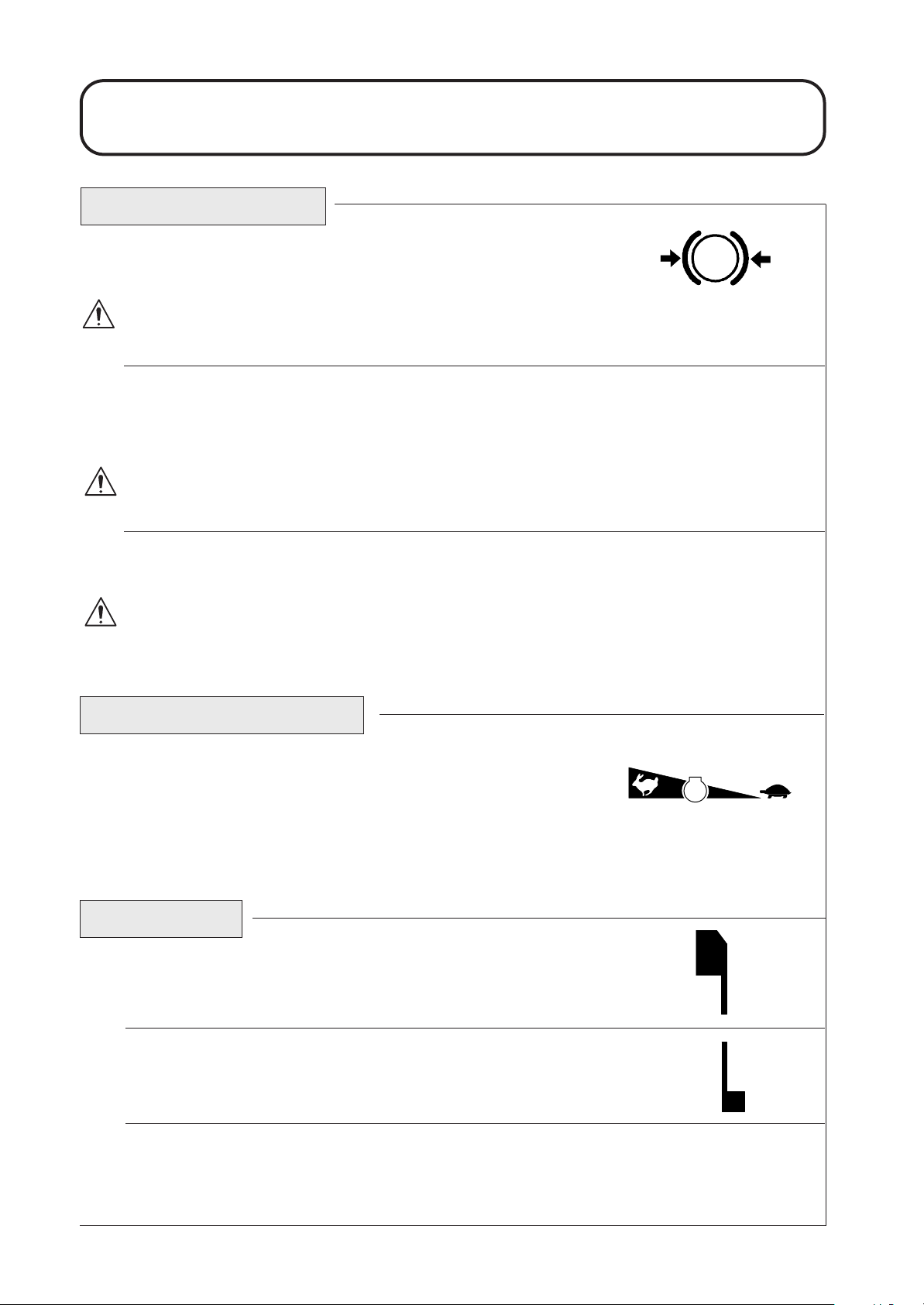

TRANSPORT LATCHES

WARNING : PREVENT ACCIDENTS - ALWAYS raise the

cutterheads to the transport position and secure with the transport

latches and safety locks when travelling between work areas.

