Toro GrandStand 74549, GrandStand 74553, GrandStand 79548, GrandStand 79549, GrandStand 79553 Operator's Manual

...Page 1

FormNo.3379-934RevB

GrandStand

®

Mower

With48in,52in,or60inTURBOFORCE

CuttingUnit

ModelNo.74549—SerialNo.314000001andUp

ModelNo.74553—SerialNo.314000001andUp

ModelNo.74578—SerialNo.314000001andUp

ModelNo.79548—SerialNo.314000001andUp

ModelNo.79549—SerialNo.314000001andUp

ModelNo.79553—SerialNo.314000001andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3379-934*B

Page 2

WARNING

g018327

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

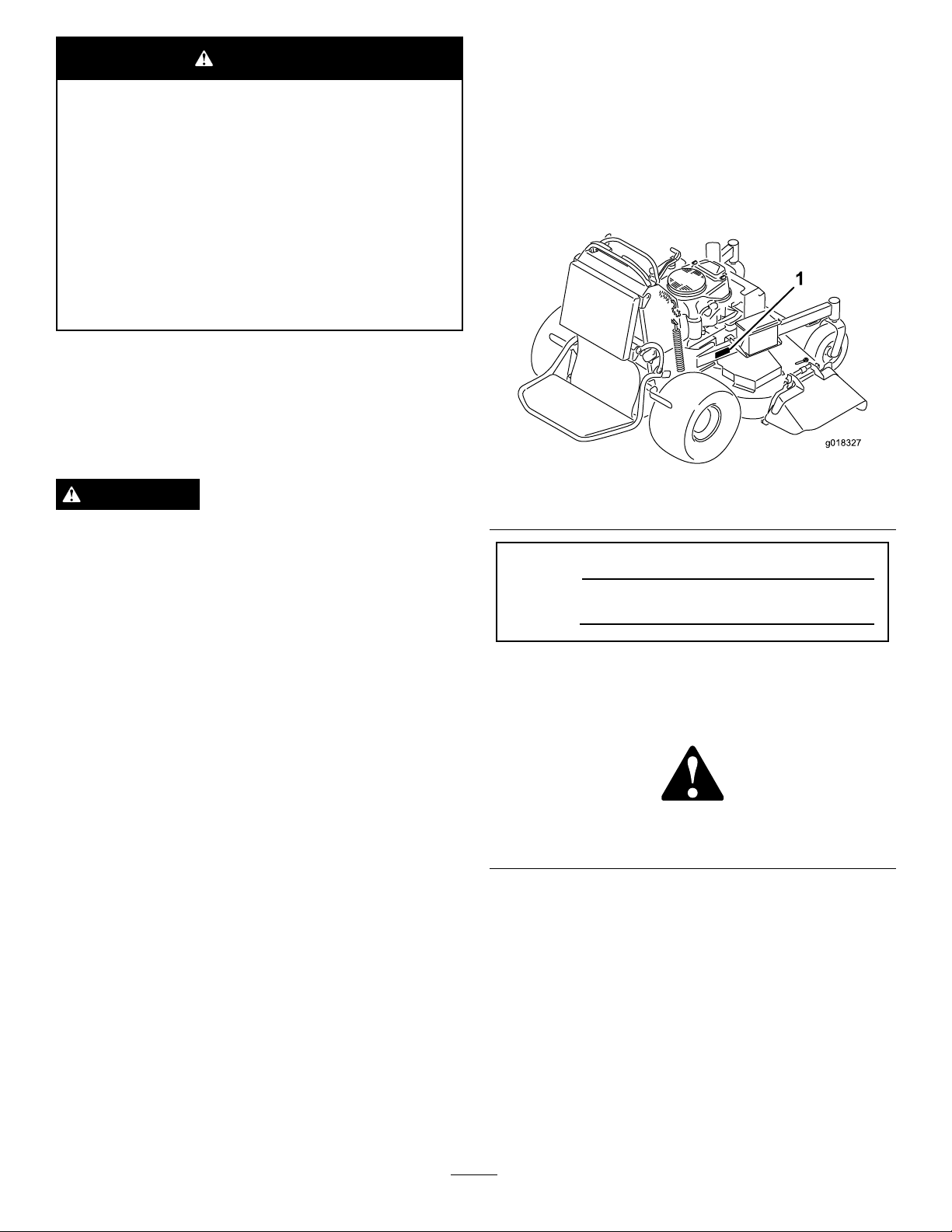

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Figure1identiesthelocationofthe

Figure1

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Introduction

Thisrotaryblade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators,orresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyandalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Figure2),

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................13

Specications........................................................14

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngine-oilLevel..................................16

BreakinginaNewMachine......................................16

ThinkSafetyFirst...................................................16

OperatingtheParkingBrake....................................16

OperatingtheMower-Blade-controlSwitch

(PTO)...............................................................17

OperatingtheThrottle............................................17

OperatingtheChoke...............................................17

OperatingtheIgnitionSwitch..................................18

UsingtheFuelShut-offValve...................................18

StartingandStoppingtheEngine..............................18

TheSafety-interlockSystem.....................................20

OperatingthePlatform...........................................21

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................23

UsingtheRotationIndicator....................................23

PushingtheMachinebyHand..................................24

TransportingtheMachine........................................24

LoadingtheMachine..............................................24

SideDischargingorMulchingtheGrass.....................25

AdjustingtheHeight-of-Cut....................................25

AdjustingtheAnti-scalpRollers(60-inchMower

Decksonly)........................................................26

AdjustingtheFlowBafe........................................26

PositioningtheFlowBafe......................................26

UsingtheMid-sizeWeight.......................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

PremaintenanceProcedures........................................29

RaisingtheMowerforAccess...................................29

ReleasingtheCushionforRearAccess.......................30

Lubrication...............................................................31

LubricatingtheMachine..........................................31

GreasingtheFrontCasterPivots..............................31

LubricateCaster-wheelHubs...................................32

EngineMaintenance..................................................33

ServicingtheAirCleaner.........................................33

ServicingtheEngineOil..........................................33

ServicingtheSparkPlug..........................................36

CheckingtheSparkArrester(ifequipped)..................37

FuelSystemMaintenance...........................................37

DrainingtheFuelTank...........................................37

ServicingtheFuelFilter...........................................38

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

ServicingtheFuses.................................................40

DriveSystemMaintenance.........................................40

AdjustingtheTracking...........................................40

CheckingtheTirePressure......................................42

AdjustingtheCaster-pivotBearing............................42

ServicingtheCasterWheelsandBearings...................42

AdjustingtheElectricClutch....................................43

CoolingSystemMaintenance......................................44

CleaningtheAir-intakeScreen..................................44

CleaningtheCoolingSystem....................................44

CleaningtheHydraulic-oilCooler(52and60-inch

MowerModelsonly)...........................................44

ServicingtheHydraulic-oilCooler(52and60-inch

MowerModelsonly)...........................................44

BrakeMaintenance....................................................45

ServicingtheBrake.................................................45

BeltMaintenance......................................................47

ReplacingtheMower-deckBelt................................47

ReplacingthePump-driveBelt.................................48

ControlsSystemMaintenance.....................................49

AdjustingtheMotion-control-handle

Positions............................................................49

HydraulicSystemMaintenance....................................51

ServicingtheHydraulicSystem.................................51

MowerDeckMaintenance...........................................54

ServicingtheCuttingBlades.....................................54

CorrectingtheMowerQuality-of-Cut........................56

AdjustingtheDeck-liftSpring..................................59

ReplacingtheGrassDeector..................................59

Cleaning...................................................................60

CleaningUndertheMower......................................60

DisposingoftheWaste............................................60

Storage........................................................................60

CleaningandStorage..............................................60

Troubleshooting...........................................................62

Schematics...................................................................64

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthisOperator’s

Manual.Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorizedT oro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes(rubberboots,gloves,

andhearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly .

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

4

Page 5

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

ToroMowerSafety

SlopeOperation

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatinginreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly .Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,T orodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Checkbrakeoperationfrequently .Adjustandserviceas

required.

