Page 1

EATON 750, 780 HYDROSTATIC TRANSAXLE

Table of Contents – Page 1 of 1

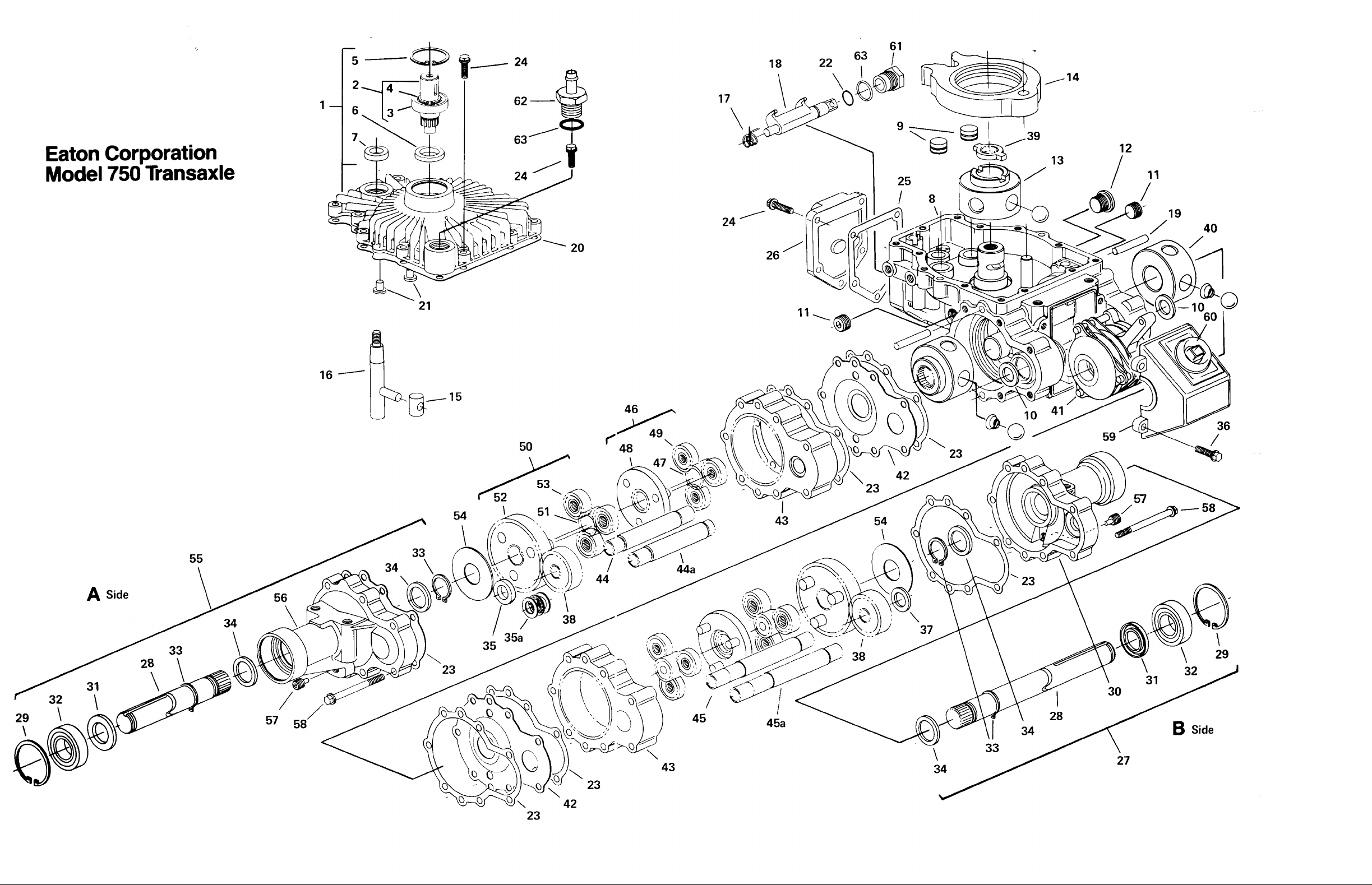

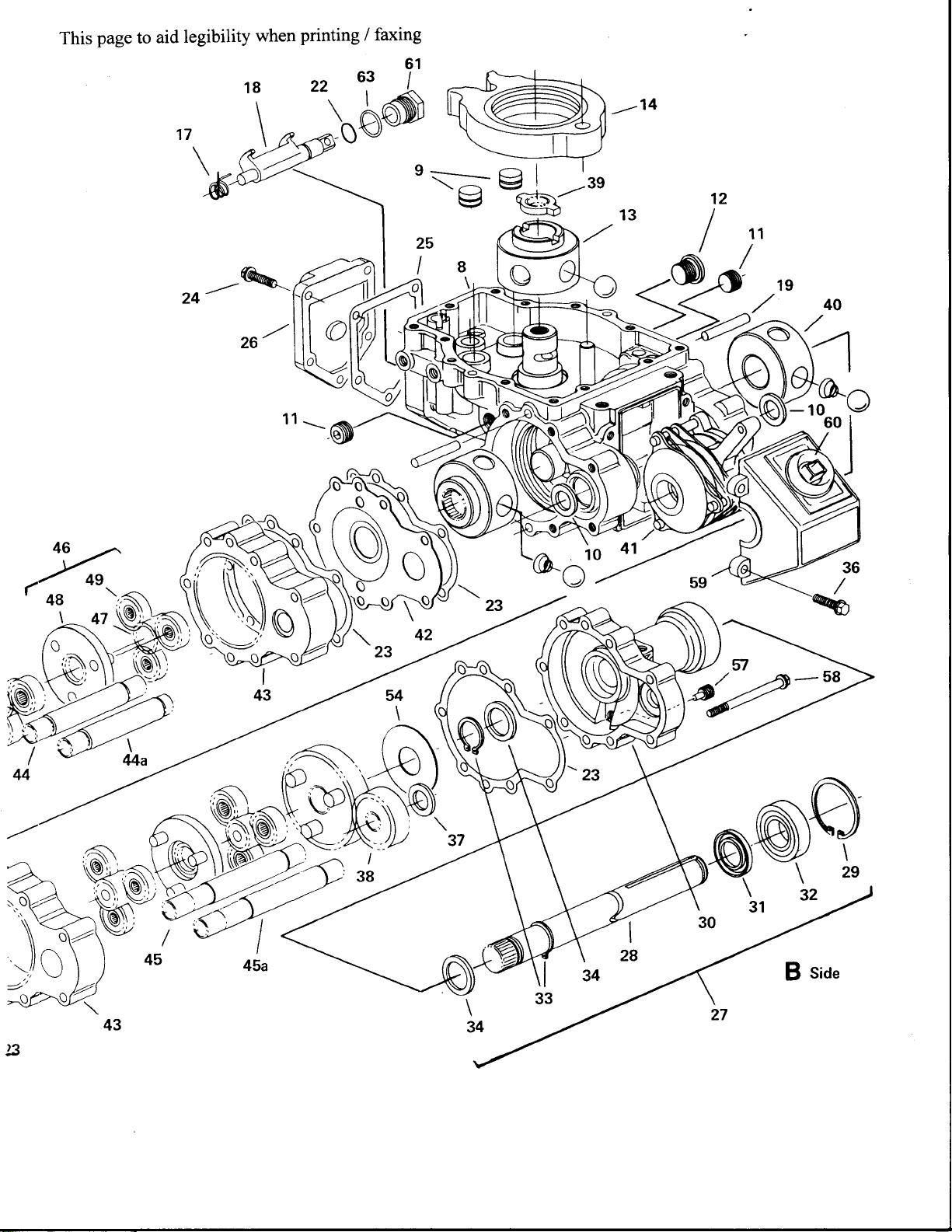

TRANSAXLE SERIES 750

TRANSAXLE PARTS DRAWING

TRANSAXLE PARTS LIST

TOOL REQUIREMENTS

PRODUCT IDENTIFICATION AND ORDERING INFORMATION

COMPLETE DISASSEMBLY

AXLE DISASSEMBLY PROCEDURES

HOUSING DISASSEMBLY PROCEDURES

ROTOR ASSEMBLIES-DISASSEMBLY AND INSPECTION

REASSEMBLY

HOUSING REASSEMBLY

COVER REASSEMBLY

AXLE REASSEMBLY

FLUID RECOMMENDATIONS

TRANSAXLE SERIES 780

FINAL DRIVE REDUCTION OPTIONS - PARTS LIST

TRANSAXLE PARTS DRAWING

TRANSAXLE PARTS LIST

Page 2

NO.

7-413

Hydraulics

Division

Revised

September,

1990

Hydrostatic Transaxle Series

750

Page 3

Page 4

Page 5

Page 6

750

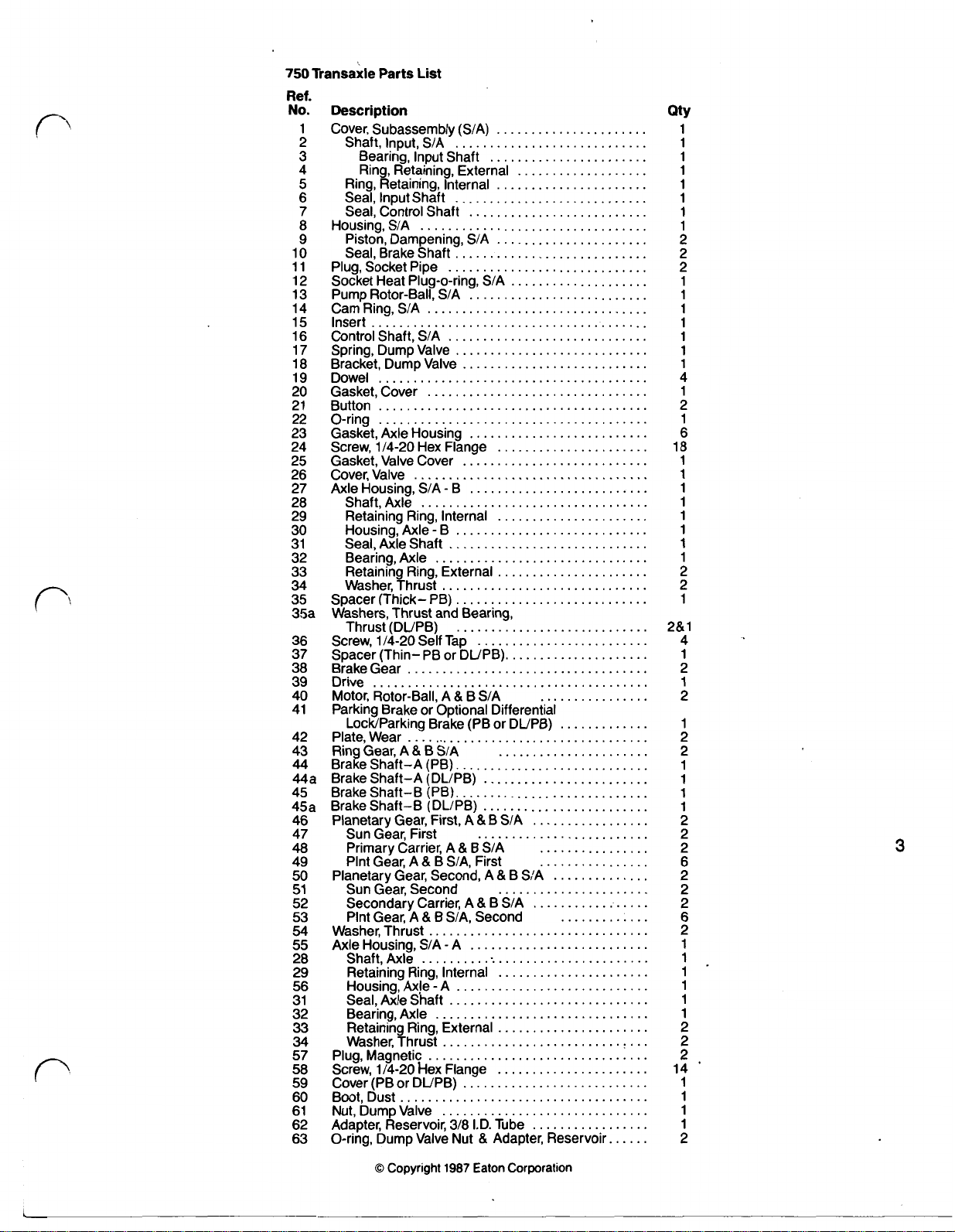

Transaxle Parts List

.

Ref

No

.

Description

1 Cover. Subassembly (S/A)

2 Shaft. Input. S/A

3 Bearing. Input Shaft

4 Ring. Retaining. External

5

Ring. Retaining. Internal

6 Seal. Input Shaft

7

Seal. Control Shaft

8 Housing. S/A

9 Piston. Dampening. S/A

10 Seal. Brake Shaft

11 Plug. Socket Pipe

12 Socket Heat Plug-O-ring. S/A

13 Pump Rotor-Ball. S/A

