Toro GrandStand 74574, GrandStand 74576, GrandStand 79574, GrandStand 79575, GrandStand 74575 Operator's Manual

Page 1

FormNo.3390-203RevA

GrandStand

®

Mower

With48in,52in,or60inTURBOFORCE

CuttingUnit

ModelNo.74574—SerialNo.315000001andUp

ModelNo.74575—SerialNo.315000001andUp

ModelNo.74576—SerialNo.315000001andUp

ModelNo.79574—SerialNo.315000001andUp

ModelNo.79575—SerialNo.315000001andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3390-203*A

Page 2

WARNING

g026962

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

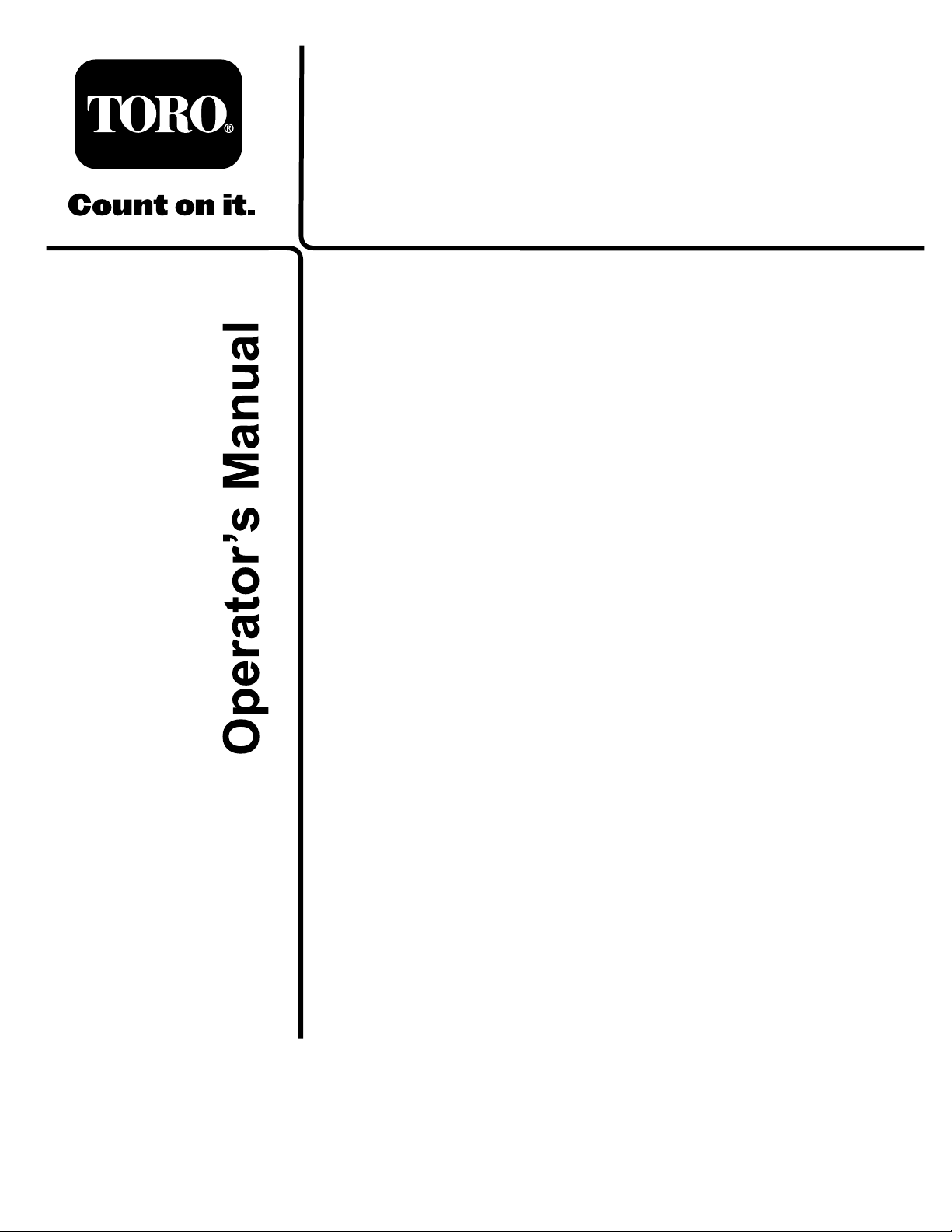

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Introduction

Thisrotaryblade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators,orresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyandalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................13

Specications........................................................14

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngine-OilLevel.................................16

BreakinginaNewMachine......................................16

ThinkSafetyFirst...................................................16

OperatingtheParkingBrake....................................16

OperatingtheMower-Blade-ControlSwitch

(PTO)...............................................................17

OperatingtheThrottle............................................17

OperatingtheChoke...............................................17

OperatingtheIgnitionSwitch..................................18

UsingtheFuelShut-OffValve..................................18

StartingandStoppingtheEngine..............................18

TheSafety-InterlockSystem....................................20

OperatingthePlatform...........................................21

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................23

UsingtheRotationIndicator....................................23

PushingtheMachinebyHand..................................24

TransportingtheMachine........................................24

LoadingtheMachine..............................................24

SideDischargingorMulchingtheGrass.....................25

AdjustingtheHeight-of-Cut....................................25

AdjustingtheAnti-ScalpRollers(60-inchMower

Decksonly)........................................................26

AdjustingtheFlowBafe........................................26

PositioningtheFlowBafe......................................26

UsingtheMid-SizeWeight.......................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

PremaintenanceProcedures........................................29

RaisingtheMowerforAccess...................................29

ReleasingtheCushionforRearAccess.......................30

Lubrication...............................................................31

LubricatingtheMachine..........................................31

GreasingtheFrontCasterPivots..............................31

LubricateCaster-WheelHubs..................................32

EngineMaintenance..................................................33

ServicingtheAirCleaner.........................................33

ServicingtheEngineOil..........................................34

ServicingtheSparkPlug..........................................36

CheckingtheSparkArrester(ifequipped)..................37

FuelSystemMaintenance...........................................37

DrainingtheFuelTank...........................................37

ServicingtheFuelFilter...........................................38

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

ServicingtheFuses.................................................40

DriveSystemMaintenance.........................................40

AdjustingtheTracking...........................................40

CheckingtheTirePressure......................................42

AdjustingtheCaster-PivotBearing............................42

ServicingtheCasterWheelsandBearings...................42

AdjustingtheElectricClutch....................................43

CheckingtheWheel-LugNuts..................................43

CheckingtheWheel-HubNuts.................................43

CoolingSystemMaintenance......................................44

CleaningtheAir-IntakeScreen.................................44

CleaningtheCoolingSystem....................................44

CleaningtheHydraulic-OilCooler(52and60-inch

MowerModelsonly)...........................................44

ServicingtheHydraulic-OilCooler(52and60-inch

MowerModelsonly)...........................................44

BrakeMaintenance....................................................45

ServicingtheBrake.................................................45

BeltMaintenance......................................................47

ReplacingtheMower-DeckBelt...............................47

ReplacingthePump-DriveBelt................................48

ControlsSystemMaintenance.....................................49

AdjustingtheMotion-Control-Handle

Positions............................................................49

HydraulicSystemMaintenance....................................51

ServicingtheHydraulicSystem.................................51

MowerDeckMaintenance...........................................54

ServicingtheCuttingBlades.....................................54

CorrectingtheMowerQuality-of-Cut........................56

AdjustingtheDeck-LiftSpring.................................59

ReplacingtheGrassDeector..................................59

Cleaning...................................................................60

CleaningUndertheMower......................................60

DisposingoftheWaste............................................60

Storage........................................................................60

CleaningandStorage..............................................60

Troubleshooting...........................................................62

Schematics...................................................................64

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthisOperator’s

Manual.Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorizedToro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoesorrubberboots,gloves,

andhearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’ sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

4

Page 5

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

SlopeOperation

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow .

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatinginreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly.Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

