Toro GrandStand 74504, GrandStand 74505, GrandStand 79504, GrandStand 79505 Operator's Manual

Page 1

FormNo.3403-282RevB

GrandStand

®

Mower

With48inor52inTURBOFORCE

Unit

ModelNo.74504—SerialNo.316000001andUp

ModelNo.74505—SerialNo.316000001andUp

ModelNo.79504—SerialNo.316000001andUp

ModelNo.79505—SerialNo.316000001andUp

®

Cutting

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3403-282*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalT oro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Introduction

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thisrotaryblade,ride-onlawnmowerisintendedtobeused

byprofessional,hiredoperators,orresidentialhomeowners.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................13

Operation....................................................................14

ThinkSafetyFirst...................................................14

AddingFuel...........................................................14

CheckingtheEngine-OilLevel.................................15

BreakinginaNewMachine......................................15

OperatingtheParkingBrake....................................15

OperatingtheMower-Blade-ControlSwitch

(PTO)...............................................................16

OperatingtheThrottle............................................16

OperatingtheChoke..............................................16

OperatingtheIgnitionSwitch..................................17

UsingtheFuel-ShutoffValve...................................17

StartingandShuttingofftheEngine..........................18

TheSafety-InterlockSystem....................................19

OperatingthePlatform...........................................19

DrivingForwardorBackward..................................20

StoppingtheMachine.............................................21

PushingtheMachinebyHand..................................22

TransportingtheMachine........................................22

LoadingtheMachine..............................................22

SideDischargingorMulchingtheGrass.....................24

AdjustingtheHeight-of-Cut....................................24

AdjustingtheFlowBafe........................................25

PositioningtheFlowBafe......................................25

UsingtheMid-SizeWeight.......................................26

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

PremaintenanceProcedures........................................28

ReleasingtheCushionforRearAccess.......................28

Lubrication...............................................................28

GreasingtheT orsionIdler.......................................28

GreasingtheFrontCasterPivots..............................29

GreasingtheCaster-WheelHubs..............................29

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

ServicingtheSparkPlug..........................................33

CheckingtheSparkArrester.....................................34

FuelSystemMaintenance...........................................35

DrainingtheFuelTank...........................................35

RemovingtheFuelTank..........................................35

ServicingtheFuelFilter..........................................36

ElectricalSystemMaintenance....................................36

ServicingtheBattery...............................................36

ServicingtheFuses.................................................38

DriveSystemMaintenance.........................................39

AdjustingtheTracking............................................39

CheckingtheTirePressure......................................39

AdjustingtheCaster-PivotBearing............................40

ServicingtheCasterWheelsandBearings...................40

UsingtheClutchShim............................................41

CheckingtheWheel-LugNuts..................................42

CheckingtheWheel-HubNuts.................................42

CoolingSystemMaintenance......................................43

CleaningtheAir-IntakeScreen.................................43

CleaningtheCoolingSystem....................................43

BrakeMaintenance....................................................43

ServicingtheBrake.................................................43

BeltMaintenance......................................................44

ReplacingtheMower-DeckBelt...............................44

ReplacingtheTransmissionBelt..............................44

ControlsSystemMaintenance.....................................45

AdjustingtheMotion-ControlLevers........................45

HydraulicSystemMaintenance....................................46

ServicingtheHydraulicSystem.................................46

MowerDeckMaintenance...........................................48

ServicingtheCuttingBlades.....................................48

CorrectingtheMowerQualityofCut........................50

AdjustingtheDeck-LiftSpring.................................53

ReplacingtheGrassDeector..................................53

Cleaning...................................................................54

CleaningundertheMower.......................................54

DisposingoftheWaste............................................54

Storage........................................................................54

CleaningandStorage..............................................54

Troubleshooting...........................................................56

Schematics...................................................................58

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionsmayresultinpersonalinjuryordeath.

Thismachinewasmanufacturedaccordingtotheappropriate

regulatorystandardsineffectatthetimeofmanufacture.

Modifyingthismachineinanywaymaycauseittobeoutof

compliancewiththosestandardsandwiththeinstructionsin

thisOperator’ sManual.Modicationstothismachineshould

onlybemadebyeitherthemanufactureroranAuthorized

ToroDealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Theadditionofattachmentsmadebyothermanufacturers

thatdonotmeetAmericanNationalStandardsInstitute

certicationmaycausenoncomplianceofthismachine.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadthemanual

language,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsyouneedtoproperlyandsafelyperformthe

job.Useonlyaccessoriesandattachmentsapprovedby

themanufacturer.

•Wearappropriateclothing;includingsafetyglasses,long

pants,substantialslip-resistantfootwear,gloves,and

hearingprotection.Tiebacklonghair.Donotwear

jewelry.

•Inspecttheareawhereyouwillusetheequipmentand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operateonlyinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Starttheengine

onlyfromtheoperator’ sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.Reducedfooting

couldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besurethatallinterlocks

areattached,adjustedproperly,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessyouareusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

4

Page 5

•Stoponlevelground,disengagedrives,engagethe

parkingbrake,shutofftheenginebeforeleavingthe

operator'spositionforanyreason,includingemptyingthe

catchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemachinewhiletired,ill,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,shutoffthe

engine,andremovethekeyordisconnectspark-plugwire.

Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorefuelnearamesordrainthefuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Connectthe

positiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

5

Page 6

ToroMowerSafety

SlopeOperation

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationthatyoumustknow.

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.W arrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.,branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatingthemachine

inreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

•Neverremoveortamperwithsafetydevices.Checktheir

properoperationregularly.Neverdoanythingtointerfere

withtheintendedfunctionofasafetydeviceortoreduce

theprotectionprovidedbyasafetydevice.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Checktheoperationofthebrakesfrequently.Adjustand

servicethemasrequired.

