Page 1

Micro-Irrigation

Performance:

• Flow range 35 to 2400 GPM

Bermad Valves

Application:

Bermad plastic and metal control valves have cutting edge

features which ensure optimum performance and high efficiency

over a long life cycle. The valves are designed to provide control

solutions for irrigation projects in micro irrigation, sprinklers,

pump control and other applications. This versatile family of

valves provides a full range of sizes, pressure ratings and options

to meet the demands of today's most complex irrigation systems.

• Operating pressure range 5 to 230 psi

1

• Valve sizes from 1

⁄2" to 10"

• Hydraulically operated diaphragm valves with 3 way control

Options:

• Manual on/off or Electric on/off

• Pressure Reduction- maintains constant downstream pressure

• Pressure Sustaining- maintains constant upstream pressure

• Quick Pressure Relief- minimizes damage from water hammer

• Options can be combined to create the optimum valve

for each application

Features:

• Valve body and diaphragm design results in low friction

loss and low energy use

• User friendly design allows in-line maintenance and

simple service

Plastic Valves

• Engineered plastic valves for light weight

and corosion resistance

• Threaded or articulated flange valves

available for easy installation

• All typical irrigation options available

• Engineered materials provide chemical resistance for long life

• Diaphragms operate under low flow conditions with

excellent regulation performance

• Regulating pilots are responsive to small pressure

changes, enabling constant, accurate control

Metal Valves

• Iron valves with weather resistant coating

provide durability

• Threaded or flanged connections available

• All possible valve configurations available

Page 2

High-Performance Plastic Valves

Made from industrial grade, durable glass-filled

nylon, Bermad plastic valves are engineered to

withstand rough service conditions and are

resistant to cavitation and chemical attack.

The Y pattern valve body together with a one

iece diaphragm provides a look through

p

passage resulting in ultra high flow capacity

and minimal friction loss.

Features Benefits

Lightweight construction Easy to ship and move in portable irrigation systems

Chemically resistant engineered plastic

Remote control through a wide range of

electric solenoids or hydraulic command.

Low friction losses Reduced energy cost

Low flow and low pressure operation

Plastic Manual Electric Pressure Reducing Pressure Sustaining Low Friction Loss Low Maintenance

105 Series

110 Series

120 Series

12055 Series

130 Series

• • • • • • •

• • • • • • •

• • • • • •

• • • • • • •

• • • • • • •

Provides long life in harsh environments and

corrosive injection applications.

Saves labor and optimizes water application

through accurate scheduling

Maintains peak uniformity in systems with flow

and pressure variations

Hydraulic Control Metal Valves

At the leading edge of control valve design, Bermad

metal valves combine simple and reliable construction

with superior performance. The diaphragm performs

under all service conditions with no distortion from

uneven hydraulic forces or pressure surges. These

automatic control valves are designed for operation in

vertical and horizontal installations and can be

configured to solve most irrigation control applications.

Features Benefits

Metal construction of the valve and pilots

230 PSI operating pressure

Remote control with a wide range of electric

solenoid or hydraulic controls.

Available in sizes 11⁄2" through 10"

Stable regulation at low flows and high

differential pressures

Metal Manual Electric Pressure Reducing Quick Pressure Relief Low Friction Loss Low Maintenance

