Page 1

PowerClear

ModelNo.38754—SerialNo.400000000andUp

®

721R-CCommercialSnowthrower

FormNo.3428-994RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisitdesigned

forclearinggravelsurfaces.Usingthisproductfor

purposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

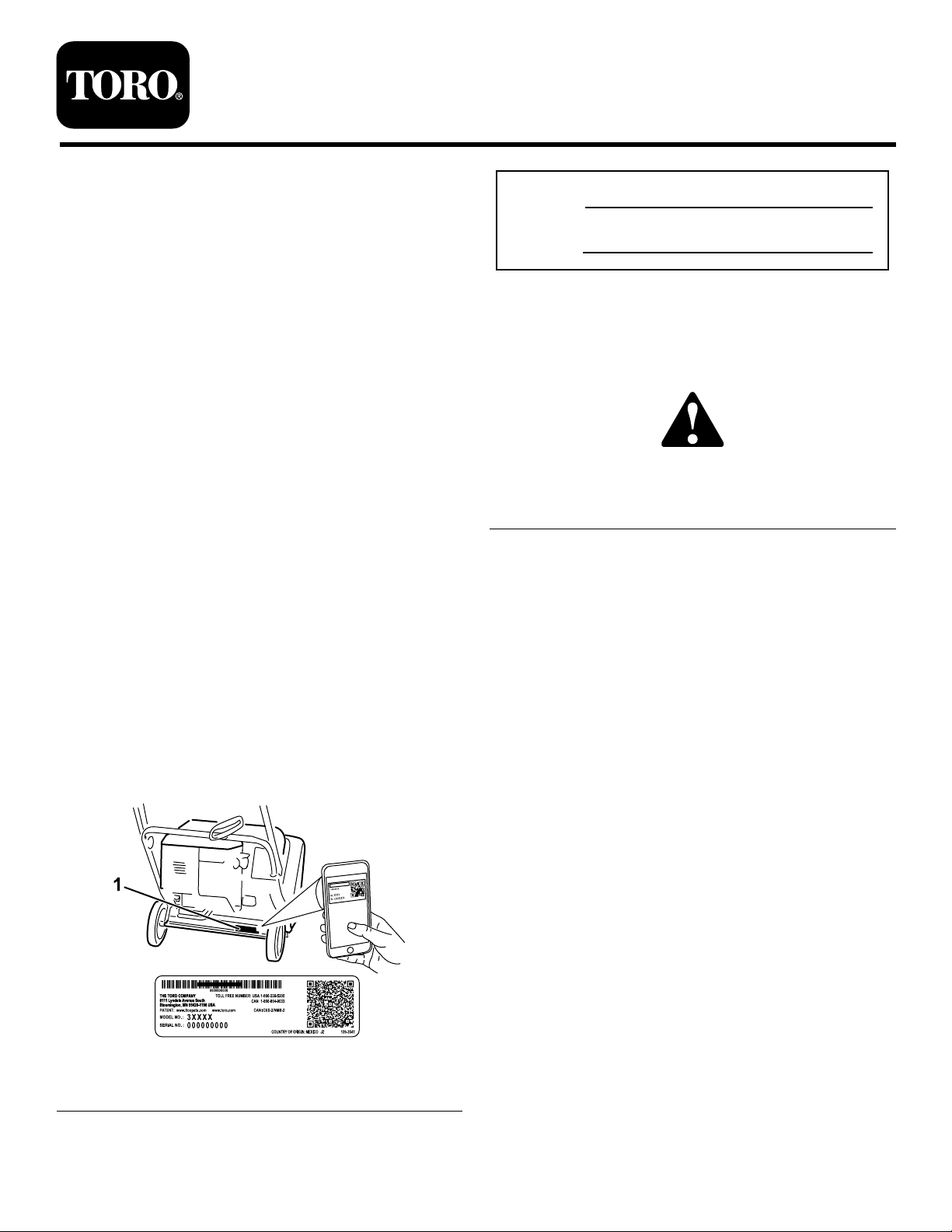

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

g291503

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

©2018—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedinMexico

AllRightsReserved

*3428-994*A

Page 2

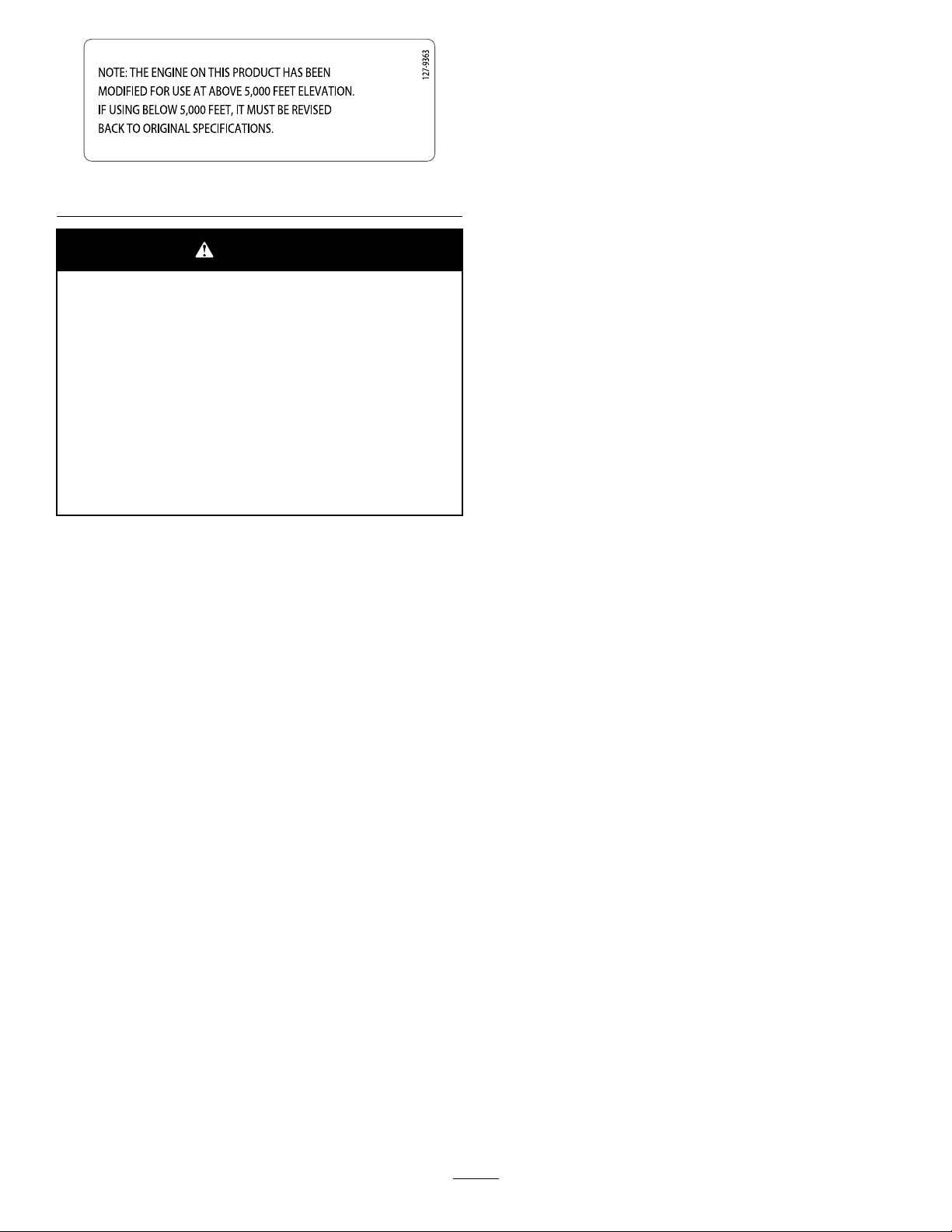

Figure3

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Contents

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

decal127-9363

SafetyandInstructionalDecals..........................4

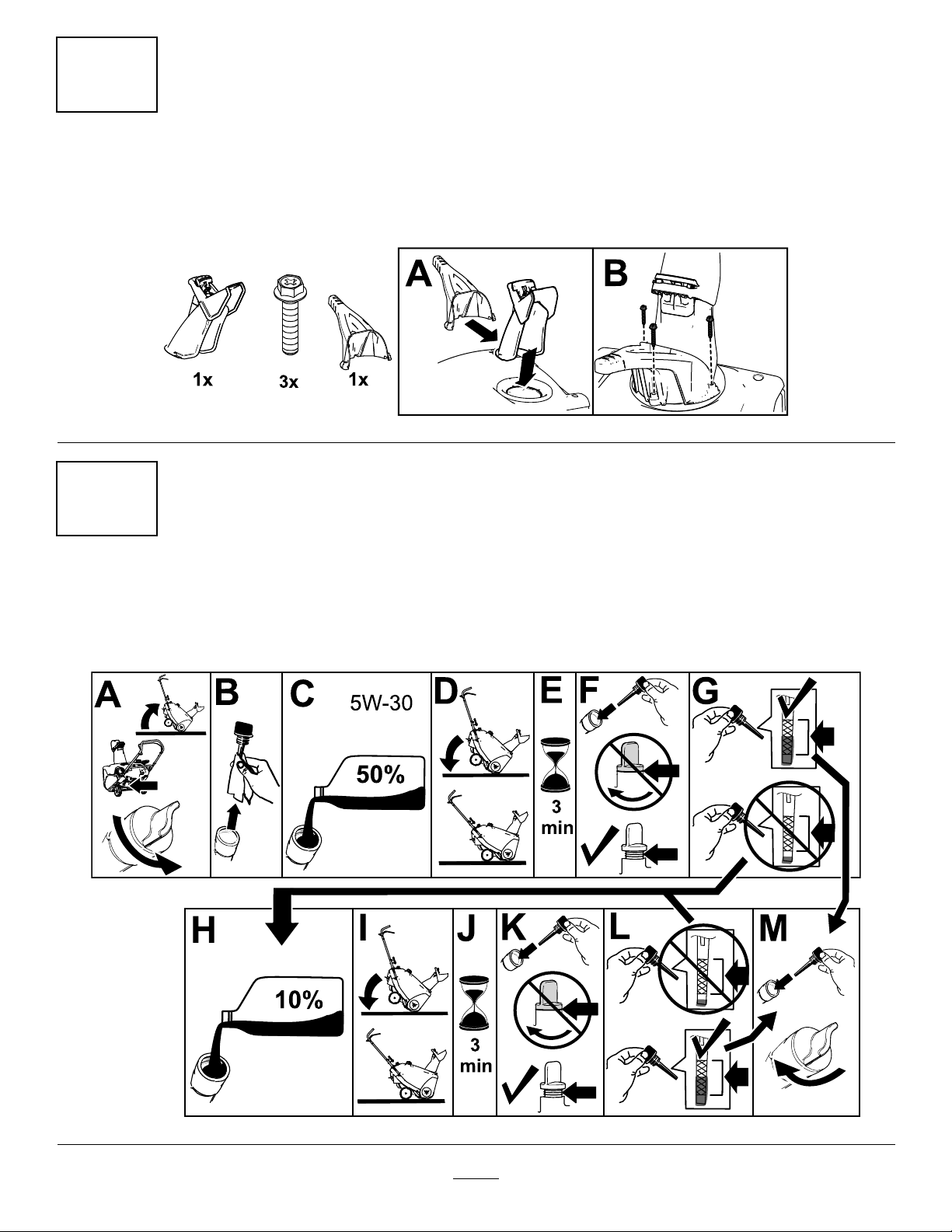

Setup........................................................................5

1UnfoldingtheHandle.......................................5

2InstallingtheRecoil-StartGuideand

Rope...............................................................5

3InstallingtheDischargeChute.........................5

4FillingtheEnginewithOil.................................6

5AdjustingtheControlCable..............................7

ProductOverview.....................................................8

Specications....................................................8

Attachments/Accessories...................................8

Operation..................................................................9

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

FillingtheFuelT ank............................................9

CheckingtheEngine-OilLevel..........................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingtheEngine............................................11

EngagingtheRotorBlades...............................12

DisengagingtheRotorBlades..........................12

ShuttingOfftheEngine.....................................12

AdjustingtheDischargeChuteandChute

Deector.......................................................12

ClearingaCloggedDischargeChute................13

OperatingTips.................................................13

AfterOperation....................................................13

AfterOperationSafety......................................13

PreventingFreeze-upafterUse........................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

MaintenanceSafety..........................................14

CheckingandAdjustingtheControl

Cable............................................................14

InspectingtheRotorBlades..............................15

ChangingtheEngineOil...................................16

ReplacingtheSparkPlug.................................17

ReplacingtheDriveBelt...................................18

Storage...................................................................19

StorageSafety..................................................19

StoringtheMachine..........................................19

2

Page 3

Safety

Thismachinehasbeendesignedinaccordancewith

ANSI/OPEIB71.3specications.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

•Shutofftheenginewheneveryouleavethe

operatingpositionforanyreason.

•Donotputyourhandsorfeetnearmovingparts

onthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepclearofanydischargeopening.Keep

bystanders,especiallysmallchildren,outofthe

operatingarea.

•Neverallowchildrentooperatethemachine.

