Page 1

FormNo.3391-391RevB

FrontLiftFrame

SandPro

ModelNo.08712—SerialNo.311000336andUp

®

/IneldPro

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

®

5040TractionUnit

WARNING

CALIFORNIA

Operator'sManual

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Nopartsrequired

StraighthydraulicttingwithO-ring

90-degreehydraulicttingwithO-ring

Liftvalve

Valveplate1

Bolt(1/4x3inches)

Locknut(1/4inch)

Bolt(#10x1-1/4inches)

Locknut(#10)

Liftlever

Rightplowplate1

Leftplowplate

Bolt(1/2x2inches)

Locknut(1/2inch)

Hitchframebracket

Bolt(1/2x1-3/4inches)

Qty.

Use

–

–

2

2

1

3

3

2

2

1

1

4

4

1

2

Preparethemachine.

Removetheshrouds.

Installtheliftvalve.

Installtheplowplates.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3391-391*B

Page 2

ProcedureDescription

5

6

7

8

9

Hitchframe

Bolt(3/8x2inches)

Nut(3/8inch)

Capscrew(3/8x1-1/2inches)

Locknut(3/8inch)

Cylinderpin

Adapterplate1

Pusharmtube1

Pinassembly2

Thread-formingscrew

Bolt(5/8x1-1/2inches)

Washer(1.68-inchoutsidediameterx

0.65-inchinsidediameter)

Tube1

Clevispin

Cotterpin

45-degreehydraulicttingwithO-ring

Hydrauliccylinder1

90-degreehydraulicttingwithO-ring

Smallretainingring

Pin1

Largeretainingring2

Tubeassembly1

Hydraulichose(PartNo.108-8449)

Hydraulichose(PartNo.108-8453)

Hydraulichose(PartNo.108-8454)

Wirehoseholder1

Threadformingscrew(5/16x3/4inch)

Plasticcabletie3

Leverguideplate1

Flange-headscrew2

Washer2

Controlpaneldecal

Controlpanel

Knob1

Plasticcabletie3

Operator’sManual

Qty.

Use

1

2

2

2

2

2

Installthepusharmsandhitchframe.

2

2

2

1

1

1

1

1

1

1

1

2

1

1

1

Installthehydrauliccylinder.

Installthehydraulichoses.

Installthecontrolpanelandleverguide

plate.

Readthedocumentationandstoreitin

asafelocation.

2

Page 3

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowertheattachments.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey .

2

RemovingtheShrouds

NoPartsRequired

Procedure

1.Jackuptherearofthemachineandposition

blocksundertherearwheelmotormounts.

2.Removetherightreartire.