405 Series

410 Series

420 Series

42055 Series

43Q Series

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • •

Metal valves and compontents offer structural

strength where long term reliability is essential

Strength to withstand high pressure or water

hammer risk

Saves labor and optimizes water application

through accurate scheduling

Wide range of sizes and flows enables

matching valves to system requirements

Enables system to operate at peak irrigation

uniformity

Page 3

Principles of Operation

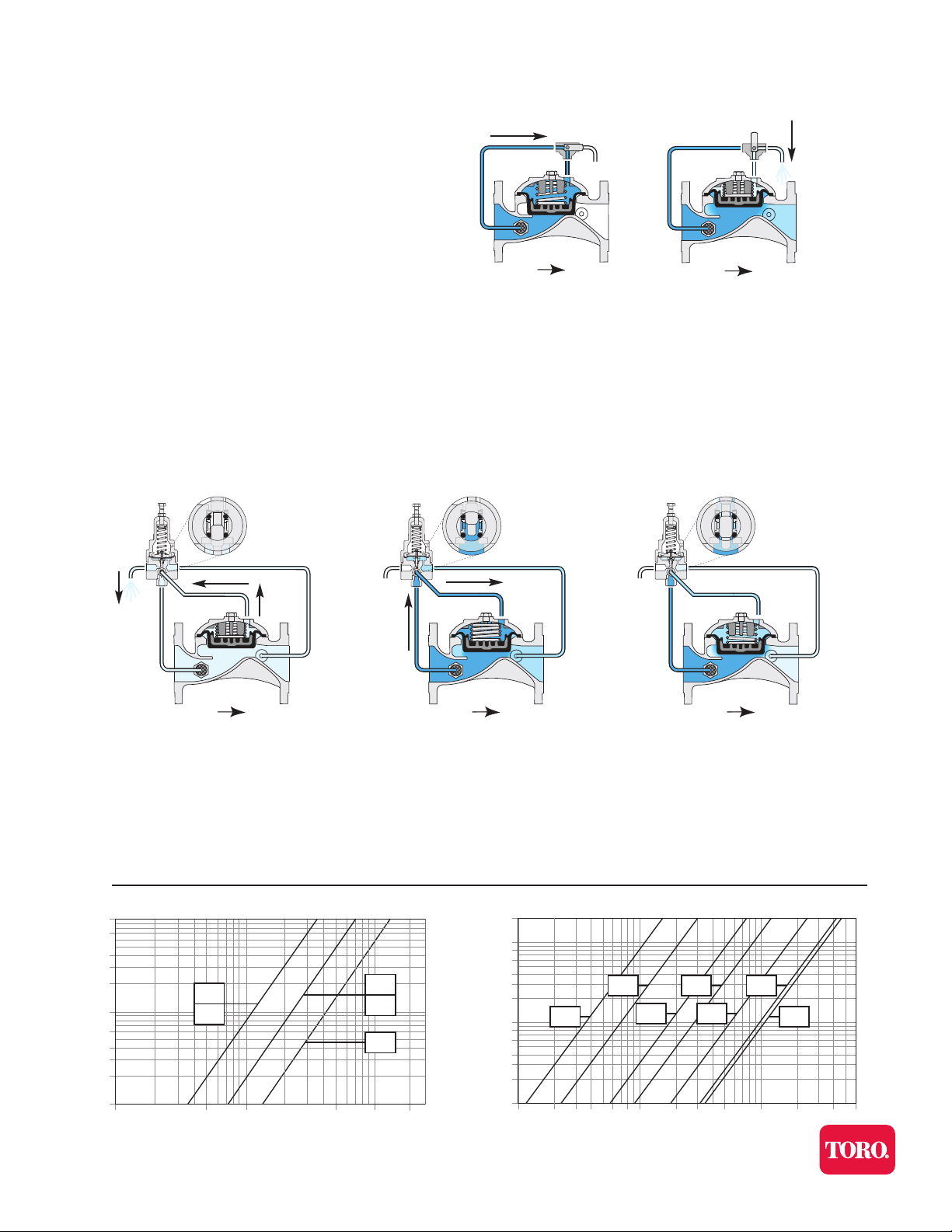

10 50 100 500 1000 2000

Pressure Loss (psi)

Flow Rate (gpm)

10.O

1.0

0.2

0.3

0.4

0.6

2.0

3.0

4.0

7.0

0.1

2”-Y

3”-Y

3”L

4”

6”

20.0

0.1

0.2

0.3

0.4

0.6

0.8

1.0

2.0

3.0

4.0

6.0

8.0

10.0

Pressure Loss (psi)