6

Page 7

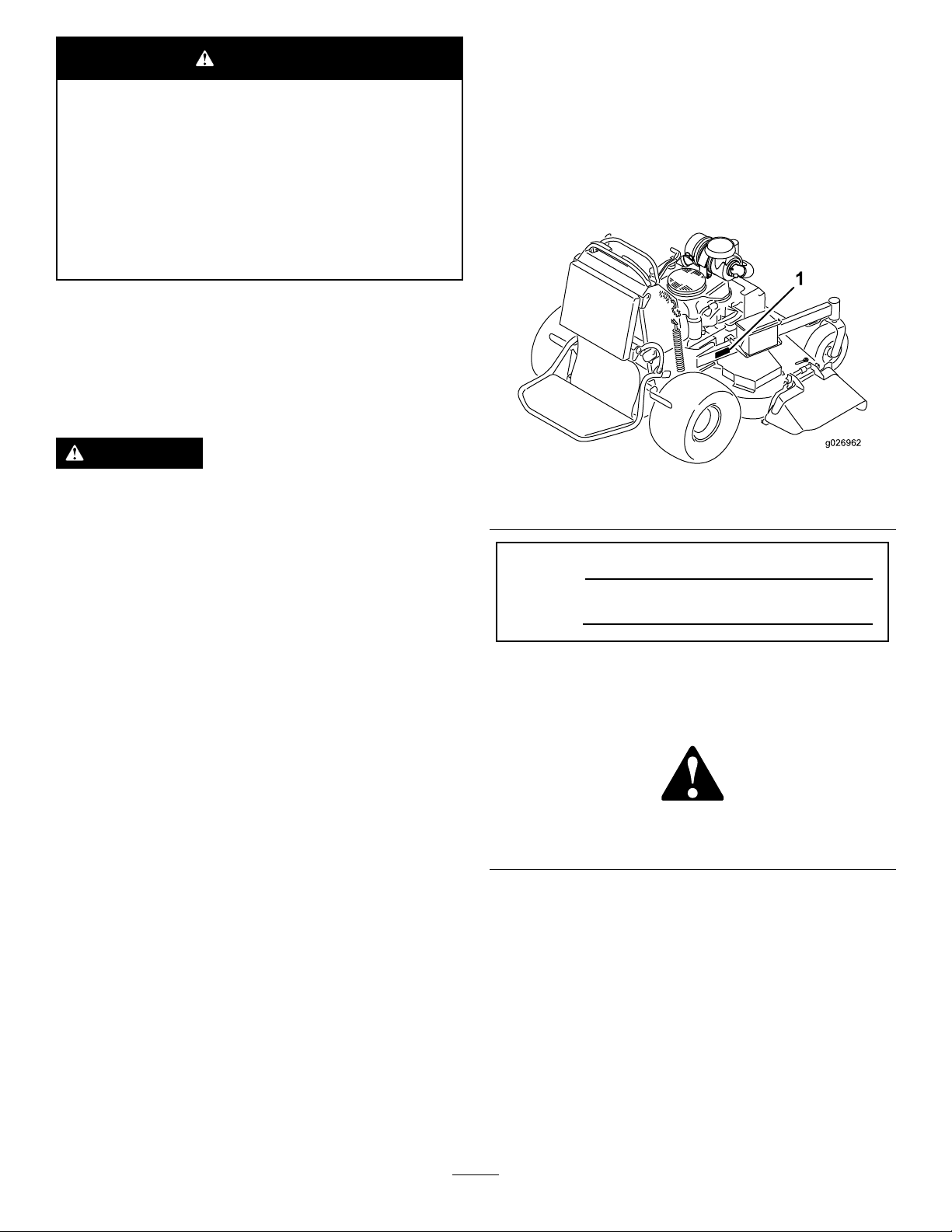

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

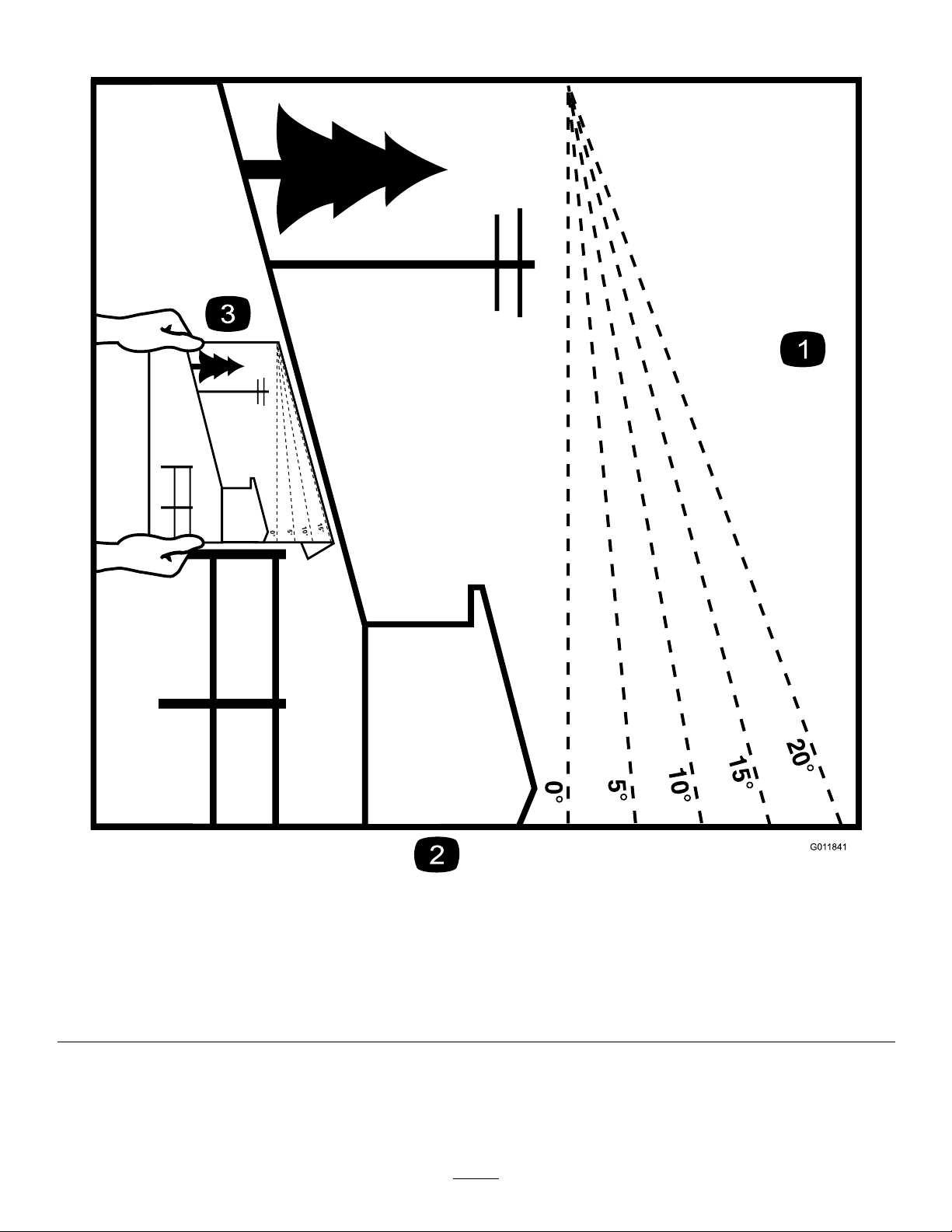

Manufacturer'sMark

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N-m(85to110

ft-lb).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

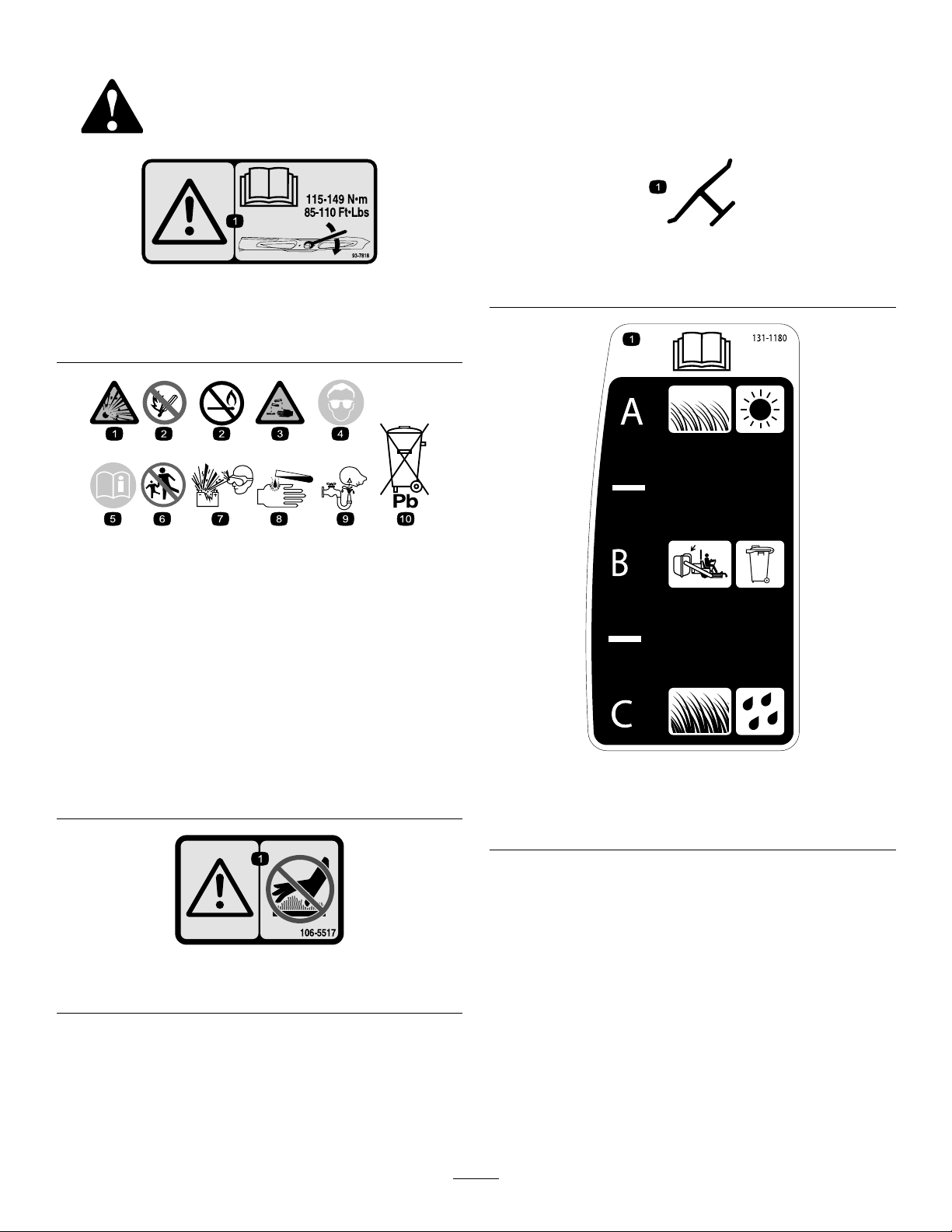

131-1180

1.ReadtheOperator'sManual.(A)Short,lightgrass;dry

conditions;maximumdispersion;(B)Baggingsetting;(C)

Tall,densegrass;wetconditions;maximumgroundspeed

1.Warning—donottouchthehotsurface.

