Page 1

Aqua-Clear

Fiberglass Sand Filters

Addendum to the Installation & Users Guide

Automatic Backwash Filter Assembly

See Installatio n & U s er’s Guide for Import ant Safety

Instructions

Page 2

System Contents ........................................................................................................................ 3

Overview .................................................................................................................................... 5

Assembly of the Automatic Backwash valves ............................................................................. 5

Hydraulic Control Filter Assembly .............................................................................................. 6

Manifold Assembly ..................................................................................................................... 7

Assembly of the Air Vents .......................................................................................................... 9

Connection of the Hydraulic Command Tubing .........................................................................10

Operation of the Automatic Filters .............................................................................................11

Programming the Automatic Backwash Controller ....................................................................12

Wiring the Controller .................................................................................................................16

Appendix 1: Manifold Construction Detail .................................................................................19

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 2

Page 3

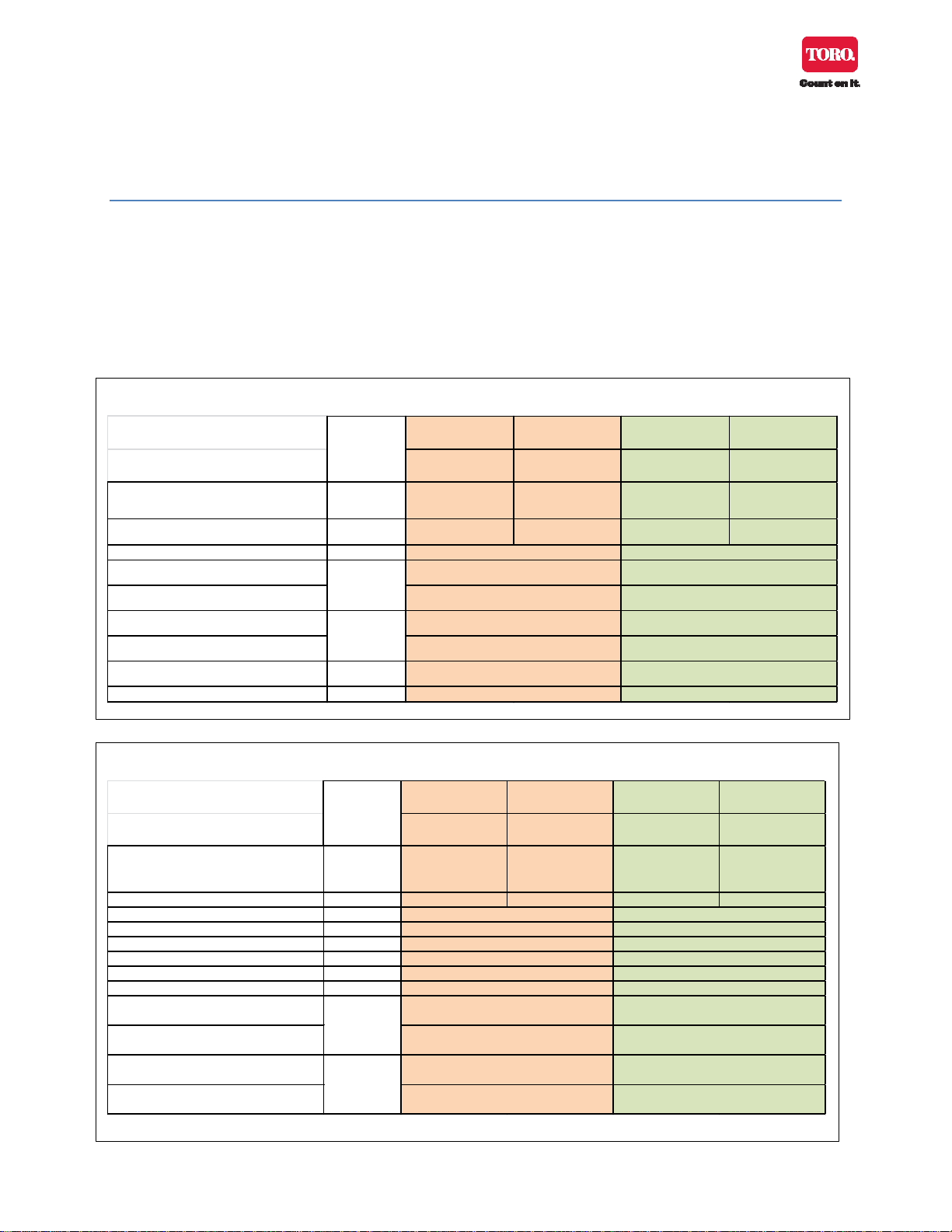

Table 2

ACS-218-12VDCL ACS-224-12VDCL ACS-230-12VDCL ACS-236-12VDCL

ACS-218-24VAC ACS-224-24VAC ACS-230-24VAC ACS-236-24VAC

Aqua-Clear Automat ic Filter St

Qty 2 x 18" 2 x 24" 2 x 30" 2 x 36"

Filter Body 2 AC-40 AC-60 AC-100 AC-140

Aqua-Clear Hydraulic Kit 1

Backwash Controller - 12v DCL

Backwash Controller - 24v AC

Backwash Valve (12v DCL)

Backwash Valve (24v AC)

3" Fitting Kit

2

Operations Manual Addendum

1

System

Part

Numbers

ALT227

ALT227

2

either

AC or DC

B2x2350S551DSPBZVI

B3x3350S551DSPBZVI

B2x2350S554RCPBZVI

B3x3350S554RCPBZVI

n/a

ACK-3F

ACK-HYD1

ACK-HYD1

1

either

AC or DC

B-EXFP111002DP

B-EXFP111002DP

B-EXFP211002DP

B-EXFP211002DP

Table 1

ACX-118-12VDCL ACX-124-12VDCL ACX-130-12VDCL ACX-136-12VDCL

ACX-118-24VAC ACX-124-24VAC ACX-130-24VAC ACX-136-24VAC

Aqua-Clear - Expansion Filter

Qty 1 x 18" 1 x 24" 1 x 30" 1 x 36"

Filter Body 1 AC-40 AC-60 AC-100 AC-140

Bulkhead Adapters (2") 1

3" Fitting Kit

Air release valve 1

Tee, Plastic [8mm Compression] 1

8MM Hydraulic Tube - 10' Coil 1

Operations Manual 1

Backwash Valve (12v DCL)

Backwash Valve (24v AC)

Controller Expansion board (12v DCL)

Controller Expansion board (24v AC)