10 20 30 40 60 80 100 200 400 600 1,000 2,000 4,000 6,000

Flow Rate (gpm)

1 ½” 10”

2” 4” 8”

3” 6”

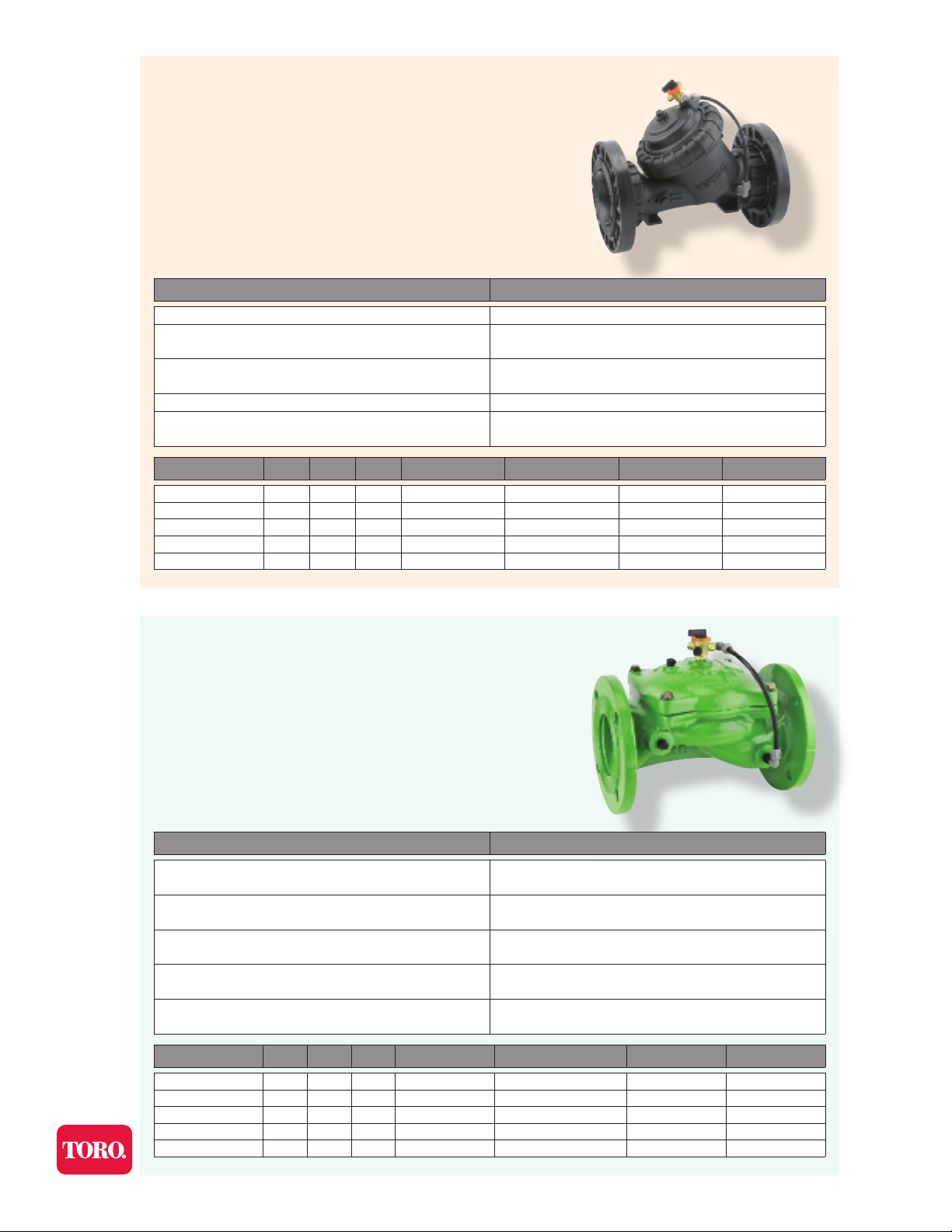

On/off Control

Application: On/off manual,

electric or hydraulic command

for master valve and zone

control. In the diagram a

manual 3-way selector is

shown controlling the valve.

