Page 1

Micro-Irrigation

Chemical Injection

®

azzei

M

Mazzei injectors offer an economical highly efficient means of injecting

gases and liquids, such as chlorine, fertilizers, and other agricultural

chemicals into a pressurized water system. Mazzei injectors use differential

pressure to create a low-pressure zone which draws the chemicals into a

pressurized water line.

Operation:

Mazzei injectors are venturi-type injectors:

When pressurized water enters the injector inlet, it is constricted toward the

injection chamber and changes into a high-velocity jet stream. The increase

in velocity through the injection chamber results in a decrease in pressure,

thereby enabling an additive material to be drawn through the suction port

and entrained into the water stream. As the jet stream is diffused toward the

injector outlet, its velocity is reduced and it is reconverted into pressure

energy (but at a pressure lower than injector inlet pressure).

Application:

• Agricultural irrigation systems using drip and/or sprinkler irrigation,

or any pressurized water system where a gas or liquid needs to be injected

njectors

I

Features and Benefits:

• Saves labor

• Safe to use as the chemicals are under vacuum, not pressure

• Ensures even distribution of chemicals

• No external power source is required in most systems

• Low maintenance - no moving parts

• Chemicals cannot be injected when the irrigation system is off

• Available in Polypropylene or PVDF (Kynar

resistant to most chemicals, including acids

• Available with NPT or BSPT threads

Why PVDF (Kynar)?

Kynar is extremely resistant to most agricultural chemicals: Sulfuric acid,

Nitric acid, Chlorine, and Gypsum (Gypsum is very abrasive). Polypropylene

is not recommended for the above materials.

®

) - Kynar is extremely

Page 2

Required Information for Liquid Injection Applications

The following information and calculations are required to determine the proper size and model of

Mazzei injector for liquid fertilizer injection. Below is a worksheet.

1. Determine total water flow (gpm or lpm): ______

2. Determine rate of injection required in (gph or l/min): ______

3. Determine pressure differential across injector:

a. System, or pump pressure at inlet to injector in (psi or Kg/cm2) ______

b. Pressure (back pressure) at outlet of injector in (psi or Kg/cm2) ______

2

c. Available pressure differential (3a – 3b) in (psi or Kg/cm

d. Percentage pressure differential [(3c/3a)x(100)] ______%

3.4. Determine installation method:

) ______

a. If the pressure differential (3d above) is 20% or greater, the injector can be

utilized without a booster pump. See “Typical Installations” page.

b. If the pressure differential (3d above) is less than 20%, the injector must be

installed in series with a booster pump. See “Typical Installations” page.

Injector Selection:

The injector performance tables in this

brochure list the motive flow values and suction

capacities for Mazzei®injectors under various

pressure conditions. Other applications exist

that are not covered in this brochure. Please

consult a Toro Micro Irrigation representative for

help with those inquires.

From the calculations above, use the

performance tables in the back of this brochure

to select an injector model that can exceed the

required injection (suction) rate. The total

water flow of the system must be greater than

the injector’s motive flow capacity (water flow

through the injector). The injector may be

installed in a “bypass” so that only the required

part of the total water flow passes through the

injector.

1. Locate the injector inlet pressure (psi or

Kg/cm2), step 3a above, which most

closely corresponds to your maximum

available water pressure.

2. Locate the injector outlet pressure (psi

or Kg/cm2), step 3b above,which most

closely corresponds to your system

pressure downstream of the injector

after installation.

3. Review the performance tables to

locate an injector model that has a

suction capacity that is greater than the

required suction capacity (gph or

l/min), step 2 above. Use a metering

valve or orifice assembly to obtain the

precise suction required.