Front cutterhead transport latches:

Centre cutterhead transport latch:

1

2

1. Transport latch.

2. Safety lock.

1.28

1.28

SPEED CONTROL PEDAL

The speed control pedal can be adjusted to provide two speed ranges.

Securing the speed control cable through hole ‘A’ will provide 0-22 km/hr

(0-14 mph) forward and 0-11 km/hr (0-7 mph) reverse. Securing the cable

through hole ‘B’ will provide 0-19 km/hr (0-12 mph) forward and

0-8 km/hr (0-5 mph) reverse.

WARNING: PREVENT ACCIDENTS - Ensure that the control cable

is securely fastened to the travel control pedal mechanism. Ensure

that both the cable and pedal articulate freely through their full

range of travel and that the mechanism freely returns to neutral

when released.

WARNING: PREVENT ACCIDENTS - Ensure that the control cable

is correctly routed underneath the operator platform such that it is

clear of any obstructions and impediments to its operation.

1

1

2

2

1D924P07A

3D924S03A

Section through

operator platform

Speed control cable

Speed

control pedal

B

A

Page 29

111-1033TH051006

OPERATING THE MOWER

WARNING: PREVENT ACCIDENTS - Never operate the mower

without first checking that the operator platform latching mechanism

is fully engaged and in good working order. Check behind the seat and

ensure that the top of the platform is flush with the top of the fuel tank.

Also check beneath the tool tray and ensure that the release lever is

padlocked in the correct position.

IMPORTANT: PREVENT DAMAGE - Engage the parking brake and

lower the cutterheads to the ground. Remove ignition key and close

ignition cover before raising or lowering the platform.

Releasing the platform: Release and remove the tool tray from the left hand side of the platform.

Release the padlock securing the locking latch handle with the key provided. Move the locking latch

handle towards the front of the mower (position A) until the latch hooks clear the locking bar and raise

the platform. The gas spring will provide assistance.

Securing the platform: Lower the platform carefully. The gas spring will provide assistance. Move the

locking latch handle towards the front of the mower (position A) as the platform nears the fully lowered

position. This will ensure that the latch hooks clear the locking bar. Fully lower the platform and move

the locking handle towards the rear of the mower (Position B) until the latch hooks fully engage the

locking bar. Replace the padlock in order to secure the locking latch handle in place.

OPERATOR PLATFORM LATCHING MECHANISM

1.29

1.29

1. Tool tray

2. Locking latch handle

3. Padlock

A. Releasing

B. Securing

924868 REV .0

1

B

A

2

3D924S002A

3

3D924S004A

Page 30

111-1033TH051006

OPERATING THE MOWER

WARNING: PREVENT ACCIDENTS - Never operate the mower without first checking that the

steering column adjuster mechanism is in good working order and that, once adjusted and locked,

the steering wheel remains securely in position.

WARNING: PREVENT ACCIDENTS - Adjustment of the steering wheel and steering column

should only be carried out when the mower is at a standstill with the parking brake engaged.

Adjusting the angle of inclination of the steering wheel: Move lever ‘A’

downwards to adjust the angle of steering wheel. Release the lever to lock

the steering wheel in position.

Adjusting the length of the steering column: Move the lever ‘A’ upwards

to adjust the length of the steering column. Release the lever to lock the

steering column in position.

ADJUSTABLE STEERING COLUMN

1.30

1.30

A

1D924T1

A

1D924T2

Page 31

111-1033TH051006

OPERATING THE MOWER

WARNING: PREVENT ACCIDENTS - Never operate the mower without first checking that the

operator seat mechanisms are in good working order and that, once adjusted and locked, the seat

remains securely in position.

WARNING: PREVENT ACCIDENTS - Adjustment of the seat mechanisms should only be carried

out when the mower is at a standstill with the parking brake engaged.

Fore/Aft Adjustment: Move lever ‘B’ upwards to adjust the Fore/Aft posi-

tion of the seat. Release the lever to lock the seat in position.