14 Cam Ring. S/A

15 Insert

16 Control Shaft. S/A

17 Spring. Dump Valve

18 Bracket. Dump Valve

19 Dowel

20 Gasket. Cover

21 Button

22 O-ring

23 Gasket. Axle Housing

24 Screw. 1/4-20 Hex Flange

25 Gasket. Valve Cover

26 Cover. Valve

27 Axle Housing. S/A - B

28 Shaft. Axle

29 Retaining Ring. Internal

30 Housing. Axle - B

31 Seal. Axle Shaft

32 Bearing. Axle

33 Retaining Ring. External

34

35

35a

36 Screw. 1/4-20 Self Tap

37 Spacer (Thin- PB or DL/PB)

38 Brake Gear

39 Drive

40 Motor. Rotor-Ball. A & B S/A

41 Parking Brake or Optional Differential

42 Plate. Wear

43 Ring Gear. A & B S/A

44

44a Brake Shaft-A (DL/PB)

45 Brake Shaft-B (PB)

45a

46 Planetary Gear. First. A & B S/A

47 Sun Gear. First

48

49 Plnt Gear. A & B

50

51 Sun Gear. Second

52 Secondary Carrier. A

53 Plnt Gear, A & B

54

55

28 Shaft. Axle

29 Retaining Ring. Internal

56 Housing. Axle

31

32 Bearing. Axle

33 Retaining Ring. External

34

57 Plug. Magnetic

58 Screw. 1/4-20 hex Flange

59 Cover (PB or DUPE)

60 Boot. Dust

61 Nut. Dump Valve

62 Adapter. Reservoir, 318 I.D. Tube

63 O-ring. Dump Valve Nut

........................................

