Page 1

PowerClear

G016241

ModelNo.38751—SerialNo.314000001andUp

®

721R-CCommercialSnowthrower

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3379-508RevA

Operator'sManual

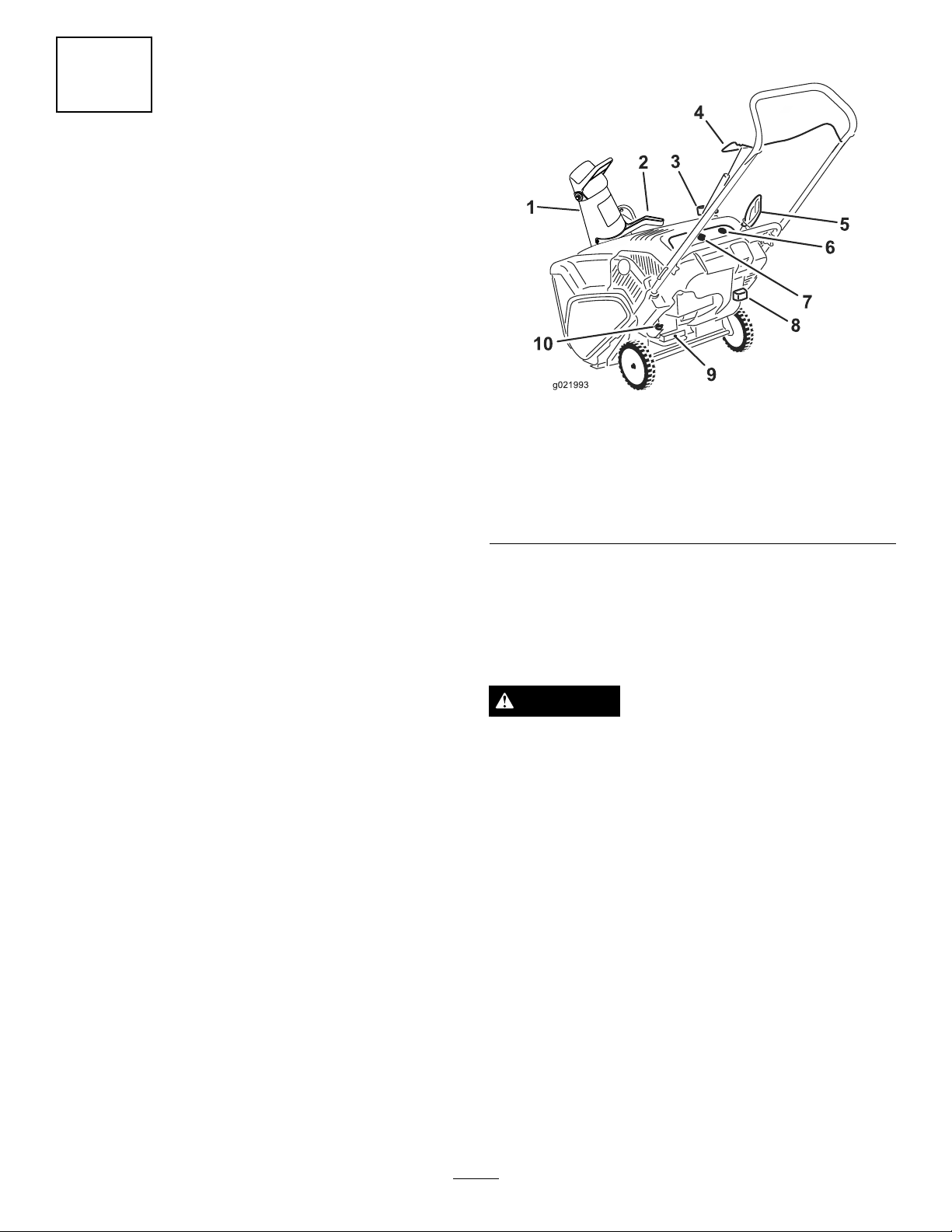

Figure1

1.Modelandserialnumberlocation

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnowfrompavedsurfaces,such

asdrivewaysandsidewalks,andothersurfacesfor

trafconresidentialorcommercialproperties.Itisnot

designedforremovingmaterialsotherthansnow,noris

itdesignedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

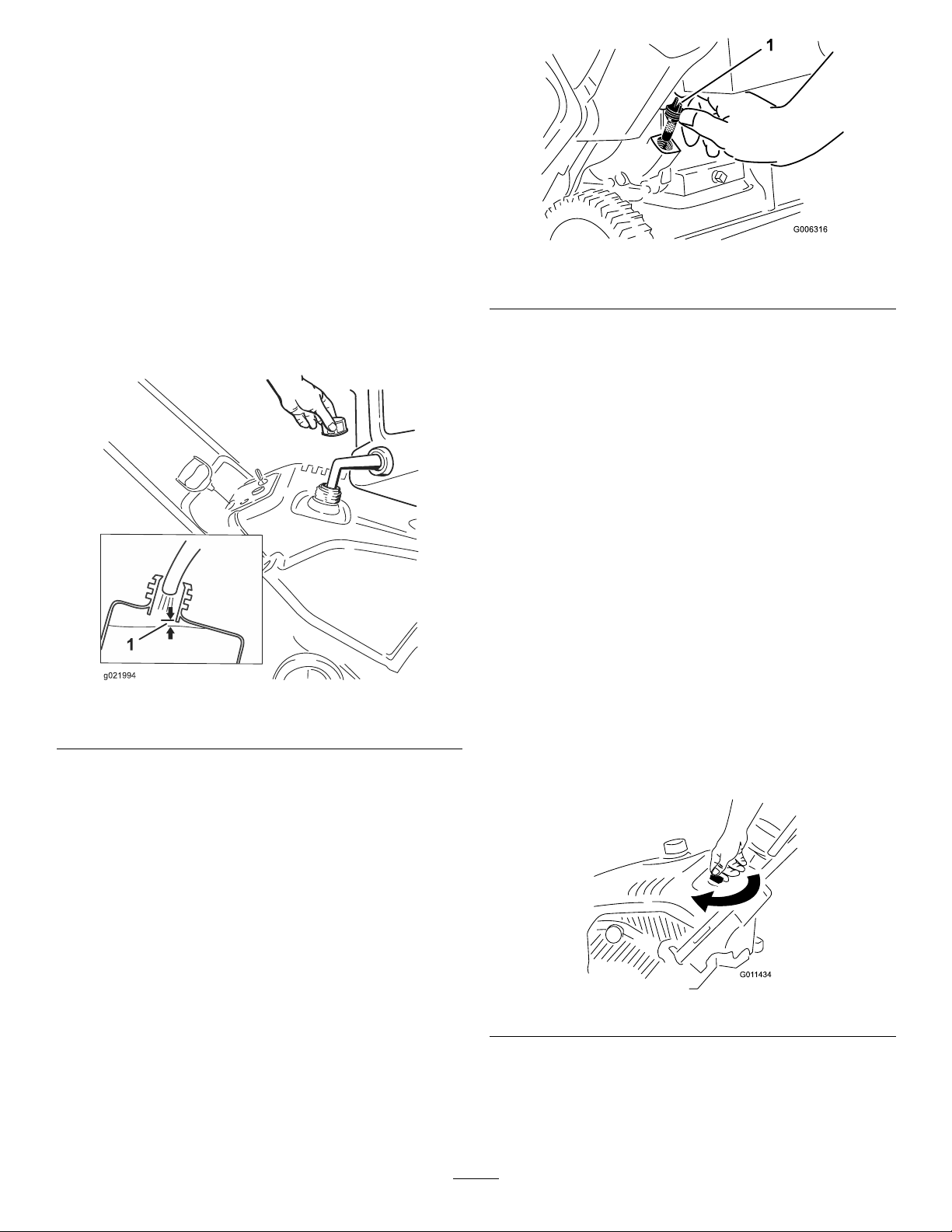

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Contents

Introduction..................................................................1

Training.................................................................2

Preparation.............................................................2

Operation...............................................................2

ClearingaCloggedDischargeChute..........................3

MaintenanceandStorage..........................................3

ToroSnowthrowerSafety.........................................3

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3379-508*A

Page 2

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1UnfoldingtheHandle............................................5

2InstallingtheDischargeChute................................5

3FillingtheEnginewithOil......................................6

4AdjustingtheControlCable...................................6

ProductOverview..........................................................7

Operation.....................................................................7

FillingtheFuelTank................................................8

CheckingtheEngineOilLevel..................................8

StartingtheEngine..................................................8

EngagingtheRotorBlades........................................9

DisengagingtheRotorBlades..................................10

StoppingtheEngine...............................................10

AdjustingtheDischargeChute.................................10

ClearingaCloggedDischargeChute.........................10

PreventingFreeze-upafterUse.................................11

OperatingTips......................................................11

Maintenance.................................................................12

RecommendedMaintenanceSchedule(s)......................12

AdjustingtheControlCable.....................................13

InspectingtheRotorBlades.....................................14

ChangingtheEngineOil.........................................14

ServicingtheSparkPlug..........................................15

ReplacingtheDriveBelt..........................................17

Storage........................................................................18

StoringtheSnowthrower.........................................18

Safety

Readandunderstandthecontentsofthismanualbefore

youstarttheengine.

ThesafetyalertsymbolshowninFigure2isusedto

alertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossible

injuryordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.Toreducethispotential,

complywiththefollowingsafetyinstructions.

Preparation

•Thoroughlyinspecttheareawherethemachineistobe

usedandremovealldoormats,sleds,boards,wires,and

otherforeignobjects.

•Donotoperatethemachinewithoutwearingadequate

wintergarments.Avoidloosettingclothingthatcanget

caughtinmovingparts.Wearfootwearthatwillimprove

footingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Neverll

