Page 1

FormNo.3373-685RevA

CCR™6053R/ESQuickClearSnowthrower

ModelNo.38567—SerialNo.313000001andUp

ModelNo.38569—SerialNo.313000001andUp

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.It

isdesignedprimarilyforremovingsnowfrom

pavedsurfaces,suchasdrivewaysandsidewalks,

andothersurfacesfortrafconresidentialor

commercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisit

designedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourmachineproperlyandtoavoidinjury

andmachinedamage.Youareresponsibleforoperating

themachineproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

machineandaccessoryinformation,helpndinga

dealer,ortoregisteryourmachine.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourmachineready.

Figure1identiesthelocationofthemodelandserial

numbersonthemachine.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Safety

Readandunderstandthecontentsofthismanual

beforeyoustarttheengine.

Thisisthesafetyalertsymbol.Itisusedtoalert

youtopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthismachine

couldresultininjuryordeath.T oreducethis

potential,complywiththefollowingsafety

instructions.

Training

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren.

•Exercisecautiontoavoidslippingorfalling.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Avoidloosetting

clothingthatcangetcaughtinmovingparts.Wear

footwearthatwillimprovefootingonslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

llthefueltankindoors.

–Neverllcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersontheground,awayfromyour

vehicle,beforelling.

–Whenpractical,removegas-poweredmachinery

fromthetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuelsuch

machineryonatrailerwithaportablecontainer,

ratherthanfromagasolinedispensernozzle.

–Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimes,until

refuelingiscomplete.Donotuseanozzle

lock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilled

fuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

–Donotsmokewhilehandlinggasoline.

•Useextensioncordsandreceptaclesasspecied

bythemanufacturerforallmachineswithelectric

startingmotors.

•Donotattempttoclearsnowfromagravelor

crushedrocksurface.Thismachineisintendedfor

useonlyonpavedsurfaces.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwhenspecically

recommendedbymanufacturer).

•Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repairtoprotecteyesfromforeignobjectsthatmay

bethrownfromthemachine.

•Lettheengineandmachineadjusttooutdoor

temperaturesbeforestartingtoclearthesnow.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removetheignitionkey,thoroughlyinspectthe

machineforanydamage,andrepairthedamage

beforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtherotorbladehousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairing,orinspectingthemachine,

stoptheengineandmakecertainthattherotor

bladesandallmovingpartshavestopped.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards

andothersafetyprotectivedevicesinplaceand

working.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildren

andothersaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Lookbehindandusecarewhenbackingupwiththe

machine.

•Disengagepowertotherotorbladeswhenthe

machineisbeingtransportedornotinuse.

•Neveroperatethemachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

rmholdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer(

Figure3).

2

Page 3

Figure3

ClearingaCloggedDischarge

Chute

Handcontactwiththerotatingrotorbladesinsidethe

dischargechuteisthemostcommoncauseofinjury

associatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent,

suchashotwaterheaters,spaceheaters,orclothes

dryers.Allowtheenginetocoolbeforestoringin

anyenclosure.

•AlwaysrefertotheOperator’sManualforimportant

detailsifthemachineistobestoredforanextended

periodoftime.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upoftherotorblades.

ToroSnowthrowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingrotorbladescaninjurengersor

hands.Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Beforeadjusting,cleaning,repairing,andinspecting

themachine,andbeforeuncloggingthedischarge

chute,stoptheengine,removethekey,andwait

forallmovingpartstostop.

•Beforeleavingtheoperatingposition,stopthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.Also,tightenanyloosefasteners.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine

andremovethekey.Ifmajorrepairsareeverneeded,

contactanAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,

drainthefuelfromthefueltanktopreventa

potentialhazard.Storefuelinanapprovedfuel

container.Removethekeyfromtheignitionswitch

beforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

SoundPressure

Thismachinehasasoundpressurelevelattheoperator’s

earof88dBA,whichincludesanUncertaintyValue(K)

of1dBA.Thesoundpressurelevelwasdetermined

accordingtotheproceduresoutlinedinENISO11201.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof104

dBA,whichincludesanUncertaintyValue(K)of3.75

dBA.Thesoundpowerlevelwasdeterminedaccording

totheproceduresoutlinedinENISO3744.