6

Page 7

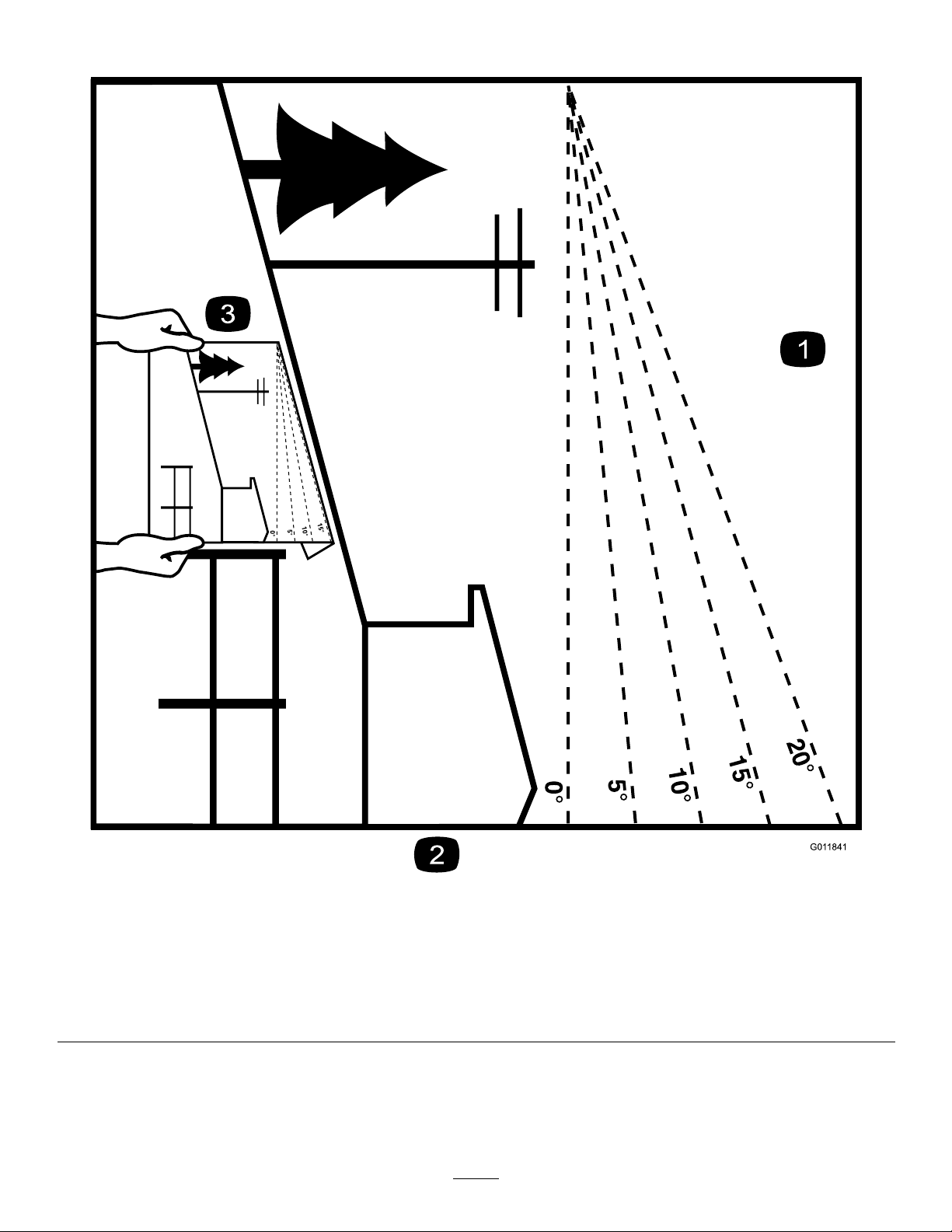

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

7

Page 8

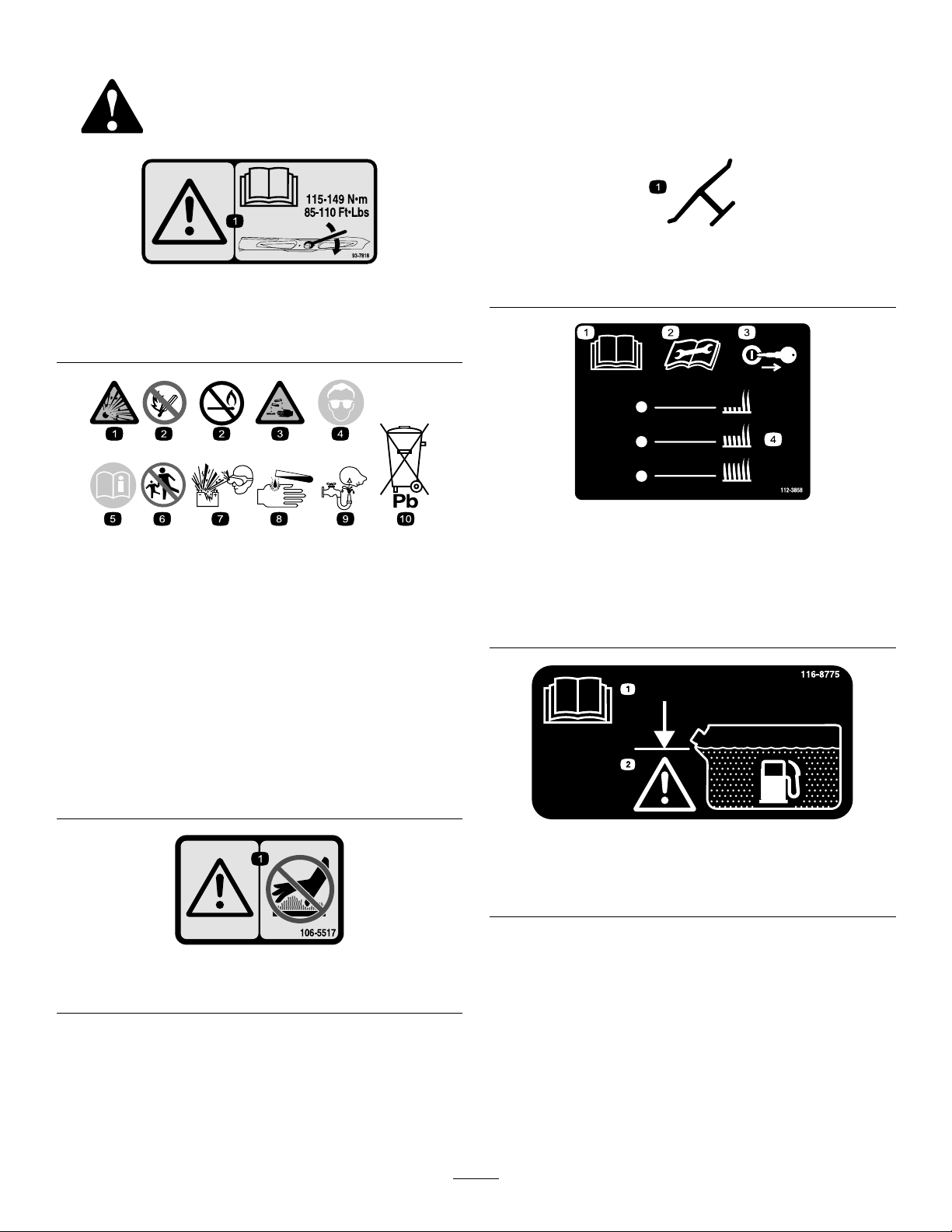

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

112-3858

1.ReadtheOperator's

Manual.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

4.Height-of-cutsettings.

1.Warning—donottouchthehotsurface.

116-8775

1.ReadtheOperator’s

Manual.

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

106-5517

8

Page 9

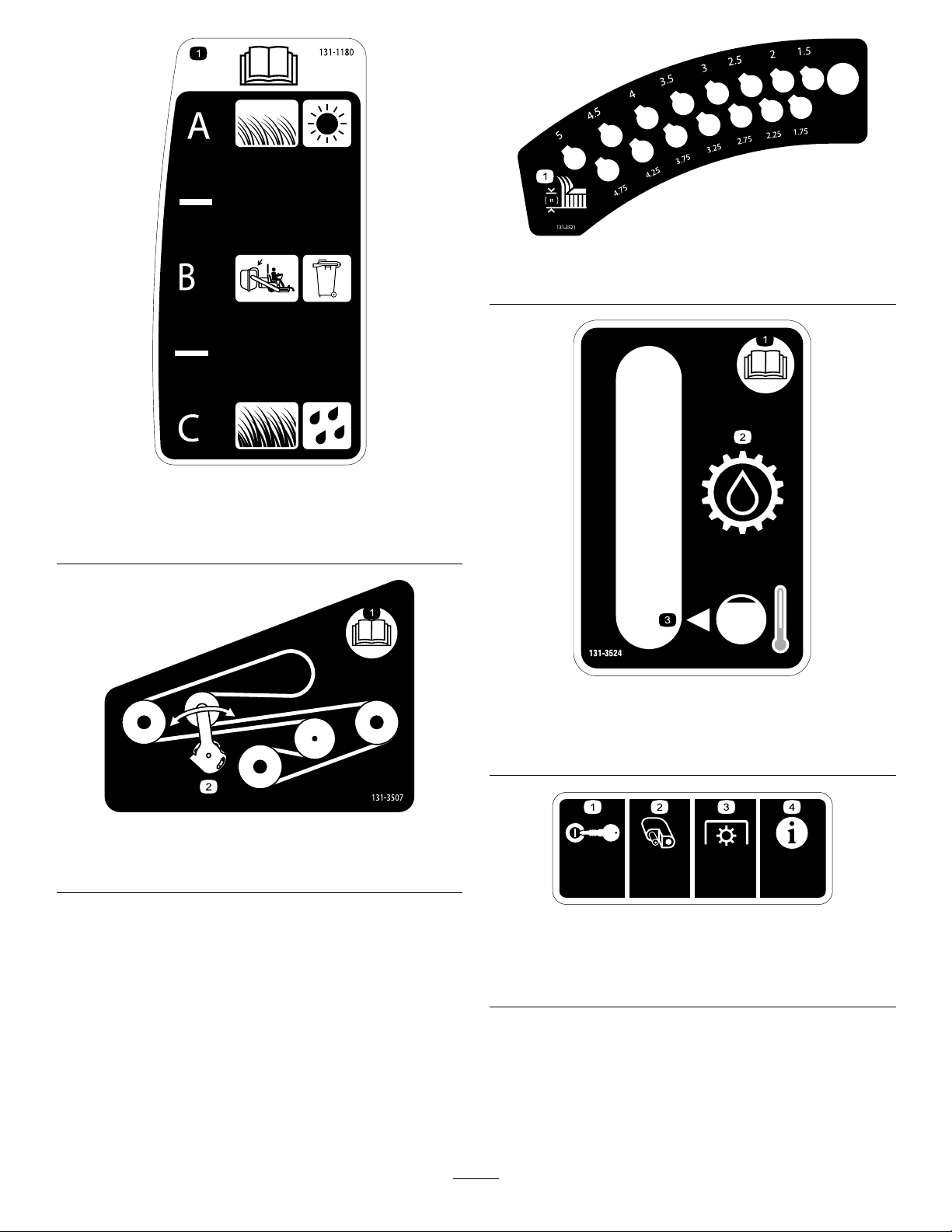

131-1180

131-3528

15A 15A 10A

7.5A

1.ReadtheOperator'sManual.(A)Short,lightgrass;dry

conditions;maximumdispersion;(B)Baggingsetting;(C)

Tall,densegrass;wetconditions;maximumgroundspeed

131-3521

1.Height-of-cut

131-3524

1.ReadtheOperator's

Manual.

1.ReadtheOperator's

Manual.

2.Transmissionoil

3.Oillevel

131-3507

2.Belttensioner

131-3528

1.Ignition—15A

2.Accessoryport—15A

3.Powertakeoff(PTO)—10

A

4.Infocenter—7.5A

9

Page 10

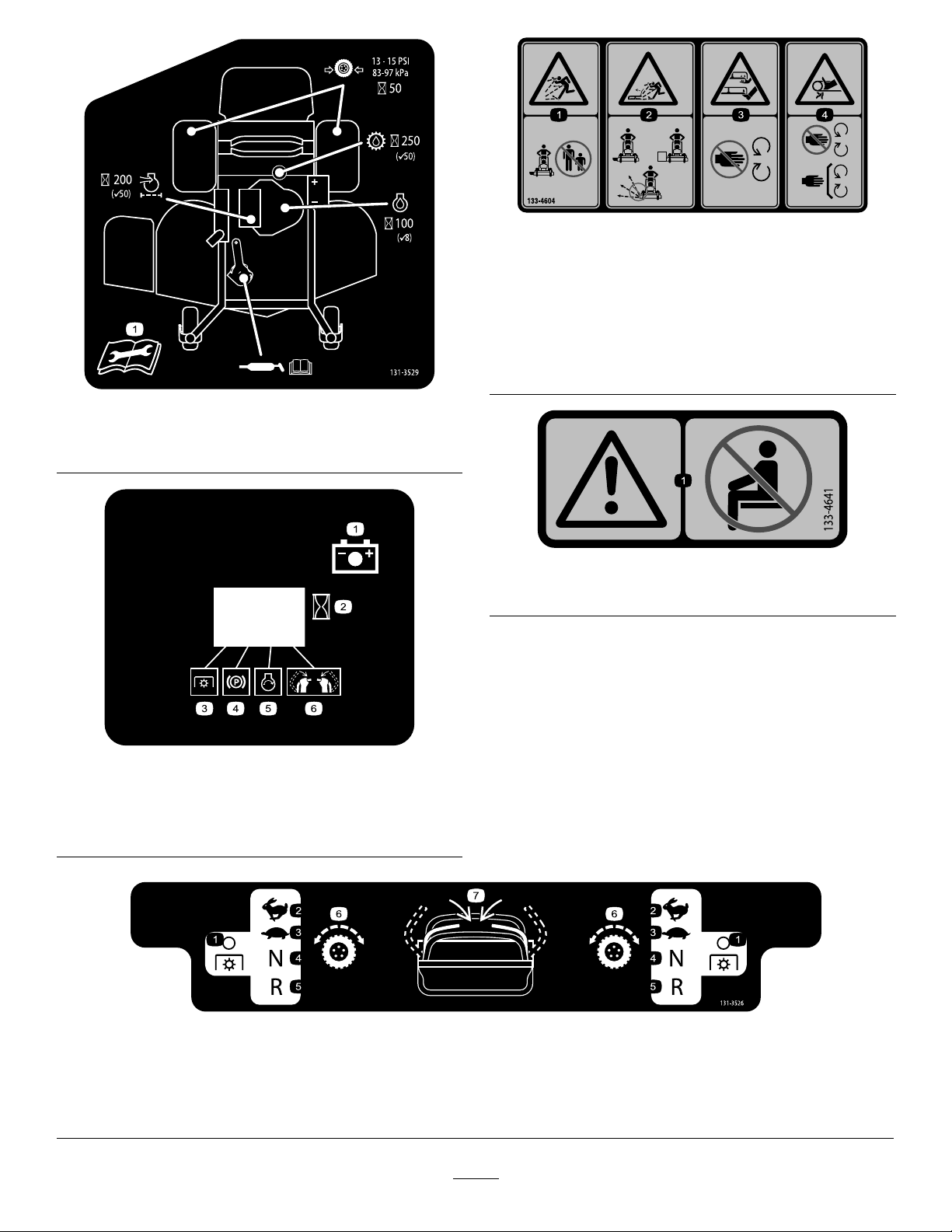

133-4604

131-3529

1.ReadtheOperator'sManualformoreinformationon

maintenanceintervalsandprocedures.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

openbafe—onlyoperate

themachinewithabafe

oragrasscollector.