1

either

AC or DC

B-S-TG-0208

B-S-TG-0208

B-S-TG-0215

B-S-TG-0215

System

Part

Numbers

B-8MMHYD-10

B-8MMHYD-10

ALT227

ALT227

1

either

AC or DC

B2x2350S551DSPBZVI

B3x3350S551DSPBZVI

B2x2350S554RCPBZVI

B3x3350S554RCPBZVI

n/a

ACK-3F

ARV-BBK1

ARV-BBK1

B-FT98-T

B-FT98-T

AC-BHA-2

AC-BHA-2

Automatic Backwash Filter

Operating Manual Addendum

System Contents

Please check immediately to see that you have received all the parts for the system. For two

filter systems, reference Table 1. For one filter expansion systems, reference Table 2. Systems

may contain kits, the detailed contents of which appear in Table 3.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 3

Page 4

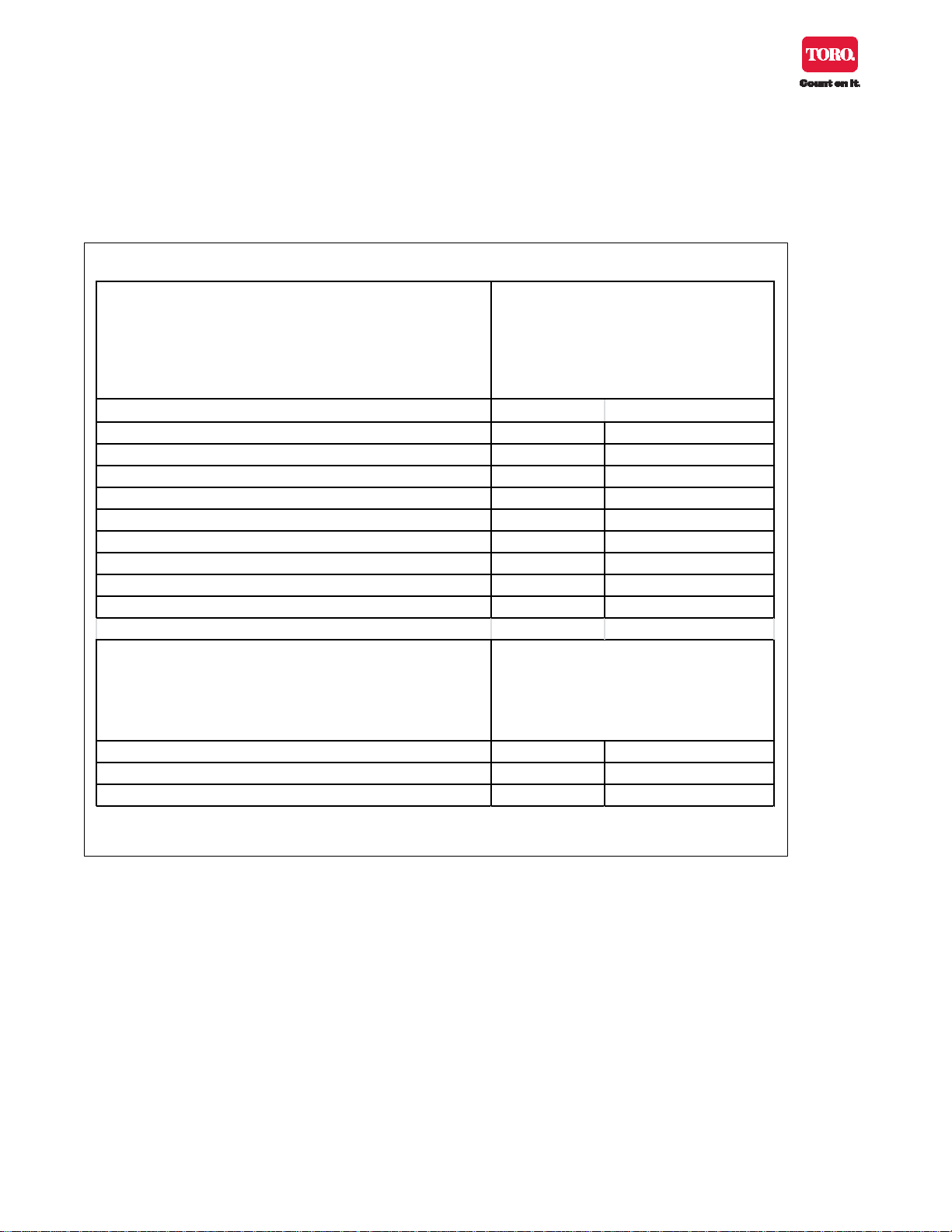

Table 3

H ydraulic Kit Contains:

Description

Qty SKU

Pressure gauge (0-100 psi) 2 GPM0100

8MM Hydraulic Tube - 10' Coil 2 B-8MMHYD-10

3/4" disc filter 1 ALFD75150-L

Air release valve 2 ARV-BBK1

Reducing Bushing 1/4" x 1/8", Brass 2 28-102

Tee, Plastic [8mm Compression X 1/8" NPT] 1 B-FT98-1T

Elbow, Plastic [8mm Compression X 1/8" NPT] 1 B-FT28-EL

Tee, Plastic [8mm Compression] 1 B-FT98-T

Bulkhead Adapters (2") 2 AC-BHA2

3" Fitting Kit

Grooved Couplings (3") 3 B-DS-V2030

Grooved Nipples 3 VG03PE

Air V ent Cover Adapter 1 T-60403

The Aqua Clear Hydraulic Kit is

included with the Filter station; Part

numbers are provided here for

parts reference.

The Aqua Clear Hydraulic Kit is

included with the Filter station; Part

numbers are provided here for

parts reference.

System Contents (cont.)

