Page 1

Groundsmaster® 7200 & 7210

The first zero-radius turn Groundsmaster combines the power, maneuverability and versatility for almost any job.

TM

Add the PolarTrac

System to transform the Groundsmaster 7200 into a powerful snow removal machine.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

31

Page 2

ENGINE

RADIATOR

FUEL CAPACITY

ENGINE OIL W/ FILTER

HYDRAULIC OIL

TRANSMISSION

WHEEL DRIVE

PTO CLUTCH

STEERING CONTROL

GROUND SPEED

(MOWING CONFIGURATION)

ALTERNATOR/GENERATOR

BATTERY

INSTRUMENTATION

SAFETY LOGIC CONTROLS

INTERLOCKS

SERVICE BRAKE

PARKING BRAKE

DRIVE TIRES

FRONT CASTOR TIRES

ROLLOVER PROTECTION (ROPS)

SEAT

STORAGE

IGNITION

THROTTLE

DECK HYDRAULIC LIFT

REAR HYDRAULIC LIFT

(OPTIONAL)

CURB CLIMBING

TIE DOWNS

FUEL ECONOMY**

CERTIFICATION

WARRANTY

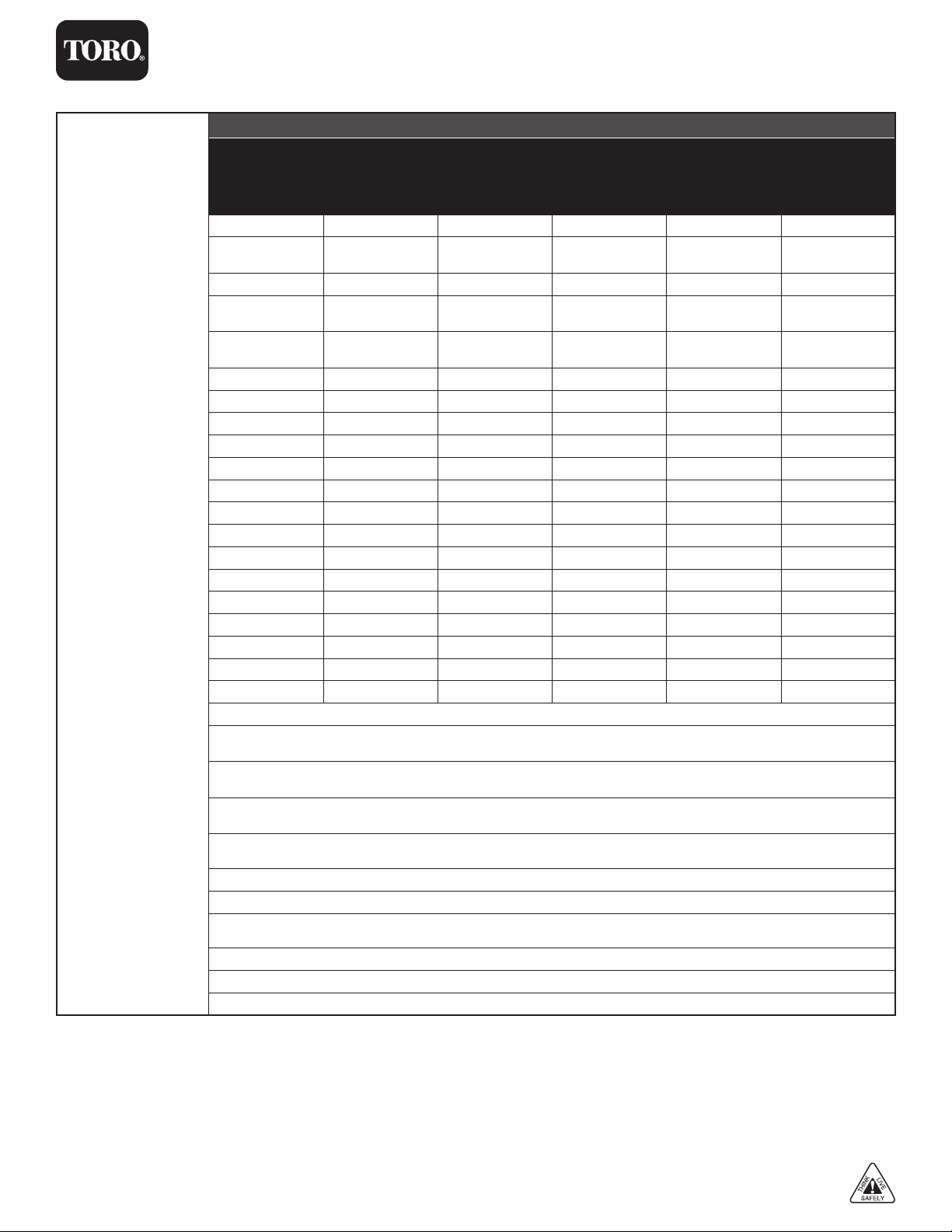

Groundsmaster® 7200 Series Specifications*

GROUNDSMASTER 7200 (30495) GROUNDSMASTER 7210 (30695)

Kubota,® 3-cylinder, liquid-cooled diesel. Power: 24.8 hp (18.5 kW) gross, at

rated speed of 3000 rpm. Torque peak: 52.7 ft. lbs. (71.5 Nm) @ 2200 rpm.

Displacement: 1123cc. High idle: 3200 rpm no load (uninstalled) 3100-3200

rpm installed. Remote mounted 5" Donaldson® air cleaner. Fuel filter/water

separator. EPA Tier IV Final Compliant.

Rear mount, cross flow, 6.5 fins per 1” (25 mm), 8 quart (7.6 liter) capacity

11.5 gallons (43.5 liters), diesel. Biodiesel-Ready for use up to Kubota engine: B-20 (20% biodiesel and 80% petroleum blend); Yanmar engine: B-7 (7% biodiesel and

80% petroleum blend)

3.9 quarts (3.69 liter). 5.5 quarts (6.1 liter)

3.5 gallons (13.25 liter).

Transmission directly mounted to engine via bell housing, two independent closed-loop circuits. One pump/motor controlling left side forward, neutral, and reverse, and