Page 3

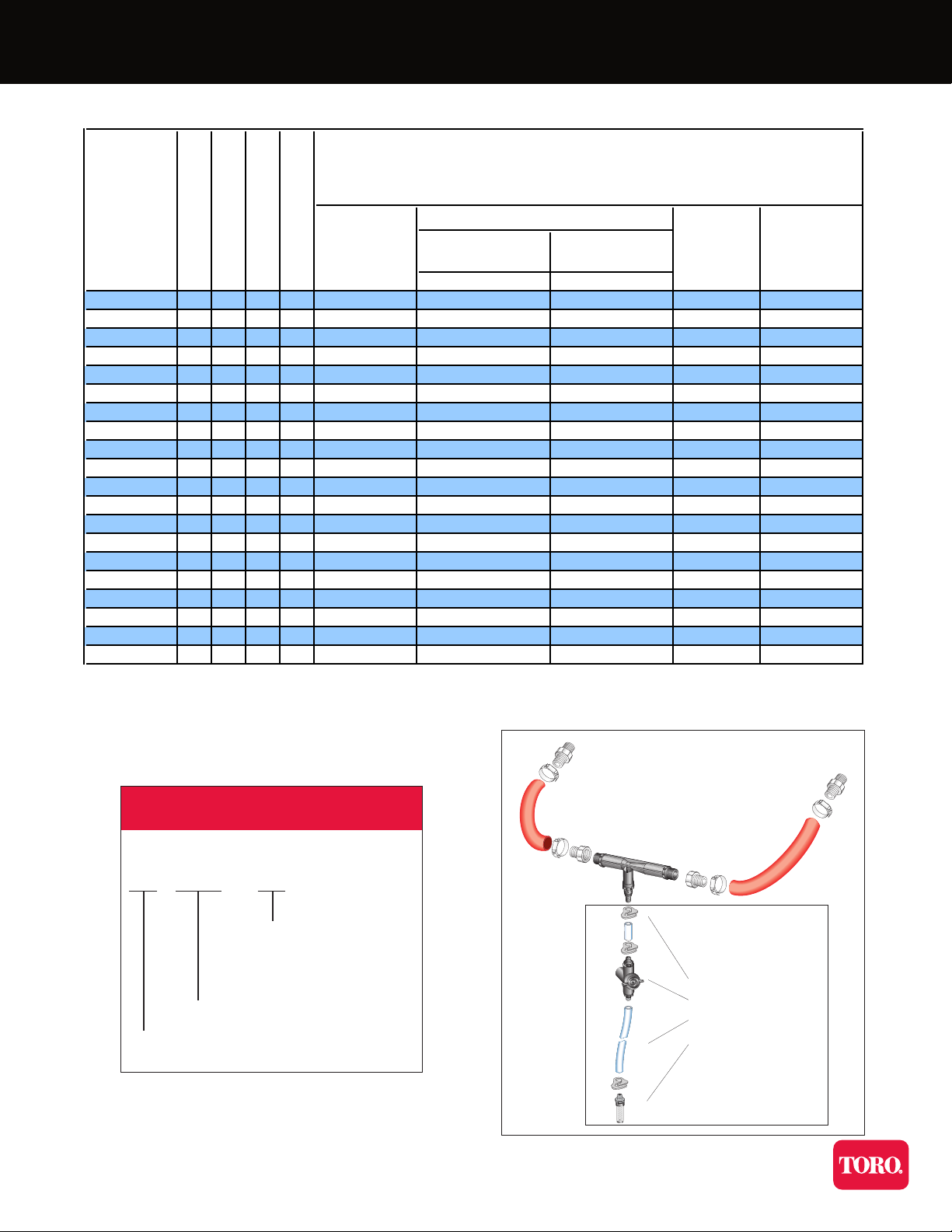

Injector Product Range

I

njector Injector Suction Bypass &

Model Size Line Kit Suction

Numbers In/Out Only Line Kit

MNPT or BSPT

gph lph

283 x x 1/2" 6.0 gph 22.7 lph K-184 K-184-A

287 x x 1/2" 8.3 gph 31.4 lph K-184 K-184-A

384 x x 1/2" 14.1 gph 53.4 lph K-184 K-184-A

384X x x 1/2" 33.9 gph 128.4 lph K-184 K-184-A

484 x x 1/2" 17.4 gph 65.9 lph K-184 K-184-A

584C x x 1/2" 25.6 gph 96.9 lph K-184 K-184-A

484A x x x 3/4" 17.4 gph 65.9 lph K-184 K-184-B

484X x x 3/4" 41.7 gph 157.8 lph K-184 K-184-B

584 x x x x 3/4" 25.6 gph 96.9 lph K-184 K-184-B

684 x x 3/4" 25.0 gph 95.0 lph K-184 K-184-B

878-02 x x x 1.0" 74.8 gph 283 lph K-183 K-181-A 02

885X-02 x x x x 1.0" 140 gph 530 lph K-183 K-181-A 02

1078-02 x x x x 1.0" 92.4 gph 350 lph K-183 K-181-A 02

1583A x x x x 1.5" 227 gph 860 lph K-183 K-183-A

1585X x x x 1.5" 323 gph 1222 lph K-183 K-183-A

1587 x x x 1.5" 261 gph 988 lph K-183 K-183-A

2081A x x x x 2.0" 631.0 gph 2388 lph K-282 K-282-A

2083X x x x 2.0" 1175.0 gph 4448 lph K-282 K-282-A

3090 x x 3.0" 1236 gph 4678 lph N/A N/A

4091 x x 4.0" 2820 gph 10673 lph N/A N/A

* Bypass and suction line kit combination is not available with BSPT threads for 1" and larger injectors

** 1/2" NPT threads are compatible with 1/2" BSPT threads

*** The 1" injectors ending with part number 02 have a new check valve design the same as the 1 1/2" injectors

NPT Polypropylene Black

NPT PVDF Black

Injector Models and Kit Assemblies

Maximum Suction Capacity

BSPT Polypropylene Green

BSPT PVDF Blue

@ 50 psi

@ 3.4 bars

Bypass and Suction Line Kit:

Specifying Information

AIV1583A-P (1.5" MNPT black poly injector)

XXX XXXXX - XXX

Example part number:

(blank) PVDF (Kynar®)

P Polypropylene black

PPG Polypropylene green

Injector model number

Suction Line Kit:

1. Tubing clamp

2. Metering Valve

3. Tubing (10FT.)

AIV NPT threads

AIC BSPT threads

4. Strainer

Note: Injector not

included in the kits

Page 4

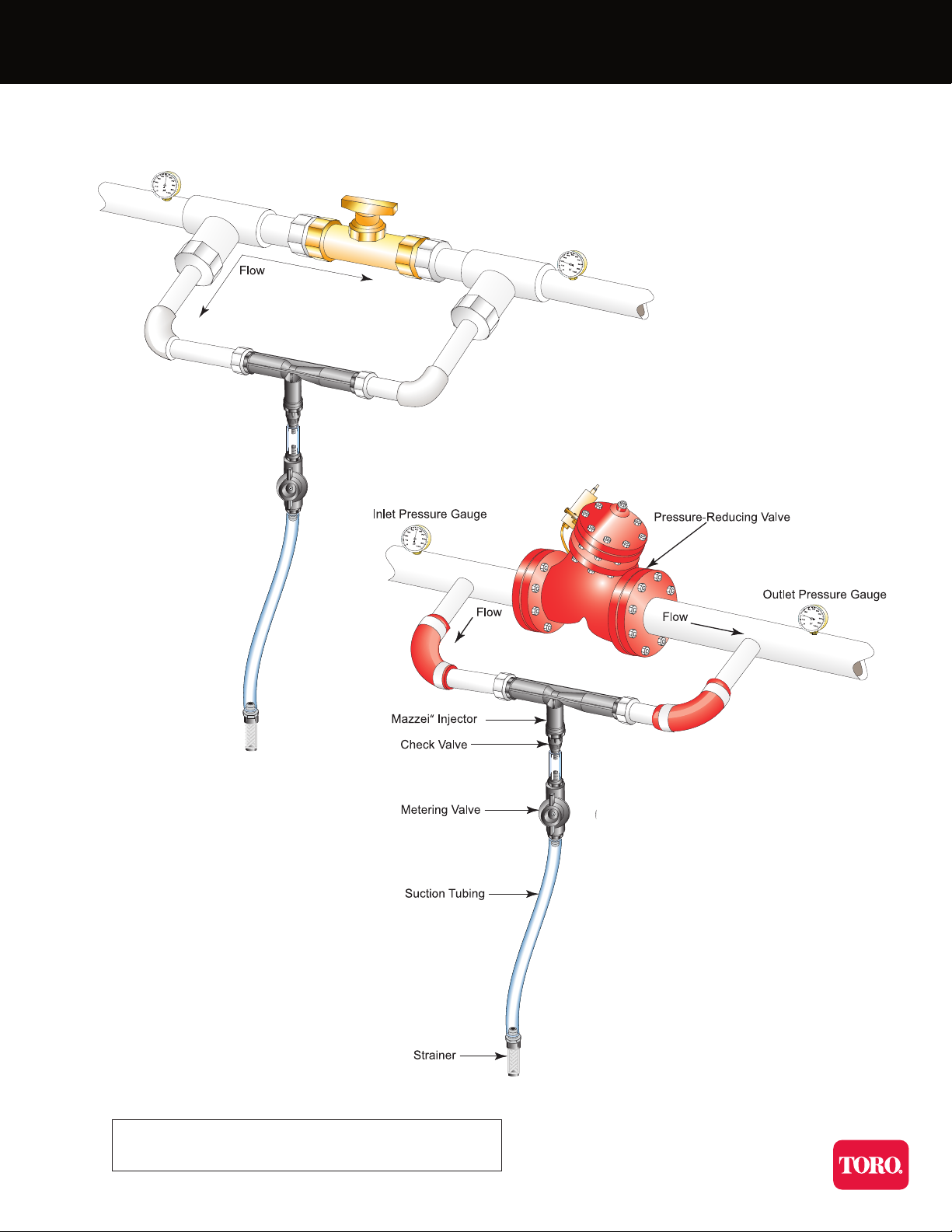

Typical Installations

Bypass installation

Note: Always consult state and local requirements

for backflow protection and chemical use

Injector installed around a

point of restriction such as a

regulator valve or gate valve

which creates a differential

pressure, thereby allowing the

injector to produce a vacuum.

