Page 1

TM

Plus

User’s Guide

IRRIGATION CONTROLLER

TM

Plus

English - Español - Français

Page 2

i

Thank you for purchasing the Irritrol Systems IBOC Plus battery

operated controller. Listed below are some of the standard IBOC Plus

features:

• Operates on one 6-volt alkaline lantern battery. Can be optionally

powered by solar panel converter (SPC-2).

• Easy-to-read, self-prompting display information.

• English/Spanish display option.

• Operates standard 24 V d.c. latching solenoid valves (E2002).

• Three independent watering programs.

• Concurrent operation of up to three watering stations (one station

per program) and a master valve.

• Station watering time adjustable from one minute to 23 hours and

59 minutes in 1-minute increments.

• Up to 8 start times per program for a total of 24 starts per day.

• Program cycle looping enables repeat program operation within a

selectable watering window.

• Watering day scheduling by Weekday, one to 62-day Skip routine,

or Odd/Even days.

• Master valve operation selectable by program.

• Manual operations by program or station.

• Station Test mo de.

• Program Review mode.

• Rain Delay mode – postpones automatic operation from one to 30

days.

• Battery or solar power (if using SPC-2) capacity displayed in %

remaining.

• Rain Sensor ready – sensor input selectable by program.

• Water Budgeting 10–200% in 10% increments.

• Non-volatile memory – retains program information without power.

• Electronic circuit breaker automatically detects short and open

circuit conditions on station output – allows remaining stations to

operate as programmed.

CONTROLLER FEATURES

Features

Page 3

1

Features....................................................................................................i

Controller Components.....................................................................2–3

General Information..........................................................................4–7

How the Backup System Works.......................................................4

Installing the Battery........................................................................4

How the Electronic Circuit Breaker Works.....................................5

How the Sensor Feature Works.......................................................6

Control Options...............................................................................6

Program Erase............................................................................6

Display Language Option .........................................................7

Rain Sensor Operation.............................................................7

Programming the Controller...........................................................8–16

Getting Started.................................................................................8

Setting the Current Time and Date...............................................11

Setting the Station Run Time........................................................12

Master Valve Operation.................................................................12

Setting Program Start Time(s) .......................................................13

Program Looping Feature...............................................................13

Selecting the Days to Water..........................................................14

Program Review..............................................................................16

Installation Procedures ..................................................................16–20

Selecting an Installation Site.........................................................16

Mounting the Controller...............................................................17

Converting The Solenoids.............................................................17

Connecting Field Wiring...............................................................18

Connecting a Rain Switch Sensor.................................................18

Connecting an Earth Ground........................................................19

Operating the Controller ...............................................................20–23

Testing Station Operation ..............................................................20

Water Budgeting ............................................................................21

Off and Rain Delay Modes.............................................................22

Manual Operations.........................................................................22

Appendix A - Troubleshooting...........................................................24

Appendix B - Specifications ................................................................25

TABLE OF CONTENTS

Table of Contents

Page 4

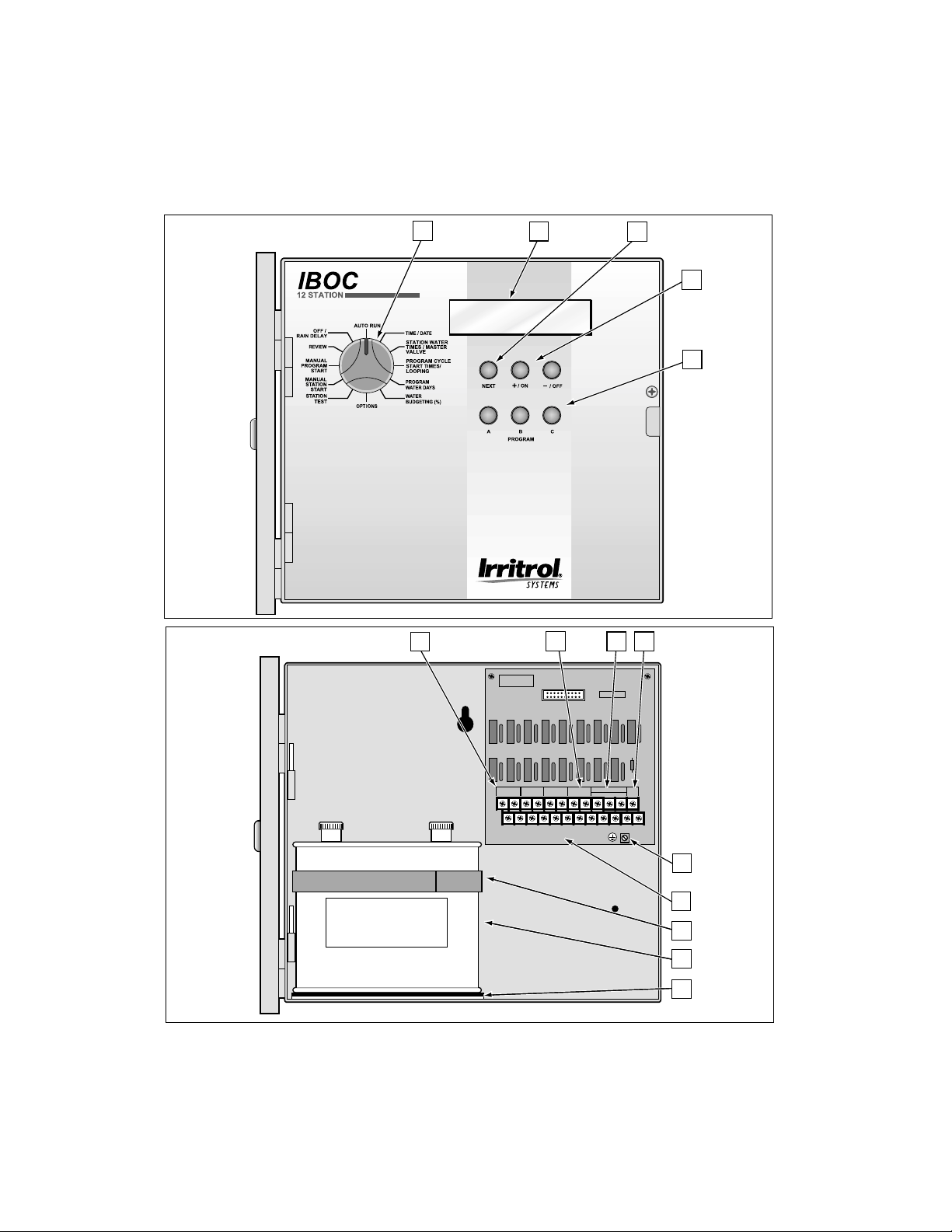

2

Controller Components

▲ Figure 1

1 Function Dial: For selecting the programming and operating

functions.

2 LCD Display: For viewing time, program and status information.

3 Next Button: For selection of information to be programmed or

reviewed.

4 + /On and – /Off Buttons: For adjustment or entry of program data.

5 Program Buttons: For selection of Program A, B and C to be

programmed or reviewed.

▲ Figure 2

6 Battery or Solar Panel Converter Connection Terminals

7 Rain Sensor Connection Terminals

8 Valve Common Connection Terminals

9 M as t er Valve Ou tp ut Connection Terminal

10 Earth Ground Lug

11 Valv e Power Connection Terminals

12 Battery Retainer Strap

13 6-Volt Alkaline Lantern Battery (not included)

14 Battery Insulator Plate

CONTROLLER COMPONENTS

Page 5

3

TM

Plus

6-VOLT

LANTERN

BATTERY

MV/

PUMP

EARTH

GND

1 2 3 4 5 6 7 8 9 10 11 12

FOR SERVICE

USE ONLY

INPUT GND

L N

BATTERY

INPUT GND

+ -

RAIN SENSOR

INPUT GND

+ -

VALVE COM

1

23

4

5

Figure 1

Figure 2

Controller Components

6

12

13

11

10

7

8

9

14

Page 6

4

HOW THE BACKUP SYSTEM WORKS

The IBOC Plus utilizes non-volatile memory storage to prevent

watering program information from becoming lost in the event of a

power failure. Even the time and date will be retained for the first

10 minutes without power.

A fully charged 6-volt alkaline lantern battery will operate the

controller for more than a year. The SPC-2 (Solar Power Converter)

module will operate the IBOC Plus controller for up to six years,

assuming it receives sunlight for an average of two hours per day.

Once a power source is applied, the controller can be fully

programmed for operation.

Note: If you wish to program the controller prior to installation,

connect the battery at this time. Battery removal will be necessary

prior to installing the controller cabinet. The program memory will be

retained with the battery disconnected.

INSTALLING THE BATTERY

Note: A battery is not provided with the controller. A common 6-volt

alkaline lantern battery (type: NEDA 918A) with screw-type

terminals is required. Use an Energizer type #521, Duracell MN 918 or

equivalent.

Caution: Batteries contain hazardous material. Always handle

and discard batteries properly in accordance with the battery

manufacturer’s recommendations.