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 4

Page 5

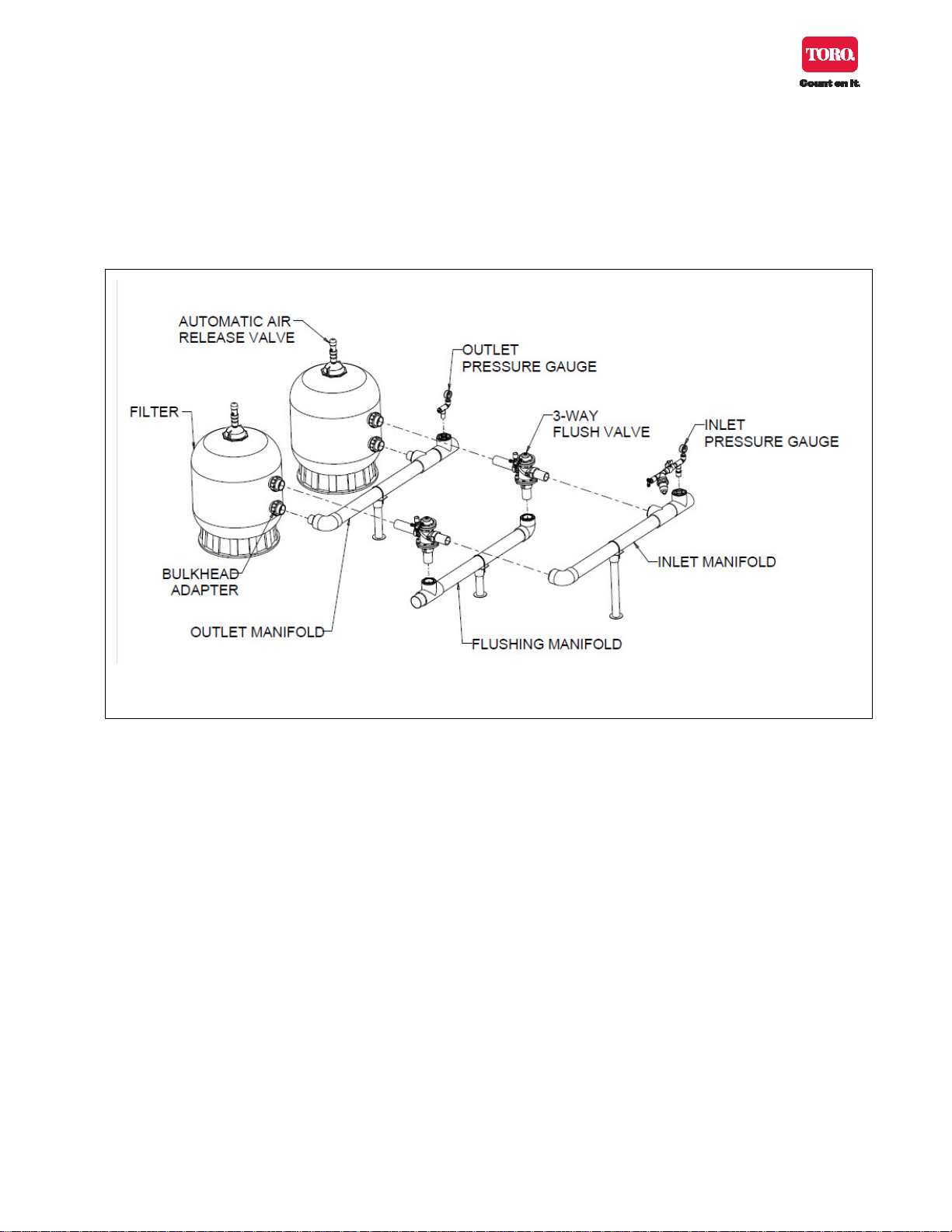

Overview

Construct the manifold system shown below, using only schedule 40 PVC pipe and fittings.

VERY IMPORTANT to always support the PVC manifolds or any long runs to prevent any

added stress on the filter bulkheads and glue joints. In general, use as short a length of PVC

pipe as practical, and do not add unnecessary fittings and elbows; this will prevent unnecessary

pressure losses and improve efficiency.

Figure 1

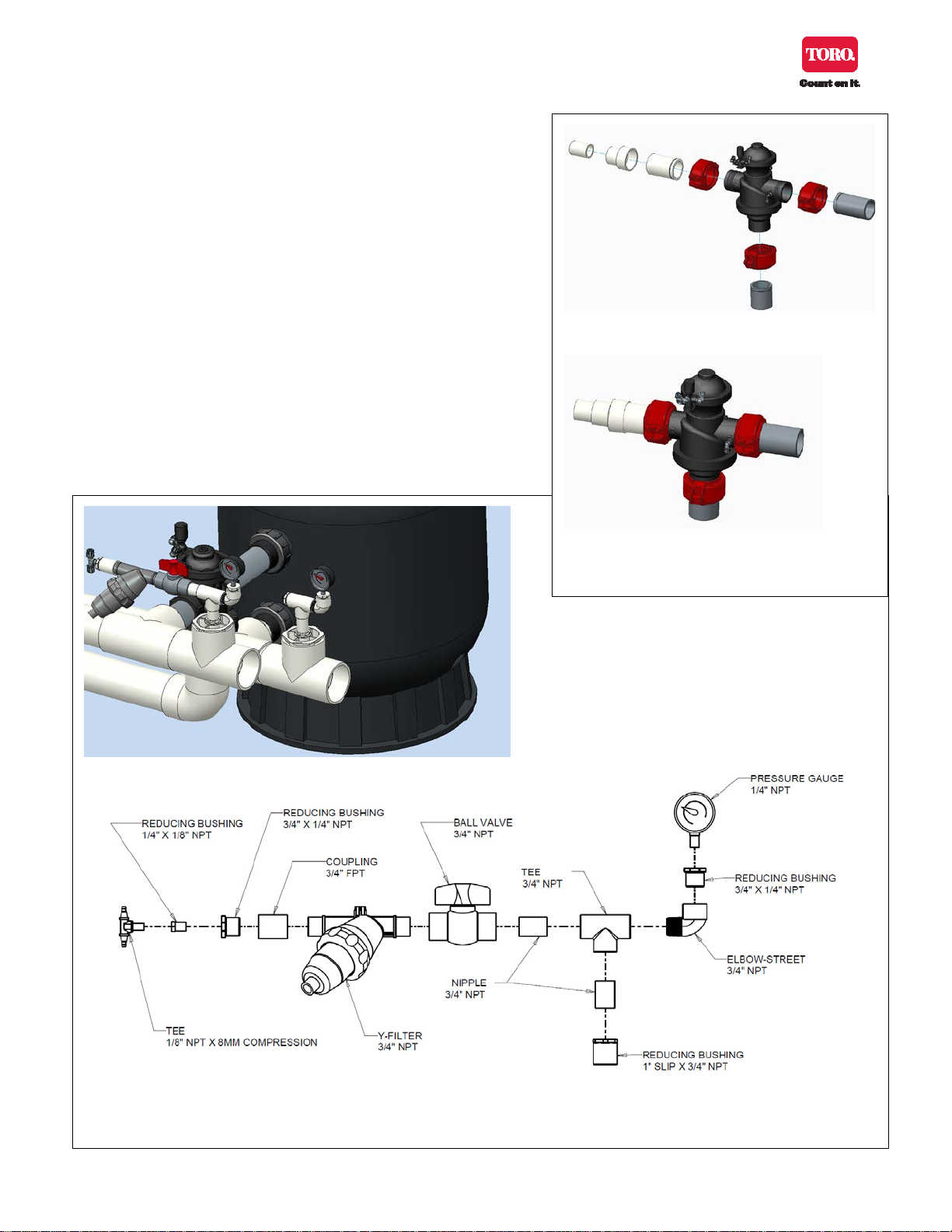

Assembly of the Automatic Backwash valves

1. The 3” backwash valve model has grooved fittings. The valve will need to be assembled

to PVC grooved adapters (included). Basic assembly instructions for grooved fittings

follow (See Figure 2):

• Use a light coating of non-petroleum based lubricant, and slide the rubber gasket all

the way onto the valve body.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 5

Page 6

• Position the valve connection to the PVC

grooved adapter.

• Slide the gasket toward the PVC fitting so

that it equally straddles the grooved fitting on

the valve, and the grooved fitting on the

adapter.