Operator weight adjustment: Rotate handle ‘C’ clockwise as shown to

increase suspension stiffness and counter-clockwise to decrease. Dial ‘D’

indicates when the optimum suspension adjustment has been set according

to operator weight (kg).

Height adjustment: Manually lift the seat for incremental height adjustment.

To lower lift the seat to beyond its highest setting, then allow it to drop to the

lowest setting.

Backrest adjustment: Pull handle ‘E’ outwards to adjust the seat backrest

angle. Release the handle to lock the seat backrest in position.

OPERATOR SEAT

1.31

1.31

B

1D924T3

CCW

C

1D924T5

CW

D

1D924T4

E

1D924T6

Page 32

111-1033TH051006

OPERATING THE MOWER

1.32

1.32

The R.O.P.S frame may be folded down to allow access into areas of restricted height.

WARNING: PREVENT ACCIDENTS - While the R.O.P.S frame is folded down it does not provide any

protection in the event of a roll-over and should not be considered as a Roll Over Protective Structure.

1). Lower all cutterheads, apply the parking brake and switch of the engine.

2). Support the weight of the upper frame (item 1) while removing the handnuts, washers and retaining

bolts (items 2,3 & 4) from the pivot brackets. Refer - fig.1.

3). Carefully lower the frame downwards until it rests on the stops.

4). Insert the retaining bolts in the lower hole and fully tighten the hand nuts to support the upperframe in

its lowered position.

5). To raise the frame, follow these instructions in reverse order.

WARNING: PREVENT ACCIDENTS - When in the raised position, both retaining bolt assemblies

(items 2, 3 & 4) must be installed and fully tightened to ensure full R.O.P.S protection.

WARNING: PREVENT ACCIDENTS - Be careful lowering and raising the R.O.P.S frame to prevent

entrapment of fingers between fixed part and pivot part of the structure.

Keep all nuts, bolts and screws correctly torqued ensure that the equipment is in safe working condition.

Replace worn or damaged parts for safety.

Ensure that the Seat Belt and Mountings are in safe working order.

FOLDING THE ROPS

Page 33

111-1033TH051006

OPERATING THE MOWER

1.33

1.33

fig.1

1

4

3

2

3

4

Page 34

111-1033TH051006

OPERATING THE MOWER

WARNING SYSTEMS

Engine coolant overheating warning : The engine coolant warning

light illuminates and the horn is actuated.

Hydraulic oil overheating warning : The hydraulic oil warning light

illuminates and the horn is actuated when the hydraulic oil in the reservoir exceeds 95˚C (103˚F)approx.

Low battery charge warning : The battery charge warning light illuminates.

Low engine oil pressure warning light : The engine oil pressure warning

light illuminates.

AUDIBLE WARNING HORN

Depress the horn button to provide an audible warning.

IMPORTANT : PREVENT DAMAGE - The horn is automatically

actuated when an engine coolant or hydraulic oil overheat condition

occurs. STOP the engine immediately and effect remedial action

before restarting.

1.34

1.34

Page 35

111-1033TH051006

OPERATING THE MOWER

E = Empty.

F = Full.

IGNITION KEY

0

= Engine off.

I = Engine run / Auxiliary on.

II = Engine pre-heat.

III = Engine start.

WARNING : PREVENT ACCIDENTS - Always remove the ignition key when the mower is not in

use.

IMPORTANT : PREVENT DAMAGE - Always fit the protective cap when the ignition key is

removed to prevent ingress of dirt and moisture from damaging the mechanism.

ENGINE PRE-HEAT INDICATOR LIGHT

Turn the ignition key to position II. The engine pre-heat indicator light

will illuminate.When the correct pre-heat temperature is achieved the

indicator light will switch off. When this condition is achieved turn the

ignition key to position III to start the engine.

IMPORTANT: PREVENT DAMAGE. Attempting to start a cold

engine before the pre-heat indicator light switches off can cause

unnecessary wear to the battery.