Washer. Thrust

Spacer (Thick- PB)

Washers. Thrust and Bearing.

Thrust (DL/PB)

........................................

Lock/Parking Brake (PB or DL/PB)

Brake Shaft-A (PB)

Brake Shaft-B (DL/PB)

Primary Carrier.

Planetary Gear. Second. A & B S/A

Washer. Thrust

Axle Housing.

Seal. Axle Shaft

Washer. Thrust

.................................

.............................

................................

.............................

.......................................

................................

.......................................

.......................................

..................................

.................................

.............................

...............................

..............................

...................................

....................................

A

S/A,

S/A,

................................

S/A - A

..................................

-

A

...............................

..............................

................................

....................................

..............................

......................

............................

.......................

...................

......................

............................

..........................

......................

............................

....................

..........................

............................

...........................

..........................

......................

...........................

..........................

......................

............................

......................

............................

............................

.........................

.....................

......................

............................

........................

............................

........................

.................

.........................

&

B S/A

First

......................

&

B

S/A

Second

..................

..........................

......................

............................

.............................

......................

......................

...........................

.................

&

Adapter. Reservoir

................

.............

................

................

..............

.............

......

Qty

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

4

1

2

1

6

18

1

1

1

1

1

1

1

1

2

2

1

2&1

4

1

2

1

2

2

2

1

1'

2

2

2

14'

1

1

1

1

2

3

©

Copyright

1987

Eaton Corporation

Page 7

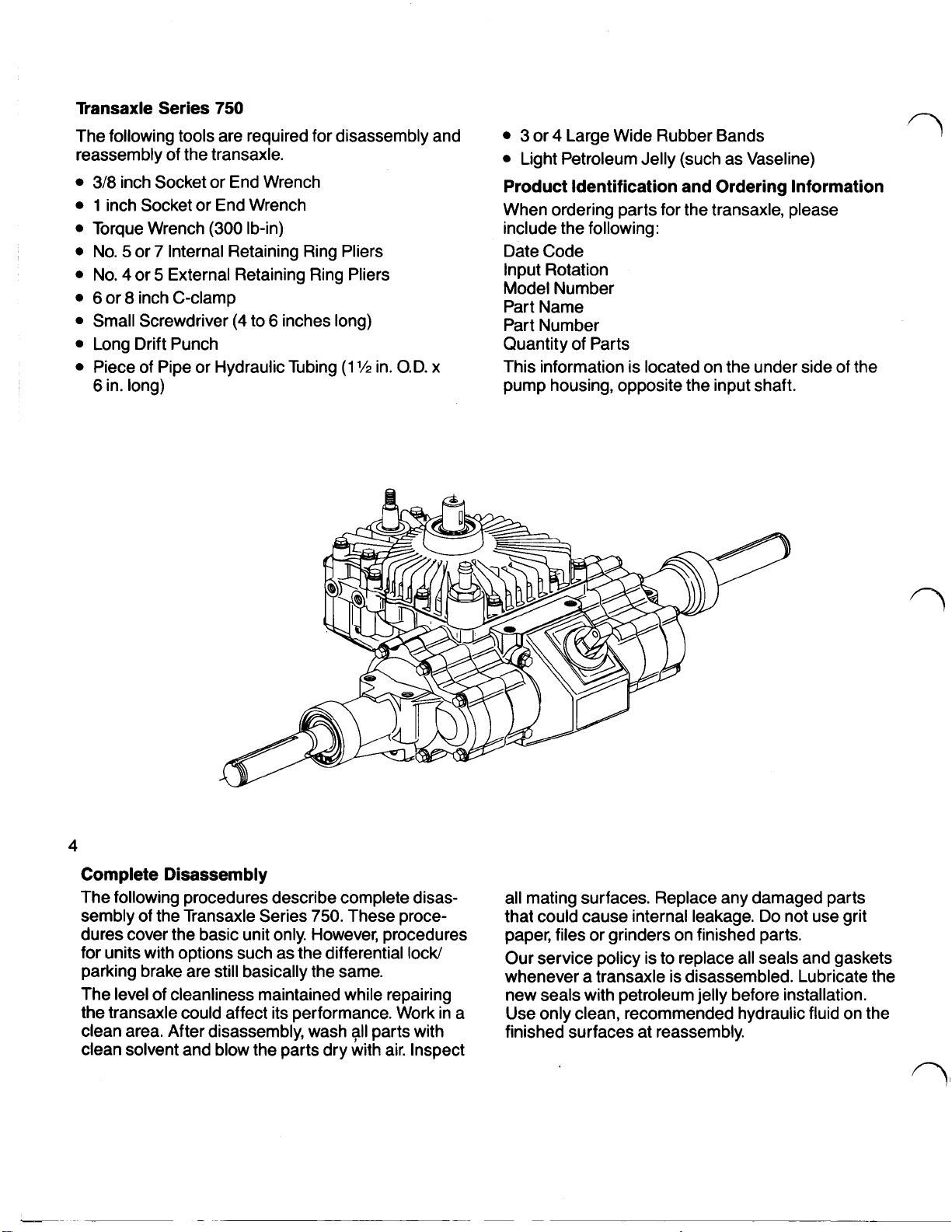

Transaxle Series

The following tools are required for disassembly and

reassembly of the transaxle.

3/8

inch Socket or End Wrench

1

inch Socket or End Wrench

Torque Wrench

No. 5 or 7 Internal Retaining Ring Pliers

No. 4 or 5 External Retaining Ring Pliers

6

or 8 inch C-clamp

Small Screwdriver

Long Drift Punch

Piece of Pipe or Hydraulic Tubing

6

in. long)

750

(300

Ib-in)

(4

to 6 inches long)

(1

½

in. O.D.

x

3

or 4 Large Wide Rubber Bands

Light Petroleum Jelly (such as Vaseline)

Product Identification and Ordering Information

When ordering parts for the transaxle, please

include the following:

Date Code

Input Rotation

Model Number

Part Name

Part Number

Quantity of Parts

This information

pump housing, opposite the input shaft.

is

located on the under side of the

4

Complete Disassembly

The following procedures describe complete disassembly of the Transaxle Series

dures cover the basic unit only. However, procedures

for units with options such as the differential lock/

parking brake are still basically the same.

The level of cleanliness maintained while repairing

the transaxle could affect its performance. Work in a

clean area. After disassembly, wash

clean solvent and blow the parts dry with air. Inspect

750.

These proce-

all

parts with

all mating surfaces. Replace any damaged parts

that could cause internal leakage. Do not use grit

paper, files or grinders on finished parts.

Our service policy is to replace all seals and gaskets

whenever a transaxle is disassembled. Lubricate the

new seals with petroleum jelly before installation.

Use only clean, recommended hydraulic fluid on the

finished surfaces at reassembly.

