Toro Reelmaster 5010-H Series, Reelmaster 03406, Reelmaster 03408 Installation Instructions Manual

Page 1

FormNo.3397-977RevC

RearRollerBrushKit

Reelmaster

ModelNo.03406

ModelNo.03408

ThisproductcomplieswithallrelevantEuropeandirectives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Therearrollerbrushkitismountedtothereelmowersonaride-onmachineandisintendedtobeusedby

professional,hiredoperatorsincommercialapplications.Itisprimarilydesignedtokeeptherearrollerofthe

cuttingunitfreeofgrassanddebris,whichleadstoabetterafter-cutappearanceonwell-maintainedlawnsin

parks,sportselds,andoncommercialgrounds.

®

5010-HSeriesCuttingUnitwith5inor7inReel

InstallationInstructions

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Nopartsrequired

Roller-brushhousing

Hex-socketbolt,3/8x1inch

Roller-brushassembly

Shoulderbolt

Rightbeltcover/plateassembly

Leftbeltcover/plateassembly

Bolt(5/16x1/2inch)

Spacer

Drivepulley

Flange-headbolt(3/8x2inches)

Belt

Shimwasher(asrequiredforbeltalignment)

Rightdriveshaft

Leftdriveshaft

Highheight-of-cutbrush(optional)

Endweightkit(Model03413)forthe

Reelmaster5010-Hwith5-inchcuttingunit

Qty.

10

20

—

—

Use

–

5

5

5

2

3

5

5

5

5

5

2

3

Determinetherollerbrushorientation.

Installtherollerbrush.

Installthehighheight-of-cutbrush—forHOCgreaterthan

2.5cm(1inch).

InstalltheendweightkitfortheReelmaster5010-Hwith

5-inchcuttingunits.

Note:Determinetheleftandrightsidesofthecutting

unitfrombehindthecuttingunit.

Important:UsetheRearRollerBrushKitonly

whencuttingintheheight-of-cutrangeof6to

25mm(1/4to1inch).Usethehighheight-of-cut

brushwhencuttingabove25mm(1inch).Referto

theprocedureforInstallingtheHighHeight-of-Cut

Brush(Optional).

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww .T oro.com.