A solenoid or hydraulic relay

can be substituted to allow

electric or hydraulic operation.

Pressure Reduction 3-Way Control

Application: Reduction of upstream pressure to a lower constant downstream pressure.

Adjustable pressure reducing valves optimize the performance of pressure sensitive

emission devices by providing constant operating pressure.

Line pressure applied to the control chamber of the valve

creates a hydraulic force that moves the valve to the

closed position. Discharging pressure from the control

chamber to atmosphere allows the line pressure to push

the diaphragm up, thus opening the valve

Fully Open Position When upstream

pressure drops, the pilot blocks the

upstream pressure sensing port and

opens the drain port, venting the

control chamber to the atmosphere.

This fully opens the valve, minimizing

head loss.

Friction Loss Charts

Adjusting To Close When upstream

pressure rises, the pilot blocks the

drain port and opens the supply

pressure port. This pressurizes the

control chamber, forcing the valve

to modulate closed.

Metal ValvesPlastic Valves

Locked Position When sensed

pressure is equal to set point, the

pilot blocks both the drain and

the upstream pressure sensing

ports. This locks the pressure in

the control chamber, freezing the

diaphragm in its last position until

conditions change.

Page 4

Plastic Control Valves

Standard Configuration:

• Plastic Valve Y configuration (Y)

• Pressure Rating: Minimum operating 5 psi,

Maximum inlet 145 psi

• Connections: Threaded 2" thru 3" NPT (NP)

- Plastic articulated flange 4" thru 6" (FF)

• 2" thru 6" valves are constructed using plastic

tubing, fittings and plastic mini pilots

• 2" thru 3" valves have flow control stem

• Manual, electric and hydraulic valves are

normally closed (NC)

Flow Ranges

Valve Size

2" 35 140

3" 35 300

3L" 75 580

4" 75 580

6" 140 1000

Flow Rate GPM

From To

105 Series -

Manual control, hydraulic actuation with 3-way selector

Threaded - NPT (NP) Flanged - Plastic - (FF)

2" 3" 3"L 4" 6"

B105-Z-02-Y-NP B105-Z-03-Y-NP B105-Z-03L-Y-NP B105-Z-04-Y-FF B105-Z-06-Y-FF

Manual selector standard

Application: Manual command for master valve and zone control.

110 Series -

Electric control, manual override on solenoid

Threaded - NPT (NP) Flanged - Plastic - (FF)

2" 3" 3"L 4" 6"

B110-3W-02-Y-NP B110-3W-03-Y-NP B110-3W-03L-Y-NP B110-3W-04-Y-FF B110-3W-06-Y-FF

Standard solenoid: S-400-3W 24VAC-R

Application: Electrically controlled valve for computerized irrigation systems and conventional timer

controlled systems. The 110 series electric valves are ideal for master valve and zone control applications

.

120 Series -

Pressure reducing, manual control with 3-way selector

Threaded - NPT (NP) Flanged - Plastic - (FF)

2" 3" 3"L 4" 6"

B120-XZ-02-Y-NP B120-XZ-03-Y-NP B120-XZ-03L-Y-NP B120-XZ-04-Y-FF B120-XZ-06-Y-FF

Standard pilot: model PC-X-P plastic mini pilot for 7-40 psi downstream pressure.*

Manual selector standard

Application: The 120 series valves protect downstream components from erratic and high pressures.