6

Page 7

SlopeIndicator

G011841

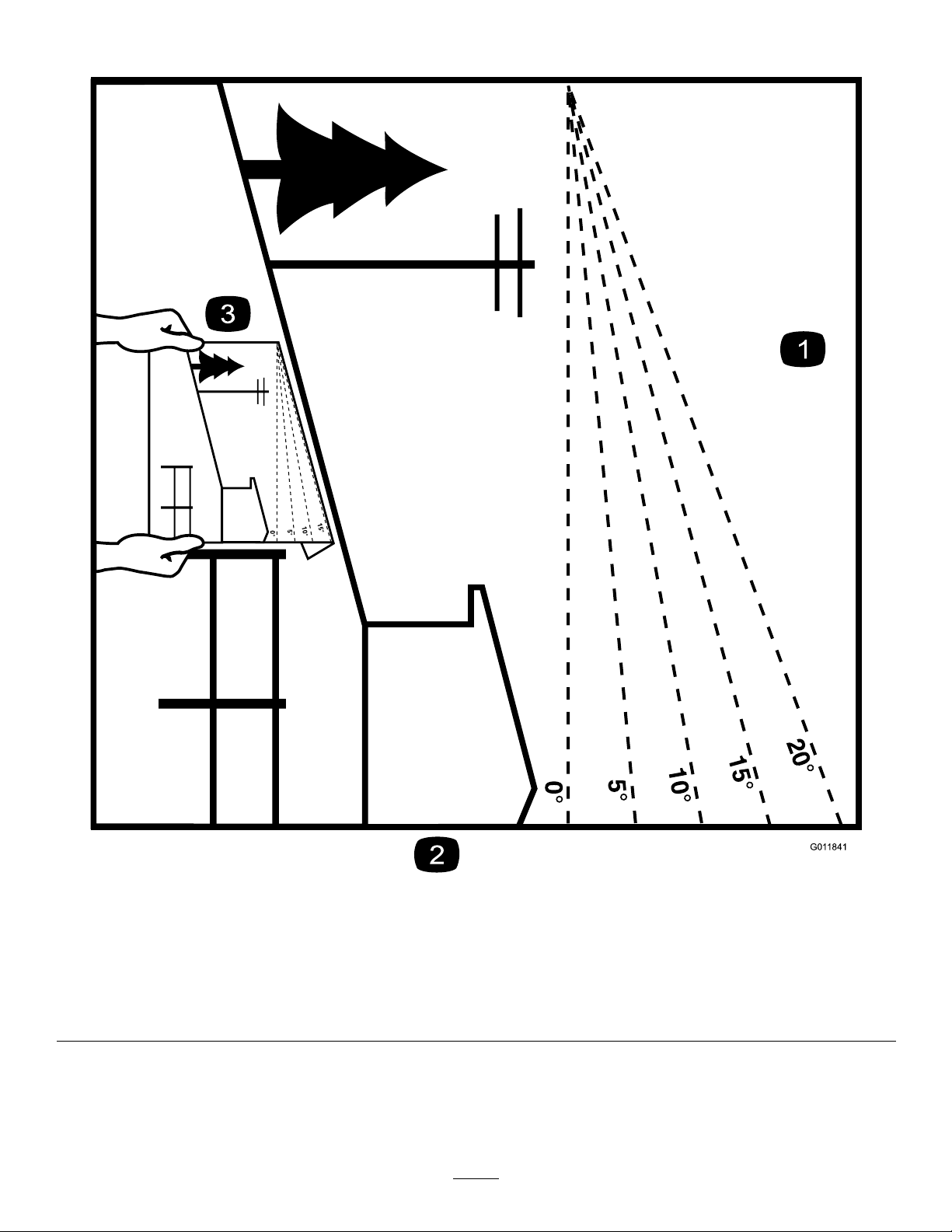

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

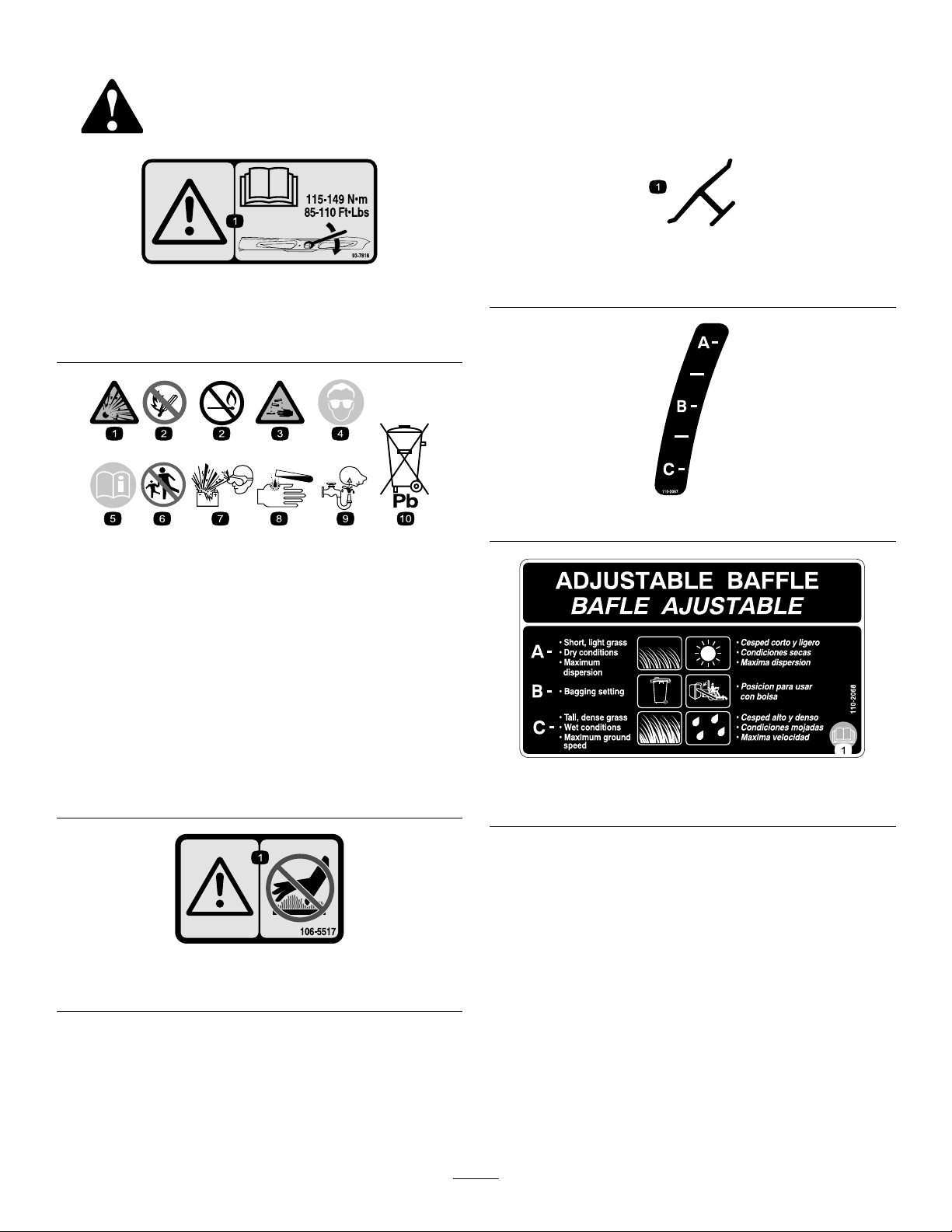

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115to149N-m(85to1 10

ft-lb).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

110-2067

110-2068

1.ReadtheOperator'sManual.

1.Warning—donottouchthehotsurface.

106-5517

8

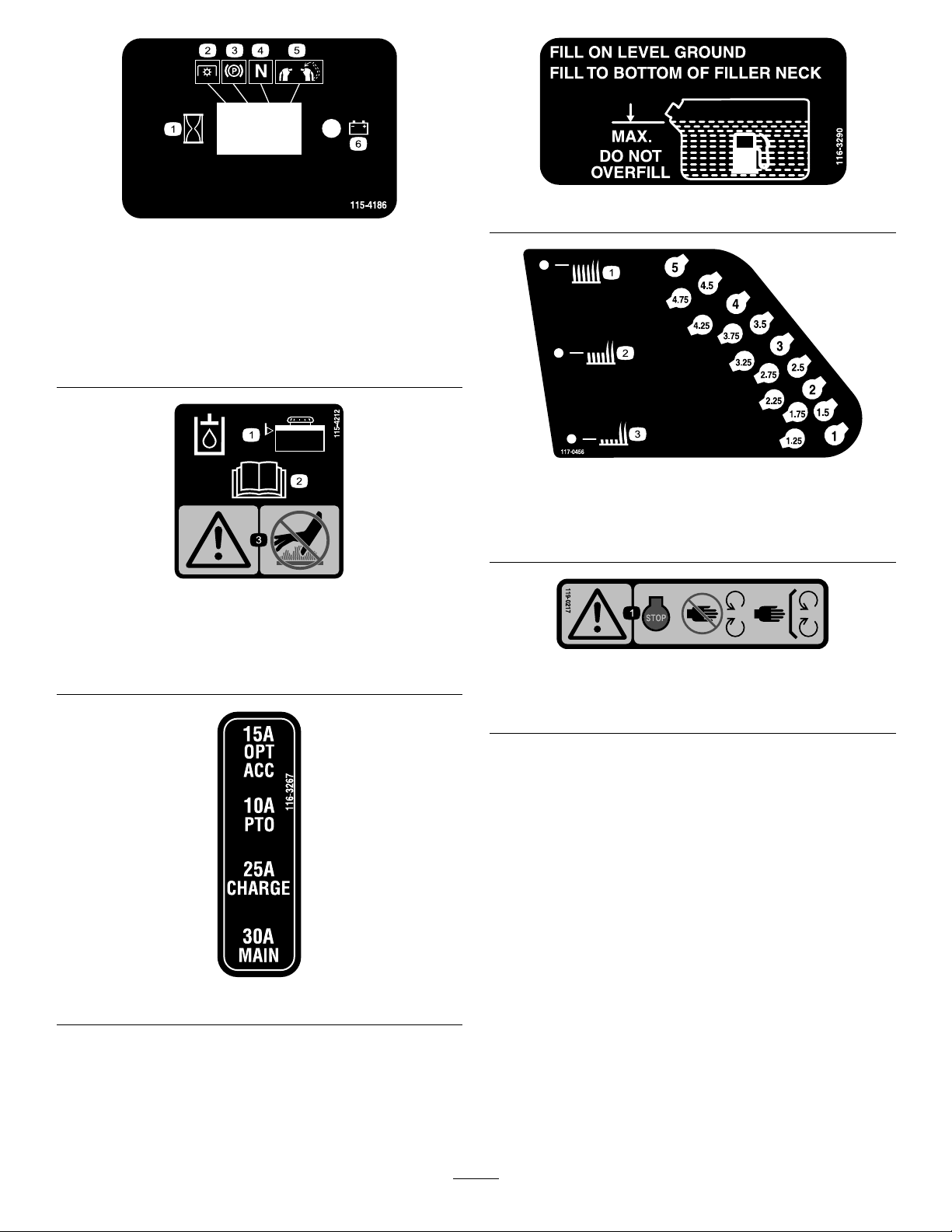

Page 9

1.Interval

2.PowerT ake-off(PTO)