• Clamp the Grooved fitting over the rubber

gasket, tightening the two bolts equally.

• Some flexibility of this joint when complete is

normal; it is one of the advantages of a

grooved fitting connection.

Hydraulic Control Filter Assembly

See Figure 3 for detail on construction of Hydraulic

Control Filter Assembly

Figure 2 Grooved Fitting Assembly

Figure 3 Hydraulic Control Filter Assembly

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 6

Page 7

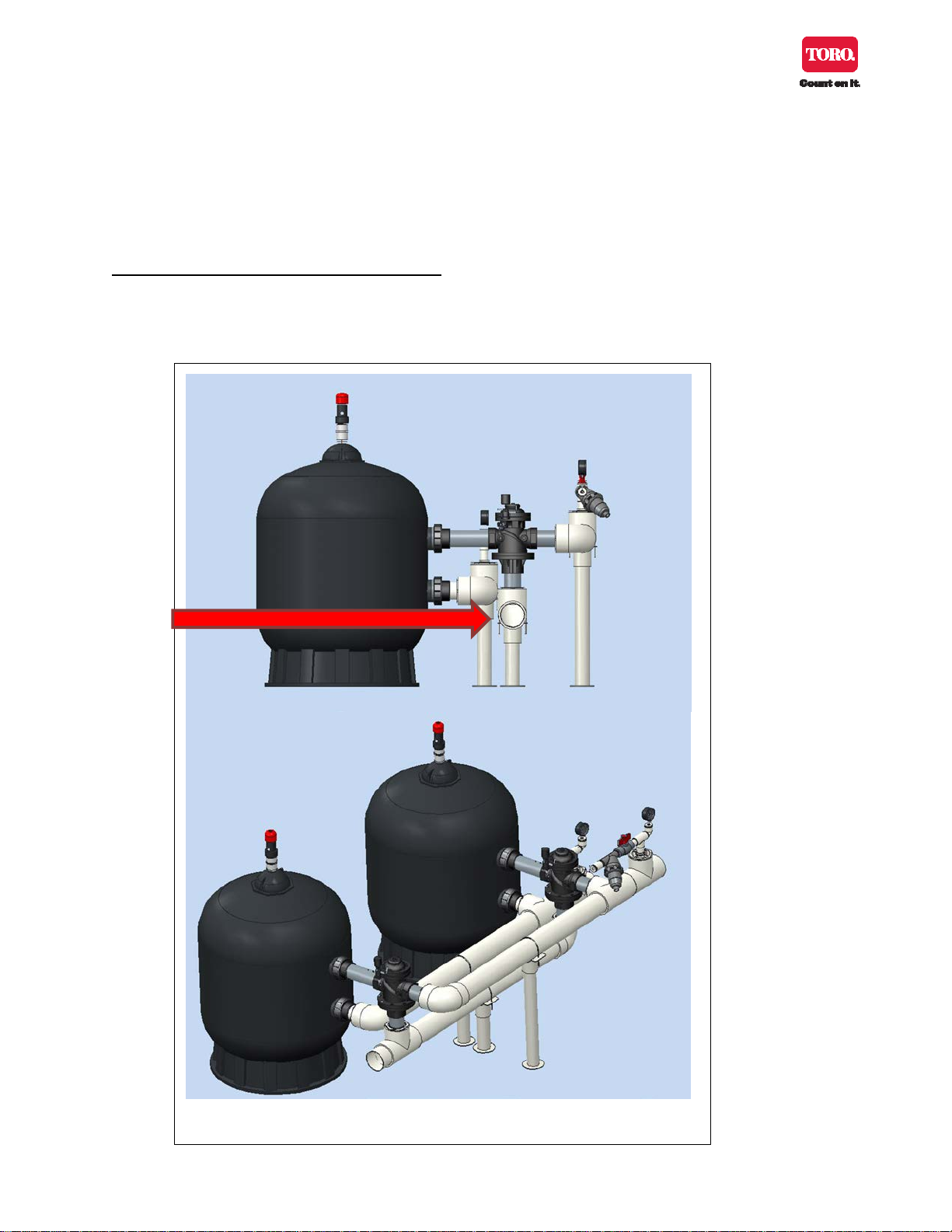

Manifold Assembly

Be certain to allow sufficient clearance to allow the installation of all three manifolds (see Figure

4)

It is Very Important to support manifolds to prevent stresses to bulkhead fittings on filters.

Excessive stress can lead to failure of the filter.

A chart showing the basic recommended fittings and pipe lengths is in Table 4.