106-5517

8

Page 9

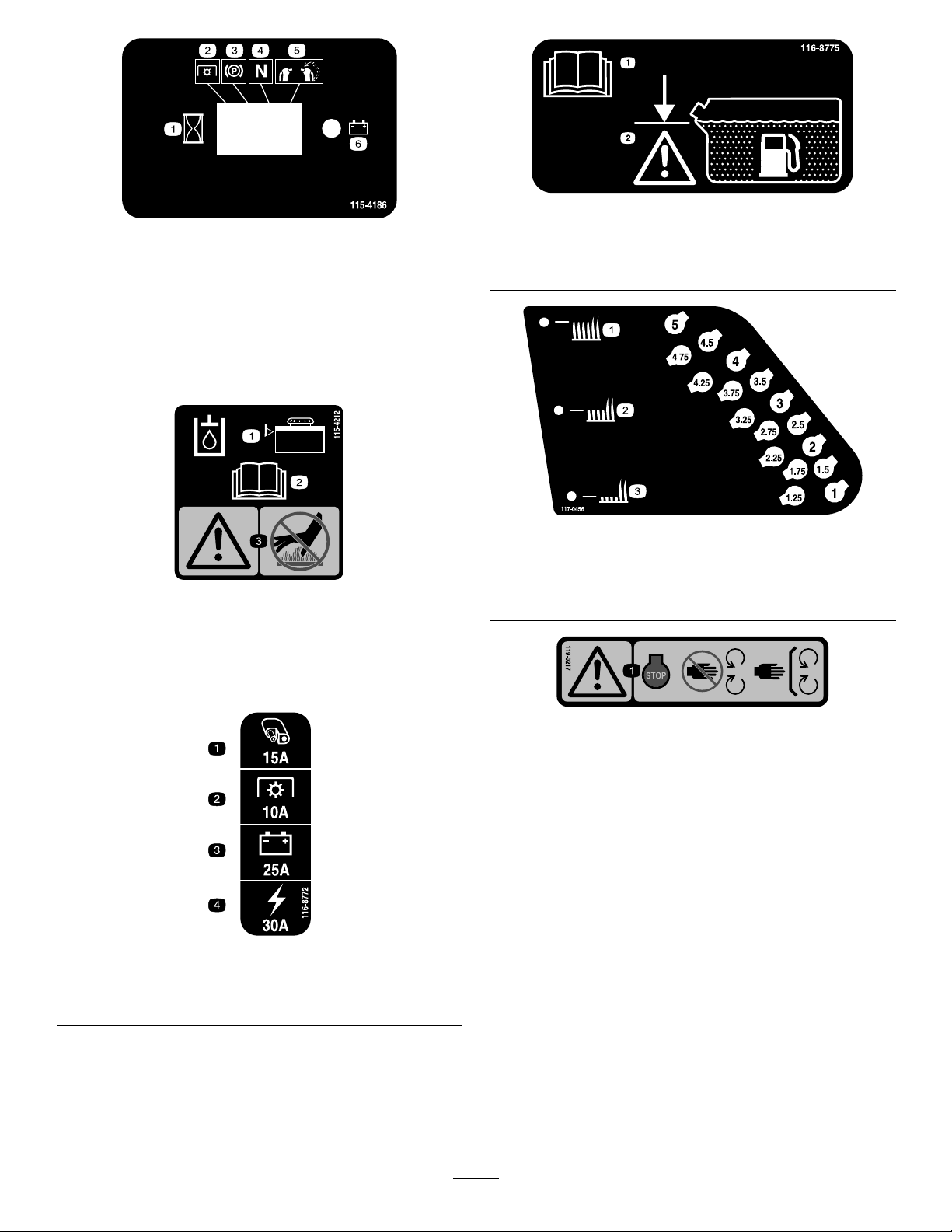

1.Interval

2.PowerTake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

116-8775

115-4186

1.ReadtheOperator’s

Manual

2.Filltobottomofllerneck;

warning—Donotoverll

thetank

117-0456

1.Heightofcut(HOC)—high3.Heightofcut(HOC)—low

2.Heightofcut

115-4212

(HOC)—medium

1.Hydraulicoillevel3.Warning—donottouchthe

2.ReadtheOperator's

Manual.

hotsurface.

116-8772

1.Accessory,15A

2.PTO,10A

3.Charge,25A

4.Main,30A

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

9

Page 10

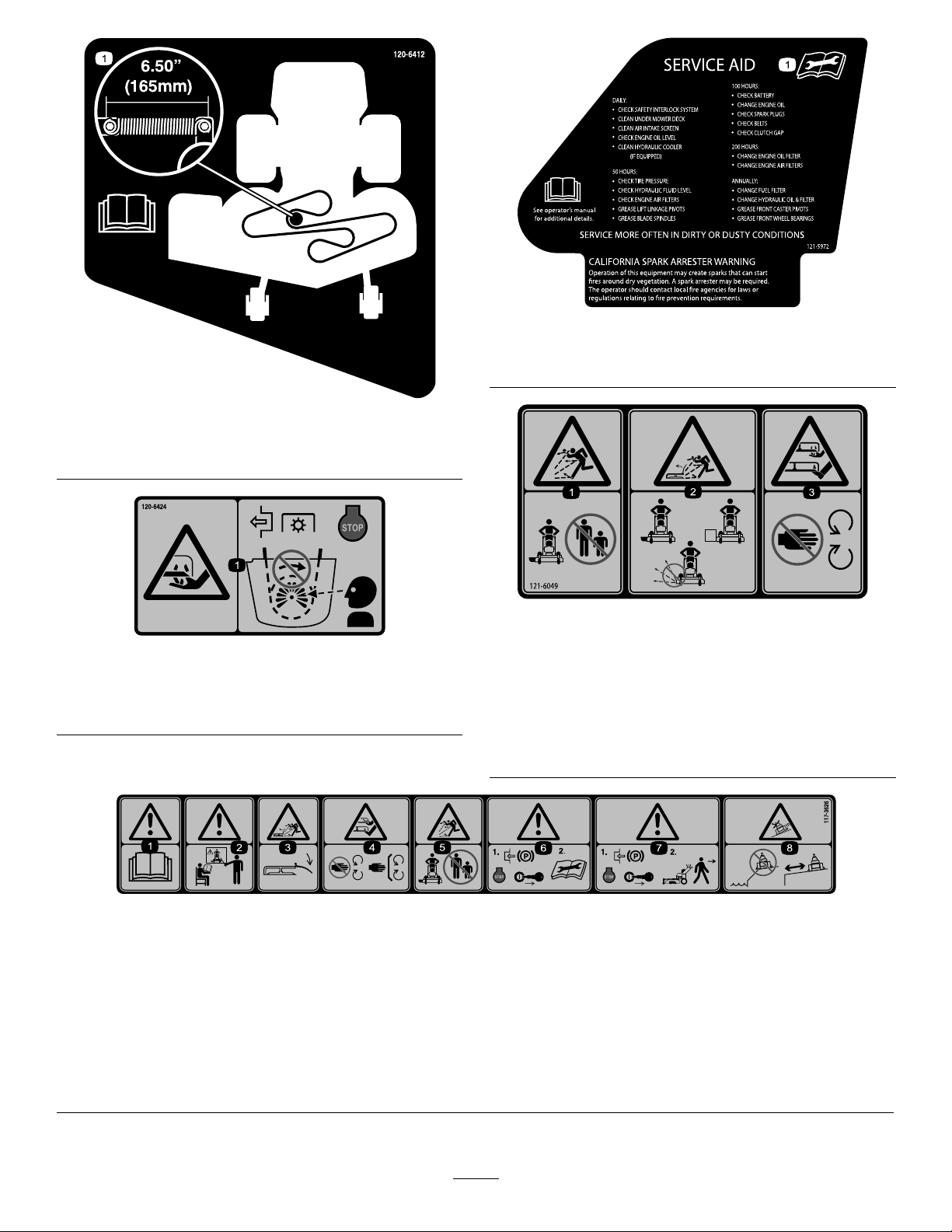

120-6412

1.Belttensionadjustment;readtheOperator'sManualfor

moreinformation.

121–5972

1.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

121–6049

120-6424

1.Cutting/dismembermenthazard,hand—disengagethe

powertake-off(PTO),stoptheengineandwatchforall

movingpartstostop.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

themowerwithguardsor

shieldsremoved.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—keephands

awayfrommovingparts.

117–3626

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.6.Warning—engagetheparkingbrake,stoptheengine

3.Thrownobjecthazard—keepdeectorinplace.

4.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingpartsandkeepallguardsandshieldsinplace.

themachine.

andremovethesparkplugwirebeforeperformingany

maintenanceonthemachine.

7.Warning—engagetheparkingbrakeandstoptheengine

beforeleavingthemachine.

8.Slidingandlossofcontrolhazard—donotoperatethe

machineneardrop-offsorwater;keepasafedistancefrom

drop-offs.