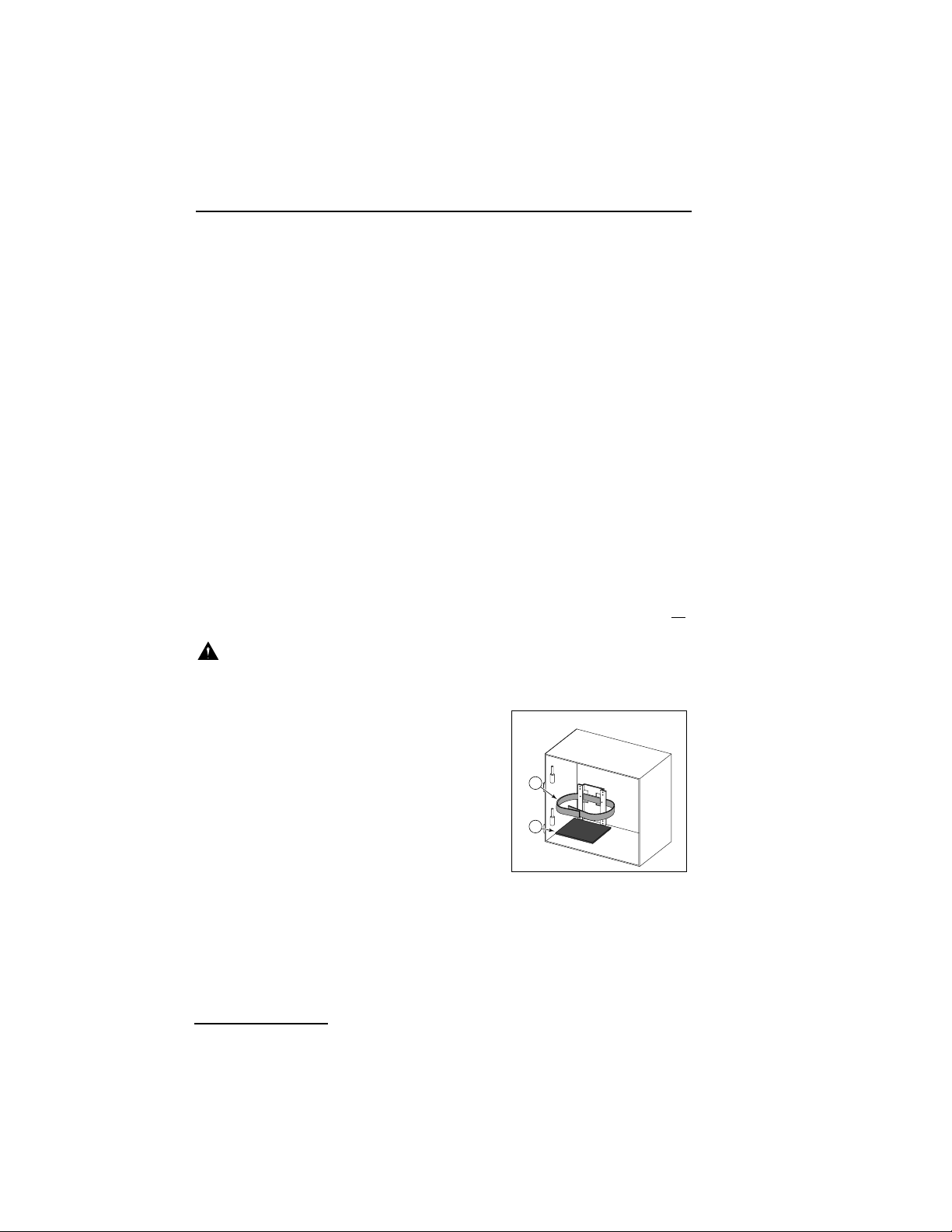

1. Remove the phillips screw from the

right edge of the control panel enabling

the panel to swing outward.

2. Install the battery insulator plate (A) and

retainer strap (B) as shown in Figure 3.

3. Install the battery and secure with the

retainer strap.

4. Using the wires provided, connect the

positive (+) battery terminal to the

terminal board terminal labeled “Battery Input.” Connect the

negative (–) battery terminal post to “Battery Gnd.”

Note: The battery condition is displayed as a percentage of capacity

remaining while the controller is idle. The battery should be replaced

when the capacity drops below 40%.

GENERAL INFORMATION

General Information

A

B

Figure 3

Page 7

5

General Information

HOW THE ELECTRONIC CIRCUIT

BREAKER WORKS

The controller is equipped with an electronic circuit breaker. If the

controller detects a short or open circuit, the affected station (valve)

will be turned off automatically. The display will then show

information for the station or stations regarding the problem

condition. The controller continues to automatically water the other

stations. Each automatic start will attempt another cycle and retest

the short-circuited valve.

Listed below are the most common conditions which will activate the

electronic circuit breaker.

Condition: The word “Short” displays with one or more station

numbers.

Diagnosis: One or more stations are shorted.

Solution: Check the wiring of the displayed stations for the cause of

the shorted condition. Repair valve(s) and/or wiring as

needed.

Diagnosis: Overload condition caused by more than one valve

connected to the same station terminal.

Solution: Ensure only one valve is connected to each station

terminal.Three valves may be operated concurrently, but

they must be on separate stations operating on separate

programs.

Condition: The word “Open” displays with one or more station

numbers.

Diagnosis: An open circuit condition exists at one or more valve

solenoids.

Solution: Check wiring of the reported station(s) for loose or

broken connections.

Note: If a master valve is not installed, ensure that master valve

operation is disabled. See Master Valve Operation on page 12 for

details.

After correcting the problem, return the controller to normal

operation as follows:

1. Set the dial to the following

AUTO RUN

positions.

2. Press the

–/

OFF

button to clear the display and return the

controller to the normal operating mode.

Page 8

6

HOW THE SENSOR FEATURE WO RKS

The IBOC Plus is equipped to operate with an optional rain sensing

device, commonly called a “Rain Switch,” to prevent automatic

watering during rain.

The rain switch is a simple device, typically installed on a roof

overhang or stationary structure exposed to rainfall and full sun, and

shielded from irrigation spray. The rain switch wiring is connected to

the sensor terminals provided on the controller terminal board.

Rain sensor operation is selectable by program, enabling sensor control

to be allocated to specific watering programs as needed.

When rain occurs, the switch senses the moisture and causes the

controller to terminate all output to the field. The electronic

programming portion of the controller is isolated from the rain sensor

switch, and continues to operate as programmed. When rain stops and

the rain switch returns to its normal state, field output is restored,

enabling watering to resume as scheduled.

CONTROL OPTIONS

This dial position provides access to the following features: Program

Erase, Language Option Select and Sensor Enable.

PROGRAM ERASE

Use this feature to clear the memory of a selected program and reset it

to default values (no active days, start times or station run times and

100% water budgeting).

To erase and reset a program:

1. Turn the function dial to the

OPTIONS

position.

2 Select the program to be reset by pressing

PROGRAM

button

A, B

or C.

3. Press the

+ /ONbutton. A prompt will be displayed confirming

program erasure.

4. Repeat steps 2 and 3 for remaining programs as required.

5. Return the function dial to the

AUTO RUN

position if finished, or press

the

NEXT

button to continue.

General Information

Page 9

7

DISPLAY LANGUAGE OPTION

Use this feature to select either Spanish or English display prompts.

By default, English display prompts will be shown.

To change the display language:

1. Ensure the function dial is in the

OPTIONS

position.

2. Press the

NEXT

button to display “Language”.

3. Press the

+/ONbutton to select the desired language.

4. Return the function dial to the

AUTO RUN

position if finished or press

the next button to continue.

RAIN SENSOR OPERATION

Use this feature to enable/disable rain sensor operation mode for each

program.

Important: A rain sensor device must be properly connected to the

controller Rain Sensor terminals before sensor operation is enabled

for an automatic watering program. If a rain sensor is not installed

and the rain sensor operation is enabled, automatic watering for the

program will NOT occur. By default, rain sensor operation is

disabled for all programs.

To select the rain sensor mo de:

1. Ensure the function dial is in the

OPTIONS

position.

2. Press the

NEXT

button as required to display “Rain Sensor.”

3. Select the program by pressing Program button

A, B

or C.

4. Press the

+/ONbutton to enable or –/

OFF

button to disable sensor

operation for the selected program.

5. Repeat steps 3 and 4 as required to set rain sensor operation for

additional programs.

6. Return the function dial to the

AUTO RUN

position when finished.

Programming the Controller

Page 10

8

This section covers the following topics:

•

Getting Started

•

Setting the Current Time and Date

•

Setting the Station Run Time

•

Master Valve Operation

•

Setting Program Start Times

•

Program Looping Feature

•

Selecting the Days to Water

•

Reviewing Program Information

GETTING STARTED

WHAT IS A WATERING PROGRAM?

In basic terms, a watering program is a small set of instructions which tells

the controller when to start a watering cycle, which stations will operate

during the cycle, which days the cycle will be active and how long each

station will operate during the cycle. The IBOC Plus has three independent

watering programs for your use. Separate programs are usually used to group

stations with similar watering requirements. For example, you might use one

program to water lawns in full sun every day. Another program could be

used to water lawns in partial shade only on Monday, Wednesday and

Friday. Trees and shrubs using drip irrigation could run on a separate

program once every two weeks. The garden area requirements might include

watering every other day. As you can see, the availability of three programs

allows you to have unique watering programs for your varied landscape

needs.

Programming the Controller

PROGRAMMING THE

CONTROLLER

Page 11

WHAT IS A PROGRAM WATERING CYCLE?

When a watering start time is selected, that time becomes the beginning

of an automatic watering cycle. A watering cycle operates each station

assigned to the program, one by one, in numerical order.

In the following example, (also shown on the sample watering plan on

page 10) we have set up Program A to start at 2:00 a.m. and again at

3:00 a.m. on a 1-day interval (every day). Stations 1, 2, 4 and 5 are front

and back yard lawn areas which get full sun throughout the day. These

stations will run for 10 minutes each for a total of 20 minutes run time

per day. Stations 3, 6 and 7 are lawn areas which are shaded during the

afternoon hours. These areas require less water, so we have assigned them

to Program B and set them to run for 20 minutes on a 2-day interval

(every other day).

At 2:00 a.m., Program A watering cycle starts. Station 1 turns on, runs

for 10 minutes, and shuts off. Station 2 turns on, runs for 10 minutes, and

turns off. Stations 4 and 5 operate sequentially in the same manner, each

running for their set run time. When Station 5 shuts off, the watering

cycle is completed for the first start time. At 3:00 a.m., the watering

cycle starts again and repeats the same station-by-station watering

sequence.

Note that we have 40 minutes total watering time per cycle in

Program A. If we had set the next start time at 2:30 a.m., the start time

would have been delayed until 2:40 a.m., enabling the first cycle to finish

as programmed. This function is called “start time stacking”, and can

occur within each program.