Page 5

Typical Installations

Bypass with reduced pressure

differental requirement.

Chemical injection can be turned

on or off with a controller.

Injector installed across

the differential pressure

created by an existing

booster or supply pump

in the system. It is

plumbed from the

discharge side to the

intake side of the pump.

Booster pump installation

Page 6

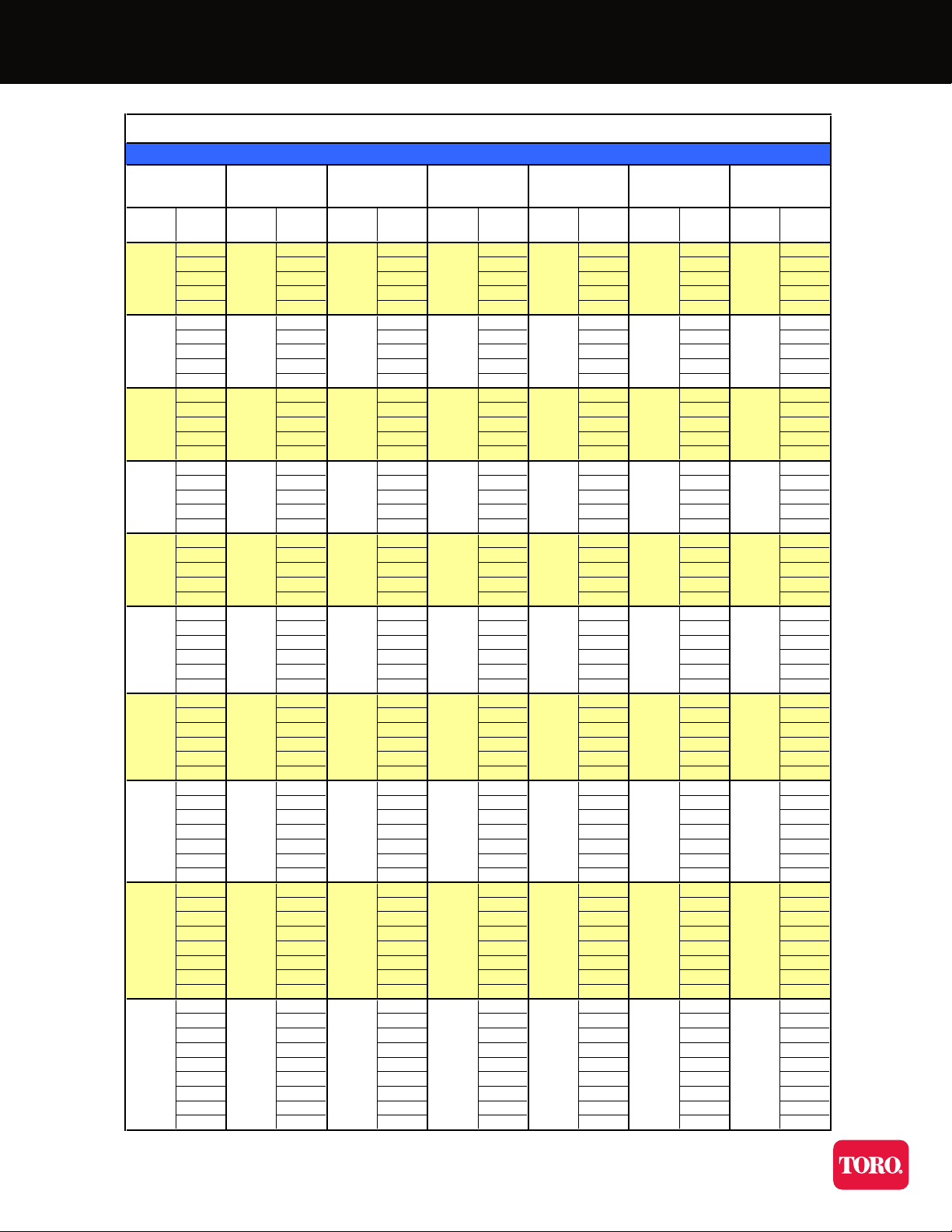

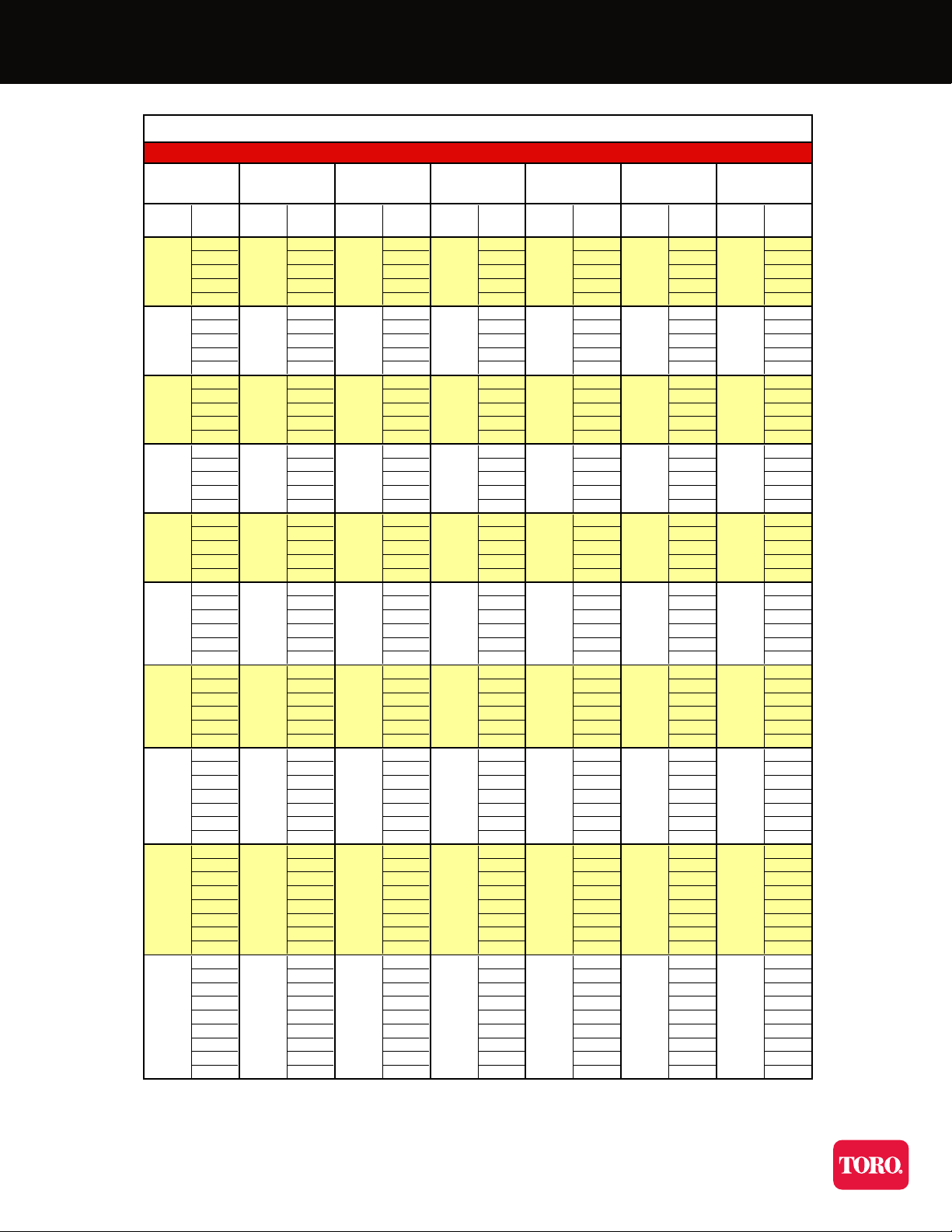

Performance Table

I

njector

Inlet

I

njector

Outlet

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

03.25.210.311.714.623.5

12.02.68.78.710.516.7

21.11.87.54.06.711.9

3 1.25.1 1.07.4

4

(

3.5)

(

3.5)

(

3.9) (2.9) (4.4) (3.5)

0

4.7 6.2 15.3 17.5 18.8 29.8

22.84.811.513.614.023.1

51.21.97.62.06.111.9

7 0.8 2.1 2.8 3.8

8

(

7.0)

(

7.7)

(

8.2) (6.6) (8.4) (7.5)

05.46.813.427.818.838.7

52.74.111.411.711.421.0

71.72.98.54.28.315.7

1

01.34.91.0

12

(10.5) (11.5)

(12.9) (9.6) (12.5) (9.6)

05.87.013.129.718.039.5

53.76.113.217.215.727.7

10 2.0 3.4 9.3 3.0 9.5 13.4

12 0.6 1.9 6.4 7.8 8.4

15

(15.0)

(16.0)

0.5

(16.5)

2.5

(12.4) (17.0)

1.0

(13.2)

05.97.814.233.117.939.6

54.86.914.322.417.332.1

10 2.6 4.4 12.7 11.2 13.8 22.0

15 0.7 2.3 6.7 7.4 9.9

20

(18.5)

(19.5)

(20.5) (15.0) (21.6)

1.0

(16.5)

06.08.014.233.917.239.8

55.87.914.424.717.038.1

10 3.8 5.6 13.9 17.3 16.6 28.8

15 2.4 3.6 10.7 7.0 11.3 17.0

20 0.8 1.7 4.5 7.1

25

(22.5)

(24.5)

(25.2) (18.0) (25.5) (19.8)

06.08.114.533.817.340.3

56.08.014.529.117.439.3

10 4.8 6.8 14.5 19.2 17.4 33.9

15 3.4 5.0 13.7 10.7 17.4 24.3

20 1.7 3.0 9.4 11.1 14.8

25

(26.0)

0.6

(27.0)

1.1

(28.6)

3.0

(20.8) (29.5)

4.0

(23.5)

06.08.114.234.017.140.8

56.08.114.231.617.738.7

10 5.5 7.4 14.0 24.1 17.7 38.5