one pump/motor controlling right side forward, neutral, and reverse. Pumps are variable displacement piston type with slippers and full stroke capacity of 18cc/rev.

Independent high-torque, low-speed wheel motors with 310cc displacement.

Hydraulically actuated wet multi-disc clutch.

Adjustable twin sticks with high performance KYB® hydraulic dampers. Rev/N/Forward, located on sides of operator.

Forward 0-12.5 mph (0-20 km/h), variable. Reverse 0-8.5 mph (0-13.7 km/h), variable.

12-volt, 40 amp internal regulated charging @ 3150 rpm. 12-volt, 55 amp internal regulated charging @ 3150 rpm.

BCI Group No.: 26, 540 cold cranking amps @ 0° F.

Hour meter, glow indicator, high temp indicator, oil pressure indicator,

alternator indicator.

Toro Standard SCM.

Tractor neutral, operator presence (engine shuts down if operator is not in seat and traction sticks are moved to the operation position), parking brake, PTO on,

auxiliary hydraulics on, high temp (PTO shuts down but engine still running), over temp (engine shuts down).

Twin levers with dynamic braking through hydrostatic transmission.

Hand actuated brake lever with two 10.25" diameter disc brakes mounted on the rear wheel motors.

24 x12-12, 6-ply pneumatic tubeless, demountable and interchangeable. Tread “Toro Turf Tread”.

4-ply ribbed tread, tubeless 15 x 6-6, 20-22 psi.

Two-post foldable style ROPS certified per OSHA 1928.52 specification.

Two piece, high back cushion seat with drain hole, deluxe low profile suspension, adjustable for operator weight, seat back angle, seat fore/aft position, lumbar

support and armrest height, retractable seat belt.

Built-in cup holder, and personal storage reached from seat. Storage for raingear, tools, etc.

Off/run/start, located right of operator.

Low - high idle, located right of operator.

Raise/hold/lower/float; switch located on at end of right handle.