Watering programs, however, operate independently, which means that

two or more programs can run simultaneously. In our example,

Program B will also start at 2:00 a.m. Therefore, Stations 1 and 3 will

turn on at the same time, and Station 2 will turn on while Station 3 is

running. This feature enables more watering to be completed within the

prime “watering window”, which is generally between Midnight and

6:00 a.m.

Note: When scheduling watering programs to run simultaneously, it is

important to ensure the water supply has sufficient pressure and volume

to maintain optimum sprinkler performance.

9

Programming the Controller

Page 12

10

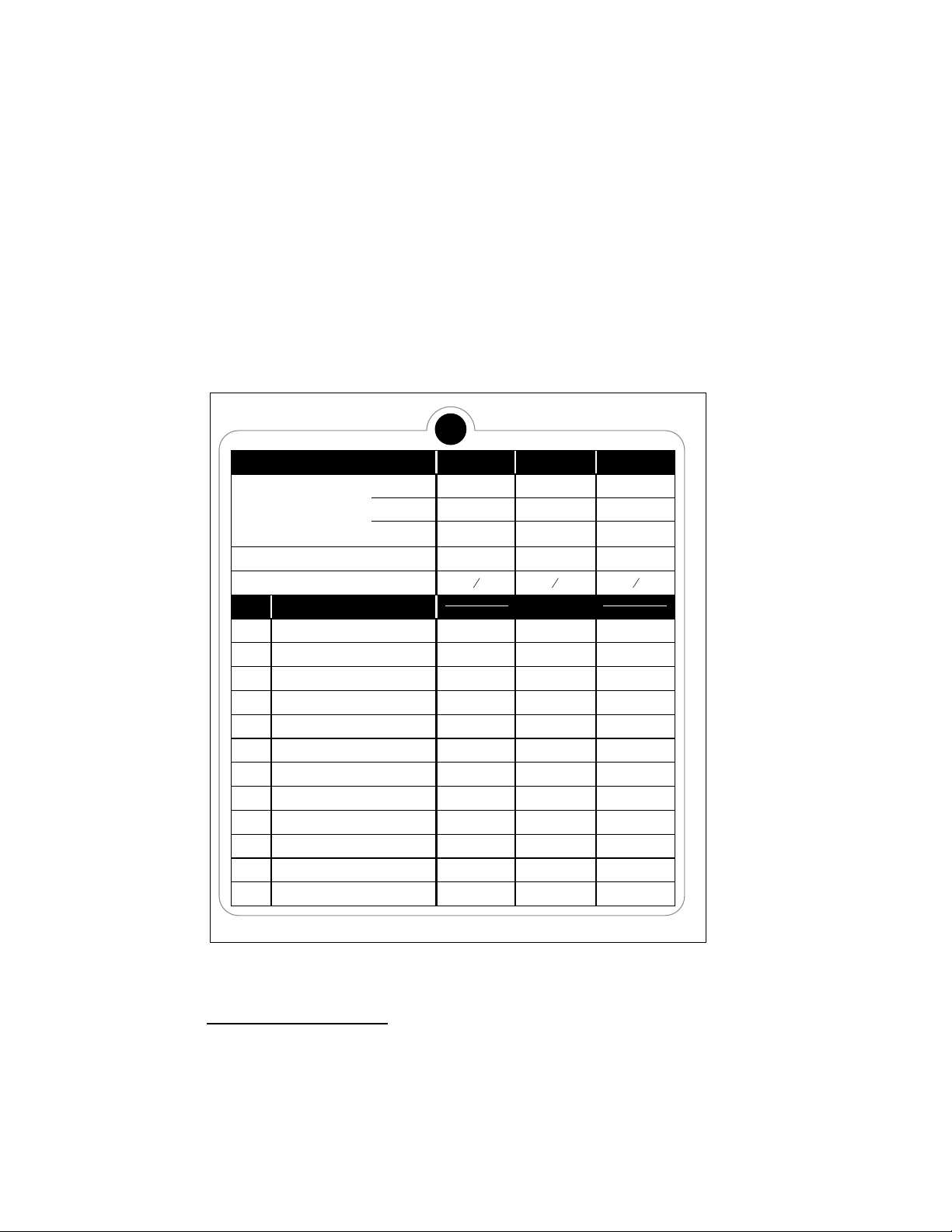

WATERING SCHEDULE FORM (SAMPLE)

For your convenience, a Watering Schedule Form / Programming and

Operating Quick Reference card is provided. Use the form to plan and

record your automatic watering activities. Use the convenient quick

reference instructions as a memory jogger after you familiarized yourself

with the programming and operation of the controller by reading the

User’s Guide. Keep the card with the controller by attaching it to the

inside front cover.

Programming the Controller

Watering Day Schedule

Week Days

Odd/Even Days

Skip Days

1

Program Cycle Start Times

Program Looping Start/Stop Time

Program A Program B Program C

Watering Schedule Form

Station

Station Description

Station Run Time

2

3

4

5

6

7

8

9

10

11

12

Front Lawn (sun) 10 min

Front Lawn (sun) 10 min

Side Lawn (shade) 20 min

Back Lawn (sun) 10 min

Back Lawn (sun) 10 min

Back Lawn (shade) 20 min

Back Lawn (shade) 20 min

2 am 3 am 2 am

1 day

2 day

Page 13

11

SETTING THE CURRENT TIME AND DATE

Before you can program the controller for automatic watering, you must

set the controller clock to the current time and date. This controller

features a 365-day calendar with automatic

leap year compensation and is

year 2000 (Y2K) compliant. Once the date is set, the controller keeps

track of the

date and enables trouble-free, odd-even day of the month

watering required in some locations. The time and date apply to all

programs. To set the time and date, follow the steps below.

1. Turn the function dial to the

TIME / DATE

position. The hour digits

will begin flashing.

2. Press the +

/ON

and/or –

/OFF

button(s) to display to the current

hour and a.m./p.m. designation.

Note: Continuous pressure on the +

/ON

or –

/OFF

button causes the

display to change rapidly.

3. Press the

NEXT

button to select the minutes digits. Press the +

/ON

and/or –

/OFF

button(s) to display to the current minute.

4. Press the

NEXT

button to select the month. Press the +

/ON

and/or

–

/OFF

button(s) to display the current month.

5. Press the

NEXT

button to select the day digit(s). Press the +

/ON

and/or –

/OFF

button(s) to display the current calendar day.

6. Press the

NEXT

button to select the year digits. Press the +

/ON

and/or –

/OFF

button(s) to display the current year.

7. Return the function dial to the

AUTO RUN

position when the

current time and date have been set.

Programming the Controller

Page 14

12

SETTING THE STATION RUN TIME

A station is assigned to a program when it is given a run time (from one

minute to 23 hours and 59 minutes) in that program. Each station is

limited to one run time assignment per program. However, stations can

be assigned to one, two or three programs and have a different run time

assignment in each.

To set the run time for each station:

1. Turn the function dial to

STATION WATER TIMES/MASTER VALVE

.

2. Select Program

A, B

or Cwith the

PROGRAM

button.

3. Press the

NEXT

button to select the station number you wish to set

(if other than the one displayed).

4. Use the +/

ON

and/or –/

OFF

button(s) to display the desired station

run time minutes (0–59).

5. Press the

NEXT

button select hours.

6. Use the +/

ON

and/or –/

OFF

button(s) to display the desired station

run time hours (0–23).

Note: The factory setting for each station is “Off.” If the station

has a run time and you wish to remove it from this program, use

the +/

ON

and/or –/

OFF

button(s) to select 0 minutes and 0 hours .

7. Repeat steps 3 through 6 to set a run time for each station you

wish to assign to the selected program.

8. Repeat steps 2 through 5 for each program as necessary.

9. When finished, return the function dial to

AUTO RUN.

MASTER VALVE OPERATION

The IBOC Plus enables master valve operation to be selected

independently for each watering program. By default, the master valve

circuit is activated for each watering program.

Note: If a master valve is not installed, its operation must be disabled

to prevent an “Open MV” fault from occurring.

To select master valve operation:

1. Turn the function dial to

STATION WATER TIMES/MASTER VALVE

.

2. Select Program

A, B

or Cwith the

PROGRAM

button.

3. Press the

NEXT

button repeatedly until “Master Valve” is displayed.

4. Press the +/

ON

or –/

OFF

button to display the operation of the

master valve for the selected program.

5. Repeat steps 2 through 4 for each program as necessary.

6. When finished, return the function dial to

AUTO RUN.

Programming the Controller

Page 15

13

SETTING PROGRAM START TIME(S)

This procedure is used to set the watering cycle start time(s) for each

program. A maximum of eight start times per program can be assigned.

Each start time will initiate a sequential watering cycle of all stations

with an assigned run time in the program.

Note: It is important to remember that a start time initiates the entire

watering program cycle, not an individual station.

PROGRAM LOOPING

The Program Looping feature enables a watering program to start and

run consecutive repeat cycles until a predetermined stop time is reached.

Each program can have one loop operating cycle assigned in addition to

eight regular start time assignments. If a program loop is not assigned, the

display shows “Loop Strt Off.”

To set program cycle start times and/or program loop time:

1. Turn the function dial to the

PROGRAM CYCLE START TIMES/

LOOPING

position.

2. Select Program

A, B

or Cwith the

PROGRAM

button.

3. Use the +/

ON

or –/

OFF

button to adjust the start time hour.

4. Press the

NEXT

button to select the minutes digits.

5. Use the +/

ON

and/or –/

OFF

button to adjust the start time minutes.

Note: To remove a start time, adjust the time to display “Off”

which is located between 11:59 p.m. and 12:00 a.m.

6. Press the

NEXT

button and repeat steps 3 through 5 to assign up to

eight start times for the selected program.

7. Press the

NEXT

button to display “Loop Strt.”

8. Use the

+/

ON

and/or –/

OFF

button(s) to adjust the loop time hour.

9. Press the

NEXT

button.

10. Use the +/

ON

and/or –/

OFF

button(s) to adjust the loop time minutes.

11. Press the

NEXT

button to display “Loop Stop” and repeat steps

8 through 10 to set the loop stop time.