FUEL LEVEL GAUGE

Displays fuel tank level.

HOURMETER

Displays engine running hours.

1.35

1.35

O

I

II

III

FUEL

E

F

WS044

D

WS023

3 4 5 5 9

Page 36

111-1033TH051006

1.36

1.36

OPERATING THE MOWER

TRANSMISSION NEUTRAL INDICATOR LIGHT

Illuminates when the travel control pedal is in the

neutral position and the ignition key is turned to position ‘I’.

Note: The parking brake must be engaged for the transmission neutral indicator light to illuminate.

CUTTERDECK DRIVE SWITCH INDICATOR LIGHT

Illuminates when the cutterdeck drive switch is in the ‘off’ position and the ignition

key is turned to position ‘I’.

PARKING BRAKE INDICATOR LIGHT

Illuminates when the parking brake is engaged and the ignition key is turned to position 'I’.

HYDRAULIC RETURN FILTER INDICATOR LIGHT

Illuminates when the return filter element is blocked.

Note: The engine must be running for the hydraulic return filter indicator light

to illuminate. The indicator light may illuminate briefly when the hydraulic oil

is cold.

HYDRAULIC TRANSMISSION FILTER INDICATOR LIGHT

Illuminates when the transmission filter element is blocked.

Note: The engine must be running for the hydraulic return filter indicator light

to illuminate. The indicator light may illuminate briefly when the hydraulic oil

is cold.

N

WS041

WS046

P

WS045

WS043

WS042

Page 37

111-1033TH051006

OPERATING THE MOWER

CUTTERHEAD POSITION CONTROL

The cutterheads may be raised or lowered independently using the bank of 3

lift control levers.

To lower the cutterheads, operate the lift control levers in a downward

direction until locked in position 1. If the cutterhead drive switch is in the

‘ON’ position, the cylinder drive will engage when the cutterheads are

approximately 300mm(11.8") above ground level.

IMPORTANT: PREVENT DAMAGE - The lift control levers must be

locked in position 1 whilst mowing. NEVER mow with the lift control

levers in position 2 (neutral).

To raise the cutterheads, operate the lift control levers in an upward direction

and hold in position 3. If the cutterhead drive switch is in the ‘ON’ position

the cylinder drive will disengage when the cutterheads are approximately

300mm(11.8") above ground level. Release the lift control levers when the

cutterheads are at the required height. The control levers will automatically

return to position 2 (neutral).

CUTTERHEAD DRIVE ENGAGEMENT

The cutterhead drive can be engaged only when the operator is seated

correctly, refer - OPERATOR PRESENCE CONTROLS.

Release the cutterhead latches. Operate the cutterhead position controls to

the down / float position and lower all cutterheads to the ground ready for

mowing.

Forward rotation cutterhead drive engagement : Operate the cutterhead

drive switch to the 'Forward' position.

Reverse rotation cutterhead drive engagement : Operate the cutterhead

drive switch to the 'Reverse' position.

To disengage all cutterhead drives : Operate the cutterhead drive switch to

the 'Off' position.

WARNING : PREVENT ACCIDENTS - Refer OPERATOR

PRESENCE CONTROLS for additional information.

1. Forward.

2. Off.

3. Reverse.

1. Down / float.

2. Neutral.

3. Raise.

4. Left hand cutterhead

5. Centre cutterhead.

6. Right hand cutterhead

1.37

1.37

4A953B03A

1

2

3

45

6

1

2

3

WS047

Page 38

111-1033TH051006

OPERATING THE MOWER

WEIGHT TRANSFER / TRACTION ASSISTANCE

A variable hydraulic weight transfer system is provided for improving tyre grip with the grass surface -

‘Traction Assistance’.

Hydraulic pressure in the cutterhead lift system provides a lifting force which reduces cutterhead weight

on the ground and transfers the weight as a downward force onto the mower’s tyres. This action is

known as ‘Weight Transfer’.

To engage weight transfer: The amount of weight transfer can be varied to suit operating conditions by

rotating the weight transfer hand wheel as follows;

Release the lock wheel underneath the hand wheel 1/2 turn anti-clockwise and hold.