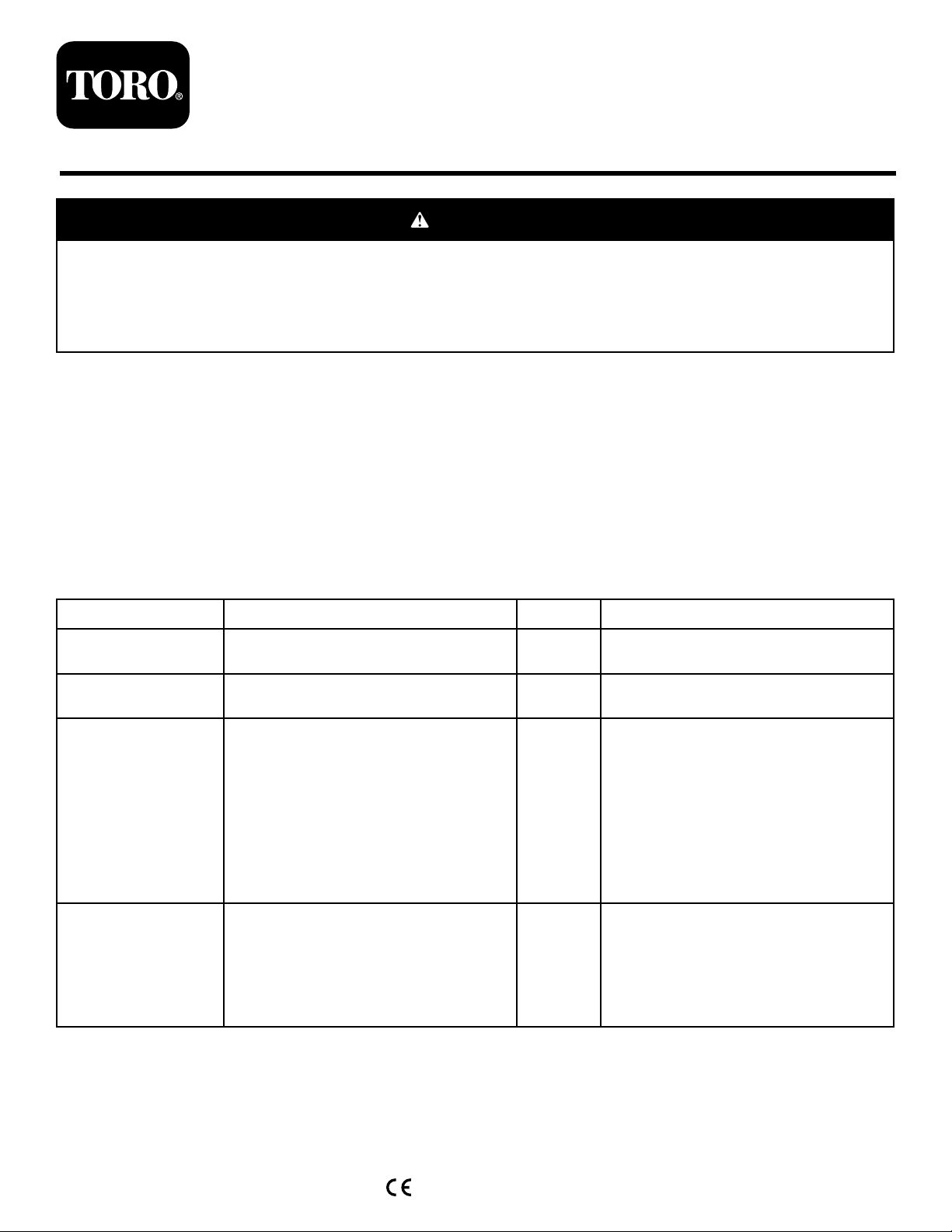

3.Removethe4washersandboltsmountingthe

controlpaneltotheconsole(Figure1).

4.Unplugthewirefromthehourmeter.

5.Removethecontrolpanel(Figure1).

6.Removethe3boltssecuringtheconsoletothe

frame(Figure1).Removetheconsolebygently

liftingthebottomedgeoftheconsolearound

thesupportbracketandslidingitupbeyondthe

brakehandle.

