Page 1

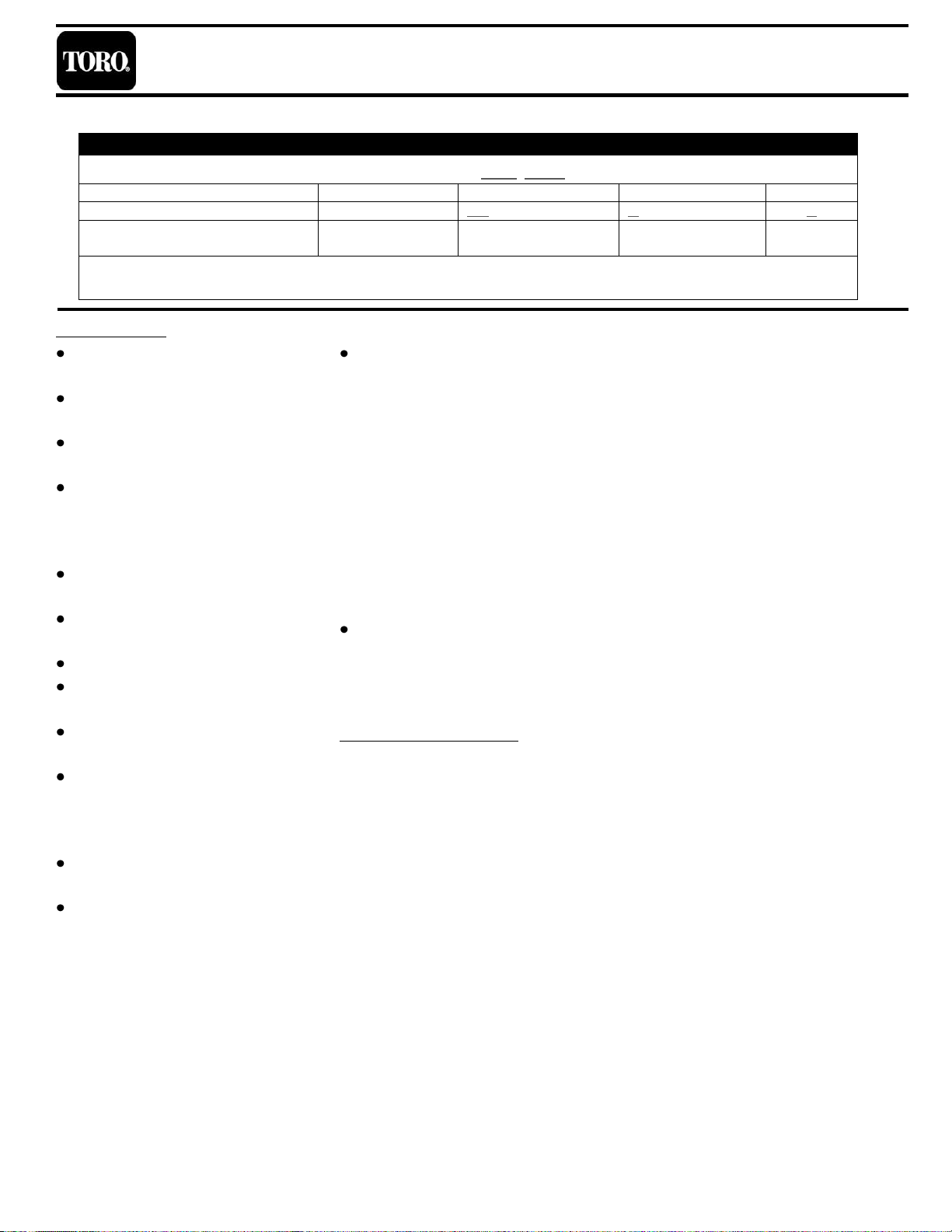

TS90 Series Sprinklers with Optional TurfCup™

Specifying Information – TS90 Series Sprinkler

TS90TP-02XX-X-E

Description

Threads

TurfCup™

Nozzle

Optional

TS90TP

02

XX X E

TS90TP—TS90TP 1” (25mm) Toro

with TruJectory

02—NPT thread

TC--TurfCup™ option

1, 2, 3, 4, 5, 6, 7, 8, 9

E–Effluent

Example:

A TS90 Series sprinkler with TruJectory, NPT threads, TurfCup™, and 82’ (25m) radius would be specified as:

TS90TP-02TC-6

Specifications

Radius: 53’-95’ at 25° (16,2 –

29,0m) trajectory

Flow rate: 14.0-61.5 gpm (53-233

lpm)

Precipitation rate: .56-.60”/hr

(14,2-15,2mm/hr)

Arc: Full- & Part-circle in one

-Full-circle: 360° unidirectional

clockwise rotation

-Part-circle: 40°-330°

Rotation Speed: 3 minutes ± 30

seconds

Recommended operating pressure

range: 40-100 psi (2,8-7,0 Bar)

Inlet size: 1” (40mm) NPT or BSP

Check valve capable of checking up

to 10’ (3m) of elevation difference

Rubber cover for personnel safety

and protection

Available in TurfCup™ versions

for seamless on-field installations

on natural and artificial turf sports

field installations

Effluent indicator plug for

installation on rubber cover

Dimensions, non-TurfCup

versions:

-Body height: 10” (254mm)

-Overall popped-up height: 12.5”

(317mm)

-Retracted height: 8.5” (216mm)

-Overall pop-up height: 4”

(402mm)

-Pop-up height to main nozzle: 3”

(75mm)

-Exposed cap diameter: 2.2”

(26mm)

-Body diameter: 4 ” (402mm)

Dimensions, TurfCup versions:

-Body height: 10” (254mm)

-Overall popped-up height: 14.5”

(37mm)

-Retracted height: 10.7” (27mm)

-Overall pop-up height: 4”

(402mm)

-Pop-up height to main nozzle

from top of outer cover: 1”

(25mm)

-Body diameter: 4 ” (402mm)

-Overall diameter with stabilizing

spacer: 6.25” (16mm)

Nozzle options: 9 main, 3

intermediate, 1 inner, 1 molded-in

inner (no molded in inner on

TurfCup™ versions)

Bidding Specifications

The sprinkler shall be of geardrive, rotary type, capable of

covering a _____ foot (meter) radius

at _____ PSI (bar; kPa) with a

discharge rate of _____ GPM (lpm).

The sprinkler shall be available with

nine (9) distinct main nozzles for

distance coverage, three (3) distinct

intermediate nozzles for mid-range

coverage, one (1) inner nozzle for

close-in coverage and one (1) molded

in inner nozzle (not available for

TurfCup™ versions) for mid-closerange coverage. The nine (9)

different nozzle sets shall be formed

by combinations of the main,

intermediate and inner nozzles. The

main nozzle shall be adjustable from

7° to 30°, in 1° increments, from

horizontal. The option of a back

nozzle shall be available.

The sprinkler shall have both fullcircle and adjustable part-circle

operation in a single unit. The

sprinkler shall be minutely adjustable

from 40° to 360° in part-circle mode.

It shall be adjustable in all phases of

installation (i.e., before installation,

after installation while static, and

after installation while in operation).

When in 360° mode, it shall rotate

only in the clockwise direction. The

sprinkler shall be equipped with a

self-adjusting stator to ensure

constant rotation speed regardless of

nozzle installed.

The sprinkler shall have a clutch

mechanism to allow the nozzle turret

to be manually advanced to the ends

of its arcs, thus allowing quick

determination of arc limits, without

having to wait for the gear drive

mechanism to drive the nozzle turret

to the limits. The sprinkler shall have

hard arc limits that provide the

operator with positive end of arc

stops when manually advancing the

nozzle turret. The riser shall have a

ratchet feature that allows the entire

riser/nozzle turret assembly to be

rotated to a new position, when not

under water pressure.

The sprinkler shall be equipped

with a drain check valve to prevent

low head drainage, and be capable of

checking up to 10 feet in elevation

change. The sprinkler shall have a

minimum of 4-inch pop-up stroke to

June 2012

Page 2

TS90 Series Sprinklers with Optional TurfCup™

bring the rotating nozzle turret into a

clean environment.