Rotate the hand wheel: - Anti-clockwise to reduce weight transfer.

- Clockwise to increase weight transfer.

Tighten the lock wheel.

STARTING THE ENGINE

WARNING: PREVENT ACCIDENTS - Before starting the engine check that ;

- The area is clear of bystanders.

- The cutterhead drive is disengaged.

- The parking brake is engaged.

- The travel control pedals are in neutral.

- You have read and understood the SAFETY PRECAUTIONS section in this

manual.

This machine is fitted with an Engine Start Lockout, refer - OPERATOR PRESENCE

CONTROLS.

1. Weight transfer hand wheel

2. Lock Wheel

3. Control Panel

1.38

1.38

1

10

QUARTZ

HOURS

CURTIS

1

2

4A922A02A

3

Page 39

111-1033TH051006

OPERATING THE MOWER

STOPPING THE ENGINE

To stop the engine: Turn the ignition key to position '0'.

WARNING: PREVENT ACCIDENTS - If the engine fails to stop when the ignition key is turned to

'O' operate the engine stop lever in a forward direction. Keep hands clear of moving objects and hot

engine parts whilst the engine is running.

1. Engine stop lever.

STARTING THE ENGINE Continued.

Starting a cold engine: Set the throttle control lever to approximately 70% full

throttle.

Turn the ignition key to the ‘ignition on’ position "I" and check that the engine

oil pressure and battery charge warning lights illuminate.

Turn the ignition key to the ‘preheat’ position "II" and hold until the engine

pre-heat indicator light goes out.

Turn the ignition key to the ‘start’ position "III" and hold to crank the engine.

As soon as the engine starts release the ignition key back to position 'I'.

WARNING: PREVENT DAMAGE - When the engine is operating all warning lights should be ‘off’.

If a warning light illuminates, stop the engine immediately and have the fault rectified before

restarting.

Starting a warm engine: Engine pre-heating is unnecessary when restarting an engine which has been

stopped for a few minutes. Follow the cold engine starting procedure without holding in ‘preheat’ position

“II”.

1. Engine pre-heat

indicator light

STOP

1.

T

1.39

1.39

O

I

1

II

III

QUARTZ

HOURS

CUR

O

I

II

III

1D31238A.DRW

Page 40

111-1033TH051006

1.40

1.40

OPERATING THE MOWER

UNBLOCKING CUTTING CYLINDERS

WARNING: PREVENT ACCIDENTS - Before attempting to clear any blockage from the cutting

cylinders on this machines ensure all of the following:

- Stop the machine on level ground.

- Apply the parking brake and disengage all drives.

- Lower the cutting units to the ground or securely lock in the designated transport positions.

- Stop the engine and remove the ignition key to isolate all power sources and check that they

are stopped.

- Release all stored energy devices.

- Check that all moving parts are stationary.

NEVER ATTEMPT TO ROTATE THE CUTTING CYLINDERS BY HAND as there may be some

residual pressure in the hydraulic system which could cause injury through sudden movement of the cylinder(s) when the blockage is released.

Always wear protective gloves and use a suitable strong wooden instrument. Ensure that this will fit between

the blades and through the cylinder and is long enough to provide sufficient leverage to release the blockage and any residual hydraulic system pressure by rotating or rocking the cylinder. Make sure that the wooden instrument is properly supported in the cylinder and avoid the use of excessive force to prevent damage.

Only when the cylinder has a degree of free movement should the source of the blockage be removed.

Ensure that the wooden instrument is also removed before restarting the power source.

If the cylinder requires readjustment or repair, refer - MAINTENANCE - Cutterheads.

CENTRE CUTTERHEAD HEIGHT OF CUT CORRECTION ADJUSTMENT

With all cutterheads set at the same HOC via the indicator rings, it may be noticeable that the centre unit produces a

higher cut finish compared to the wing units. The centre unit is pulled and the wing units are pushed this presents

marginally different cutting angles relative to the ground. The amount of HOC variation, which results from this will

be influenced by the terrain but satisfactory results can usually be achieved by setting the centre cutterhead HOC

indicator ring lower than the wing unit settings.