fueltankindoors.

–Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainers

ontheground,awayfromyourvehicle,beforelling.

–Whenpractical,removegas-poweredmachineryfrom

thetruckortrailerandrefuelitontheground.If

thisisnotpossible,thenrefuelsuchmachineryona

trailerwithaportablecontainer,ratherthanfroma

gasolinedispensernozzle.

–Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimes,untilrefueling

iscomplete.Donotuseanozzlelock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilledfuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Donotattempttoclearsnowfromagravelorcrushed

rocksurface.Thismachineisintendedforuseonlyon

pavedsurfaces.

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwhenspecicallyrecommendedby

manufacturer).

•Alwayswearsafetyglassesoreyeshieldsduringoperation

orwhileperforminganadjustmentorrepairtoprotect

eyesfromforeignobjectsthatmaybethrownfromthe

machine.

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.Failuretoobservethefollowing

safetyinstructionscouldresultinseriousinjury.

Training

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren.

•Exercisecautiontoavoidslippingorfalling.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,remove

theignitionkey ,thoroughlyinspectthemachineforany

damage,andrepairthedamagebeforerestartingand

operatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtherotorbladehousing

2

Page 3

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairing,orinspectingthemachine,stop

theengineandmakecertainthattherotorbladesandall

movingpartshavestopped.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinorout

ofthebuilding.Opentheoutsidedoors;exhaustfumes

aredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguardsand

othersafetyprotectivedevicesinplaceandworking.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltankinsidea

buildingwhereignitionsourcesarepresent,suchashot

waterheaters,spaceheaters,orclothesdryers.Allowthe

enginetocoolbeforestoringinanyenclosure.

•AlwaysrefertotheOperator’sManualforimportantdetails

ifthemachineistobestoredforanextendedperiod.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Neverdirectthedischargetowardpeopleorareaswhere

propertydamagecanoccur.Keepchildrenandothers

away.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnowattoofastarate.

•Lookbehindandusecarewhenbackingupwiththe

machine.

•Disengagepowertotherotorbladeswhenmachineis

transportedornotinuse.

•Neveroperatethemachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer(

Figure3

Figure3).

•Runthemachineafewminutesafterthrowingsnowto

preventfreeze-upoftherotorblades.

ToroSnowthrowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknow .

•Rotatingrotorbladescaninjurengersorhands.

Staybehindthehandlesandawayfromthedischarge

openingwhileoperatingthemachine.Keepyourface,

hands,feet,andanyotherpartofyourbodyor

clothingawayfrommovingorrotatingparts.

•Beforeadjusting,cleaning,repairing,andinspectingthe

machine,andbeforeuncloggingthedischargechute,stop

theengine,removethekey,andwaitforallmoving

partstostop.

•Beforeleavingtheoperatingposition,stoptheengine,

removetheignitionkey,andwaitforallmovingpartsto

stop.

•Ifashield,safetydevice,ordecalisdamaged,illegible,or

lost,repairorreplaceitbeforebeginningoperation.Also,

tightenanyloosefasteners.

1.Symbolstampedontheexhaustbafeindicatingahot

surface.

ClearingaCloggedDischarge Chute

Handcontactwiththerotatingrotorbladesinsidethe

dischargechuteisthemostcommoncauseofinjury

associatedwithsnowthrowers.Neveruseyourhandtoclean

outthedischargechute.