Page 8

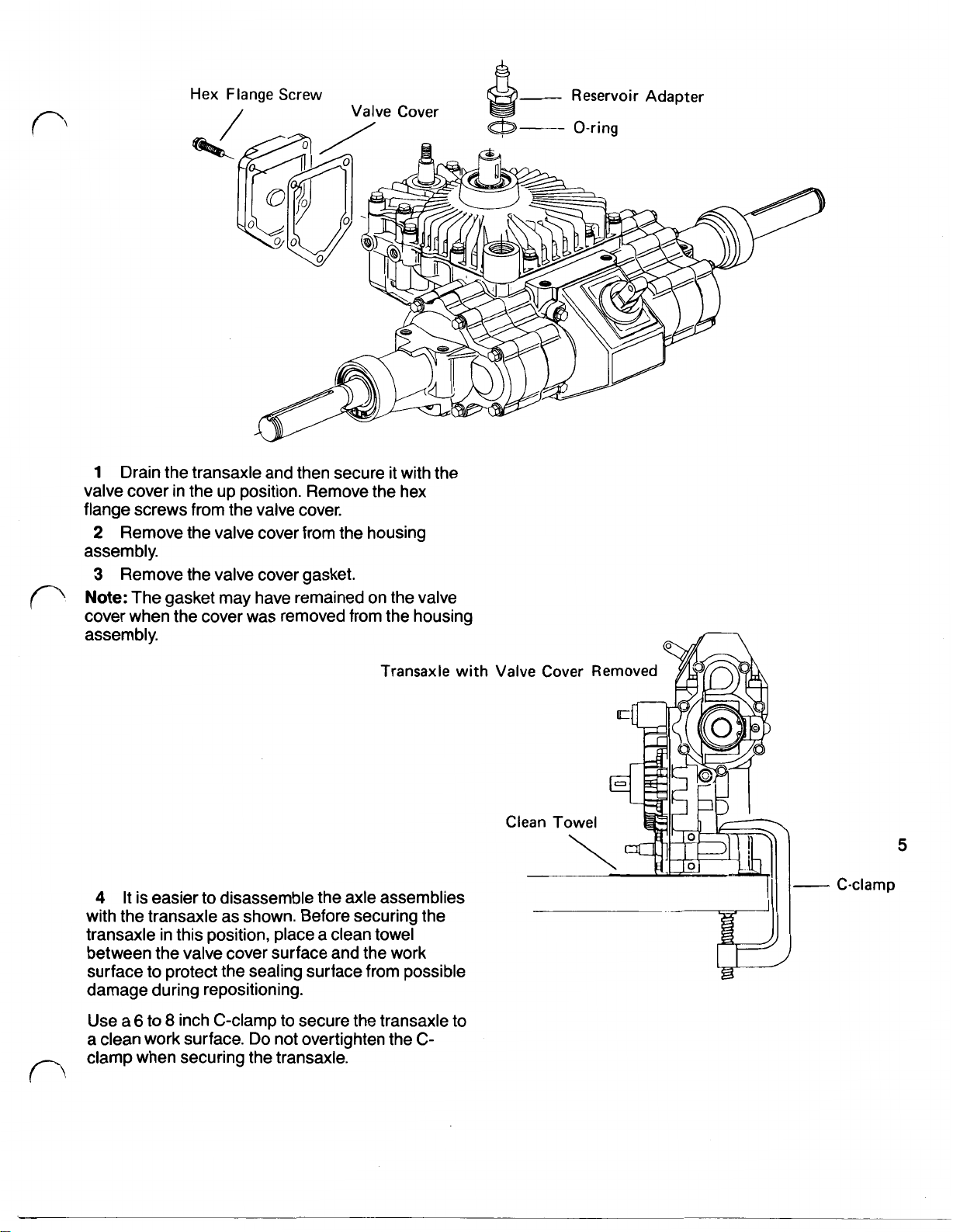

Hex Flange Screw Reservoir Adapter

Valve Cover

1

Drain the transaxle and then secure it with the

valve cover in the up position. Remove the hex

flange screws from the valve cover.

2

Remove the valve cover from the housing

assembly.

3

Remove the valve cover gasket.

Note:

The gasket may have remained on the valve

cover when the cover was removed from the housing

assembly.

Transaxle with

4

It is easier to disassemble the axle assemblies

with the transaxle as shown. Before securing the

transaxle in this position, place a clean towel

between the valve cover surface and the work

surface to protect the sealing surface from possible

damage during repositioning.

6

Use a

to 8 inch C-clamp to secure the transaxle to

a clean work surface. Do not overtighten the Cclamp when securing the transaxle.

5

C-clamp

Page 9

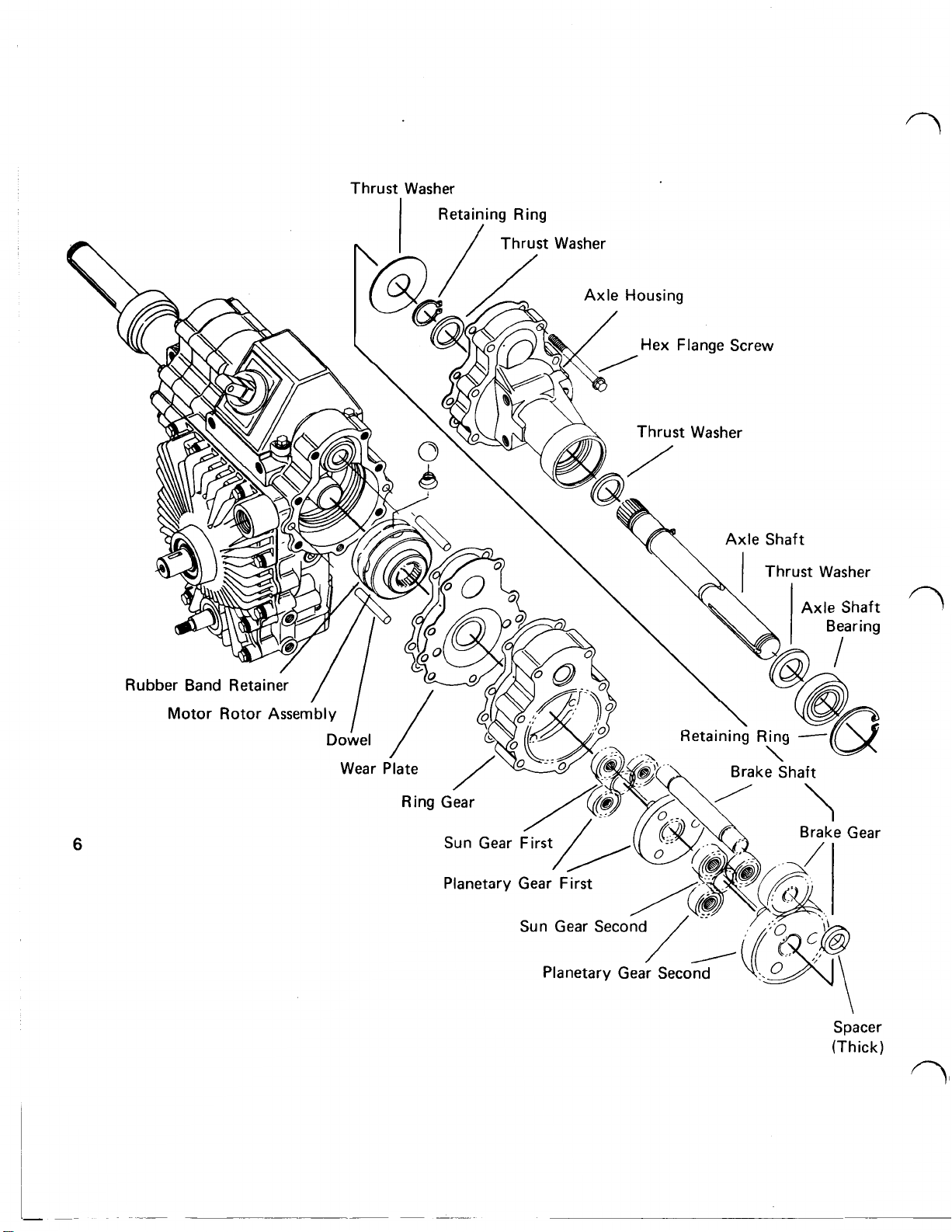

Thrust Washer

Retaining Ring

6

\

Spacer

(Thick)

Page 10

5

Remove the hex flange screws from either axle

assembly.