Raise/hold/lower/float. Electric switch right side of operator. Remote hydraulics selector switch, located on right console.

Capable of climbing 8" (20.3 cm) curbs.

Four loops, one located on each corner of the machine.

TBD 1.1 gallons/hr (4.8 liters/hr)

Cutting unit meets specification of American National Standard ANSI B71.4-2012, Safety Specifications for commercial turf care equipment. Cutting units sold in EU

meets specifications of European standard per ISO EN 5395

2-year limited warranty. Refer to the Operator’s Manual for further details.

Yanmar; 3-cylinder common-rail, liquid-cooled, diesel with EGR and diesel

particulate filter (DPF), 36.8hp (27.5 Kw) rated @ 3000 rpm, 80 ft-lbs @ 1950

rpm, High idle 3000 rpm, Low idle 1400 rpm, displacement 1642 cc. Remote

mounted Donaldson air filter, external spin-on oil filter and high flow fixed fan.

EPA Tier IV Final Compliant.

InfoCenter™: Onboard LCD display shows gauges, alerts/faults, service

reminders, electrical system diagnostics. Indicates, coolant temp, intake

temperature, low oil pressure, alternator, engine hours, engine rpm, hydraulic

oil temperature, voltage

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes only.

Actual products offered for sale may vary in use, design, required attachments and safety features. See distributor for details on all warranties.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

32

®

The Groundsmaster

in Tomah, WI, ISO 9002 Certified Plant.

7200 and 7210 are manufactured

Page 3

CUTTING DECK

CONFIGURATIONS

DECK MODEL NUMBER

COMPLETION KIT

(BLADES AND BAFFLES)

WIDTH OF CUT

BLADE TIP SPEED

(@3250 ENGINE RPM)

5/16” THICK RUBBER

DISCHARGE CHUTE

CUTTING DECK DEPTH

DECK ANTI-SCALP ROLLERS

BUMPER SKIDS

LEAF MULCHING KIT

STRIPING KIT

RECYCLER KIT

TALL GRASS BAFFLE KIT

MEDIUM FLOW BLADE

HIGH FLOW BLADE

ATOMIC MULCHING BLADE

FLAT BLADE

STANDARD BLADE

BLADE AND BELT KIT

MOWING RATE (ACRES/HR)**

SHIPPING WEIGHT

HEIGHT OF CUT

60” & 72” SIDE DISCHARGE

DECK CONSTRUCTION

62” & 72” BASE DECK

CONSTRUCTION

FINE CUT GUARDIAN®

RECYCLER COMPLETION KIT

SPINDLE ASSEMBLY

CUTTER DRIVE

BLADES

DECK SUSPENSION

BELT IDLER

DECK SKID

ANTI-SCALP CUPS

Groundsmaster® 7200 Series Specifications* (continued)

CUTTING DECKS (SOLD SEPARATELY)

62"

DECK W/

GUARDIAN® RECYCLER

KIT

30457 30457 30353 30481 30353 30456

30306 30469 30304 or 30346 NA 30549 NA

62" (158 cm) 62" (158 cm) 72" (182.8 cm) 72" (182.8 cm) 72" (182.8 cm) 60” (152.4 cm)

16,000±1,000 ft./min. 16,000±1,000 ft./min. 16,000±1,000 ft./min. 18,000±1,000 ft./min. 16,000±1,000 ft./min. 18,000±1,000 ft./min.

NA Yes NA Yes Yes Yes

4.25" (10.8 cm) 4.25" (10.8 cm) 4.25" (10.8 cm) 5.5" (13.9 cm) 4.25" (10.8 cm) 5.5" (13.9 cm)

4 4 4 5 4 5

2 2 2 1 2 1

NA NA NA PN 108-5273 NA NA

NA NA NA 105-7273 NA NA

NA NA NA 30347 NA 30348

PN 105-7269 PN 105-7269 PN 105-7269 NA PN 105-7269 NA

NA NA NA PN 110-0621-03 NA PN 110-4701-03

NA NA NA PN 110-0622-03 NA PN 110-4702-03

NA PN 107-0214-03 NA PN 110-0624-03 NA PN 110-4703-03

NA NA NA NA PN 112-9586 NA

PN 92-5608-03 PN 92-5608-03 PN 108-1958 NA PN 108-1958 NA

PN 105-7270 PN 105-7270 PN 105-7271 PN 105-7272 PN 105-7271 NA

4.9 4.9 5.8 5.8 5.8 4.8

424 lb. (192 kg.) 424 lb. (192 kg.) 472 lb. (214 kg.) 600 lb. (272 kg.) 472 lb. (214 kg.) 525 lb. (238 kg.)