Figure 4 Manifold Clearance Recommendation

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 7

Page 8

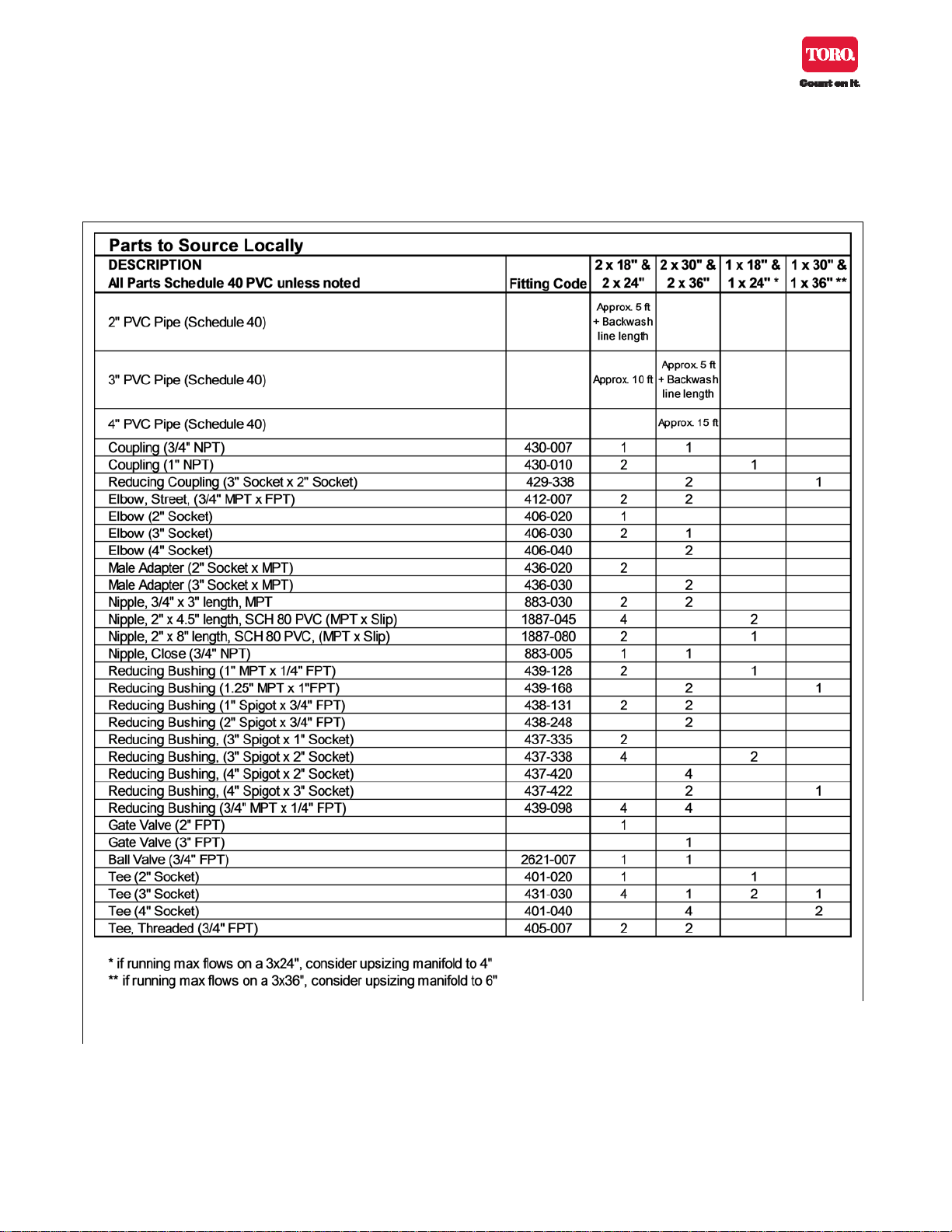

Table 4 Parts toSource Locally

A detailed assembly diagram for these parts is in the appendix.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 8

Page 9

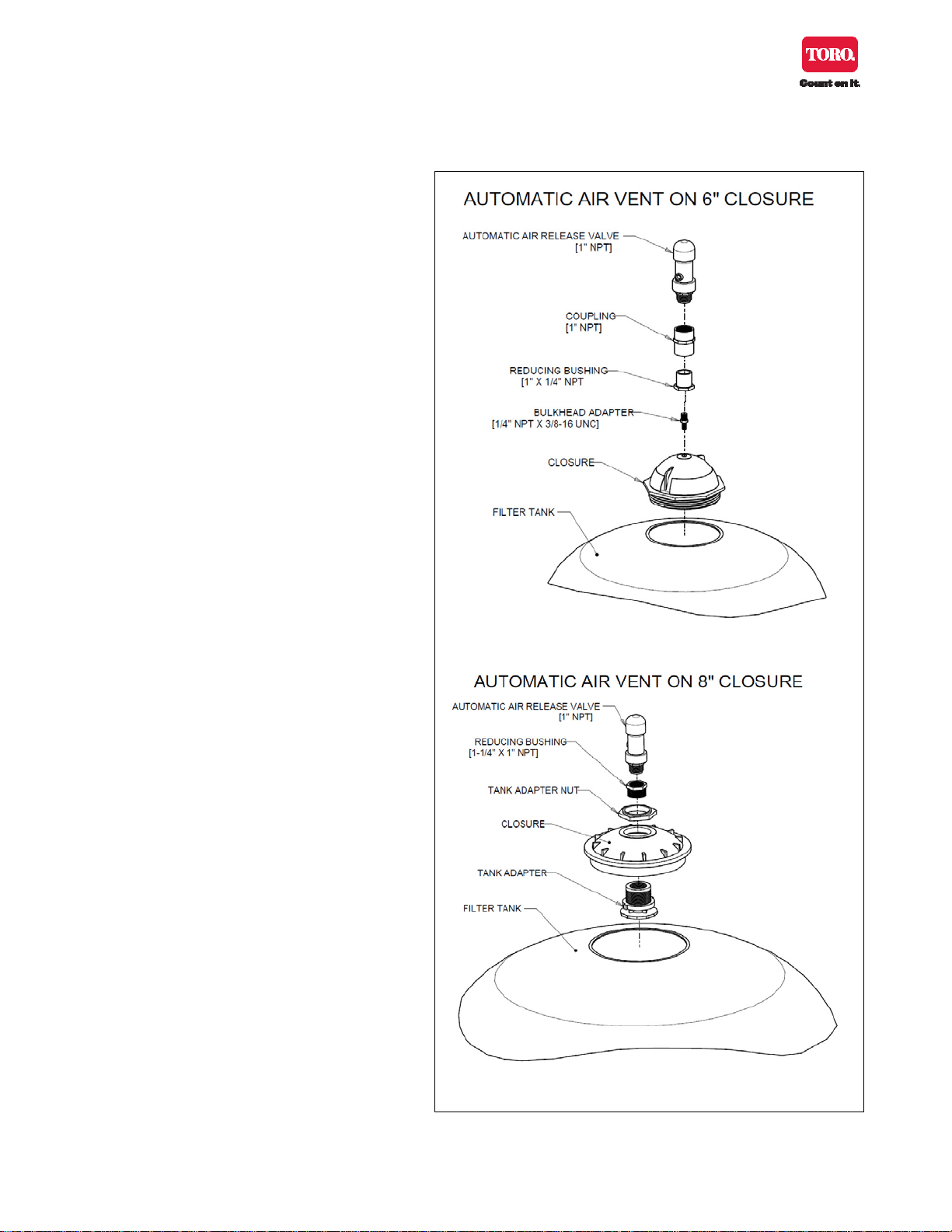

Assembly of the Air Vents

See Figure 5.

For the 18” and 24” models, the air vent

is attached to the ¼” threaded nipple

which comes attached to the manual air

bleed assembly. The rest of the manual

air bleed assembly is not needed. This

¼” threaded nipple is then installed onto

the 6” closure on top of the filter.

For the 30” and 36” models, the air vent

adapter should first be installed on the

8” closure on top of the filter. The A ir

Vent can then be threaded onto this

adapter. Note: This fitting is reverse

thread, so to tighten, twist the nut

counterclockwise.

There is a plastic air relief tube (item #9

on the Replacement Parts diagram of

the Filter Manual) inside the filter

attached to the Lower Piping Assembly;

it has a small screen filter on the upper

end. This tube is not attached to any

part of the external Air Vent structure.

The tube with the screen filter should be

placed inside the dome of the top cover

during final assembly.