6 Carefully remove the axle assembly from the

housing assembly.

7 In most cases the brake shaft will remain in the

housing assembly when the axle assembly is

removed.

this time.

Important: Be extremely careful when removing

the motor rotor assemblies. The ball pistons are

spring loaded in the bores and must remain

intact because each ball piston is matched to its

respective bore.

8

blies is to place a separate motor race on top of the

existing motor race in the housing assembly. Hold

the separate race securely in position. Then

carefully pull the motor rotor assembly outward until

the ball pistons are fully engaged

located in the center of the separate race. Carefully

remove the rotor assembly and race together as a

set, handling the motor rotor assembly only.

Note:

a wide rubber band around the outside

rotor to hold the ball pistons in their bores. It is

essential that the ball pistons be retained in their

bores during handling. This is especially true for the

motor rotors, as the motor ball pistons are spring

loaded in the bores.

9 Reposition the transaxle and remove the hex

flange screws from the remaining axle assembly.

10 Carefully remove the axle assembly from the

housing assembly.

11 Remove the remaining brake shaft from the

housing assembly.

12 Using a separate race or wide rubber band to

retain the ball pistons in their bores, carefully remove

the other motor rotor assembly.

If

this occurs, remove the brake shaft at

The best way to remove the motor rotor assem-

in

the groove

If

a separate motor race is not available, work

of

the motor

Axle Disassembly Procedures

13 The following procedures apply to both axle

assemblies.

Remove the axle housing gasket from the wear

plate.

Note: This gasket may have remained on the

housing assembly when the axle assembly was

removed.

14 Remove the wear plate from the axle assembly.

15 Remove the axle housing gasket from the ring

gear assembly.

16 Remove the first sun gear from the primary

carrier assembly.

Note: The first sun gear may have remained in the

motor rotor during removal

17 Remove the primary carrier assembly from the

ring gear assembly.

18 Remove the second sun gear from the

secondary carrier assembly.

19 Remove the ring gear assembly from the axle

housing.

20 Remove the gasket and dowel pins from the

axle housing.

21 Remove the brake gear from the axle housing.

22 Remove the spacer washer from the axle

housing.

23 Remove the secondary carrier assembly from

the axle shaft. Both the primary and secondary

carrier assemblies may be disassembled for

inspection.

24 Remove the large thrust washer from the axle

housing.

of

the axle assembly.

7

Page 11

25

Reposition the axle housing with the splined

4

or

end of the axle in the up position. Use a no.

5

external retaining ring pliers to remove the retaining

ring and thrust washer from the axle shaft.

26

Reposition the axle housing assembly with the

wheel end of the axle in the up position. Use a no.

or

7

internal retaining ring pliers to remove the

5

bearing retaining ring from the axle housing.

27

Remove the axle from the axle housing by

using a small press or by tapping the splined end of

the axle with a plastic tipped hammer. This

will

dislodge the seal and bearing from the axle bore.

28

Press the bearing from the axle shaft. Remove

the seal and thrust washer from the axle shaft. The

thrust washer may have remained in the axle

housing when the axle shaft was removed,

Note:

The retaining ring remaining on the axle shaft

need not be removed.

Page 12

Brake

PB

or

DL/PB

Cover

Self

Tap

Screw

Housing Disassembly Procedures

29 Remove the four self tap screws from the brake

cover.

30 Remove the brake cover from the housing

g

assembly.

31 Remove the PB or DL/PB assembly from the

housing assembly.

32 In most cases further disassembly of the PB or

DL/PB is not necessary.

Page 13

Retaining Ring

Hex

Control Shaft Seal

\

Control Shaft

Dump Valve Nut

O-ring

\

Insert

\

‘I

Input Shaft

Cam Ring S/A

S/A

Sea

I

10

O-ring

Pump Rotor Assembly

Page 14

33 Reposition the housing assembly and remove

the cap screws from the cover assembly.

Note: One of the hex flange screws is located in

the case drain port.

34 Carefully separate and remove the cover from

the housing assembly.

35 To remove the input shaft assembly, first

remove the retaining ring from the input shaft with a

no.

5

or 7 internal retaining ring pliers.

36 Reposition and support the cover with the input

shaft in the down position. Use a plastic hammer or

press to remove the input shaft assembly from the

cover.

37 Remove the input shaft seal from the cover with

a screwdriver.

38 Reposition the cover and then pry the control

shaft seal from the cover assembly with a small

screwdriver.

39 Remove the two buttons from the cam ring

assembly.

Note: These buttons may have remained in the

cover assembly.

40 Remove the cover gasket from the housing.

Note: This gasket may have remained on the cover

when it was removed.

41 Remove the drive from the pump rotor

assembly.

42 Remove the control shaft and insert from the

housing and cam ring assembly.

43 Remove the cam ring insert from the control

shaft.

44 Carefully remove the pump rotor assembly from

the housing, making sure the ball pistons are not

dislodged from their bores.

Important: It is essential that the pump rotor

assembly remain intact during handling as each

ball piston is matched to its respective bore.

45 Install a wide rubber band around the pump

rotor to retain the ball pistons in their bores.

Rotor Assemblies-Disassembly and

Inspection

46 Inspect the rotor assemblies in the following

manner. Remove the piston balls from the rotor, one

at a time, working clockwise from the letter stamped

in the rotor face. Place the piston balls in a container

such as an egg carton or ice cube tray. The balls

must be replaced in the same bores from which they

were removed because they are all select fit.

Check for broken or collapsed springs in the motor

rotor assembly. When broken or collapsed springs

are found with no other irregularities, the springs

complete motor rotor assembly.

journals for irregularities or excessive clearance.

may be replaced individually without replacing the

Inspect the piston balls. They must be smooth and

completely free of any irregularities.

Inspect the rotor bores, rotor bushing and pintle

The ball piston to rotor bore clearance is select fit

electronically from

larities are noted, replace the complete rotor

assembly.

47 Install the pistons in their matching bores. Hold

them in place with a rubber band or separate race.

48 Remove the cam ring assembly from the

housing.

49 The pump and motor journals and cam ring

dowel cannot be removed once they have been

installed in the housing assembly.

Note: Inspect the pump and motor journals for any

irregularities.

replaced as a complete assembly.

50

Reposition the housing assembly and remove

the dump valve nut from the housing assembly.

51 Remove the O-ring from the dump valve nut.

53 Remove the dump valve bracket and spring

from the housing assembly by sliding them over and

lifting upward. Remove the spring from the dump

valve bracket.

54 Remove the O-ring from the dump valve

bracket.

55

Reposition the housing assembly on its side.

Using a long drift punch, remove the brake shaft seal

from the housing. Turn the housing assembly over

and remove the other brake shaft seal.

56 Removal of the check valve assemblies for

inspection

flushing should be all that is required to clean the

check valves.