Note:5-inchcuttingunitsdrivenbyelectricreel

motorsneedtheadditionalend-weightkit(Model

03413).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3397-977*C

Page 2

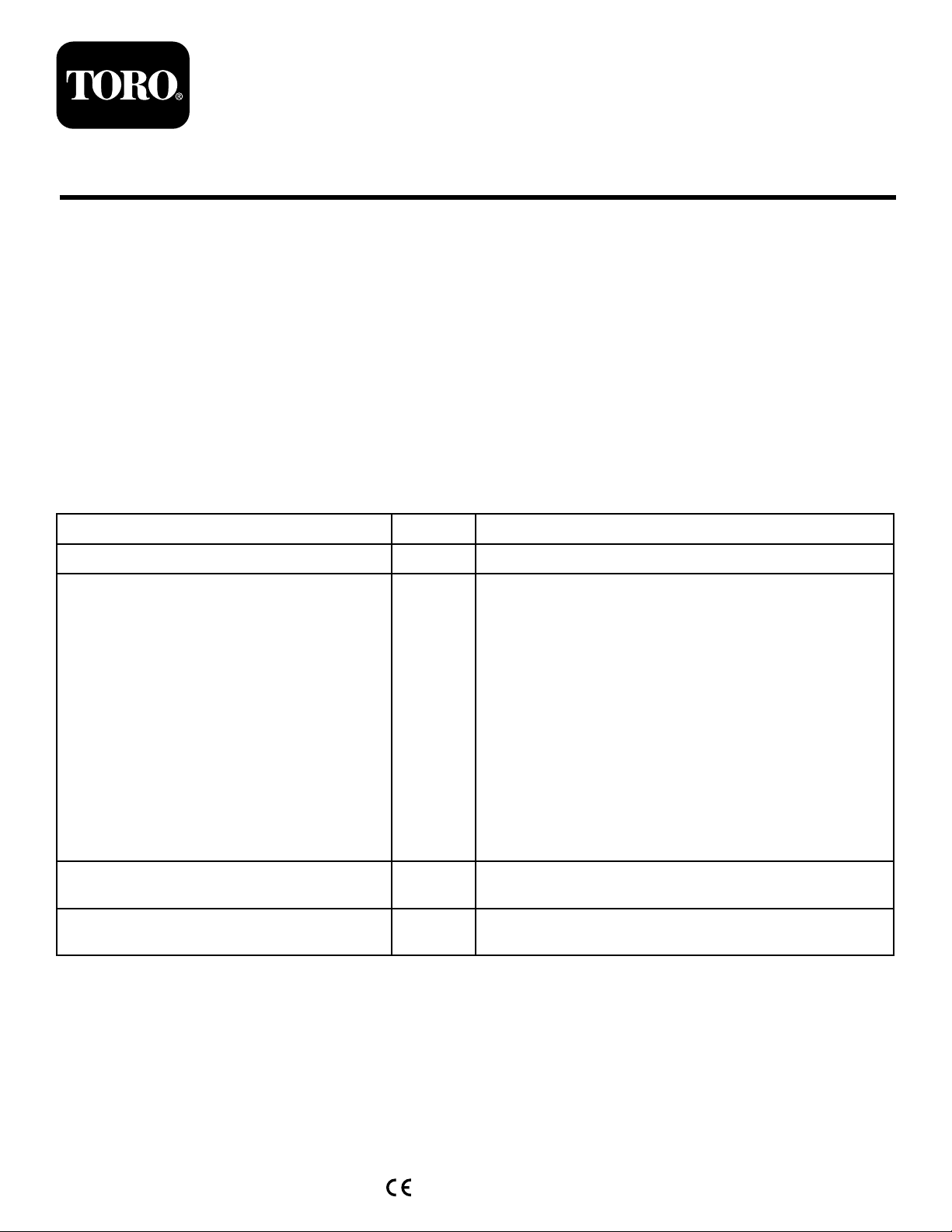

DeterminingtheRoller

BrushOrientation

Allcuttingunitsareshippedwiththecounterweight

mountedtotheleftendofthecuttingunit.Referto

Figure1todeterminethepositionoftherollerbrush

andreelmotors.

InstallingtheRollerBrush

InstallingtheDriveshaft

1.Parkthemachineonalevelsurfaceandsetthe

parkingbrake.

2.Ensurethatthecuttingunitsaredisengaged.

3.Shuttheengineoffandremovethekey .

4.Removeallthecuttingunitsfromthemachine.

Important:Checkthecuttingunitforthe

desiredheightofcutandattitude.Make

adjustmentspertheOperator’sManual,if

required,beforeinstallingthekit.

Figure1

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit2

3.Cuttingunit3

4.Cuttingunit48.Leftroller-brushdrive

6.Reelmotor

7.Rightroller-brushdrive

assembly

assembly

Note:Theseinstructionsandillustrationsshowthe

installationofthekitoncuttingunitswiththeend

weightsmountedontheleftendofthecuttingunit.