10

Page 11

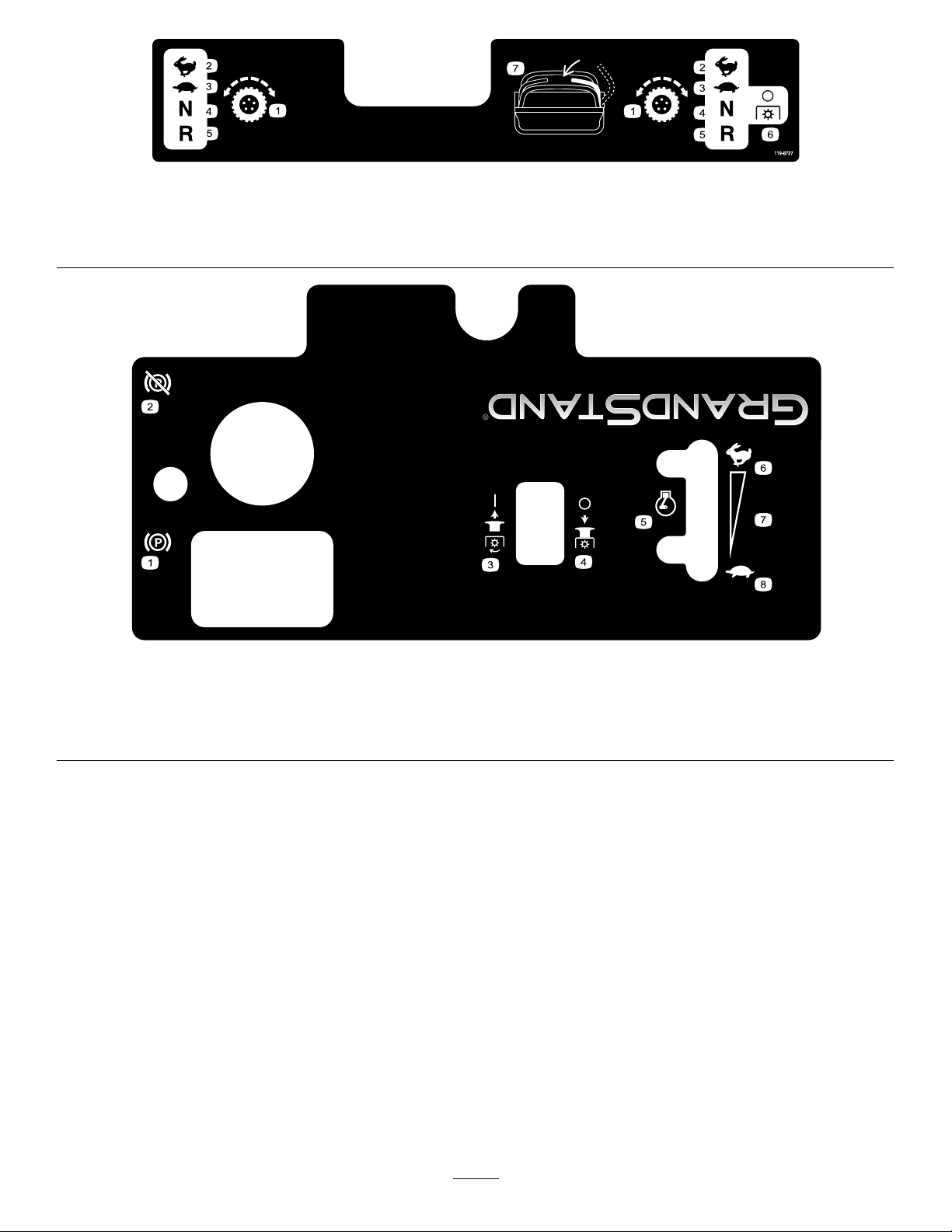

119-8727

1.Tractioncontrol

2.Fast4.Neutral

3.Slow

5.Reverse

6.PowerTake-off

(PTO)—disengage

7.Operatorpresenceswitch

120-6464

1.Parkingbrake—engage

2.Parkingbrake—disengage

3.PowerTake-off

(PTO)—engage

4.PowerTake-off

(PTO)—disengage

5.Enginespeed

6.Fast

7.Continuousvariablesetting

8.Slow

11

Page 12

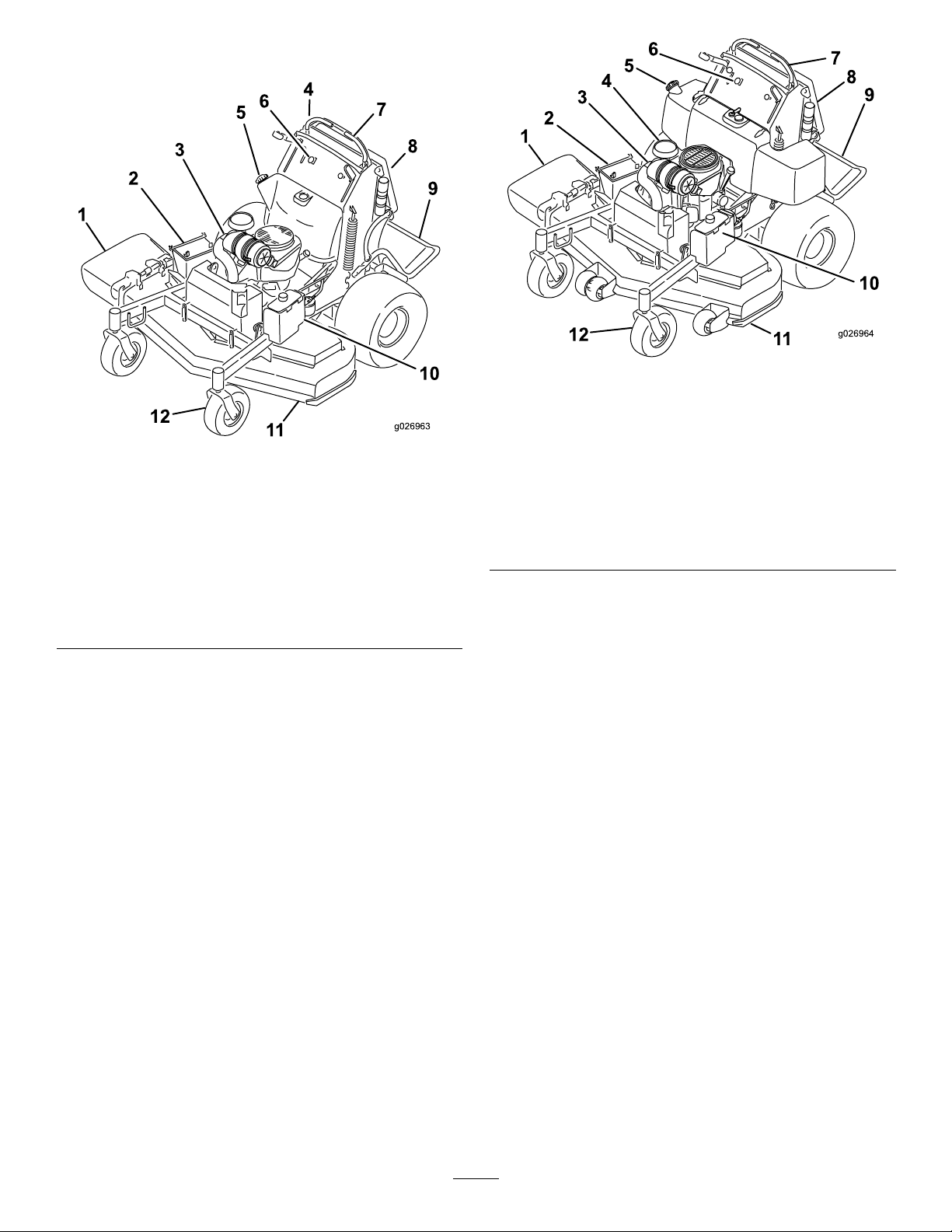

ProductOverview

g026963

g026964

1

2

3

4

5

6

7

8

9

10

11

12

Figure4

48inch(shown)and52-inchmachines

1.Side-dischargechute7.Controllevers

2.Battery8.Manualtube

3.Engine

4.Fuelshut-offvalve(behind

cushion)

5.Fueltank11.Mowerdeck

6.Controls

9.Platform(downposition)

10.Hydraulictank

12.Frontcasterwheel

Figure5

60-inchmachine

1.Side-dischargechute7.Controllevers

2.Battery8.Manualtube

3.Engine

4.Fuelshut-offvalve(behind

cushion)

5.Fueltank11.Mowerdeck

6.Controls

9.Platform(downposition)