NOTE: For all threaded connections, be

certain to use adequate amount of

Teflon tape or paste to create a good

seal.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 9

Figure 5 Automatic Air Vent Installation

Page 10

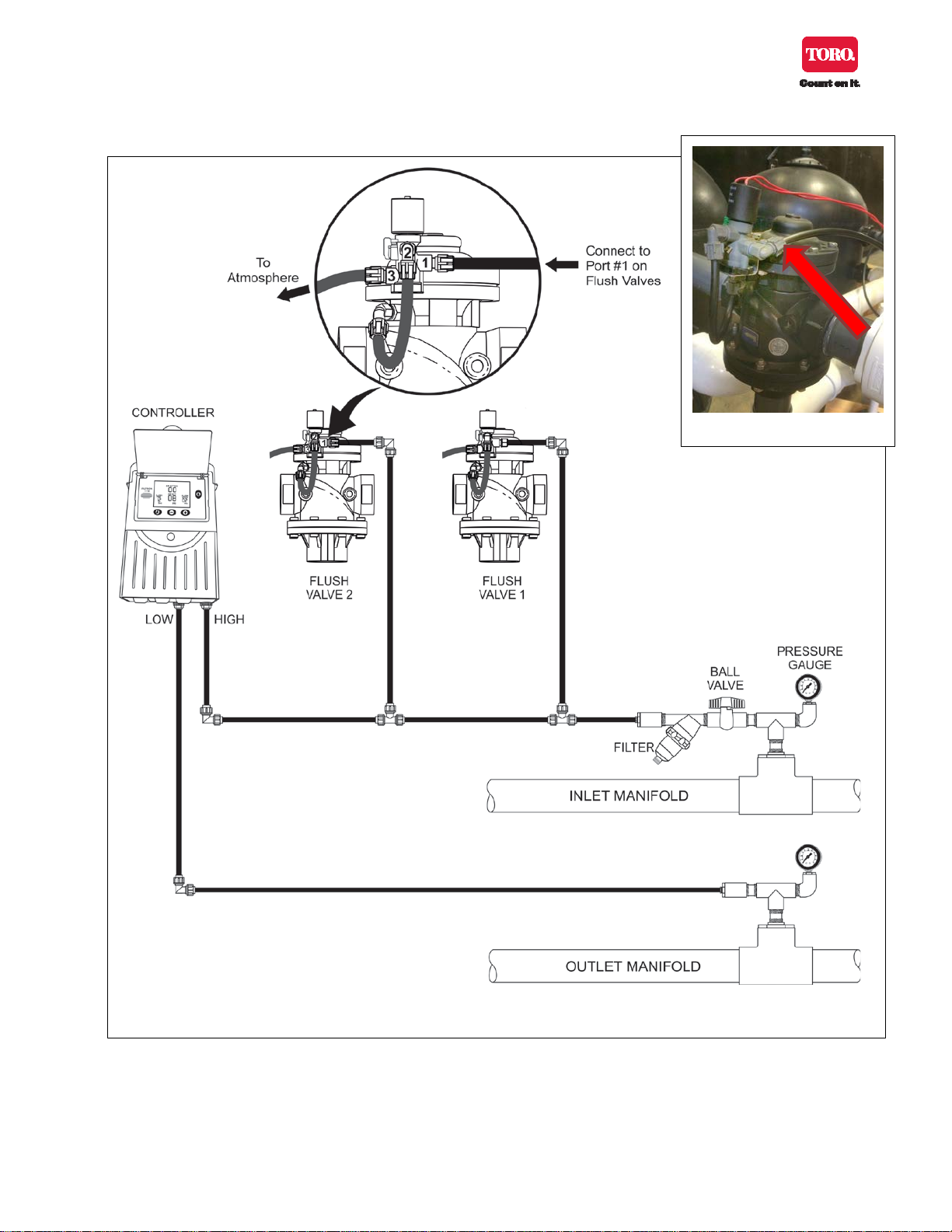

Figure 6

Connection of the Hydraulic Command Tubing

Figure 7 Hydraulic Command Tube Connections

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 10

Page 11

Hydraulic command tube serves two purposes in an automatic backwash system:

1. It communicates the pressure levels to the controller, which manages the backwash

2. It provides the pressure to open and close the backwash valves.

Follow the circuit diagram in

Figures 6,7 to connect the

Hydraulic Command Tubing.

The filter on the Hydraulic

Command assembly assures

that the water used to control

the valves is clean of debris.

This filter will become clogged

over time, and should be

cleaned. Closing the ball

valve upstream of the filter will

allow you to clean the filter

even when the system is in

operation. Cleaning this filter

should be a routine

maintenance check, and a

troubleshooting step any time

the backwash is not occurring

as it should.