g027187

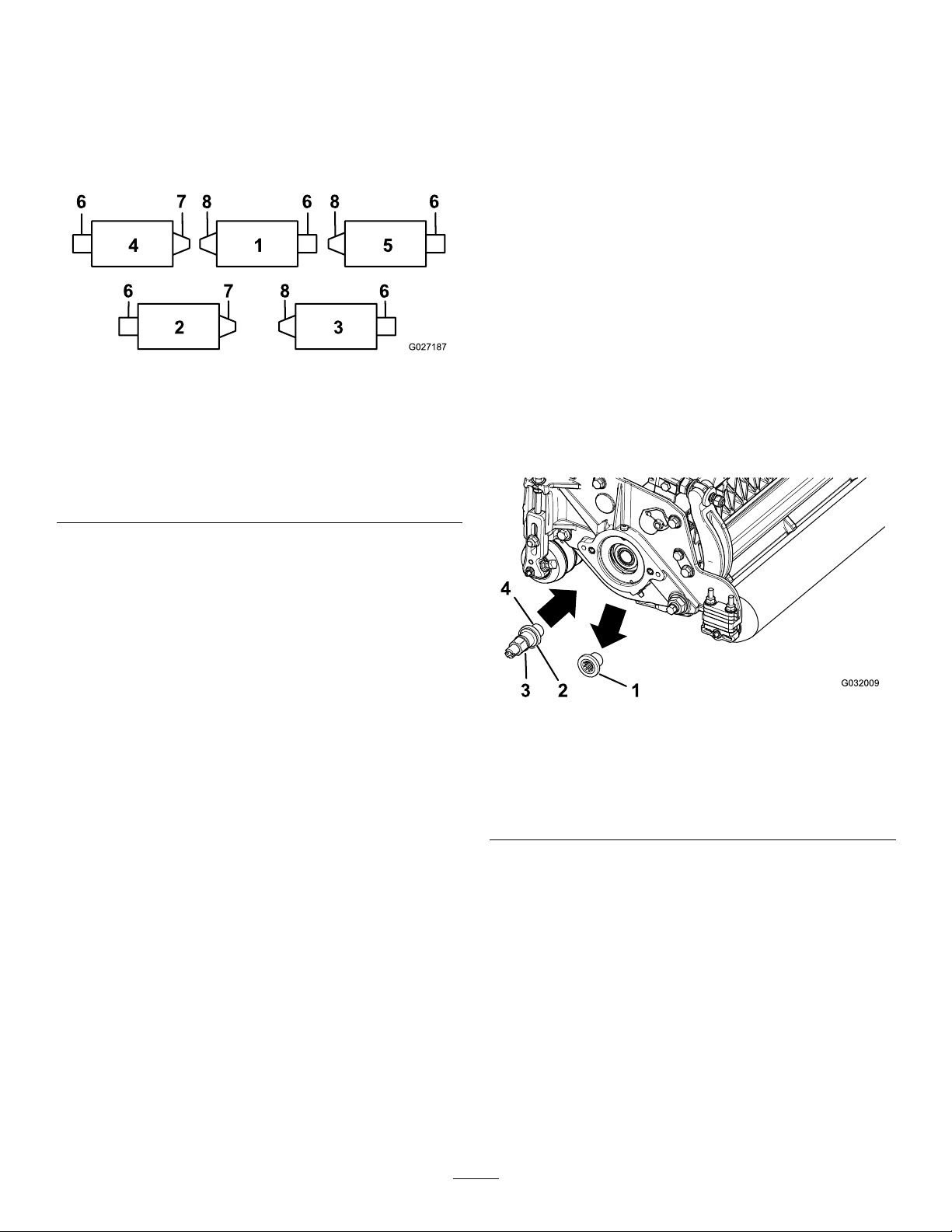

5.Restrainthereelforremoval;refertoRestraining

theReelforRemovingThreadedInserts(page

10).

6.Removethecutting-unitthreadedinsertforthe

rear-roller-brushdrive(Figure1)anddiscardit

(Figure2).

g032009

Figure2

1.Threadedinsert

(left-handedinsertshown)

2.Theleft-handinserthasa

grooveonthefaceofthe

inserthere.

3.Driveshaft

4.Applythread-locking

compoundhere.

Note:Left-handedinsertsareoncuttingunits

1,3,and5(Figure1).

7.Restrainthereelforinstallation;referto

RestrainingtheReelforInstallingThreaded

Inserts(page11).

8.Applythread-lockingcompoundtothedriveshaft

threads(Figure2)andinstallthedriveshaft,

torquingitto1 15to128N·m(85to95ft-lb).