3

Page 4

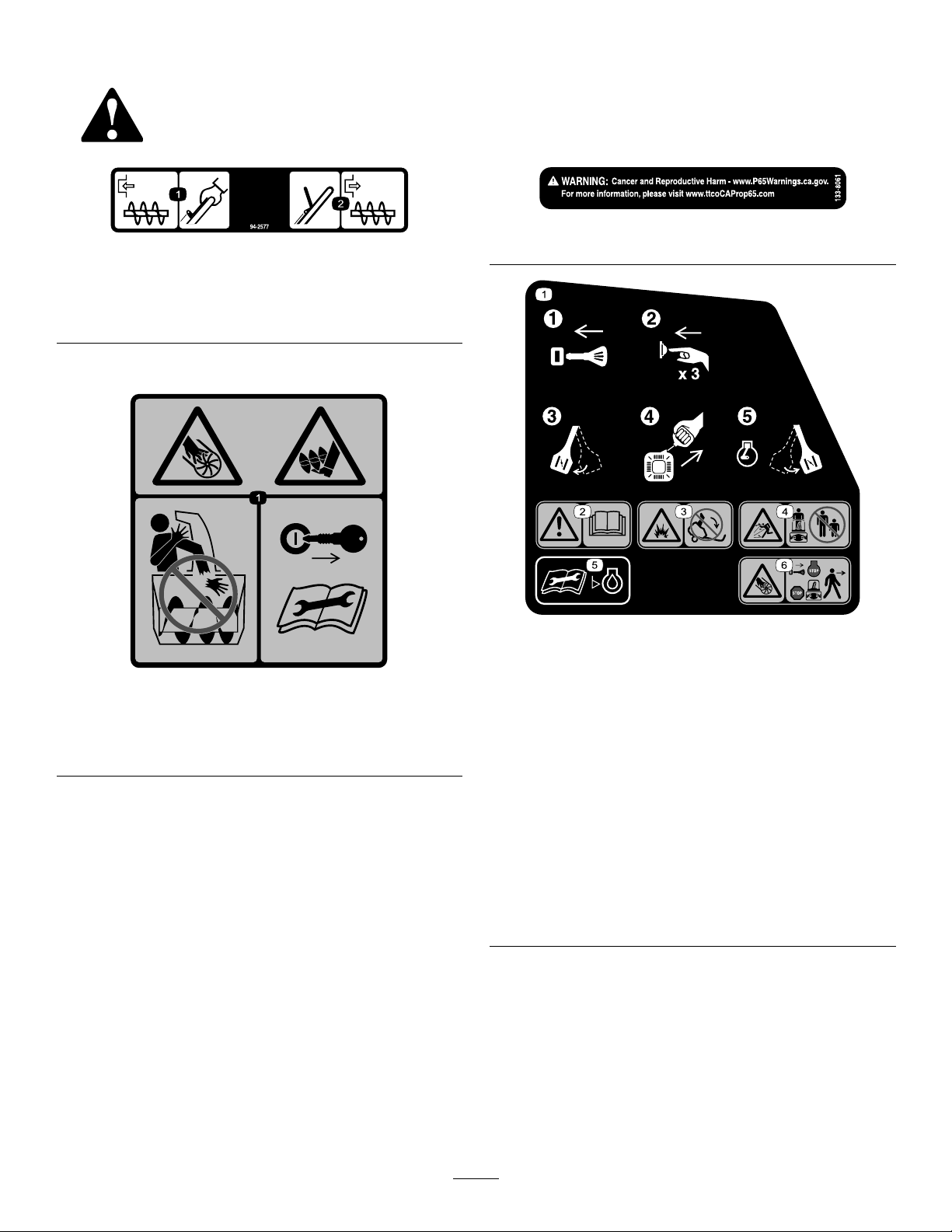

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

94-2577

1.Toengagetherotorblades,holdthecontrolbaragainst

thehandle.

2.Todisengagetherotorblades,releasethecontrolbar.

Orderpartno.117-9121

decal133-8061

decal94-2577

133-8061

115-5698

1.Cutting/dismembermenthazard,impellerandauger—do

notplaceyourhandinthechute;removethekeyandread

theOperator’sManualbeforeperformingmaintenance.

decal139-3505

139-3505

decal115-5698

1.Insertthekey,pressthe

primer3times,movethe

chokelevertotheleft,pull

therecoil-starthandle,and

oncetheengineisrunning

movethechokeleverto

theright.

2.Warning—readthe

Operator’sManual.

3.Explosionhazard—donot

tipthemachine.

4.Thrownobject

hazard—keepbystanders

away.

5.ReadtheOperator’s

Manualbeforeservicing

theengineoillevel.

6.Cutting/dismemberment

hazardofthehand,

rotor—shutofftheengine,

removethekey ,andwait

forallmovingpartsto

stopbeforeleavingthe

machine.