12. Repeat steps 2 through 11 for each program as necessary.

13. When finished, return the function dial to

AUTO RUN.

Programming the Controller

Page 16

14

SELECTING THE DAYS TO WATER

Several watering day scheduling options are available. Each watering

program can utilize any ONE of the following schedules:

• Days of the week

Use this type of schedule to water on specific days of the week. The

days are displayed as three-letter abbreviations. For example, Sunday is

Sun, Monday is Mon, etc. Only the days you select to water will

remain on the display.

• Odd or Even Days

To select every o dd or even number calendar day, use this option.

Because the 31st and the 1st are both odd number days, the 31st is

automatically removed from the schedule. This watering day option

also enables selected days of the week to be removed from the

schedule.

• Skip Days

Selecting watering days by Skip Days enables a specific number of days

between watering to be selected. For example, selecting Skip 1-day

schedules watering for every day. Skip 2-days schedules watering for

every other day. Skip day scheduling is selectable from 1 to 62 days.

Another setting within the Skip Days schedule is the Day # or current

day of the schedule. The Day # can be set for any day within the Skip

Days schedule. When the Day # equals the Skip Days number, a

watering day occurs. The Day number automatically increases by one

every day. For example, to water today then every third day, a Skip 3

would be set with D

AY # 3. Or, to water every 5 days starting

tomorrow, a Skip 5 would be selected with D

AY # 4.

To set a watering day schedule for each program:

1. Turn the function dial to the

PROGRAM WATER DAYS

position. The

display will show the current watering day schedule for the

selected program.

2. Select Program

A, B

or Cwith the

PROGRAM

button.

3. Set the watering day schedule for the program using one of three

procedures provided on page 15: Weekdays, Odd/Even Days or

Skip Days.

4. Repeat steps 2 and 3 as necessary for each program.

5 When finished, return the function dial to

AUTO RUN.

Programming the Controller

Page 17

15

Weekdays

A. Press the

NEXT

button until the “Weekdays” is displayed.

B. Press the +/

ON

button, “Sun” will begin flashing.

C. To select the day, press the +/

ON

button. To remove the day

from the schedule, press the –/

OFF

button. The next day

abbreviation will begin flashing.

D. Repeat step C for the remaining days of the week.

Odd or Even Days

A. Press the

NEXT

button until “Odd/Even” is displayed.

B. Press the +/

ON

button to select an Even day schedule or –/

OFF

to select an Odd day schedule.

Optional: To remove selected days of the week from the

Odd/Even watering schedule:

1. Press the

NEXT

button until “OK to water on:” is

displayed.

2. Press the +/

ON

button. “Sun” will begin flashing.

3. To exclude the day from the schedule, press the –/

OFF

button. To keep the day in the schedule, +/ONbutton. The

next day abbreviation will begin flashing.

4. Repeat Step 3 for all weekdays.

Skip Days

A. Press the

NEXT

button until the “Skip Days” option is

displayed.

B. Press the +/

ON

button to select this option. The current skip

day number (1–62) will begin flashing.

C. Use the +/

ON

or –/

OFF

button to select the number of days to

skip between watering (1–62 days).

E. Press the

NEXT

button.

F. Use the +/

ON

or –/

OFF

button to select the current day in the

skip cycle.

Programming the Controller

Page 18

16

PROGRAM REVIEW

This controller feature enables the various operational settings and status

conditions of each program to be easily reviewed. Within the review

sequence, the following program settings are displayed: Master Valve

On/Off, Rain Sensor On/Off, Watering Days, Start Time(s) and Water

Budget percent factor.

Note: Program changes cannot be made while in the review mode.

To review a program, use the following procedure:

1. Turn the function dial to the

PROGRAM REVIEW

position.

2. Select the program to be reviewed by pressing the

PROGRAM

button

A, B

or C.

3. Press the

NEXT

button to step through the various review displays.

Press and hold the button to automatically advance through the

displays, briefly pausing at each program element.

4. Repeat steps 2 and 3 to review remaining programs.

5. When finished, return the function dial to

AUTO RUN

.

This section includes instructions for mounting the controller cabinet

and making the necessary wiring connections. To ensure safe

operation, it is important to follow the instructions carefully.

SELECTING AN INSTALLATION SITE

Selecting the proper installation site for the controller is essential to

safe and reliable operation. The IBOC Plus features a weather-resistant

cabinet enabling outdoor installation.

The controller should be installed on a vertical wall or other sturdy

structure with the display at approximately eye level. An optional

pedestal mount, model # P2B is available for stand-alone installation.

It is important to select a location that shades the controller during

the hottest hours of the day and provides as much protection from

rain, wind and snow as possible. Never install the controller where it

will be exposed to direct spray from the sprinklers.

Note: When mounting the IBOC Plus controller with a SPC-2 Solar

Power Convertor, it is important to select a location that provides

maximum protection from rain, snow and direct irrigation spray while

providing the SPC-2 exposure to sunlight for a minimum of two hours

per day.

Installation procedures

INSTALLATION PROCEDURES

Page 19

17

MOUNTING THE CONTROLLER

1. Position the mounting template (provided) on the wall at

approximately eye level. Using a small punch or nail, mark the

locations of the top and bottom centerline mounting holes and

the additional lower holes if extra cabinet support is desired.

2. Drill pilot holes at least 1-1/4" (32mm) deep using a 3/32"

(2.5mm) drill for wall stud application, or 1/4" (6.5mm) drill for

masonry.

3. For the masonry wall installation only, insert the plastic screw

anchors (provided) into the pilot holes.

4. Place a small plastic washer and a rubber washer (provided) on each

screw. Install the #10 screws into the top and bottom locations

leaving the screw head about 1/2" (13mm) from the wall.

Note: If installing additional lower mounting screws, remove

plastic hole plugs at this time.

5. Unlock and open the cabinet cover. Remove the cover by sliding

it toward the top of the cabinet.

6. Remove the phillips screw from the right edge of the control panel

enabling the panel to swing outward.

7. To remove the control panel from the cabinet, first disconnect the

ribbon cable from the terminal board. With the panel in the fully

opened position, slide it toward the top of the cabinet.

8. Hang the cabinet on the screws using the keyhole slots. Ensure the

screws engage the slotted portion of the keyhole with the plastic

washer positioned between the screw head and the inner cabinet

wall. Tighten the screws securely. Install additional screws in the

lower left and/or right mounting holes as required.

9. Reinstall the control panel and cover.

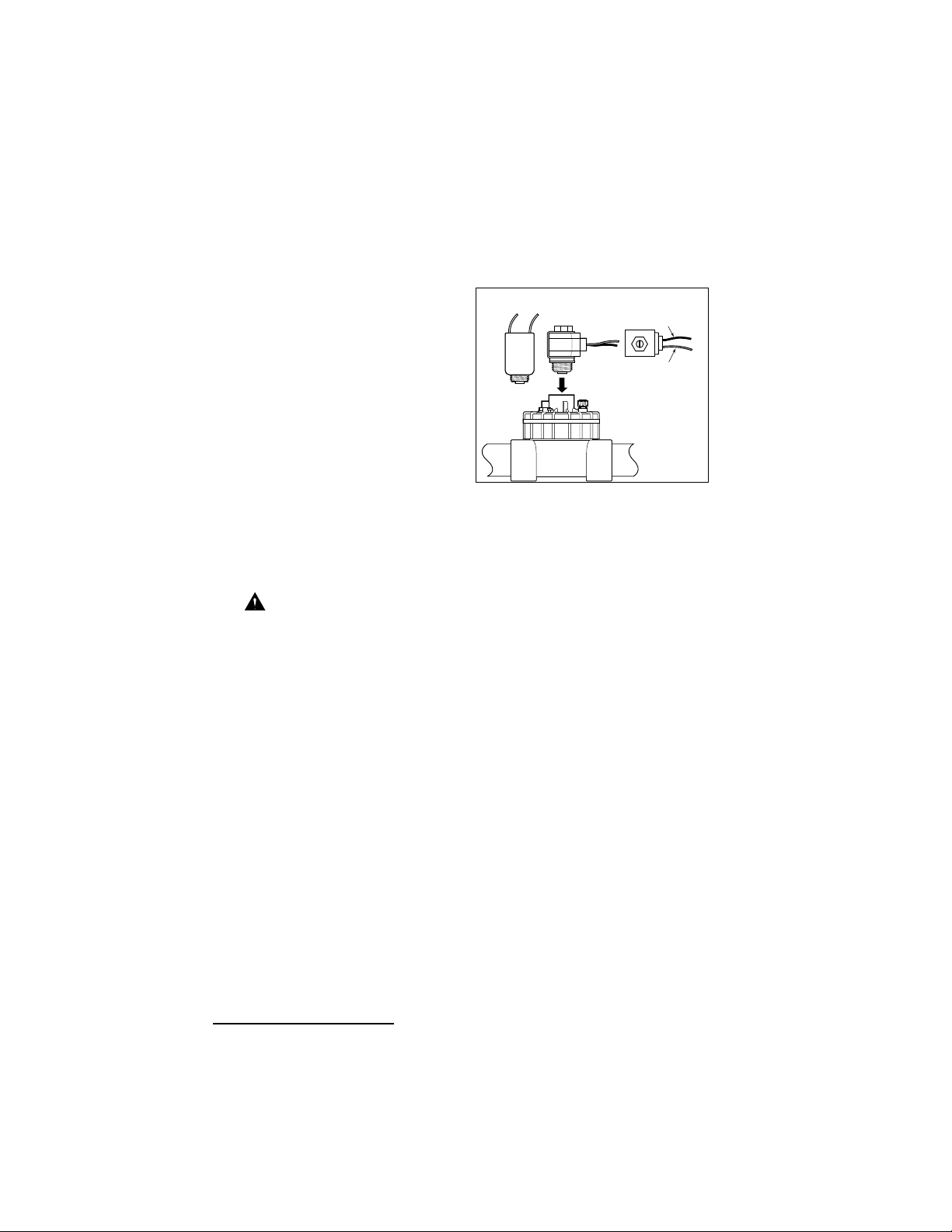

CONVERTING THE SOLENOIDS

The IBOC Plus controller activates valves by means of an electric

pulse, which latches and releases the solenoid position rather than

providing continuous power to the solenoids. This requires a DC

latching solenoid for each irrigation control valve.