Standard non-TurfCup™ only:

The sprinkler shall have a black

rubber cover firmly attached to the

top of the riser. When specified,

there shall be a lavender-colored

TPE (thermoplastic elastomer) plug

that can be affixed to the rubber

cover to indicate the use of reclaimed

water.

The sprinkler shall have an

exposed surface diameter after

installation of 2.2 inches (56mm) and

have an overall height of 8.5 inches

(216mm). The sprinkler shall be

installed no more than ½” (13mm)

below grade.

The sprinkler shall be serviceable

after installation by unscrewing the

cap locking screw on the side of the

body cap, unscrewing the body cap,

removing the riser assembly, and

extracting the inlet filter screen. The

retraction spring shall be removable

by removing the inner seal

retainer/o-ring assembly, which, in

turn is retained by body cap.

TurfCup™ versions only:

The sprinkler shall have all the

same features as the stock TS90, with

the additional feature of a modified

nozzle turret which allows the

attachment of a TurfCup™ with a

screw fastener. There shall be a

form-fitting outer cover that fits over

the body cap and the TurfCup™.

There shall also be a stabilizing

spacer that fits over the outer cover

and prevents lateral movement of the

sprinkler, after installation. There

shall be pre-installed artificial turf

firmly attached to the turf disk,

which is attached to the bottom of

the TurfCup™.

The TurfCup™, outer cover and

stabilizing spacer shall all be

constructed of black rubber. The

screw fastener that attaches the

TurfCup™ to the top of the nozzle

turret shall be constructed of

stainless steel. The pre-installed

artificial turf shall be made of green

nylon or polypropylene fibers.

The sprinkler shall have an

exposed surface diameter after

installation of 2.6 inches (66mm),

with only the edge of the TurfCup™,

edge of the outer cover and strands

of the pre-installed artificial turf

visible. The sprinkler shall be

installed such that the pre-installed

artificial turf is even with the

surrounding turf.

The sprinkler shall be serviceable

after installation by removing the

stabilizing spacer, prying off the

outer cover, unscrewing the cap

locking screw on the side of the body

cap, unscrewing the body cap,

removing the riser assembly, and

extracting the inlet filter screen. The

retraction spring shall be removable

by removing the inner seal

retainer/o-ring assembly, which, in

turn is retained by body cap.

All models:

The unit shall have a 1-inch

Female national Pipe Thread (FNPT)

inlet. When specified, the unit shall

have a 1-inch Female British

Standard Pipe Thread inlet.

The body of the sprinkler shall be

constructed of corrosion resistant,

impact resistant, heavy-duty ABS

plastic. It shall have a stainless steel

spring for positive retraction of the

riser when irrigation is complete.

The sprinkler shall carry a five-year

exchange warranty (not prorated).

The sprinkler shall be developed

and manufactured by an ISO 9001certified facility. The sprinkler shall

be model number_______________

and shall be manufactured by The

Toro Company, Irrigation Division.

Recommended Installation

Procedures

The TS90 Series sprinkler with

optional TurfCup™ is designed

specifically for turf areas requiring

______ coverage. These products

offer the most economical method of

irrigation where flows and system

pressures are available to support a

medium- to long-range radius.

The TS90 Series sprinkler with

optional TurfCup™ should be

specified for installation on a swing

joint. The swing joint should be

specified as a triple-swing type,

allowing movement up, down,

laterally, and at an angle to grade.

The sprinkler should be installed with

the top of the cap at finished grade.

The TS90 Series sprinkler with

optional TurfCup™ is engineered to

provide a smooth, consistent curtain

of water across the arc, with

provision made for head-to-head

coverage. For proper spacing, ensure

that system design and installation

accounts for prevailing wind

conditions.

It is recommended that sprinklers

are installed 2” (5 cm) from

hardscaping and 6”-12” (15.2-30.5

cm) from buildings or other vertical

impediments to allow for normal

maintenance procedures and to

minimize overspray on buildings.

Where possible, sprinklers should be

installed in a manner that will

minimize nozzle stream contact with

trees, controller enclosures,

shrubbery or other obstructions.

June 2012

Loading...

Loading...