3

Page 4

Hand-ArmVibration

Measuredvibrationlevelforthelefthand=8.4m/s

2

Measuredvibrationlevelfortherighthand=10.7m/s

2

UncertaintyValue(K)=4.3m/s

2

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

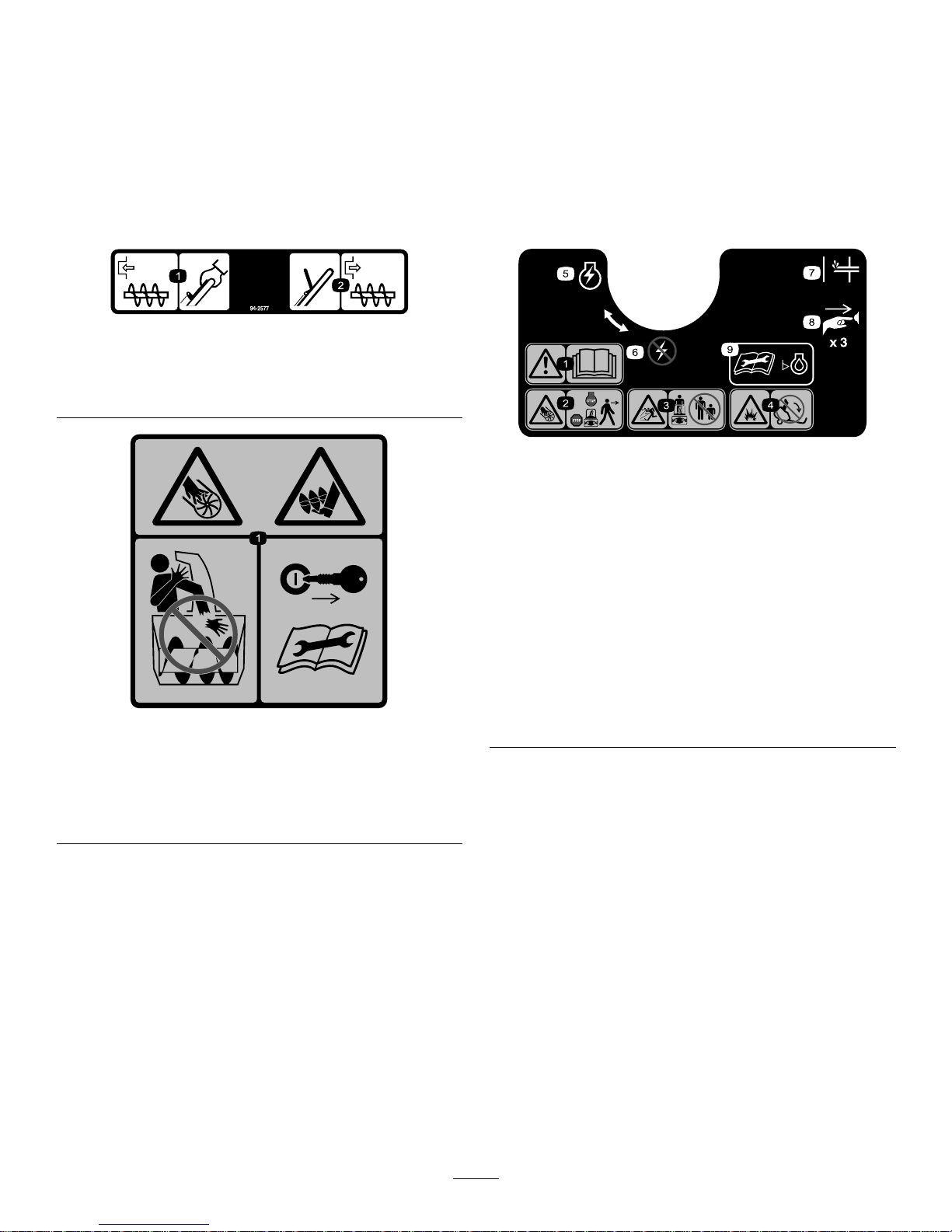

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

94-2577

1.Toengagetherotorblades,holdthecontrolbaragainst

thehandle.