1”-6” (25 - 152 mm) adjustable in 0.25” (6 mm) increments.

7-gauge (4.5 mm) 5.5” steel (14 cm) deep; welded deck with grass discharged on the right side. An 5/16” (8 mm) thick rubber discharge chute covers the discharge

opening to limit the throw distance of clippings.

7-gauge (4.5 mm) 4.25” steel (11 cm) deep; welded deck. Requires Guardian® Recycler® or rear discharge completion kit.

Three deflectors inside the chamber redirect clippings that are elevated in the chambers so that they are cut and re-cut. Deck chambers prevent throwing of objects

out from deck.

Ductile cast iron 9" (23 cm) diameter conical spindle housing; Dual greaseable tapered roller bearings; Spindle shaft is 1.25" (3.2 cm) diameter, solid cold finished

steel, splined connection between spindle shaft and pulley; Welded blade retainer plus anti-scalp cups.

Isolation mounted, splined PTO-driven gearbox transfers power to three separate spindles via two separate "B" section belts.

Three 0.25” (6 mm) thick, 2.5” (63 mm) wide, heat-treated steel blades.

Frame which supports deck via 4 vertically suspended chains. Front drag links provide fore/aft and left/right stability. Hydraulic deck lift includes load holding check

valves and gravity lower. Weight transfer system consisting of two torsion springs counterbalances some cutting deck weight to reduce turf damage.

Spring-loaded (torsion) idler.

Replaceable, bolt-on, non-marking UHMW skid on both sides for Base decks and on left side on side discharge decks. Interchangeable left to right on base decks.

Anti-scalp cup located on each blade spindle.

62" DECK

W/ REAR DISCHARGE

KIT

72" DECK

W/GUARDIAN® KIT OR

FINE CUT GUARDIAN®

KIT

72" SIDE

DISCHARGE*

72" DECK

W/REAR DISCHARGE

KIT

60" SIDE

DISCHARGE

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes

only. Actual products offered for sale may vary in use, design, required attachments and safety features. See distributor for details

on all warranties.

** Assumes 8 mph mow speed, no overlap and 100% efficiency.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

33

The Groundsmaster

in Tomah, WI, ISO 9002 Certified Plant.

®

7200 and 7210 are manufactured

Page 4

REQUIRED HP OF MOWING UNIT

WIDTH OF CUT

HEIGHT OF CUT

DECK CONSTRUCTION

DISCHARGE

WING DECK ARTICULATION

SPINDLE ASSEMBLY

CUTTER DRIVE

BLADES

BLADE TIP SPEED

DECK SUSPENSION

CASTOR WHEELS

BELT IDLER

DECK SKID

DECK ANTI-SCALP ROLLERS

ANTI-SCALP CUPS

DECK COVERS

CUTTING DECK DEPTH

WING DECK TRANSPORT

LOCKS

WEIGHT

WIDTH

OPTIONAL ACCESSORIES

CERTIFICATION

MOWING RATE

Groundsmaster® 7200 Series Specifications*

100" CUTTING DECK, MODEL 31101

Greater than 33 hp (24.6 kw)

100" (254cm), by five blades

1”-5” (25 - 127 mm) adjustable in 0.25” (6 mm) increments

Center deck with two wing decks; Welded .120" (11 gauge) high strength steel with steel .180" (7 gauge) stiffener plates and .1046" (12 gauge) chambers.

Rear Discharge – complete width of deck.

15 degrees, up or down.