Toclearthechute:

•EnsurethattheengineisintheOffposition.

•Wait10secondstobesuretherotorbladeshavestopped

rotating.

•Alwaysuseaclean-outtool,notyourhands.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoonafter

ithasstoppedbecausetheenginemaybehotenoughto

causeaburn.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Beforeperforminganymaintenance,service,

oradjustment,stoptheengineandremovethekey .If

majorrepairsareeverneeded,contactanAuthorized

ServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,drain

thefuelfromthefueltanktopreventapotentialhazard.

Storefuelinanapprovedfuelcontainer.Removethekey

fromtheignitionswitchbeforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

3

Page 4

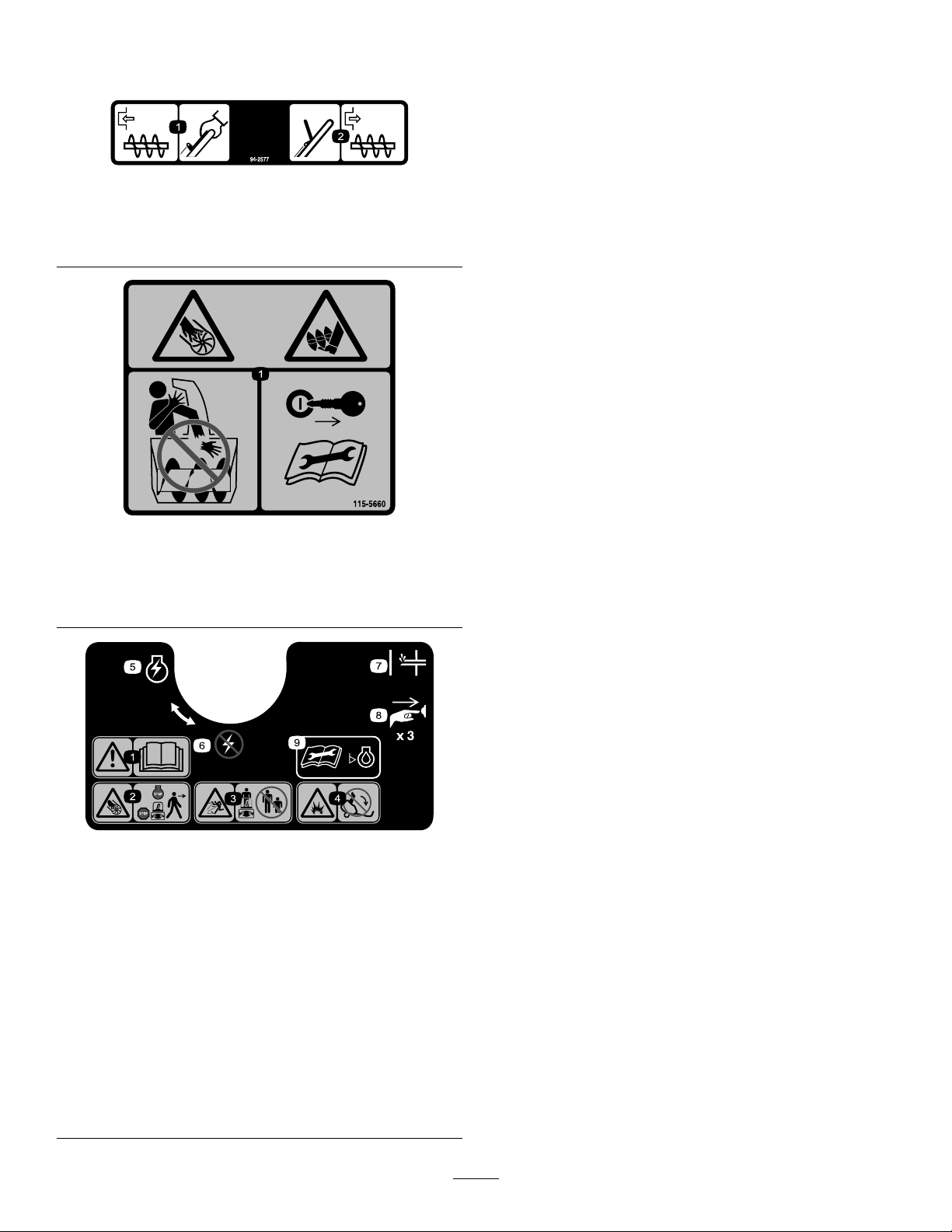

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

94-2577

1.Toengagetherotorblades,holdthecontrolbaragainst

thehandle.

2.Todisengagetherotorblades,releasethecontrolbar.

115-5660

1.Cuttingdismembermenthazards,impellerandauger—do

notplaceyourhandinthechute;removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance.

117-9102

Orderpartno.117-6036

1.Warning—readthe

Operator'sManual.

2.Cutting/dismemberment

hazard,impeller—stopthe

enginebeforeleavingthe

machine.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

4.Fuelspillhazard—donot

tipmachinebackward.

5.EngineswitchOn

6.EngineswitchOff

7.Primer

8.Pushtheprimerthree

timestoprimetheengine.

9.ReadtheOperator's

Manualbeforechecking

engineoillevel.