2.Todisengagetherotorblades,releasethecontrolbar.

115–5698

Orderpartno.117-9121

1.Cuttingdismembermenthazards,impellerandauger—do

notplaceyourhandinthechute;removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance.

117-9102

Orderpartno.117-6036

1.Warning—readthe

Operator'sManual.

6.EngineswitchOff

2.Cutting/dismemberment

hazard,impeller—stopthe

enginebeforeleavingthe

machine.

7.Primer

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

8.Pushtheprimerthree

timestoprimetheengine.

4.Fuelspillhazard—donot

tipmachinebackward.

9.ReadtheOperator's

Manualbeforechecking

engineoillevel.

5.EngineswitchOn

4

Page 5

117-9103

Orderpartno.117-6046

1.Warning—readthe

Operator'sManual.

6.EngineswitchOff

2.Cutting/dismemberment

hazard,impeller—stopthe

enginebeforeleavingthe

machine.

7.Primer

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

8.Pushtheprimerthree

timestoprimetheengine.

4.Fuelspillhazard—donot

tipmachinebackward.

9.ReadtheOperator's

Manualbeforechecking

engineoillevel.

5.EngineswitchOn

10.Plugthemachineinto

powertheelectricstarter .

5

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

Nopartsrequired

–

Unfoldthehandle.

Screws

3

2

Chuteassembly

1

Installthedischargechute.

1

UnfoldingtheHandle

NoPartsRequired

Procedure

1.Loosenthehandleknobs,pulloutthe“U”-shaped

handlelocksuntilyoucanmovethehandlefreely,

androtatethehandletotheoperatingposition

(

Figure4).

Figure4

1.“U”-shapedhandlelock(2)

2.Handleknobs

2.Inserttheendofthe“U”-shapedhandlelockinto

theopenholeinthehandleandtightenthehandle

knobsuntiltheyaresnug(Figure5).

Figure5

Important:Ensurethatyoudonotpinchor

kinkthecontrolcableortheQuickShoot™

cables(Figure6).

Figure6

1.Controlcable2.QuickShoot™cables

6

Page 7

2

InstallingtheDischargeChute

Partsneededforthisprocedure:

3

Screws

1

Chuteassembly

Procedure

Installthedischargechuteasshown(Figure7).

Figure7

1.Dischargechute

2.Screw(3)

Note:Foreasierinstallation,useasmallratchetwrench

totightenthescrews.

Important:Donotovertightenthescrews;

otherwiseyoumaydamagethedischargechuteand

preventitfromturningfreely.

3

FillingtheEnginewithOil

NoPartsRequired

Procedure

Yourmachinedoesnotcomewithoilintheengine,but

itdoescomewithabottleofoil.

Important:Beforestartingtheengine,llthe

enginewithoil.

Note:Thebottleofoilmaycontainmorethanis

required.Donotoverlltheengine.

Maxll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

Use

Figure8belowtoselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Figure8

1.UsingSAE30atoutdoor

temperaturesbelow40°F

(4°C)willresultinhard

starting.

2.Using10W-30atoutdoor

temperaturesabove

80°F(27°C)mayresultin

increasedoilconsumption;

therefore,checktheoil

levelmorefrequentlyin

thesecircumstances.

Note:0W30syntheticoilisacceptableforuseincold

temperatures.

1.Movethemachinetoalevelsurface.

2.Cleanaroundtheoilllcap(

Figure9).

Figure9

1.Oilllcap

3.Unscrewtheoilllcapandremoveit.

4.Withthemachineintheoperatingposition,carefully

pouroilintothecrankcase.Wait3minutes,thenadd

oiluntilthepointofoverow .

7

Page 8

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

5.Screwtheoilllcapintotheoilllholeandtighten

itsecurely.