4

Page 5

Setup

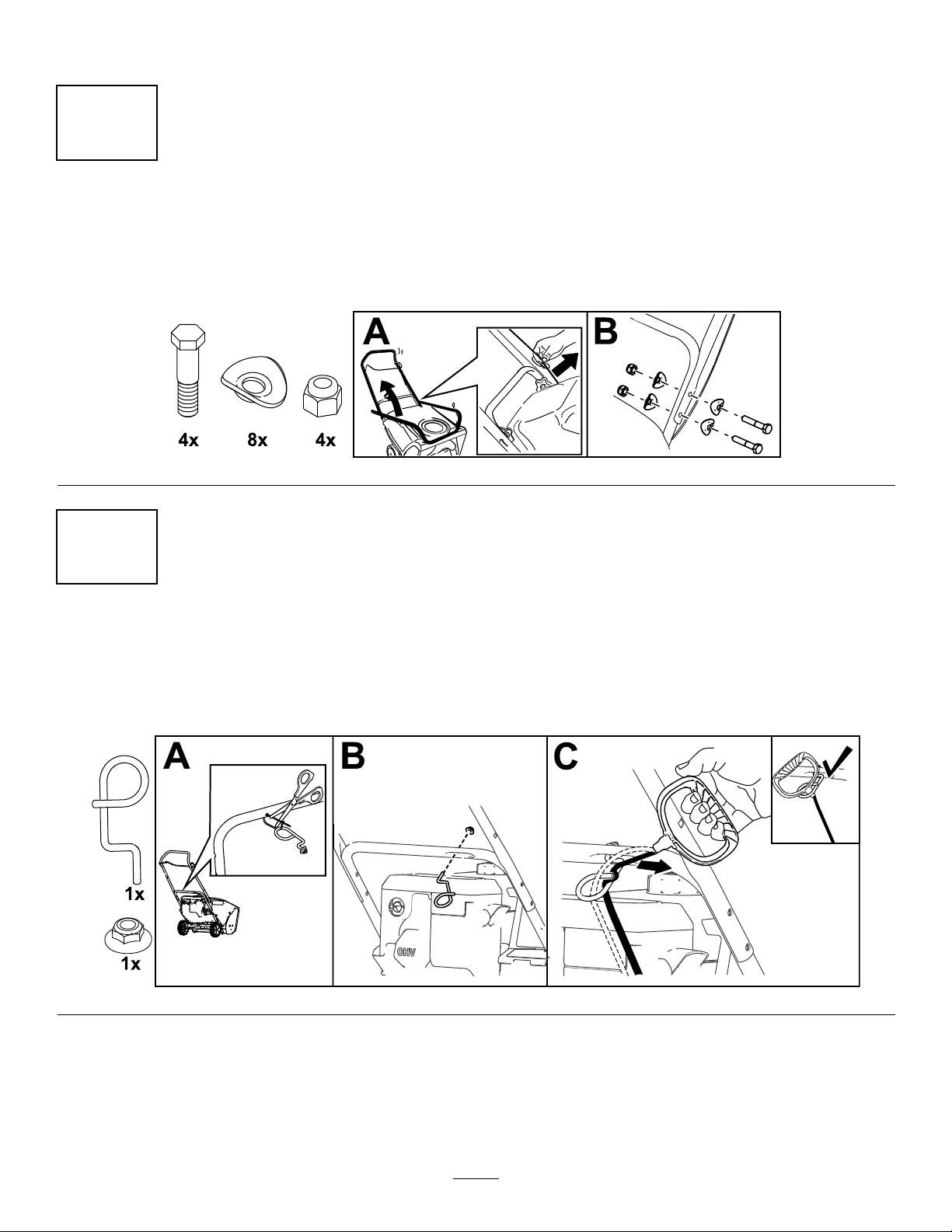

1

UnfoldingtheHandle

NoPartsRequired

Procedure

g287662

2

InstallingtheRecoil-StartGuideandRope

NoPartsRequired

Procedure

g286483

5

Page 6

3

InstallingtheDischargeChute

NoPartsRequired

Procedure

4

g287665

FillingtheEnginewithOil

NoPartsRequired

Procedure

g286445

6

Page 7

5

AdjustingtheControlCable

NoPartsRequired

Procedure

RefertoAdjustingtheControlCable(page15).

7

Page 8

ProductOverview

Figure8

1.Chutedeector5.Controlbar

2.Chute-deectortrigger6.Oil-drainplug

3.Chutehandle7.Oilll/dipstick

4.Fuel-tankcap

Specications

ModelWeightLengthWidthHeight

38kg122cm54cm107cm

38754

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

g291536

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

(84lb)(48

inches)

(21

inches)

(42

inches)

Figure9

1.Recoil-starthandle5.Key

2.Electric-startplug-in

(electric-startmodelsonly)

3.Electric-startbutton

(electric-startmodels

only)

4.Choke

g280282

6.Primer

7.Fuel-tankcap

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Inspecttheelectricalcordbeforepluggingitinto

apowersource.Ifthecordisdamaged,replace

it.Unplugthepowercordwheneveryouarenot

startingthemachine.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Donotllabovethebottomofthefueltankneck

(Figure10).

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

g216203

Figure10

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,youmayusefuelstabilizer/conditioner

inthemachineatalltimestokeepthefuelfresh

longerwhenusedasdirectedbythefuel-stabilizer

manufacturer.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

9

Page 10

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine-oillevelandaddoilifnecessary.

Figure11

g293393

10

Page 11

DuringOperation

DuringOperationSafety

GeneralSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastick.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Exerciseextremecautionwhenoperatingthe

machineonaslope.

•Lookbehindandusecarewhenbackingupthe

machine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingthe

machineonwalksorroads.Stayalertforhidden

hazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

removethekey,andinspectthemachinefor

damage.Repairanydamagebeforestartingthe

machine.

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors;exhaustfumesare

dangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeclearingorunclogging

thecollector,rotor,ordischargechute,andwhen

makinganyrepairs,adjustments,orinspections.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

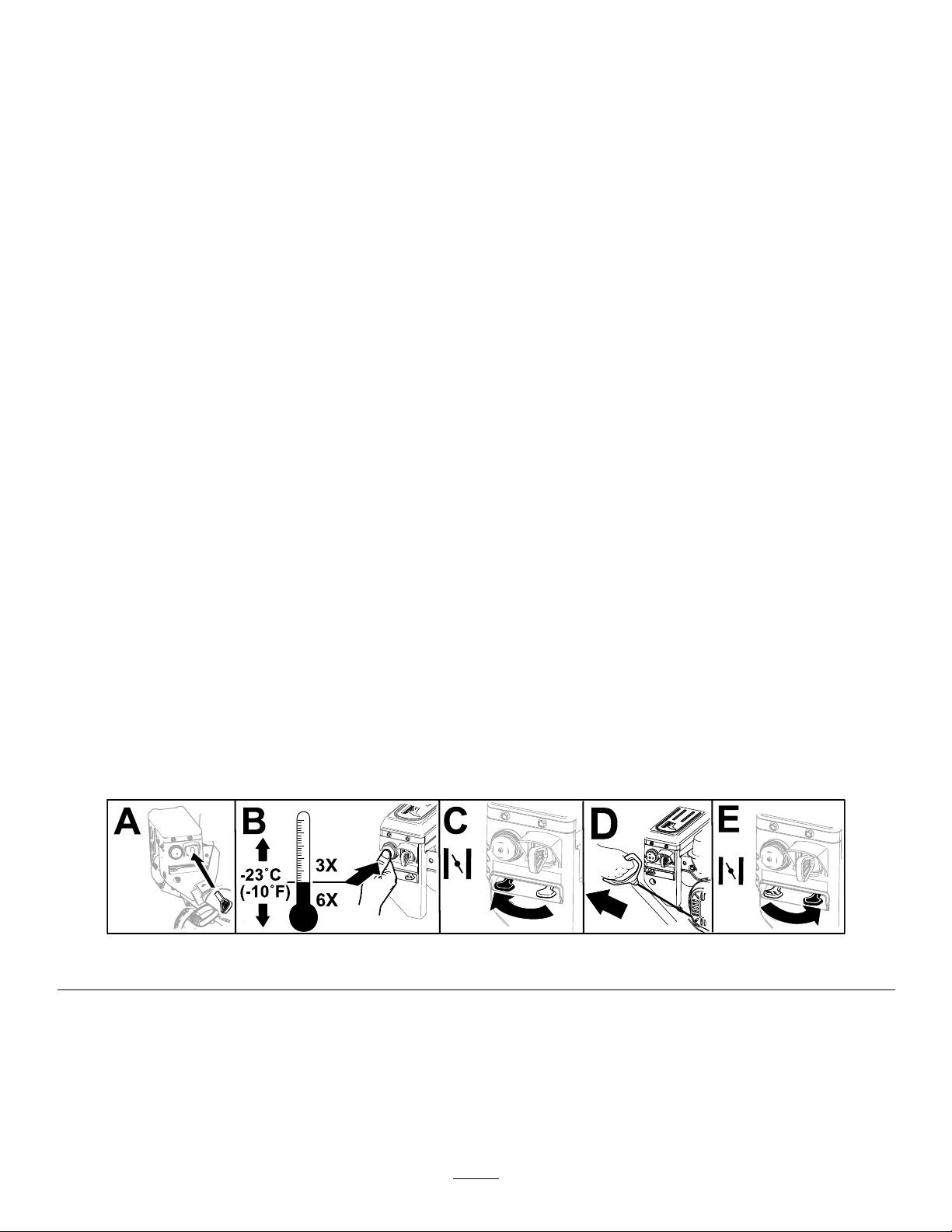

StartingtheEngine

Note:Removeyourglovewhenyoupushintheprimersothataircannotescapefromtheprimerhole.