g003660

Figure1

1.Controlpanel3.Consolemountingbolt

locations

2.Console

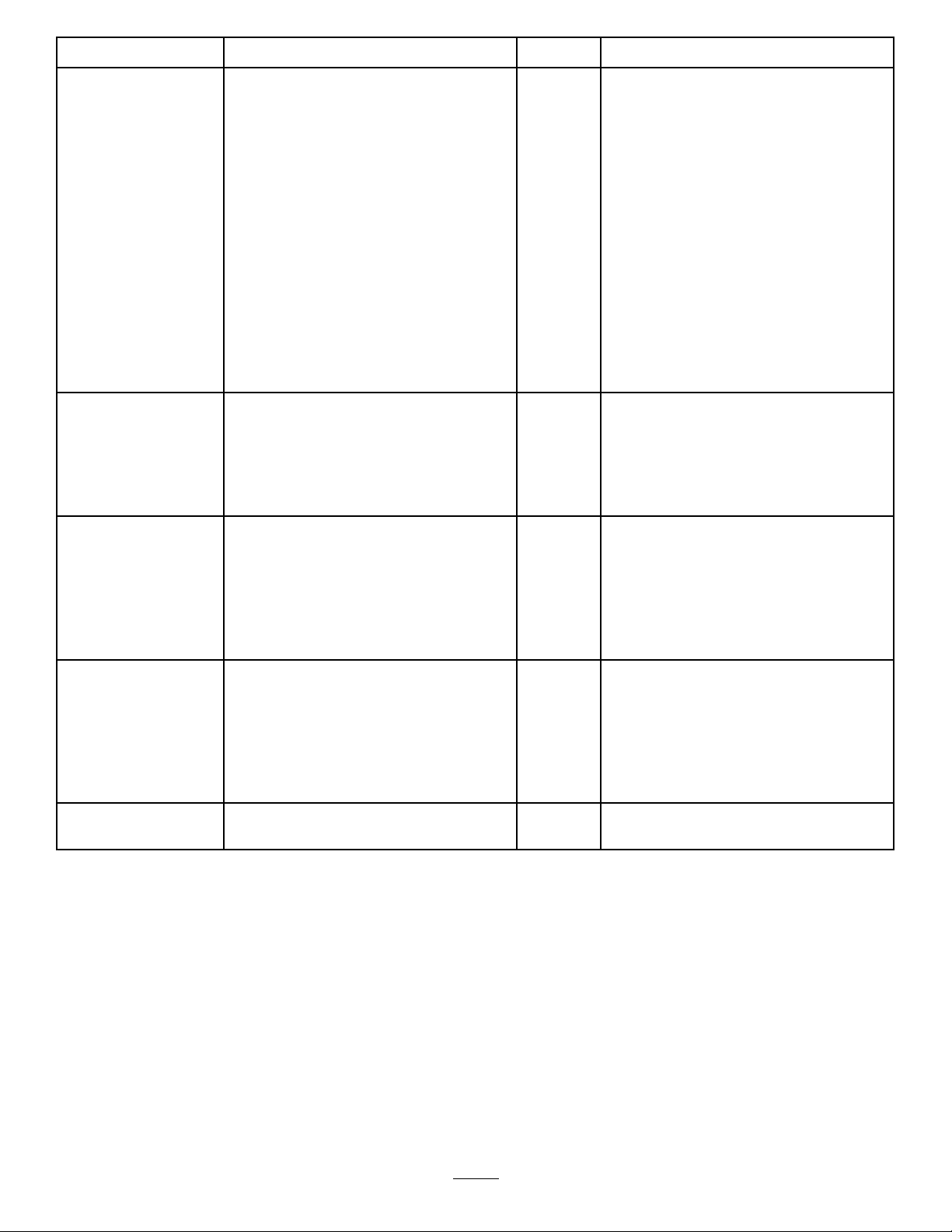

7.Removethe4boltssecuringtherighthand

wheelshroudtotheframeandremovethe

shroud(Figure2).

g003661

Figure2

1.Righthandwheelshroud

8.Disconnectandremovethecentershroudfrom

theframe(Figure3).

3

Page 4

Figure4

1.Straighttting3.Liftvalve

2.90-degreetting

g003663

Figure3

1.Centershroud

3

InstallingtheLiftValve

Partsneededforthisprocedure:

2

StraighthydraulicttingwithO-ring

2

90-degreehydraulicttingwithO-ring

1

Liftvalve

1Valveplate

3

Bolt(1/4x3inches)

3

Locknut(1/4inch)

2

Bolt(#10x1-1/4inches)

2

Locknut(#10)

1

Liftlever

g003662

2.Mountthevalveassembly,pivotbracket,and

valveplatetotheframewith3bolts(1/4x3

inches)and3locknuts(Figure5).Positionthe

valveplateagainstthefrontoftheframemember

whenmounting,andtorquethefastenersto10

to12N∙m(90to110in-lb).

Note:Thevalveinstallationisverysimilarto

thevalvecurrentlyinstalled.

3.Looselymountthepivotleverassemblytothe

valvespoolandtotheoffsetlinkwith2bolts

(#10x1-1/4inch)and2locknuts(Figure5).

Note:Donottightenthefastenersatthistime.

Procedure

1.Threadthe2ttings(90-degree)andthe2

straighthydraulicttingsintothenewliftvalve.

Note:PositionthettingsasshowninFigure

4.Donottightenthe90-degreettingsatthis

time.MakesurethatallO-ringsarelubricated

andproperlypositionedonthettingsbefore

installation.