Removal of the dampening pistons for inspection

cleaning is also not recommended. Once again,

normal flushing should be all that is required for

cleaning.

or

.0002

to

.0006

inch. When irregu-

If

any are found, the housing must be

11

cleaning is not recommended. Normal

or

Page 15

Retaining Ring

Control Shaft Seal

Hex Flange

Cover

Control Shaft

Dump Valve Nut

O-ring

\

Insert

\

‘I

Input Shaft

Cam Ring

S/A

S/A

12

Page 16

Reassembly

57 Before reassembling the Transaxle Series

clean all parts and assemblies with clean solvent

and blow them dry with compressed air. Inspect and

replace all scratched or damaged parts. Replace all

gaskets, shaft seals and O-rings. Lubricate all shaft

seals and O-rings with petroleum jelly (Vaseline) for

retention during assembly. Freely lubricate all

bearings and finished part surfaces with clean

hydraulic fluid to provide lubrication at start-up.

Housing

58 Position the housing assembly on its side.

Lubricate and install the brake shaft seal with the

seal lip pointing away from the housing. Press or

drive the seal into the counterbore.

59 Turn the housing assembly over and repeat the

same procedure for the other brake shaft seal.

60 Lubricate and install the O-ring in the groove

located in the dump valve bracket.

61 Install the spring on the dump valve bracket with

the right angle bend of the spring pointing inward.

62 With the housing assembly in an upright

position, install the spring and dump valve bracket in

the housing assembly. The spring is properly

installed when the longest leg points toward the

check valve assembly.

63 Lubricate and install the O-ring around the

dump valve nut.

64 Install the nut over the dump valve bracket, into

the housing assembly, making sure you do not

damage the dump valve O-ring during installation.

Torque the dump valve nut to

65 Reposition the housing assembly. Install the

cam ring assembly in the housing assembly with the

flush side of the cam ring facing outward.

66 Install the cam ring insert on the control shaft

pivot dowel.

Reassembly

150

Ib-in.

750,

67 Install the control shaft assembly, first aligning

the cam ring insert with the cam ring assembly and

then with the housing assembly.

68 Remove the rubber band from the pump rotor

assembly. Lubricate and install the pump rotor

assembly on the pump journal located in the housing

assembly.

69 install the cover gasket on the housing

assembly.

70

Install the drive in the pump rotor assembly.

Cover Reassembly

71 Lubricate and install the control shaft seal with

the seal lip pointing inward. Press or drive the seal

into the seal counterbore.

72 Lubricate and install the input shaft seal with

the seal lip pointing inward. Press or drive the seal

into the counterbore.

73 Press or drive the input shaft assembly into the

cover.

74 Install the retaining ring on the input shaft,

making sure it is firmly seated in the retaining ring

groove.

75 Apply a small amount of petroleum jelly to the

buttons for retention during assembly. Install the

buttons in the cover assembly.

76 Install the cover assembly by carefully aligning

it with the control shaft, cam ring pivot dowel and

pump rotor drive.

77 After engaging the control shaft and pivot dowel

in the cover assembly, carefully rotate the input shaft

to engage the pump rotor drive. When all mating

parts are aligned and engaged, the cover assembly

should fall into position on the housing assembly.

78 Install the hex flange screws in the cover

assembly and torque them to

125

Ib-in.

13

Page 17

Brake

Shaft

Seal

Brake

Shaft

Seal

79 Before installing the parking brake assembly,

make sure the brake is in the unlocked position.

Note: On transaxles with the differential Iock/parking

brake option, do not move the lever unnecessarily,

especially when it is out of the housing assembly.

The differential lock/parking brake assembly incor-

porates automatic self-adjusting brakes. Unnecessary activation of the lever may cause the brake to

expand and make installation of the assembly very

difficult.

Install the parking brake assembly in the housing

assembly, aligning it with the four notches cast in the

housing assembly.

Note: Make sure the parking brake handle is

pointing

or

leaning towards the cover side of the

housing assembly.

80 To ensure correct installation of the axle

14

housings in the housing assembly, the housing and

axle assemblies are marked with an

A

and

B.

The B

side of the transaxle must be assembled first.

There are two different brake

or

differential shaft

lengths that are used in the axle housing assemblies. The shorter shaft is always used in the

housing, regardless of whether the parking brake

A

axle

or

differential lock option is used. The longer shaft is

always used in the B axle housing assembly.

Apply a small amount of petroleum jelly to the brake

shaft seal. Carefully install the longer of the two

brake shafts in the

B

side of the housing assembly.

Note: Make sure the brake shaft seal is not

damaged during installation.

81 The next step is to engage the brake shaft with

the parking brake. To align and engage the splines,

hold the parking brake disk with one hand and then

rotate the brake shaft slightly with the other hand.

82 Reposition the housing assembly and carefully

install the motor rotor assembly on the motor journal,

into the housing assembly.

Note:

If

a rubber band was used to retain the ball

pistons, remove it now.

83 The first sun gear is longer than the second sun

gear. Install the smaller end of the first sun gear into

the motor rotor assembly.

84 Install the two dowel pins and the first of three

identical gaskets on the B side of the housing

assembly.

85 Install the wear plate, bowed side toward the

motor rotor assembly, aligning it with the two dowels.

86 Install the second of three gaskets on the wear

plate, aligning

it

with the dowels.

87 Install the ring gear assembly on the housing

it

assembly, aligning

with the brake shaft and

dowels.

Caution: The two ring gear assemblies are

identical and can be installed on either side of

the housing assembly. However, when installing

the ring gear assembly, the side with the bearing

must face the axle housing assembly.

88 Lubricate and assemble the three planetary

gears on the primary carrier assembly.

89 Install the primary carrier assembly into the ring

gear assembly by aligning and engaging it with the

previously installed sun gear.

90 Install the second sun gear in the primary

carrier assembly.

91 Lubricate and assemble the three planetary

gears on the secondary carrier assembly.

92 Install the secondary carrier, aligning and

engaging the three planetary gears with the ring

gear assembly and second sun gear.

93 Install the brake gear on the brake shaft.

94 Two different spacer thicknesses are used in

the axle housing assemblies. On transaxles with

parking brakes, the thicker spacer is used in the

A

axle assembly and the thinner spacer is used in the

B axle assembly.

On transaxles with the differential lock/parking brake

option, the A axle housing assembly uses two thin

thrust washers and a thrust bearing to replace the

thick spacer. The

B

axle housing assembly always

uses the thinner spacer, regardless of whether the

parking brake

or

differential lock/parking brake

option is used.

Page 18

For retention during assembly, apply a small amount

of petroleum jelly to the thin spacer. Install the

spacer on the brake shaft and brake gear.

95

Install the third and final gasket on the ring gear

assembly.

Axle

Reassembly

96

Lubricate and install the axle shaft and thrust

washer in the axle housing.

97

Position the axle housing assembly with the

axle end pointing downward. Install the inner thrust

washer and axle shaft retaining ring.

98

Reposition the axle assembly with the output

end pointing upward. Protecting the lip of the axle

Spacer

(Thin)

seal from the retaining ring groove and keyway,

lubricate and install the seal with the lip pointing

inward toward the axle housing.

99

Use a piece of hydraulic tubing

(1

½

in.

O.D.

x

6

in. long) to press the seal into the counterbore.

100

Press the sealed bearing over the axle shaft,

Use

and into the counterbore.

a no. 5 or 7 internal

retaining ring pliers to install the retaining ring in the

axle housing.