4

AdjustingtheControlCable

NoPartsRequired

Procedure

RefertoAdjustingtheControlCableinMaintenance.

ProductOverview

Figure10

1.Chutedeectortrigger

8.Electric-startbutton

(model38569only)

2.Dischargechute9.Ignitionkey

3.Fueltankcap

10.Chokelever

4.Controlbar11.Oildrainplug

5.QuickShoot™control12.Oilllcap

6.Recoilstarthandle

13.Chutedeector

7.Primer

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

8

Page 9

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemay

resultwhichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

•DoNotaddoiltogasoline.

Figure11

1.1/4inch(6mm)

Important:Donotaddoiltothegasoline.

Important:DonotuseE85orE20fuel.Alternative

fuelswithhighalcoholcontentcancausehard

starting,poorengineperformance,andmaycause

internalenginedamage.

Note:Forbestresults,purchaseonlythequantityof

gasolinethatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedgasoline

tokeepitfreshforupto6months.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengineoillevelandaddoilif

necessary.

1.Movethemachinetoalevelsurface.

2.Cleanaroundtheoilllcap(

Figure12).

Figure12

1.Oilllcap

3.Unscrewtheoilllcapandremoveit.

4.Iftheoillevelislow,keepthemachineinthe

operatingpositionandcarefullypouroilintothe

crankcase.Wait3minutes,thenaddoiluntilthe

pointofoverow .(Max.ll:20oz.(0.6l),type:SAE

30detergentoilwithanAPIserviceclassication

ofSJ,SL,orhigher.)

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

5.Screwtheoilllcapintotheoilllholeandhand

tightenitsecurely.

StartingtheEngine

1.TurntheignitionkeyclockwisetotheOnposition

(

Figure13).

Figure13

2.Pulloutthechokelever(Figure14).

9

Page 10

Figure14

1.Chokelever

3.Firmlypushintheprimerwithyourthumb3times

(0°For-18°Corabove)or6times(0°For-18°Cor

below),holdingtheprimerinaforasecondbefore

releasingiteachtime(Figure15andFigure16).

Figure15

Figure16

1.Symbolsonthechokeleverindicatingtomovethechoke

levertothelefttoactivatethechoke.

Note:Removeyourglovewhenyoupushinthe

primersothataircannotescapefromtheprimer

hole.

Important:Donotusetheprimerorthechoke

iftheenginehasbeenrunningandishot.

Excessiveprimingmayoodtheengineand

preventitfromstarting.

4.Connectanextensioncordtoapowersourceand

themachine,andpushtheelectric-startbutton

(model38569only)(

Figure17),orpulltherecoil

starthandle(Figure18).

Figure17

Note:UseonlyaUL-listed,16-gaugeextension

cordrecommendedforoutdoorusethatisnot

longerthan50feet(15m).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthe

cordisdamaged,donotuseittostartthe

machine.Replaceorrepairthedamagedcord

immediately.ContactanAuthorizedService

Dealerforassistance.

10

Page 11

Figure18

Important:Runtheelectricstarternomore

than10timesatintervalsof5secondson,then

5secondsoff.Runningtheelectricstarter

extensivelycanoverheatanddamageit.Ifthe

enginedoesnotstartafterthisseriesofattempts,

waitatleast40minutestoallowthestarterto

coolbeforeattemptingtostartitagain.Ifthe

enginedoesnotstartafterthesecondseriesof

attempts,takethemachinetoanAuthorized

ServiceDealerforservice(model38569only).

Note:Ifyoupulltherecoilhandleandfeelno

resistance,thestartermaybefrozen.Thawoutthe

starterbeforeattemptingtostartthemachine.

5.Whiletheengineisrunning,pushinthechokelever

slowly.

6.Unplugtheextensioncordfromthepowersource

andthemachine(model38569only).

CAUTION

Ifyouleavethemachinepluggedintoapower

source,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty

(model38569only).

Unplugthepowercordwheneveryouarenot

startingthemachine.

EngagingtheRotorBlades

Toengagetherotorblades,holdthecontrolbaragainst

thehandle(Figure19).