4

Page 5

Figure5

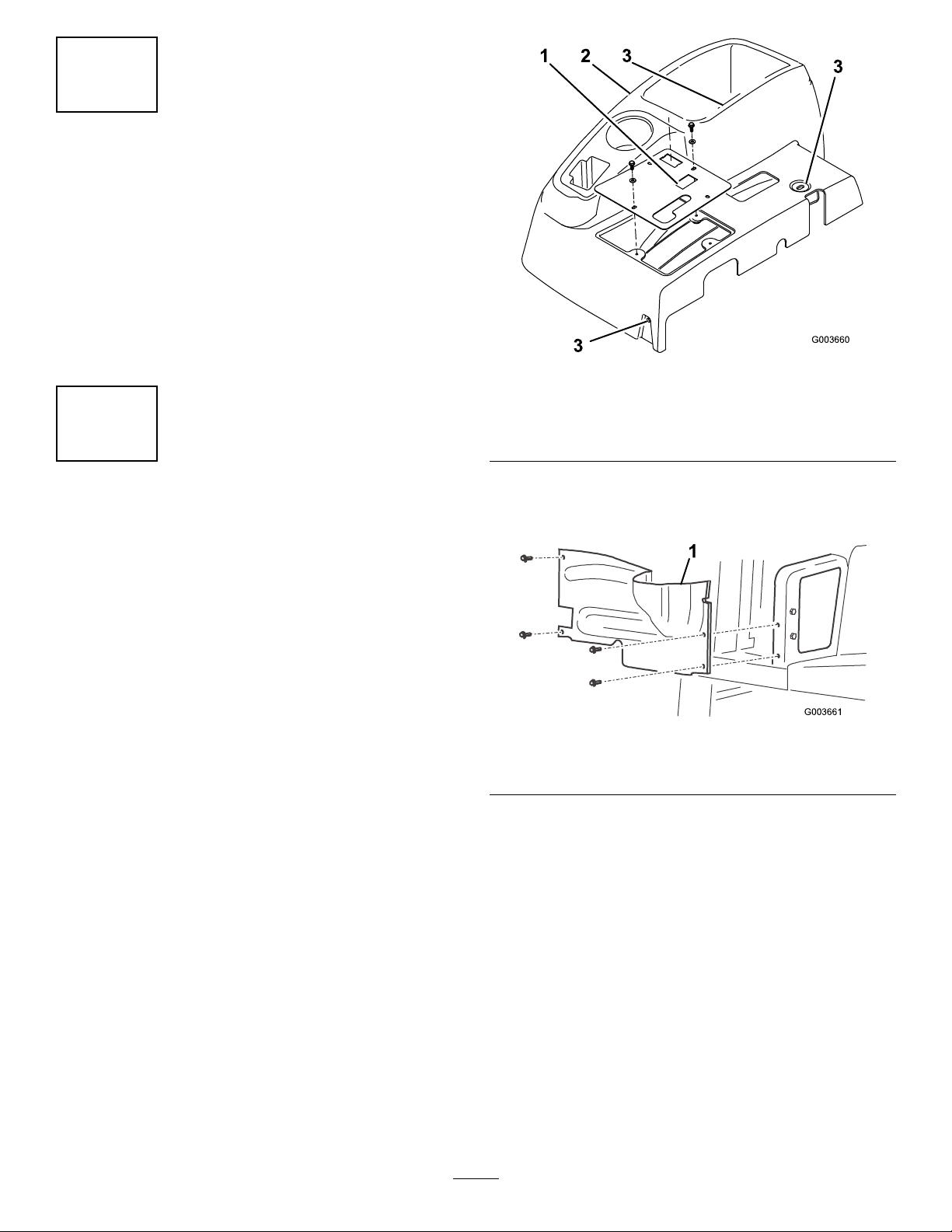

4.Removeanddiscardthe2boltssecuringthe

frontofthesteeringpivottothetopofthecaster

fork(Figure6).

5.Usingthecasterforkandsteeringpivotmounting

holes,mountthehitchframebrackettothe

undersideofthecasterforkwith2bolts(1/2x

1-3/4inches);refertoFigure6.

Note:Itmayberequiredtopartiallydeate

thetiretogainclearance.Thewheelmotor

hydraulichoseshouldnotrestontopofthehitch

framebracket.

g003664

1.Valveassembly

2.Pivotbracket5.Pivot

3.Valveplate6.Lever

4.Offsetlink

4

InstallingthePlowPlates

Partsneededforthisprocedure:

1Rightplowplate

1

Leftplowplate

4

Bolt(1/2x2inches)

4

Locknut(1/2inch)

1

Hitchframebracket

2

Bolt(1/2x1-3/4inches)

Procedure

1.Looselymounttherighthandplowplatetothe

rightsideofthecasterforkwith2bolts(1/2x2

inches)andlocknutsasshowninFigure6.

Figure6

1.Rightplowplate

2.Leftplowplate4.Hitchframebracket

3.Steeringpivot

g003665

Note:Donottightenthefastenersyet.

2.Repeattheprocedurewiththelefthandplow

plate(Figure6).

3.Jackupthefrontofthemachineuntilthefront

wheelisofftheoor.

5

Page 6

3.Insertacylinderpinintoeachpusharmtubeas

showninFigure8.

5

InstallingthePushArms

andHitchFrame

Partsneededforthisprocedure:

1

Hitchframe

2

Bolt(3/8x2inches)

2

Nut(3/8inch)

2

Capscrew(3/8x1-1/2inches)

2

Locknut(3/8inch)

2

Cylinderpin

1Adapterplate

1Pusharmtube

2Pinassembly

2

Thread-formingscrew

2

Bolt(5/8x1-1/2inches)

Washer(1.68-inchoutsidediameterx0.65-inchinside

2

diameter)

1Tube

1

Clevispin

1

Cotterpin

4.Insertthepusharmtubesontotherightandleft

plowplatesaligningthecylinderpinguideswith

theholesintheplowplates(Figure8).