4

Page 5

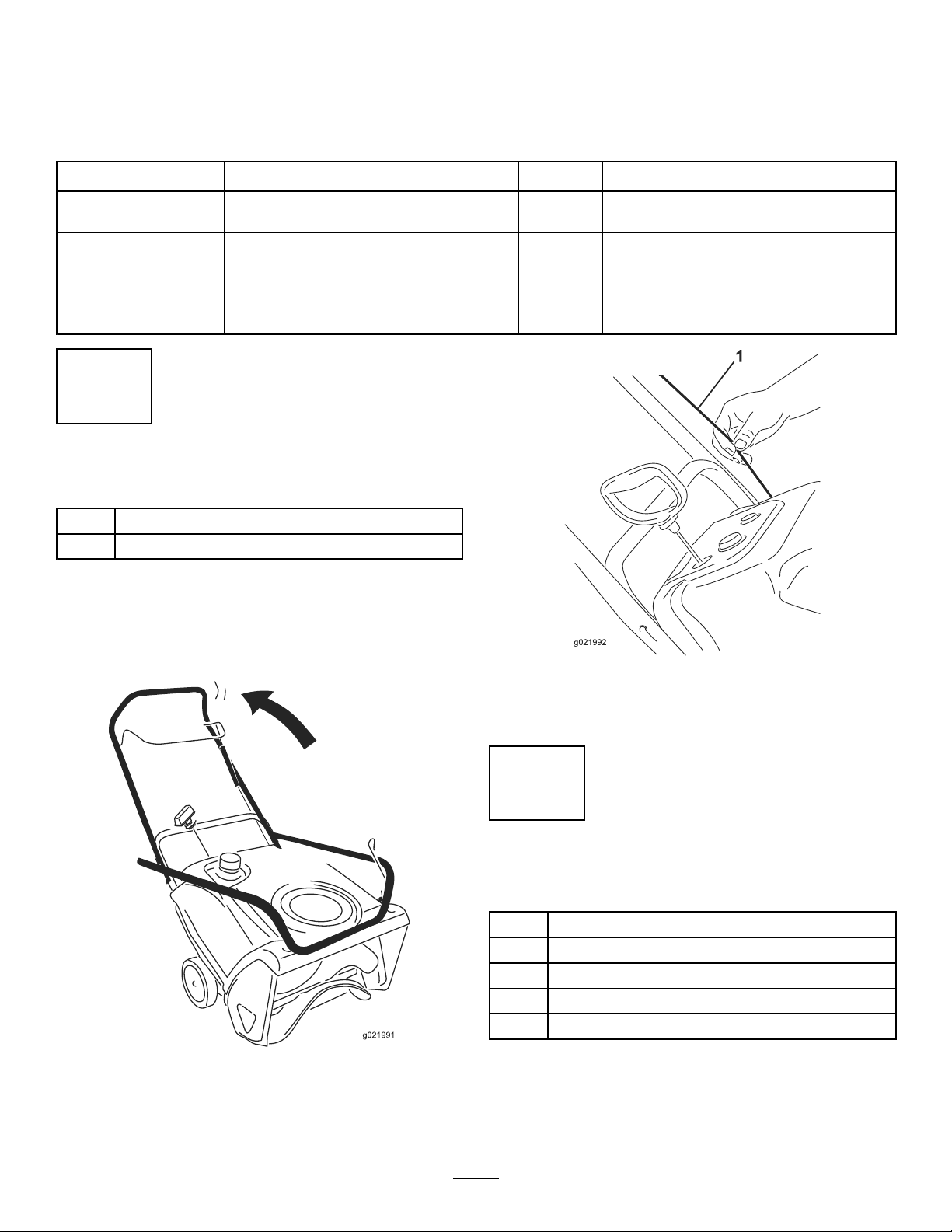

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Bolt2

1

2

Nut2

Dischargechute1

Chutehandle

Phillipsheadbolts3

Washers3

Locknuts3

1

UnfoldingtheHandle

Partsneededforthisprocedure:

2Bolt

2Nut

Procedure

1.Rotatethehandletotheoperatingposition,install2

nutsand2bolts,thentightenthe2nutsand2bolts

alreadyinstalledholdingthehandleinplace(Figure4).

Qty.

Use

Unfoldthehandle.

1

Installthedischargechute.

Figure5

Figure4

2.Ensurethatyoudonotpinchorkinkthecontrolcable

(Figure5).

1.Controlcable

2

InstallingtheDischargeChute

Partsneededforthisprocedure:

1Dischargechute

1

Chutehandle

3Phillipsheadbolts

3Washers

3Locknuts

Procedure

Installthedischargechuteasshown(Figure6).

5

Page 6

Figure7

1.Movethemachinetoalevelsurface.

Figure6

3

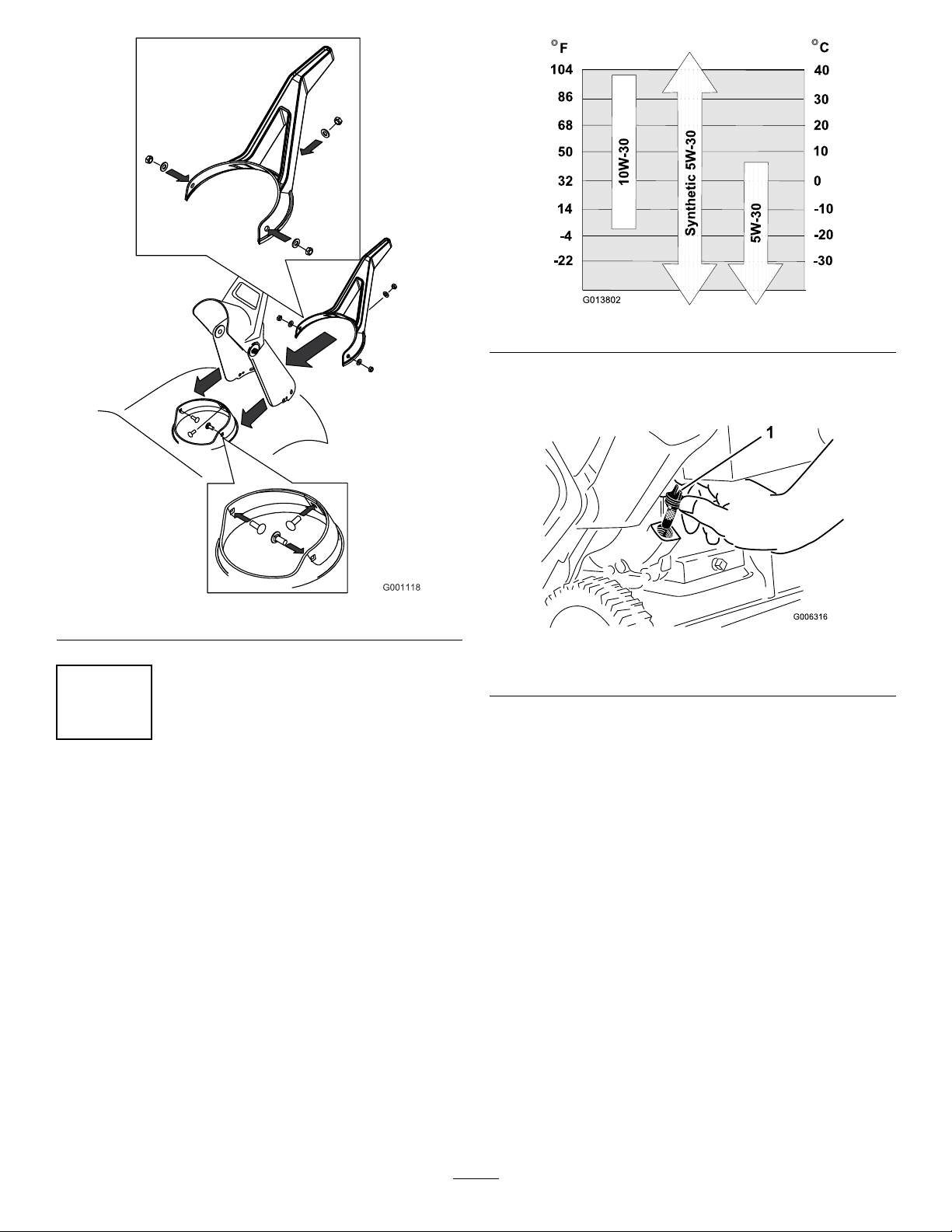

FillingtheEnginewithOil

NoPartsRequired

Procedure

Yourmachinedoesnotcomewithoilintheengine,butit

doescomewithabottleofoil.