Figure19

1.Controlbar

DisengagingtheRotorBlades

Todisengagetherotorblades,releasethecontrolbar

(Figure20).

Figure20

StoppingtheEngine

Tostoptheengine,turntheignitionkeycounterclockwise

totheOffposition(Figure21).

Figure21

11

Page 12

AdjustingtheDischargeChute

andChuteDeector

Toadjustthedischargechute,pressthetriggerofthe

QuickShoot™controlontherighthandsideofthe

handleandmoveitupordownalongthehandle.Moving

thecontroldownthehandlerotatesthedischargechute

totheleft;movingthecontrolupthehandlerotatesthe

dischargechutetotheright(

Figure22).

Figure22

Toraiseorlowertheangleofthechutedeector,press

thetriggeronthechutedeectorandmovethechute

deectorupordown(Figure23).

Figure23

1.Chutedeectortrigger2.Chutedeector

ClearingaCloggedDischarge

Chute

Important:Handcontactwiththerotatingrotor

bladesinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwithsnow

throwers.Neveruseyourhandtocleanoutthe

dischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands

(

Figure24).

Figure24

PreventingFreeze-upafterUse

•Lettheenginerunforafewminutestoprevent

movingpartsfromfreezing.Stoptheengine,wait

forallmovingpartstostop,andremoveiceand

snowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthe

chute.

•Rotatethedischargechuteleftandrighttofreeit

fromanyicebuildup.

•WiththeignitionkeyintheOffposition,pullthe

recoilstarterhandleseveraltimesorconnectthe

electricalcordtoapowersourceandthemachine

andpushtheelectricstartbuttononce(model38569

12

Page 13

only)topreventtherecoilstarterand/ortheelectric

starterfromfreezingup.

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessiveforce

whentryingtooperatefrozencontrols.Ifyouhave

difcultyoperatinganycontrolorpart,startthe

engineandletitrunforafewminutes.

OperatingTips

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Ifthemachinedoesnotpropelitselfforwardon

slipperysurfacesorinheavysnow,pushforwardon

thehandle,butallowthemachinetoworkatitsown

pace.

•Overlapeachswathtoensurecompletesnow

removal.

•Dischargethesnowdownwindwheneverpossible.

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

Aftertherst2hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevelandaddoilifnecessary.

Yearly

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Servicethesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

Yearlyorbeforestorage

•Preparethemachineforstorage.

AdjustingtheControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Check

thecontrolcableandadjustitif

necessary.

Yearly—Checkthecontrolcableand

adjustitifnecessary.

Movethecontrolbarbacktowardthehandletoremove

theslackinthecontrolcable(Figure25).

13

Page 14

Figure25

1.Controlbar2.1/16-inchto1/8-inch(2

mmto3mm)gap

Note:Ensurethata1/16-inchto1/8-inch(2mmto3

mm)gapexistsbetweenthecontrolbarandthehandle

(

Figure25).

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespring

fromtheadjusterlink(Figure26).

Figure26

1.Adjusterlink

3.Springcover

2.Z-tting

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe1/16-inchto

1/8-inch(2mmto3mm)gapbetweenthecontrol

barandthehandle(Figure25).

Note:MovingtheZ-ttinghigherdecreasesthe

gapbetweenthecontrolbarandthehandle;moving

itlowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethe

springcoverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingtheControl

Cable.

Note:Afterextendeduse,thedrivebeltmaywear

andloseitsproperbelttension.Ifthedrivebelt

slips(continuouslysqueals)underaheavyload,

disconnectthespringfromtheadjustorlinkand

movetheupperendofthespringtotheholethat

isfurtherfromthepivotpointinthecontrolbar

(

Figure27).Thenconnectthespringtotheadjustor

linkandadjustthecontrolcable.

Figure27

1.Removetheupperendof

springfromthishole

3.Pivotpoint

2.Inserttheupperendof

springintothishole

4.Upperendofspring

Note:Thebeltmayslip(squeal)inwetconditions;

todryoutthedrivesystem,starttherotorandrun

itwithoutaloadfor30seconds.