2

Page 3

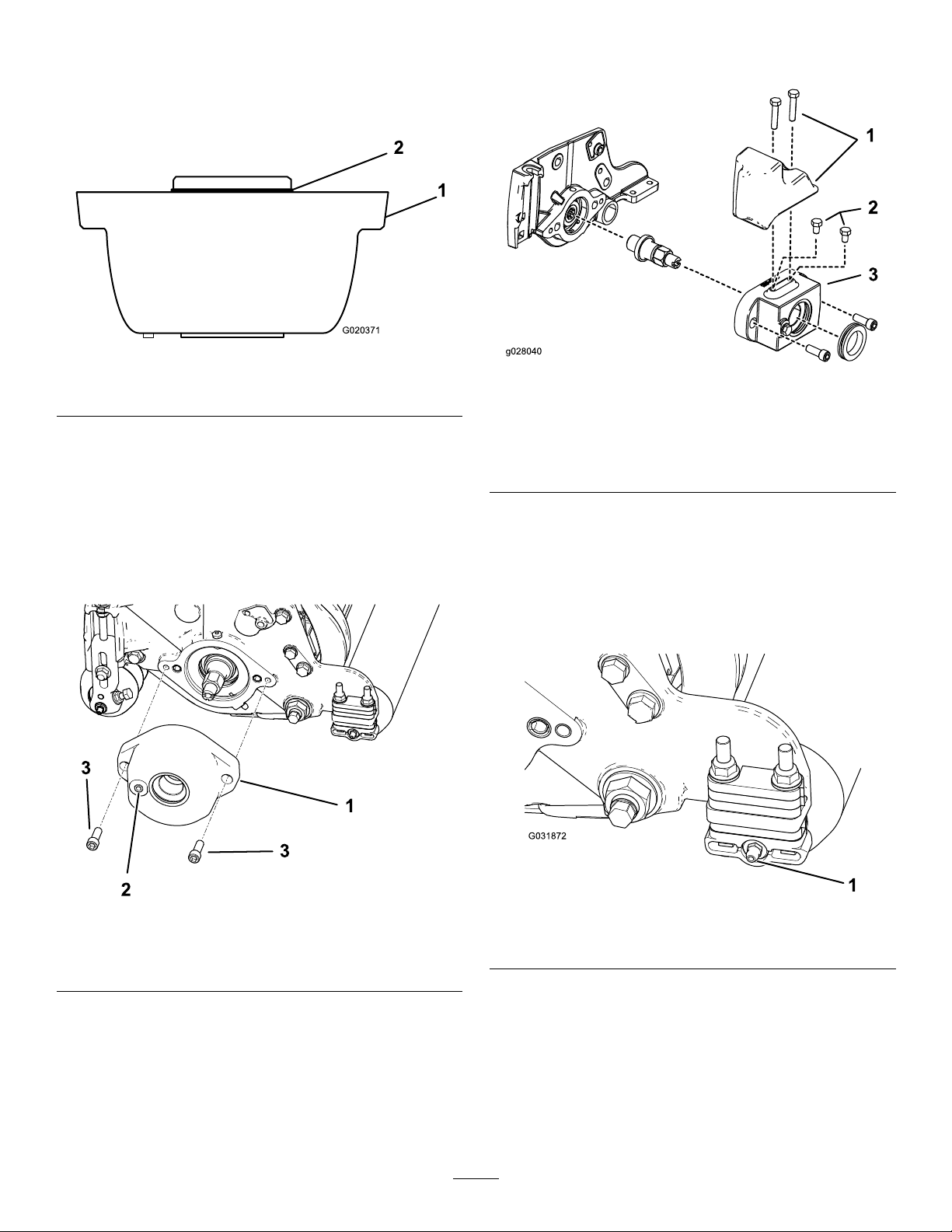

MountingtheRoller-Brush

Housing

1.EnsurethattheO-ringisinstalledonthe

roller-brushhousing(Figure3).

Figure3

1.Roller-brushhousing

2.ForModel03408only:Mounttheroller-brush

housingtothereel-bearinghousingwith2

hex-socketbolts(3/8x1inch);refertoFigure4.

2.O-ring

housingwith2bolts(5/16-18x11/2inches);

refertoFigure5.

g020371

g028040

Figure5

1.End-weightkit(Model

03413,electricreelmotor)

2.Bolts(5/16-18x1/2inch),

hydraulicreelmotor

3.Roller-brushhousing

Note:Positiontheroller-brushhousingsothat

thethreadedholeistowardthefrontofthe

cuttingunit.

Note:EnsurethattheO-ringisproperly

positionedintheroller-brushhousing.

Figure4

1.Roller-brushhousing3.Hex-socketbolt

2.Threadedhole

3.ForModel03406kitwithRM5010tractorswith

thefollowing:

•Hydraulic5-inchreelmotors,install2

bolts(5/16-18x1/2inches)ontopofthe

roller-brushhousing(Figure5).