Adjustable reducing valves optimize performance, of pressure sensitive emission devices by providing

constant operating pressure

Electrical Specifications:

3-Way Solenoid with plastic base for 2" thru 6" 110 or 12055 plastic valves

Part Number Voltage Normally Open/Closed Inrush (Amp) Holding (Amp) Power (Watt)

S400-3W-24VAC-R (standard) 24VAC NO 0.6 0.3 3.5

S400-3W-12 VDC 12VDC NO 0.33 0.33 4.0

S400-3W-24VAC-R-NC 24VAC NC 0.6 0.3 3.5

Add optional solenoid part number to the end of valve part number to receive pre-installed non standard solenoids

Solenoid Note: Normally Open (NO) solenoids are used to construct normally closed valves. Normally Closed solenoids are

used to construct normally open valves. Manually actuated valves may be converted to normally open or normally closed by

arrangement of the hydraulic control connections.

Page 5

Plastic Control Valves

H

L

h

W

H(T) H(F)

L(T)

L(F)

h(T)

h(F)

W

H(G) H(F)

L

h(G)

h(F)

W

12055 Series -

Pressure reducing, electric control

Threaded - NPT (NP) Flanged - Plastic - (FF)

2" 3" 3"L 4" 6"

B12055-X-02-Y-NP B12055-X-03-Y-NP B12055-X-03L-Y-NP B12055-X-04-Y-FF B12055-X-06-Y-FF

Standard pilot: model PC-X-P plastic mini pilot for 7-40 psi downstream pressure.*

Standard solenoid: S-400-3W 24VAC-R

Application: Pressure reducing, electric valves combine the features of electric control and adjustable

pressure reduction. The 12055 establishes a reduced pressure zone to optimize emission device performance.

130 Series -

Pressure sustaining, manual control with 3-way selector

Threaded - NPT (NP) Flanged - Plastic - (FF)

2" 3" 3"L 4" 6"

B130-XZ-02-Y-NP B130-XZ-03-Y-NP B130-XZ-03L-Y-NP B130-XZ-04-Y-FF B130-XZ-06-Y-FF

Standard pilot: model PC-X-P plastic mini pilot for 7-40 psi upstream pressure.*

Manual selector standard

Application: Sustaining valves are used to relieve excess line pressures and to protect systems with erratic supply pressures. Sustaining valves, maintains preset minimum upstream pressure during fluctuating flows or varying pressure conditions. Normally open pressure sustaining valves are used to maintain adequate upstream

pressures during filter back flushing and line filling.

Pilot Spring Options:

For Plastic Valves with model PC-X-P plastic mini pilots (*)

Spring

Code

To add a pre-installed optional pilot

spring to plastic valves. Add the

correct spring code to the end of

the valve part number.

Optional Pilot springs may be required for different pressure ranges.

Choose an optional pilot spring when valves operate outside the

range of the standard spring.

-K

-N 11-95 psi

-H 15-100 psi

Operating

Range

7-40 psi

Standard

Pilot and Copper Tube Options:

For plastic valves

Option

Brass fitting and copper tubing

upgrade

Brass Pilot -R

To upgrade add the option code to

the end of the part number

Plastic Globe Pattern Valves Dimensions and Weights

Threaded Flanged

Size 2" 3" 3"L 4" 6"

L (inch) 9 1⁄16 11 3⁄4 12 1⁄8 13 3⁄4 18 7⁄8

H (inch) 7 5⁄16 7 11⁄16 10 1⁄16 11 9⁄16 11 1⁄4

h (inch) 1 9⁄16 1 15⁄16 3 15⁄16 4 7⁄16 5 11⁄16

W (inch) 5 5⁄16 5 5⁄16 7 7⁄8 8 13⁄16 15 3⁄16

Weight(lb) 3 4 8 11 27

Option

Code

-CB

2",3",3"L NPT 4" Flanged 6" Y Boxer

Other valve options and configurations are available.

For inquires, please contact Toro Micro-Irrigation Customer Service.