The DC latching solenoid is designed as a direct replacement for the

standard 24 V a.c. solenoid (which will not work with the IBOC Plus

controller). No additional adapting is required for solenoid installation.

Installation Procedures

Page 20

18

Note: When connecting the DC latching solenoid to the controller,

unlike an AC solenoid which has no specific wiring polarity, the DC

latching solenoid has a power and a common wire. To enable valve

operation, the black wire must be

connected to the valve common and

the red wire to a valve output

terminal. Ensure the solenoid is

assembled with the red and black

wires oriented as shown in Figure 4.

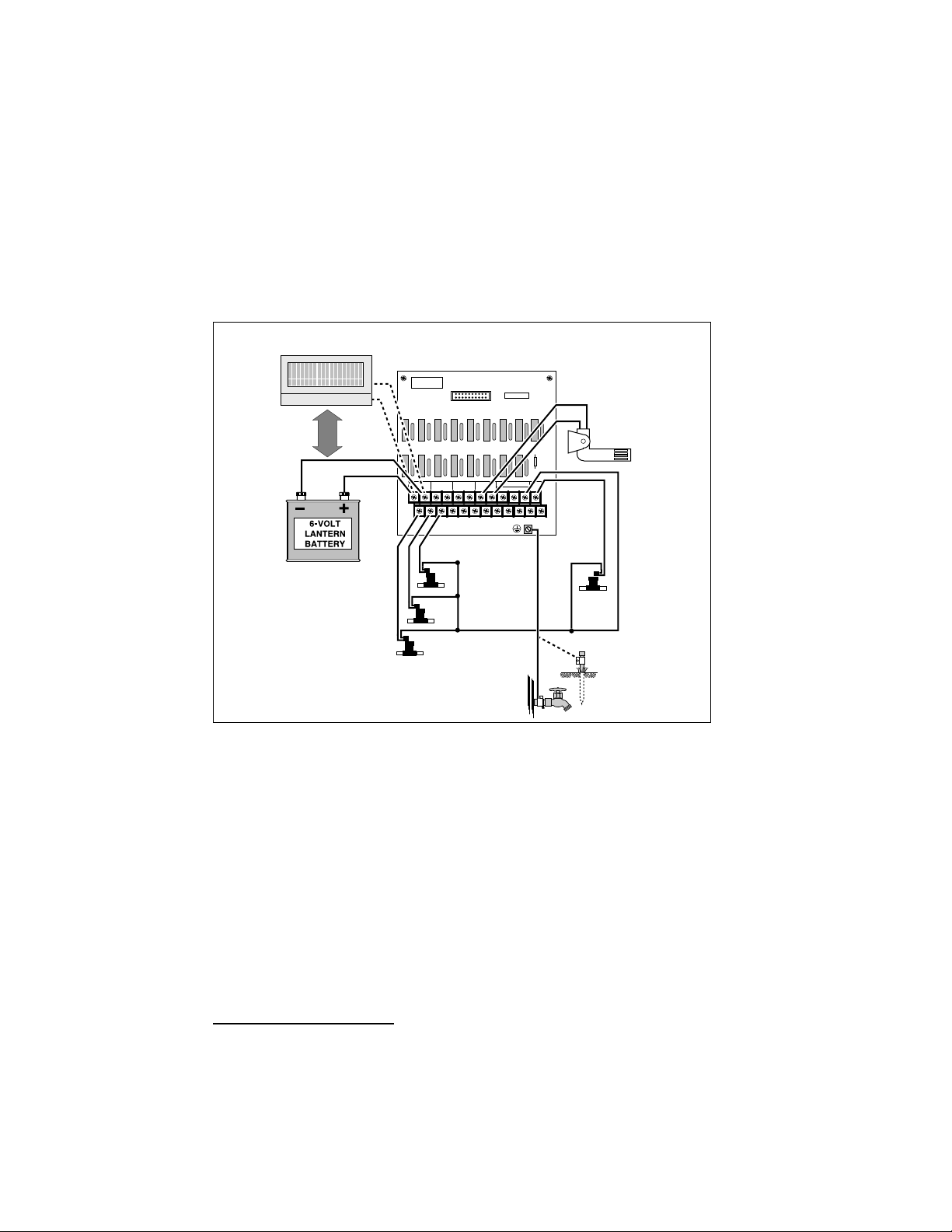

CONNECTING THE

FIELD WIRING

Note: Refer to the recommended

wire size information on page 25.

1. To provide a field common wire, splice one wire to the black wire of

each valve solenoid and optional master valve.

2. Attach a separate control wire to each red valve solenoid wire. Label

the control wires with the intended station number for identification

at the controller.

Caution: All wiring splices must be waterproofed to prevent

short circuits and corrosion.

3. Route all field wires into the controller cabinet through the

2" (52mm) access opening. Remove approximately 1/2" (13mm)

insulation from the ends of each wire.

4. Attach the field common wire to one of the three valve common

terminals labeled “Valve Com.” See Figure 5.

5. Connect each valve control wire to a separate station number

terminal (1-12) and tighten securely. See Figure 5.

6. Connect the Master Valve wire to the terminal labeled MV/Pump.

CONNECTING A RAIN SWITCH SENSOR

The IBOC Plus is designed for use with a normally closed rain sensor

or “Rain Switch.”

Connect a rain switch sensor as follows:

1. Route the two wires from the sensor into the cabinet through the

field wire access opening.

2. Connect the wires to the terminals labeled “Rain Sensor.” See

Figure 5.

Installation Procedures

Figure 4

AC Solenoid

DC Latching

Solenoid

(Top View)

Red

Black

X

Page 21

19

Installation Procedures

Note: Although the battery and the SPC-2 share the same input

terminals, only one power source can be connected to the IBOC

Plus at any given time. If using the SPC-2, connect the Orange

6-Volt (+) wire and Black negative (–) wire to the IBOC’s battery

input terminals.

3. By default, sensor operation is disabled for all automatic watering

programs. To enable operation of the sensor, refer to the “Rain

Sensor Operation” on page 7.

Note: Do not connect the rain switch directly to the valve

common wire. Refer to the installation instructions provided with

the rain sensor for additional information.

CONNECTING AN EARTH GROUND

A power surge is a sudden rise in voltage on the power main line. It is

then often followed by a drop in voltage as the power line equipment

tries to protect area users. A lightning strike on the power grid is the

most common cause of power surges and can be damaging to the

controller. Surge protection is built into the IBOC Plus terminal board

to help protect the controller from surge damage by shunting the

voltage to earth ground.

Solar Panel (optional)

Note: Refer to instructions supplied with solar panel for

installation procedure.

Rain Switch

(optional)

DC Latching

Master Valve

(optional)

Valve Common

Earth Ground

DC Latching

Control Valves

Figure 5

OR

FOR SERVICE

BATTERY

INPUT GND

+ -

12345 6789101112

INPUT GND

RAIN SENSOR

INPUT GND

VALVE COM

+ -

EARTH

GND

USE ONLY

L N

MV/

PUMP

3

2

1

Page 22

Therefore, an important step in the installation process is to properly

connect the controller to an earth ground source, especially if the

controller is located in a lightning-prone area.

Caution: The built-in surge protection components cannot

effectively protect the controller circuitry from power surge

unless properly connected to an earth ground source.

To connect an earth ground:

1. Route a #12 (2mm

2

) solid copper wire in the shortest and most

direct path from the “Earth Gnd” lug, located on the terminal

board, to an earth ground source such as metal water pipe or

copper-clad ground rod.

2. Clamp the end of the ground wire securely to the pipe or ground

rod. Make sure the wire contact area is free of dirt and corrosion.

This section includes instructions for the following controller

operations:

• Testing Station Operation

• Water Budget

• Off and Rain Delay Modes

• Manual Operations

TESTING STATION OPERATION

This feature enables you to quickly check system operation by

running each station for a selectable test duration from 1 to 10

minutes. Once started, each station will run in numerical order for

the selected test run time.

To perform the station test operation, use the following procedure:

1. Turn the function dial to the

STATION TEST

position. The display

will prompt you to set a watering run time.

2. Use the +/

ON

and/or –/

OFF

button(s) to set the station water

time from 1–10 minutes.

3. Press the

NEXT

button, “Station 1 –Off–” will be displayed.

20

Operating the Controller

OPERATING THE CONTROLLER

Page 23

21

4. Press the +/ONbutton to begin operation. Allow station 1 to

continue operating for the set run time or change the run time by

using the +/

ON

or –/

OFF

button(s). (Decreasing the run time to less

than one minute will turn off the station.) Each station will run

automatically in numerical sequence or may be manually advanced

to another station by pressing the

NEXT

button until that station is

displayed. Each time the station is advanced (either automatically or

manually) the previous operating station will turn off, enabling only

one station to run at a time.

Note: To stop the test operation at any time, simply turn the

function dial to the

OFF/RAIN DELAY

position and press the –/

OFF

button.

5. When finished, return the function dial to the

AUTO RUN

position.

WATER BUDGETING

The Water Budgeting feature enables you to easily increase or decrease

the station run time (by percentage) of all

stations assigned to a

selected program. This is handy for making temporary overall station

run time adjustments without changing the original run time settings.

Water Budgeting % values range from 10% to 200% in 10%

increments, with 100% being the normal setting.

For example, as the fall season approaches and the temperature

decreases, you may want to reduce the water time for the stations in

program A by 30%. Later you can return station times to their original

values by setting the Water Budgeting % value back to 100%.

Note: It is possible to inadvertently cause start time stacking when

increasing station run time. Careful use of Water Budgeting % will

help prevent this from occurring.

To change the Water Budgeting % values:

1. Turn the function dial to the

WATER BUDGETING (%)

position.