101

Reposition the axle housing assembly and

install the large thrust washer on the axle shaft.

102

Install the B axle housing assembly, aligning

and engaging the axle shaft with the secondary

carrier assembly.

Note:

To

ensure correct installation, the axle

housings are marked with the letters

A

and

B.

Each

side of the housing assembly is also marked with an

A

or

B.

Make sure the axle housings are assembled

with the corresponding letters on the housing

assembly.

103

Install the hex flange screws in the housing

and torque them to

125

Ib-in.

15

Page 19

104 Reposition the housing assembly. Apply a

small amount of petroleum jelly to the brake shaft

seal. Carefully install the remaining brake shaft.

105

To

align and engage the brake shaft splines,

hold the parking brake disk with one hand and rotate

the brake shaft slightly with the other hand.

106 Reposition the housing assembly and install

the remaining motor rotor assembly.

107 Install the smaller end of the first sun gear into

the motor rotor assembly.

108 Install the two dowel pins and the first of three

identical gaskets on the A side of the housing

assembly.

109 Install the wear plate with the bowed side

facing the motor rotor assembly, aligning it with the

two dowels.

110 Install the second of three gaskets on the wear

plate, also aligning it with the dowels.

11 1 Install the ring gear assembly on the housing

assembly, aligning it with the brake shaft and

dowels.

Caution: When the ring gear assembly is

installed, the side with the bearing must face the

axle housing.

112 Install the primary carrier assembly in the ring

gear, aligning and engaging it with the previously

installed sun gear.

113 Install the second sun gear in the primary

carrier assembly.

114 Install the secondary carrier, aligning and

engaging the three planetary gears with the ring

gear assembly and second sun gear.

115 Install the brake gear on the brake shaft.

116 Apply a small amount of petroleum jelly to the

spacer for retention. Install the thick spacer on the

brake shaft.

Differential Iock/parking brake option only, apply a

small amount of petroleum jelly to the thrust washers

and bearing for retention during assembly. Install the

thrust washers and bearing on the brake shaft.

Note: At assembly, the thrust bearing must be

positioned between the two thrust washers.

11 7 Install the third gasket on the ring gear

assembly.

118 Install the large thrust washer on the axle

shaft.

11 9 Install the A axle housing assembly, aligning

and engaging the axle shaft with the secondary

carrier assembly.

120 Install the hex flange screws in the housing

and torque them to

125

Ib-in.

121 Reposition the transaxle assembly and install

the cover

(PB

or

DL/PB)

by inserting the lever

through the dust boot.

122 Install the self tap screws in the brake cover

and torque them to

105

Ib-in.

16

Page 20

n

Self Tap Screw

Spacer

(Thick)

17

Page 21

123 Reposition the transaxle assembly and install

the valve cover gasket.

124 Install the valve cover.

125 Install the hex flange screws in the valve cover

and torque them to

Hex Flange Screw Reservoir Adapter

Valve Cover

125

Ib-in.

18

Build Date Code Effective January

Original Build (example

Build Date Code prior to January 1, 1990

A

=January G

B

=

February

C

=March

D

April

E

May

F

=

June

July

H

=

August

I

=

September

J

=October

K

November

L

=

December

01

0190)

x x

1,

1990

Day

01-31

Factory Rebuild (example

01 01 times rebuilt

0101901)

Month Customer Part

(example

L

31

G

=

1986

H = 1987

I = 1988

J

=

1989

J)

-Year

A=1980

B

C

D

E

1981

=

1982

=

1983

=

1984

Latest Date

No.

of

Rebuild

Date

of

Number

of

Rebuilt. (Example

Times Unit has been

Build

Shows

Two

Housing

Times).

Page 22

Fluid Recommendations

A reputable supplier can help you make the best

selection of hydraulic fluid for use in Eaton hydrostatic products.

For satisfactory operation, the following recommen-

dations apply:

1.

The filter system used in the hydraulic circuit

should be capable

the hydraulic fluid to meet

18/13 per SAE J1165. This code allows a

maximum of 2500 particles per milliliter greater

than

5µm

and a maximum of 80 particles per

milliliter greater than 15µm.

2.

At normal operating temperatures, optimum

viscosity ranges are from 80-180

Viscosity should never fall below 60

and, at the lowest expected start-up temperature,

should not exceed

3.

The fluid should be chemically stable, incorporating rust and oxidation inhibitors.

Specific types of fluid meeting these requirements

are:

Premium hydraulic oil; such as Mobil DTE-26

Engine crankcase oil-SAE 2Ow-20, SAE 30 or

40

SAE

Note:

milky, it is possible that a water contaminant problem

exists.

For accurate level readings, take readings when the

fluid is cold.

If

the natural color

of

cleaning and maintaining

IS0

Cleanliness Code

SUS

(16-39 cSt).

SUS

(10

10,000

SUS

(2158 cst).

of

the fluid has become

cSt)

19

Page 23

Eaton Corporation

Eaton G.m.b.H.

Hydraulics

Hydraulics

Division

Division

15151 Highway 5, Eden Prairie,

MN

55344 Telephone

(61

2) 937-9800

100 410 D-5620 Velbert 1 West Germany 49-2051-2070

Printed

In

U.S.A.

FORM

NO. 7-41

July,

1987

3

Page 24

NO. 6-417

Hydraulics

Division

Revised

September,

1990

Hydrostatic Transaxle, Series

780

!

i

I

Page 25

PARTS DRAWING (FOLD OUT) PARTS LIST

13:1

Ref.

No.

Part

51

54

56 990418

57

58

59

60 990406

61

62

63

Ref.

No.

51

54

56

57

58

59

60

61

62

63

No.

104551

1

04341

NSS

NSS

NSS

NSS

NSS

NSS

Part

No.

104073

104341

990405

NSS

NSS

NSS

990406

NSS

NSS

NSS

Description Qty.

Motor, Rotor-Ball, A & B S/A, 15T

Ring Gear, A

Planetary Gear, First, A

Planetary Gear, Second, A B

16:1 Final Drive Reduction

Options

Final Drive Reduction

.

.

. .

.

. .

. . .

.

. . .

. .

.

.

.

. .

.

. .

. .

2

2

2

2

.

2

6

2

.

2

.

.

.

.

.

.

&

B S/A, 54T

Sun Gear, First, 24T

Primary Carrier, A

Plnt Gear, A

Sun Gear, Second,

Secondary Carrier, A

Plnt Gear, A

18T..

Description Qty.

Motor, Rotor-Ball, A & B S/A, 18T

Ring Gear, A

Planetary Gear, First, A

Sun Gear, First, 18T

Primary Carrier, A & B S/A, 18T

Plnt Gear, A

Planetary Gear, Second, A

Sun Gear, Second,

Secondary Carrier, A

Plnt Gear, A

18T..

&

B S/A, First, 15T

&

B S/A, Second,

.

. . .

. . .

. .

&

B S/A, 54T

&

B S/A, First, 18T

&

B S/A, Second,

. . .

. .

. .

&

B S/A

.

. .

. . . . .

&

B S/A, 18T

18T

. . .

&

B S/A

. .

. . . . . . . . . . .

&

B S/A,

.

. . . . . . . .

18T

. . . . . .

&

B

.

. .

. .

. . . . . .

. .

.

&

S/A

. . .

. . . .

&

S/A

. . . . .

.

. . . . .

B S/A

. . .

.

.