14

Page 15

InspectingtheRotorBlades

ServiceInterval:Yearly—Inspecttherotorbladesand

haveanAuthorizedServiceDealer

replacetherotorbladesandscraperif

necessary.

Beforeeachsession,inspecttherotorbladesforwear.

Whenarotorbladeedgehasworndowntothewear

indicatorhole,haveanAuthorizedServiceDealer

replacetherotorbladesandthescraper(

Figure28).

Figure28

1.Thewearindicatorholeis

intact;youdonotneedto

replacetherotorblades.

2.Thewearindicatorholeis

exposed;replacetherotor

blades.

ChangingtheEngineOil

ServiceInterval:Aftertherst2hours

Yearly

Runtheengineafewminutesbeforechangingtheoil

towarmit.Warmoilowsbetterandcarriesmore

contaminants.

1.Siphonthefuelfromthefueltankintoanapproved

fuelcontainer,orruntheengineuntilitstops.

2.Movethemachinetoalevelsurface.

3.Placeanoildrainpanundertheoildrainplug,

removetheoildrainplug,andtipthemachine

backwardanddraintheusedoilintheoildrainpan

Figure29).

Figure29

4.Afterdrainingtheusedoil,returnthemachinetothe

operatingposition.

5.Installtheoildrainplugandtightenitsecurely.

6.Cleanaroundtheoilllcap(

Figure30).

Figure30

1.Oilllcap

7.Unscrewtheoilllcapandremoveit(Figure30).

8.Withthemachineintheoperatingposition,carefully

pouroilintotheoilllhole.Waitthreeminutes,

thenaddoiltothepointofoverow(

Figure32).

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

Maxll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

Use

Figure31belowtoselectthebestoilviscosity

fortheoutdoortemperaturerangeexpected:

15

Page 16

Figure31

1.UsingSAE30atoutdoor

temperaturesbelow40°F

(4°C)willresultinhard

starting.

2.Using10W-30atoutdoor

temperaturesabove

80°F(27°C)mayresultin

increasedoilconsumption;

therefore,checktheoil

levelmorefrequentlyin

thesecircumstances.

Note:0W30syntheticoilisacceptableforusein

coldtemperatures.

Figure32

9.Screwtheoilllcapintotheoilllhole,andhand

tightenitsecurely.

10.Wipeupanyspilledoil.

11.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Y early—Servicethesparkplugand

replaceitifnecessary.

UseaNGKBPR6ESorChampionRN9YCspark

plugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Rotatethedischargechutesothatitfacesforward.

3.Removethedischargechute,thedischargechute

handle,andthechutesealbyremovingthe3large

screwsandonesmallscrew(

Figure33).

Figure33

1.Fueltankcap

4.Smallscrew

2.Largescrews(3)5.Chuteseal

3.Dischargechute

4.Removethe4screwsthatsecuretheshroud

(Figure34).

Figure34

1.Screw(4)3.Sparkplug

2.Shroud4.Spark-plugwire

16

Page 17

5.Removethefueltankcap.

6.Removetheshroud(Figure34).

7.Installthefueltankcap.

8.Disconnectthewirefromthesparkplug.

9.Cleanaroundthesparkplug.

10.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

11.Setthegapontheplugto0.030inch(0.76mm)

(

Figure35).

Figure35

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

12.Installthesparkplugandtorqueitto20–22ft-lb

(27–30N-m).

13.Connectthewiretothesparkplug.

Note:Ensurethatthebreathertubeisroutedabove

thesparkplugwireasshowninFigure36.

Figure36

1.Breathertube

2.Carburetordrainbolt

14.Removethefueltankcap.

15.Installtheshroudwiththescrewsyouremovedin

step4.

Note:Ensurethattheupperandlowershroudst

togetherinthesidegrooves.

16.Installthefueltankcap.

17.Installthechuteseal,thedischargechute,andthe

dischargechutehandleontothemachineusingthe

hardwareyouremovedinstep

3.

Note:Thesmallscrewgoesthroughthesmallhole

inthechutesealatthefrontofthedischargechute

opening.