Note:Ifunabletogetthepusharmtubes

aroundtheplowplates,loosenthenutssecuring

theplowplatestothecasterfork.

5.Mounteachcylinderpintoeachplowplate

withabolt(5/8x1-1/2inches)andawasher

(1.68-inchoutsidediameterx0.65-inchinside

diameter)asshowninFigure8.

Note:T orquetheboltsto203N-m(150ft-lb).

g003666

Figure8

Procedure

1.Lowerthemachinesothatthefrontwheelison

theoor.

2.Securethepusharmtubetotheadapter

platewith2pinassembliesandsecurethe

pinassembliestotheadapterplateswith2

thread-formingscrews.

Note:Positionthecomponentsasshownin

Figure7.

Figure7

1.Pusharmtube3.Pinassembly

2.Adapterplate

4.Thread-formingscrew

1.Cylinderpin

2.Pusharmtube

6.Mountthetopofthehitchframetothehitch

framebracketwith2bolts(3/8x2inches)and

nuts(Figure9).

7.Mountthehitchframetubestotheplowplates

withbolts(3/8x1-1/2inches)andnuts(Figure

9),andtightenthefasteners.

g003787

6

Page 7

Figure9

1.Hitchframebracket3.Hitchframetube

2.Hitchframe

8.Securetheframeadaptertothehitchframewith

atube,aclevispin,andacotterpin(Figure10).

g028340

Figure11

Important:Ensurethattheexistinghoses

areroutedabovetheguide,asshownin

Figure11.

g018349

6

InstallingtheHydraulic Cylinder

Partsneededforthisprocedure:

1

45-degreehydraulicttingwithO-ring

1Hydrauliccylinder

1

90-degreehydraulicttingwithO-ring

1

Smallretainingring

1Pin

2Largeretainingring

1.Frameadapter

2.Tube

Figure10

3.Clevispinwithgrease

tting

Procedure

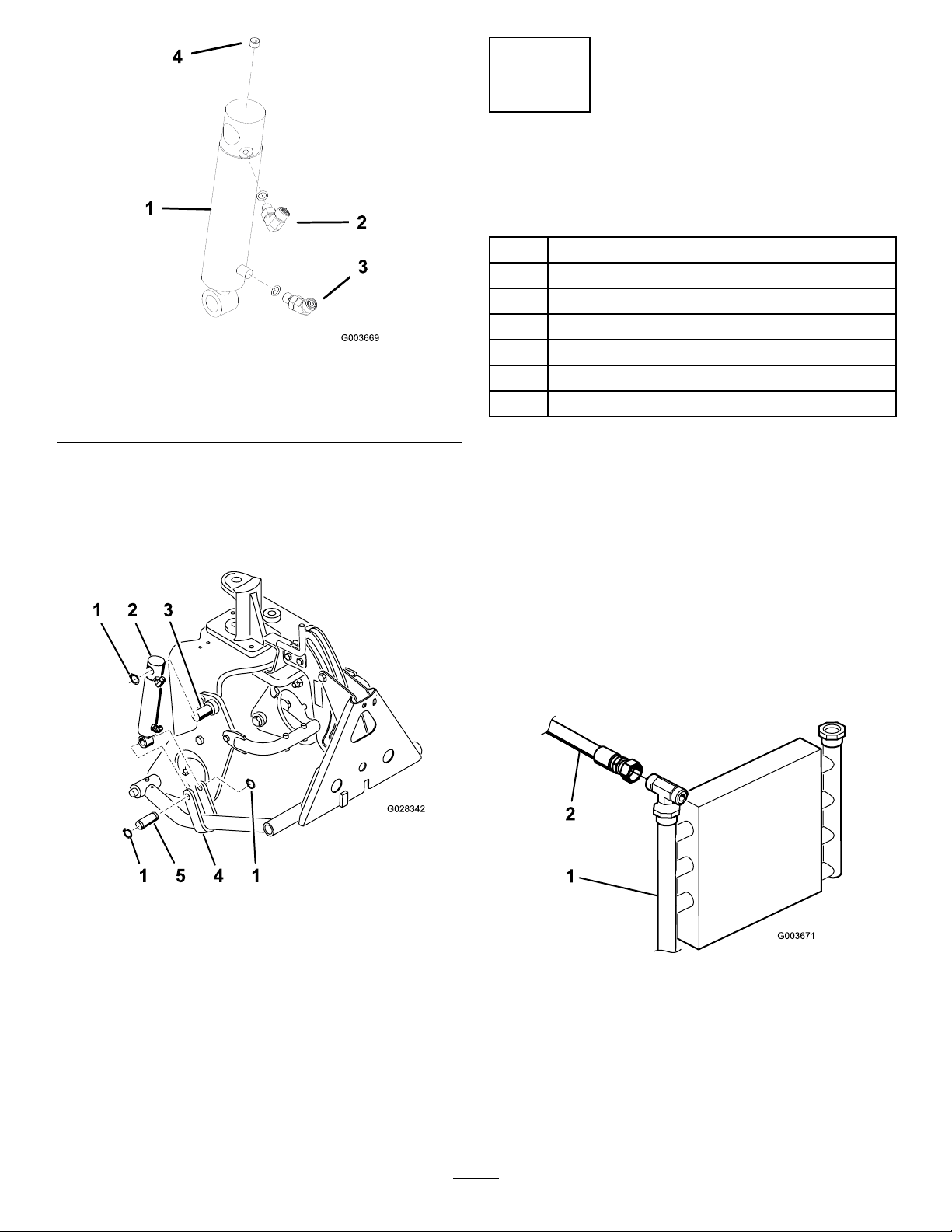

1.Threada90-degreettingintotheupperport

inthehydrauliccylinder.Positionthettingas

showninFigure12.

g018307

7

Note:MakesurethatallO-ringsarelubricated

andproperlypositionedonttingsbefore

installation.

Note:T opreventcontaminationtothehydraulic

ttingsorhoses,donotremovethecapsfrom

thettingsorhosesuntiltheyareinstalled.

2.Threada45-degreettingintothelowerport

inthehydrauliccylinder.Positionthettingas

showninFigure12.

Page 8

Figure12

1.Hydrauliccylinder

2.90-degreetting4.Plug(1/8inch)

3.45-degreetting

7

InstallingtheHydraulic Hoses

Partsneededforthisprocedure:

1Tubeassembly

1

Hydraulichose(PartNo.108-8449)

1

Hydraulichose(PartNo.108-8453)

1

Hydraulichose(PartNo.108-8454)

g003669

1Wirehoseholder

2

Threadformingscrew(5/16x3/4inch)

3Plasticcabletie

3.Mountthetopofthehydrauliccylinderbarrel

tothepinontheright-handplowplatewitha

retainingring(Figure13).

Note:Positionthecylinderhydraulicports

forward.

Figure13

Procedure

1.Locatethehydraulictubethatgoesfromtheoil

coolertotheexistingliftvalve(Figure14).

2.Removethefastenersandtubeclampsecuring

thehydraulictubestotheframe.

3.Disconnectandremovethehydraulictubefrom

theoilcoolerandtheliftvalve(Figure14).

Note:Tominimizeoillosswhenremoving

thehydraulictube,havethereplacementhose

readyorcapthettingonthecoolerusingoneof

theprotectiveshippingcapsremovedfromthe

tubeassembly,PartNo.108-8447(Figure15).

g028342

1.Retainingring4.Pusharmstrap

2.Hydrauliccylinder5.Pin

3.Pin(onplowplate)

4.Mountthecylinderrodtothepusharmstraps

withapinand2retainingrings(Figure13).

Figure14

1.Oilcooler

4.Securetheremaininghydraulictubetothe

framewiththeclampandfastenerspreviously

removed

5.Connectthetubeassembly,PartNo.108-8447,

tothe90-degreettingontheleftsideofthe

8

2.Hydraulictube

g003671

Page 9

newvalveandthevacatedttingontheexisting

liftvalve(Figure15).

6.Connectthe45-degreettingendofhydraulic

hose,PartNo.108-8449,tothe90-degreetting

ontherightsideofthevalveandthestraight

endofthehosetothevacantoilcoolertting

(Figure15).RefertoFigure16andFigure17

forhoserouting.

7.Mountthewirehoseholdertotheleftframetube

with2thread-formingscrews(5/16x3/4inch);

refertoFigure15.

8.Connecttheshort90-degreettingendof

hydraulichose,PartNo.108-8453,tothetop

straightttingontherearofthevalve.Routethe

hosethroughthewirehoseholderandconnect

thestraightendofthehosetothetophydraulic

cylindertting(Figure15).RefertoFigure16

andFigure17forhoserouting.

9.Connectthelong90-degreettingendofthe

hydraulichose,PartNo.108-8454,tothebottom

straightttingontherearofthevalve.Routethe

hosethroughthewirehoseholderandconnect

thestraightendofthehosetothebottom

hydrauliccylindertting(Figure15).Referto

Figure16andFigure17forhoserouting.

Important:Makesurethatthehosesare

routedawayfromanysharp,hot,ormoving

components.

10.Tightenallfastenersandttings.