10.Hydraulictank

12.Frontcasterwheel

12

Page 13

Controls

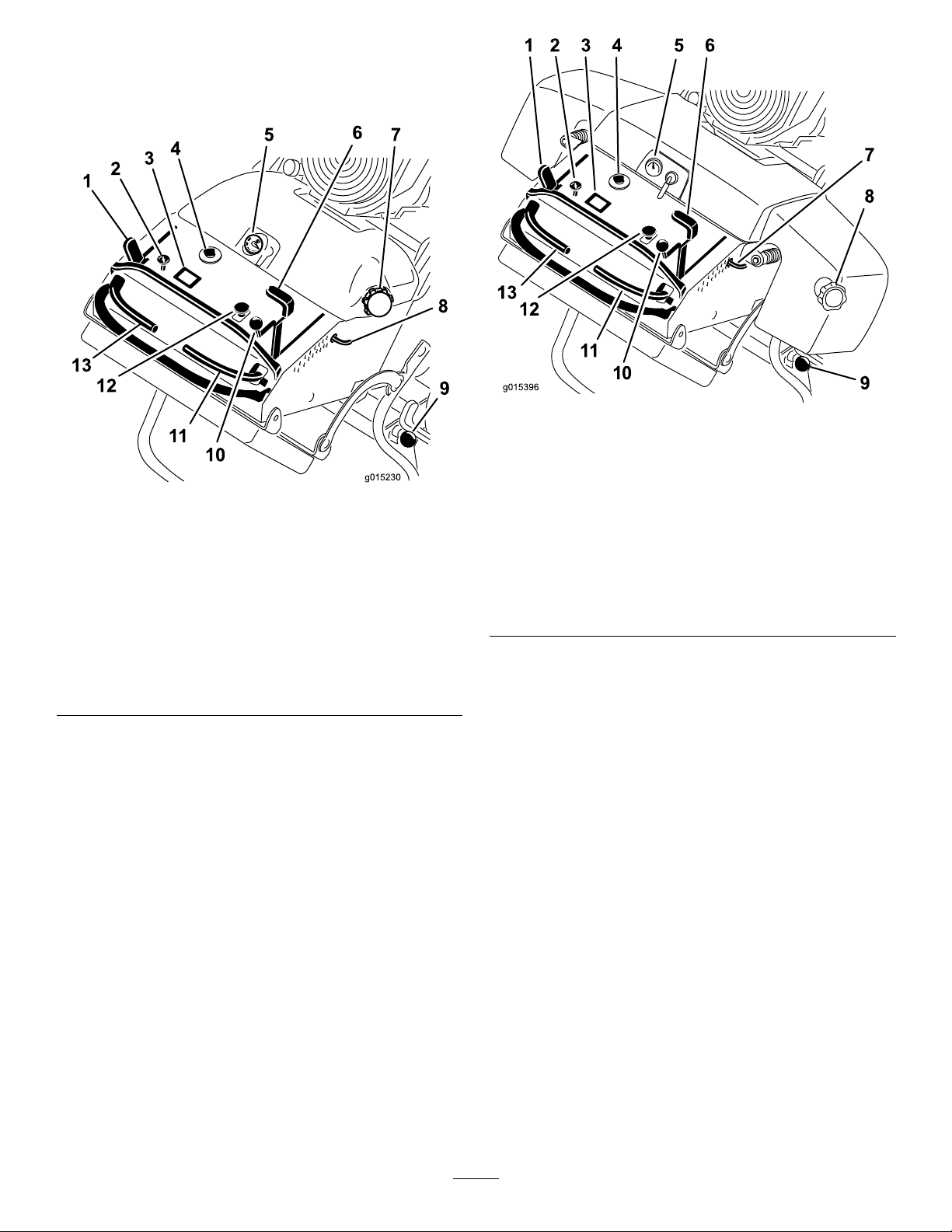

g015230

3

4

5

6

7

8

9

10

11

12

13

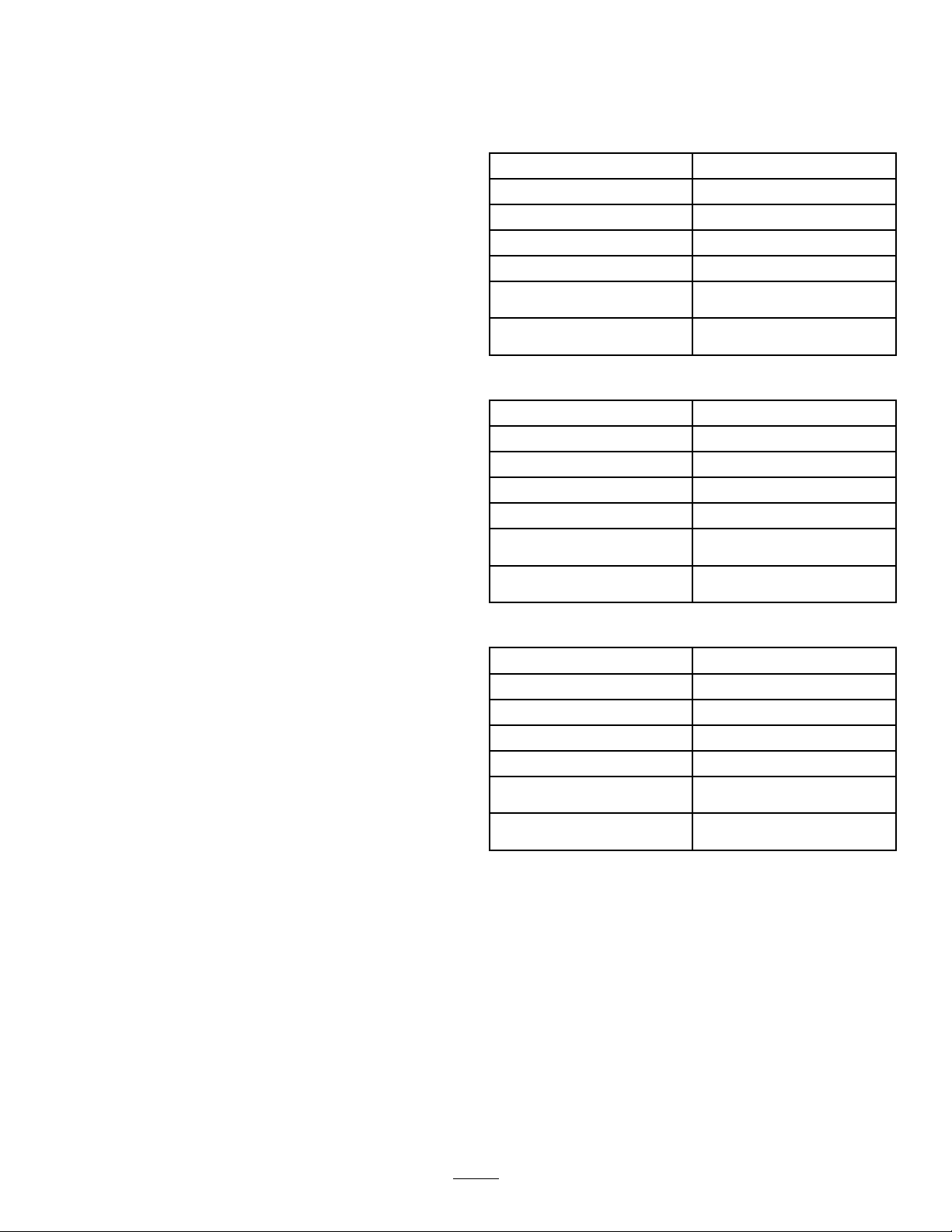

g015396

1 2 3 4 5 6

7

8

9

10

11

12

13

Becomefamiliarwithallthecontrols(Figure6)beforeyou

starttheengineandoperatethemachine.

Figure6

48inchand52-inchmachines

1.Parking-brakelever

2.Choke9.Platformlatch

3.Hourmeter10.Throttlecontrol

4.Ignitionswitch11.Rightmotion-controllever

5.Fuelgauge12.Blade-controlswitch

6.Height-of-cutlever13.Leftmotion-controllever

7.Fuelcap

8.Height-of-cutpin

(PTO)

Figure7

60-inchmachine

1.Parking-brakelever8.Fuelcap

2.Choke9.Platformlatch

3.Hourmeter10.Throttlecontrol

4.Ignitionswitch11.Rightmotion-controllever

5.Fuelgauge12.Blade-controlswitch

(PTO)

6.Height-of-cutlever13.Leftmotion-controllever

7.Height-of-cutpin

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure7).

FuelGauge

Thefuelgaugeislocatedonthetop,middleofthetank

(Figure6).

Safety-InterlockIndicators

Symbolsonthehourmeterindicatewithablacktrianglethat

theinterlockcomponentisinthecorrectposition(Figure7).

Battery-IndicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

7).

13

Page 14

ThrottleControl

Specications

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengagethe

electricclutchtodrivethemowerbladeswiththerightside

motion-controlleverinthecenter,unlockedposition.Pull

theswitchuptoengagethebladesandrelease.Todisengage

theblades,pushtheblade-controlswitch(PTO)downor

moveorreleasetherightsidemotion-controlleverintothe

neutral-lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhasthree

positions:Off,RunandStart.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

48-inchMowers

Widthwithdeectordown161.3cm(63.5inches)

Widthwithdeectorraised125.7cm(49.5inches)

Lengthwithplatformdown188cm(74inches)

Lengthwithplatformup149.9cm(59inches)

Height

Weightformodel74578406.9kg(897lb)

Weightformodel79548409.6kg(903lb)

121.9cm(48inches)

52-inchMowers

Widthwithdeectordown171.7cm(67.6inches)

Widthwithdeectorraised135.9cm(53.5inches)

Lengthwithplatformdown188cm(74inches)

Lengthwithplatformup149.9cm(59inches)

Height

Weightformodel74549411.9kg(908lb)

121.9cm(48inches)

FuelShut-OffValve

Closethefuelshut-offvalve(locatedbehindtheoperator

cushionontheright-handsideofthefueltank)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Weightformodel79549414.6kg(914lb)

60-inchMowers

Widthwithdeectordown192.0cm(75.6inches)

Widthwithdeectorraised156.2cm(61.5inches)

Lengthwithplatformdown197.9cm(77.9inches)

Lengthwithplatformup159.8cm(62.9inches)

Height

Weightformodel74553419.1kg(924lb)

Weightformodel79553421.8kg(930lb)

121.9cm(48inches)

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

15

Page 16

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

G009027

1

2

atalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefueltankcapandremovethecap.

Addunleadedregulargasolinetothefueltank,untilthe

levelis6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full.

3.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page34).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;referto

ServicingtheBrake(page45).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

SettingtheParkingBrake

Pulltheparkingbrakeleverrearwardandoverintoengaged

position(Figure9).