Important:Donotusetheprimerorthechokeiftheenginehasbeenrunningandishot.Excessive

primingmayoodtheengineandpreventitfromstarting.

Figure12

g280295

11

Page 12

EngagingtheRotorBlades

ShuttingOfftheEngine

Toengagetherotorblades,holdthecontrolbar

againstthehandle(Figure13).

Figure13

DisengagingtheRotor

Blades

Todisengagetherotorblades,releasethecontrolbar

(Figure14).

Toshutofftheengine,removethekeyfromthe

ignition.

AdjustingtheDischarge

ChuteandChuteDeector

Toraiseorlowertheangleofthechutedeector,

pressthetriggeronthechutedeectorandmovethe

chutedeectorupordown.

Toadjustthedischargechute,movethechutehandle.

g216251

Figure14

g278630

Figure15

1.Chutehandle

g006457

2.Trigger

12

Page 13

ClearingaClogged

DischargeChute

AfterOperation

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstoensurethattherotorblades

havestoppedrotating.

•Alwaysuseaclean-outtool;neveruseyourhands.

OperatingTips

WARNING

Therotorbladescanthrowstones,toys,

andotherforeignobjectsandcauseserious

personalinjurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattherotorbladescouldpickup

andthrow.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Overlapeachswathtoensurecompletesnow

removal.

•Dischargethesnowdownwindwheneverpossible.

•Ifthemachinedoesnotpropelitselfforwardon

slipperysurfacesorinheavysnow,pushforward

onthehandle,butallowthemachinetoworkat

itsownpace.

•Themachinemayleaverubbermarksonnew

brushedorlight-coloredconcrete.Testonan

inconspicuouslocationbeforeuse.Thesemarks

arenotpermanent.

AfterOperationSafety

GeneralSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertoStorage(page19)forimportant

information.

•Runthemachineafewminutesafterthrowing

snowtopreventfreeze-upofthecollectorand

rotor.

PreventingFreeze-upafter

Use

•Lettheenginerunforafewminutestoprevent

movingpartsfromfreezing.Shutofftheengine,

waitforallmovingpartstostop,andremoveice

andsnowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthe

chute.

•Rotatethedischargechuteleftandrighttofree

itfromanyicebuildup.

•Withthekeyremoved,pulltherecoil-starthandle

severaltimesorconnecttheelectricalcordto

apowersourceandthemachineandpushthe

electric-startbuttononcetopreventtherecoil

starterand/ortheelectricstarterfromfreezingup

(electric-startmodelsonly).

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.Ifyou

havedifcultyoperatinganycontrolorpart,start

theengineandletitrunforafewminutes.

13

Page 14

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst2hours

Beforeeachuseordaily

Every100hours

Yearly

MaintenanceProcedure

•Checkthecontrolcableandadjustitifnecessary.

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary.

•Replacethesparkplug.

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Shutofftheengine,removethekey ,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

g006401

Figure16

1.Controlbar2.2mmto3mm(1/16inch

to1/8inch)gap

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineTororeplacementparts

andaccessories.

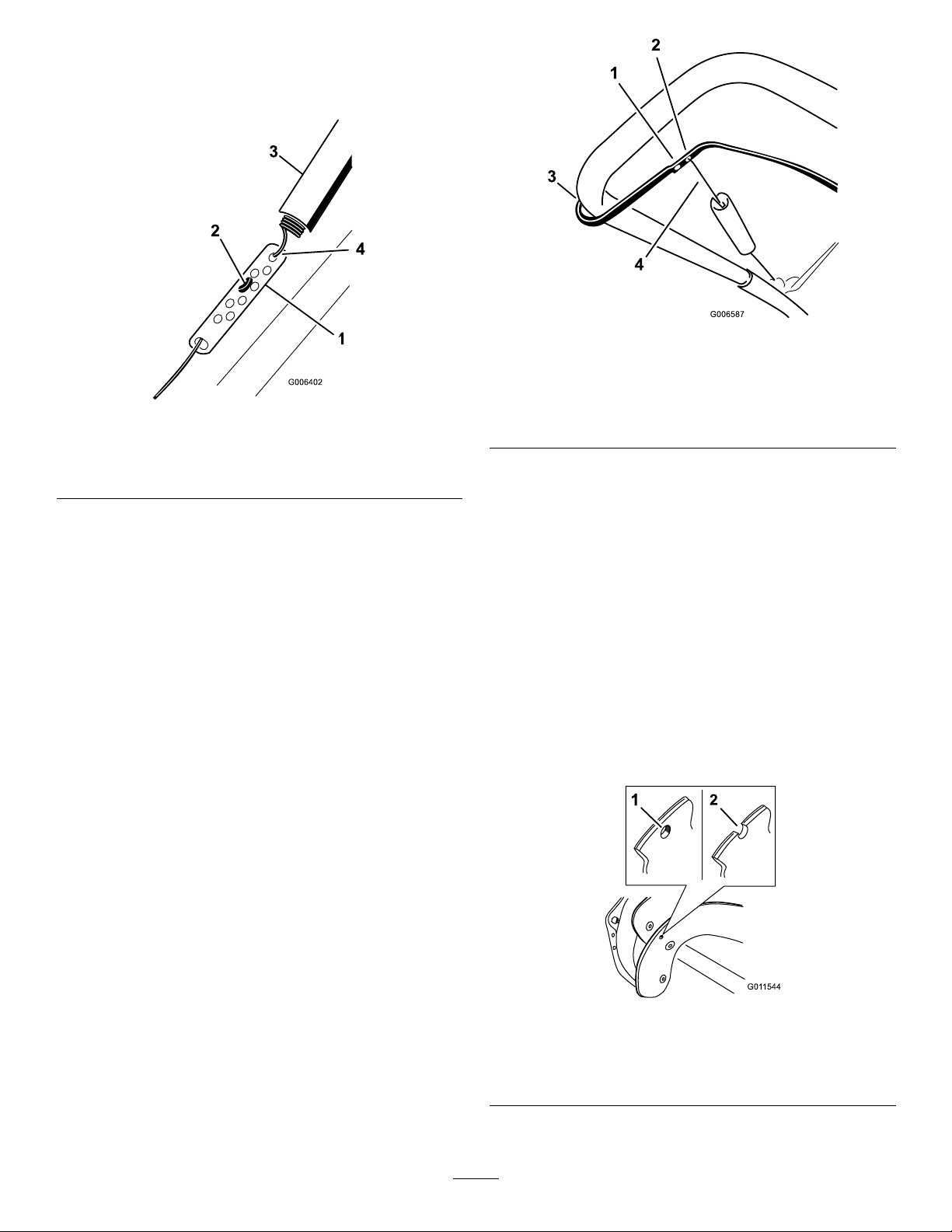

CheckingandAdjustingthe

ControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Checkthe

controlcableandadjustitif

necessary.