15 4.2 6.3 14.0 14.3 17.7 29.9

20 2.6 4.3 12.6 3.6 15.2 20.7

25 1.2 2.7 7.5 11.4 6.5

30

(29.5)

(31.0)

0.3

(32.0)

2.0

(22.8) (33.3)

4.0

(26.1)

06.08.113.733.917.241.4

56.08.113.831.617.239.1

10 5.8 8.1 13.8 30.8 17.5 37.9

15 4.9 6.9 13.7 19.0 17.5 35.0

20 3.4 5.5 13.8 11.1 16.7 26.9

25 2.7 4.0 12.2 1.4 13.9 18.2

30 1.0 2.4 6.1 10.3

35

(33.5)

(35.0)

(36.1) (26.1) (36.8)

3.7

(29.6)

06.08.314.133.917.441.7

56.08.314.132.817.440.5

10 6.0 8.3 14.1 31.7 17.7 39.2

15 5.7 8.0 14.1 25.3 17.7 37.4

20 4.7 5.9 13.6 15.2 17.7 29.5

25 3.5 4.5 13.6 6.7 16.5 20.3

30 2.1 3.0 10.1 12.7 8.2

35 0.7 1.2 6.1 7.8

40

(37.0)

(39.0)

(39.6) (28.7) (41.0) (32.6)

1.21

.2

5

10

0

.170.290.70.7

0.24

0.32

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

1.7

2.1

1.7

50

45

25

30

35

15

Injector Performance Table

Water Suction Capacity • Injector Inlet Pressure 5-50 PSIG

Model 384X

Model 484

Model 484X

Model 283

Model 287

Model 384

O

perating Pressure

P

SIG

1

/2" & 3/4" Threads

1.0

1.0

1.2

1.9

1.9

20

40

0.35

0.41

2.1

0.32

0.51

1.4

1.4

2.4

2.4

0.28

1.2

0.42

2.7

0.39

0.65

1.7

1.7

2.9

2.9

0.58

1.6

1.6

3.2

0.43

0.75

2.0

2.0

3.4

3.4

0.70

2.7

2.1

2.1

3.6

3.2

3.6

0.48

0.85

2.2

2.2

3.8

3.8

0.46

0.81

3

/4" Threads

1

/2" Threads

1

/2" Threads

1

/2" Threads

1

/2" Threads

Page 7

Performance Table

I

njector

Inlet

I

njector

Outlet

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

029.227.462.978.1101.5135.8

128.920.336.162.646.484.5

228.513.823.842.722.253.3

325.46.67.315.52.7

4

(

4.4)

10.0

(

4.3)

5.6

(

4.0)

1.7

(

4.0) (4.0) (4.4)

0

28.3 27.2 93.8 115.9 105.8 219.9

228.227.362.090.875.7143.8

527.518.536.544.841.878.8

713.310.915.819.419.242.0

8

(

9.0)