1.Warning—donotcarryanypassengers.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

133-4641

131-3536

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

131-3526

1.Powertakeoff(PTO)—disengaged

2.Fast6.Tractiondrive

3.Slow

4.Neutral

5.Reverse

7.Engagethehandles.

10

Page 11

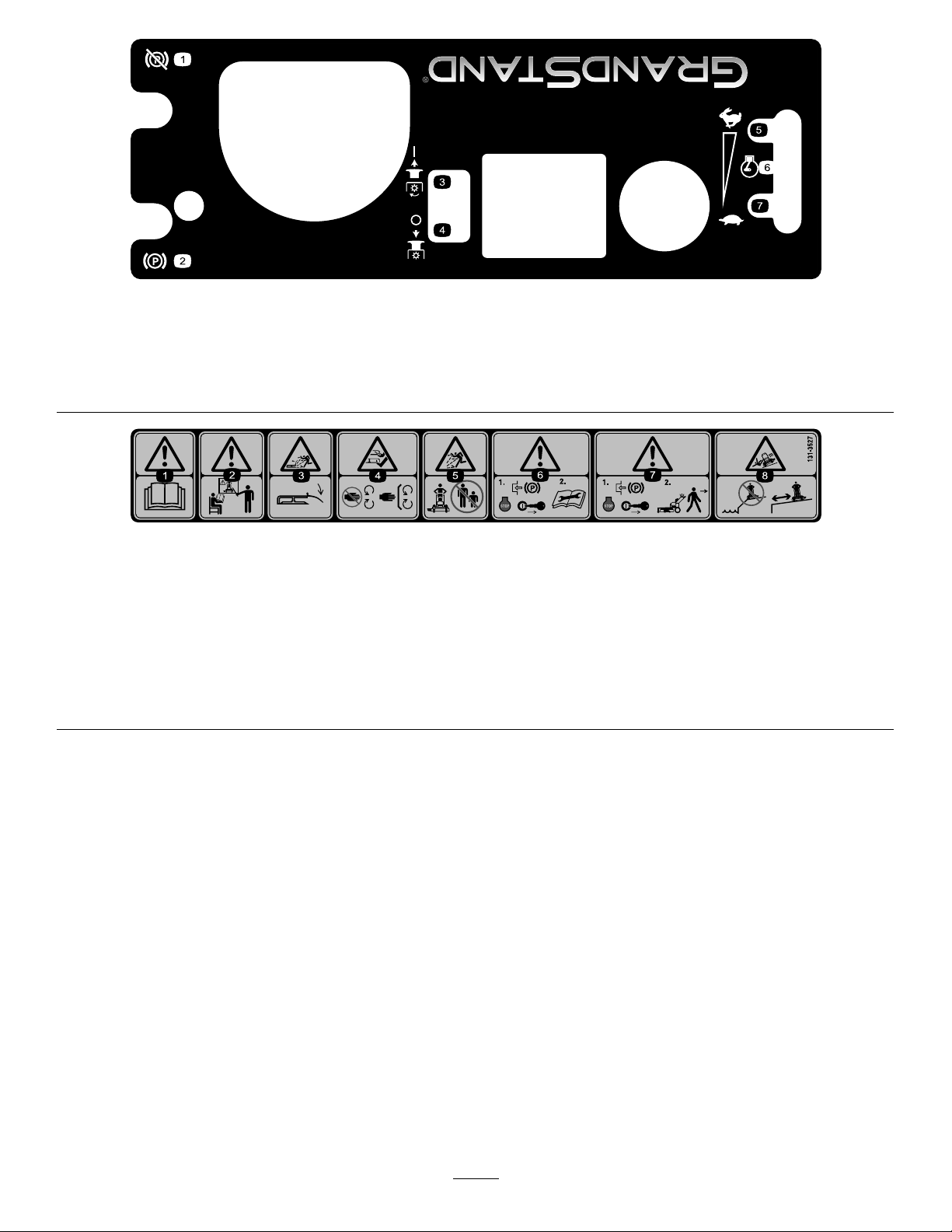

131-3525

1.Disengagetheparkingbrake.5.Fast

2.Engagetheparkingbrake.6.Engine—speed

3.EngagethePTO.7.Slow

4.DisengagethePTO.

131-3527

1.Warning—readtheOperator'sManual.5.Thrownobjecthazard—keepbystandersawayfromthe

2.Warning—receivetrainingbeforeoperatingthemachine.6.Warning—1)Engagetheparkingbrake,shutofftheengine,

3.Thrownobjecthazard—keepthedeectorloweredduring

operation.

4.Cutting/severinghazardofhandorfoot—keepawayfrom

movingparts;keepallguardsandshieldsinplace.

machine.

andremovethekeyfromtheignition;2)ReadtheOperator's

Manualbeforeservicingorperformingmaintenance.

7.Warning—engagetheparkingbrake,shutofftheengine,and

removethekeyfromtheignitionbeforeleavingthemachine.

8.Tippinghazard—donotoperateneardrop-offsornearwater.

11

Page 12

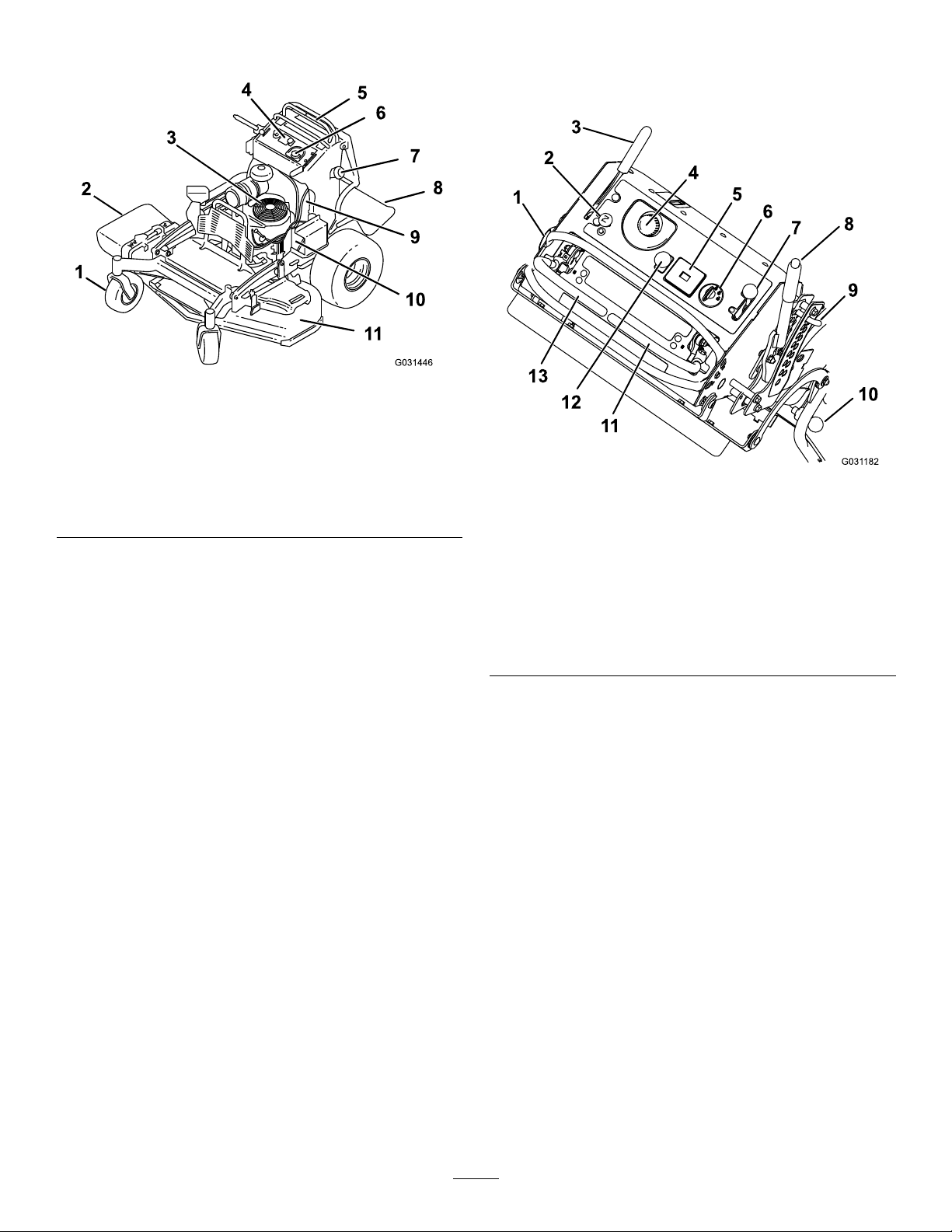

ProductOverview

Figure4

1.Frontcasterwheel7.Fueltank

2.Side-dischargechute8.Platform(downposition)

3.Engine

4.Controls

5.Controllevers

6.Hydraulictank

9.Fuel-shutoffvalve

10.Battery

11.Mowerdeck

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

Figure5

1.Fuelcap

2.Choke9.Height-of-cutpin

3.Parking-brakelever

4.Hydraulic-tankcap11.Rightmotion-controllever

5.Hourmeter12.Blade-controlswitch

6.Ignitionswitch

7.Throttlecontrol

8.Height-of-cutlever

10.Platformlatch

(PTO)

13.Leftmotion-controllever

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure5).