2. Select Program

A, BorC

with the

Program

button.

3. Use the +/

ON

and/or –/

OFF

button(s) to increase or decrease the

percentage value (10–200%).

4. Repeat steps 2 and 3 for other programs as required.

5. Turn the function dial to the

AUTO RUN

position.

Operating the Controller

Page 24

22

OFF AND RAIN DELAY MODES

Use these function modes to immediately stop all current watering

activity, suspend watering indefinitely or delay automatic watering

programs for a selected number of days (Rain Delay mode).

Turning Off Current Watering Activity

When the function dial is turned to the the

OFF / RAIN DELAY

position

while any station is active, the “Press –/Off to stop all watering”

prompt to be shown. Pressing the –/

OFF

button immediately shuts off

all active stations and suspends all watering activity until the

function dial is turned to another position.

Using the Rain Delay Mode

When the function dial is turned to the

OFF / RAIN DELAY

position while

the controller is inactive, the display prompt “Rain Off Press +/– for

OFF days” will be shown. A number from 1–30 days is entered and the

controller will delay all automatic watering programs until the delay

period lapses. Once the controller is placed in the Rain Delay mode, the

function dial can be turned to other positions for programming,

reviewing and manual operations. The display will show the number of

days remaining in the delay period. The number will automatically

decrease by one digit each day. Automatic operation will resume when

the display shows no delay days remaining.

To select the Rain Delay mo de:

1. Turn the function dial to the

OFF / RAIN DELAY

position.

2. Use the +/

ON

or –/

OFF

button(s) to select the number of days

(1–30) to delay operation.

3. Turn the function dial to the

AUTO RUN

position.

To cancel the Rain Delay mo de:

1. Turn the function dial to the

OFF / RAIN DELAY

position.

2. Press the –/

OFF

button until the display shows no delay days

remaining.

3. Turn the function dial to the

AUTO RUN

position.

MANUAL OPERATIONS

Manual operation allows you to run individual stations or start

automatic watering programs as needed. Separate dial positions are

provided for both types of manual operation: Manual Station Start and

Manual Program Start.

Operating the Controller

Page 25

23

MANUAL STATION START

This option enables individual stations to be operated for a selectable

duration from 1–59 minutes. Each station selected to operate is given a

temporary run time. As one station finishes operation, the next station

in sequence begins operation.

1. Turn the function dial to the

MANUAL STATION START

position.

2. Select the Master Valve On or Off for this operation by pressing the

+/

ON

or –/

OFF

button.

3. Press the

NEXT

button to select the first station you wish to run.

4. Press the

+/

ON

or –/

OFF

button to select a run time (1–59 minutes).

5. Repeat steps 3 and 4 for each station you wish to operate.

Note: Once a station is running, selecting 0 minutes will terminate

the current station activity and advance to the next station with a

manual run time assigned.

6 When the manual operation is complete, return the dial to the

AUTO RUN

position.

MANUAL PROGRAM START

Use this feature to manually operate a selected watering program. You

can run the entire program or start anywhere within the station

sequence of the program.

Note: Only the stations with an assigned run time in the program will

operate during the program watering cycle.

1. Turn the function dial to the

MANUAL STATION START

position.

2. Select program

A, B

or Cwith the

PROGRAM

button.

3. Press the

NEXT

button to select the first station of the watering

sequence (if other than the station number displayed).

4. Press the +/

ON

button to start the watering cycle. Watering will

start with the selected station and will be followed by all

subsequent stations with an assigned run time in the program. The

display will show the run time remaining for the operating station.

5. When the manual operation is complete, return the dial to the

AUTO RUN

position.

Operating the Controller

Page 26

24

❖ Problem Possible Solution

❖ Controller 1. Check for active Rain Delay mode.

will not run 2. Rain sensor operation enabled without sensor

automatically installed. Refer to Rain Sensor Operation on

page 7.

❖ No display 1. Dead battery or disconnected power source.

Correct as necessary.

2. Ensure control panel module is connected to

the terminal board.

❖ Valve 1. Check station run time and water budgeting

remains on setting.

2. Turn function dial to Off/Rain Delay

position and press –/OFF button.

3. Solenoid may be stuck or malfunctioning

control unit. Replace as necessary.

4. Check for leakage at valve manual bleed

and/or solenoid. Repair as necessary.

❖ Valve will 1. Check for proper valve wiring. Black to

not turn on common, Red to power. Refer to page 16.

2. Possible valve or solenoid malfunction.

Repair as necessary. Check for “Open” or

“Short” condition on display.

3. Solenoid may be assembled incorrectly.

Check solenoid wires for correct orientation.

Refer to Figure 3 on page 18.

4. Check for low battery condition. If less than

40%, replace battery.

❖ “Short” or 1. See “How the Electronic Circuit Breaker

“Open” Works” on page 5 for troubleshooting

is displayed these conditions.

❖ Waters too 1. Too many program start times set. Check

often each program to determine the number of

start times assigned and remove as necessary.

Refer to “Setting Program Start Time(s)” on

page 13.

2. Possible program loop set. Refer to page 13.

Note: For Irritrol Systems product assistance, phone 1-800-634-8873.

Appendix A

TROUBLESHOOTING

Troubleshooting

Page 27

25

Cabinet:

Metal, weather-resistant, indoor/outdoor, wall mount with key-actuated

locking cover

Dimensions:

10.75" W x 9.5" H x 5.75" D

(27.3cm W x 24.1cm H x 14.6cm D)

Wiring/Conduit Provision:

Field Wiring - 2" (51mm) dia. conduit access

Power Input:

6V alkaline lantern battery or 6 V d.c. solar panel (SPC-2)

Sensor Input: Normally closed rain switch

Temperature Limit Specifications:

Operating - +32°F to +140°F (0°C to 60°C )

Storage - –22°F to +149°F (–30°C to +65°C )

Fuse:

250V, 2A (not user replaceable)

Recommended Valve Wire Size (single-strand copper)

Wire Size (AWG) 20 18 16 14 12

Length (Feet) 400 600 1000 1600 2400

Wire Size (mm

2

) 0,5 0,8 1,5 2,5 3,5

Length (Meters) 120 180 300 244 720

Appendix B

SPECIFICATIONS

Specifications

Page 28

Electromagnetic Compatibility

Domestic: This equipment generates and uses radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer's

instructions, may cause interference to radio and television reception. It has been

type tested and found to comply with the limits for a FCC Class B computing

device in accordance with the specifications in Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such

interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does

cause interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

•Reorient the receiving antenna.

•Relocate the irrigation controller with respect to the receiver.

•Move the irrigation controller away from the receiver.

•Plug the irrigation controller into a different outlet so that the irrigation

controller and receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet

prepared by the Federal Communications Commission helpful:

"How to Identify and Resolve Radio-TV Interference Problems". This booklet is

available from the U.S. Government Printing Office, Washington, DC 20402.

Stock No. 004-000-00345-4.

International: This is a CISPR 22 Class B product

Technical Assistance:

U.S A.

Irritrol Systems

P.O. Box 489

Riverside, CA 92502

Phone: (800) 634-8873 or (909) 785-3623

Australia

Irritrol Systems PTY Ltd.

53 Howards Road

Beverley, SA 5009 Australia

Phone: (08) 8300 3633

Europe

Irritrol Systems Europe, s.p.a.

Via dell’Artigianato 1/3-Loc Prato della Corte

00065 Fiano Romano (Roma) Italy

Phone: (39) 0765 455201

© 2000 Irritrol Systems Form Number 373-0140 Rev. C

Page 29

TM

Plus

Guía del Usuario

PROGRAMADOR DE RIEGO

TM

Plus

Español

Page 30

i

Le damos las gracias por haber adquirido el programador IBOC Plus de Irritrol

Systems de operación a pilas. Se enumeran a continuación algunas de las

características estándar del programador IBOC Plus:

• Funciona con una pila alcalina de 6 voltios para linterna. Opcionalmente,

puede funcionar con la corriente provista por un convertidor de panel solar

(SPC-2).

• Información en pantalla fácil de leer y con instrucciones de operación.

• Opción de visualización en inglés o español.

• Acciona válvulas con solenoide a impulsión de 24 V C.C. (E2002)

• Tres programas de riego independientes.

• Operación simultánea de hasta tres estaciones de riego (una estación por

programa) y una válvula maestra.

• Tiempo de riego de cada estación ajustable desde 1 minuto hasta 23 horas

y 59 minutos en incrementos de 1 minuto.

• Hasta 8 tiempos diferentes de arranque por programa, con un total de 24

arranques por día.

• Programa de ciclo continuo: esta función permite repetir la operación de

un programa dentro de una ventana de riego seleccionable.

• Planificación de los días de riego por días laborables, rutina de omisión de

riego de 1 a 62 días y función de riego los días impares o pares.

• Operación de la válvula maestra seleccionable por programa.

• Operaciones manuales por programa o estación.

• Mo dalidad de Prueba de estación.

• Mo dalidad de Revisión de programa.

• Mo dalidad de Suspensión Temporal por lluvia - pospone la operación

automática desde 1 a 30 días.

• Visualización del Porcentaje de capacidad eléctrica de la pila o de la

energía solar (si se usa el SPC-2).

• Sensor de lluvia listo – entrada del sensor seleccionable por programa.

• Water budget del 10% al 200% en incrementos de 10%.

• Memoria Permanente (no volátil) – retiene la información de los programas

sin necesidad de energía eléctrica.

• Disyuntor de circuito electrónico que detecta automáticamente cualquier

cortocircuito o circuito abierto en la salida de las estaciones – permite que

las estaciones restantes operen tal como han sido programadas.