2

6

2

2

2

2

2

6

2

2

2

6

Complementary Component

78 104973 Reservoir Assembly for

79 104276

80

104443

81

104946

990474

105636 Adapter, Reservoir,

3/8

in. I.D. Hose-Two Line

.

.

. . .

.

.

. .

Cover

Gasket

Reservoir

23:1 Steel Gear Kit

1

21T Plnt Gear, Second (3)

Secondary Carrier

(Two Kits Required Per Unit)

. . .

5T Sun Gear, Second

.

.

. . . .

. .

.

. . . .

. .

.

. .

3/8

. .

. . . .

(1

I.D. Tube

. . . . .

)

. . . .

.

. .

.

.

. .

. .

. . . . .

.

.

. . . . .

.

. .

.

. . . . .

(1

)

90"

1

.

1

1

1

.

1

Page 26

Page 27

Ref

.

No

.

Part

1

I06071

106073

2

3

NSS

4

NSS

5

101 680-1 56

93955

6

7

93895

8

10471 6

8a

10471 7

9

104294

10581 4*

10

104020

11

103757-088

12

104988

13

104989

14

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

NSS

15

95653-038

16

104684

17

105660

18

19

20

104664

21

25090-01

22

104435

23

104859-008

24

104943

25

104429

26

10441 3

27

10581 3

28

103621

29

104935

30

104537

No

.

8761 -1 21

8761 -01 3

8785-01

0

0

Description

Cover. Subassembly (S/A)

Shaft. Input. S/A

Bearing. Input Shaft

Ring. Retaining. External

Ring. Retaining. Internal

Seal. Input Shaft

Seal. Control Shaft

Housing. S/A CW (A)

Housing. S/A CW (B)

Piston. Dampening. S/A

Piston. Dampening. S/A

Seal. Brake Shaft (B housing

Only)

......................

Screw. Hex Flange

Washer

Cup. Seal

O-ring

Pluget, Lee

Journal. Pump. S/A

Retainer

Ball. Grade 200

Body, Valve

Dowel. Cam Ring Pilot

Journal. Motor. S/A

Race. Motor

Plug. Socket Pipe

Shaft. Bushing (B Housing Only)

Journal. Motor. RIA

Flange

Screw.

Plug. Socket Pipe

With Dump Valve Option

Spring. Dump Valve

Bracket. Dump Valve

O-ring. Dump Valve Bracket

O-ring. Tube Fitting

Nut. Dump Valve Fitting

Without Dump Valve Option

O-ring Plug. S/A

Protector. Shipping

Clamp. Hose

Adapter. Reservoir. 318 I.D. Tube

Adapter. Reservoir. 318 I.D. Tube

Pump Rotor Ball. S/A

Cam Ring. S/A

Insert

Control Shaft. S/A

Dowel

......................

........................

......................

.......................

¼

..........................

..........................

...............

..........

...............

.............

.............

.............

.............

.....................

...................

............

................

...................

..........

............

...................

..............

............

Hex Socket

...........

................

............

...........

............

.........

...............

...............

....................

.............

..................

...............

Qty.

780

........

.....

........

........

........

.

14

.....

...

...

Ref

.

No .

Part

No

.

Description

2

2

2

2

2

2

2

1

1

4

4

1

2

2

2

2

5

2

4

4

4

2

2

2

2

2

2

2

4

2

2

2

6

2

2

4

4

1

2

2

2

2

2

4

31 105327 Gasket. Cover

32 101597

33 103757-088 Screw. ¼-20 Hex Flange 10

34 104416

35 104393

36 104442 Gasket. Axle Housing

37 104822-008

38 104821 -008

39 10481 5-008 Shaft. Axle

40 101680-206 Retaining Ring. Internal

41 105745 Housing. Axle-B

42 105748 Housing. Axle-A

43 103960 Seal. Axle Shaft

44 104928 Bearing. Axle Shaft

45 103983-098 Retaining Ring. External

46 103966 Washer. Thrust

47 104436-1

48 Spacer

49 103933

50 104107

51 104551 Motor Rotor Ball.

52 104084 Parking Brake Assembly

53 104337

54 104340

55 104596 Shaft. Brake

56 990408 Planetary Gear

57 NSS Sun Gear. First. 15T

58 NSS Primary Carrier. A

59 NSS Plnt Gear. A

60 990409 Planetary Gear. Second.

NSS

61

62 NSS Secondary Carrier.

63

NSS

64

65 103772 Plug. Magnetic

66 103757-275 Screw. ¼-20 Hex Flange

67 104387 Cover. Brake

68 104391 Boot. Dust

69 95862-100 Bolt. 5/16-18 Hex Head

70 95897-031

71 96081-031

72 103222-062 Retaining Ring. External

73 104447 Plug. Seal

74 8761-021 O-ring

75 104730

76 105949-062 Torx Button Head Screw 14

77 105948 Flange

NSS

Not

Sold

Separately

Input Shaft Change from . 750 Dia . to 17mm Dia . Effective Date August

1990

.

Previous parts. cover

shaft seal

able with 17

*

Through Center

(104538).

mm

input shaft parts

Piston. Dampening. S/A ( Wide Band Neutral Not Shown. Has Orifice Hole

)

.

Button 4

Gasket. Valve Cover

Cover. Valve

Axle Housing. S/A-B

Axle Housing. S/A-A

00

Screw. ¼-20 Self-Tap

Gear. Brake 1

Drive

..........................

Plate. Wear 2

Ring Gear.

Sun Gear. Second. 15T

Plnt Gear. A & B S/A, Second.

21T 2

Washer. Thrust

Washer

Nut. Hex

..........................

Dowel 2

..........................

(104410)

.

are subject

input shaft subassembly (103768) and input

to

availability and they are

.

...................

.........................

..........

.............

....................

............

............

............

....................

.........

..............

..............

...............

............

................

.............

.........................

.....................

A

&

B S/A,

..........

.....................

A

&

B S/A,

57T

....................

.

First. A &

B S/A

............

&

B S/A, 15T

&

B S/A, First. 21T

A

&

.........

A

&

B S/A

........................

................

..................

..........

....................

......................

............

........................

........................

..........

......................

..........

.........................

not

Qty

780

........

30

15T

...

........

...

. .

. .

B S/A 2

...

14

1.

interchange-

.

2

2

2

6

1

1

2

2

1

1

2

2

4

4

1

2

2

1

2

1

2

2

2

2

2

2

2

2

1

1

4

8

4

1

1

1

2

The axle housings (Ref

64)

and spacer (Ref

you

must replace the axle housing(s)

.

No

.

No .

.

48)

41

are

and

42)

no

longer used

.

Effective November.

have been redesigned

or

available . If these parts need to

1989

so

the thrust washer (Ref

be

.

No .

replaced

Page 28

HOW

TO

ORDER

REPLACEMENT PARTS

EACH ORDER MUST INCLUDE

THE FOLLOWING INFORMATION

1.

Product Number

2.

Date Code

3.

Part

Name

4.

Part Number

5.

Quantity

of

Parts

Eaton

Corporation

Eaton

G.m.b.H.

Hydraulics

Hydraulics

Division

Division

15151

Highway

100

410

5,

Eden

D-5620

Velbert

Printed

in

Prairie,

1

West

U.S.A.

MN

55344

Germany

Telephone

(612)

49-2051-2070

937-9800

FORM

NO.

July,

6-41

1987

7

Loading...

Loading...