Yearly—Checkthecontrolcableandadjustit

ifnecessary .

Movethecontrolbarbacktowardthehandleto

removetheslackinthecontrolcable(Figure16).

Note:Ensurethata2to3mm(1/16to1/8inch)

gapexistsbetweenthecontrolbarandthehandle

(Figure16).

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

14

Page 15

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespring

fromtheadjusterlink(Figure17).

g006587

Figure18

Figure17

1.Adjusterlink

2.Z-tting

3.Springcover

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkand

cabletomakeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeon

theadjusterlinkasneededtoobtainthe2to3

mm(1/16to1/8inch)gapbetweenthecontrol

barandthehandle(Figure16).

Note:MovingtheZ-ttinghigherdecreasesthe

gapbetweenthecontrolbarandthehandle;

movingitlowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethe

springcoverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingthe

ControlCable(page14).

1.Removetheupperendof

springfromthishole.

g006402

2.Inserttheupperendof

springintothishole.

3.Pivotpoint

4.Upperendofspring

Note:Thebeltmayslip(squeal)inwet

conditions;todryoutthedrivesystem,startthe

rotorandrunitwithoutaloadfor30seconds.

InspectingtheRotorBlades

ServiceInterval:Y early—Inspecttherotorblades

andhaveanAuthorizedService

Dealerreplacetherotorbladesand

scraperifnecessary .

Beforeeachsession,inspecttherotorbladesfor

wear.Whenarotor-bladeedgehasworndownto

thewear-indicatorhole,haveanAuthorizedService

Dealerreplacetherotorbladesandthescraper

(Figure19).

Note:Afterextendeduse,thedrivebeltmay

wearandloseitsproperbelttension.Ifthedrive

beltslips(continuouslysqueals)underaheavy

load,disconnectthespringfromtheadjustorlink

andmovetheupperendofthespringtothehole

thatisfurtherfromthepivotpointinthecontrol

bar(Figure18).Thenconnectthespringtothe

adjustorlinkandadjustthecontrolcable.

1.Thewear-indicatorholeis

intact;youdonotneedto

replacetherotorblades.

15

g011544

Figure19

2.Thewear-indicatorholeis

exposed;replacetherotor

bladesandscraper.

Page 16

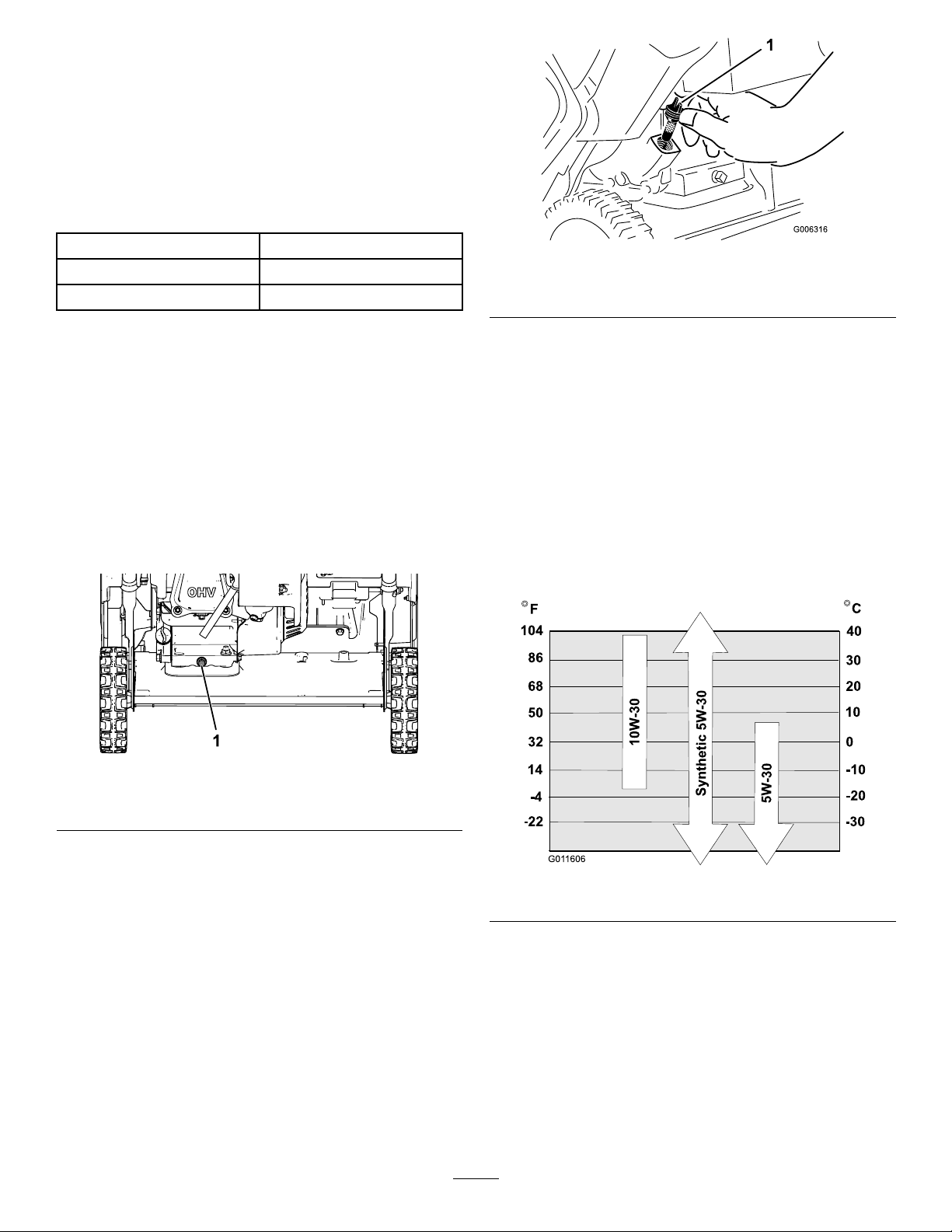

ChangingtheEngineOil

ServiceInterval:Aftertherst2hours

Yearly

Ifpossible,runtheengineforafewminutesbefore

changingtheoiltowarmit.Warmoilowsbetterand

carriesmorecontaminants.