Page 41

111-1033TH051006

OPERATING THE MOWER

GENERAL OPERATING HINTS

The rotational speed of the cutting cylinders should always be kept as high as possible in order to

maintain the highest quality of cut. This in turn requires that the engine speed be kept as high as

possible.

The quality of cut will deteriorate if the forward speed is excessive. Always balance the quality of cut

with the workrate required and set the forward speed accordingly.

Never let the engine labour. Reduce the forward speed or increase the height of cut. Check that the

cutting cylinders are not in heavy contact with their bottom blades.

Regularly check the cutting cylinder to bottom blade adjustment every few hours even though cutting

performance appears to be satisfactory. Heavy contact or excessive clearances between the cylinder and

bottom blades will cause rapid wear to take place.

Always disengage the cutterhead drive when travelling across ungrassed areas. Grass will lubricate the

cutting edges whilst mowing. Excessive heat will build up if the cutting cylinders are run when not

mowing and this will cause rapid wear to take place. For this reason it is also wise to reduce cutting speed

when mowing lightly grassed areas or when the grass is dry.

Cutting performance is best when cutting against the lie of the grass. In order to take advantage of this

fact, the operator should attempt to alternate the direction of mowing between cuts.

Take care not to leave uncut strips of grass at the overlap points between adjacent cutterheads by

avoiding tight turns.

It is generally wise to remove rear roller scrapers where conditions allow, as optimum grass discharge is

achieved without them. Scrapers should be refitted when conditions are such that mud and grass start to

build up on the rollers. When refitting the scraper wires care must be taken to ensure that they are correctly tensioned, refer - MAINTENANCE - EVERY 50 HOURS.

WARNING : PREVENT ACCIDENTS -Take care when travelling over obstacles such as roadside

kerbs. ALWAYS travel at slow speed over obstacles to prevent damage to the machines tyres,

wheels and steering system. Ensure that tyres are inflated to the recommended pressures.

1.

2.

3.

4.

5.

6.

7.

8.

1.41

1.41

Page 42

111-1033TH051006

OPERATING THE MOWER

CUTTERHEAD GENERAL INFORMATION

The mower is designed to be used with MK3 200mm (8") fixed or floating cutterheads or MK3

254mm (10") fixed cutterheads.

It is essential that the relationship between the bottom blades and the cutting cylinders are kept in good

adjustment and that cutting edges are kept sharp to ensure good cutting performance, minimum power

consumption and prolonged life for the cutting edges, refer - MAINTENANCE - Cutterheads.

Fixed MK3 200mm (8") / 254mm (10") Cutterheads:

When the mower is set up with fixed cutterheads the height of

cut is gauged by the rear roller and the cutterhead is allowed to

pivot laterally to follow ground contours. This arrangement is

normally recommended for general mowing requirements.

(MK3 200mm (8") Cutterhead illustrated).

Floating MK3 200mm (8") Cutterheads: When the mower

is set up with floating cutterheads the height of cut is gauged

by the front and rear rollers. The cutterhead is allowed to pivot

fore and aft as well as laterally. This arrangement is recommended for high quality grass areas and performs well where

grass is short and the ground undulations are severe.

Grass deflectors: The rear grass deflectors must always be

correctly fitted. The deflectors should be set as low as possible

to deflect grass discharge to the ground.

WARNING: PREVENT ACCIDENTS - Always ensure

that the grass deflectors are angled below horizontal level,

otherwise risks to health and safety may result.

Height of cut gauge: An optional height of cut gauge is

available to assist in achieving accurate cut height settings. It

is suitable for both fixed and floating cutterheads.

Part No. 63-01-760

1.42

1.42

1D876P02A

1D876P03A

1D876P04B

Page 43

111-1033TH051006

OPERATING THE MOWER

MK3 200mm ( 8") FIXED CUTTERHEAD

Pivot knuckle fixing: Secure the bolt in the front “fixed” hole

position ‘A’ as shown.

