Toro Aqua-Traxx PC Testimonials

Vol 9 • No. 1 • January 2005

1Vegetables WEST / January 2005

Whole Leaf Lettuce Program

Restaurant Trade Generates Demand

By Patrick Cavanaugh, Editor

Greg Lazzerini, farm manager with

Boss Farms LLC, is a partner with Mills

Family Farms, both of Salinas, Calif.

Of the 3,500 acres he oversees, one

crop that garners a lot of attention is leaf

lettuce for Mills’ whole-leaf lettuce program.

The whole-leaf product is used by

the restaurant trade throughout the country as a garnish on plates or on appetizer

trays or to decorate salad bars—and a

variety of other uses.

Lazzerini oversees fields in both the

Salinas Valley and in San Benito

County. The crops include iceberg, leaf

lettuce, spinach, broccoli, cauliflower,

kale, parsley, green onions and other

minor crops.

The biggest crop is leaf lettuce using romaine, green and red leaf varieties, where the leaves are separated from

the stalk and then processed in-house

before it’s shipped out.

“We use certain proprietary varieties with attributes such as a special leaf

texture and leaves that are a little thicker

and that stack well—not over-curled,”

said Lazzerini. “That’s what the trade is

looking for.”

To help encourage good leaf pro-

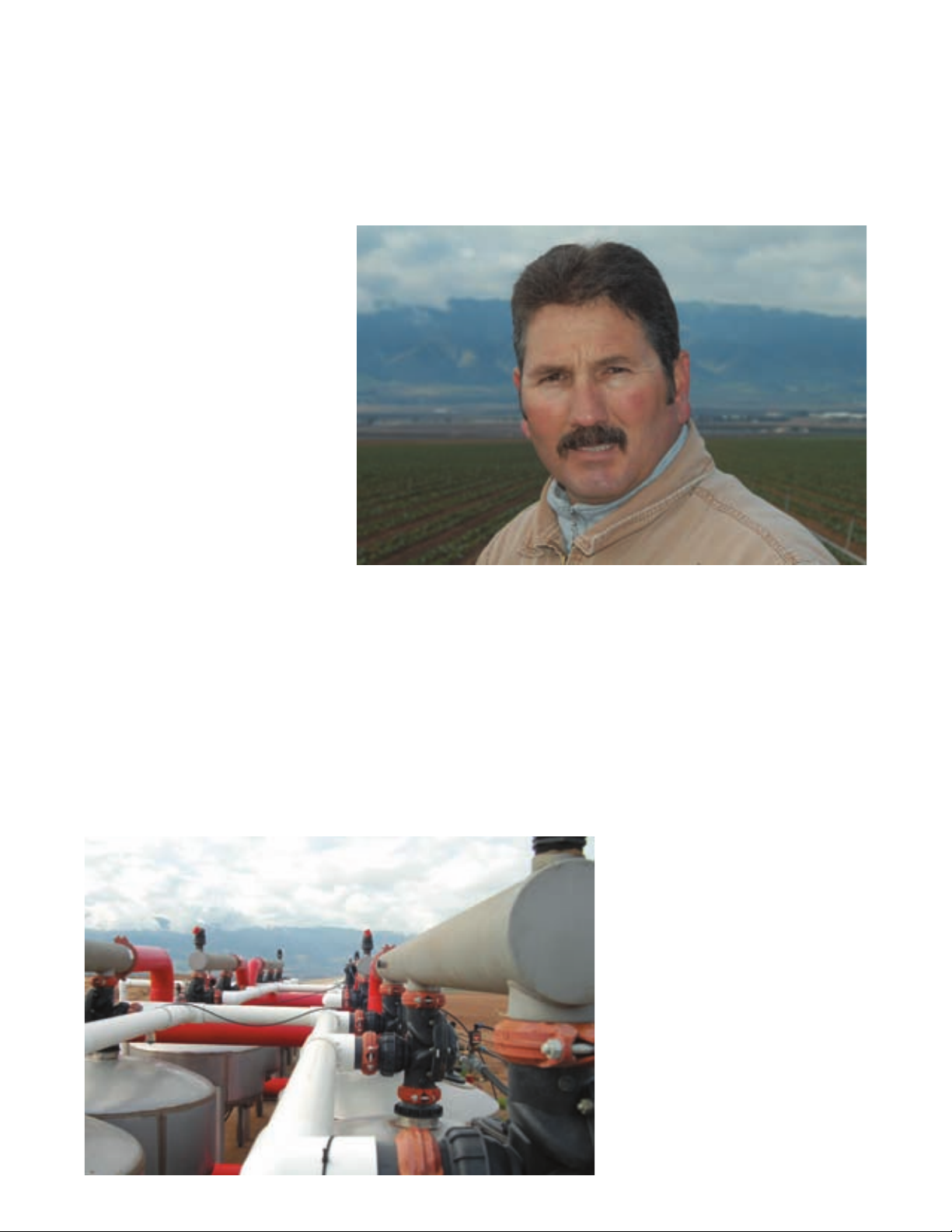

One of 18 filtration stations that serve the Boss Farms Land. All fields are started with

sprinklers and then finished off with drip tape.

2 Vegetables WEST / January 2005

Greg Lazzerini said the whole-leaf program requires special varieties and growing

practices. He is the farm manager of 3,500 acres in partnership with Mills Family Farms

duction, the crops are farmed a little

differently. “We do different spacings,

(which again are proprietary,) in order

to get equal growth of the leaf with

more room to grow,” said Lazzerini.

“We want uniformity and a good leaf

count.”

In the field, the heads are cut,

trimmed and put in totes. The leaves are

separated, washed and packed at the

processing facility.

“We remove the cover leaves and

use every leaf down to the core. The

smaller leaves at the core are used in a

baby spring mix,” noted Lazzerini. The

leaves get smaller as you go into the

stalk. Of course, there is more profit in

the larger leaves because it doesn’t take

as many to make a full box.

“We have the patent in doing the

whole-leaf process. By carefully snapping the leaf off the core in a certain

way by hand you do not disturb the cells

as you would if using a knife. The

special snapping of the leave helps retain freshness and increases shelf life,”

Lazzerini said.

The crop is grown in the spring and

summer in Salinas and then moved to

Yuma in winter. In April, the daily

harvest begins again in Salinas.

Mills Family Farms has been producing the whole-leaf product for about

10 years. Lazzerini became a partner

with Mills in 1999 and at that time Boss

Farms began. The name “Boss” refers

to a popular Hansen Farms label that

had been around for many years. Mills

(continued on page 3)

Loading...

Loading...