Operation of the Automatic Filters

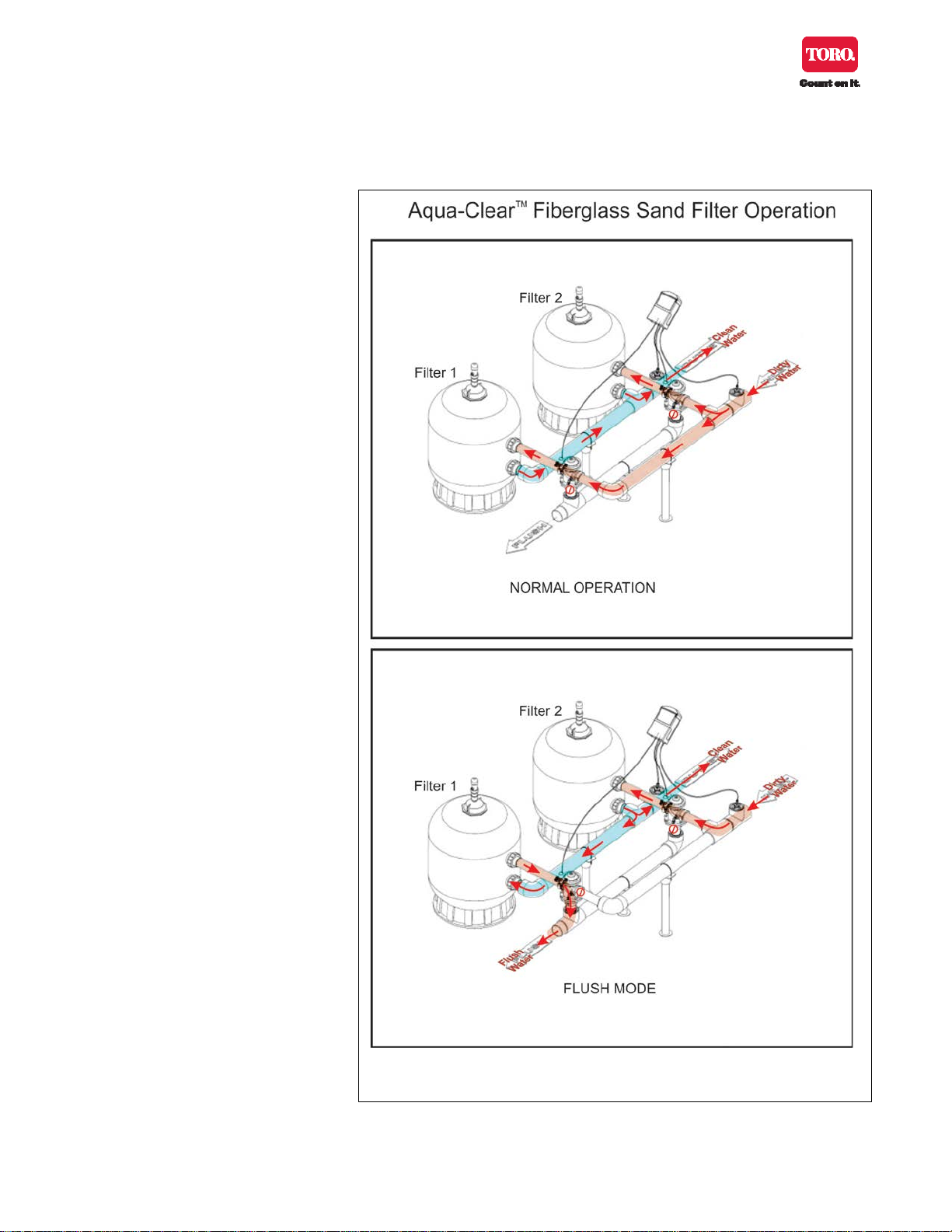

The top illustration in Figure 8

shows the filters operating in

“filtration” mode. The lower

illustration shows the water

flow when Filter #1 is in

“backwash” mode. After Filter

#1 has been backwashed, the

controller will backwash Filter

#2.

Figure 8 Filter Operation

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 11

Page 12

Figure 9 Enter

Key

Programming the Automatic Backwash Controller

General Information

The controller comes with its own manual which provides good detail. The information below is

abbreviated, and explains some terms found in the controller manual.

The general function of the backwash controller is to sense the need for the filters to be

backwashed, and to manage a backwash cycle in which each filt er is individually flushed.

As the filters become dirty and need to be flushed, the pressure loss through filters increases.

The controller senses the need for the filters to be backwashed by tracking the pressure of the

system both upstream, and downstream of the filters. The controller is physically connected by

hydraulic tube to a point upstream of the filters, and also downstream of the filters. This

difference in the upstream and downstream pressure is called the pressure differential

(sometimes abbreviated PD, or DP). The controller can be instructed to initiate a backwash

sequence when the PD hits a specified limit (typically 5-7 psi).

The controller will also initiate a backwash sequence after a specified period of time has

elapsed, whether the PD sensor has called for a backwash or not. This is typically operated as

a backup trigger to the PD actuation, in case of a sensor failure.

The controller also keeps track of the number of backwashes that have occurred between

resets, enabling the operator to evaluate the operation of the system over time.

Getting Started

There are two stages to programming. Steps 1-4 of this section assign values to commonly

manipulated settings: how long, when, and how frequently to backwash, as well as some

readouts from the controller on how many times the filter has backwashed.

Steps 5-13 of this section are sometimes referred to as ‘configuration’. You will be instructing

the controller what values to use for the various functions it can perform, and some information

about the system being controlled. Typically the system is configured once at the initial

assembly stage, however, it can be re-configured at any time.

Basic Program

To perform steps 1-4, briefly press the ENTER key. After entering the

desired value for a function, press the ENTER key to move to the

next function to be programmed. For each function, the + and – keys

will scroll through the available selections for that function. See the

steps which follow for explanation of function and typical settings.

Initial Configuration

After performing the Basic Program entry, press and hold the enter key for 3 seconds, and you

will enter the configuration stage, steps 5-13. . After entering the desired value for a function,

press the ENTER key to move to the next function to be programmed. For each function, the +

and – keys will scroll through the available selections for that function. See the steps which

follow for explanation of function and typical settings.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 12

Page 13

If you decide during the initial programming to change a variable which you have already

passed, you can reach it by cycling all the way through the remaining functions to be

programmed, and loop back to the function to be changed.

Any time changes to the configuration settings are desired, this stage can be entered by

pressing and holding the ENTER key.

Program Settings

Following is the sequence of controller functions that will appear after entering the programming

cycle:

1. Flush Time

Defines the duration of the flushing time per station. The following options are selectable:

5-20 seconds in steps of 1 second

20-55 seconds in steps of 5 seconds

1-6 minutes in steps of 0.5 minutes

A typical flush time setting is 1 to 2 minutes. The proper flush time can vary with the

contaminant load of the water, season, and several other factors. See the general filter

instruction manual for guidance on how to fine tune the flush time based on observation of the

flush water.

2. The PD Set Point

This sets the value of the pressure differential that will initiate a flushing cycle.

Typical setting is 5-7 psi.

3. The Flush Mode

This sets the method by which the controller will trigger a backwash cycle.

The typical setting is “By Time”. In this setting, both the time and the pressure differential can

trigger a backwash cycle; if the PD sensor calls for a backwash before the timer does, a

backwash will occur (and the timer will be re-set). If the PD sensor has not called for a

backwash within the timer cycle, the tim er will trigger a backwash, and the timer will re-set.

The length of time to set in this field varies widely with how dirty the water is, how much the

filters are used, and several other factors. To optimize this setting, growers often check how

frequently the filters are backwashing by the PD trigger, and set the timer for a period of time

20% longer than the frequency called for by the PD sensor. A typical initial setting is 4-8 hours.

4. Accumulations Readout

There is nothing to set at this point – it is an informational readout on the amount of

backwashing that has been occurring. There are three consecutive readouts: DP, time, and

manual. Each step indicates the # of backwash cycles triggered by either DP, time, or manual.

Cycle through these using the ENTER key.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 13

Page 14

5. Main Valve

The standard controller is not equipped for this function; an expansion board can be added

which enables the controller to command a master valve when a backwash cycle is triggered.

Please speak with your Toro dealer if you wish to add this functionality. The standard setting

should be “No” to indicate no main valve function.

6. Dwell Time

The controller backwashes the filters one at a time. The Dwell time is the pause between the

filters in a backwashing cycle. This Dwell Time allows the system to come back to full pressure

for the next backwash. A typical dwell time setting is 30 seconds.

7. DP Delay

This is the delay during which the PD sensor reading is expected to remain stable before the

controller triggers a backwash. This delay prevents the filter from backwashing due to a short

spike in the pressure differential; if the pressure differential exceeds the value of the set point

for the length of time set here, then a backwash will trigger. A typical setting is 10-15 seconds.

8. Looping Limit

Sometimes a fault in the PD sensor, or another problem occurs in the system, and the filter can

enter an ‘endless loop’ of consecutive backwashing cycles. This could create flooding or

washout conditions where the backwash water exits, and so a limit to the number of consecutive

backwash cycles commanded by the PD sensor is set in this field. If the filter enters into an

‘endless loop’ of consecutive backwash cycles called for by the PD sensor, when the limit set in

this field is reached, the PD sensor will be ignored, and the filter will be triggered only by the

timer. When the PD sensor returns once again to a reading below its trigger setpoint, the

looping limit will re-set, and the PD sensor will now be available to trigger backwash cycles

again. Typical setting is 5.