2.Cleanaroundtheoil-llcap(

Figure8

1.Oil-llcap

3.Unscrewtheoil-llcapandremoveit.

4.Withthemachineintheoperatingposition,carefully

pouroilintothecrankcase.Wait3minutesfortheoil

tosettleandaddenoughtobringittothepointof

overow .Thereshouldbeverylittle,ifany ,oilleftin

thebottle.

Note:Y oumaytipthemachineforward(handleup)

tomakeaddingoileasier.Remembertoreturnthe

machinetotheoperatingpositionbeforecheckingthe

oillevel.

Figure8).

Important:Beforestartingtheengine,lltheengine

withoil.

Note:Thebottleofoilmaycontainanounceortwomore

thantheenginerequires.Donotoverllorunderllthe

engine.

Maxll:0.6L(20oz),type:automotivedetergentoilwithan

APIserviceclassicationofSJ,SL,orhigher.

Use

Figure7belowtoselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutofthe

machine.

5.Screwtheoil-llcapintotheoil-llholeandtightenit

securely.

6

Page 7

4

AdjustingtheControlCable

NoPartsRequired

Procedure

RefertoAdjustingtheControlCable(page13)inMaintenance

(page12).

ProductOverview

Figure9

1.Dischargechute6.Primer

2.Discharge-chutehandle7.Ignitionkey

3.Fuel-tankcap

4.Controlbar9.Oil-drainplug

5.Recoil-starthandle

8.Chokelever

10.Oil-llcap

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

7

Page 8

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Figure11

1.Oil-llcap

3.Unscrewtheoil-llcapandremoveit.

4.Iftheoillevelislow,keepthemachineintheoperating

positionandcarefullypouroilintothecrankcase

untilthepointofoverow .Wait3minutesfortheoil

tosettleandaddenoughtobringittothepointof

overow .(Max.ll:0.6L(20oz),type:automotive

detergentoilwithanAPIserviceclassicationofSJ,

SL,orhigher.)

Figure10

1.6mm(1/4inch)

Note:Forbestresults,purchaseonlythequantityofgasoline

thatyouexpecttousein30days.Otherwise,youmayadd

fuelstabilizertonewlypurchasedgasolinetokeepitfreshfor

upto6months.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine

oillevelandaddoilifnecessary.

Note:Y oumaytipthemachineforward(handleup)

tomakeaddingoileasier.Remembertoreturnthe

machinetotheoperatingpositionbeforecheckingthe

oillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutofthe

machine.

5.Screwtheoil-llcapintotheoil-llholeandhand

tightenitsecurely.

StartingtheEngine

1.TurntheignitionkeyclockwisetotheOnposition

(

Figure12).

1.Movethemachinetoalevelsurface.

2.Cleanaroundtheoil-llcap(Figure11).

Figure12

2.Pulloutthechokelever(Figure13andFigure14).

8

Page 9

Figure13

1.Chokelever

Figure14

1.Symbolsonthechokeleverindicatingtomovethechoke

levertotherighttoactivatethechoke.

3.Firmlypushintheprimer3timeswithyourthumb,

holdingtheprimerinaforasecondbeforereleasingit

eachtime(Figure15).

Figure16

Note:Ifyoupulltherecoilhandleandfeelno

resistance,thestartermaybefrozen.Thawoutthe

starterbeforeattemptingtostartthemachine.

5.Whiletheengineisrunning,pushinthechokelever

slowly.

EngagingtheRotorBlades

Toengagetherotorblades,holdthecontrolbaragainstthe

handle(Figure17).

Figure15

Note:Removeyourglovewhenyoupushinthe

primersothataircannotescapefromtheprimerhole.

Important:Donotusetheprimerorthechokeif

theenginehasbeenrunningandishot.Excessive

primingmayoodtheengineandpreventitfrom

starting.

4.Pulltherecoil-starthandle(Figure16).

Figure17

1.Controlbar

9

Page 10

DisengagingtheRotorBlades

G0 16 29 7

Todisengagetherotorblades,releasethecontrolbar(Figure

18).

Figure20

1.Chutehandle2.Chutedeectorhandle

ClearingaCloggedDischarge

Figure18

StoppingtheEngine

Tostoptheengine,turntheignitionkeycounterclockwiseto

theOffposition(Figure19).

Figure19

Chute

Important:Handcontactwiththerotatingrotorblades

insidethedischargechuteisthemostcommoncauseof

injuryassociatedwithsnowthrowers.Neveruseyour

handtocleanoutthedischargechute.

Toclearthechute:

•EnsurethattheengineisintheOffposition.

•Wait10secondstobesuretherotorbladeshavestopped

rotating.

•Alwaysuseaclean-outtool,notyourhands(

Figure21).

AdjustingtheDischargeChute

Toadjustthedischargechute,movethechutehandleandthe

chutedeectorhandleasshown(Figure20).

Figure21

10

Page 11

PreventingFreeze-upafterUse

1

2

G016654

3

4

•Lettheenginerunforafewminutestopreventmoving

partsfromfreezing.Stoptheengine,waitforallmoving

partstostop,andremoveiceandsnowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthechute.

•Rotatethedischargechuteleftandrighttofreeitfrom

anyicebuildup.

•WiththeignitionkeyintheOffposition,pulltherecoil

starterhandleseveraltimesorconnecttheelectricalcord

toapowersourceandthemachineandpushtheelectric

startbuttononcetopreventtherecoilstarterand/orthe

electricstarterfromfreezingup.

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

OperatingTips

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Ifthemachinedoesnotpropelitselfforwardonslippery

surfacesorinheavysnow,pushforwardonthehandle,

butallowthemachinetoworkatitsownpace.

•Overlapeachswathtoensurecompletesnowremoval.

•Dischargethesnowdownwindwheneverpossible.