Page 6

Metal Control Valves

Standard Configuration:

• Cast Iron Globe configuration (G)

• Pressure Rating: Minimum operating 10 psi,

Maximum inlet 230 psi

• Connections: Threaded 1 1/2" thru 3" NPT

(NP) - Iron flanged 4" thru 10" (A1)

• 3" thru 4" valves are constructed using plastic

tubing, fittings and plastic mini pilots

• 6" thru 10" valves and 1 1/2" thru 3" Quick

Relief valves are constructed using copper

tubing and brass pilots

Flow Ranges

Valve Size

3" 60 400

4" 90 700

6" 180 1400

8" 310 2200

10" 340 2400

• Pressure check points and outlet isolation ball

valves are furnished on metal pressure

reducing valves

• Manual, electric and hydraulic valves are

normally closed (NC)

Flow Rate GPM

From To

405 Series -

Manual control, hydraulic actuation with 3-way selector

Threaded - NPT (NP) Flanged (A1)

3" 4" 6" 8" 10"

B405-Z-03-G-NP B405-Z-04-G-A1 B405-Z-06-G-A1 B405-Z-08-G-A1 B405-Z-10-G-A1

Manual selector standard

Application: Manual command for master valve and zone control. Manual valves may be easily upgraded.

410 Series -

Electric control, manual override on solenoid

Threaded - NPT (NP) Flanged (A1)

3" 4" 6" 8" 10"

B410-X-03-G-NP B410-X-04-G-A1 B410-X-06-G-A1 B410-X-08-G-A1 B410-X-10-G-A1

Standard solenoid: 3" thru 4" metal valves S-400-3W-24VAC-R : 6" thru 10" metal valves ASC-3W24VAC-NO

Application: Electrically controlled valve for computerized irrigation systems and conventional timer

controlled systems. The 410 series electric valves are ideal for master valve and zone control.

420 Series -

Pressure reducing, manual control with 3-way selector

Reduces upstream pressure to lower constant downstream pressure.

Manual on/off with 3 way selector.

Threaded - NPT (NP) Flanged (A1)

3" 4" 6" 8" 10"

B420-XZ-03-G-NP B420-XZ-04-G-A1 B420-XZ-06-G-A1 B420-XZ-08-G-A1 B420-XZ-10-G-A1

Standard pilot: 3" thru 4" metal valves- model PC-X-P plastic mini pilot for 7-40 psi downstream pressure.(*)

Standard pilot: 6" thru 10" metal valves- model X brass pilot for 7-150 psi downstream pressure.(#)

Application: The 420 series pressure reducing valves protect downstream components from erratic and

high pressure. Adjustable pressure reducing valves optimize performance of pressure sensitive emission

devices by providing constant operating pressure.

Electrical Specifications:

3-Way Solenoid with plastic base for 3" thru 4" 410, 42055 metal valves.

Part Number Voltage Normally Open/Closed Inrush (Amp) Holding (Amp) Power (Watt)

S400-3W-24VAC-R (standard) 24VAC NO 0.6 0.3 3.5

S400-3W-12 VDC 12VDC NO 0.33 0.33 4.0

S400-3W-24VAC-R-NC 24VAC NC 0.6 0.3 3.5

3-Way Solenoid with metal base for 6" thru 10" 410 and 42055 metal valves

Part Number Voltage Normally Open/Closed Inrush (Amp) Holding (Amp) Power (Watt)

ASC-3W24VAC-NO (standard) 24VAC NO 1.25 0.66 6.1

ASC-3W12VDC-NO 12VDC NO – – 10.6

ASC-3W24VAC-NC 24VAC NC 1.25 0.66 6.1

Add optional solenoid part number to the end of valve part number to receive pre-installed non standard solenoids

Other solenoid options available upon request.