11.0

(

8.5)

6.1

(

8.7)

3.7

(

7.5) (8.1)

4.4

(

8.6)

028.226.187.4135.3101.3225.2

527.926.162.183.279.9163.8

728.025.145.558.064.7124.4

1

014.012.923.619.234.386.5

12

(13.5)

11.0

(13.0)

7.0

(12.5)

7.2

(11.0) (13.1)

17.0

(13.0)

14.6

024.825.182.9141.998.2228.0

524.825.280.5117.495.4205.4

10 23.7 25.2 48.6 57.7 70.0 143.5

12 19.2 18.4 33.6 36.2 51.5 131.7

15

(18.0)

14.6

(16.5)

10.4

(16.5)

21.0

(14.0) (17.3)

30.3

(17.9)

66.2

025.224.882.3142.796.0226.8

525.224.981.3135.896.7226.4

10 25.1 24.9 73.2 96.5 89.4 193.9

15 20.8 24.4 45.3 38.4 68.2 148.1

20

(22.0)

12.2

(21.0)

5.2

(21.0)

20.1

(17.0) (21.9)

31.9

(22.1)

49.0

025.324.579.9144.194.4226.5

525.424.679.2140.794.5226.4

10 24.9 24.6 77.0 125.3 94.5 211.6

15 25.2 24.6 65.4 69.3 82.1 167.3

20 18.2 14.7 35.4 14.3 55.4 125.5

25

(27.0)

11.6

(26.0)

6.8

(26.1)

9.1

(20.5) (26.0)

17.9

(26.0)

18.3

025.524.779.4142.494.0226.7

525.524.679.4141.794.0226.5

10 25.4 24.7 77.5 135.7 94.0 224.2

15 25.3 24.8 74.5 106.7 91.9 205.7

20 21.9 24.9 52.3 54.2 74.1 164.8

25

(31.5)

16.5

(29.5)

12.9

(30.1)

30.3

(24.0) (30.0)

47.3

(29.4)

89.1

025.625.077.5141.093.2227.3

525.625.077.5141.193.2228.7

10 25.6 25.1 77.5 139.1 93.2 227.2

15 25.5 25.0 77.5 128.0 93.2 220.5

20 25.2 25.1 73.6 90.5 91.9 192.8

25 21.3 24.7 50.6 36.9 72.2 153.4

30

(35.5)

15.0

(35.0)

10.8

(34.4)

28.2

(27.0) (34.4)

42.7

(33.4)

81.5

025.925.079.6140.992.8227.9

526.025.079.6139.792.8228.3

10 26.0 25.0 79.6 139.2 92.8 228.0

15 25.9 25.1 79.6 134.8 92.8 223.5

20 25.7 25.1 78.8 112.1 93.9 212.4

25 23.6 25.1 67.0 74.5 86.9 174.9

30 19.4 20.6 44.2 23.2 66.2 113.1

35

(40.0)

13.5

(37.5)

8.4

(38.4)

22.0

(31.0) (38.7)

36.7

(37.5)

47.1

025.625.074.8139.692.4227.4

525.625.074.8140.592.4227.4

10 25.6 25.0 74.8 140.5 92.4 226.3

15 25.5 25.1 74.8 139.1 92.4 225.6

20 25.4 24.9 74.8 128.1 92.4 224.4

25 24.5 25.0 68.3 106.8 92.4 203.7

30 21.6 17.1 56.2 59.0 86.4 172.4

35 15.8 9.2 36.6 12.9 64.3 120.6

40

(45.0)

2.8

(42.0)

6.7

(42.3)

9.6

(36.0) (43.9)

35.0

(41.9)

40.5

5.5

9.3

1

" Threads

1

" Threads

5.1

8.6

9.0

8.7

1

" Threads

1

.5" Threads

14.5

28.4

21.5

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

32.2

6.6

11.1

11.6

11.3

11.0

10.7

6.3

10.5

17.3

33.9

5.9

9.9

10.3

10.1

15.5

30.3

9.7

9.4

7.1

11.0

8.0

3.6

4.7

7.8

8.2

3.65.51

0.7

3.0

5.0

5.2

5.0

7.7

15.2

Model 1078

Water Suction Capacity • Injector Inlet Pressure 5-50 PSIG

Model 1583A

12.2

24.0

Model 885X

3.53.76.1

6.3

15

13.4

26.3

16.4

6.2

9.5

18.6

4.2

7.0

7.3

10

Model 584

Model 684

2

.1

O

perating Pressure

P

SIG

1

/2" & 3/4" Threads

3

/4" Threads

Injector Performance Table

50

45

25

30

35

20

40

Model 878

5

Page 8

Performance Table

I

njector

I

nlet

I

njector

O

utlet

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

M

otive

Flow

G

PM

W

ater

Suction

G

PH

0123.5244.363045610502100

174.8102.96301589001500

226.391.5630 7561200

354.2215456840

4

(

3.5) (4.1) (4.5)

136

(

1.4) (4.0) (4.5)

360

0241.5269.763056114462820

2

155.9 249.1 630 154 1446 2820

543.4103.7468 8701860

758.3149396780

8

(

6.5) (8.7)

14.4

(

9.0)

30

(

2.4) (8.5) (8.8)

240

0262.0270.663167114342820

5157.7184.7623 14282820

786.6154.2576 10442280

10 98.6 213 552 720

12

(9.4) (13.5)

38.0

(13.3)

77

(3.7) (13.5)

300

(13.1)

360

0308.6267.163175714162820

5231.9265.763123714162820

10 120.2 174.6 468 1170 2700

12 39.3 142.0 299 792 1800

15

(12.7) (17.0)

88.0

(17.5)

152

(5.7) (17.0)

432

(17.5)

720

0324.6265.263181213442820

5275.5264.963142913442820

10 204.5 229.6 627 1356 2820

15 50.5 156.8 404 930 1980

20

(15.4) (22.1)

55.1

(22.3)

134

(7.1) (21.5)

114

(21.7)

420

0323.1263.563184913082820

5299.7261.563178013082820

10 251.2 268.3 631 1308 2820

15 137.5 200.4 511 1284 2580

20 164.8 341 576 1380

25

(19.3) (25.6)

33.4

(26.0)

62

(8.8) (25.5) (26.0)

240

0326.3285.763185312902820

5318.1284.763167012902820

10 286.7 287.7 631 288 1266 2820

15 204.1 251.8 627 1266 2820

20 66.7 191.7 460 906 2640

25

(22.4) (29.0)

143.8

(30.5)

256

(10.4) (29.5)

396

(30.5)

1440

0324.3287.063189712542820

5321.3284.963192012542820

10 307.8 282.6 631 389 1254 2820

15 257.1 278.4 631 1254 2820

20 146.6 244.5 524 1110 2820

25 11.9 180.3 394 714 1860

30

(25.5) (33.2)