Figure22

11

Page 12

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst2hours

Beforeeachuseordaily

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary .

•Changetheengineoil.

•Checktheengineoillevelandaddoilifnecessary.

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Checkthesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary .

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

•Preparethemachineforstorage.

12

Page 13

AdjustingtheControlCable

Note:Y oucanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

CheckingtheControlCable

ServiceInterval:Afterthersthour—Checkthecontrol

cableandadjustitifnecessary.

Yearly—Checkthecontrolcableandadjustitif

necessary.

Movethecontrolbarbacktowardthehandletoremovethe

slackinthecontrolcable(

1.Controlbar2.2mmto3mm(1/16-inch

Figure23).

Figure23

to1/8-inch)gap

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe2mmto3mm

(1/16-inchto1/8-inch)gapbetweenthecontrolbar

andthehandle(Figure24).

Note:MovingtheZ-ttinghigherdecreasesthegap

betweenthecontrolbarandthehandle;movingit

lowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethespring

coverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingtheControl

Cable.

Note:Afterextendeduse,thedrivebeltmaywear

andloseitsproperbelttension.Ifthedrivebeltslips

(continuouslysqueals)underaheavyload,disconnect

thespringfromtheadjustorlinkandmovetheupper

endofthespringtotheholethatisfurtherfrom

thepivotpointinthecontrolbar(Figure25).Then

connectthespringtotheadjustorlinkandadjustthe

controlcable.

Note:Ensurethata2mmto3mm(1/16-inchto1/8-inch)

gapexistsbetweenthecontrolbarandthehandle(Figure23).

Important:Thecontrolcablemustcontainsomeslack

whenyoudisengagethecontrolbarfortherotorblades

tostopproperly.

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespringfrom

theadjusterlink(

Figure24).

Figure25

1.Upperendofspring

2.Inserttheupperendof

springintothishole

3.Pivotpoint

4.Removetheupperendof

springfromthishole

Note:Thebeltmayslip(squeal)inwetconditions;

todryoutthedrivesystem,starttherotorandrunit

withoutaloadfor30seconds.

1.Adjusterlink

2.Z-tting

Figure24

3.Springcover

4.Unhookthespringhere.

13

Page 14

InspectingtheRotorBlades

ServiceInterval:Y early—Inspecttherotorbladesandhave

anAuthorizedServiceDealerreplacethe

rotorbladesandscraperifnecessary.

Beforeeachsession,inspecttherotorbladesforwear.When

arotorbladeedgehasworndowntothewearindicatorhole,

haveanAuthorizedServiceDealerreplacetherotorblades

andthescraper(Figure26).

Figure26

1.Thewearindicatorholeis

intact;youdonotneedto

replacetherotorblades.

2.Thewearindicatorholeis

exposed;replacetherotor

blades.

Figure28

1.Oil-llcap

7.Unscrewtheoil-llcapandremoveit(Figure28).

8.Withthemachineintheoperatingposition,carefully

pouroilintotheoilllhole.Wait3minutesforthe

oiltosettleandaddenoughtobringittothepointof

overow .Thereshouldbeverylittle,ifany ,oilleftin

thebottle.(Figure30).

Note:Y oumaytipthemachineforward(handleup)

tomakeaddingoileasier.Remembertoreturnthe

machinetotheoperatingpositionbeforecheckingthe

oillevel.

ChangingtheEngineOil

ServiceInterval:Aftertherst2hours

Yearly

Runtheengineafewminutesbeforechangingtheoiltowarm

it.Warmoilowsbetterandcarriesmorecontaminants.

1.Siphonthefuelfromthefueltankintoanapproved

fuelcontainer,orruntheengineuntilitstops.

2.Movethemachinetoalevelsurface.

3.Placeanoil-drainpanundertheoil-drainplug,remove

theoildrainplug,andtipthemachinebackwardand

draintheusedoilintheoil-drainpan

Figure27

Figure27).

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutofthe

machine.

Maxll:0.6L(20oz),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

UseFigure29belowtoselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

Figure29

4.Afterdrainingtheusedoil,returnthemachinetothe

operatingposition.

5.Installtheoil-drainplugandtightenitsecurely .

6.Cleanaroundtheoil-llcap(Figure28).

14

Page 15

Figure30

G016327

9.Screwtheoil-llcapintotheoilllhole,andhand

tightenitsecurely.

10.Wipeupanyspilledoil.

11.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Y early—Checkthesparkplugandreplace

itifnecessary.

UseaNGKBPR6ESorChampionRN9YCsparkplug

orequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Rotatethedischargechutesothatitfacesforward.

3.Removethedischargechutebyremovingthethree

screwsholdingthechute,andthescrewsholdingthe

chuteseal(Figure31).

Figure31

4.Removethe4screwsthatsecuretheshroud(Figure32).

15

Page 16

13.Connectthewiretothesparkplug.

Note:Ensurethatthebreathertubeisroutedabove

thesparkplugwireasshowninFigure34.

Figure34

Figure32

1.Screw(4)3.Sparkplug

2.Shroud4.Spark-plugwire

5.Removethefuel-tankcap.

6.Removetheshroud(Figure32).

7.Installthefuel-tankcap.

8.Disconnectthewirefromthesparkplug.

9.Cleanaroundthesparkplug.

10.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

11.Setthegapontheplugto0.76mm(0.030inch)(Figure

).

33

1.Breathertube

2.Carburetor-drainbolt

14.Removethefuel-tankcap.

15.Installtheshroudwiththescrewsyouremovedinstep

4.

Note:Ensurethattheupperandlowershroudst

togetherinthesidegrooves.

16.Installthefuel-tankcap.

17.Installthechuteseal,thedischargechute,andthe

dischargechutehandleontothemachineusingthe

hardwareyouremovedinstep

3.

Note:Thesmallscrewgoesthroughthesmallhole

inthechutesealatthefrontofthedischargechute

opening.

Figure33

1.Center-electrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

12.Installthesparkplugandtorqueitto27to30N-m

(20to22ft-lb).

16

Page 17

ReplacingtheDriveBelt

Ifdrivebeltbecomesworn,oil-soaked,excessivelycracked,

frayed,orotherwisedamaged,replacethebelt.

1.Removethedrive-beltcoverbyremovingthe3boltsas

showninFigure35.

Figure35

1.Drive-beltcover6.Drivebelt

2.Bolt(3)7.Rotorshaft

3.Rotor-pulleybolt

4.Curvedwasher

5.Rotorpulley10.Enginepulley

8.Brakespring(unhookfrom

idlerarmhere)

9.Idlerpulley

looserotorpulleypositionedjustabovetherotorshaft

(

Figure35).