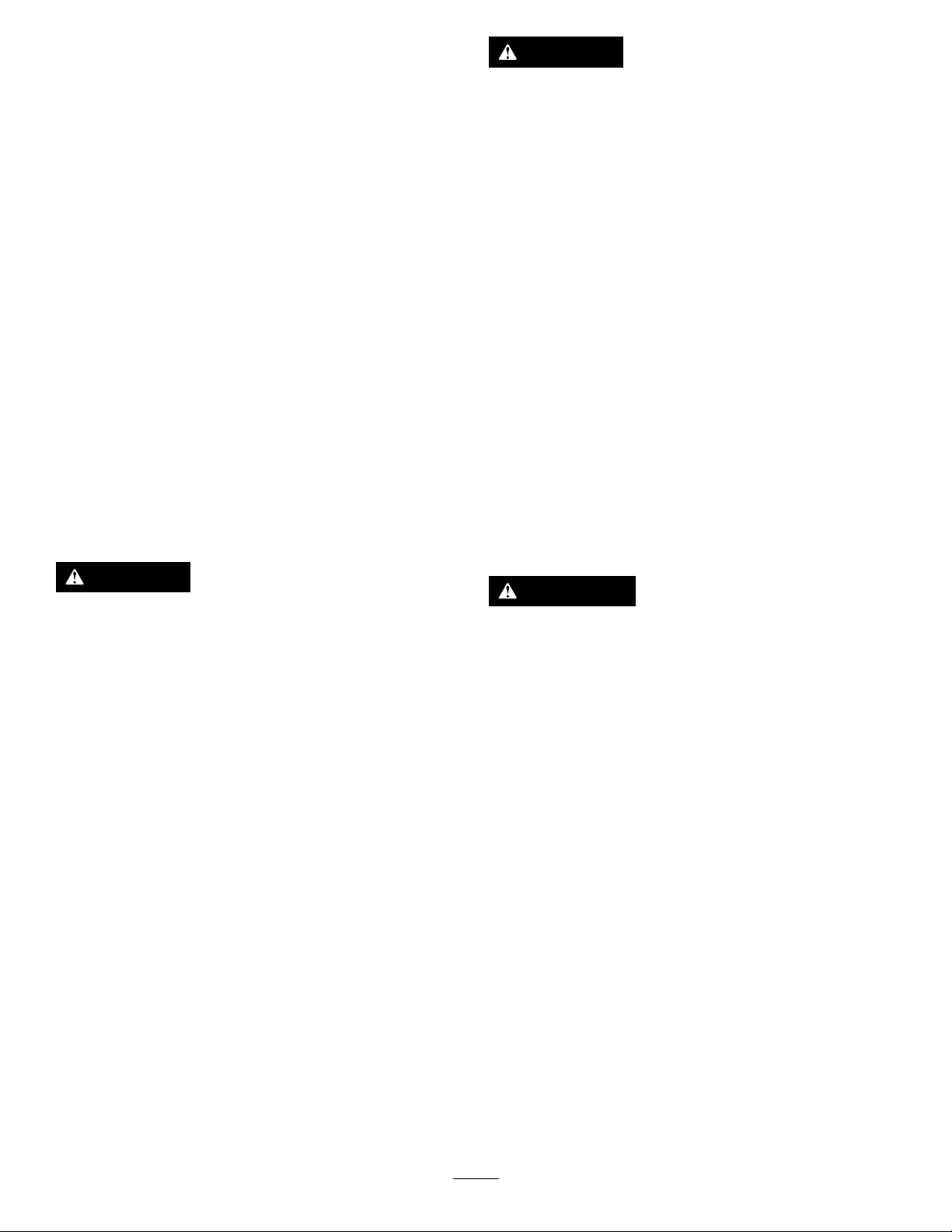

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

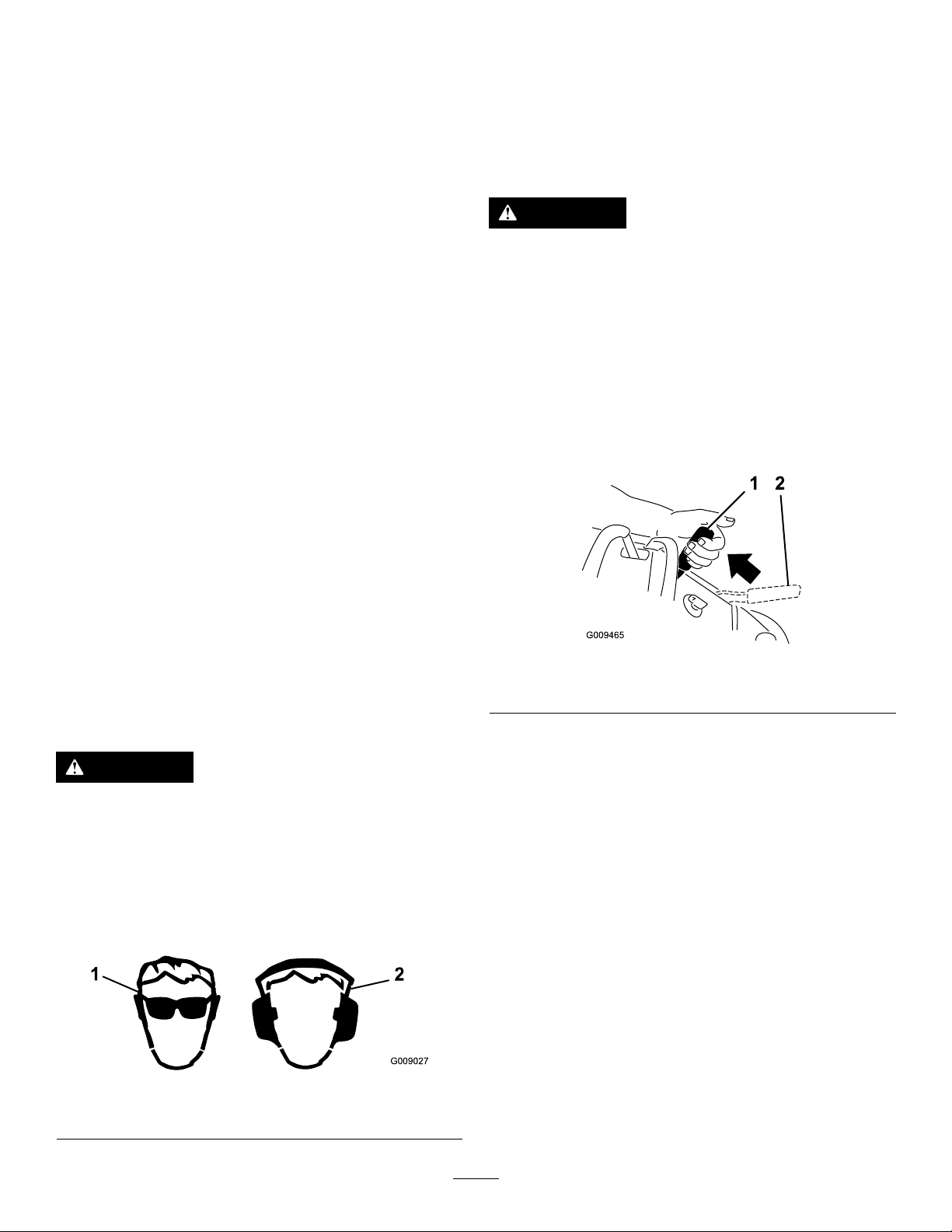

Figure9

1.Parkingbrakeengaged2.Parkingbrakereleased

ReleasingtheParkingBrake

Pullthebrakeleverbackandoverintotheslotandpushthe

parkingbrakeleverforward.

Figure8

1.Wearsafetyglasses

2.Wearhearingprotection

16

Page 17

Operatingthe

G008945

G009174

G008946

G008959

1

2

Mower-Blade-ControlSwitch

(PTO)

Theblade-controlswitch(PTO)isusedinconjunctionwith

therightsidemotion-controllevertoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetherightside

motion-controllevertothecenter,unlockedposition.

2.Pulltheblade-controlswitch(PTO)upandreleaseit

whileholdingdowntherightsidemotion-controllever

inthecenter,unlockedposition.

Figure12

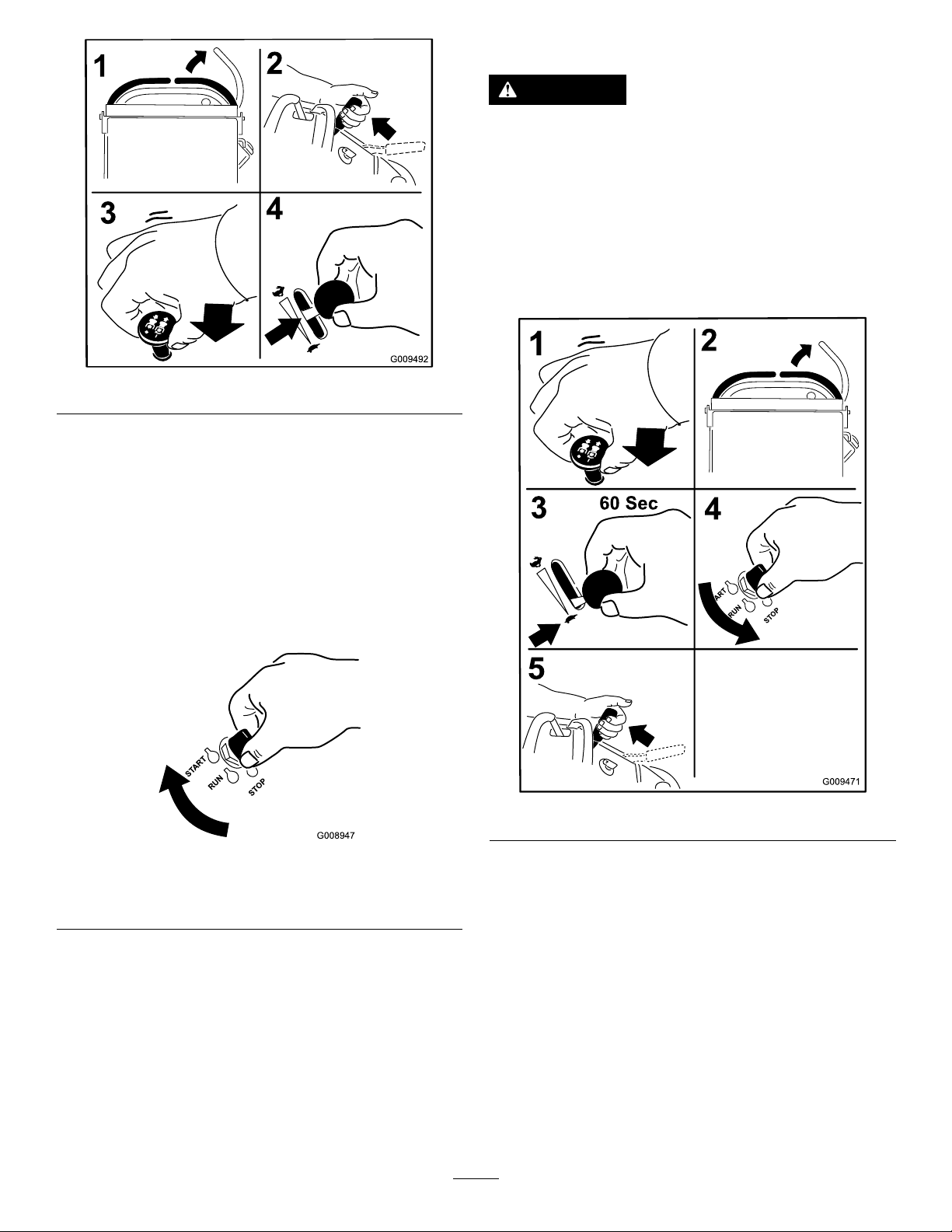

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure13).

3.Pushdownonthechokeknobtodisengagethechoke

aftertheenginehasstarted(Figure13).

Figure10

DisengagingtheMowerBlades(PTO)

Thefollowingaretwooptionsfordisengagingthemower

blades.

•Pushtheblade-controlswitch(PTO)downtotheOff

position.

•Movethemotion-controlleverstoneutralandmove

therightsidemotion-controlleverintotheneutral-lock

position.

Figure13

1.Onposition2.Offposition

Figure11

OperatingtheThrottle

ThethrottlecontrolmovesbetweenFastandSlowpositions

(Figure12).

AlwaysusetheFastpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

17

Page 18

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g026965

G008948

1

2

UsingtheFuelShut-OffValve

1.TurntheignitionkeytotheStartposition(Figure14).

Whentheenginesstarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure14

Closethefuelshut-offvalvefortransport,maintenance,and

storage(Figure15).

Ensurethatthefuelshut-offvalveisopenwhenstartingthe

engine.

2.Turntheignitionkeytostoptoturnofftheengine.

Figure15

1.Onposition2.Offposition

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Movetherightmotion-controllevertoneutrallocked

position.

4.Settheparkingbrake;refertoSettingtheParking

Brake.

5.Movetheblade-controlswitch(PTO)totheOff

position.

6.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

Note:Awarmorhotenginemaynotrequirechoking.

18

Page 19

Figure16

START

RUN

STOP

G008947

7.TurntheignitionkeytotheStartposition(Figure14).

Whentheenginesstarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure17

1.Offposition3.Startposition

2.Runposition

Figure18

Important:Makesurethefuelshut-offvalveisclosed

beforetransportingorstoringthemachine,asfuel

leakagemayoccur.Beforestoringthemachine,pull

wireoffsparkplug(s)topreventpossibilityofaccidental

starting.

19

Page 20

TheSafety-InterlockSystem

3.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunless:

•Therightsidemotion-controlleverismovedtothe

center,unlockedposition.

•Theblade-controlswitch(PTO)ispulledon.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoumoveorreleasetherightsidemotion-control

leverintotheneutral-lockposition.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllight

upinthecorrespondingsquare.

Note:Thebladesshouldnotrotate.

4.Movethemotion-controlleversforward.

Note:Theengineshouldstoprunning.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

7.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

8.Moveorreleasetherightsidemotion-controlleverinto

theneutral-lockposition.

Note:Thebladesshouldstoprotatingandtheengine

continuestorun.

9.Pushtheblade-controlswitchdownandmovethe

rightsidemotion-controllevertothecenter,unlocked

position.

10.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

11.Pushtheblade-controlswitch(PTO)downtotheOff

position.

Figure19

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Starttheengine;refertoStartingandStoppingthe

Engine(page18).

2.Settheparkingbrake.

Note:Thebladesshouldstoprotating.

12.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleaseitwithoutholdingrightside

motion-controllevertothecenter,unlockedposition.

Note:Thebladesshouldnotrotate.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Theplatformmaysuddenlydropifnot

supportedwhenthelatchpinispulledout.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringorraisingthe

operatorplatform.

•Makesuretheplatformissupportedwhenthe

latchpinispulledout.

•Makesurethelatchsecurestheplatformwhen

foldingitintheupposition.Pushittightagainst

thecushionforthelatchpintolockintoplace.

•Keepbystandersawaywhenraisingorlowering

theplatform.