Safety-InterlockIndicators

Symbolsonthehourmeterindicatewithablacktrianglethat

theinterlockcomponentisinthecorrectposition(Figure5).

Battery-IndicatorLight

IftheignitionkeyisturnedtotheONpositionforafew

seconds,thebatteryvoltagedisplaysintheareawherethe

hoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

5).

ThrottleControl

ThethrottlecontrolisvariablebetweentheFASTandSLOW

positions(Figure5).

12

Page 13

Choke

Specications

Usethechoketostartacoldengine(Figure5).

Blade-ControlSwitch(PTO)

Usetheblade-controlswitch(PTO)toengageanddisengage

themowerblades(Figure5).

IgnitionSwitch

Usetheignitionswitchtostartthemowerengine(Figure5).

Theswitchhas3positions:OFF,RUN,andSTART.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethemachine

forwardandreverseandtoturneitherdirection(Figure5).

Fuel-ShutoffValve

Closethefuel-shutoffvalve(locatedontheleftsideofthe

fueltank)whentransportingorstoringthemower(Figure4).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

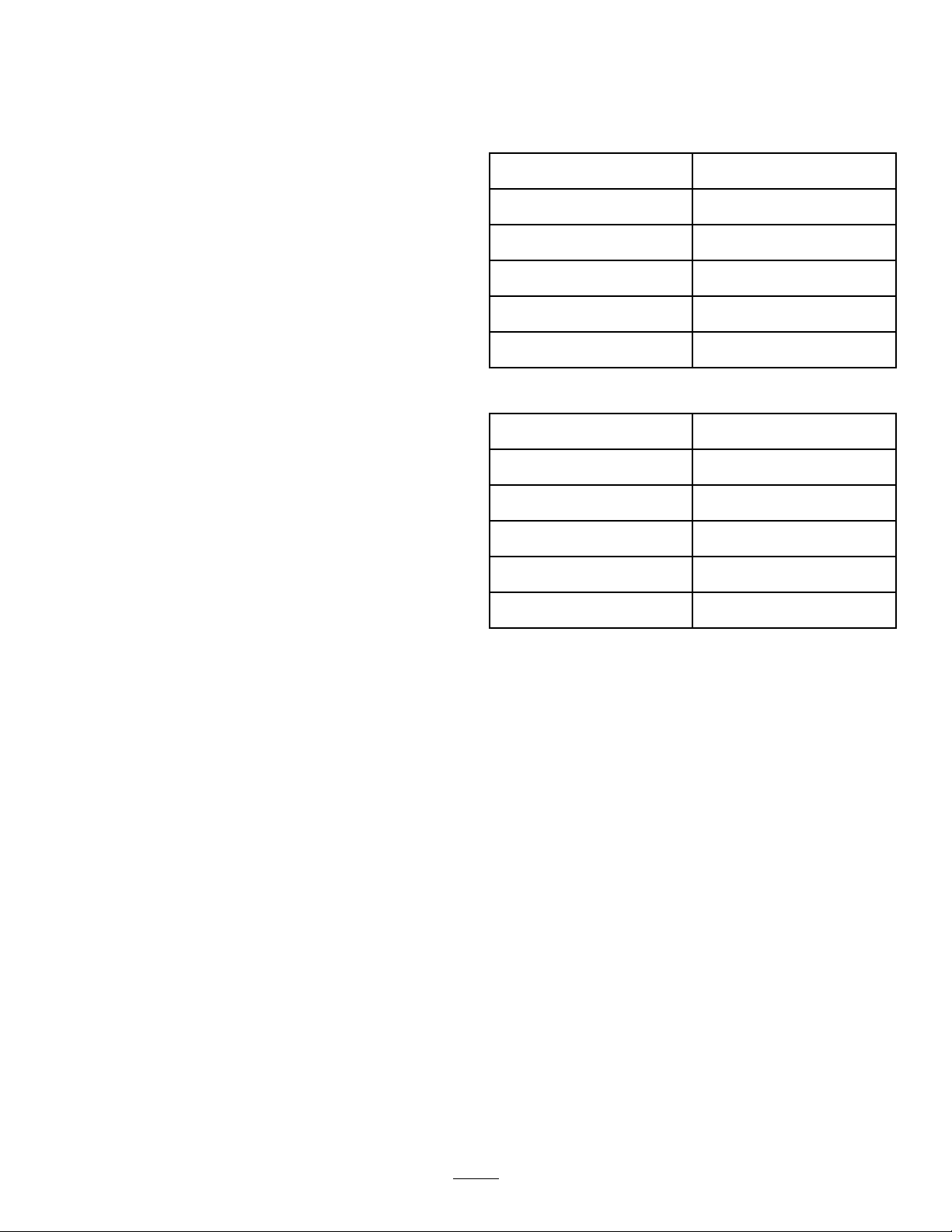

48-inchMowers

Widthwithdeectordown163cm(64inches)

Widthwithdeectorraised127cm(50inches)

Lengthwithplatformdown191cm(75inches)

Lengthwithplatformup155cm(61inches)

Height

Weight

122cm(48inches)

408kg(899lb)

52-inchMowers

Widthwithdeectordown173cm(68inches)

Widthwithdeectorraised137cm(54inches)

Lengthwithplatformdown191cm(75inches)

Lengthwithplatformup155cm(61inches)

Height

Weight

122cm(48inches)

412kg(908lb)

13

Page 14

Operation

G009027

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossfromextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

Useprotectiveequipmentforyoureyes,ears,andfeet.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Figure6

1.Weareyeprotection.2.Wearhearingprotection.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark,which

canignitethegasolinevapors.Areorexplosion

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

containerratherthanfromagasoline-dispenser

nozzle.

•Ifyoumustuseagasoline-dispensernozzle

mustbeused,keepthenozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

14

Page 15

WARNING

BreakinginaNewMachine

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorage,drainthefueltank.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;referto

AdjustingtheBrakes(page43).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended.

SettingtheParkingBrake

Pulltheparking-brakeleverrearwardintotheENGAGED

position(Figure7).

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefuel-tankcapandremovethecap.

3.Addunleadedregulargasolinetothefueltank,until

thelevelis6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.

Note:Thisspaceinthetankallowsthegasolineto

expand.Donotllthefueltankcompletelyfull.

4.Installthefuel-tankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page31).

Figure7

1.Parkingbrake—engaged2.Parkingbrake—released

ReleasingtheParkingBrake

Pushtheparking-brakeleverforward(Figure7).

15

Page 16

Operatingthe

G009174

G008946

G008959

1

2

OperatingtheThrottle

Mower-Blade-ControlSwitch

(PTO)

Usetheblade-controlswitch(PTO)inconjunctionwiththe

motion-controlleverstoengageanddisengagethemower

blades.

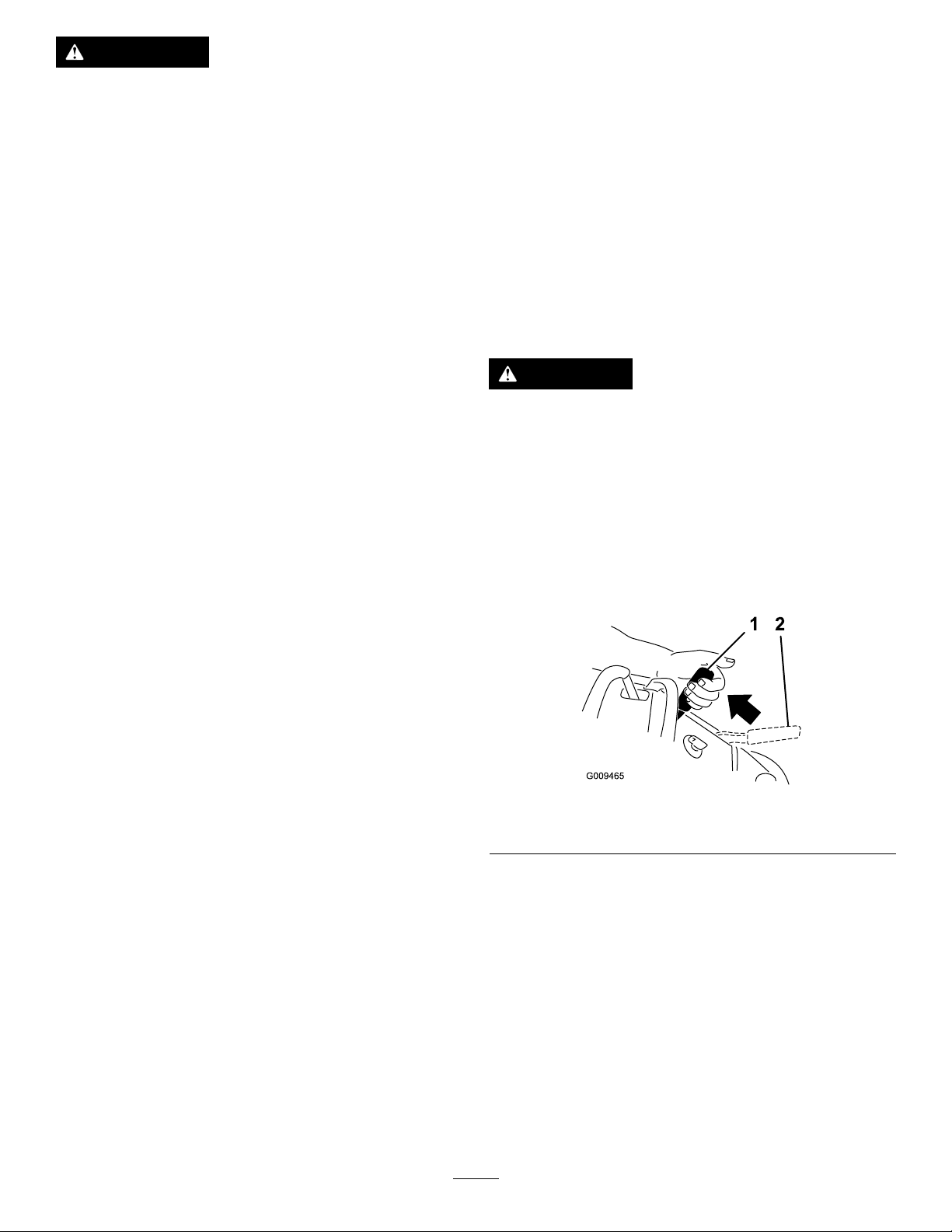

EngagingtheMowerBlades(PTO)

Figure8

ThethrottlecontrolmovesbetweenFASTandSLOWpositions

(Figure11).