Ductile cast iron 9" (23 cm) diameter conical spindle housing; Dual greaseable tapered roller bearings; Spindle shaft is 1.25" (3.2 cm) diameter, solid cold finished steel, and

splined connection between spindle shaft and pulley; Welded blade retainer plus anti-scalp cups.

Isolation mounted, PTO driven gearbox with 1.25:1 spiral bevel gears. “B” section belt drive to all spindles.

Wing Decks: 25.2" (64cm) long,.25" (6mm) thick, 2.5 (63mm) wide, heat treated steel blade in each wing; Center Deck: Three 18"(45.7cm) long, .25" (6mm) thick, 2.5" (63mm)

wide, heat treated steel blades.

16,000 ± 1,000 ft/min at 3250 engine rpm

Center deck is supported via 4 vertically suspended chains to the frame of the machine. Wing decks are supported by pin connections to center deck and castor wheels on the

ground. Hydraulic deck lift includes load holding check valves and gravity lower.

Four 8 x 3.50-4, 4-ply, smooth, pneumatic, sealed precision ball bearings. Tensioning caps, made from impact modified thermoplastic alloy, are used to hold the castor wheels on

the castor arms.

Fixed and spring loaded idlers.

Replaceable, bolt-on, non-marking UHMW skid on both sides.

5

Anti-scalp cup located on each blade spindle.

Steel and plastic with rubber latch connectors.

4.25" (108 mm)

Manual latches (standard)

Approximately 790 lbs (358 kg)

Mow: 108" (274 cm) Transport: Overall width with wing decks raised: 88 in (223.5 cm); center deck is 54.5 in (138.4 cm) wide and 5" (12.7 cm) off ground when raised.

Leaf Mulching Kit (Model 31105)

American National Standard ANSI B71.4-2012. European standard per ISO EN 5395 , CE approved.

Mow up to 8.0 acres/hr (3.2 hectare/hr) at 8 mph (12.9 km/hr). Assumes no overlap and 100% efficiency.

MOWING POSITION

100” (254 cm) Mowing Width

108” (274 cm) Total Width

TRANSPORT/TRAILERING POSITION

5” (12.7 cm)

54.5” (138.4 cm)

67” (170.2 cm)

73.5” (186.7 cm)

88” (223.5 cm) Total Width

12”

(30.5 cm)

18”

(45.7 cm)

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

34

Page 5

Groundsmaster® 7200 Series Accessories*

PART NUMBER

30349

30552

30358

30374

30382

112-1688

114-4050

30483

110-6406

103-6771

DIMENSIONS

HEIGHT ROPS UP

OVERALL LENGTH

OVERALL WIDTH

WHEELBASE

GENERAL

TRACTION DRIVE

GROUND SPEED

SAFETY CERTIFICATIONS

HYDRAULIC LIFT

ATTACHMENT SYSTEM

ATTACHMENT CONTROLS

SNOW ATTACHMENTS

POLAR TRAC™ CAB

CAB LIGHT SYSTEM

MOWING UNIT ACCESSORIES

Universal Mount Sunshade, White

Universal Mount Sunshade, Red

Bimini Canvas Shade

Road Light Kit (30382 required, not required for Polar Trac™ system)

12V Power Port/Electrical Accessory Kit

Spark Arrestor Kit

Slow Moving Vehicle (SMV) Sign

Jack Stand Kit

Semi-Pneumatic Tire Assembly (front caster wheel)

Lug Tire (use in applications requiring greater traction) Does not work with rear discharge deck configuration

GROUNDSMASTER 7200 SERIES WITH CUTTING DECKS

72" (182.8 cm) 72" (182.8 cm)

97" (246.4 cm) 100" (254 cm)

78" (198.2 cm) (72" (182.8 cm) Base Deck)

68" (172.7 cm) (62" (157.5 cm) Base Deck)

75" (190.5 cm) (72"(182.8 cm) Side Discharge)

64" (162.5 cm) (60" (152.4 cm) Side Discharge)

57" (144.8 cm) NA

GROUNDSMASTER® 7200/7210 WITH

POLAR TRAC™ SYSTEM & NO ATTACHMENT

49.5" (125.7 cm)

POLAR TRAC™ SYSTEM

Polar Trac™ system converts the Groundsmaster 7200 into a snow removal machine complete with two rubber tracks and a climate controlled cab. Estimated

conversion time is four hours for two people. Consists of two models: Cab (30474), Tracks and Front Frame: (30675)

Three wheels per side with rear wheel mounted in place of mower traction wheel. Front two wheels are mounted to a walking axle that permits motion without

losing track tension. Track tread is made of a Kevlar® reinforced rubber compound designed to maintain traction on snow and ice.