11.Usingcableties,securethehosestothe

machineatthelocationsshowninFigure16and

Figure17.

Figure15

1.Newvalve3.Existingvalve5.Wirehoseholder

2.Tubeassembly(PartNo.

108-8447)

4.Hydraulichose(PartNo.

108-8449)

6.Hydraulichose(PartNo.

108-8453)

g003672

7.Hydraulichose(PartNo.

108-8454)

9

Page 10

Figure16

g218466

1.Cabletie2.Hydraulichose(PartNo.

108-8449)

3.Hydraulichose(PartNo.

108-8453)

4.Hydraulichose(PartNo.

108-8454)

10

Page 11

Figure17

1.Cabletie3.Hydraulichose(PartNo.108-8453)

2.Hydraulichose(PartNo.108-8449)4.Hydraulichose(PartNo.108-8454)

g218467

11

Page 12

8

InstallingtheControlPanel andLeverGuidePlate

Partsneededforthisprocedure:

1Leverguideplate

2Flange-headscrew

2Washer

1

Controlpaneldecal

1

Controlpanel

1Knob

3Plasticcabletie

Procedure

1.Inserttheleverguideplateovertheliftleverand

looselysecureittotheframewith2ange-head

screwsandwashers(Figure18).

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintothe

skinitmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliar

withthistypeofinjury.Gangrenemay

resultifthisisnotdone.

•Keepbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertond

hydraulicleaks.

•Safelyrelieveallpressureinthe

hydraulicsystembeforeperforming

anyworkonthehydraulicsystem.

•Makesurethatallhydraulic-uid

hosesandlinesareingoodcondition

andallhydraulicconnectionsand

ttingsaretightbeforeapplying

pressuretothehydraulicsystem.

3.Startthetractionunitengineandcheckthe

ttingconnections.

4.Installthewheelshroud,thecentershroud,and

theconsole.

Figure18

1.Leverguideplate2.Flange-headscrews

2.Checkthehydraulic-uidlevelandreplenishthe

uidasrequired.

Note:Donotinstallthecontrolpanelatthis

time.Makesurethattheshroudsdotheinterfere

withthehoses.Routethehosesasrequired.

Reversetheshroudinstallationprocedureused

instep1.

5.Installthereartireandremovetheblocksfrom

undertherearofthemachine.

6.Torquethelugsnutsto61to75N∙m(45to55

ft-lb).

g003675

7.WiththeenginerunningandliftleverintheFloat

position,slidetheleverguideplateuntilthelift

cylindercanbeextendedandretractedbyhand

(Figure18).

WARNING

Theenginemustberunningsothatthe

naladjustmentoftheliftleverdetent

platecanbeperformed.Contactwith

movingpartsorhotsurfacesmaycause

personalinjury.

Keephands,feet,face,andotherbody

partsawayfromrotatingparts,the

mufer,andotherhotsurfaces.

8.Tightenbothliftleverguideplatemounting

screwstosecuretheadjustment(Figure18).

12

Page 13

9.Removethehourmeterfromtheoldcontrol

panelandinstallitinthenewcontrolpanel.

10.Installthenewcontrolpanelandplugthewire

intothehourmeter.

11.Securethecontrolpanelinplacewiththe

fastenerspreviouslyremoved(Figure19).

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

OperatingTips

•Thefrontliftframeisdesignedtoacceptonly

certainattachments.Donottrytoinstallarear

mountattachmenttothefrontliftframe,asdamage

tothemachinemayoccur.

•T olowerthefrontliftframe,pushtheliftlever

forward.

•T oallowthefrontliftframetooat,pushthelift

leverforwardandtothesideintothedetent.

Figure19

1.Knob

12.Installtheknobontotheliftlever(Figure19).

13.Greasethefrontliftframe;refertoGreasingthe

LiftFrame(page13).

14.Checkthehydraulic-uidlevelandreplenishthe

uidasrequired.

2.Controlpanel

9

Reading/Storingthe Documentation

Partsneededforthisprocedure:

1

Operator’sManual

g003676

•T oraisethefrontliftframe,pulltheliftlever

rearward.

•Becomefamiliarwiththesafeoperationofthe

equipment,withtheoperatorcontrols,andsafety

signs.

•Keephandsandfeetawayfrommovingpartsand

hotsurfaces.

Maintenance

GreasingtheLiftFrame

Thefrontliftframehas5greasettings(Figure20)

thatmustbelubricatedregularlywithNo.2lithium

grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every100hoursofoperation.Lubricatethebearings

andbushingsimmediatelyaftereverywashing,

regardlessoftheintervallisted.