•Electric5-inchreelmotors,installthe

end-weightkitontopoftheroller-brush

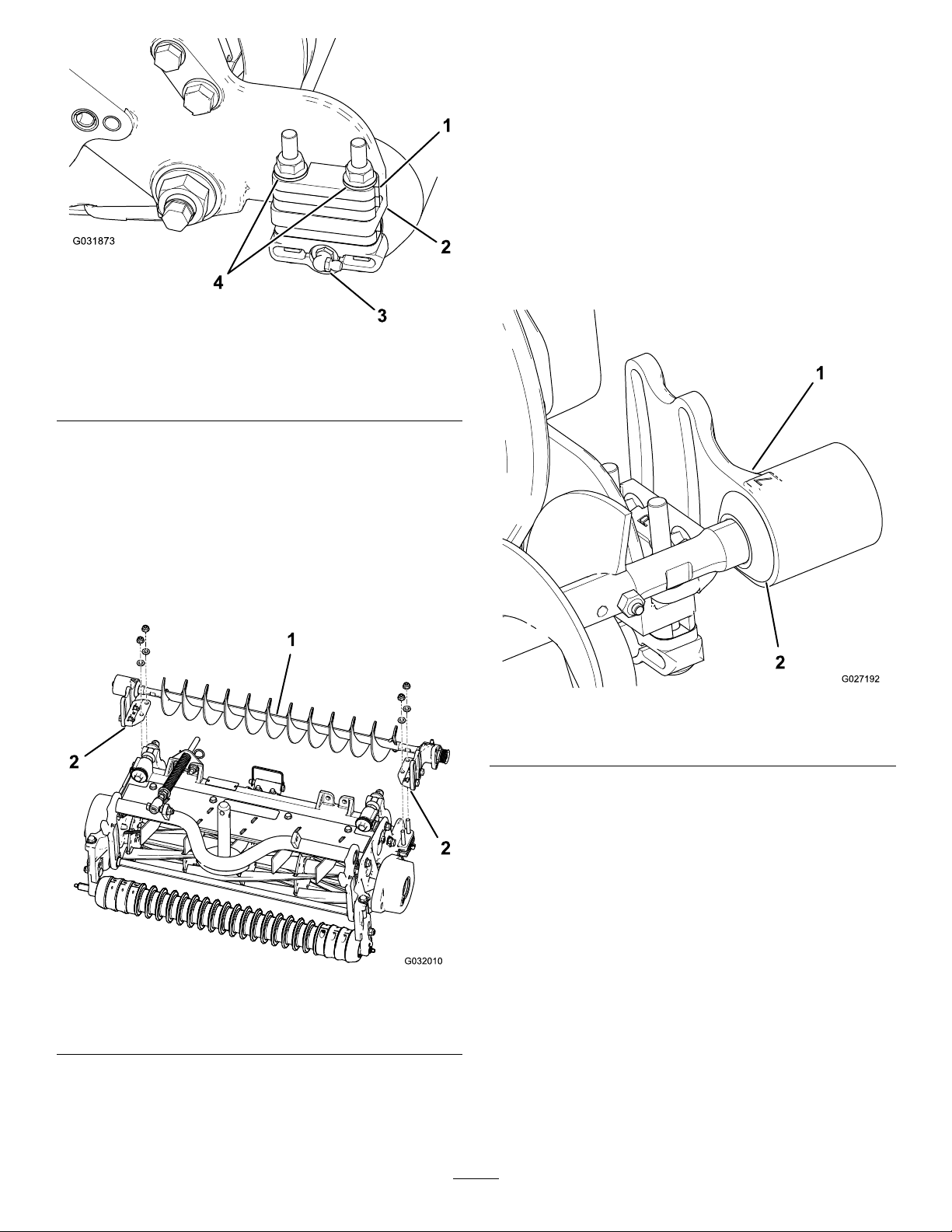

InstallingtheRollerBrush

Assembly

1.Removethegreasettingfortherollerfromthe

sideofthecuttingunitthathastheroller-brush

housing(Figure7).

g221538

1.Greasetting

Figure6

2.Installthe90-degreegreasettingsothatit

facesbackward(Figure6).

g031872

3

Page 4

Figure7

1.6mm(1/4inch)spacer3.90-degreegreasetting

2.Side-platemountingange4.Flangelocknuts(remove)

3.Removethe2angelocknutssecuringeach

rollerbrackettothesideplates(Figure7).

Note:Donotremovethebolts.Also,remove

any6mm(1/4inch)spacerspositioned

onthetopsideoftheside-platemounting

ange.

4.Positiontheleftorrightroller-brushassembly

mountingbracketsontotheroller-bracketbolts

(Figure8).

roller-brushmountingbracketsandthe

side-platemountinganges.Savethe

additional6mm(1/4inch)spacersfor

potentiallateruse.

5.Securethebrush-assemblymountingbrackets

tothecutting-unitsideplateswiththenuts

previouslyremoved.

InstallingtheRollerBrushPlate

1.Slideeachexcludersealoutwarduntilthelip

sealsareinlightcontactwitheachbearing

housing(Figure9).

g031873

Figure8

1.Leftroller-brushassembly

2.Roller-brushmounting

bracket

Important:Mounttheroller-brushassembly

mountingbracketsdirectlytothetopsurface

ofthecutting-unitside-platemounting

ange.Donotputspacersbetweenthe

g027192

Figure9

1.Bearinghousing2.Excluderseal

2.Applyacoatingofgreasetotheinnerdiameter

ofthegrommetintheroller-brushhousing

(Figure10).

g032010

4

Page 5

Figure10

Note:Theshoulderboltshouldnotclampthe

platetothehousing.

8.Checktoensurethattheroller-brushplateis

paralleltothecutting-unitsideplate.Ifitisnot

parallel,proceedasfollows:

A.Loosenthe2angelocknutssecuring

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure1 1).

B.Rotatetheroller-brushbearinghousinguntil

thebrushplateisparalleltothecutting-unit

sideplate(Figure11).

C.Tightenthe2angelocknutssecuring

g218675

theroller-brushmountingbrackettothe

cutting-unitsideplate(Figure1 1).

1.Bolt

2.Shoulderbolt

3.Grommet

4.Cleanoutanypaint

fromthethreadsusing

a5/16–18tapbefore

screwingintheshoulder

bolt.

5.Roller-brushhousing

6.Roller-brushpivotplate

assembly

3.Installtheleftorrightroller-brushpivotplate

(Figure10).