20

Page 21

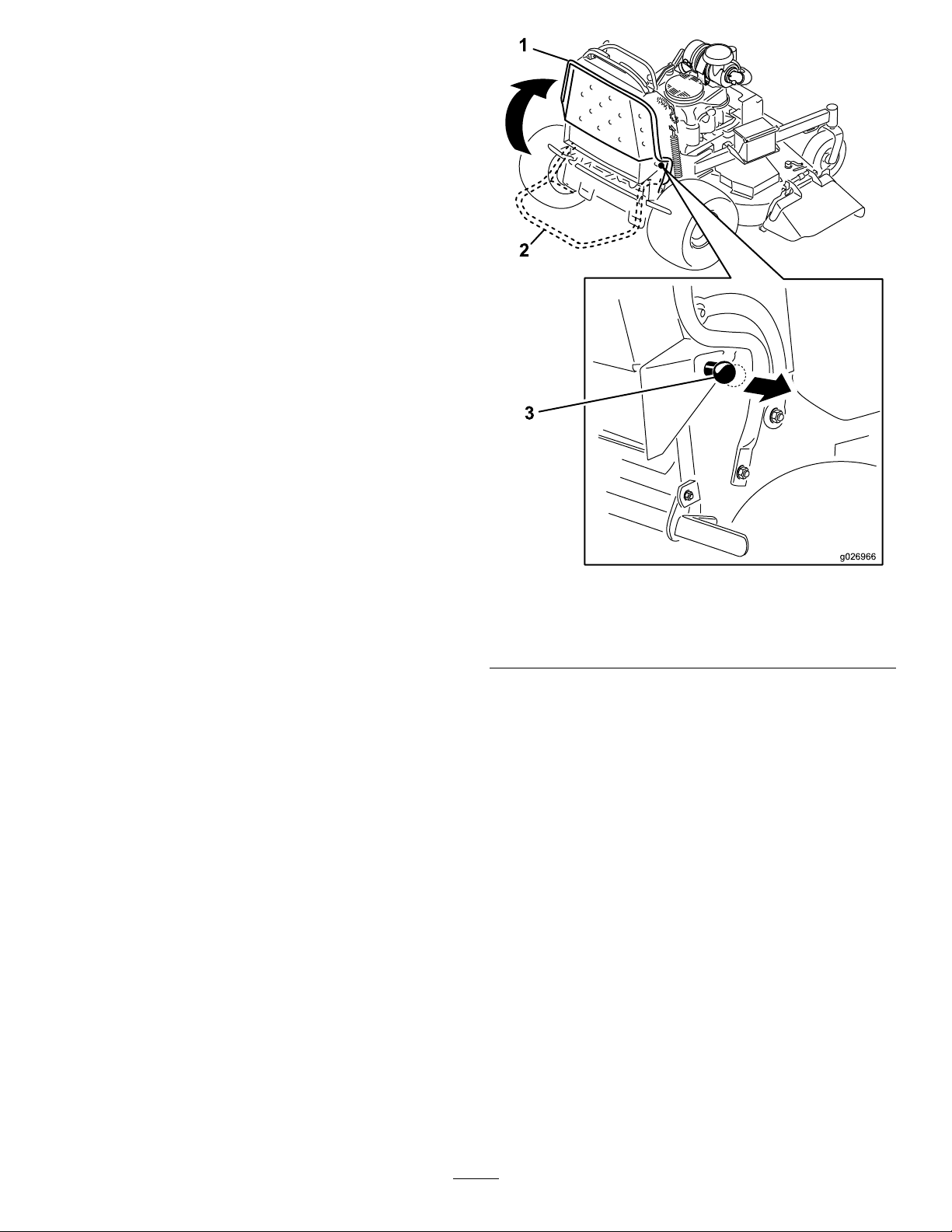

OperatingthePlatform

g026966

Themachinecanbeusedwiththeplatformintheupordown

position.Itistheoperator'spreferenceonwhichposition

touse.

OperatingtheMachinewiththe

PlatformUp

Operatingthemachinewiththeplatformupisrecommended

forthefollowing:

•Mowingneardrop-offs

•Mowingsmallareaswherethemachineistoolarge

•Areaswithlow ,over-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformupsothat

thelatchpinandknoblockitintoplace.Pushittightagainst

thecushionforthelatchpintolockitintoplace.

OperatingtheMachinewiththe

PlatformDown

Operatingthemachinewiththeplatformdownis

recommendedforthefollowing:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforwardagainstthe

cushiontoreleasepressureonthelatchpin,thenpullthe

knobout,andlowertheplatform(Figure20).

1.Platformup

2.Platformdown

Figure20

3.Pulltheknobouttorelease

theplatform.

21

Page 22

DrivingForwardorBackward

G015234

4

5

1

2

3

3 4

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperatethe

machineinthefullthrottlepositionwhenmowing.

CAUTION

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofmachine,andmaycause

personalinjuryordamagetomachine.

Slowthemachinedownbeforemakingsharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page16).

2.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

Figure21

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar

3.Togoforward,movethespeed-controllevertothe

desiredspeed.

4.Slowlypushthemotion-controlleversforward(Figure

22).

Note:Theenginewillkillifamotion-controlleveris

movedwiththeparkingbrakeengaged.

Note:Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinewillmove

inthatdirection.

Note:Tostop,pullthemotion-controlleversbackto

theneutralposition.

4.Rightcontrollever

5.Rightcontrolleverinthe

neutrallockposition

22

Page 23

StoppingtheMachine

G017978

1

1 2

1

Tostopthemachine,movethemotion-controlleversto

neutral,movetherightsidemotion-controlleverintothe

neutral-lockposition,disengagethepower-takeoff(PTO),

andturntheignitionkeytotheOffposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page16).Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure22

DrivingBackward

1.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward(Figure

23).

UsingtheRotationIndicator

Theslotsinthetopofthebeltcoversallowtheoperatorto

verifyifthebladeshavestoppedrotatingafterdisengagingthe

powertake-off(PTO)switch.

Disengagethepowertake-off(PTO)switch,stoptheengine,

removethekey,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

Figure23

Figure24

52-inchmowerdeckshown

1.RotationIndicator—slots

inthetopofthebeltcover

2.Side-dischargechute

23

Page 24

PushingtheMachinebyHand

g026967

Thebypassvalvesallowthemachinetobepushedbyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausehydraulicdamagemayoccur.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedpositionandsettheparkingbrake.

2.Openthebypassvalveonbothpumpsbyturningthem

counterclockwise1to2turns.Thisallowshydraulic

uidtobypassthepumpsandthewheelstoturn

(Figure25).

Note:Rotatethebypassvalvesamaximumof2turns

sothevalvedoesnotcomeoutofthebodycausing

uidtorunout.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure26).

Figure26

1.Tractionunittie-downloop

Figure25

1.Pump-bypassvalve

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closethebypassvalves,butdonotovertightenthem.

Torqueto12to15N-m(9to11ft-lb).

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallthenecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.

Totransportthemachine:

1.Raisetheplatformofthemachinebeforedrivingonto

thetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

LoadingtheMachine

Useextremecautionwhenloadingunitsontotrailersor

trucks.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideoftheunit(Figure27).Theplatform

whendownandlockedintoposition,extendsbackbetween

therearwheelsandservesasastopfortippingbackward.

Havingafull-widthrampprovidesasurfacefortheplatform

tocontactiftheunitstartstotipbackward.Withtheplatform

up,afull-widthrampprovidesasurfacetowalkonbehindthe

unit.Theoperatorshoulddetermineifitisbesttohavethe

platformupordownwhenloading,dependingonconditions.

Ifitisnotpossibletouseonefull-widthramp,useenough

individualrampstosimulateafull-width,continuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed20degrees(Figure27).Asteeperanglemaycause

mowercomponentstogetcaught,astheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

24

Page 25

WARNING

g019208

DANGER

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-over,andcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda20-degreeanglebetweenramp

andground,orbetweenaramp,atrailer,ora

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Donotremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

theOffposition.Alsoremovethekeyandpull

thewire(s)offthesparkplug(s).

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom25to127mm(1to5

inches)in6mm(1/4inches)increments.

Figure27

1.Trailer3.Notgreaterthan

2.Full-widthramp

20degrees

4.Full-widthramp(sideview)

SideDischargingorMulching theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

1.Movetheheight-of-cutlevertothetransportposition

(allthewayup).

2.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesiredand,insertthepin(Figure

28).

3.Lowertheheight-of-cutlevertothepin(Figure28).

Figure28

1.Height-of-cutholes3.Height-of-cutlever

2.Height-of-cutpin

25

Page 26

AdjustingtheAnti-Scalp

g018324

g012676

1 2

G012677

Rollers(60-inchMowerDecks

only)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethenutandboltpositiontheanti-scalprollers

andinstallthenutandbolt.

4.Ensurethespacersandbushingsareinstalled(Figure

29).

Figure29

1.Bushing4.Bolt

2.Anti-scalproller5.Nut

3.Spacer

Figure30

1.Slot

2.Nut

PositioningtheFlowBafe

Thefollowingguresareonlyforrecommendeduse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

Note:Iftheenginepowerdrawsdown,andthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefull,rearposition(seeFigure31).Thesuggested

useforthispositionisasfollows:

•Inshort,lightgrassmowingconditions

•Indryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthemower

AdjustingtheFlowBafe

Themower-dischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

providethebestqualityofcut.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(Figure30).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure31

26

Page 27

PositionB

G012678

G012679

Usethispositionwhenbagging(Figure32).

Figure32

PositionC

UsingtheMid-SizeWeight

•Weightsareinstalledtoimprovehandling,balance,and

improveperformance.W eightscanbeaddedorremoved

tocreateoptimizedperformanceunderdifferentmowing

conditionsandforoperatorpreference.

•Itisrecommendedthatweightsbeaddedorremovedone

atatimeuntilthedesiredhandingandbalanceisachieved.

Note:ContactanAuthorizedServiceDealertoordera

WeightKit.

WARNING

Excessiveweightchangescanaffectthehandling

andoperationofthemachine.Thiscouldcause

seriousinjurytoyouorbystanders.

Makeweightchangesinsmallincrementsonly.

Evaluatethemoweraftereachweightchangeto

ensurethemachinecanbeoperatedsafely.

Thisisthefull,openposition(Figure33).Thesuggesteduse

forthispositionisasfollows:

•Intall,densegrassmowingconditions

•Inwetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

Figure33

27

Page 28

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydrauliclter.

•Checkthewheel-lugnuts.

•Checkthewheel-hubnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Cleandebrisfromthehydraulic-oilcooler(ifequipped).

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Greasetheliftlinkage(moreoftenindirtyordustyconditions).

•Greasethemowerdeckspindles(moreoftenindirtyordustyconditions).

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Checkthehydraulic-uidlevel.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Checktheelectricclutch.

•Checkandcleantheenginecoolingnsandshrouds.

•Servicethehydraulic-oilcoolerindirtyconditions(ifequipped).

•Checkthemower-deckbelt.

•Checkthepump-drivebelt.

•Checkthehydraulichoses.

Every200hours

Every250hours

Every500hours

Every800hours

Beforestorage

Yearly

•Changetheengine-oillter.

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

•ChangethehydrauliclterandhydraulicoilwhenusingMobil®1oil.

•Replacethesecondaryairlter.

•Adjustthecaster-pivotbearing.