115.5

(33.5)

169

(11.6) (32.5)

228

(35.0)

900

0326.0259.863194812602820

5324.1259.263174912602820

10 318.1 260.4 631 486 1260 2820

15 287.2 257.1 631 1260 2820

20 210.2 256.9 607 1200 2820

25 106.9 225.9 508 960 2820

30 157.1 341 582 2400

35

(28.7) (38.3)

73.5

(38.0)

149

(13.4) (36.0) (38.9)

960

0323.0260.5631117512362820

5319.3259.7631127812362820

10 315.5 259.7 631 579 1236 2820

15 296.7 258.3 631 1236 2820

20 251.8 257.3 631 1236 2820

25 156.8 252.4 588 1194 2820

30 45.4 205.4 453 882 2640

35 137.2 300 498 1620

40

(32.4) (41.0)

75.1

(41.5)

115

(14.4) (40.5) (43.1)

360

242

416

32.2

53.1

103

33.9

56.0

108

28.6

28.4

46.8

91

402

30.3

50.09726.4

24.0

39.67721.8

26.3

43.38423.1

1701

5.225.04813.1108214

Water Suction Capacity • Injector Inlet Pressure 5-50 PSIG

M

odel

4091

171

307

M

odel

2083X

1

7.734

30.7598.418.9

153

272

27.7

202

24.4

360

216

382

M

odel

1587

1

0.7

15

187

21.5

35.4

68

M

odel

3090

7618.6

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

1

.5" Threads

2

" Threads

2

" Threads

3

" Threads

332

229

16.1

132

251

5

10

M

odel

1585X

O

perating Pressure

P

SIG

1

.5" Threads

Injector Performance Table

50

45

25

30

35

20

40

M

odel

2081

4

" Threads

Page 9

Performance Table – metric

Injector

Inlet

Injector

Outlet

Motive

Flow

l

/min.

Water

Suction

l

/min.

Motive

Flow

l

/min.

Water

Suction

l

/min.

Motive

Flow

l

/min.

Water

Suction

l

/min.

Motive

Flow

l

/min.

Water

Suction

l

/min.

Motive

Flow

l

/min.

Water

Suction

l

/min.

Motive

Flow

l

/min.

Water

Suction

l

/min.

0.00 0.20 0.33 0.65 0.74 0.92 1.48

0.07 0.13 0.16 0.55 0.55 0.66 1.05

0.14 0.07 0.11 0.47 0.25 0.42 0.75

0.21 0.08 0.32 0.06 0.46

0.28

(0.25)

(0.25) (0.27) (0.20) (0.31) (0.25)

0.00 0.30 0.39 0.97 1.11 1.18 1.88

0.14 0.18 0.30 0.73 0.86 0.88 1.46

0

.35 0.08 0.12 0.48 0.38 0.75

0.49 0.05 0.13 0.18 0.24

0

.56

(0.49)

(0.54) (0.58) (0.46) (0.59) (0.53)

0.00 0.34 0.43 0.84 1.75 1.18 2.44

0.35 0.17 0.26 0.72 0.74 0.72 1.32

0.49 0.11 0.18 0.53 0.26 0.52 0.99

0.70 0.08 0.31 0.06

0.84

(

0.74) (0.81) (0.91) (0.68) (0.88) (0.68)

0.00 0.37 0.44 0.82 1.87 1.14 2.49

0.35 0.23 0.38 0.83 1.08 0.99 1.74

0.70 0.13 0.21 0.58 0.19 0.60 0.84

0

.84 0.04 0.12 0.40 0.49 0.53

1.05

(1.06)

(1.13)

0.03

(1.16)

0.16

(0.87) (1.20)

0.06

(0.93)

0.00 0.37 0.49 0.89 2.09 1.13 2.50

0.35 0.30 0.44 0.90 1.41 1.09 2.03

0.70 0.16 0.28 0.80 0.71 0.87 1.39

1.05 0.04 0.15 0.42 0.47 0.63

1.41

(1.30)

(1.37) (1.44) (1.06) (1.52)

0.06

(1.16)

0.00 0.38 0.50 0.90 2.14 1.09 2.51

0.35 0.37 0.50 0.91 1.56 1.08 2.41

0.70 0.24 0.35 0.88 1.09 1.05 1.82

1.05 0.15 0.23 0.68 0.44 0.71 1.07

1.41 0.05 0.11 0.29 0.45

1.76

(1.58)

(1.72) (1.77) (1.27) (1.79) (1.39)

0.00 0.38 0.51 0.91 2.13 1.09 2.54

0.35 0.38 0.50 0.91 1.83 1.10 2.48

0.70 0.30 0.43 0.91 1.21 1.10 2.14

1.05 0.21 0.32 0.87 0.68 1.10 1.53

1.41 0.11 0.19 0.59 0.70 0.93

1.76

(1.83)

0.04

(1.90)

0.07

(2.01)

0.19

(1.46) (2.07)

0.25

(1.65)

0.00 0.38 0.51 0.89 2.14 1.08 2.57

0.35 0.38 0.51 0.89 1.99 1.12 2.44

0.70 0.35 0.47 0.88 1.52 1.12 2.43

1.05 0.26 0.40 0.88 0.90 1.12 1.89

1.41 0.16 0.27 0.80 0.22 0.96 1.31

1.76 0.08 0.17 0.47 0.72 0.41

2.11

(2.07)

(2.18)

0.02

(2.25)

0.13

(1.60) (2.34)

0.25

(1.84)

0.00 0.38 0.51 0.87 2.14 1.09 2.61

0.35 0.38 0.51 0.87 2.00 1.09 2.46

0.70 0.37 0.51 0.87 1.94 1.10 2.39

1.05 0.31 0.44 0.87 1.20 1.10 2.21

1.41 0.21 0.35 0.87 0.70 1.05 1.70

1.76 0.17 0.25 0.77 0.09 0.87 1.15

2.11 0.06 0.15 0.39 0.65

2.46

(2.36)

(2.46) (2.54) (1.84) (2.59)

0.23

(2.08)

0.00 0.38 0.52 0.89 2.14 1.10 2.63

0.35 0.38 0.52 0.89 2.07 1.10 2.55

0.70 0.38 0.52 0.89 2.00 1.12 2.47

1.05 0.36 0.50 0.89 1.60 1.12 2.36

1.41 0.30 0.37 0.86 0.96 1.12 1.86

1.76 0.22 0.28 0.86 0.42 1.04 1.28

2.11 0.13 0.19 0.64 0.80 0.52

2.46 0.04 0.08 0.38 0.49

2.81

(2.60)

(2.74) (2.78) (2.02) (2.88) (2.29)