Note:Whenyouinserttheprotrusiononthe

pivotplateintothegrommetintheroller-brush

housing,ensurethatthegrommetstaysproperly

seatedinthehousing.Theroller-brushpivot

plateisproperlyseatedwhenthereisno

resistancefromtherubbergrommetanditpivots

freely.

Note:Ensurethattheidler-pulleyassemblyis

installedonthebottomasshowninFigure10.

4.Applythread-lockingcompoundtothe2bolts

(5/16x1/2inch)andusethemtomountthe

brushplatetotheroller-brushbearinghousing

(Figure10).

g027194

Figure11

1.Loosentheseboltsforpositioningtherollerbrush.

2.Loosenthesenutsformakingtheroller-brushplateparallel.

Note:Torquetheboltsto20to25N·m(15to

19ft-lb).

5.Cleanoutanypaintfromthethreadsinthe

roller-brushhousing,usinga5/16–18tap,before

screwingintheshoulderbolt(Figure10).

Important:Ifthethreadsarenotcleaned

beforetheshoulderboltisscrewedin,the

boltcouldbreak.

6.Applythread-lockingcompoundtotheshoulder

bolt(Figure10).

7.Securethebrushplatetotheroller-brush

housingwiththeshoulderbolt(Figure10).

Note:T orquetheboltto20to25N·m(15to

19ft-lb).

PositioningtheRollerBrush

1.Loosenthe2boltssecuringeachroller-brush

bearinghousingtotheroller-brushmounting

bracket(Figure11).

Note:Theboltsshouldbeloosefromthe

factory.

2.Positiontherollerbrushsothatitisjusttouching

orrestingontherearroller(Figure12).

Important:Theroller-brushshaftmustnot

contactthecutting-unitsideplate.

Important:Heavybrushcontactonthe

rollerwillcauseprematurebrushwear.

5

Page 6

Important:Iftheboltisnotproperly

torqued,theboltwillcomeloose.

Figure13

g027195

Figure12

1.Bearinghousing(some

partsnotshown)

2.Sideplate

3.Rollerbrush

4.Ensurethatthereis

clearancehere.

5.Lightcontact

6.Rearroller

7.Greasetting

Note:Theroller-brushshaftmustbeparallel

totherearroller.

Important:Positionbothroller-brush

bearinghousingssothattheyareparallel

tothegroundtoensureclearanceforthe

rear-rollergreasetting.

3.Tightenthe2boltssecuringeachroller-brush

bearinghousingtotheroller-brushmounting

brackets.

1.Driveshaft

2.Spacer

g027303

3.Drivepulley

4.Flange-headbolt—torque

to47to54N·m(35to40

ft-lb)

InstallingtheBelt

1.Installthebeltontothepulleysasfollows:

•Loopthebeltaroundthedrivepulleyand

thenoverthetopoftheidlerpulley(Figure

14).

InstallingtheDrivePulley

1.Insertthespacerontotheshaftinthebearing

housing(Figure13).

2.Insertthedrivepulleyintothespacerandonto

thedriveshaft(Figure13).

Note:Ensurethatthepulleytabsarepositioned

intheslotinthedriveshaft.

3.Securethepulleyandspacertothedriveshaft

withaange-headbolt(3/8x2inches);refer

toFigure13.

Note:Torquetheboltto47to54N·m(35to

40ft-lb).

g027196

Figure14

1.Drivepulley3.Belt

2.Idler-pulleyassembly4.Drivenpulley

•Startthebeltonthedrivenpulley(Figure

15).

•Usea9/16-inchdeep-wellsockettorotate

thebrushassemblyandguidethebeltonto

thedrivenpulley(Figure15).

6

Page 7

Figure15

g027197

Figure16

2.Slidethebeltcoverontothemountingboltsand

securethecoverwith2angenuts(Figure17).

Important:Donotovertightenthenutsas

damagetothecovermayoccur.

g020390

1.Belt

2.9/16-inchdeep-wellsocket

Important:Ensurethattheribsonthebelt

areproperlyseatedinthegroovesineach

pulleyandthatthebeltisinthecenterofthe

idlerpulley .

2.Pushdownontheidlerpulleytoensurethatthe

idler-pulleyassemblypivotsfreely.

CompletingtheInstallation

1.Checkthealignmentofthebeltandpulleysas

follows:

•Thebeltmustbeproperlytensioned

(installed)priortocheckingthealignment.

•Layastraightedgealongtheouterfaceof

thedrivepulley(Figure16).Donotlaythe

straightedgeacrossboththedrivepulleyand

thedrivenpulley.

•Theouterfacesofthedrivepulleyandthe

drivenpulleyshouldbeinlinewithin0.76

mm(0.030inch).