AlwaysusetheFASTpositionwhenengagingthemower

bladeswiththeblade-controlswitch(PTO).

Figure11

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure12).

2.Pushdownthechokeknobtodisengagethechoke

aftertheenginehasstarted(Figure12).

DisengagingtheMowerBlades(PTO)

Figure9andFigure10show2waystodisengagethemower

blades.

Figure9

1.Onposition2.Offposition

Figure10

Figure12

16

Page 17

OperatingtheIgnitionSwitch

UsingtheFuel-ShutoffValve

Important:Donotengagethestarterformorethan

5secondsatatime.Iftheenginefailstostart,wait

15secondsbetweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Youmayneedtorepeatthecycleforstartingthe

enginewhenyoustartitforthersttimeafteryouhavelled

acompletelyemptyfuelsystemwithfuel.

Figure13

Closethefuel-shutoffvalvefortransport,maintenance,and

storage(Figure15).

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

Figure14

Figure15

1.ONposition2.OFFposition

17

Page 18

StartingandShuttingoffthe

ShuttingofftheEngine

Engine

StartingtheEngine

Important:Donotengagethestarterformorethan

5secondsatatime.Iftheenginefailstostart,wait

15secondsbetweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Youmayneedtorepeatthecycleforstartingthe

enginewhenyoustartitforthersttimeafteryouhavelled

acompletelyemptyfuelsystemwithfuel.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

Figure16

Figure17

Important:Makesurethatthefuel-shutoffvalveis

closedbeforetransportingorstoringthemachine

topreventafuelleak.Beforestoringthemachine,

disconnectthesparkplug(s)topreventthepossibility

ofaccidentalstarting.

18

Page 19

TheSafety-InterlockSystem

Note:Thebladesshouldnotrotateandtheengine

shouldstoprunning.

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventthemower

bladesfromrotatingunlessyoudo1ofthefollowing:

•Moveeithermotion-controllevertothecenter,unlocked

position.

•Pulltheblade-controlswitch(PTO)totheONposition.

Thesafety-interlocksystemisdesignedtostopthemower

bladesifyoumoveorreleasebothmotion-controllevers

intotheNEUTRAL-LOCKposition.

Thehourmeterhassymbolstonotifytheuserwheneach

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglelightsup

inthecorrespondingsquare(Figure18).

3.Starttheengineandreleasetheparkingbrake.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Continueholdingthemotion-controlleverinthe

center,unlockedposition,pullupontheblade-control

switch(PTO),andreleasetheswitch.

Note:Theclutchshouldengageandthemower

bladesrotate.

6.Moveorreleasethemotion-controlleversintothe

NEUTRAL-LOCKposition.

Note:Thebladesshouldstoprotatingandtheengine

shouldcontinuetorun.

7.Pushtheblade-controlswitchdownandmoveeither

motion-controllevertothecenter,unlockedposition.

8.Continueholdingthemotion-controlleverinthe

center,unlockedposition,pullupontheblade-control

switch(PTO),andreleasetheswitch.

Note:Theclutchshouldengageandthemower

bladesshouldrotate.

9.Pushtheblade-controlswitch(PTO)downtotheOFF

position.

Note:Thebladesshouldstoprotating.

Figure18

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition.

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.

Note:Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Starttheengine;refertoStartingtheEngine(page18).

2.Movethemotion-controlleverstothecenter,unlocked

position.

10.Withtheenginerunning,pulluptheblade-control

switch(PTO)andreleaseitwithoutholdingeither

motion-controllevertothecenter,unlockedposition.

Note:Thebladesshouldnotrotate.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenloweringandraisingtheoperator

platform.Carefullylowerorraisetheoperator

platform,assuddenlydroppingitcouldinjureyou.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringorraisingthe

operatorplatform.

•Makesurethattheplatformissupportedwhen

youpullthelatchpinout.

•Makesurethatthelatchsecurestheplatform

whenfoldingitup.Pushittightagainstthe

cushionforthelatchpintolockintoplace.

•Keepbystandersawaywhenraisingorlowering

theplatform.

OperatingthePlatform

Youcanusethemachinewiththeplatformintheupordown

position.Itisyourpreferenceonwhichpositiontouse.

19

Page 20

OperatingtheMachinewiththe

PlatformUp

Operatethemachinewiththeplatformupunderthe

followingconditions:

•Mowingneardrop-offs

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatethe

machineintheFULL-THROTTLEpositionwhenmowing.

•Mowingsmallareaswherethemachineistoolarge

•Areaswithlow ,over-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformupsothat

thelatchpinandknoblockitintoplace.Pushittightagainst

thecushionforthelatchpintolockitintoplace.

OperatingtheMachinewiththe

PlatformDown

Operatethemachinewiththeplatformdownunderthe

followingconditions:

•Mowingmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforwardagainstthe

cushiontoreleasepressureonthelatchpin,thenpullthe

knoboutandlowertheplatform(Figure19).

CAUTION

Themachinecanspinveryrapidly,andyoumay

losecontrolofmachine,causingpersonalinjuryto

youanddamagetomachine.

Slowthemachinedownbeforemakingsharpturns.

DrivingForward

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page15).

2.Movethemotion-controlleverstothecenter,unlocked

position.

1.Platformup

2.Platformdown

Figure19

3.Pulltheknobouttorelease

theplatform.

Figure20

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar6.Leftcontrolleverinthe

3.Slowlypushthemotion-controlleversforward(Figure

21).

Note:Theenginestopsifyoumoveamotion-control

leverwhiletheparkingbrakeisengaged.

Note:Thefartheryoumovethemotion-controllevers

ineitherdirection,thefasterthemachinemovesinthat

direction.

Note:Tostopthemachine,pullthemotion-control

leversbacktotheNEUTRALposition.

20

4.Rightcontrollever

5.Rightcontrolleverinthe

NEUTRAL-LOCKposition

NEUTRAL-LOCKposition

Page 21

Figure21

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutral,movebothmotion-controlleversintothe

NEUTRAL-LOCKposition,disengagethepowertakeoff

(PTO),andturntheignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page15).

Note:Remembertoremovethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjurediftheymove

orattempttooperatethemachine.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended.

DrivingBackward

1.Movebothmotion-controlleverstothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward(Figure

22).

Figure22

21

Page 22

PushingtheMachinebyHand

TransportingtheMachine

Thebypassvalvesallowyoutopushthemachinebyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Donot

towthemachine,becausehydraulicdamagemayoccur.

Important:Donotstartoroperatethemachinewith

thebypassvalvesopen.Damagetosystemmayoccur.

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallthenecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.

1.Raisetheplatformofthemachinebeforedrivingonto

thetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure24).

Figure23

Figure24

1.Tractionunittie-downloop

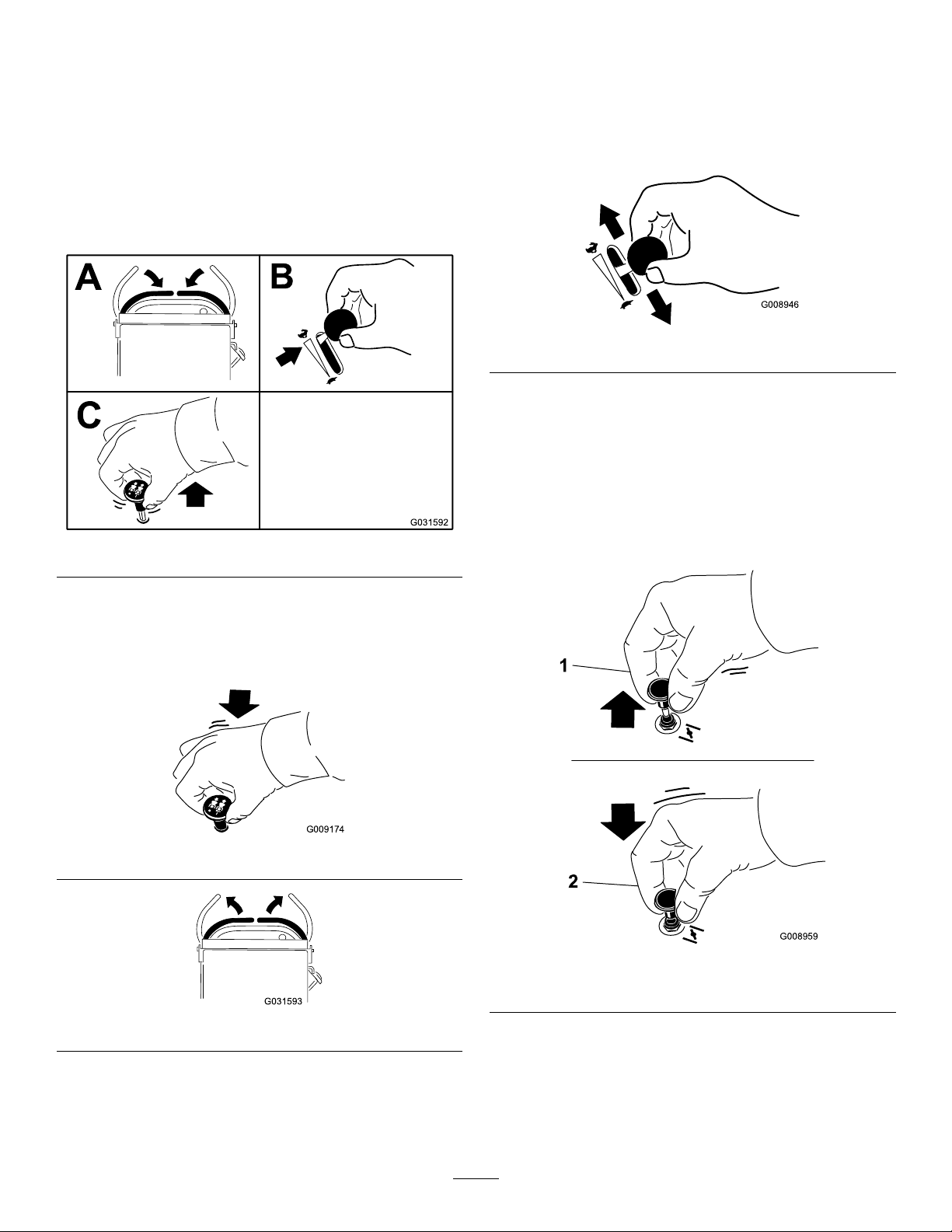

LoadingtheMachine

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backthemachineupthe

rampandwalkitforwarddowntheramp(Figure25).