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

13.55

13.55

1.82

3.22

8.48

8.48

14.27

14.27

1.74

3.07

8.06

8.06

11.96

12.76

12.76

2.65

7.12

11.96

7.12

2.84

7.61

7.61

5.37

2.20

6.59

6.02

1.93

5.37

6.02

9.01

4.66

11.05

10.11

11.05

9.01

7.83

10.11

7.83

2.46

6.59

1

.213.79

1.59

2.69

1.10

2.69

6

.403.79

1.41

2.81

1.32

1.55

1.48

1.21

1.63

0

.35

0.70

4.66

1.05

1.06

3.52

3.16

1.76

2.11

2.46

M

odel

283

0.64

0

.91

Injector Performance Table

Water Suction Capacity • Injector Inlet Pressure 0.35-3.52 Kg/cm

2

M

odel

384X

M

odel

484

M

odel

484X

M

odel

287

M

odel

384

Operating Pressure

Kg/cm

2

1/2" Threads

1/2" Threads

6

.40

4.50

4.50

1/2" Threads

1/2" Threads

1/2" & 3/4" Threads

3/4" Threads

Page 10

Performance Table – metric

Injector

I

nlet

Injector

O

utlet

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

0.00 1.84 1.73 3.97 4.92 6.40 8.57

0.07 1.82 1.28 2.28 3.95 2.93 5.33

0.14 1.80 0.87 1.50 2.69 1.40 3.36

0.21 1.60 0.42 0.46 0.98 0.17

0.28

(0.31)

0.63

(0.30)

0.35

(0.28)

0.11

(0.28) (0.28) (0.31)

0

.00 1.78 1.72 5.92 7.31 6.67 13.87

0

.14 1.78 1.72 3.91 5.73 4.78 9.07

0.35 1.73 1.17 2.30 2.82 2.64 4.97

0.49 0.84 0.69 1.00 1.22 1.21 2.65

0

.56

(

0.63)

0

.69

(

0.60)

0

.38

(

0.61)

0

.23

(

0.53) (0.57)

0

.28

(

0.61)

0.00 1.78 1.65 5.51 8.54 6.39 14.21

0.35 1.76 1.65 3.92 5.25 5.04 10.33

0.49 1.77 1.58 2.87 3.66 4.08 7.85

0.70 0.88 0.81 1.49 1.21 2.16 5.46

0.84

(

0.95)

0.70

(

0.91)

0.44

(

0.88)

0.45

(

0.77) (0.92)

1.07

(

0.91)

0.92

0.00 1.57 1.59 5.23 8.95 6.20 14.39

0.35 1.57 1.59 5.08 7.40 6.02 12.96

0.70 1.50 1.59 3.07 3.64 4.42 9.06

0

.84 1.21 1.16 2.12 2.28 3.25 8.31

1.05

(1.27)

0.92

(1.16)

0.66

(1.16)

1.33

(0.98) (1.22)

1.91

(1.26)

4.18

0.00 1.59 1.57 5.19 9.00 6.05 14.31

0.35 1.59 1.57 5.13 8.56 6.10 14.28

0.70 1.59 1.57 4.62 6.09 5.64 12.23

1.05 1.31 1.54 2.86 2.42 4.30 9.34

1.41

(1.55)

0.77

(1.48)

0.33

(1.48)

1.27

(1.20) (1.54)

2.01

(1.55)

3.09

0.00 1.60 1.55 5.04 9.09 5.95 14.29

0.35 1.60 1.55 5.00 8.88 5.96 14.28

0.70 1.57 1.55 4.86 7.90 5.96 13.35

1.05 1.59 1.55 4.12 4.37 5.18 10.55

1.41 1.15 0.93 2.23 0.91 3.50 7.92

1.76

(1.90)

0.73

(1.83)

0.43

(1.84) (1.44) (1.83)

1.13

(1.83)

1.15

0.00 1.61 1.56 5.01 8.98 5.93 14.30

0.35 1.61 1.55 5.01 8.94 5.93 14.29

0.70 1.60 1.56 4.89 8.56 5.93 14.14

1.05 1.59 1.56 4.70 6.73 5.80 12.98

1.41 1.38 1.57 3.30 3.42 4.68 10.40

1.76

(2.22)

1.04

(2.07)

0.82

(2.12)

1.91

(1.69) (2.11)

2.98

(2.07)

5.62

0.00 1.62 1.57 4.89 8.89 5.88 14.34

0.35 1.61 1.58 4.89 8.90 5.88 14.43

0.70 1.62 1.59 4.89 8.77 5.88 14.33

1.05 1.61 1.58 4.89 8.08 5.88 13.91

1.41 1.59 1.58 4.64 5.71 5.79 12.17

1.76 1.35 1.56 3.19 2.33 4.56 9.68

2.11

(2.50)

0.95

(2.46)

0.68

(2.42)

1.78

(1.90) (2.42)

2.69

(2.35)

5.14

0.00 1.63 1.58 5.02 8.89 5.86 14.38

0.35 1.64 1.58 5.02 8.81 5.86 14.40

0.70 1.64 1.58 5.02 8.78 5.86 14.38

1.05 1.63 1.58 5.02 8.51 5.86 14.10

1.41 1.62 1.58 4.97 7.07 5.92 13.40

1.76 1.49 1.59 4.23 4.70 5.48 11.03

2.11 1.22 1.30 2.79 1.46 4.18 7.13

2.46

(2.81)

0.85

(2.64)

0.53

(2.70)

1.39

(2.18) (2.72)

2.32

(2.64)

2.97

0.00 1.61 1.58 4.72 8.81 5.83 14.35

0.35 1.61 1.58 4.72 8.86 5.83 14.35

0.70 1.61 1.58 4.72 8.86 5.83 14.28

1.05 1.61 1.58 4.72 8.77 5.83 14.23

1.41 1.60 1.57 4.72 8.08 5.83 14.16

1.76 1.54 1.57 4.31 6.73 5.83 12.85

2.11 1.36 1.08 3.54 3.72 5.45 10.88

2.46 0.99 0.58 2.31 0.82 4.06 7.61

2.81

(3.16)

0.18

(2.95)

0.42

(2.97)

0.60

(2.53) (3.09)

2.21

(2.95)

2.55

Injector Performance Table

M

odel

885X

M

odel

684

M

odel

878

Water Suction Capacity • Injector Inlet Pressure 0.35-3.52 Kg/cm

2

50.76

13.25

13.82

3/4" Threads

1" Threads

1" Threads

13.70

1" Threads

3.52

3.16

1.76

2.11

2.46

1.41

2.81

1.05

99.5

62.19

23.35

35.88

70.3

46.33

90.8

26.99

41.45

81.2

1

9.0829.3057.4

M

odel

1078

M

odel

1583A

13.47

20.74

40.6

1.5" Threads

0.70

M

odel

584

7.91

Operating Pressure

Kg/cm

2

1

1.20

1/2" & 3/4" Threads

0.35

1

8.7719.57

19.38

32.48

33.88

15.82

26.53

27.67

22.97

23.96

33.04

17.68

29.67

30.92

30.17

22.37

37.51

39.10

38.15

20.93

35.09

36.56

35.69

41.48

40.46

54.84

107.4

58.63

114.8

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

121.8

25.02

41.94

43.72

42.66

65.56

128.4

23.73

39.78

Page 11

Performance Table – metric

Injector

Inlet

Injector

Outlet

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

Motive

Flow

l/min.