•Checkthewheel-hubnuts.

•ChangethehydrauliclterandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil.

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Replacethefuellter.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

28

Page 29

CAUTION

g018098

g017900

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

Premaintenance

Procedures

RaisingtheMowerforAccess

Thefrontofthemowercanberaisedandsupportedonits

backforaccessunderthemachineformaintenance.

1.Raisetheplatform;refertoOperatingthePlatform

(page21).

2.Removethebattery.

Figure34

1.Wingnut

2.Batterycover5.Battery

3.Negative-batterycable(–)

3.Drainthefuelfromthefueltank;refertoDraining

theFuelTank(page37).

4.Removethecapofthehydraulictank,andplaceapiece

ofplasticovertheopeningandinstallthehydrauliccap.

4.Positive-batterycable(+)

Figure35

1.Cap

2.Pieceofplastic

5.With2people,raisethefrontofthemowersothat

itrestsonthedrivetiresandtheplatformintheup

position.

6.Performanymaintenanceonthemachine.

7.With2people,lowerthefrontofthemowertothe

ground.

8.Removetheplasticunderthehydraulictankcap.

9.Installthebatteryforthemachine.

3.Hydraulictank

Note:Thiswillsealthehydraulictankandprevent

itfromleakingout.

29

Page 30

Figure36

g019209

1.Removethebattery

2.Frontendofthemower

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothemachinefor

maintenanceoradjustment.

1.Lowertheplatform.

2.Removethehairpin-cotterpinsoneachsideofthe

cushion.

3.Slidethelargewasherswiththeplasticbushingstothe

inside.

4.Removethecushion,andlowerittotheplatform.

5.Performanymaintenanceoradjustmentonthe

machine.

6.Raisethecushionandslideitontothepinsonboth

sidesofthemachine(Figure37).

7.Slidethelargewasherswiththeplasticbushings

intothecushionbracket,andsecurethemwitha

hairpin-cotterpin(Figure37).

1.Plasticbushingwiththe

largewasher

2.Cushionbracketwiththe

keyhole

Figure37

3.Hairpin-cotterpin

30

Page 31

Lubrication

G019356

g026968

g026969

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

6.Wipeupanyexcessgrease.

LubricatingtheMachine

ServiceInterval:Every50hours—Greasetheliftlinkage

(moreoftenindirtyordustyconditions).

Every50hours—Greasethemowerdeckspindles

(moreoftenindirtyordustyconditions).

Every800hours/Yearly(whichevercomes

rst)—Greasethefrontwheelbearings(moreoftenin

dirtyordustyconditions).

Every800hours/Yearly(whichevercomes

rst)—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Usethefollowinggraphicsforlocatingthegreasepoints.

Figure39

Figure40

GreasingtheFrontCaster Pivots

ServiceInterval:Yearly

Figure38

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecasterpivots;refer

toAdjustingtheCaster-PivotBearing(page42).

Note:Keepthedustcapoffuntilgreasingisdone.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

5.Removethegreasettinginthehole.Installthehex

plugandcap.

31

Page 32

LubricateCaster-WheelHubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey .

Figure41

13.Torquethenutto8to9N-m(71to80in-lb),loosen,

thentorqueitto2to3N-m(20to25in-lb).

Note:Makesureaxledoesnotextendbeyondeither

nut.

14.Installthesealguardsoverthewheelhubandinsert

wheelintocasterfork.

15.Installcasterboltandtightennutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoftenbyspinningthecaster

tire.Thetireshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntilthere

isaslightamountofdrag,andapplythread-locking

adhesive.

1.Sealguard2.Spacernutwithwrench

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutthesealsandinspectbearingsforwearor

damage,andreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1sealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto

onespacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

ats

Note:Donotthreadspacernutallofthewayonto

theendoftheaxle.Leaveapproximately3mm(1/8

inch)fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandthenewsealintothe

wheel.

12.Applyathread-lockingadhesivetothesecondspacer

nut,andthreaditontotheaxlewiththewrenchats

facingoutward.

32

Page 33

EngineMaintenance

g026970

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacetheprimaryair

lter.

Every250hours—Checkthesecondaryairlter.

Every500hours—Replacethesecondaryairlter.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pushdowntoreleasetheretainingclampsontheair

cleaner,andpulltheair-cleanercoverofftheair-cleaner

body(Figure42).

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

Figure42

1.Aircleanerclamps

2.Aircleanercover

3.Primaryairlter

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure42).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

5.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure42).Avoidknockingthelterintothe

sideofthebody.

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

Note:Holesinthelterwillappearasbrightspots.

Note:Ifthelterisdamageddiscardit.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Donotattempttocleanthesecondarylter.

Ifthesecondarylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,alwaysoperate

theenginewithbothairltersandthecoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.

Note:Donotuseadamagedlter.

2.Ifthesecondarylterisbeingreplaced,carefullyslide

itintothelterbody(Figure42).

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure42).

4.Ensurethatitisfullyseatedbypushingontheouter

rimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

5.Installtheair-cleanercoverwiththebreathercapdown,

androtatesothattheretainingclampslockthecover

inplace(Figure42).

33

Page 34

ServicingtheEngineOil

g026971

G008792

1

2

5

6

7

3

9

10

4

8

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.(moreoften

indirtyordustyconditions)

Every200hours—Changetheengine-oillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethatthecorrectamount

ofoilisused.

Important:Remembertoadd80%oftheoil,andthen

graduallyllittotheFullmarkonthedipstick.

OilType::Detergentoil(APIserviceSF,SG,SH,SJorSL)

EngineOilCapacity:2.1L(71oz)withthelterremoved;

1.8L(61oz)withoutthelterremoved

Viscosity:Refertothetablebelow .

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure44).

3.Checktheengine-oillevelasshowninFigure44.

Figure43

CheckingtheEngine-OilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Figure44

Important:Donotoverllthecrankcasewithoil,

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLowmark,becausetheengine

maybedamaged.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

ChangingtheEngineOil

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

34

Page 35

2.DisengagethePTO ,movethemotion-controlleversto

g026971

G008796

2

3

4

5

6

1

theneutral-lockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.ChangetheengineoilasshowninFigure45.

Figure46

Figure45

5.Slowlypourapproximately80%ofthespeciedoil

intothellertube,andslowlyaddtheadditionaloilto

bringittotheFullmark(Figure46).

6.Starttheengineanddrivetoaatarea.

7.Checktheengineoillevel.

ChangingtheEngine-OilFilter

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page34).

2.Placearagundertheoilltertosoakupanyspilledoil.

Important:Spilledoilmaydrainundertheengine

andontotheclutch.Oilspilledontheclutchmay

damagetheclutch,causethebladestostopslowly

whentheclutchisintheOffposition,andcause

theclutchtoslipwhentheclutchisswitchedto

theOnposition.Wipeupanyspilledoil.

3.Changetheengine-oillter(Figure47).

35

Page 36

g026971

G012845

3/4

2

3

4

5

6

1

RemovingtheSparkPlug

g026971

G008794

1

2

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.RemovethesparkplugasshowninFigure48.

Figure47

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenanextra3/4turniscompleted.

4.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheEngineOil(page34).

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.

Figure48

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.75mm(0.03inch).

Figure49

Useasparkplugwrenchforremovingandinstallingthespark

plug(s)andagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplug(s)ifnecessary.

TypeforallEngines:NGK

AirGap:0.75mm(0.03inch)

®

BPR4ESorequivalent

36

Page 37

InstallingtheSparkPlug

3

2

1

G015200

g026972

1

Tightenthesparkplug(s)to22N-m(16ft-lb).

Figure50

CheckingtheSparkArrester (ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotrefuelorruntheengineunlessthespark

arresterisinstalled.

FuelSystem

Maintenance

DrainingtheFuelTank

Note:Thereisnootherrecommendedwaytodrainfuel

fromthetank,otherthanusingasyphonpump.Asyphon

pumpcanbepurchasedatahardwarestore.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopename,orwhereasparkmay

ignitethegasolinefumes.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure52).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoacleangas

can(Figure51).

7.Wipeupanyspilledfuel.

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey .

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arrester,shakelooseparticlesoutofthearrester,and

cleanthescreenwithawirebrush(soakinsolventif

necessary).

5.Installarresteronexhaustoutlet.

Figure51

1.Fuelcap

37

Page 38

ServicingtheFuelFilter

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichevercomes

rst)

Donotinstalladirtylterifitisremovedfromthefuelline.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closethefuelshut-offvalve(behindtheoperator

cushion).

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure52).

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure52

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openthefuelshut-offvalve.

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

DANGER

Donotdrinkelectrolyte,andavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

38

Page 39

WARNING

g018098

Incorrectbattery-cableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.Installthepositive(red)batterycabletopositive(+)

batteryterminalwithanut,awasher,andabolt(Figure

53).

4.Slidetherubbercoveroverthepost.

5.Installthenegativebatterycableandthegroundwire

tothenegative(-)batteryterminalwithanut,awasher,

andabolt(Figure53).

6.Slidetherubbercoveroverthepost.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lifttheblack,rubbercoveronthenegativecable.

4.Disconnectthenegativebatterycablefromthenegative

(-)batteryterminal(Figure53).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page38).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthebattery.

4.Chargethebatteryfor1hourat25to30ampsor6

hoursat4to6amps.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure54).

Figure53

1.Wingnut4.Positivebatterycable

2.Batterycover5.Battery

3.Negativebatterycable

5.Slidetheredterminalbootoffthepositive(red)battery

terminal.

6.Removethepositive(red)batterycable(Figure53).

7.Removethebatteryholddownplate(Figure53),and

removethebattery.

InstallingtheBattery

1.Placethebatteryontothemachine(Figure53).

6.Installthebatteryontothemachineandconnectthe

batterycables;refertoInstallingtheBattery(page39).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure54

1.PositiveBatteryPost

2.NegativeBatteryPost

39

3.Red(+)ChargerLead

4.Black(-)ChargerLead

Page 40

ServicingtheFuses

g017915

1

g015241

DriveSystem

Theelectricalsystemisprotectedbyfuses,andrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

1.Releasethecushionfromtherearofthemachine.

2.Pulloutonthefusetoremoveorreplaceit(Figure55).

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseisinstalled

Figure55.

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.

Note:Ifitdoes,stopthemachineandsettheparking

brake.

3.Releasethecushionfromtherearofthemachine.

4.Rotatetherightcableadjustmenttopositiontheright

motioncontrolinthecenterofthecontrolpanel

neutral-lockslot(Figure57).

Figure55

1.Fuses

1.Leftmotion-controllever