EngineOilSpecications

Engineoilcapacity

OilviscosityRefertoFigure22.

APIserviceclassicationSJorhigher

0.6L(20oz)*

*Thereisresidualoilinthecrankcaseafteryoudrain

theoil.Donotpourtheentirecapacityofoilintothe

crankcase.Fillthecrankcasewithoilasdirectedin

thefollowingsteps.

1.Siphonthefuelfromthefueltankintoan

approvedfuelcontainer,orruntheengineuntil

itshutsoff.

2.Movethemachinetoalevelsurface.

3.Placeanoil-drainpanundertheoil-drainplug,

removetheplug,andtipthemachinebackward

anddraintheusedoilinthepan(Figure20).

g006316

Figure21

1.Dipstick

8.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

Note:Y oumaytipthemachineforward(handle

up)tomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingposition

beforecheckingtheoillevel.

Important:Donottipthemachineallthe

wayforwardontoitsnose,orfuelmayleak

outofthemachine.

UseFigure22belowtoselectthebestoil

viscosityfortheoutdoortemperaturerange

expected.

Figure20

1.Oil-drainplug

4.Afterdrainingtheusedoil,returnthemachineto

theoperatingposition.

5.Installtheoil-drainplugandtightenitsecurely.

6.Cleanaroundtheoilll/dipstick.

7.Unscrewthedipstickandremoveit(Figure21).

g286519

g011606

Figure22

16

Page 17

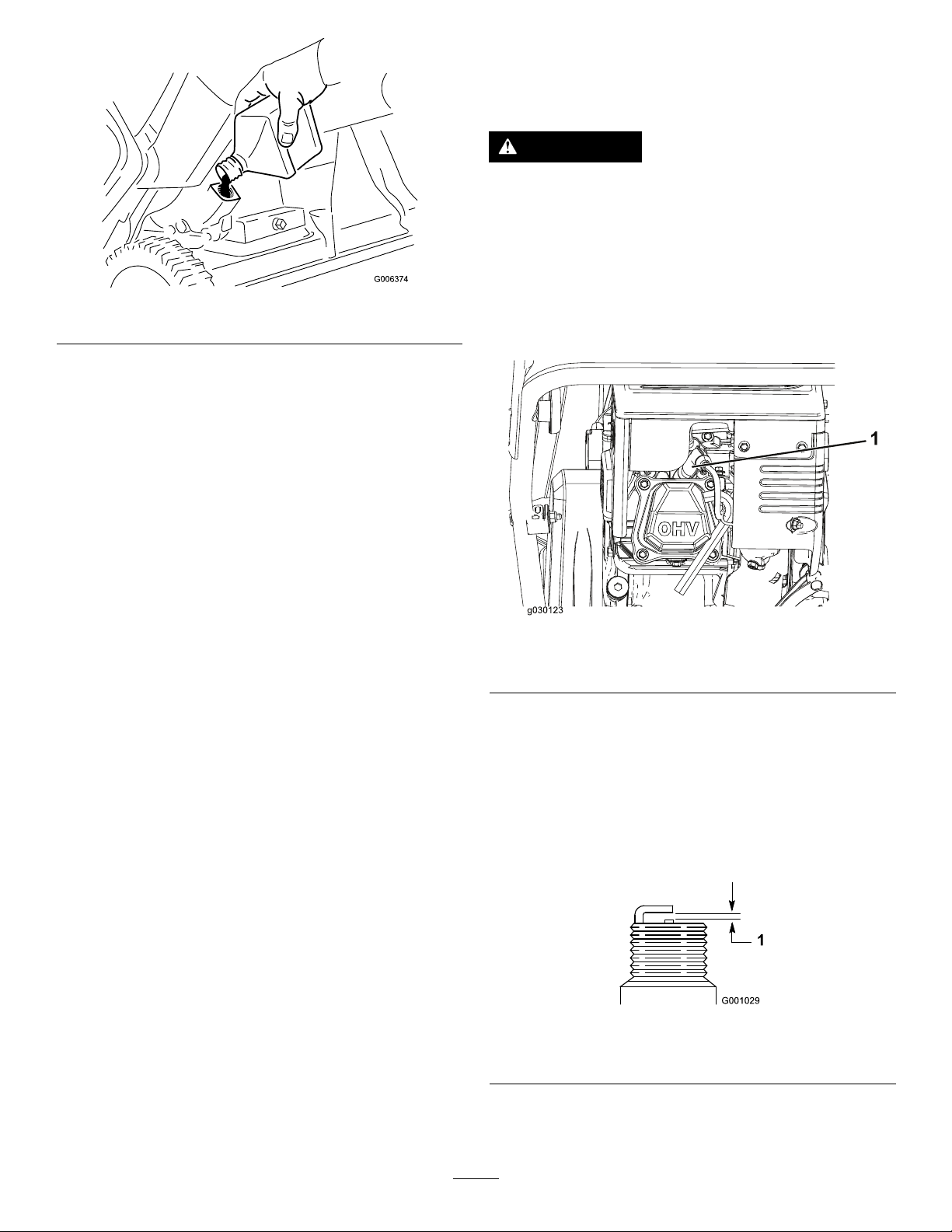

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

Figure23

9.Wait3minutesfortheoiltosettleintheengine.

10.Wipethedipstickcleanwithacleancloth.

11.Withthemachineintheoperatingposition,

insertthedipstickintotheoil-lltube,butdonot

screwitin,thenremovethedipstick.

12.Readtheoillevelonthedipstick.

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilinto

theoil-lltube,wait3minutes,andrepeat

steps10through12untiltheoillevelonthe

dipstickiscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

13.Installthedipstickintotheoil-lltubesecurely.

14.Recycletheusedoilproperly.

g006374

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure24).

g030123

Figure24

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

3.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextension

toremovethesparkplug.

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure25.