6.Installtherotorpulleyontotherotorshaft(Figure35).

7.Installthecurvedwasherandtherotorpulleyboltand

tightenthemsecurely(Figure35).

Note:Theconcavesideofthecurvedwashergoes

againsttheoutsideofthepulley.

8.Installthebrakespringontotheidlerarm(Figure36).

9.Installthedrivebeltcoverwiththeboltsyouremoved

instep

1.

Note:Ensurethatthedrivebeltisproperlyadjusted

andoperating;refertoCheckingtheControlCableand

AdjustingtheControlCable.

2.Unhookthebrakespringfromtheidlerarmtorelease

thebelttension(Figure35).

3.Removethescrewandcurvedwasherthatholdsthe

rotorpulley(Figure35).

4.Removetherotorpulleyandthedrivebelt(

5.Installthenewdrivebelt,routingitasshownin(Figure

36).

Figure36

1.Brakespring(installon

idlerarmhere)

2.Idlerpulley4.Rotorpulley

3.Enginepulley

Figure35).

Note:Routethenewdrivebeltrstaroundtheengine

pulley,thentheidlerpulley ,andnallyaroundthe

17

Page 18

Storage

StoringtheSnowthrower

WARNING

•Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethe

machineinanareawithanopename,the

gasolinefumesmayigniteandcausean

explosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

1.Onthelastrefuelingoftheseason,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

16.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheenginetocool

beforestoringitinanyenclosure.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Stoptheengine,allowittocool,andsiphonthefuel

tankorruntheengineuntilitstops.

4.Starttheengineandrunituntilitstops.

5.Chokeorprimetheengine,startitathirdtime,and

runtheengineuntilitwillnotstart.

6.Drainthefuelinthecarburetorthroughthecarburetor

drainbolt(Figure34)intoanapprovedgasoline

container.

7.Disposeofunusedfuelproperly.Recycleitaccording

tolocalcodes,oruseitinyourautomobile.

8.Whiletheengineisstillwarm,changetheengineoil.

RefertoChangingtheEngineOil.

9.Removethesparkplug.

10.Squirt2teaspoonsofoilintothesparkplughole.

11.Installthesparkplugbyhandandthentorqueitto27

to30N-m(20to22ft-lb).

12.WiththeignitionkeyintheOffposition,pulltherecoil

starterslowlytodistributetheoilontheinsideofthe

cylinder.

13.Cleanthemachine.

14.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedServiceDealer.Sandaffectedareasbefore

painting,andusearustpreventativetopreventthe

metalpartsfromrusting.

15.Tightenanyloosefasteners.Repairorreplaceany

damagedparts.

18

Page 19

Notes:

19

Page 20

Notes:

20

Page 21

Notes:

21

Page 22

EmissionControlWarrantyStatement

FortheUnitedStates,California,andCanada

TheCaliforniaAirResourcesBoard(CARB),theU.S.EnvironmentalProtectionAgency(EP A),andTheT oroCompany ,arepleasedtoexplainthe

emissioncontrolsystemwarrantyonyour2012–2013smalloff-roadengine/equipment.InCaliforniaandtheUnitedStates,newsmalloff-road

engines/equipmentmustbedesigned,built,andcertiedtomeetstringentanti-smogstandards.TheT oroCompanywarrantstheemissioncontrol

systemonyoursmalloff-roadengine/equipmentfortheperiodoftimelistedabove,providedtherehasbeennoabuse,neglect,orimpropermaintenance

ofyoursmalloff-roadengine/equipment.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,theignitionsystem,catalyticconverter,fueltanks,fuellines,

fuelcaps,valves,canisters,lters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,TheT oroCompanywillrepairyoursmalloff-roadengine/equipmentatnocosttoyouincludingdiagnosis,

partsandlabor.

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuanttoanagreementbetweenthem,jointlywarrantthe2012–2013smalloff-road

engine/equipmentfortwoyearsfromthedateofdelivery.Ifanyemission-relatedpartonyourengine/equipmentisdefective,thepartwillberepairedor

replacedbyTheToroCompany .

Asthesmalloff-roadengineowner,youareresponsiblefortheperformanceoftherequiredmaintenancelistedinyourOperator'sManual.Werecommend

thatyouretainallreceiptscoveringmaintenanceonyoursmalloff-roadengine/equipment,butwecannotdenywarrantysolelyforthelackofreceipts.

Asthesmalloff-roadengine/equipmentowner,youshouldhoweverbeawarethatwemaydenyyouwarrantycoverageifyoursmalloff-road

engine/equipmentoraparthasfailedduetoabuse,neglect,impropermaintenanceorunapprovedmodications.

Youareresponsibleforpresentingyoursmalloff-roadengine/equipmenttoanAuthorizedServiceDealerassoonasaproblemexists.Thewarranty

repairsshouldbecompletedinareasonableamountoftime,nottoexceedthirty(30)days.

Ifyouhaveanyquestionsregardingyourwarrantycoverage,contactusat:

CustomerCareDepartment,ConsumerDivision

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat800–348–2424(U.S.customers)

Tollfreeat800–544–5364(Canadiancustomers)

ATwo-YearLimitedWarranty

YourWarrantyRightsandObligations

Manufacturer’sWarrantyCoverage

OwnerResponsibilities

GeneralEmissionsWarrantyCoverage

TheT oroCompanyanditsafliate,T oroW arrantyCompany ,jointlywarranttotheinitial

ownerandeachsubsequentpurchaserthatthesmalloff-roadengine/equipmentis:

•Designed,built,andcertiedtoconformwithallapplicableemissionsregulations;and

•Freefromdefectsinmaterialsandworkmanshipthatcouldcausethefailureofawarrantedpart;and

•Identicalinallmaterialrespectstothepartsasdescribedintheapplicationforcertication.

Thewarrantyperiodbeginsonthedatethesmalloff-roadengine/equipmentisdeliveredtoanultimatepurchaser.Thewarrantedperiodistwoyears.

Subjecttocertainconditionsandexclusionsasstatedbelow,thewarrantyonevaporativeemissions-relatedpartsisasfollows:

1.Anywarrantedpartthatisnotscheduledforreplacementasrequiredmaintenanceinthewritteninstructionssupplied,iswarranted

forthewarrantyperiodstatedabove.Ifthepartfailsduringtheperiodofwarrantycoverage,thepartwillberepairedorreplacedby

TheT oroCompany .Anysuchpartrepairedorreplacedunderwarrantywillbewarrantedfortheremainderofthewarrantyperiod.