3.Parkingbrake

4.Neutral

5.Operatorpresenceswitch

6.Battery

116-3290

115-4186

117-0456

1.Heightofcut(HOC)—high3.Heightofcut(HOC)—low

2.Heightofcut

(HOC)—medium

115-4212

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

116-3267

119-0217

1.Warning—stoptheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

9

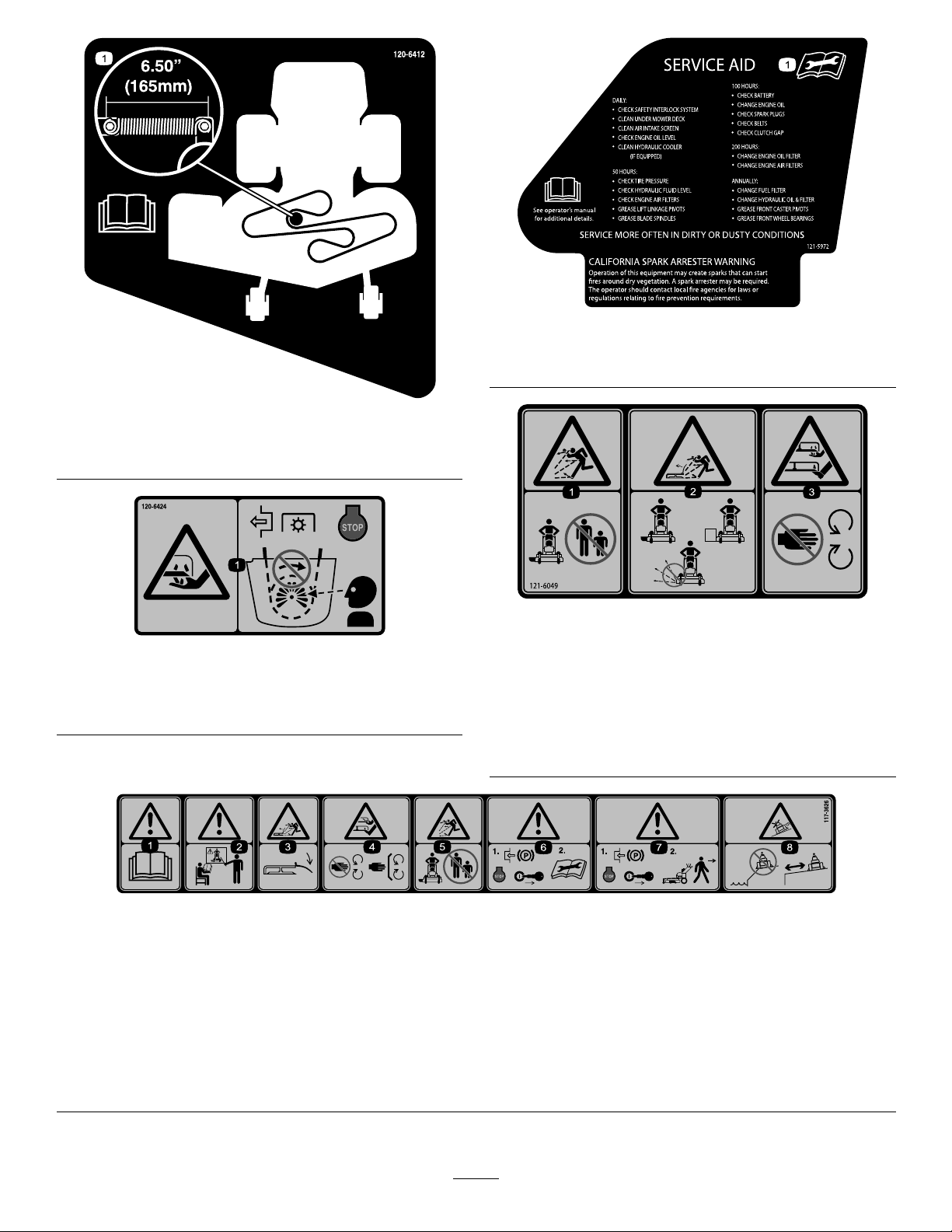

Page 10

120-6412

1.Belttensionadjustment;readtheOperator'sManualfor

moreinformation.

121–5972

1.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

121–6049

120-6424

1.Cutting/dismembermenthazard,hand—disengagethe

powertake-off(PTO),stoptheengineandwatchforall

movingpartstostop.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

themowerwithguardsor

shieldsremoved.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—keephands

awayfrommovingparts.

117–3626

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.6.Warning—engagetheparkingbrake,stoptheengine

3.Thrownobjecthazard—keepdeectorinplace.

4.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingpartsandkeepallguardsandshieldsinplace.

themachine.

andremovethesparkplugwirebeforeperformingany

maintenanceonthemachine.

7.Warning—engagetheparkingbrakeandstoptheengine

beforeleavingthemachine.

8.Slidingandlossofcontrolhazard—donotoperatethe

machineneardrop-offsorwater;keepasafedistancefrom

drop-offs.

10

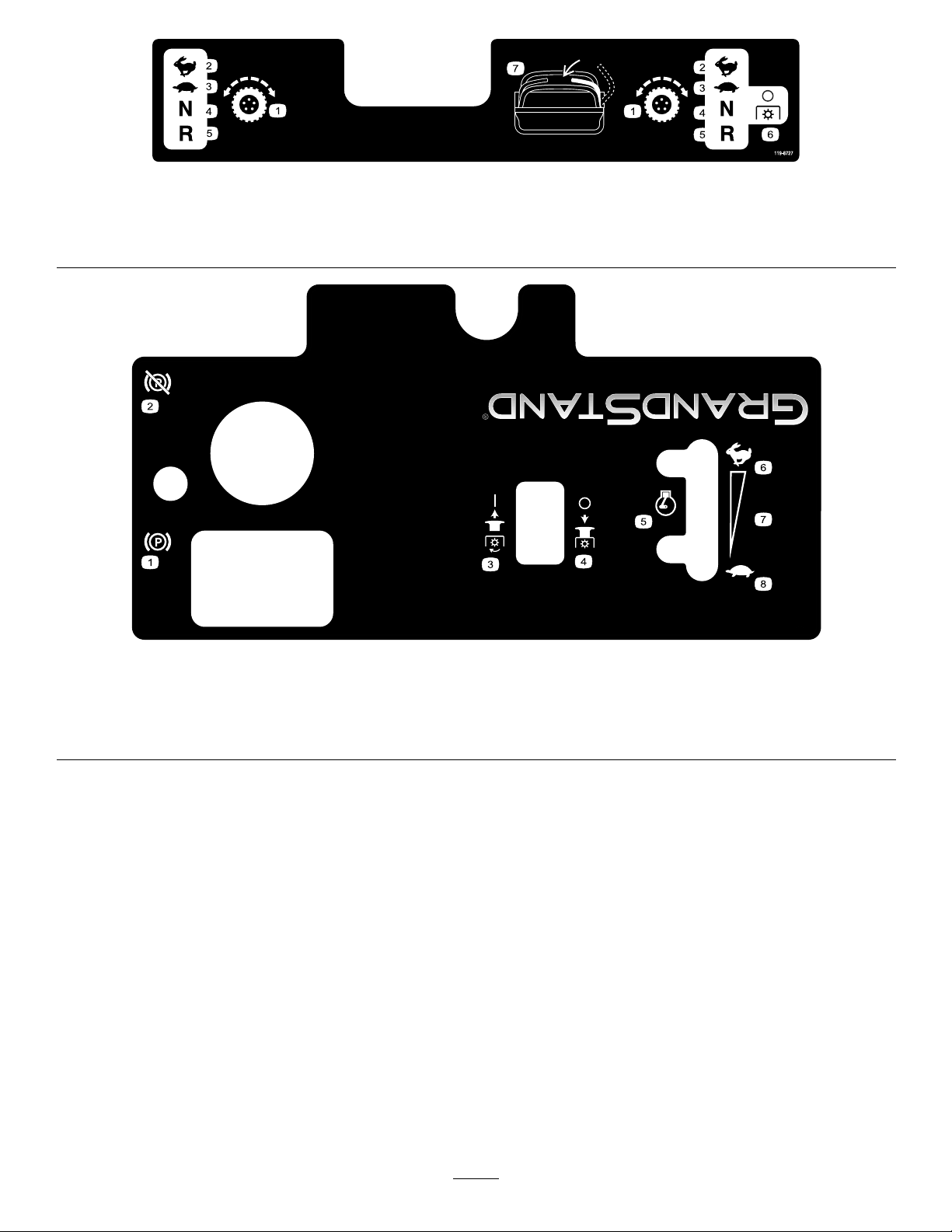

Page 11

119-8727

1.Tractioncontrol

2.Fast4.Neutral

3.Slow

5.Reverse

6.PowerT ake-off

(PTO)—disengage

7.Operatorpresenceswitch

120-6464

1.Parkingbrake—engage

2.Parkingbrake—disengage

3.PowerT ake-off

(PTO)—engage

4.PowerT ake-off

(PTO)—disengage

5.Enginespeed

6.Fast

7.Continuousvariablesetting

8.Slow

11

Page 12

ProductOverview

G015229

g018323

1

2

3

4

5

6

7

8

9

10

11

12

Figure4

48inch(shown)and52-inchmachines

1.Side-dischargechute7.Controllevers

2.Battery8.Manualtube

3.Engine

4.Fuelshut-offvalve(behind

cushion)

5.Fueltank11.Mowerdeck

6.Controls

9.Platform(downposition)

10.Hydraulictank

12.Frontcasterwheel

Figure5

60-inchmachine

1.Side-dischargechute7.Controllevers

2.Battery8.Manualtube

3.Engine

4.Fuelshut-offvalve(behind

cushion)

5.Fueltank11.Mowerdeck

6.Controls

9.Platform(downposition)

10.Hydraulictank

12.Frontcasterwheel

12

Page 13

Controls

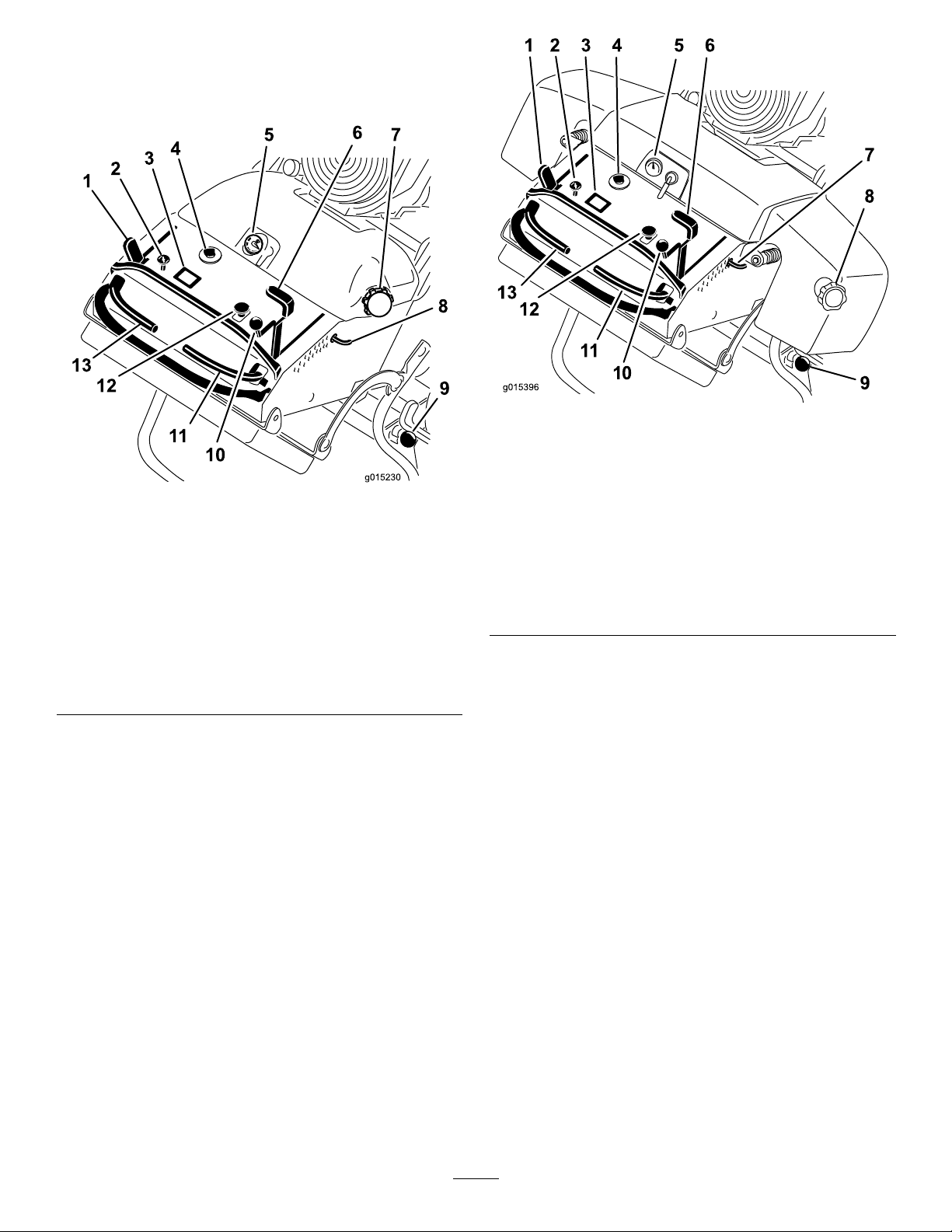

g015230

3

4

5

6

7

8

9

10

11

12

13

g015396

1 2 3 4 5 6

7

8

9

10

11

12

13

Becomefamiliarwithallthecontrols(Figure6)beforeyou

starttheengineandoperatethemachine.