Figure25

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

22

Page 23

Important:Donotusenarrowindividualrampsfor

g027996

5

1

2

6

eachsideofthemachine.

Ensurethattherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees(Figure26).Onat

ground,thisrequiresaramptobeatleast4timesaslongas

theheightofthetrailerortruckbedtotheground.Asteeper

anglemaycausemowercomponentstogetcaughtasthe

machinemovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

youareloadingthemachineonornearaslope,positionthe

trailerortrucksothatitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethatthelengthoftherampisatleast4

timesaslongastheheightofthetrailerortruck

bedtotheground.Thiswillensurethatthe

rampangledoesnotexceed15degreesonat

ground.

•Backthemachineuptherampandwalkit

forwarddowntheramp.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonaramp,asthiscould

causealossofcontroloratip-oversituation.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

Figure26

4.Therampisatleast4

timesaslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

23

Page 24

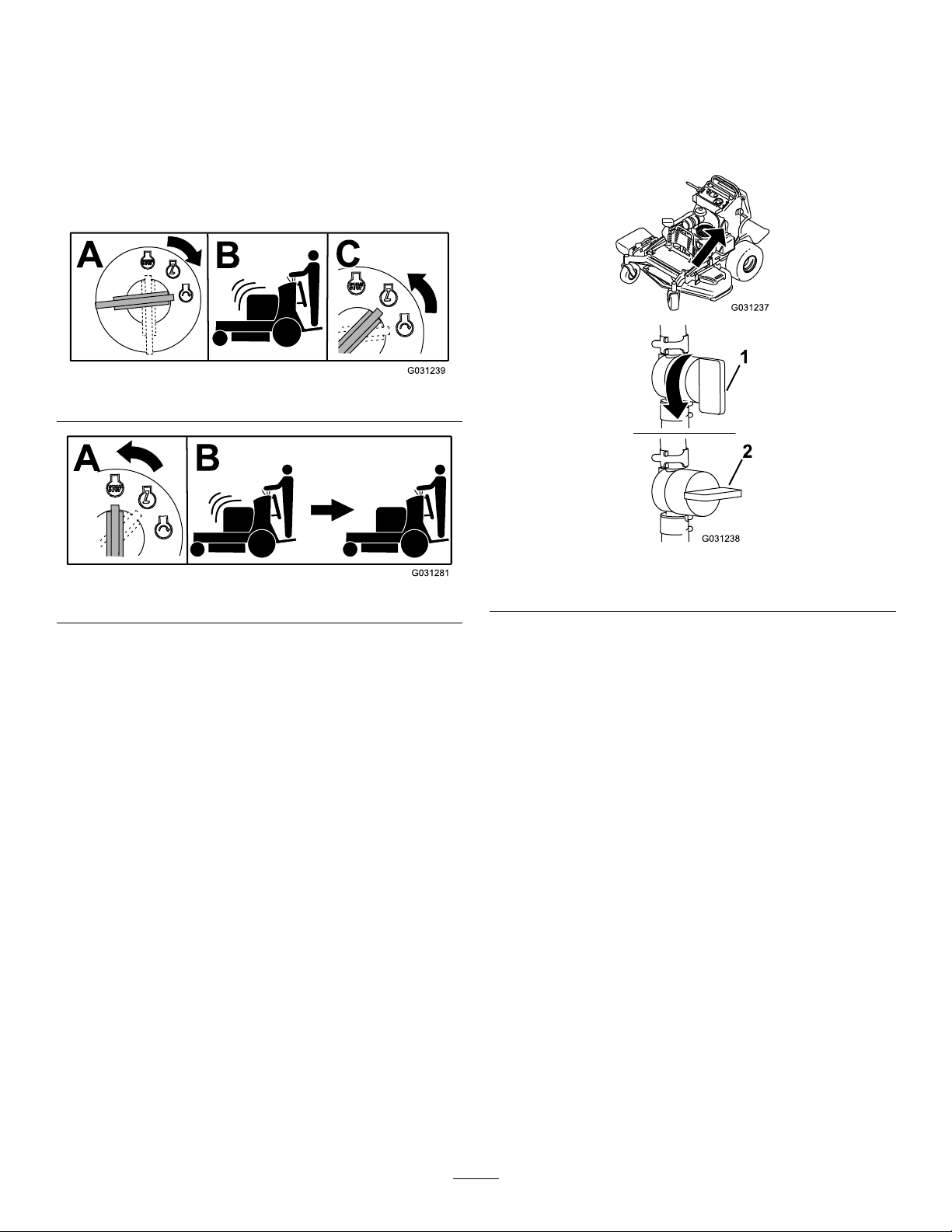

SideDischargingorMulching

AdjustingtheHeight-of-Cut

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriscauseinjuryordeath.

•Donotremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkey

totheOFFposition.Alsoremovethekeyand

disconnectthewire(s)offthesparkplug(s).

Theheight-of-cutcanbeadjustedfrom38to127mm(1-1/2

to5inches)in6mm(1/4inch)increments.

Note:Usingaheight-of-cutunder51mm(2inches)increases

thewearonthemower-deckbelt.Useaheight-of-cutthatis

greaterthan51mm(2inches)wheneverpossible.

Figure27

24

Page 25

AdjustingtheFlowBafe

g012676

1 2

G012677

PositioningtheFlowBafe

Youcanadjustthemower-dischargeowfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

providethebestqualityofcut.

1.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Toadjustthebafe,loosenthenut(Figure28).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Thefollowingguresareonlyforrecommendeduse.

Adjustmentsvarybygrasstype,moisturecontent,andthe

heightofthegrass.

Note:Iftheenginepowerdrawsdown,andthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefull,rearposition(seeFigure29).Usethisposition

forthefollowing:

•Inshort,lightgrassmowingconditions

•Indryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthemower

Figure28

1.Slot

2.Nut

Figure29

25

Page 26

PositionB

G012678

G012679

Usethispositionwhenbagging(Figure30).

UsingtheMid-SizeWeight

•Installweightstoimprovebalance.Youcanaddor

removeweightstocreateoptimizedperformanceunder

differentmowingconditionsandforyourpreference.

•Addorremoveweights1atatimeuntilyouachievethe

desiredhandlingandbalance.

Note:ContactanAuthorizedServiceDealertoordera

WeightKit.

WARNING

Excessiveweightchangescanaffectthehandling

andoperationofthemachine.Thiscouldcause

seriousinjurytoyouorbystanders.

•Makeweightchangesinsmallincrementsonly.

Figure30

PositionC

Thisisthefull,openposition(Figure31).Useforthis

positionforthefollowing:

•Intall,densegrassmowingconditions

•Inwetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

•Evaluatethatyoucanoperatethemowerafter

eachweightchangesafely.

Figure31

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every250hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Checkthewheel-lugnuts.

•Checkthewheel-hubnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthebrakes.

•Inspecttheblades.

•Cleanthemowerdeck.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Check,cleanandgapthesparkplug.

•Checkthebattery .

•Checkandcleantheenginecoolingnsandshrouds.

•Checkthemower-deckbelt.

•Changetheengine-oillter.

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

Every300hours

Every500hours

Every800hours

Every1,000hours

Beforestorage

Yearly

•Checkandadjustthevalveclearance.SeeanAuthorizedServiceDealer.

•Replacethesecondaryairlter.

•Adjustthecaster-pivotbearing.

•Checkthewheel-hubnuts.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Replacethefuellter.

•Replacethetransmissionbelt.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethetorsionidler.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasethecaster-wheelhubs.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwiresfromthesparkplugsbeforeyoudo

anymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

27

Page 28

Premaintenance

Lubrication

Procedures

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothemachinefor

maintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthemachine

(Figure32).

Figure32

1.Twistknob

2.Cushion

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

6.Wipeupanyexcessgrease.

GreasingtheTorsionIdler

ServiceInterval:Yearly

Greasethetorsionidleronthemowerdeckusing

high-temperaturegreaseatthegreasettingshowninFigure

33.

Important:Onlyusehigh-temperaturegrease.

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinsonboth

sidesofthemachine.

6.Tightenthetwistknobs.

Figure33

1.Greasetting

28

Page 29

GreasingtheFrontCaster Pivots

ServiceInterval:Yearly

1.Removethedustcapandadjustthecasterpivots;refer

toAdjustingtheCaster-PivotBearing(page40).

Note:Keepthedustcapoffuntilyouhavenished

greasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

GreasingtheCaster-Wheel

8.Ifbothspacernutsintheaxleassemblyhavebeen

removed(orbrokenloose),applyathread-locking

adhesiveto1spacernut,threadingitontotheaxlewith

thewrenchatsfacingoutward.

Note:Donotthreadspacernutallofthewayonto

theendoftheaxle.Leaveapproximately3mm(1/8

inch)fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandthenewsealintothe

wheel.

12.Applyathread-lockingadhesivetothesecondspacer

nut,threadingitontotheaxlewiththewrenchats

facingoutward.

Hubs

ServiceInterval:Yearly

1.Shutofftheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey .

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub(Figure34).

Figure34

1.Sealguard2.Spacernutwithwrench

ats

13.Torquethenutto8to9N∙m(71to80in-lb),loosenit,

thentorqueitto2to3N∙m(20to25in-lb).

Note:Makesurethataxledoesnotextendbeyond

eithernut.

14.Installthesealguardsoverthewheelhubandinsert

wheelintocasterfork.

15.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoftenbyspinningthecaster

tire.Thetireshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntilthere

isaslightamountofdrag,andapplythread-locking

adhesive.

4.Remove1spacernutfromtheaxleassemblyinthe

casterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryouttheseals,inspectbearingsforwearordamage,

andreplacethemifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1newsealintothewheel.

Note:Youmustreplacetheseals.

29

Page 30

EngineMaintenance

g026970

ServicingtheAirCleaner

ServiceInterval:Every300hours

Every250hours—Replacetheprimaryairlter.