Height of cut adjustment: The height of cut is gauged by the

position of the rear roller.

Turn the adjusting nut assembly ‘B’ both ends clockwise to

decrease height of cut ‘E’ or anti-clockwise to increase height of

cut ‘E’.

IMPORTANT: PREVENT DAMAGE - Do not attempt to

unlock the nut assemblies, ‘B’.

Ensure that all cutterheads are set at the same height of cut by

either referring to the indicator rings ‘C’ or by using a height of

cut gauge across the full width of each cutterhead for greater

accuracy as shown.

MK3 254mm (10") FIXED CUTTERHEAD

Height of cut adjustment: The height of cut is gauged by the

position of the rear roller.

Turn the adjusting nut assembly ‘B’ both ends clockwise to

decrease height of cut ‘E’ or anti-clockwise to increase height of

cut ‘E’.

IMPORTANT: PREVENT DAMAGE - Do not attempt to

unlock the nut assemblies ‘B’.

Ensure that all cutterheads are set at the same height of cut by

either referring to the indicator rings ‘C’ or by using a height of

cut gauge across the full width of each cutterhead for greater

accuracy as shown.

A

1.43

1.43

1D876P05A

B

E

1D876P08B

C

E

1D876P09A

=

B

E

1D876P16A

C

E

1D876P09A

=

Page 44

111-1033TH051006

OPERATING THE MOWER

MK3 200mm (8") FLOATING CUTTERHEAD

A

F

1.44

1.44

Pivot knuckle fixing: Secure the bolt in the rear “floating” slot posi-

tion ‘A’ as shown.

Height of cut adjustment: The height of cut is gauged by the position

of the front and rear rollers.

To alter the rear roller position, turn the adjusting nut assembly ‘B’ both

ends clockwise to decrease height of cut ‘E’ or anti-clockwise to

increase height of cut ‘E’.

IMPORTANT: PREVENT DAMAGE - Do not attempt to unlock

the nut assemblies, ‘B’.

To alter the front roller position loosen bolts ‘F’. Release and turn

adjusting nuts ‘D’ both ends clockwise to increase the height of cut or

anti-clockwise to decrease the height of cut.

Ensure that all cutterheads are set at the same height of cut by referring

to the indicator rings ‘C’ or use the height of cut gauge across the full

width of each cutterhead as shown.

Tighten nuts ‘D’ and ‘F’ both ends.

1D876P07A

B

D

A

E

1D876P06B

C

E

1D876P10A

=

Page 45

111-1033TH051006

MAINTENANCE

MAINTENANCE

WARNING : PREVENT ACCIDENTS - When carrying out maintenance procedures it is essential that:

- The engine is switched off and the ignition key removed.

- The parking brake is applied.

- There is no pressure in the hydraulic system.

- The cutterheads are fully down on the ground.

- The safety precautions in this manual have been read and understood.

IMPORTANT: PREVENT DAMAGE: Regular maintenance is essential for the continued safe

operation of the machine. Correct servicing will prolong the working life of the machine and

safeguard the "Toro Warranty". Always fit genuine service parts as these are

accurately matched to the required duty.

Dirt and contamination are the enemies of any hydraulic system. When carrying out maintenance

procedures on the hydraulic system always ensure that the work area and the components are

thoroughly clean before, during and after refitting. Ensure that all open hydraulic lines and ports, etc. are

plugged during maintenance procedures.

The recommended service intervals are based on normal operating conditions. Severe or unusual

conditions will necessitate shorter service intervals.

ALWAYS grease pivot points immediately after pressure washing or steam cleaning, refer - EVERY 50

HOURS, GREASE PIVOT POINTS.

WARNING: PREVENT ACCIDENTS - The engine, transmission oil and hydraulic systems will be

hot after machine use. Allow the systems to cool before working on the machine, particularly

before working on the engine or when changing oil or oil filters.