Figure6

48inchand52-inchmachines

1.Parking-brakelever

2.Choke9.Platformlatch

3.Hourmeter10.Throttlecontrol

4.Ignitionswitch11.Rightmotion-controllever

5.Fuelgauge12.Blade-controlswitch

6.Height-of-cutlever13.Leftmotion-controllever

7.Fuelcap

8.Height-of-cutpin

(PTO)

Figure7

60-inchmachine

1.Parking-brakelever8.Fuelcap

2.Choke9.Platformlatch

3.Hourmeter10.Throttlecontrol

4.Ignitionswitch11.Rightmotion-controllever

5.Fuelgauge12.Blade-controlswitch

6.Height-of-cutlever13.Leftmotion-controllever

7.Height-of-cutpin

(PTO)

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(

Figure7).

FuelGauge

Thefuelgaugeislocatedonthetop,middleofthetank

(Figure6).

Safety-interlockIndicators

Symbolsonthehourmeterindicatewithablacktrianglethat

theinterlockcomponentisinthecorrectposition(Figure7).

Battery-indicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(

7).

13

Figure

Page 14

ThrottleControl

Specications

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.

Blade-controlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengagethe

electricclutchtodrivethemowerbladeswiththerightside

motion-controlleverinthecenter,unlockedposition.Pull

theswitchuptoengagethebladesandrelease.Todisengage

theblades,pushtheblade-controlswitch(PTO)downor

moveorreleasetherightsidemotion-controlleverintothe

neutral-lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhasthree

positions:Off,RunandStart.

Motion-controlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

FuelShut-offValve

Closethefuelshut-offvalve(locatedbehindtheoperator

cushionontheright-handsideofthefueltank)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

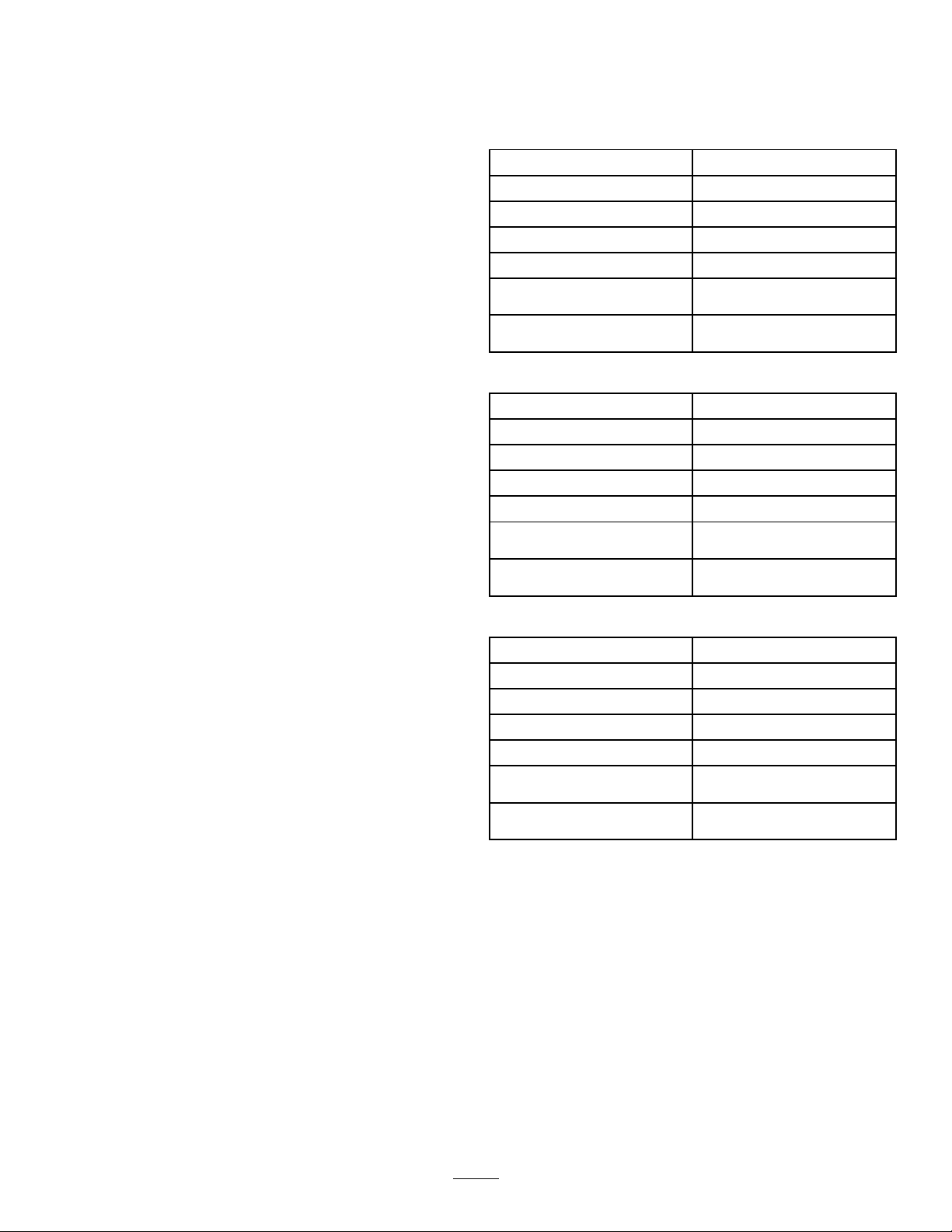

48-inchmowers:

Widthwithdeectordown161.3cm(63.5inches)

Widthwithdeectorraised125.7cm(49.5inches)

Lengthwithplatformdown188cm(74inches)

Lengthwithplatformup149.9cm(59inches)

Height

Weightformodel74578406.9kg(897lb)

Weightformodel79548409.6kg(903lb)

52-inchmowers:

Widthwithdeectordown171.7cm(67.6inches)

Widthwithdeectorraised135.9cm(53.5inches)

Lengthwithplatformdown188cm(74inches)

Lengthwithplatformup149.9cm(59inches)

Height

Weightformodel74549411.9kg(908lb)

Weightformodel79549414.6kg(914lb)

60-inchmowers:

Widthwithdeectordown192.0cm(75.6inches)

Widthwithdeectorraised156.2cm(61.5inches)

Lengthwithplatformdown197.9cm(77.9inches)

Lengthwithplatformup159.8cm(62.9inches)

Height

Weightformodel74553419.1kg(924lb)

Weightformodel79553421.8kg(930lb)

121.9cm(48inches)

121.9cm(48inches)

121.9cm(48inches)

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

15

Page 16

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

G009027

1

2

atalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefueltankcapandremovethecap.

Addunleadedregulargasolinetothefueltank,untilthe

levelis6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full.

3.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine-oil

Level(page34).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;referto

ServicingtheBrake(page45).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

SettingtheParkingBrake

Pulltheparkingbrakeleverrearwardandoverintoengaged

position(Figure9).