17

Page 18

AdjustingtheQuickShoot™

Control

Ifthereismorethan1/2inch(13mm)ofslackinthe

QuickShootcable(

Figure37)orthedischargechute

doesnotrotateleftandrightinequalangles,adjustthe

QuickShootcontrolcables.

Figure37

1.1/2inch(13mm)maximumslack

1.LoosenthetwoQuickShootcontrolcableclamps

(Figure38).

Figure38

1.Cableclamps

2.PositiontheQuickShootcontrolbetweenthetwo

arrowslocatedontherighthandsideoftheupper

handle(

Figure39).

Figure39

1.Arrows

3.Rotatethedischargechutesothatitfacesstraight

aheadandthearrowonthebackofthedischarge

chutealignswiththearrowontheshroud(

Figure40).

Figure40

4.Holdthedischargechuteinthestraight-ahead

position,pullthelowercablecasingdownwarduntil

youremovetheslackinthecable,andtightenthe

screwonthelowercableclampsecurely(Figure41).

18

Page 19

Figure41

1.Lowercablecasing

5.Pulltheuppercablecasingforwarduntilyouremove

theslackinthecable,andtightenthescrewonthe

uppercableclampsecurely(Figure42).

Figure42

1.Uppercablecasing

Note:Donotover-tensionthecables.Ifthecables

areover-tensioned,theQuickShootwillbehardto

operate.

19

Page 20

Storage

StoringtheMachine

WARNING

•Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethe

machineinanareawithanopename,the

gasolinefumesmayigniteandcausean

explosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

1.Onthelastrefuelingoftheseason,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Stoptheengine,allowittocool,andsiphonthefuel

tankorruntheengineuntilitstops.

4.Starttheengineandrunituntilitstops.

5.Chokeorprimetheengine,startitathirdtime,and

runtheengineuntilitwillnotstart.

6.Drainthefuelinthecarburetorthroughthe

carburetordrainbolt(

Figure36)intoanapproved

gasolinecontainer.

7.Disposeofunusedfuelproperly.Recycleitaccording

tolocalcodes,oruseitinyourautomobile.

8.Whiletheengineisstillwarm,changetheengineoil.

RefertoChangingtheEngineOil.

9.Removethesparkplug.

10.Squirt2teaspoonsofoilintothesparkplughole.

11.Installthesparkplugbyhandandthentorqueitto

20–22ft-lb(27–30N-m).

12.WiththeignitionkeyintheOffposition,pullthe

recoilstarterslowlytodistributetheoilontheinside

ofthecylinder.

13.Cleanthemachine.

14.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sandaffected

areasbeforepainting,andusearustpreventativeto

preventthemetalpartsfromrusting.

15.Tightenanyloosefasteners.Repairorreplaceany

damagedparts.

16.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheengineto

coolbeforestoringitinanyenclosure.

20

Page 21

Notes:

21

Page 22

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheW ayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

374-0282RevB

Page 23

IntlDistList

Distributor:

Country:

PhoneNumber:

AtlantisSuveSulamaSisstemleriLt

Turkey902163448674

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

Korea82325512076

CascoSalesCompany

PuertoRico7877888383

CeresS.A.CostaRica

5062391138

CSSCTurfEquipment(pvt)Ltd.SriLanka

941 12746100

CyrilJohnston&Co.

NorthernIreland442890813121

EquiverMexico525553995444

FemcoS.A.Guatemala

5024423277

G.Y .K.CompanyLtd.

Japan81726325861

GeomechanikiofAthensGreece

30109350054

GuandongGoldenStarChina

862087651338

HakoGroundandGardenSweden

4635100000

HakoGroundandGarden

Norway4722907760

HayterLimited(U.K.)

UnitedKingdom441279723444

HydroturfInt.CoDubai

UnitedArabEmirates97143479479

HydroturfEgyptLLC

Egypt2025194308

IbeaS.P .A.

Italy390331853611

IrriamcPortugal351212388260

IrrigationProductsInt'lPvtLtd.India862283960789

JeanHeybroekb.v.Netherlands3130639461 1

MaquiverS.A.Colombia

5712364079

MaruyamaMfg.Co.Inc.