Page 7

Metal Control Valves

H

R

L

W

L

H

R

W

42055 Series -

Pressure Reducing, Electric control

Threaded - NPT (NP) Flanged (A1)

3" 4" 6" 8" 10"

B42055-X-03-G-NP B42055-X-04-G-A1B42055-X-06-G-A1B42055-X-08-G-A1B42055-X-10-G-A1

Standard solenoids: 3" thru 4" metal valves S-400-3W-24VAC-R : 6" thru 10" metal valves ASC-3W24VAC-NO

Standard pilot: 3" thru 4" metal valves model- PC-X-P plastic mini pilot for 7-40 psi downstream pressure.(*)

Standard pilot: 6" thru 10" metal valves- model- X brass pilot for 7-150 psi downstream pressure.(#)

Application: Pressure reducing, electric 42055 metal valves combine the features of electric control and

adjustable pressure reduction. The 42055 establishes a continuous, reduced pressure zone to optimize

emission device performance.

43Q Series -

Quick Pressure Relief, relieves excessive line pressure by

immediately opening when preset line pressure is met.

Threaded - NPT (NP)

11⁄2" 2" 3"

B43Q-015-G-NP B43Q-02-G-NP B43Q-03-G-NP

Application: The 43Q adjustable quick pressure relief valves provide systems with protection from excessive pressure.

Quick relief valves are located at the irrigation headwords or other positions where water hammer may occur

due to rapid valve closure, power failure or erratic pressure situations. 43Q valves eliminate momentary peak

pressure spikes and are often used to protect sand media filters. Globe (G) is the standard configuration for

43Q valves. The Angle (A) configuration is also available.

Pilot Spring Options:

For Plastic Valves with model PC-X-P

plastic mini pilots (*)

Spring

To add a pre-installed

optional pilot spring to

plastic valves. Add the

correct spring code to the

end of the valve part

number.

Optional Pilot springs may be required for different

pressure ranges. Choose an optional pilot spring when

valves operate outside the range of the standard spring.

Operating

Code

Range

7-40 psi

-K

Standard

-N 11-95 psi

-H 15-100 psi

For Metal Valves with model X Brass pilots (#)

Spring

To add a pre-installed

optional pilot spring to 3"

thru 4", 420 and 42055

series metal valves add

correct spring code to the

end of the valve part

number.

Operating

Code

-10

-16 15-230 psi

Range

7-150 psi

Standard

Pilot and Copper

Tube Options:

For 3" thru 4" Metal Valves

Option

Brass fitting and copper

tubing upgrade

Brass Pilot -R

To upgrade 3" thru 4" metal

valves add the option code to

the end of the part number

Metal Globe Pattern Valves Dimensions and Weights

Threaded Flanged

Size 1 1⁄2" 2" 3" 4" 6" 8" 10"

L (inch) 6 7 1⁄16 10 12 5⁄8 16 5⁄16 19 11⁄16 23 13⁄16

H (inch) 3 3⁄8 5 6 1⁄2 9 1⁄2 13 9⁄16 16 15⁄16 18 1⁄8

W (inch) 3 7⁄8 4 11⁄16 6 11⁄16 8 3⁄4 12 14 3⁄8 15 15⁄16

R (inch) 1 1⁄8 1 1⁄2 2 3⁄16 4 1⁄2 5 1⁄2 6 11⁄16 7 15⁄16

Weight(lb) 5 9 29 62 150 276 309

Option

Code

-CB

Threaded

Other valve options and configurations are available.

For inquires, please contact Toro Micro-Irrigation Customer Service.

Flanged

Page 8

The Blue Stripe of Quality.

©2011 Toro Micro-Irrigation, 1588 N. Marshall Avenue, El Cajon, CA 92020 (800) 333-8125

with the PBX Advantage

Aqua-Traxx

®

NGE

®

Aqua-Clear

Pro-Loc™ Fittings

BlueLine™

©2014 The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue, El Cajon, CA 92020-1523, USA

Tel: +1(800) 333-8125 or +1 (619) 562-2950

Fax: +1 (800) 892-1822 or +1 (619) 258-9973

toro.com

ALT146 06/14

Loading...

Loading...