1.45

1.45

Page 46

111-1033TH051006

MAINTENANCE

WARNING : PREVENT ACCIDENTS - Use hazardous substances carefully.

The following fluids are identified as being hazardous;

When using any of the above fluids it is recommended that eye protection and gloves are worn and

that care is taken to prevent spillage.

Avoid contact with skin; wash off spillage with soap and water.

In the case of battery acid drench with water and seek medical attention. Remove any contaminated

clothing and clean thoroughly before use.

Avoid contact with eyes; wash with running water and seek medical attention if symptoms persist.

In the case of battery acid, seek medical attention immediately.

Avoid ingestion; if swallowed seek medical attention.

Keep clear of high pressure fluid escaping from pinholes, cracked connections etc. High pressure

fluid can penetrate the skin. Seek immediate medical advice if any fluid is injected into the skin.

Always use a piece of cardboard or paper when searching for leaks.

CAUTION: PREVENT ENVIRONMENTAL DAMAGE - Dispose of hazardous substances

correctly.

When disposing of hazardous waste products, take them to an authorised disposal site.

Waste products must not be allowed to contaminate surface water, drains or sewerage systems.

CAUTION: PREVENT ENVIRONMENTAL DAMAGE - Dispose of

used battery correctly. The battery has a separate collection mark. This

means that the battery must not be disposed of with general waste. It

must be taken to an authorised disposal site

Assessed risk

Low

Low

Low

Low

Medium

High

Substances

Diesel oil

Lubricating oil

Hydraulic oil

Grease

Anti - freeze

Battery acid

MAINTENANCE Continued.

1.46

1.46

Page 47

111-1033TH051006

MAINTENANCE

ENGINE

Refer to the Engine Operator's Manual for maintenance information.

RUNNING IN PERIOD

Check wheel nut torque settings:

During first 50 hours of use and in addition to routine checks. Refer DAILY AND BEFORE USE. Check wheel nut torques twice a day.

Front axle wheel nut torque setting - 200 Nm (148 Ibf.ft).

Rear axle wheel nut torque setting - 54 Nm (40 Ibf.ft).

RUNNING IN PERIOD - AT FIRST 50 HOURS

Change the transmission oil filter: Unscrew and remove the bottom of the

transmission oil filter housing. Withdraw the filter element and discard. Refit

a new filter element (part no. 924709) and replace the housing.

1.47

1.47

1. Transmission oil filter.

2. Centre cutterhead.

3. Hydraulic tank.

ENGINE

1

3

2

1P953C17

Page 48

111-1033TH051006

MAINTENANCE

RUNNING IN PERIOD - AT FIRST 50 HOURS

Change the hydraulic oil return filter: Unscrew and remove the

return filter canister and discard. Refit a new filter canister (part no.

924692).

1. Hydraulic oil return filter.

2. Engine fuel filter.

Continued.

Left Hand Side of Machine

1.48

1.48

2

1

1P953C16A

Page 49

DAILY AND BEFORE USE

Check engine oil level: If the oil level is below the upper mark on the

dipstick, top up with the correct grade of engine oil to the required level,

refer - ENGINE MANUAL.

Check engine radiator coolant level:

WARNING: PREVENT ACCIDENTS - Avoid scalding. DO NOT

remove the radiator filler cap unless the engine is cool. Turn the filler

cap slowly to release system pressure before removing the filler cap

completely.

The coolant level should be 30mm (1.2") - 40mm (1.6") below the top of

the filler neck. Top up with the correct coolant mixture, refer - ENGINE

MANUAL.

IMPORTANT: If you see RED in the Filter Blockage Indicator the air

filter needs replacing

Cleaning the air cleaner: Remove the air filter and tap it repeatedly

with the palm of the hand to remove dust particles. DO NOT damage the

air filter by hitting it against a hard object. Inspect the air filter for signs

of damage.

IMPORTANT: PREVENT DAMAGE - Always replace a damaged

air filter or damage to the engine will result. NEVER run the engine

without the air filter correctly fitted.

Clean the inside of the cleaner dust bowl with a dry cloth and check that