CARACTERISTICAS DEL PROGRAMADOR

Características

Page 31

1

Características.....................................................................................................i

Componentes del programador.....................................................................2–3

Información general ......................................................................................4–7

Cómo funciona el sistema de respaldo........................................................4

Instalación de la pila...................................................................................4

Cómo funciona el disyuntor de circuito electrónico ..................................5

Cómo funcionan los sensores ......................................................................6

Opciones de control....................................................................................6

Borrado de programas..........................................................................6

Opción de idioma en pantalla............................................................7

Operación del sensor de lluvia............................................................7

Programación del programador...................................................................8–16

Cómo empezar.............................................................................................8

Programación de la hora y fecha actuales.................................................11

Programación de los tiempos de riego de las estaciones...........................12

Operación de la válvula maestra...............................................................12

Programación de las horas de arranque de los programas.........................13

Programa de ciclo continuo......................................................................13

Selección de los días de riego....................................................................14

Revisión de los programas.........................................................................16

Procedimientos de instalación..................................................................16–20

Selección de un lugar de instalación........................................................16

Montaje del programador ..........................................................................17

Conversión de los solenoides....................................................................17

Conexión del cableado de campo.............................................................18

Conexión de un sensor de interrupción por lluvia...................................18

Conexión a tierra......................................................................................19

Operación del programador.......................................................................20–23

Prueba de la operación de las estaciones..................................................20

Water budget (%)......................................................................................21

Modalidades de Desactivación del Riego y de Suspensión

Temporal por Lluvia..................................................................................22

Operaciones manuales ..............................................................................22

Apéndice A - Localización de averías............................................................24

Apéndice B - Especificaciones........................................................................25

TABLA DE MATERIAS

Tabla de Materias

Page 32

2

Componentes del Programador

▲ Figura 1

1 Function Dial (Selector de funciones): Para seleccionar las funciones

de programación y operación.

2 LCD Display (Pantalla LCD): Para visualizar la información sobre los

tiempos, programas y estados.

3 Next (Botón Siguiente): Para seleccionar la información que ha de

programarse o revisarse.

4 + /On and – /Off (Botones +/Activar y –/Desactivar): Para ajustar o

ingresar los datos de los programas.

5 Program (Botones selectores de programas): Para seleccionar el

programa A, B o C que deba programarse o revisarse.

▲ Figura 2

6 Terminales de conexión de la pila o del convertidor del panel solar

7 Terminales de conexión del sensor de lluvia

8 Terminales de conexión común de las válvulas

9 Terminal de conexión de salida de la válvula maestra

10 Orejeta de conexión a tierra

11 Terminales de conexión de energía eléctrica a las válvulas

12 Banda de retención de la pila

13 Pila alcalina de 6 voltios para linterna (no está incluida)

14 Placa aislante de la pila

COMPONENTES DEL PROGRAMADOR

Page 33

3

TM

Plus

1

23

4

5

Figura 1

Componentes del Programador

Figura 2

6

12

13

11

10

7

8

9

14

PILA DE 6

VOLTIOS PARA

LINTERNA

6-VOLT

LANTERN

BATTERY

FOR SERVICE

BATTERY

INPUT GND

+ -

1 2 3 4 5 6 7 8 9 10 11 12

INPUT GND

RAIN SENSOR

INPUT GND

+ -

VALVE COM

EARTH

GND

USE ONLY

L N

MV/

PUMP

Page 34

4

COMO FUNCIONA EL SISTEMA DE RESPALDO

El programador IBOC Plus usa una memoria permanente (no volátil) para

almacenar la información de los programas y evitar que se pierda en el caso de

producirse un corte de la alimentación eléctrica. Incluso la hora y la fecha se

retendrán durante los primeros 10 minutos sin corriente eléctrica.

Una pila alcalina de 6 voltios para linterna completamente cargada operará el

programador durante más de un año. El módulo SPC-2 (Convertidor de energía

solar) operará el programador IBOC Plus por un período de hasta seis años,

siempre que el convertidor esté recibiendo luz solar por un término medio de

dos hora por día. Tan pronto como se le aplique una fuente eléctrica, el

programador podrá programarse totalmente para su operación.

Nota: Si desea programar el programador antes de su instalación, conecte la

pila en ese momento. Pero será necesario retirar la pila antes de instalar el

armario del programador. La memoria de los programas se retendrá aunque se

haya desconectado la pila.

INSTALACION DE LA PILA

Nota: La pila no viene incluida con el programador. Se requiere una pila

alcalina común de 6 voltios para linterna (del tipo NEDA 918A) con

terminales de tipo tornillo. Use una pila Energizer #512, Duracell MN918 o

equivalente.

Precaución: Las pilas contienen materiales dañinos. Manipule y

deseche siempre las pilas de acuerdo con las recomendaciones del

fabricante.

1.

Suelte el tornillo phillips de la esquina derecha del tablero de control para

abrirlo.

2. Instale la placa aislante de la pila (A) y la banda de retención (B), tal

como se muestra en la Figura 3.

3. Instale la pila y asegúrela con la banda de

retención.

4. Usando los cables provistos, conecte el

terminal positivo (+) de la pila al terminal

del tablero de conexiones marcado “Battery

Input” (Entrada de la pila). Conecte el

terminal negativo (–) de la pila al terminal

del tablero marcado “Battery Grnd” (Tierra

de la pila).

Nota: El estado de la pila se visualiza como un porcentaje de la capacidad

eléctrica que le queda mientras el programador no está operando. La pila

deberá reemplazarse cuando su capacidad sea inferior al 40%.

INFORMACION GENERAL

Información General

Figura 3

B

A

Page 35

5

Información General

COMO FUNCIONA EL DISYUNTOR DE

CIRCUITO ELECTRONICO

El programador está equipado con un disyuntor de circuito electrónico. Si el

programador detecta un cortocircuito, la estación afectada (válvula) será

desactivada inmediatamente. Entonces aparecerá en la pantalla la

información sobre la estación o estaciones relacionadas con la condición

problemática. El programador continuará accionando regando

automáticamente las demás estaciones. Cada arranque automático tratará de

iniciar otro ciclo y verificará de nuevo la válvula en cortocircuito.

Se enumeran a continuación las condiciones más comunes que activarán el

disyuntor de circuito electrónico.

Condición: Aparece en pantalla la palabra “Short” (Cortocircuito) con

uno o más números de estación.

Diagnóstico: Una o más estaciones están en cortocircuito.

Solución: Compruebe el cableado de las estaciones indicadas en pantalla

para determinar la causa del cortocircuito. Repare la válvula o

válvulas y/o el cableado según sea necesario.

Diagnóstico: Una condición de sobrecarga causada por más de una válvula

conectadas al terminal de la misma estación.

Solución: Asegúrese de que sólo haya una válvula conectada al terminal

de cada estación. Aunque se permite que funcionen tres

válvulas simultáneamente, éstas deben estar conectadas a

estaciones diferentes operando en programas separados.

Condición: Aparece en pantalla la palabra “Open” (Circuito abierto) con

uno o más números de estación.

Diagnóstico: Existe un circuito abierto en uno o más solenoides de válvula.

Solución: Inspeccione el cableado de la estación o estaciones reportadas

para ver si tiene conexiones flojas o rotas.

Nota: Si no hay una válvula maestra instalada, asegúrese de haber

desactivado la operación de la válvula maestra. Para más detalles, vea

Operación de la Válvula Maestra en la página 12.

Después de corregir el problema, haga lo siguiente para que el programador

reanude su operación normal:

1. Gire el selector a la siguiente posición de

AUTO RUN

(Operación

automática).

2. Oprima el botón –/

OFF

(Desactivar) para borrar la información en

pantalla y hacer que el programador vuelva a la modalidad de operación

normal.

Page 36

6

COMO FUNCIONA EL SENSOR

El programador IBOC Plus está equipado para funcionar con un sensor de

lluvia opcional, denominado comúnmente “Rain Switch” (Interruptor por

lluvia), para evitar la operación automática del programador durante la lluvia.

El interruptor por lluvia es un dispositivo sencillo que generalmente está

instalado en el voladizo del techo o sobre una estructura estacionaria expuesta

a la lluvia y a los rayos solares, y protegido del alcance del riego. El cableado

del interruptor por lluvia está conectado a los terminales del sensor

localizados en el tablero de terminales del programador.

La operación del sensor de lluvia es seleccionable por programa, lo cual

permite que el control del sensor sea asignado a programas de riego específicos

de acuerdo con las necesidades.

Cuando llueve, el interruptor por lluvia detecta la humedad y hace que el

programador interrumpa toda salida eléctrica hacia el campo. La parte de

programación electrónica del programador está aislada del interruptor del

sensor de lluvia y continúa funcionando tal como ha sido programada.

Cuando cesa de llover y el interruptor por lluvia regresa a su estado normal,

se restaura la salida eléctrica hacia el campo, permitiendo que el riego se

reanude tal como había sido programado.

OPCIONES DE CONTROL

Esta posición del selector proporciona acceso a las siguientes funciones:

Borrado de programas, Opción de idioma en pantalla y Operación del sensor

de lluvia.

BORRADO DE PROGRAMAS

Use esta función para borrar un programa seleccionado y reposicionarlo a los

valores predeterminados (ninguna indicación de días activos, horas de

arranque o tiempos de riego de estaciones, y un porcentaje de agua de riego

del 100%).

Para borrar y reposicionar un programa:

1. Gire el selector de funciones a la posición

OPTIONS

(Opciones).

2 Seleccione el programa que desee reposicionar oprimiendo el botón A, Bo

C

de

PROGRAM

(Programa).

3. Oprima el botón

+ /ON(Activar). Aparecerá una instrucción en pantalla

que confirmará el borrado del programa.

4. Repita los pasos 2 y 3 para los programas restantes, según se requiera.

5. Gire de nuevo el selector de funciones a la posición de

AUTO RUN

(Operación automática) si ha terminado, u oprima el botón

NEXT

(Siguiente)

para continuar.

Información General

Page 37

7

OPCION DE IDIOMA EN PANTALLA

Use esta función para seleccionar el idioma en el que desea que aparezcan las

instrucciones en pantalla: español o inglés. El idioma predeterminado es el

inglés.

1. Asegúrese de que el selector de funciones esté en la posición

OPTIONS

(Opciones).