8 mph (12.9 km/h).

Complies with American National Standards Institute (ANSI B71.4-2012) and applicable CE(machine directive 89/392, 91/368, 93/44, 84/538, 89/336) requirements;

ROPS certified ISO21299; Glass meets ANSI Z-26.1999 and ECE R43; EMC compliant

Two foot pedals located on center of Polar Trac™ floor board; Left pedal: Raise/Lower/Hold/Float. Right pedal: Attachment angle control–right/left.

Quick-attach A-mount on a hydraulically powered lift arm. PTO coupler to attachment is a quick connect as are the connections for the hydraulic connectors.

Two foot pedals in Polar Trac™; one pedal controls the lift and lower of the attachment. The other pedal controls either the rotation of the snow blower discharge

chute or the angular position of both the rotary broom and straight blade.

Snow blower, rotary broom, angled snow blade and powered V-plow. (Allied Attachments)

ROPS certified cab is heated and pressurized with the following standard features: heater, pressurized heater/fan, heavy-duty pantograph front windshield wiper and

washer, front windshield has 40” of visibility, interior mirror, fold away exterior side mirrors, molded front fenders, tinted full glass: rear window and both doors, rear

window opens, quick release right side window act as emergency exit, rubber sound isolator cab mounts and upholstered interior panels and headliner, textured

neoprene floor mat, interior dome light.

Standard lighting consisting of head lamps, turn signals, flashers and tail lamps. Meets ANSI/ASAE S279.12 (Lighting and Marking of Agricultural Equipment on Highways).

PART NUMBER

30675

30474

30750

30378

ALLIED

ALLIED

ALLIED

30382

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes only.

Actual products offered for sale may vary in use, design, required attachments and safety features. See distributor for details on all warranties.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

Polar Trac Frame and Rubber Tracks (required)

Polar Trac Cab (required)

V-Plow (30378 required)

V-Plow Mounting Kit

Rotary Broom (M-B Companies model MCT)

Snowthrower (Erskine Attachments)

Straight Blade (M-B Companies)

12V Power Port/Electrical Accessory Kit

POLAR TRAC™ SYSTEM ATTACHMENTS

35

®

The Groundsmaster

in Tomah, WI, ISO 9002 Certified Plant.

7200 and 7210 are manufactured

Page 6

Groundsmaster® 7200 Series Accessories* (continued)

PART NUMBER

30810 (7210)

30812 (7200/7210)

30393

08761

30380

110-6401

08756

08751

08757

08758

08754

NOTE: Front weights are required with use of certain rear attachments.

Rear Quick Attach System (30382 required for all rear attachments) for GM7210 models with Yanmar engines, MY2013+

Rear Quick Attach System (30382 required for all rear attachments) for GM7200/7210 models with Kubota engines, MY2013 +

Debris Blower (30377, 30380 required)

QAS Nail Drag (30377, 110-6401 required)

Auxiliary Hydraulic Power Kit (30377 required)

Extension Handle Kit (qty. 1 required for each 08751, 08757, 08758 attachment)

Drag Mat Carrier System (30377 required)

Tooth Rake (30377, 110-6401 required)

Steel Drag Mat (30377, 110-6401 08756 required)

Cocoa Drag Mat (30377, 110-6401 08756 required)

Finish Grader (30377 required)

E-Z VAC DFS COLLECTION SYSTEM,

Grass collection system that offers quick conversion

CONFIGURATION

COMPATIBLE MODELS

BLOWER

CAPACITY

DUMP FROM SEAT (DFS)

FEATURE

†Front weights required.

between bagging and side discharge without tools.