2.Anywarrantedpartthatisscheduledonlyforregularinspectioninthewritteninstructionssuppliediswarrantedforthewarranty

periodstatedabove.Anysuchpartrepairedorreplacedunderthewarrantywillbewarrantedfortheremainderofthewarrantyperiod.

3.Anywarrantedpartthatisscheduledforreplacementasrequiredmaintenanceinthewritteninstructionssuppliedis

warrantedfortheperiodoftimebeforetherstscheduledreplacementdateforthatpart.Ifthepartfailsbeforetherst

scheduledreplacement,thepartwillberepairedorreplacedbyTheToroCompany .Anysuchpartrepairedorreplaced

underwarrantywillbewarrantedfortheremainderoftheperiodpriortotherstscheduledreplacementpointforthepart.

4.Repairorreplacementofanywarrantedpartunderthewarrantyprovisionshereinmustbeperformedatan

AuthorizedServiceDealeratnochargetotheowner.

5.Notwithstandingtheprovisionsherein,warrantyservicesorrepairswillbeprovidedatallServiceDealers

authorizedtoservicethesubjectenginesorequipment.

6.Thesmalloff-roadengine/equipmentownerwillnotbechargedfordiagnosticlaborthatisdirectlyassociatedwithdiagnosis

ofadefective,emission-relatedwarrantedpart,providedthatsuchdiagnosticworkisperformedatanAuthorizedServiceDealer.

7.TheT oroCompanyisliablefordamagestootherengine/equipmentcomponentscausedbyafailureunderwarrantyofanyemissionspart.

8.Throughoutthesmalloff-roadengine/equipmentwarrantyperiodstatedabove,TheT oroCompany

willmaintainasupplyofwarrantedpartssufcienttomeettheexpecteddemandforsuchparts.

9.Manufacturerapprovedreplacementpartsmaybeusedintheperformanceofanywarrantymaintenanceorrepairsand

mustbeprovidedwithoutchargetotheowner.SuchusewillnotreducethewarrantyobligationsofTheT oroCompany.

10.Add-onormodiedpartsthatarenotapprovedbyTheT oroCompanymaynotbeused.Theuseofanon-approvedadd-onormodiedparts

bythepurchaserwillbegroundsfordisallowingawarrantyclaim.TheT oroCompanywillnotbeliabletowarrantfailuresofwarrantedparts

causedbytheuseofannon-approvedadd-onormodiedparts.

374-0287RevA

Page 23

WarrantedParts

Thefollowingemissionwarrantypartsarecovered,totheextentthesepartswerepresentontheT oroengine/equipmentand/orT orosuppliedfuelsystem:

1.FuelSystemParts

•Carburetorandinternalparts

•Coldstartingenrichment(primerorchoke)

•Fuelpump

•Fuelline,ttings,andclamps

•Fueltank,cap,andtether

•Carboncanister

2.AirInductionSystem

•Aircleaner

•Intakemanifold

•Crankcaseventandline(s)

•Purgelineandttings

3.IgnitionSystem

•Sparkplug(s)andwire(s)

•Magnetoignitionsystem

4.CatalyticExhaustSystem

•Catalyticconverter

•Exhaustmanifold

•Airinjectorsystemandvalve(s)

5.MiscellaneousItemsUsedinEmissionControlSystem

•Valves,switches,andlinkages

•Connectors,ttings,andbrackets

374-0287RevA

Page 24

TheToro2-YearGTSStartingGuaranteeand

TheToroTotalCoverageGuarantee

AT wo-Y earFullWarranty(1Y earLimitedWarrantyforCommercialUse)

PowerClearCommercial

Single-StageSnowthrowers

TheToroStartingGuarantee

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlyguaranteethatyourT oroGTS

(GuaranteedtoStart)engine,whenusedforresidentialpurposes*,will

startontherstorsecondpullfortwo(2)yearsfromthedateofpurchase,

ifyouprovidetheroutinemaintenanceitrequires,orwewillxitfreeof

charge.TheGTSStartingGuaranteedoesnotapplyundercommercial

use.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

TheToroTotalCoverageGuarantee

TheT oroCompanyanditsafliate,ToroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheT oroProduct

listedbelowifusedforresidentialpurposes*,ifdefectiveinmaterialsor

workmanshiporifitstopsfunctioningduetothefailureofacomponent

fortheperiodlistedbelow.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

PowerClearCommercialSnowthrowersand

Attachments

2yearsResidentialUse*

1YearCommercialUse

LimitedWarrantyforCommercialUse

Gas-poweredToroProductsusedforcommercial,institutional,orrental

use,arewarrantedfor1yearagainstdefectsinmaterialsorworkmanship.

Componentsfailingduetonormalweararenotcoveredbythiswarranty.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeservice

attheirdealership.Tolocateadealerconvenienttoyou,referto

theY ellowPagesofyourtelephonedirectory(lookunder“Lawn

Mowers”)oraccessourwebsiteatwww.T oro.com.Y oumayalso

callthenumberslistedinitem#3tousethe24-hourT oroDealer

locatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermine

ifitiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-336-5205(U.S.customers)

Tollfreeat866-854–9033(Canadiancustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceorreplacementofwearparts,suchas

rotorblades(paddles),scraperblades,belts,fuel,lubricants,oil

changes,sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorized

ToroServiceDealer

•Repairsoradjustmentstocorrectstartingdifcultiesduetothe

following:

–failuretofollowpropermaintenanceprocedures

–snowthrowerauger/paddlesstrikinganobject

–contaminantsinthefuelsystem

–improperfuel(consultyourOperator'sManualifindoubt)

–failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Specialoperationalconditionswherestartingmayrequiremorethan

twopulls:

–rsttimestartsafterextendedperiodofnon-useoverthree

monthsorseasonalstorage

–improperstartingprocedures

–startingin-10°F(-23°C)orbelowtemperatures

Ifyouarehavingdifcultystartingyourunit,pleasechecktheOperator's

Manualtoensurethatyouareusingthecorrectstartingprocedures.This

cansaveanunnecessaryvisittoaServiceDealer.

GeneralConditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingT oroapprovedreplacementparts.

RepairbyanAuthorizedT oroServiceDealerisyoursoleremedyunder

thiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,sotheaboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany .

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

*Residentialpurposesmeansuseoftheproductonthesamelotasyourhome.Useatmorethanonelocation,orinstitutionalorrentaluse,isconsidered

commercialuse,andthecommercialusewarrantywouldapply .

374-0294RevA

Loading...

Loading...