2. Oprima el botón

NEXT

(Siguiente) para que aparezca “Language” (Idioma).

3. Oprima el botón

+/ON(Activar) para seleccionar el idioma deseado.

4. Gire de nuevo el selector de funciones a la posición de

AUTO RUN

(Operación automática) si ha terminado, u oprima el botón next (Siguiente)

para continuar.

OPERACION DEL SENSOR DE LLUVIA

Use esta función para activar/desactivar la modalidad de operación del sensor

de lluvia para cada programa.

IMPORTANTE: El sensor de lluvia debe estar conectado apropiadamente

a los terminales Rain Sensor (Sensor de lluvia) del programador antes de

que pueda habilitarse la operación del sensor para un programa de riego

automático. Si el sensor de lluvia no está conectado y se habilita la

operación del sensor, NO se producirá riego automático alguno en el

programa. Si se elige el ajuste predeterminado en fábrica, la operación del

sensor de lluvia quedará inhabilitada en todos los programas.

Para seleccionar la modalidad de sensor de lluvia:

1. Asegúrese de que el selector de funciones esté en la posición

OPTIONS

(Opciones).

2. Oprima el botón

NEXT

(Siguiente) para que aparezca “Rain Sensor” (Sensor

de lluvia).

3. Seleccione el programa oprimiendo el botón A, Bo Cde program (Programa).

4. Oprima el botón

+/ONpara activar o el botón –/

OFF

para desactivar la

operación del sensor para el programa seleccionado.

5. Repita los pasos 3 y 4 para establecer la operación del sensor para programas

adicionales, según se requiera.

6. Gire de nuevo el selector de funciones a la posición de

AUTO RUN

(Operación automática) cuando haya terminado.

Programación del Programador

Page 38

8

Esta sección abarca los siguientes temas:

•

Cómo empezar

•

Programación de la hora y fecha actuales

•

Programación de los tiempos de riego de las estaciones

•

Operación de la válvula maestra

•

Programación de las horas de arranque de los programas

•

Función de ciclo continuo

•

Selección de los días de riego

•

Revisión de la información de los programas

COMO EMPEZAR

¿QUE ES UN PROGRAMA DE RIEGO?

Un programa de riego es básicamente un pequeño conjunto de instrucciones que

indican al programador la hora en que ha de arrancar un ciclo de riego, las

estaciones que han de operar durante el ciclo, los días en que el ciclo estará

activado y cuánto tiempo operará cada estación durante el ciclo. El programador

IBOC Plus tiene tres programas de riego independientes disponibles para su uso.

Se usan normalmente programas separados para agrupar las estaciones que tienen

requisitos de riego similares. Por ejemplo, usted puede usar un programa para regar

el césped a pleno sol cada día. Otro programa puede usarse para regar el césped en

penumbra solamente los lunes, miércoles y viernes. Los árboles y arbustos que usan

riego por goteo podrían ser regados por un programa separado una vez cada dos

semanas. Las necesidades de la zona de jardín pueden ser de un riego cada dos días.

Como puede ver, la disponibilidad de tres programas le permitirá utilizar programas

de riego que se adapten especialmente a las distintas necesidades de riego de sus

zonas verdes.

Programación del Programador

PROGRAMACION DEL

PROGRAMADOR

Page 39

¿QUE ES EL CICLO DE RIEGO DE UN PROGRAMA?

Cuando se selecciona una hora de arranque de riego, esa hora representa el

principio de un ciclo de riego automático. Un ciclo de riego opera todas las

estaciones asignadas al programa de una en una en orden numérico.

En el ejemplo siguiente (que también puede verse en el plan de riego de muestra

de la página 10), hemos configurado el Programa A para que arranque a las 2:00

a.m. y de nuevo a las 3:00 a.m. con un intervalo de 1 día (es decir, cada día).

Las estaciones 1, 2, 4 y 5 son áreas de césped de los patios delantero y trasero que

reciben pleno sol durante todo el día. Estas estaciones funcionarán durante 10

minutos cada una hasta que completen un tiempo de riego total de 20 minutos

por día. Las estaciones 3, 6 y 7 son áreas de césped sombreadas por la tarde. Estas

áreas necesitan menos agua, de manera que las hemos asignado al Programa B y

las hemos programado para que sean regadas durante 20 minutos a intervalos de

2 días (es decir, un día sí y otro no).

A las 2:00 a.m, arranca el ciclo de riego del Programa A. La estación 1 se activa,

funciona durante 10 minutos y se desactiva. La estación 2 se activa, funciona

durante 10 minutos y se desactiva. Las estaciones 4 y 5 funcionan

secuencialmente de la misma manera, cada una funcionando durante su tiempo

de riego establecido. Cuando la estación 5 se desactiva, el ciclo de riego se ha

completado para la primera hora de arranque. A las 3:00 a.m., el ciclo de riego

arranca de nuevo y repite la misma secuencia de riego de una estación a otra.

Observe que tenemos un tiempo de operación total de 40 minutos por ciclo en

el Programa A. Si hubiéramos establecido la siguiente hora de arranque a las

2:30 a.m., la hora de arranque se hubiera demorado hasta las 2:40 a.m.,

permitiendo que el primer ciclo terminara tal como se había programado. Esta

función se denomina “puesta en espera de las horas de arranque” y puede ocurrir

dentro de cada programa.

Los programas de riego, sin embargo, funcionan independientemente, lo que

significa que dos o más programas pueden funcionar simultáneamente. En

nuestro ejemplo, el Programa B también arrancará a las 2:00 a.m. Por lo tanto,

las estaciones 1 y 3 se activarán al mismo tiempo, y la estación 2 se activará

mientras la estación 3 está funcionando. Esta característica permite que se

complete una mayor cantidad de riego dentro de la “ventana de riego” principal,

la cual va generalmente desde medianoche a las 6:00 a.m.

Nota: Cuando se planea que los programas de riego funcionen simultáneamente,

es importante asegurarse de que el suministro de agua tenga suficiente presión y

caudal para mantener un rendimiento óptimo de los aspersores.

9

Programación del Programador

Page 40

10

FORMULARIO DEL PLAN DE RIEGO (MUESTRA)

Para su conveniencia, le proporcionamos un Formulario del Plan de Riego/Guía

de Referencia Rápida de Programación y Operación. Use el formulario para

planear y registrar sus actividades de riego automático. Use las convenientes

instrucciones de referencia rápida para que le sirvan de recordatotorio después

de haberse familiarizado con la programación y operación del programador una

vez haya leído la Guía del Usuario. Mantenga la tarjeta junto con el

programador, sujetándola al interior de su tapa delantera.

Programación del Programador

Descripción de la Estación

Días de la Semana

1

Hora de arranque/paro del de

ciclo continuo del programa

Plan de Días de Riego

Estación

2

3

4

5

6

7

8

9

10

11

12

Programa A Programa B Programa C

Formulario del Plan de Riego

Tiempo de Riego de la Estación

Días Omitidos

Horas de arranque de los ciclos

del programa

Días Impares/Pares

1 día

2 a.m., 3 a.m. 2 a.m.

/

/

/

2 día

Césped delantero (sol)

Césped delantero (sol)

Césped lateral (sombra)

Césped trasero (sol)

Césped trasero (sol)

Césped trasero (sombra)

Césped trasero (sombra)

10 minutos

10 minutos

10 minutos

10 minutos

20 minutos

20 minutos

20 minutos

Page 41

11

PROGRAMACION DE LA HORA Y

FECHA ACTUALES

Antes de que usted pueda programar el programador para su riego automático,

es necesario establecer la hora y fecha actuales en el reloj del programador.

Este programador incorpora un calendario de 365 días con compensación

automática para los años bisiestos y satisface los requisitos para el año 2000.

Una vez establecida la fecha, el programador mantiene actualizada la fecha y

permite un riego sin problemas los días impares/pares de cada mes, según lo

requieran algunas áreas. La hora y fecha se aplican a todos los programas.

Para establecer la hora y fecha, siga los pasos indicados a continuación:

1. Gire el selector de funciones a la posición de

TIME/DATE

(Hora/Fecha).

Entonces, comenzarán a destellar los dígitos de la hora.

2. Oprima el botón +

/ON

y/o el botón –

/OFF

para mostrar en pantalla la hora

actual y la designación a.m./p.m.

Nota: Si mantiene oprimido el botón +

/ON

o el botón –

/OFF

, la pantalla

cambiará rápidamente.

3. Oprima el botón

NEXT

(Siguiente) para seleccionar los dígitos de los

minutos. Oprima el botón +

/ON

y/o el botón –

/OFF

para mostrar en

pantalla el minuto actual.

4. Oprima el botón

NEXT

(Siguiente) para seleccionar el mes. Oprima el

botón +

/ON

y/o el botón –

/OFF

para mostrar en pantalla el mes actual.

5. Oprima el botón

NEXT

(Siguiente) para seleccionar el dígito o dígitos del

día. Oprima el botón +

/ON

y/o el botón –

/OFF

para mostrar en pantalla el

día calendario actual.

6. Oprima el botón

NEXT

(Siguiente) para seleccionar los dígitos del año.

Oprima el botón +

/ON

y/o el botón –

/OFF

para mostrar en pantalla el año

actual.

7. Gire el selector de funciones a la posición de

AUTO RUN

(Operación

automática) cuando haya establecido la hora y fecha actuales.

Programación del Programador

Page 42

12

PROGRAMACION DE LOS TIEMPOS DE

RIEGO DE LAS ESTACIONES

Se asigna una estación a un programa cuando se le da a esa estación un tiempo

de riego (de 1 minuto a 23 horas y 59 minutos) en un programa. Cada estación

está limitada a la asignación de un solo tiempo de riego por programa. Sin

embargo, las estaciones pueden asignarse a uno, dos o tres programas y dárseles

un tiempo de riego diferente en cada programa.

Para establecer el tiempo de riego de cada estación:

1.

Gire el selector de funciones a la posición de STATION WATER TIMES/

MASTER VALVE (Tiempos de riego de las estaciones/Válvula maestra).