•Ifthepulleysarenotaligned,referto

CheckingthePulleyAlignment(page9).

•Ifthepulleysarealigned,continuewiththe

installation.

•Donotusetheidlerpulleytocheckthe

alignment.

Important:Thebeltmayfailprematurely

ifthepulleysarenotproperlyaligned.

g027198

Figure17

1.Beltcover

2.Setscrewinstalled

3.Setscrewremoved

3.Lubricatethegreasettingsoneachofthe

roller-brushbearinghousingswithNo.2lithium

grease(Figure18).Wipeoffanyexcessgrease,

especiallyaroundtheexcluderseals.

g032011

Figure18

7

Page 8

InstallingtheHigh

Height-of-CutBrush

(Optional)

Installthehighheight-of-cutbrush(soldseparately)

whentheheightofcutis2.5cm(1inch)ormore(5or

morespacersinstalledbelowthesideplatepad).

1.Ifarollerbrushisinstalledonthecutting

unit,removethe2bolts,washers,andnuts

securingthenon-drivebearinghousingtothe

bearing-housingmountingbracket(Figure19

andFigure20).

7.Clampthebrushontotheshaftwiththe2J-bolts

andnutspreviouslyremoved(Figure21).

Important:Insertthethreadedendofthe

J-boltsthroughtheouterholesofthebrush

shaftwhilehookingthecurvedendsofthe

J-boltsintotheinnerholes.

8.TorquetheJ-boltlocknutsto2to3N·m(20to

25in-lb).

Figure19

1.Non-drivebearinghousing

2.Slidethenon-drivebearinghousingandthe

excludersealoffthebrushshaft(Figure20).

Figure20

1.Non-drivebearinghousing

2.Excluderseal

3.Removethe2J-boltsandthenuts(Figure21).

4.Slidetheexistingbrushoffthebrushshaft

(Figure21).

5.Loosenthe2bolts,washers,andnutssecuring

thedrive-bearinghousingtothebearing-housing

mountingbracket(Figure21).

6.Slidethehighheight-of-cutbrushontothebrush

shaft(Figure21).

3.Brushshaft

g027200

g027202

Figure21

1.Highheight-of-cutbrush

2.J-bolts

9.Installtheexcludersealandthenon-drive

bearinghousingontothebrushshaft(Figure20).

10.Mountthenon-drivebearinghousingtothe

bearing-housingmountingbracketwiththe2

bolts,washers,andnutspreviouslyremoved.

3.Loosenthesebolts.

Note:Becarefulnottoknockthesealspring

off.

11.Tightenthe2bolts,washers,andnutssecuring

thedrive-bearinghousingtothebearing-housing

g027201

mountingbracket.

InstallingtheEndWeight

KitfortheReelmaster

5010-Hwith5-inchCutting

Units

Note:Theendweightkitisonlyrequiredforthe

Reelmaster5010–Hwith5-inchcuttingunits.

RefertotheInstallationInstructionsfortheweightkit.

8

Page 9

Maintenance

5.Ifthepulleyneedstomoveout,adda0.8mm

(0.032inch)thickwasher(Figure23).

•Ensurethatthebrushisparalleltotherollerwith

1.5mm(0.060inch)clearancetolightcontact.

•Greasethettingsevery50hoursandafterevery

washing.

•Whenreplacingarollerbrush,torquetheJ-bolts

to2to3N·m(20to25in-lb).

•Whenreplacingthebrush-shaft-drivenpulley,

torquethenutto36to45N·m(27to33ft-lb).

•Whenreplacingthebrush-drivepulley,apply242

Loctite(blue)andtorquetheboltto47to54N·m

(35to40ft-lb).

Note:Therollerbrush,theidlerbearing,andthebelt

areconsideredconsumableitems.

CheckingthePulley

Alignment

1.Thedrivenpulley(attheroller-brushshaft)can

moveinorout(Figure22).

Note:Makenoteofwhichwaythepulleyneeds

tomove.

Note:Ifthepulleyneedstomovein,remove

theexisting0.8mm(0.032inch)thickwasher.

6.Installthepulley.

Figure23

1.Locknut

2.Drivenpulley

7.Whileholdingthebrush-shaftats,securethe

drivenpulleyontheshaftwiththe3/8-16ange

nutpreviouslyremoved.

3.Washer—0.8mm(0.032

inch)thick

4.Brush-shaftats

g009077

Figure22

1.Drivenpulley3.Driven-pulleynut

2.Idlerpulleyassembly

2.Whilerotatingthereel,whichrotatesthedrive

pulley,prythebeltoffthedrivepulley(Figure22

Note:Wearapaddedgloveoruseaheavyrag

torotatethereel.