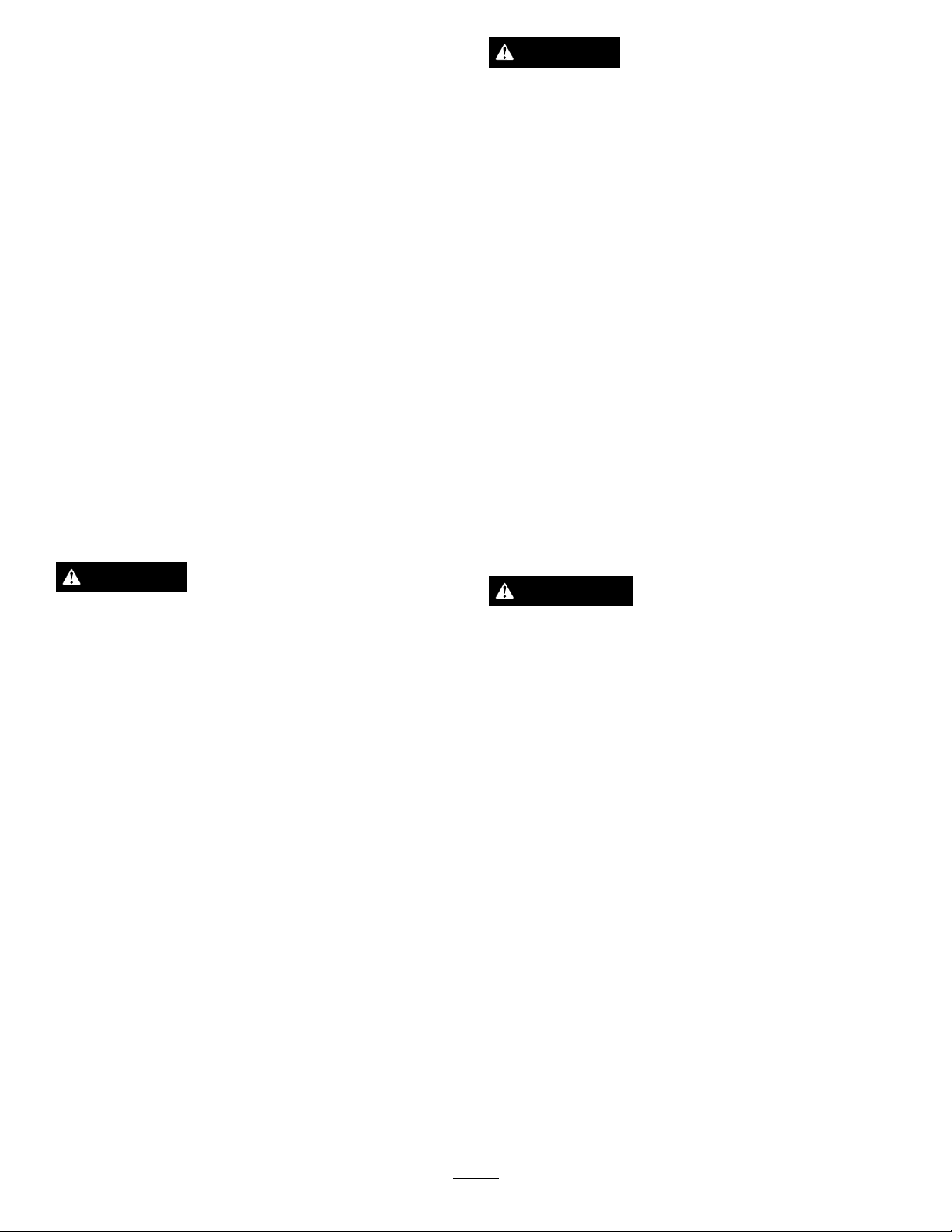

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

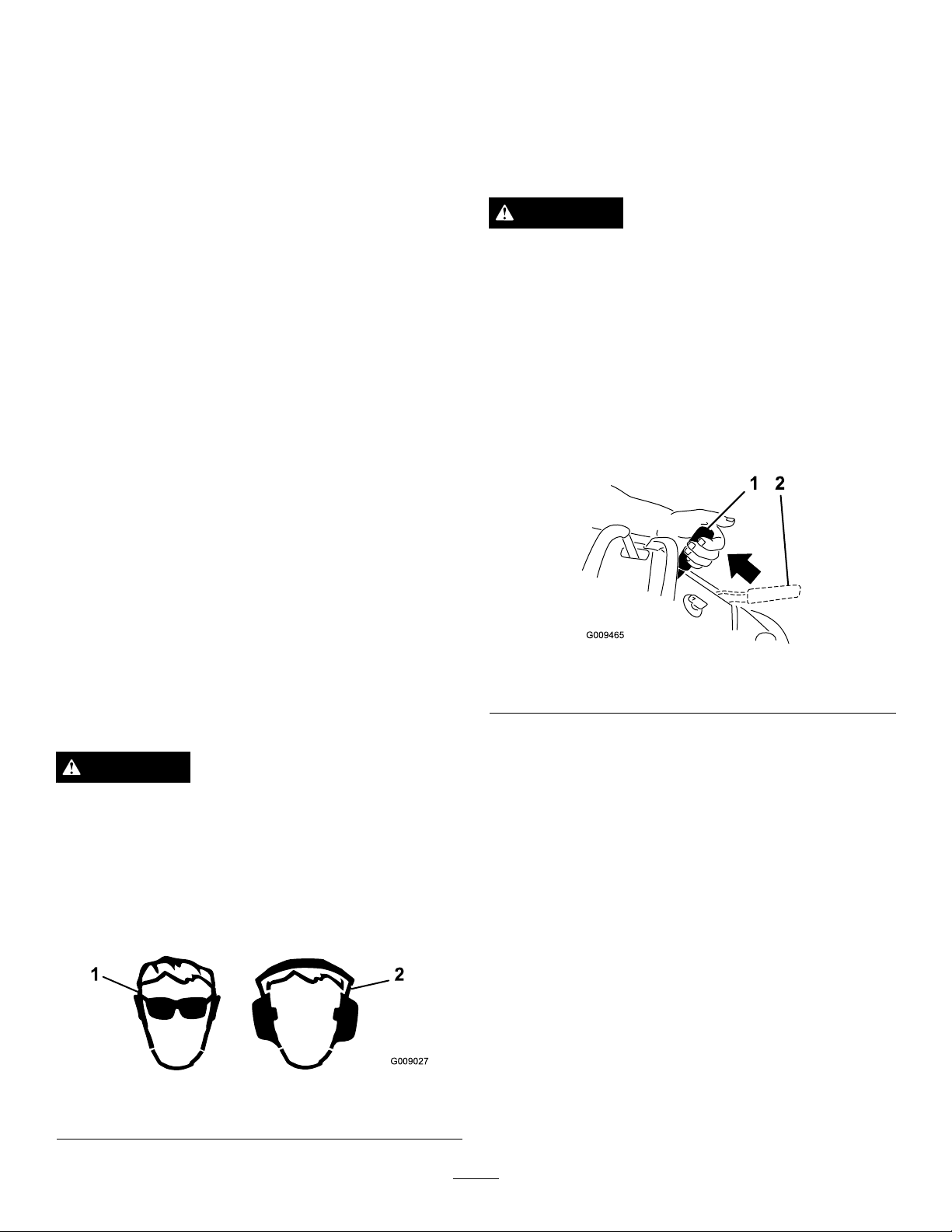

Figure9

1.Parkingbrakeengaged2.Parkingbrakereleased

ReleasingtheParkingBrake

Pullthebrakeleverbackandoverintotheslotandpushthe

parkingbrakeleverforward.

Figure8

1.Wearsafetyglasses

2.Wearhearingprotection

16

Page 17

Operatingthe

G008945

G009174

G008946

G008959

1

2

Mower-Blade-controlSwitch

(PTO)

Theblade-controlswitch(PTO)isusedinconjunctionwith

therightsidemotion-controllevertoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,movetherightside

motion-controllevertothecenter,unlockedposition.

2.Pulltheblade-controlswitch(PTO)upandreleaseit

whileholdingdowntherightsidemotion-controllever

inthecenter,unlockedposition.

Figure12

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure13).

3.Pushdownonthechokeknobtodisengagethechoke

aftertheenginehasstarted(Figure13).

Figure10

DisengagingtheMowerBlades(PTO)

Thefollowingaretwooptionsfordisengagingthemower

blades.

•Pushtheblade-controlswitch(PTO)downtotheOff

position.

•Movethemotion-controlleverstoneutralandmove

therightsidemotion-controlleverintotheneutral-lock

position.

Figure13

1.Onposition2.Offposition

Figure11

OperatingtheThrottle

ThethrottlecontrolmovesbetweenFastandSlowpositions

(Figure12).

AlwaysusetheFastpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

17

Page 18

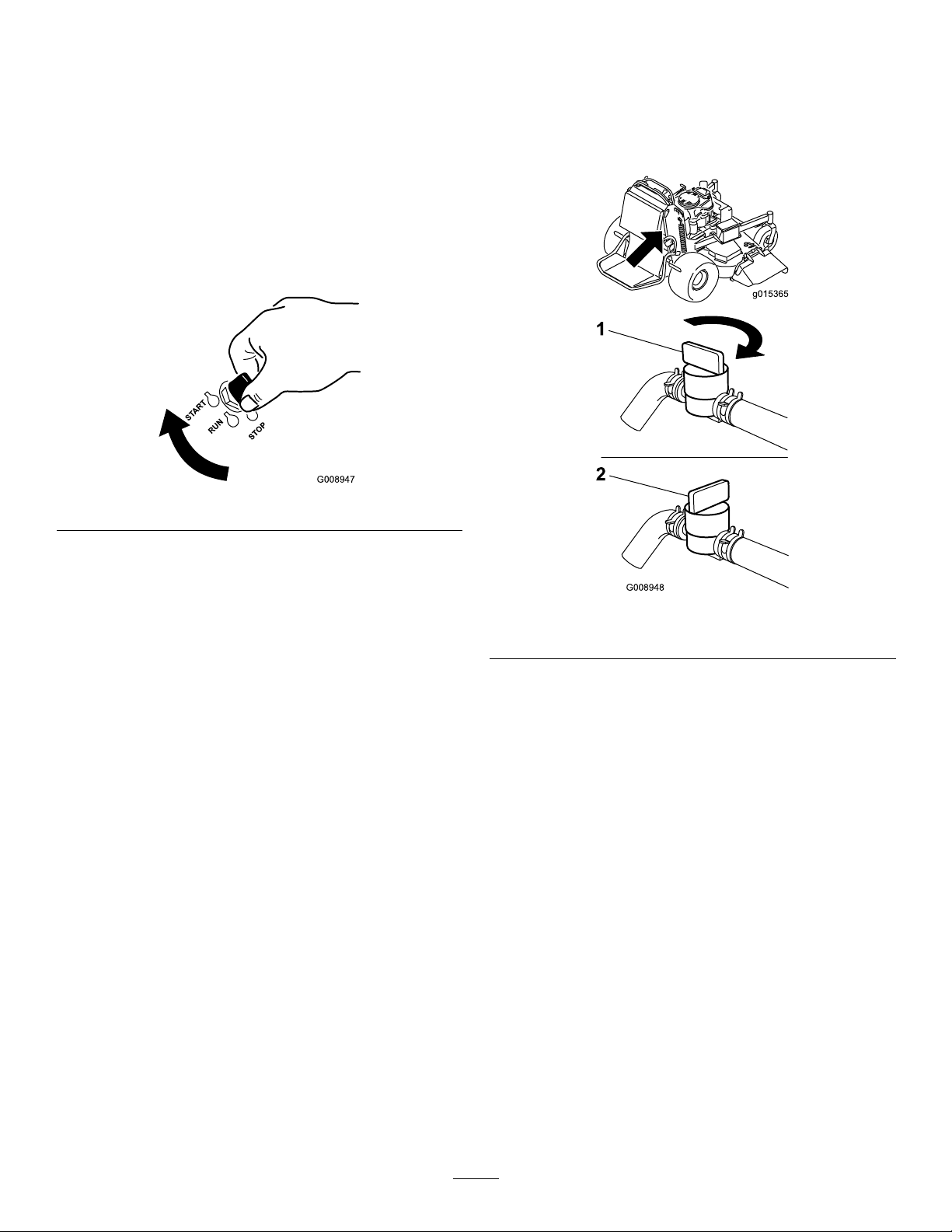

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g015365

G008948

1

2

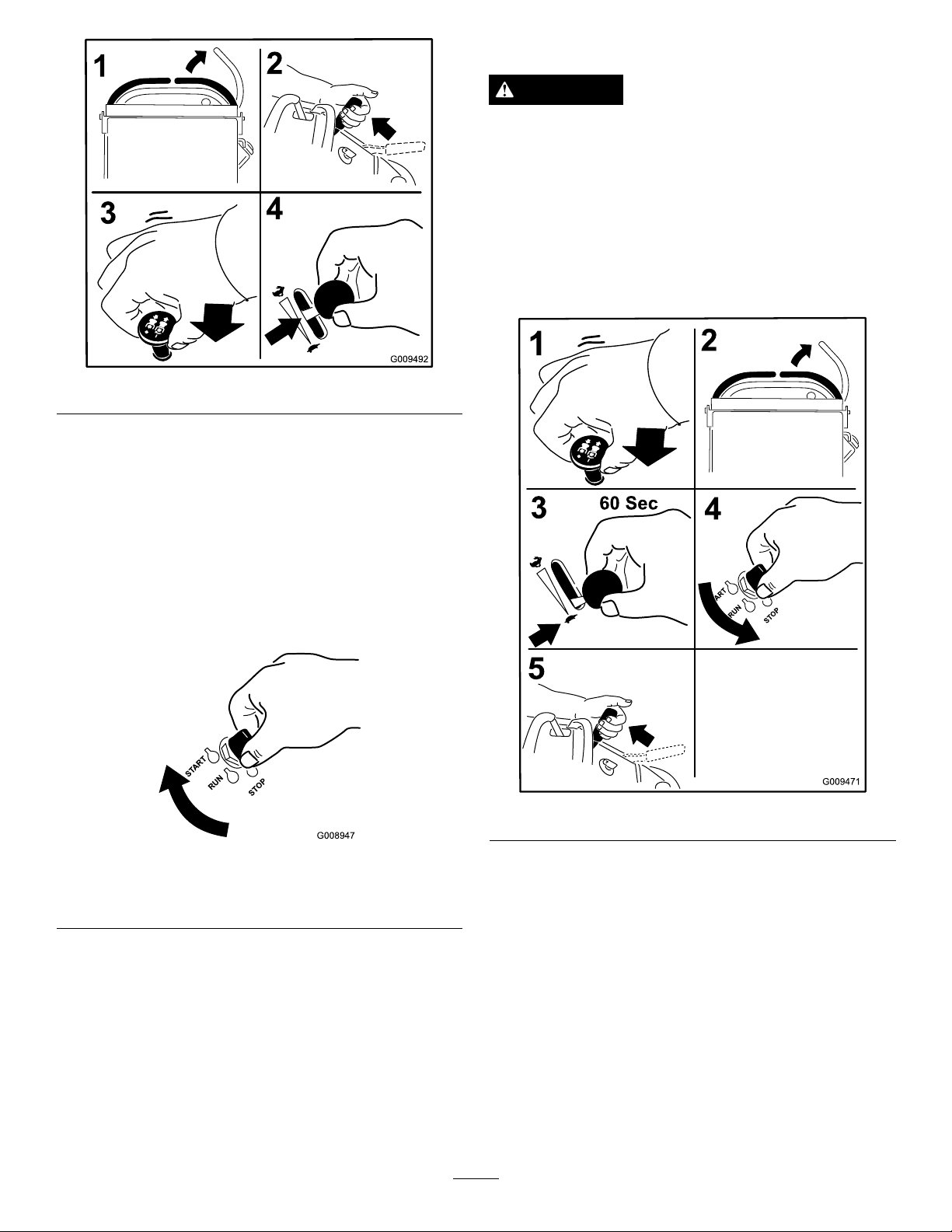

UsingtheFuelShut-offValve

1.TurntheignitionkeytotheStartposition(Figure14).

Whentheenginesstarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure14

Closethefuelshut-offvalvefortransport,maintenance,and

storage(Figure15).

Ensurethatthefuelshut-offvalveisopenwhenstartingthe

engine.

2.Turntheignitionkeytostoptoturnofftheengine.

Figure15

1.Onposition2.Offposition

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

3.Movetherightmotion-controllevertoneutrallocked

position.

4.Settheparkingbrake;refertoSettingtheParking

Brake.

5.Movetheblade-controlswitch(PTO)totheOff

position.

6.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

Note:Awarmorhotenginemaynotrequirechoking.

18

Page 19

Figure16

START

RUN

STOP

G008947

7.TurntheignitionkeytotheStartposition(Figure14).

Whentheenginesstarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure17

1.Offposition3.Startposition

2.Runposition

Figure18

Important:Makesurethefuelshut-offvalveisclosed

beforetransportingorstoringthemachine,asfuel

leakagemayoccur.Beforestoringthemachine,pull

wireoffsparkplug(s)topreventpossibilityofaccidental

starting.

19

Page 20

TheSafety-interlockSystem

3.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunless:

•Therightsidemotion-controlleverismovedtothe

center,unlockedposition.

•Theblade-controlswitch(PTO)ispulledon.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoumoveorreleasetherightsidemotion-control

leverintotheneutral-lockposition.

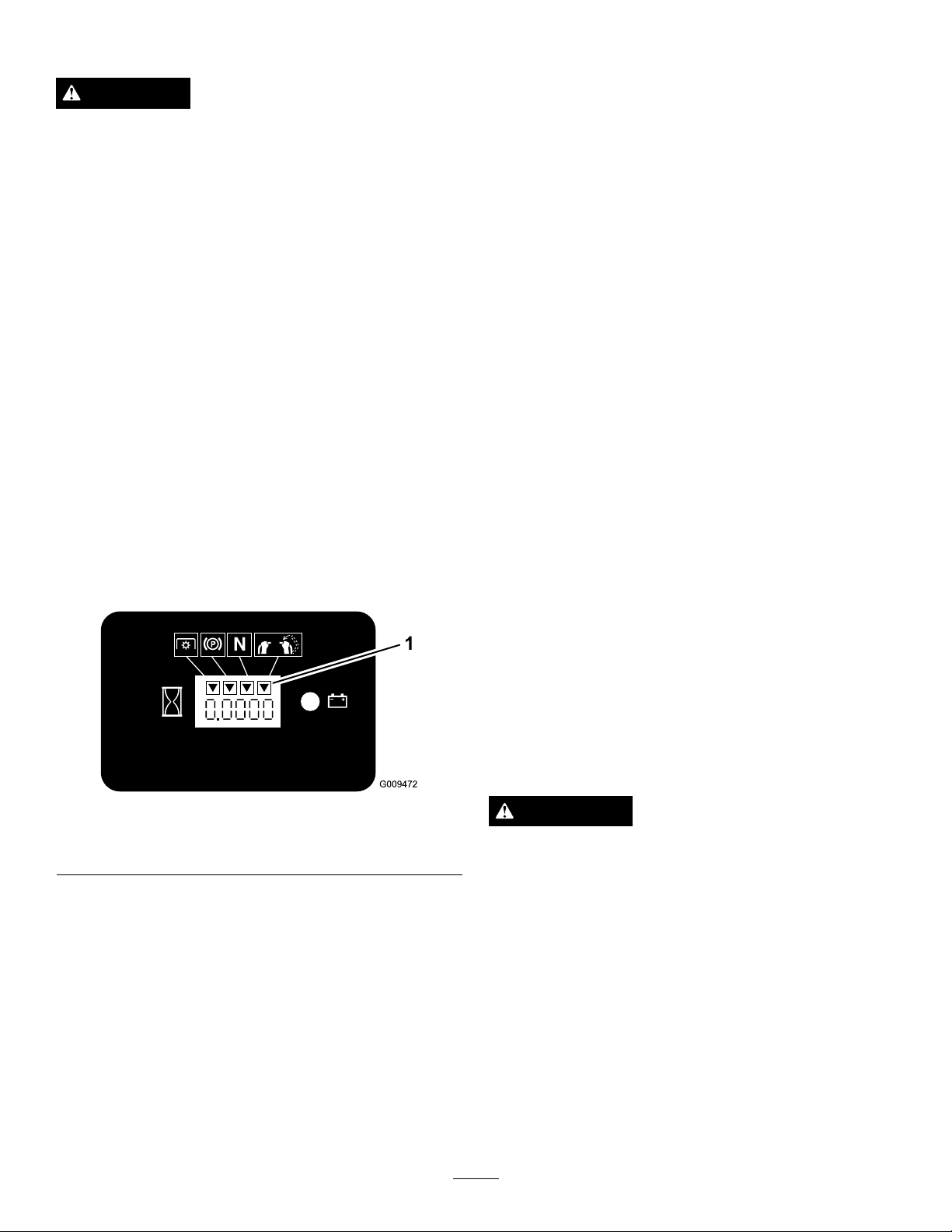

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllight

upinthecorrespondingsquare.

Note:Thebladesshouldnotrotate.

4.Movethemotion-controlleversforward.

Note:Theengineshouldstoprunning.

5.Starttheengineandreleasetheparkingbrake.

6.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

7.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

8.Moveorreleasetherightsidemotion-controlleverinto

theneutral-lockposition.

Note:Thebladesshouldstoprotatingandtheengine

continuestorun.

9.Pushtheblade-controlswitchdownandmovethe

rightsidemotion-controllevertothecenter,unlocked

position.

10.Continueholdingtherightsidemotion-controllever

inthecenter,unlockedposition,pulluponthe

blade-controlswitch(PTO),andrelease.

Note:Theclutchshouldengageandthemower

bladesrotate.

11.Pushtheblade-controlswitch(PTO)downtotheOff

position.

Figure19

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-interlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Starttheengine;refertoStartingandStoppingthe

Engine(page18).

2.Settheparkingbrake.

Note:Thebladesshouldstoprotating.

12.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleaseitwithoutholdingrightside

motion-controllevertothecenter,unlockedposition.

Note:Thebladesshouldnotrotate.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Theplatformmaysuddenlydropifnot

supportedwhenthelatchpinispulledout.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringorraisingthe

operatorplatform.

•Makesuretheplatformissupportedwhenthe

latchpinispulledout.

•Makesurethelatchsecurestheplatformwhen

foldingitintheupposition.Pushittightagainst

thecushionforthelatchpintolockintoplace.

•Keepbystandersawaywhenraisingorlowering

theplatform.