Procedure

1.Readthedocumentation.

2.Storethedocumentationinasafeplace.

Operation

Specications

Netweight

38.5kg(85lb)

13

Page 14

Figure20

g003677

14

Page 15

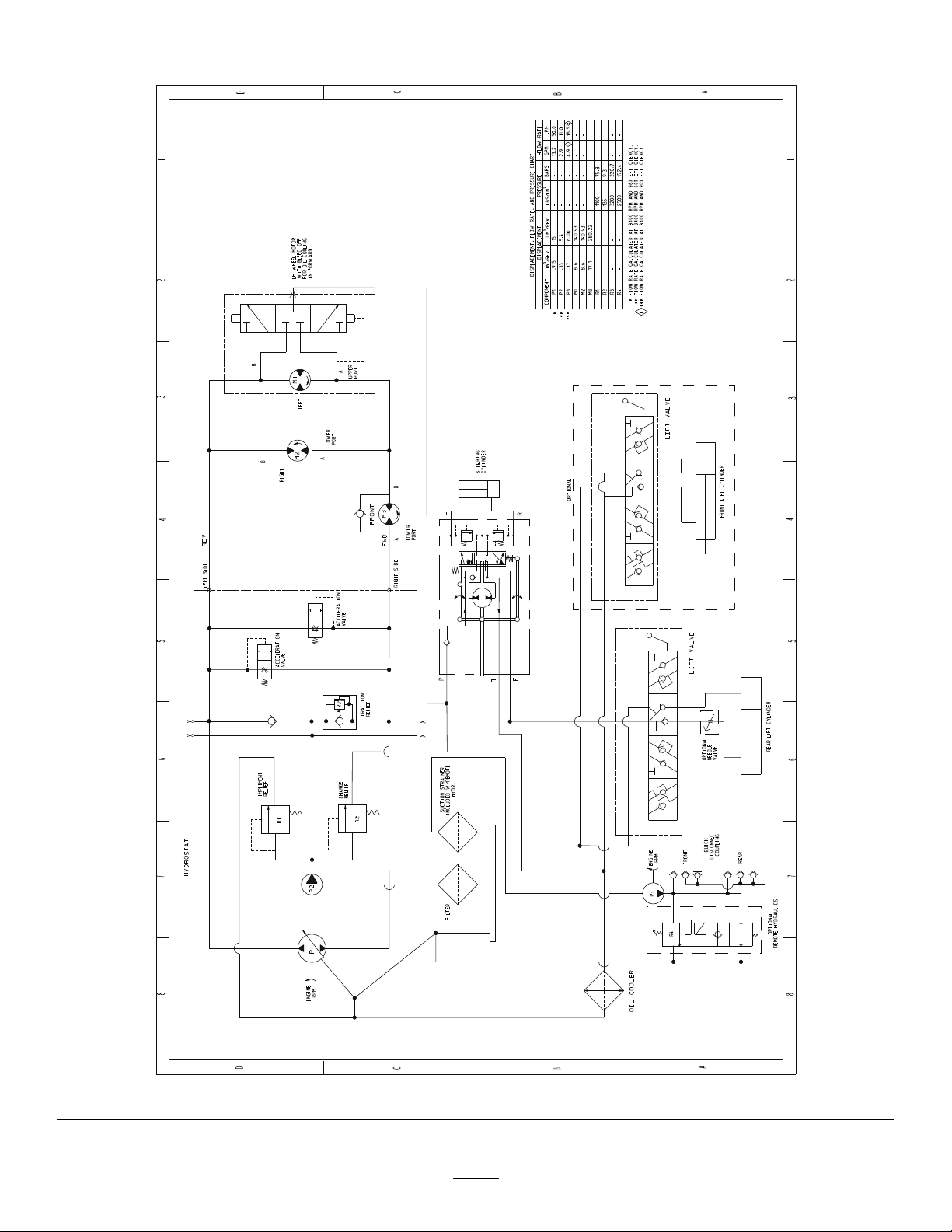

Schematics

Hydraulicschematic108-2946(Rev.E)

15

g218266

Page 16

Notes:

Page 17

Notes:

Page 18

DeclarationofIncorporation

TheToroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity .

ModelNo.

SerialNo.

08712

—

ProductDescriptionInvoiceDescription

FrontLiftFrameFRONTLIFTFRAMEKITFrontLiftFrameAssembly2006/42/EC

GeneralDescription

Directive

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

JohnHeckel

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

May31,2017

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

Tel.+3216386659

Page 19

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithToro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0282RevC

Page 20

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroW arrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather ,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheT oroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty ,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty .ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...