Every250hours—Checkthesecondaryairlter.

Every500hours—Replacethesecondaryairlter.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

Figure35

RemovingtheFilters

1.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pushdowntoreleasetheretainingclampsontheair

cleanerandpulltheair-cleanercoverofftheair-cleaner

body(Figure35).

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure35).

Note:Avoidknockingthelterintothesideofthe

body.

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

1.Air-cleanerclamps

2.Air-cleanercover

3.Primaryairlter

4.Secondaryairlter

ServicingthePrimaryFilter

1.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

2.Replacethepaperelementifitisdamaged.

Note:Donotcleanthepaperelement.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Donotattempttocleanthesecondarylter.

Ifthesecondarylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:T opreventenginedamage,alwaysoperate

theenginewithbothairltersandthecoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.

Note:Donotuseadamagedlter.

Note:Holesinthelterappearasbrightspots.

Note:Discardthelterifitisdamaged.

2.Ifthesecondarylterisbeingreplaced,carefullyslide

itintothelterbody(Figure35).

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure35).

4.Ensurethatitisfullyseatedbypushingontheouter

rimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

5.Installtheair-cleanercoverwiththebreathercapdown,

androtatesothattheretainingclampslockthecover

inplace(Figure35).

30

Page 31

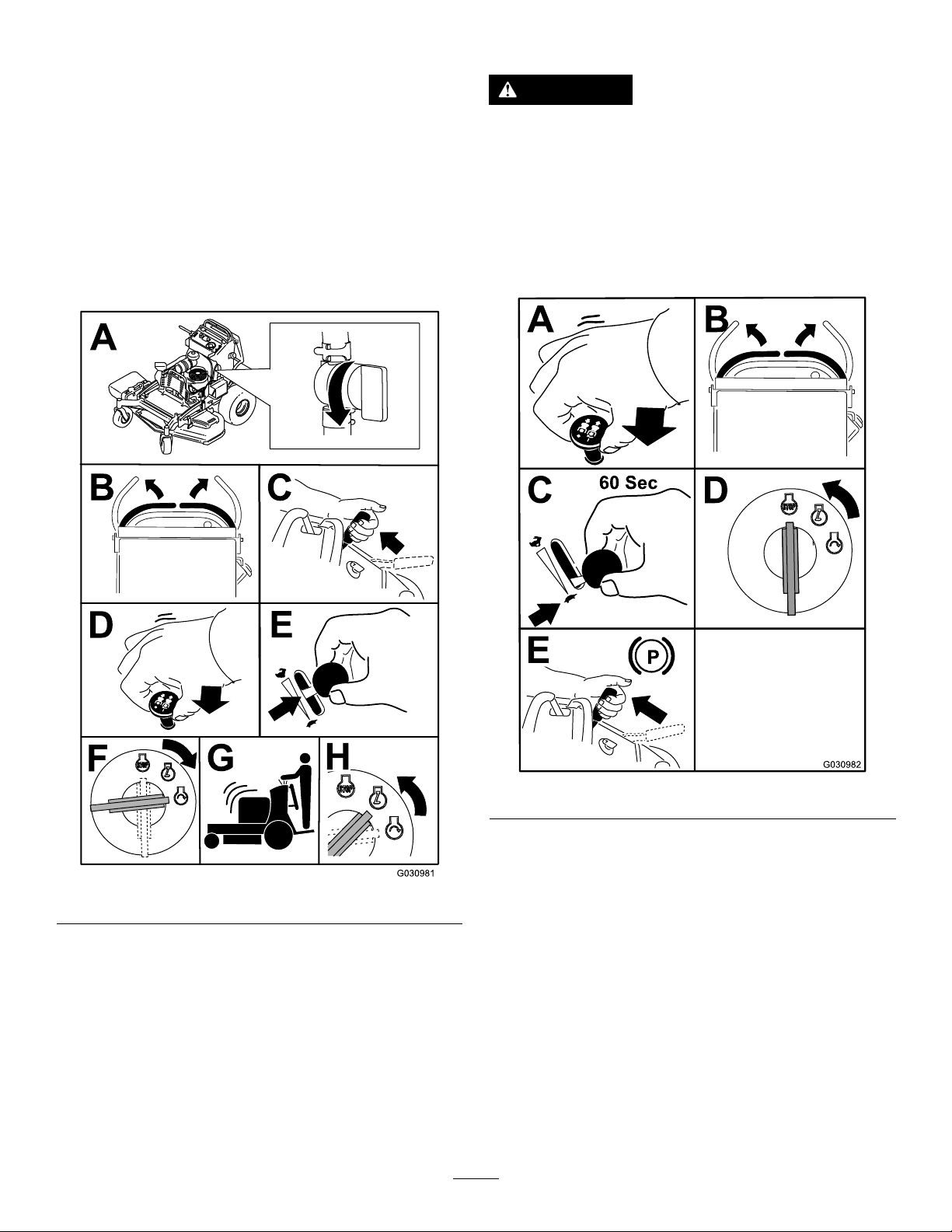

ServicingtheEngineOil

B

A

C

D

E

G027659

F

G

H

I J

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst8hours

Every100hours—Changetheengineoil(moreoften

indirtyordustyconditions).

Every200hours—Changetheengine-oillter.

Note:Therearedifferentoilcapacitiesforthedifferent

modelslistedinthismanual.Ensurethatyouusethecorrect

amountofoil.

Important:Remembertoadd80%oftheoil,andthen

graduallyllittotheFullmarkonthedipstick.

OilType::Detergentoil(APIserviceSF,SG,SH,SJorSL)

EngineOilCapacity:2.1L(71oz)withthelterremoved;

1.8L(61oz)withoutthelterremoved

Viscosity:Refertothetablebelow .

3.Checktheengine-oillevelasshowninFigure37.

Figure36

CheckingtheEngine-OilLevel

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotruntheenginewiththeoillevel

abovetheFullmarkorbelowthelowmark.Otherwise,

doingsomaydamagetheengine.

1.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure37).

Figure37

31

Page 32

ChangingtheEngineOil

B

A

C

D

E

F

g027660

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

2.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

3.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.ChangetheengineoilasshowninFigure38.

Figure39

6.Starttheengineanddrivetoaatarea.

7.Checktheengineoillevel.

Figure38

5.Slowlypourapproximately80%ofthespeciedoil

intothellertube,andslowlyaddtheadditionaloilto

bringittotheFullmark(Figure39).

32

Page 33

ChangingtheEngine-OilFilter

B

A

C D

E

F

3/4

g027477

B

A

g027478

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page32).

2.Placearagundertheoilltertosoakupanyspilledoil.

Important:Spilledoilmaydrainundertheengine

andontotheclutch.Oilspilledontheclutchmay

damagetheclutch,causethebladestostopslowly

whentheclutchisintheOFFposition,andcause

theclutchtoslipwhentheclutchisswitchedto

theONposition.Wipeupanyspilledoil.

3.Changetheengine-oillter(Figure40).

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthespark

plug(s)andagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplug(s)ifnecessary.

TypeforallEngines:NGK

AirGap:0.75mm(0.03inch)

RemovingtheSparkPlugs

1.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.RemovethesparkplugsasshowninFigure41.

®

BPR4ESorequivalent

4.Fillthecrankcasewiththepropertypeofnewoil;refer

Note:Ensurethattheoil-ltergaskettouchesthe

engine,thenrotatethelteranextra3/4turn.

toChangingtheEngineOil(page32).

Figure40

Figure41

33

Page 34

CheckingtheSparkPlug

B

A

g027479

B

A

16 ft-lb

22 N-m

g027661

C

D

CheckingtheSparkArrester

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.75mm(0.03inch).

Figure42

InstallingtheSparkPlug

IfEquipped

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

gasolinevaporsevenafteryoushutofftheengine.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials,resultingin

personalinjuryorpropertydamage.

Donotrefuelorruntheengineunlessthespark

arresterisinstalled.

1.Shutofftheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey .

2.Waitforthemufertocool.

3.Ifyouseeanybreaksinthescreenorwelds,replace

thearrester.

4.Ifthescreenisplugged,removethearrester,shake

looseparticlesoutofthearrester,andcleanthe

screenwithawirebrush(soakthescreeninsolvent

ifnecessary).

5.Installthearresterontheexhaustoutlet.

Figure43

34

Page 35

FuelSystem

Maintenance

DrainingtheFuelTank

Youcandrainthefueltankbyremovingitandpouringthe

fueloutofthellneck;refertoRemovingtheFuelTank

(page35).Youcanalsodrainthefueltankbyusingasiphon

inthefollowingprocedure.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopename,orwhereasparkmay

ignitethegasolinefumes.

Figure44

1.Fuelcap

RemovingtheFuelTank

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingtheCushionfor

RearAccess(page28).

1.DisengagethePTO,movethemotion-controlleversto

theNEUTRAL-LOCKposition,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure44).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoacleangas

can(Figure44).

7.Wipeupanyspilledfuel.

3.Removethecrossbracket.

Figure45

4.Removethefueltankandsetitontheoperator

platform.

Note:Ifyouwanttomovethefueltankfurtherfrom

themachine,removethefuelandventlinesfromthe

topofthetank.

35

Page 36

ServicingtheFuelFilter

B

A

C

D

g027518

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Y early(whichevercomes

rst)

Donotinstalladirtylterifitisremovedfromthefuelline.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page17).

4.ReplacethefuellterasshowninFigure46.

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionof4partswaterand

1partbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12V

WARNING

CALIFORNIA

Proposition65W arning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure46

DANGER

Donotdrinkelectrolyte,andavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

Batteryelectrolytecontainssulfuricacid,adeadly

poisonthatcausessevereburns.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

36

Page 37

WARNING

Incorrectbattery-cableroutingcoulddamagethe

machineandcables,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.RemovethebatteryasshowninFigure47.

InstallingtheBattery

InstallthebatteryasshowninFigure48.

Figure47

Figure48

37

Page 38

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page36).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthebattery.

4.Chargethebatteryfor1hourat25to30Aor6hours

at4to6A.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure49).

6.Installthebatteryontothemachineandconnectthe

batterycables;refertoInstallingtheBattery(page37).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Theelectricalsystemisprotectedbyfusesandrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

1.Releasethecushionfromtherearofthemachine.