Water

Suction

l/min.

0.00 7.8 15.4 39.7 28.8 66.2 132.5

0.07 4.7 6.5 39.7 10.0 56.8 94.6

0.14 1.7 5.8 39.7 47.7 75.7

0

.21 3.4 13.5 28.8 53.0

0.28

(

0.25) (0.29) (0.32)

8.6

(

0.10) (0.28) (0.32)

22.7

0

.00 15.2 17.0 39.7 35.4 91.2 177.9

0.14 9.8 15.7 39.7 9.7 91.2 177.9

0

.35 2.7 6.5 29.5 54.9 117.3

0.49 3.7 9.4 25.0 49.2

0.56

(

0.46) (0.61)

0.9

(

0.63)

1.9

(

0.17) (0.60) (0.62)

15.1

0.00 16.5 17.1 39.8 42.4 90.5 177.9

0.35 10.0 11.7 39.3 90.1 177.9

0.49 5.5 9.7 36.4 65.9 143.8

0.70 6.2 13.4 34.8 45.4

0.84

(0.66) (0.95)

2.4

(0.94)

4.8

(0.26) (0.95)

18.9

(0.92)

22.7

0.00 19.5 16.8 39.8 47.8 89.3 177.9

0

.35 14.6 16.8 39.8 14.9 89.3 177.9

0.70 7.6 11.0 29.5 73.8 170.3

0.84 2.5 9.0 18.8 50.0 113.6

1.05

(0.89) (1.20)

5.5

(1.23)

9.6

(0.40) (1.20)

27.3

(1.23)

45.4

0.00 20.5 16.7 39.8 51.2 84.8 177.9

0.35 17.4 16.7 39.8 27.1 84.8 177.9

0.70 12.9 14.5 39.5 85.5 177.9

1.05 3.2 9.9 25.5 58.7 124.9

1.41

(1.08) (1.55)

3.5

(1.57)

8.5

(0.50) (1.51)

7.2

(1.53)

26.5

0.00 20.4 16.6 39.8 53.6 82.5 177.9

0.35 18.9 16.5 39.8 49.2 82.5 177.9

0.70 15.8 16.9 39.8 82.5 177.9

1.05 8.7 12.6 32.3 81.0 162.8

1.41 10.4 21.5 36.3 87.1

1.76

(1.36) (1.80)

2.1

(1.83)

3.9

(0.62) (1.79) (1.83)

15.1

0.00 20.6 18.0 39.8 53.8 81.4 177.9

0.35 20.1 18.0 39.8 42.3 81.4 177.9

0.70 18.1 18.1 39.8 18.2 79.9 177.9

1.05 12.9 15.9 39.5 79.9 177.9

1.41 4.2 12.1 29.0 57.2 166.5

1.76

(1.58) (2.04)

9.1

(2.14)

16.1

(0.73) (2.07)

25.0

(2.14)

90.8

0.00 20.5 18.1 39.8 56.6 79.1 177.9

0.35 20.3 18.0 39.8 58.0 79.1 177.9

0.70 19.4 17.8 39.8 24.5 79.1 177.9

1.05 16.2 17.6 39.8 79.1 177.9

1.41 9.2 15.4 33.0 70.0 177.9

1.76 0.8 11.4 24.9 45.0 117.3

2.11

(1.79) (2.33)

7.3

(2.36)

10.7

(0.82) (2.29)

14.4

(2.46)

56.8

0.00 20.6 16.4 39.8 59.8 79.5 177.9

0.35 20.4 16.4 39.8 47.2 79.5 177.9

0.70 20.1 16.4 39.8 30.6 79.5 177.9

1.05 18.1 16.2 39.8 79.5 177.9

1.41 13.3 16.2 38.3 75.7 177.9

1.76 6.7 14.3 32.0 60.6 177.9

2.11 9.9 21.5 36.7 151.4

2.46

(2.02) (2.69)

4.6

(2.67)

9.4

(0.94) (2.53) (2.74)

60.6

0.00 20.4 16.4 39.8 74.1 78.0 177.9

0.35 20.1 16.4 39.8 80.6 78.0 177.9

0.70 19.9 16.4 39.8 36.5 78.0 177.9

1.05 18.7 16.3 39.8 78.0 177.9

1.41 15.9 16.2 39.8 78.0 177.9

1.76 9.9 15.9 37.1 75.3 177.9

2.11 2.9 13.0 28.6 55.6 166.5

2.46 8.7 18.9 31.4 102.2

2.81

(2.28) (2.88)

4.7

(2.92)

7.3

(1.01) (2.85) (3.03)

22.7

** Numbers in parenthesis indicate the injector outlet pressure when suction stops (Zero Suction Point). **

1522

128.4

211.8

410

108.3

916

1575

121.8

200.9

389

104.8

765

1363

818

1446

867

177.2

343

92.4

114.8

189.4

366

99.9

82.5

81.2

134.0

259

1.41

2.81

Model 2081

60.9

99.5

164.0

317

87.4

107.4

224

Injector Performance Table

1.05

130

500

950

643

57.4

94.7

183

49.6

3.52

3.16

1.76

2.11

2.46

708

1257

647

1

.5" Threads

2

" Threads

409

810

31.8

288

71.5

70.3

116.0

2

" Threads

1162

40.6

579

1030

90.8

149.7

290

0.35

0.70

3

" Threads

4

" Threads

Operating Pressure

Kg/cm

2

1

.5" Threads

67.0

Model 1587

Model 1585X

Water Suction Capacity • Injector Inlet Pressure 0.35-3.52 Kg/cm

2

Model 4091

Model 2083X

Model 3090

Page 12

Emission Devices

Micro VI PC Emitters Aqua-Traxx PC

Irrigation Controllers

Jr Max MC E Total Control

Control Valves

700 Series Valve 600 Series Valve Sentinel Valve

©2012 The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue, El Cajon, CA 92020-1523, USA

Tel: +1(800) 333-8125 or +1 (619) 562-2950

Fax: +1 (800) 892-1822 or +1 (619) 258-9973

toro.com

ALT032 08/08

Loading...

Loading...