20

Page 21

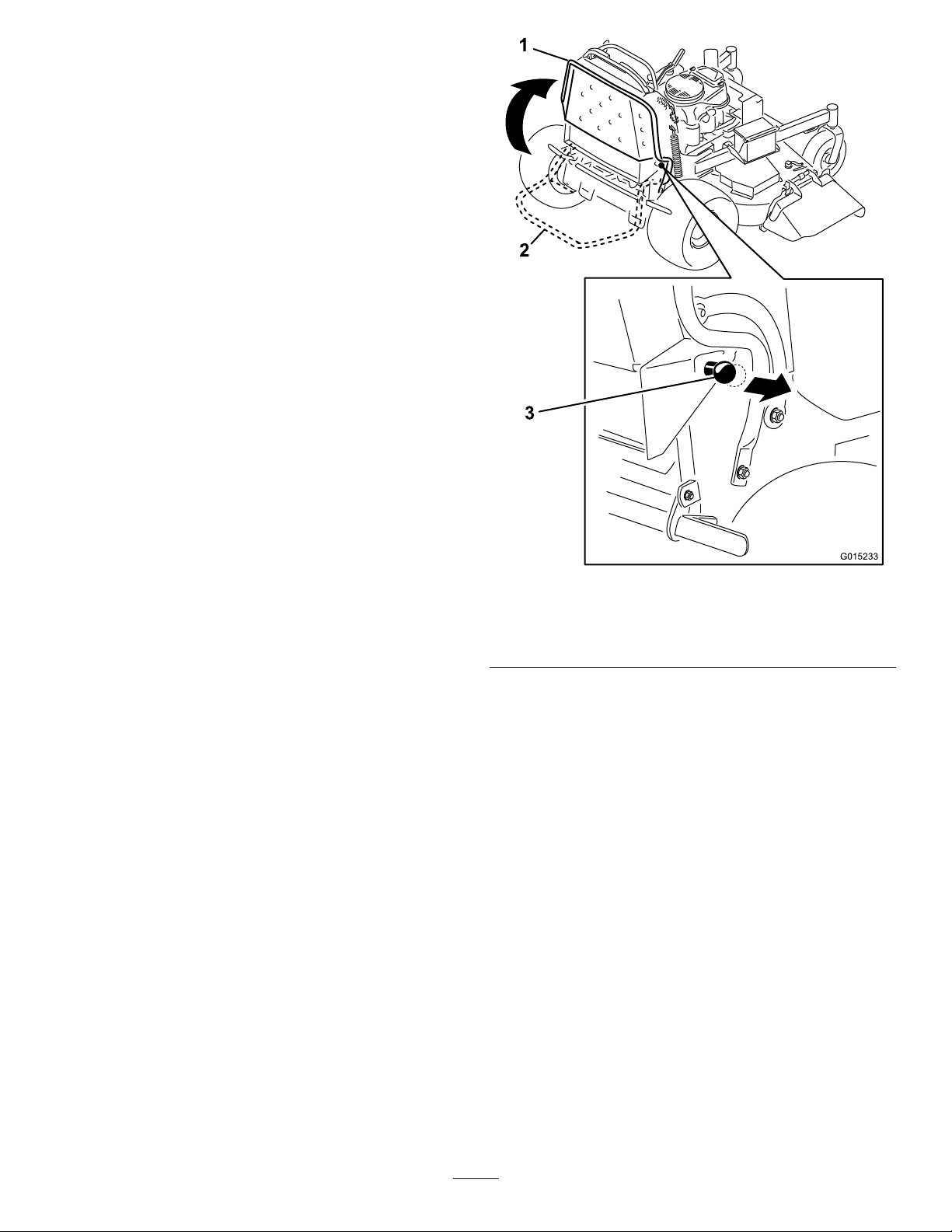

OperatingthePlatform

G015233

Themachinecanbeusedwiththeplatformintheupordown

position.Itistheoperator'spreferenceonwhichposition

touse.

OperatingtheMachinewiththe

PlatformUp

Operatingthemachinewiththeplatformupisrecommended

forthefollowing:

•Mowingneardrop-offs

•Mowingsmallareaswherethemachineistoolarge

•Areaswithlow ,over-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformupsothat

thelatchpinandknoblockitintoplace.Pushittightagainst

thecushionforthelatchpintolockitintoplace.

OperatingtheMachinewiththe

PlatformDown

Operatingthemachinewiththeplatformdownis

recommendedforthefollowing:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforwardagainstthe

cushiontoreleasepressureonthelatchpin,thenpullthe

knobout,andlowertheplatform(Figure20).

1.Platformup

2.Platformdown

Figure20

3.Pulltheknobouttorelease

theplatform.

21

Page 22

DrivingForwardorBackward

G015234

4

5

1

2

3

3 4

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperatethe

machineinthefullthrottlepositionwhenmowing.

CAUTION

Themachinecanspinveryrapidly.Theoperator

maylosecontrolofmachine,andmaycause

personalinjuryordamagetomachine.

Slowthemachinedownbeforemakingsharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page16).

2.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

Figure21

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar

3.Togoforward,movethespeed-controllevertothe

desiredspeed.

4.Slowlypushthemotion-controlleversforward(Figure

22).

Note:Theenginewillkillifamotion-controlleveris

movedwiththeparkingbrakeengaged.

Note:Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinewillmove

inthatdirection.

Note:T ostop,pullthemotion-controlleversbackto

theneutralposition.

4.Rightcontrollever

5.Rightcontrolleverinthe

neutrallockposition

22

Page 23

StoppingtheMachine

G017978

1

1 2

1

Tostopthemachine,movethemotion-controlleversto

neutral,movetherightsidemotion-controlleverintothe

neutral-lockposition,disengagethepower-takeoff(PTO),

andturntheignitionkeytotheOffposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page16).Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure22

DrivingBackward

1.Movetherightsidemotion-controllevertothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward(Figure

23).

UsingtheRotationIndicator

Theslotsinthetopofthebeltcoversallowtheoperatorto

verifyifthebladeshavestoppedrotatingafterdisengagingthe

powertake-off(PTO)switch.

Disengagethepowertake-off(PTO)switch,stoptheengine,

removethekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

Figure23

Figure24

52-inchmowerdeckshown

1.RotationIndicator—slots

inthetopofthebeltcover

2.Side-dischargechute

23

Page 24

PushingtheMachinebyHand

G015235

Thebypassvalvesallowthemachinetobepushedbyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausehydraulicdamagemayoccur.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedpositionandsettheparkingbrake.

2.Openthebypassvalveonbothpumpsbyturningthem

counterclockwise1to2turns.Thisallowshydraulic

uidtobypassthepumpsandthewheelstoturn

(

Figure25).

Note:Rotatethebypassvalvesamaximumof2turns

sothevalvedoesnotcomeoutofthebodycausing

uidtorunout.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure26

1.Tractionunittie-downloop

Figure26).

Figure25

1.Pump-bypassvalve

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closethebypassvalves,butdonotovertightenthem.

Torqueto12to15N-m(9to11ft-lb).

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallthenecessarybrakes,

lighting,andmarkingasrequiredbylaw.Pleasecarefullyread

allthesafetyinstructions.

Totransportthemachine:

1.Raisetheplatformofthemachinebeforedrivingonto

thetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

LoadingtheMachine

Useextremecautionwhenloadingunitsontotrailersor

trucks.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideoftheunit(Figure27).Theplatform

whendownandlockedintoposition,extendsbackbetween

therearwheelsandservesasastopfortippingbackward.

Havingafull-widthrampprovidesasurfacefortheplatform

tocontactiftheunitstartstotipbackward.Withtheplatform

up,afull-widthrampprovidesasurfacetowalkonbehindthe

unit.Theoperatorshoulddetermineifitisbesttohavethe

platformupordownwhenloading,dependingonconditions.

Ifitisnotpossibletouseonefull-widthramp,useenough

individualrampstosimulateafull-width,continuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed20degrees(Figure27).Asteeperanglemaycause

mowercomponentstogetcaught,astheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

24

Page 25

WARNING

g019208

DANGER

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-over,andcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda20-degreeanglebetweenramp

andground,orbetweenaramp,atrailer,ora

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Donotremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

theOffposition.Alsoremovethekeyandpull

thewire(s)offthesparkplug(s).

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom25to127mm(1to5

inches)in6mm(1/4inches)increments.

Figure27

1.Trailer3.Notgreaterthan

2.Full-widthramp

20degrees

4.Full-widthramp(sideview)

SideDischargingorMulching theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

1.Movetheheight-of-cutlevertothetransportposition

(allthewayup).

2.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesiredand,insertthepin(Figure

28).

3.Lowertheheight-of-cutlevertothepin(Figure28).

Figure28

1.Height-of-cutholes3.Height-of-cutlever

2.Height-of-cutpin

25

Page 26

AdjustingtheAnti-scalp

g018324

g012676

1 2

G012677

Rollers(60-inchMowerDecks

only)

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethenutandboltpositiontheanti-scalprollers

andinstallthenutandbolt.

4.Ensurethespacersandbushingsareinstalled(

29).

Figure29

1.Bushing4.Bolt

2.Anti-scalproller5.Nut

3.Spacer

Figure30

Figure

1.Slot

2.Nut

PositioningtheFlowBafe

Thefollowingguresareonlyforrecommendeduse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

Note:Iftheenginepowerdrawsdown,andthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefull,rearposition(seeFigure31).Thesuggested

useforthispositionisasfollows:

•Inshort,lightgrassmowingconditions

•Indryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthemower

AdjustingtheFlowBafe

Themower-dischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

providethebestqualityofcut.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure30).

Figure31

26

Page 27

PositionB

G012678

G012679

UsingtheMid-sizeWeight

Usethispositionwhenbagging(Figure32).

Figure32

PositionC

Thisisthefull,openposition(Figure33).Thesuggesteduse

forthispositionisasfollows:

•Weightsareinstalledtoimprovehandling,balance,and

improveperformance.Weightscanbeaddedorremoved

tocreateoptimizedperformanceunderdifferentmowing

conditionsandforoperatorpreference.

•Itisrecommendedthatweightsbeaddedorremovedone

atatimeuntilthedesiredhandingandbalanceisachieved.

Note:ContactanAuthorizedServiceDealertoordera

WeightKit.

WARNING

Excessiveweightchangescanaffectthehandling

andoperationofthemachine.Thiscouldcause

seriousinjurytoyouorbystanders.

Makeweightchangesinsmallincrementsonly.

Evaluatethemoweraftereachweightchangeto

ensurethemachinecanbeoperatedsafely.

•Intall,densegrassmowingconditions

•Inwetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

Figure33

27

Page 28

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydrauliclter.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Cleandebrisfromthehydraulic-oilcooler(ifequipped).

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanfoamair-cleanerelement.

•Greasetheliftlinkage(moreoftenindirtyordustyconditions).

•Greasethemowerdeckspindles(moreoftenindirtyordustyconditions).

•Checkthepaperair-cleanerelement.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Checkthehydraulic-uidlevel.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Checktheelectricclutch.

•Checkandcleantheenginecoolingnsandshrouds.

•Servicethehydraulic-oilcoolerindirtyconditions(ifequipped).

•Checkthemower-deckbelt.

•Checkthepump-drivebelt.

•Checkthehydraulichoses.

Every200hours

Every250hours

Every500hours

Every800hours

Beforestorage

Yearly

Important:Refertoyour

•Replacethepaperair-cleanerelement.

•Changetheengine-oillter.

•ChangethehydrauliclterandhydraulicoilwhenusingMobil®1oil.

•Adjustthecaster-pivotbearing.

•ChangethehydrauliclterandhydraulicoilwhenusingToro®HYPR-OIL™500

hydraulicoil.

•Greasethefrontwheelbearings(moreoftenindirtyordustyconditions).

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Replacethefuellter.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

28

Page 29

CAUTION

g018098

g017900

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

Premaintenance

Procedures

RaisingtheMowerforAccess

Thefrontofthemowercanberaisedandsupportedonits

backforaccessunderthemachineformaintenance.

1.Raisetheplatform;refertoOperatingthePlatform

(page21).

2.Removethebattery.

Figure34

1.Wingnut

2.Batterycover5.Battery

3.Negative-batterycable(–)

3.Drainthefuelfromthefueltank;refertoDraining

theFuelTank(page37).

4.Removethecapofthehydraulictank,andplaceapiece

ofplasticovertheopeningandinstallthehydrauliccap.