NOTE: Operates with GM7200/7210 models powered

by Kubota® engines ONLY.

Works with 60" (152.4 cm) side discharge decks, models

30467 & 30468

Spindle-drive horizontal blower impeller is positioned

parallel to and above the mower deck creating

continuous air flow from deck to collection system.

13.7 cu. ft. (402 liters)

Operator able to dump collected debris without leaving

seat.

MODEL 30348

REAR QUICK ATTACH SYSTEM (MOWING UNIT)

†

POWERED V-PLOW, M-B MODEL V-PLOW**

CONFIGURATION

ANGLING

BLADE WIDTHS

BLADE HEIGHT

CUTTING EDGE

SKID SHOES

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes only.

Actual products offered for sale may vary in design, required attachments and safety features. Consult your local Toro Distributor.

** Manufactured by M-B Companies, Inc. The Toro Company does not manufacture or sell the Powered V-Plow, nor does Toro guarantee

these accessories in any manner whatsoever.

This implement combines two useful snow attachments,

V-plow and angled blade, into one.

0-30 degrees, left and right, hydraulically

Straight – 57.5" (146 cm)

"V" – 50" (127 cm)

Scoop – 48.25" (123 cm)

Angled – 61" (155 cm)

23" (58 cm)

Bolt-on, trip edge

Adjustable, cast-hardened

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

36

The Groundsmaster® 7200 and 7210 are manufactured

in Tomah, WI, ISO 9002 Certified Plant.

Page 7

STAGE

WIDTH OF CUT

CUTTING HEIGHT

CUTTING EDGE

SKID SHOES

AUGER DIAMETER

FAN DIAMETER

CHUTE ROTATION

SHEAR PROTECTION

CASTING DISTANCE

APPROXIMATE SHIPPING

WEIGHT

HOSES

TYPE

SWING

BROOM SIZE

BRUSH

SHIPPING WEIGHT

OPTIONS

Groundsmaster® 7200 Series Specifications* (continued)

SNOWTHROWER, ERSKINE MODEL 1600**

2

53" (135 cm)

22" (56 cm)

51" (130 cm) bolt-on

Adjustable/Hardened

12" (30 cm) open flight

16" (41 cm)

Hydraulic

Pressure relief

Up to 25' (7.62 m)

418 lbs. (190 kg)

Included

ROTARY BROOM, M-B MODEL MCT***

Windrow type, front mounted mechanical drive broom.

Hydraulic angling, 30 degrees left and right.

Swing pivot point inline with 50 degree

CV joint

25" (63.5 cm) diameter brush,

60" (152 cm) width.

Sectional brush with choice of polypropylene, wire or com binatio n

radial segments.

60" Broom: 500 lbs., (227 kg).

Hydraulic Swing Cylinder, Electric Swing Mechanism, Dirt

Deflector, Storage Stands.

MECHANICAL

V-PLOW, MODEL 30750

CUTTING WIDTH

HITCH/MOUNT

CONSTRUCTION

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes only.

Actual products offered for sale may vary in design, required attachments and safety features. Consult your local Toro Distributor.

** Manufactured by Erskine. Attachment model ES1600. The Toro Company does not manufacture or sell the snowthrower,

nor does Toro guarantee these accessories in any manner whatsoever.

***Manufactured by M-B Companies, Inc.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

48" (121.9 cm)

V-Plow Mounting Kit 30757 required for installation.

All welded steel.

37

BLADE

CUTTING EDGE

ANGLING

WIDTH

STRAIGHT BLADE, M-B MODEL DOZER BLADE***

Heavy-duty 10-guage formed plate 60" (152.4 cm)

3/8"x 4"x 60" (.95 cm x 10.2 cm x 152.4 cm) high carbon steel

bar; reversible

0-30 degrees infinitely left & right hydraulically operated

60"

(152.4 cm)

The Groundsmaster® 7200 and 7210 are manufactured

in Tomah, WI, ISO 9002 Certified Plant.

Loading...

Loading...