3.Removethelocknutsecuringthedrivenpulley

tothebrushshaft(Figure22orFigure23).

Note:Usea1/2-inchwrenchontheroller-brush

shaftatstokeepitfromrotating.

4.Removethedrivenpulleyfromtheshaft(Figure

23).

Note:Seatthelocknut;thentorqueitto36to

45N·m(27to33ft-lb).

8.Installthebeltontothepulleysasfollows:

A.Loopthebeltaroundthedrivepulleyand

thenoverthetopoftheidlerpulley(Figure

24).

g020303

g031875

Figure24

1.Drivenpulley3.Drivepulley

2.Idler-pulleyassembly4.Belt

B.Startthebeltonthedrivenpulley(Figure

24).

C.Usea9/16-inchdeep-wellsockettorotate

thebrushassemblyandguidethebeltonto

thedrivenpulley(Figure25).

9

Page 10

Figure25

3.Placetheprybaragainsttheweldsideofthe

reelsupportplate(Figure26).

Note:Inserttheprybarbetweenthetopofthe

reelshaftandthebacksof2reelbladessothat

thereelwillnotmove.

Important:Donotcontactthecuttingedge

ofanybladeswiththeprybar;thismay

damagethecuttingedgeand/orcauseahigh

blade.

Important:Theinsertontheleftsideof

thecuttingunithasleft-handthreads.The

insertontherightsideofthecuttingunithas

right-handthreads.

g020390

1.Belt

2.9/16-inchdeep-wellsocket

Important:Ensurethattheribsonthebelt

areproperlyseatedinthegroovesineach

pulleyandthatthebeltisinthecenterofthe

idlerpulley .

9.Checkthepulleyalignmentandadjustitif

necessary.

RestrainingtheReel

WARNING

Thecuttingreelbladesaresharpandcapable

ofamputatinghandsandfeet.

•Keepyourhandsandfeetoutsideofthe

reel.

•Ensurethatthereelisrestrainedbefore

servicingit.

RestrainingtheReelforRemoving

Figure26

1.Threadedinsertfor

removal

2.Loosentheshieldbolt.5.Reelsupportplate

3.Rearshield6.Prybarinsertedalong

4.Reelshaft

theweldsideofthereel

supportplate.

4.Restthehandleoftheprybaragainsttherear

roller.

5.Completetheremovalofthethreadedinsert

whileensuringthattheprybarstaysinplace,

thenremovetheprybar.

6.Lowertherearshieldandtightentheshield-bolt.

g280383

ThreadedInserts

1.Loosentheshield-boltontheleftsideofthe

cuttingunitandraisetherearshield(Figure26).

2.Insertalong-handledprybar(recommended

3/8"x12"withscrewdriverhandle)throughthe

backofthecuttingreel,closesttothesideofthe

cuttingunitthatyouwillbetorquing(Figure26).

10

Page 11

RestrainingtheReelforInstalling

ThreadedInserts

1.Insertalong-handledprybar(recommended

3/8"x12"withscrewdriverhandle)throughthe

frontofthecuttingreel,closesttothesideofthe

cuttingunitthatyouwillbetorquing(Figure27).

2.Placetheprybaragainsttheweldsideofthe

internalcuttingreelreinforcement(Figure27).

Note:Theprybarshouldcontactabladeatthe

front,thereelshaft,andabladeatthebackof

thebackofthereel,lockingitinplace.

Important:Donotcontactthecuttingedge

ofanybladeswiththeprybar;thismay

damagethecuttingedgeand/orcauseahigh

blade.

Important:Theinsertontheleftsideof

thecuttingunithasleft-handthreads.The

insertontherightsideofthecuttingunithas

right-handthreads.

Figure27

1.Threadedinsertfor

installation

2.Reelshaft

3.Weldsideofsupportplate

4.Prybar

3.Restthehandleoftheprybaragainsttheroller

4.Pertheinsert’sinstallationinstructionsand

torquerequirements,completetheinstallationof

thethreadedinsertwhileensuringthatthepry

barstaysinplace,thenremovetheprybar.

g280384

11

Page 12

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

SerialNo.

03406

03408

—

—

ProductDescriptionInvoiceDescription

RearRollerBrushKit,

Reelmaster5010-HSeries

CuttingUnitwith5inReel

RearRollerBrushKit,

Reelmaster5010-HSeries

CuttingUnitwith7inReel

RRBONL YKIT5INCU

[RM5010]

RRBONL YKIT7INCU

[RM5010]

GeneralDescription

RollerBrushKit

RollerBrushKit

Directive

2006/42/EC

2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

JohnHeckel

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

February1,2019

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

Loading...

Loading...