2.Pulloutthefusetoremoveorreplaceit(Figure50).

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseisinstalled

Figure50.

Figure50

1.Ignitionfuse—15A3.Powertakeoff(PTO)

2.Accessory-portfuse—15

A

fuse—10A

4.Infocenterfuse—7.5A

1.Positivebatterypost

2.Negativebatterypost

Figure49

3.Red(+)chargerlead

4.Black(-)chargerlead

38

Page 39

DriveSystem

6.Checkthatthemachinedoesnotcreepfromthe

neutralpositionwiththeparkbrakesdisengaged.

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullsto1side.

Note:Ifitdoes,stopthemachineandsettheparking

brake.

3.Releasethecushionfromtherearofthemachine;refer

toReleasingtheCushionforRearAccess(page28).

Note:Foreasieraccess,youcanalsoremovethefuel

tank;refertoRemovingtheFuelTank(page35).

4.Rotatetheleftcontrolrodinquarter-turnincrements

untilthemachinetracksstraight(Figure51).

Note:Ifthemachinepullstotheright,shortenthe

controlrodbyrotatingittotheright.Ifthemachine

pullstotheleft,lengthentherodbyrotatingittothe

left.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).

Important:Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireair-pressuremaintenance.

Note:Onlyadjusttheleftcontrolrodtomatchthe

leftwheelspeedtotherightwheelspeed.Donot

adjusttherightwheelspeed,asthispositionstheright

motion-controlleveroutofthecenterforthecontrol

panelneutral-lockslot.

Important:Donotrotatethecontrolrodtoofar,

asthismaycausethemachinetocreepinneutral.

Figure51

1.Rotatelefttolengthenthe

rod.

2.Leftcontrolrod

3.Rotaterighttoshortenthe

rod.

Figure52

5.Checkforpropertracking,andadjusttherodas

necessary.

Note:Ifyouareunabletoachievepropertrackingby

adjustingtheleftcontrolrod,contactyourAuthorized

ServiceDealer.

39

Page 40

AdjustingtheCaster-Pivot

ServicingtheCasterWheels

Bearing

ServiceInterval:Every500hours/Y early(whichevercomes

rst)

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromthecasterandtightenthe

locknut(Figure53).

4.Tightenthelocknutuntilthespringwashersareat,

andthenbackoffa1/4turntoproperlysetthepreload

onthebearings(Figure53).

Important:Makesurethatthespringwashersare

installedcorrectlyasshowninFigure53.

5.Installthedustcap(Figure53).

andBearings

Thecasterwheelsrotateonarollerbearingsupportedbya

spannerbushing.Ifthebearingiskeptwelllubricated,wear

willbeminimal.Failuretokeepthebearingwelllubricated

causesrapidwear.Awobblycasterwheelusuallyindicatesa

wornbearing.

1.Removethelocknutandwheelboltholdingthecaster

wheeltothecasterfork(Figure54).

1.Springwashers

2.Locknut

Figure53

3.Dustcap

Figure54

1.Locknut

2.Wheelbolt5.Rollerbearing

3.Bushing

2.Remove1bushing,thenpullthespannerbushingand

rollerbearingoutofthewheelhub(Figure54).

3.Removetheotherbushingfromthewheelhuband

cleananygreaseanddirtfromthewheelhub(Figure

54).

4.Inspecttherollerbearing,bushings,spannerbushing

andtheinsideofthewheelhubforwear.

Note:Replaceanydamagedorwornparts(Figure54).

5.Place1bushingintothewheelhub(Figure54).

6.Greasetherollerbearingandspannerbushing,and

slidethemintothewheelhub(Figure54).

7.Placethesecondbushingintothewheelhub(Figure

54).

8.Installthecasterwheelintothecasterforkandsecure

itwiththewheelboltandlocknut(Figure54).

4.Spannerbushing

9.Tightenthelocknutuntilthespannerbushingbottoms

againsttheinsideofthecasterforks(Figure54).

10.Greasethettingonthecasterwheel.

40

Page 41

UsingtheClutchShim

Somelatermodelyearunitshavebeenbuiltwithclutchesthat

containabrakeshim.Whentheclutchbrakehasworntothe

pointwheretheclutchnolongerengagesconsistently ,you

canremovetheshimtoextendtheclutchlife.

Figure55

1.Armature5.Brakespacer

2.Fieldshell6.Regaptheshim.

3.Rotor7.Brakepole

4.Brake-mountingbolt

A.Loosenbothbrakemountingbolts1/2to1full

turnasshowninFigure57.

Note:Donotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn

tomatchthearmatureandneedstocontinueto

matchafteryouremovetheshimtoensurethe

properbraketorque.

Figure57

1.Brake-mountingbolt

B.Usingneedle-nosepliers,orbyhand,removethe

shim.

RemovingtheClutchShim

1.Shutofftheengine,waitforallmovingpartstostop,

andremovethekey.

2.Engagetheparkingbrakeandwaitformachinetocool

completely.

3.Usinganaircompressor,blowoutanydebrisunderthe

brakepoleandaroundthebrakespacers.

Figure56

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthemas

necessary.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagetheblade-controlswitch(PTO).

6.Measurethegapbetweentherotorandarmature.If

thegapisgreaterthan1mm(0.04inch),proceedwith

thefollowingsteps:

Note:Donotdiscardtheshimuntilyouconrm

thattheclutchfunctionsproperly.

Figure58

1.Shim

C.Usingapneumaticline,blowoutanydebrisunder

thebrakepoleandaroundthebrakespacers.

D.Torqueeachbolt(M6x1)to12.3to13.7N∙m

(9.5to10.5ft-lb).

E.Usinga0.010inchthick-feelergauge,verifythat

agapispresentbetweentherotorandarmature

faceonbothsidesofthebrakepoleasshownin

Figure59andFigure60.

Note:Duetothewaytherotorandarmature

faceswear(peaksandvalleys),itissometimes

difculttomeasurethetruegap.

41

Page 42

CheckingtheWheel-LugNuts

ServiceInterval:Aftertherst100hours—Checkthe

wheel-lugnuts.

Checkandtorquethewheellugnutsto115to142N∙m(85

to105ft-lb).

1.Feelergauge

1.Feelergauge

Figure59

Figure60

•Ifthegapislessthan0.010inch,theninstall

theshimandrefertoTroubleshooting(page

56).

•Ifthegapissufcient,proceedtothesafety

checkinstepF.

CheckingtheWheel-HubNuts

ServiceInterval:Aftertherst100hours—Checkthe

wheel-hubnuts.

Every500hours—Checkthewheel-hubnuts.

Checkandtorquethewheelhubnutsto286to352N∙m(211

to260ft-lb).

F.Performthefollowingsafetycheck:

i.Sitontheseatandstarttheengine.

ii.Makesurethatthebladesdonotengage

whentheblade-controlswitch(PTO)

isintheOFFpositionandtheclutchis

disengaged.

Note:Iftheclutchdoesnot

disengage,installtheshim,andreferto

Troubleshooting(page56).

iii.Engageanddisengagetheblade-control

switch(PTO)10consecutivetimesto

ensurethattheclutchisfunctioning

properly.

Note:Iftheclutchdoesnotengage

properly,refertoTroubleshooting(page

56).

42

Page 43

CoolingSystem

Maintenance

BrakeMaintenance

ServicingtheBrake

CleaningtheAir-IntakeScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,removeanybuildupofgrass,dirt,or

otherdebrisfromthecylinderandcylinder-headcooling

ns,air-intakescreenontheywheelend,andthe

carburetor-governorleversandlinkage.Thishelpsensurethat

adequatecoolingandcorrectenginespeed,andreducesthe

possibilityofoverheatingormechanicaldamagetotheengine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours—Checkandcleanthe

enginecoolingnsandshrouds.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheair-intakescreenandfanhousing(Figure

61).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheair-intakescreenandfanhousing(Figure61).

Beforeeachuse,checkthebrakesonalevelsurfaceandslope.

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

Important:Iftheparkingbrakedoesnotholdsecurely,

adjustit.

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceanddisengagethe

PTO.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Releasethebrake.

4.Engagethebrakeleverandensurethatthemachine

doesnotmove.

5.Adjustthebrakeifneeded.

AdjustingtheBrakes

1.Removethefueltank;refertoRemovingtheFuelTank

(page35).

1.Guardandengine

air-intakescreen

Figure61

2.Loosentheboltonthecableclampontheleftsideof

themachine.

2.Fanhousing

Figure62

1.Cable

2.Cableclamp

3.Pulldownonthecablesuntiltheyaretaut.

4.Tightenthenut.

3.Boltandnut

5.Installthefueltank,crossbracket,andcushion.

43

Page 44

BeltMaintenance

ReplacingtheTransmission

Belt

ReplacingtheMower-Deck

Belt

ServiceInterval:Every100hours—Checkthemower-deck

belt.

Signsofawornbeltincludesqueakingwhenthebeltis

rotating,aslippingbladewhencuttinggrass,afrayedbelt

edge,burnmarks,andcracks.Replacethedeckbeltifanyof

theseconditionsareevident.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.ReplacethebeltasshowninFigure63.

ServiceInterval:Every1,000hours—Replacethe

transmissionbelt.

1.Removethefueltank;refertoRemovingtheFuelTank

(page35).

2.Removethehydraulic-reservoircap.

3.Locatethedrainplugsinthebottomofthetransmission

andplaceadrainpanundertheplug(Figure64).

Figure64

1.Drainplug

Figure63

4.Allowthehydraulicuidtodrainfromthemachine.

5.Removethelowerhydraulichose(Figure65).

Figure65

1.Lowerhydraulichose3.T ensionspring

2.Transmissionbelt

6.Removethetensionspring(Figure65).

CAUTION

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Wearsafetyglassesandbecarefulwhen

removingthespring.

44

Page 45

7.Removethedeckbeltfromtheclutchandclutchstop

(Figure65).

ControlsSystem

8.Installthenewbelt.

9.Installthetensionspringandlowerhydraulichose.

10.Installthedrainplugs.

11.Addhydraulicuidtothelllevel.

12.Installthehydraulic-reservoircap.

13.Runthemachinefor10minutesandverifythatthe

hydraulicuidisatthecorrectlevel.

Maintenance

AdjustingtheMotion-Control Levers