Japan81332522285

MetraKft

Hungary3613263880

Mountelda.s.CzechRepublic

420255704220

MunditolS.A.

Argentina541 148219999

OslingerTurfEquipmentSA

Ecuador59342396970

OyHakoGroundandGardenAb

Finland35898700733

ParklandProductsLtd.NewZealand6433493760

Prochaska&Cie

Austria4312785100

RTCohen2004Ltd.

Israel97298617979

Riversa

Spain

34952837500

ScSvendCarlsenA/S

Denmark4566109200

SolvertS.A.S.

France33130817700

SpyprosStavrinidesLimitedCyprus

35722434131

SurgeSystemsIndiaLimited

India911292299901

T-MarktLogisticsLtd.Hungary3626525500

ToroAustraliaAustralia61395807355

ToroEuropeNVBelgium3214562960

374-0269RevC

Page 24

TheToroWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetotheoriginalpurchaser*

torepairtheT oroProductslistedbelowifdefectiveinmaterialsor

workmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

WalkPowerMowers

•CastDeck

5yearsResidentialUse

2

45DaysCommercialUse

•Engine

5yearsGTSPromise

Seeenginemanufacturer'swarranty

1

•SteelDeck

2yearsResidentialUse

2

45DaysCommercialUse

•Engine

2yearsGTSPromise

Seeenginemanufacturer'swarranty

1

ElectricHandHeldProducts2yearlimitedwarranty

Snowthrowers

•SingleStage

2yearsResidentialUse

2

45DaysCommercialUse

•TwoStage

2yearsResidentialUse

2

45DaysCommercialUse

•Electric2yearsResidentialUse

2

AllRide-OnUnitsBelow

•Engine

Seeenginemanufacturer'swarranty

1

1yearPartsonly

•Attachments1year

RearEngineRiders2yearsResidentialUse

2

90DaysCommercialUse

Lawn&GardenTractors

2yearsResidentialUse

2

90DaysCommercialUse

TimeCutterZMowers

3yearsResidentialUse

2

30DaysCommercialUse

TITANMowers3yearsor240hours

3

•Frame

Lifetime(originalowneronly)

4

TITANMXMowers3yearsor400hours

3

•Frame

Lifetime(originalowneronly)

4

ZMasterMowers—2000Series

5yearsor1200hours

3

•Frame

Lifetime(originalowneronly)

4

*OriginalPurchasermeansthepersonwhooriginallypurchasedtheT oroProduct.

1

SomeenginesusedonT oroProductsarewarrantedbytheenginemanufacturer.

2

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialusewarrantywouldapply.

3

Whicheveroccursrst.

4

LifetimeFrameW arranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthe

tractorstructurethatothercomponentssuchastheenginearesecuredto,cracksorbreaksin

normaluse,itwillberepairedorreplaced,atToro'soption,underwarrantyatnocostforparts

andlabor.Framefailureduetomisuseorabuseandfailureorrepairrequiredduetorustor

corrosionarenotcovered.

Thiswarrantyincludesthecostofpartsandlabor,butyoumustpay

transportationcosts.

Warrantymaybedeniedifthehourmeterisdisconnected,altered,or

showssignsofbeingtamperedwith.

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforanyreason

itisimpossibleforyoutocontactyourseller,youmaycontactany

ToroAuthorizedDistributortoarrangeservice.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.IfforanyreasonyouaredissatisedwiththeService

Dealer’sanalysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,RLCDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Manager:TechnicalProductSupport:001–952–887–8248

SeeattachedDistributorList

ItemsandConditionsNotCovered

Thisexpresswarrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasblades,

rotorblades(paddles),scraperblades,belts,fuel,lubricants,oil

changes,sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Engineandtransmission.Thesearecoveredbytheappropriate

manufacturer’sguaranteeswithseparatetermsandconditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingT oroapprovedreplacementparts.

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry.Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty .

374-0268RevC

Loading...

Loading...