Figure25

1.0.76mm(0.030inch)

17

g001029

Page 18

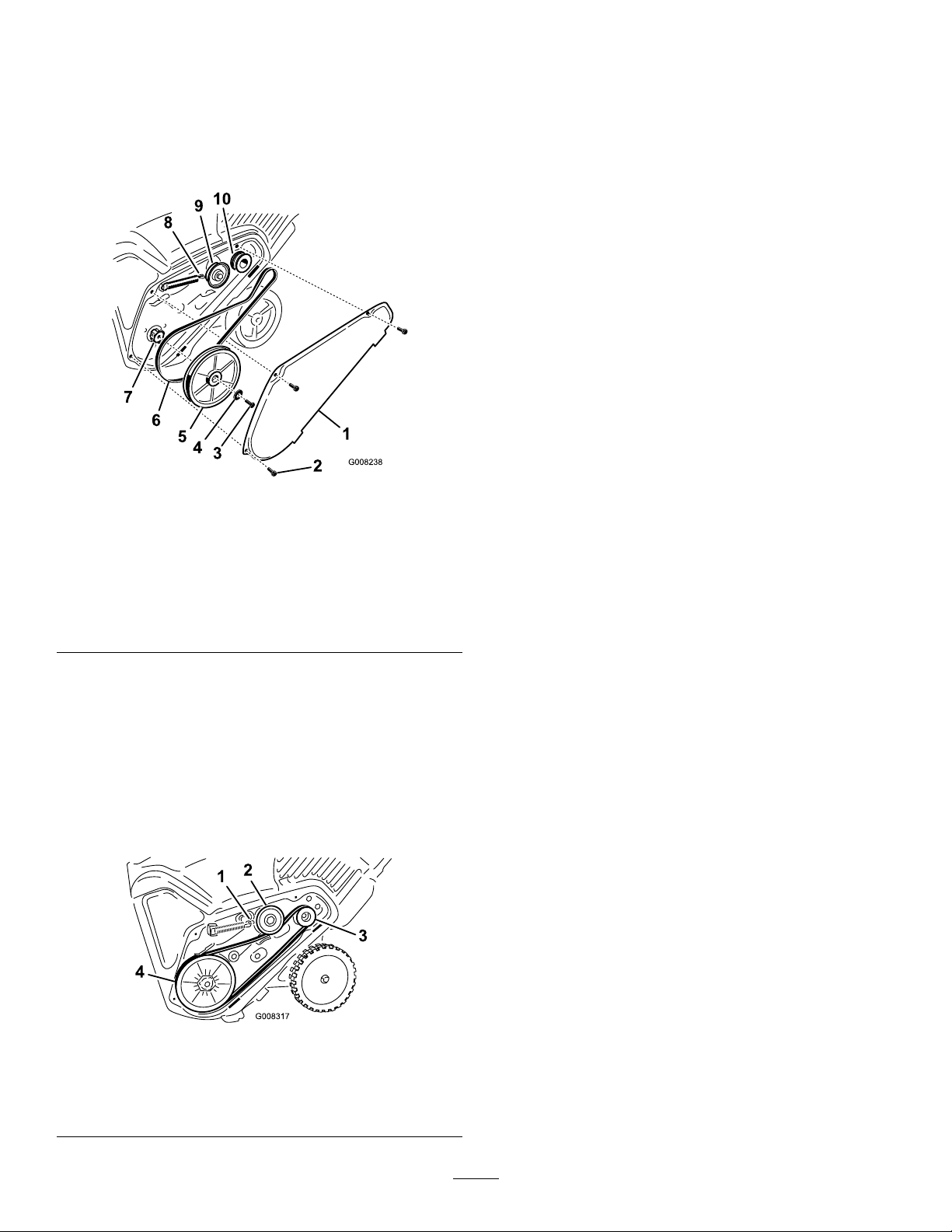

ReplacingtheDriveBelt

Ifthedrivebeltbecomesworn,oil-soaked,excessively

cracked,frayed,orotherwisedamaged,replacethe

belt.

1.Removethedrive-beltcoverbyremovingthe3

boltsasshowninFigure26.

Figure26

Note:Routethenewdrivebeltrstaroundthe

enginepulley,thentheidlerpulley,andnally

aroundthelooserotorpulleypositionedjust

abovetherotorshaft(Figure26).

6.Installtherotorpulleyontotherotorshaft(Figure

26).

7.Installthecurvedwasherandtherotor-pulley

boltandtightenthemsecurely(Figure26).

Note:Theconcavesideofthecurvedwasher

goesagainsttheoutsideofthepulley.

8.Installthebrakespringontotheidlerarm(Figure

27).

9.Installthedrive-beltcoverwiththeboltsthatyou

removedinstep1.

Note:Ensurethatthedrivebeltisproperly

adjustedandoperating;refertoCheckingthe

ControlCable(page14)andAdjustingthe

ControlCable(page15).

g008238

1.Drive-beltcover6.Drivebelt

2.Bolt(3)7.Rotorshaft

3.Rotor-pulleybolt

4.Curvedwasher

5.Rotorpulley10.Enginepulley

8.Brakespring(unhookfrom

idlerarmhere)

9.Idlerpulley

2.Unhookthebrakespringfromtheidlerarmto

releasethebelttension(Figure26).

3.Removethescrewandcurvedwasherthat

holdstherotorpulley(Figure26).

4.Removetherotorpulleyandthedrivebelt

(Figure26).

5.Installthenewdrivebelt,routingitasshownin

Figure27.

Figure27

1.Brakespring(installon

idlerarmhere)

2.Idlerpulley4.Rotorpulley

3.Enginepulley

g008317

18

Page 19

Storage

12.Withthekeyremoved,pulltherecoil-start

handleslowlytodistributetheoilontheinside

ofthecylinder.

StorageSafety

•Shutofftheengine,removethekey ,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Fuelfumesarehighlyammable,explosive,and

dangerousifinhaled.Ifyoustoretheproductinan

areawithanopename,thefuelfumesmayignite

andcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,andother

appliances.

•Donottipthemachineeitherforwardorbackward

withfuelinthefueltank;otherwise,fuelmayleak

outofthemachine.

•Donotstorethemachinewithitshandletipped

downontotheground;otherwise,oilmayleakinto

theenginecylinderandontotheground,andthe

enginemaynotstart.

13.Cleanthemachine.

14.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

15.Tightenanyloosefasteners.Repairorreplace

anydamagedparts.

16.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.Allowthe

enginetocoolbeforestoringthemachineinany

enclosure.

StoringtheMachine

1.Onthelastrefuelingoftheseason,addfuel

stabilizertofreshfuelasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotstorefuellonger

thanthatsuggestedbythefuel-stabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Shutofftheengine,allowittocool,andsiphon

thefueltankorruntheengineuntilitshutsoff.

4.Starttheengineandrunituntilitshutsoff.

5.Chokeorprimetheengine,startitathirdtime,

andruntheengineuntilitdoesnotstart.

6.Drainthefuelinthecarburetorthroughthe

carburetor-drainboltintoanapprovedgasoline

container.

7.Disposeofunusedfuelproperly.Recycleit

accordingtolocalcodes.

8.Whiletheengineisstillwarm,changetheengine

oil.RefertoChangingtheEngineOil(page16).

9.Removethesparkplug.

10.Squirt10ml(2tsp)ofoilintothespark-plughole.

11.Installthesparkplugbyhandandthentorqueit

to27to30N∙m(20to22ft-lb).

19

Page 20

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover ,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.Toroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...