4.Positive-batterycable(+)

Figure35

1.Cap

2.Pieceofplastic

5.With2people,raisethefrontofthemowersothat

itrestsonthedrivetiresandtheplatformintheup

position.

6.Performanymaintenanceonthemachine.

7.With2people,lowerthefrontofthemowertothe

ground.

8.Removetheplasticunderthehydraulictankcap.

9.Installthebatteryforthemachine.

3.Hydraulictank

Note:Thiswillsealthehydraulictankandprevent

itfromleakingout.

29

Page 30

Figure36

g019209

1.Removethebattery

2.Frontendofthemower

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothemachinefor

maintenanceoradjustment.

1.Lowertheplatform.

2.Removethehairpin-cotterpinsoneachsideofthe

cushion.

3.Slidethelargewasherswiththeplasticbushingstothe

inside.

4.Removethecushion,andlowerittotheplatform.

5.Performanymaintenanceoradjustmentonthe

machine.

6.Raisethecushionandslideitontothepinsonboth

sidesofthemachine(

7.Slidethelargewasherswiththeplasticbushings

intothecushionbracket,andsecurethemwitha

hairpin-cotterpin(Figure37).

Figure37).

1.Plasticbushingwiththe

largewasher

2.Cushionbracketwiththe

keyhole

Figure37

3.Hairpin-cotterpin

30

Page 31

Lubrication

G019356

g018325

g018326

GreasewithNo.2generalpurposelithiumbaseor

molybdenumbasegrease.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

6.Wipeupanyexcessgrease.

LubricatingtheMachine

ServiceInterval:Every50hours—Greasetheliftlinkage

(moreoftenindirtyordustyconditions).

Every50hours—Greasethemowerdeckspindles

(moreoftenindirtyordustyconditions).

Every800hours/Yearly(whichevercomes

rst)—Greasethefrontwheelbearings(moreoftenin

dirtyordustyconditions).

Every800hours/Yearly(whichevercomes

rst)—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Usethefollowinggraphicsforlocatingthegreasepoints.

Figure39

Figure40

GreasingtheFrontCaster Pivots

Figure38

ServiceInterval:Yearly

Lubricatethefrontcasterpivotsonceayear.

1.Removethedustcapandadjustthecasterpivots;refer

toAdjustingtheCaster-pivotBearing(page42).

Note:Keepthedustcapoffuntilgreasingisdone.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

5.Removethegreasettinginthehole.Installthehex

plugandcap.

31

Page 32

LubricateCaster-wheelHubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey.

Figure41

13.Torquethenutto8to9N-m(71to80in-lb),loosen,

thentorqueitto2to3N-m(20to25in-lb).

Note:Makesureaxledoesnotextendbeyondeither

nut.

14.Installthesealguardsoverthewheelhubandinsert

wheelintocasterfork.

15.Installcasterboltandtightennutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoftenbyspinningthecaster

tire.Thetireshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntilthere

isaslightamountofdrag,andapplythread-locking

adhesive.

1.Sealguard2.Spacernutwithwrench

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeoneofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutthesealsandinspectbearingsforwearor

damage,andreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1sealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto

onespacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

ats

Note:DoNotthreadspacernutallofthewayonto

theendoftheaxle.Leaveapproximately3mm(1/8

inch)fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandthenewsealintothe

wheel.

12.Applyathread-lockingadhesivetothesecondspacer

nut,andthreaditontotheaxlewiththewrenchats

facingoutward.

32

Page 33

EngineMaintenance

CleaningtheFoamAir-cleanerElement

ServiceInterval:Every25hours

ServicingtheAirCleaner

ServiceInterval/Specication

Inspectthefoamandpaperelements,andreplacethemif

theyaredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy.

Important:Donotapplyoiltothefoamorpaper

element.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(

4.Unscrewthecoverknobsandremovetheair-cleaner

cover(Figure42).

Figure42).

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAir-cleanerElement

ServiceInterval:Every50hours—Checkthepaper

air-cleanerelement.

Every200hours—Replacethepaperair-cleaner

element.

1.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

2.Replacethepaperelementifitisdamaged(

Figure42).

InstallingtheFoamandPaperElements

Important:T opreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperair-cleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure42).

5.Unscrewthehoseclampandremovetheair-cleaner

assembly(Figure42).

6.Carefullypullthefoamelementoffthepaperelement

(Figure42).

Figure42

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

2.Placetheair-cleanerassemblyontotheair-cleanerbase

orhoseandsecureit(Figure42).

3.Placetheair-cleanercoverintopositionandtighten

thecoverknob(Figure42).

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.(moreoften

indirtyordustyconditions)

Every200hours—Changetheengine-oillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethatthecorrectamount

ofoilisused.

Important:Remembertoadd80%oftheoil,andthen

graduallyllittotheFullmarkonthedipstick.

OilType::Detergentoil(APIserviceSF ,SG,SH,SJorSL)

EngineOilCapacity:2.1L(71oz)withthelterremoved;

1.8L(61oz)withoutthelterremoved

Viscosity:Refertothetablebelow .

33

Page 34

Figure43

g015238

G008792

1

2

5

6

7

3

9

10

4

8

CheckingtheEngine-oilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil,

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLowmark,becausetheengine

maybedamaged.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure44).

3.Checktheengine-oillevelasshownin

Figure44.

Figure44

ChangingtheEngineOil

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

34

Page 35

4.ChangetheengineoilasshowninFigure45.

g015238

G008796

2

3

4

5

6

1

Figure46

Figure45

5.Slowlypourapproximately80%ofthespeciedoil

intothellertube,andslowlyaddtheadditionaloilto

bringittotheFullmark(Figure46).

6.Starttheengineanddrivetoaatarea.

7.Checktheengineoillevel.

ChangingtheEngine-oilFilter

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page34).

2.Placearagundertheoilltertosoakupanyspilledoil.

Important:Spilledoilmaydrainundertheengine

andontotheclutch.Oilspilledontheclutchmay

damagetheclutch,causethebladestostopslowly

whentheclutchisintheOffposition,andcause

theclutchtoslipwhentheclutchisswitchedto

theOnposition.Wipeupanyspilledoil.

3.Changetheengine-oillter(

Figure47).

35

Page 36

g015238

G012845

3/4

2

3

4

5

6

1

RemovingtheSparkPlug

g015238

G008794

1

2

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.RemovethesparkplugasshowninFigure48.

Figure47

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenanextra3/4turniscompleted.

4.Fillthecrankcasewiththepropertypeofnewoil;refer

ChangingtheEngineOil(page34).

to

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.

Figure48

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.75mm(0.03inch).

Figure49

Useasparkplugwrenchforremovingandinstallingthespark

plug(s)andagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplug(s)ifnecessary.

TypeforallEngines:NGK

AirGap:0.75mm(0.03inch)

®

BPR4ESorequivalent

36

Page 37

InstallingtheSparkPlug

3

2

1

G015200

g015239

Tightenthesparkplug(s)to22N-m(16ft-lb).

Figure50

CheckingtheSparkArrester (ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotrefuelorruntheengineunlessthespark

arresterisinstalled.

FuelSystem

Maintenance

DrainingtheFuelTank

Note:Thereisnootherrecommendedwaytodrainfuel

fromthetank,otherthanusingasyphonpump.Asyphon

pumpcanbepurchasedatahardwarestore.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopename,orwhereasparkmay

ignitethegasolinefumes.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure52).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoacleangas

Figure51).

can(

7.Wipeupanyspilledfuel.

1.Stoptheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arrester,shakelooseparticlesoutofthearrester,and

cleanthescreenwithawirebrush(soakinsolventif

necessary).

5.Installarresteronexhaustoutlet.

Figure51

1.Fuelcap

37

Page 38

ServicingtheFuelFilter

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichevercomes

rst)

Donotinstalladirtylterifitisremovedfromthefuelline.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closethefuelshut-offvalve(behindtheoperator

cushion).

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure52).

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure52

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Openthefuelshut-offvalve.

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

DANGER

Donotdrinkelectrolyte,andavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

38

Page 39

WARNING

g018098

Incorrectbattery-cableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.Installthepositive(red)batterycabletopositive(+)

batteryterminalwithanut,awasher,andabolt(

53).

4.Slidetherubbercoveroverthepost.

5.Installthenegativebatterycableandthegroundwire

tothenegative(-)batteryterminalwithanut,awasher,

andabolt(

6.Slidetherubbercoveroverthepost.

Figure53).

Figure

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lifttheblack,rubbercoveronthenegativecable.

4.Disconnectthenegativebatterycablefromthenegative

(-)batteryterminal(

Figure53).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page38)

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthebattery.

4.Chargethebatteryfor1hourat25to30ampsor6

hoursat4to6amps.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(

.

Figure54).

Figure53

1.Wingnut4.Positivebatterycable

2.Batterycover5.Battery

3.Negativebatterycable

5.Slidetheredterminalbootoffthepositive(red)battery

terminal.

6.Removethepositive(red)batterycable(

7.Removethebatteryholddownplate(

removethebattery.

Figure53).

Figure53),and

InstallingtheBattery

1.Placethebatteryontothemachine(Figure53).

6.Installthebatteryontothemachineandconnectthe

batterycables;refertoInstallingtheBattery(page39).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure54

1.PositiveBatteryPost

2.NegativeBatteryPost

39

3.Red(+)ChargerLead

4.Black(-)ChargerLead

Page 40

ServicingtheFuses

g017915

1

g015241

DriveSystem

Theelectricalsystemisprotectedbyfuses,andrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

1.Releasethecushionfromtherearofthemachine.

2.Pulloutonthefusetoremoveorreplaceit(

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseisinstalled

Figure55.

Figure55).

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullstooneside.

Note:Ifitdoes,stopthemachineandsettheparking

brake.

3.Releasethecushionfromtherearofthemachine.

4.Rotatetherightcableadjustmenttopositiontheright

motioncontrolinthecenterofthecontrolpanel

neutral-lockslot(

Figure57).

Figure55

1.Fuses

1.Leftmotion-controllever

2.Rightmotion-controllever4.Alignthecontrollevers

5.Rotatetheleftcableadjustmenttomatchtheleft

wheelspeedtothepreviouslysetrightwheelspeed.

6.Adjustinquarter-turnincrementsuntilthemachine

tracksstraight.

Note:Onlyadjusttheleftcabletomatchtheleft

wheelspeedtotherightwheelspeed.Donotadjust

therightwheelspeedasthiswillpositiontheright

motion-controlleveroutofthecenterforthecontrol

panelneutral-lockslot.

Figure56

3.Neutral-lockedposition

fronttoback

40

Page 41

3

g017848

Figure57

G015609

1 6

2 3 4

4

2

5

6

6.Testthesafety-interlocksystembeforeoperation.