9. Alarm

The standard controller is not equipped for this function; an expansion board can be added

which enables the controller to close a switch and trigger an alarm. Please speak with your

Toro dealer if you wish to add this functionality. The standard setting should be “No” to indicate

no alarm function.

10. Delay Valve

The standard controller is not equipped for this function; an expansion board can be added

which enables the controller to command a master valve when a backwash cycle is triggered,

and this setting would manage the delay between actuating the main valve and the backwash

cycle. Please speak with your Toro dealer if you wish to add this functionality. The standard

setting should be “No” to indicate no delay valve function.

11. View Outputs

This function is not used on the standard controller; press ENTER to pass by it.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 14

Page 15

Figure 10

12. Pressure Units

Select PSI for US units, or Bar for metric units.

13. Calibration

This will calibrate the PD sensor. While the controller sensor ports are disconnected from the

hydraulic tubing, select the Calibration = Yes. The calibration occurs very quickly, and the

sensor ports on the controller should be reconnected after passing through this program step.

This will conclude the programming of the controller, and it is ready to use. If you want to revisit

any of the settings, simply cycle through them at this point. If you wish to change setting 1-4,

briefly press the ENTER key. If you wish to re-visit steps 5-13, press and hold the ENTER key

for at least 3 seconds.

Manual Backwashing

A flushing sequence can be manually triggered by the MANUAL key (hand

Icon, or M). By pressing the MANUAL key again the cycle will be

terminated.

M

Manual Key

symbols

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 15

Page 16

Wiring the Controller

Solenoids

Each of the solenoids must be connected

to the board inside the controller, as shown

in Figures 11, 12.

DC models: The black wire from each

solenoid should be attached to the

common terminal (C) as shown in Figure

11. The red wires should be attached as

shown to terminals Out A and Out B

respectively.

AC models: The solenoid wires will be

the same color. One wire from each

solenoid should be attached to the

common terminal (C), and the other wires

from each solenoid connected to terminals

Out A and Out B see Figure 12.

Figure 11 Wiring for DC Solenoids

Figure 12 Wiring for AC Solenoid

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 16

Page 17

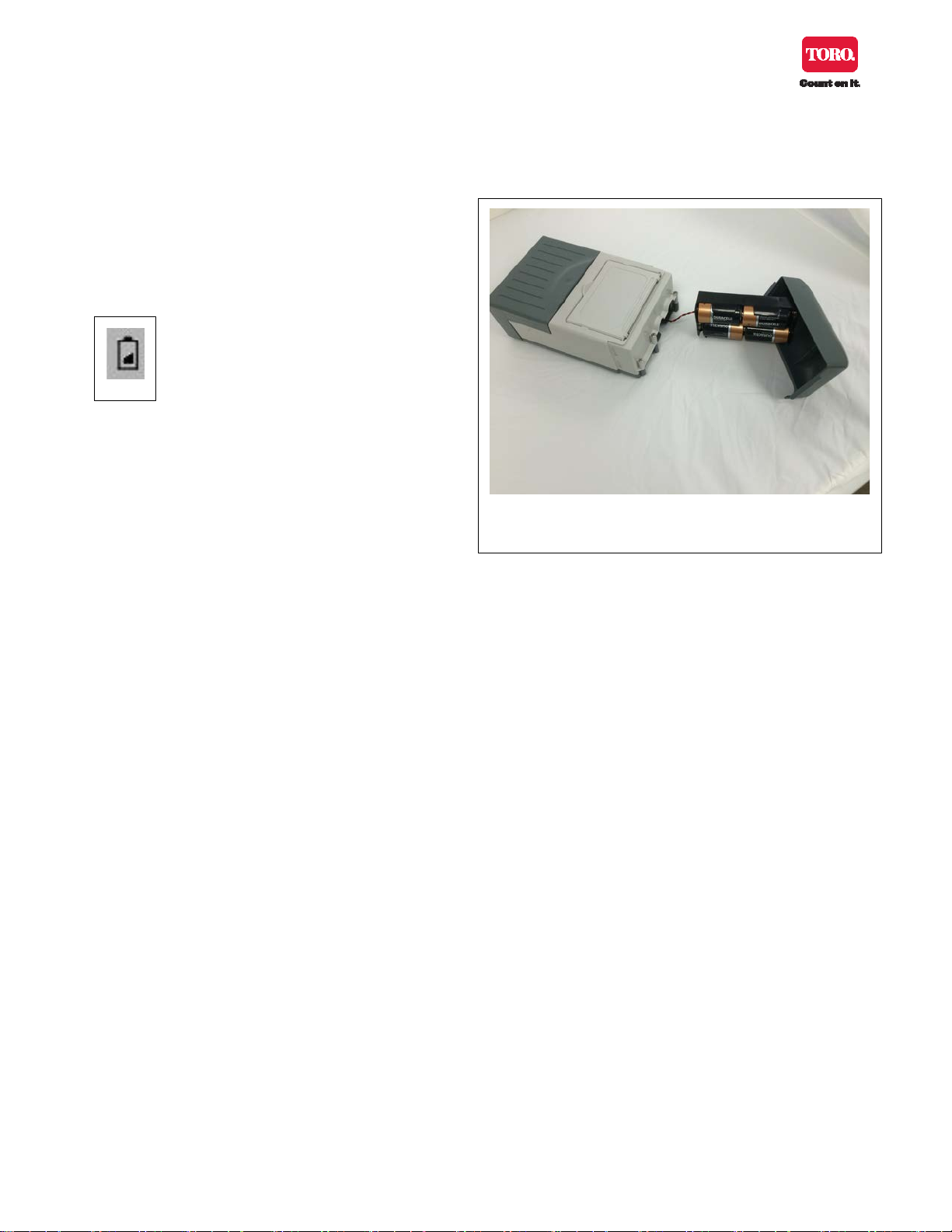

Powering the Controller

DC Model

The DC model requires four D Cell batteries,

which should power the controller for a year.

Install the batteries by removing the top of the

controller, and installing four D size batteries

as shown in Figure 13.

The unit has two levels of low battery

indication. When the battery voltage

drops to the first level, the low battery

sign will appear on the screen.

When the battery voltage drops further to the

second level, all outputs will shut down, and

the screen will be cleared leaving only the low

battery icon.

The DC model must always be used with

12v DC Latching solenoid valves.

Figure 13 Add batteries to top of Controller

AC Model

The AC model is connected by a transformer to an external power source. The AC model

must always be used with 24v AC solenoid valves.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 17

Page 18

Figure 14 Finished Assembly

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 18

Page 19

Appendix 1: Manifold Construction Detail

Figure 15

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 19

Page 20

Aqua-Clear

Filtros de Arena de Fibra de Vidrio

Anexo a la Guía de Instalación y al Manual de Usuario

Montaje del Filtro de Retrolavado Automático

Véase la Guía de Instalación y el Manual de Usuario

para obtener las Instrucciones de Seguridad

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 20

Page 21

Contenido del Sistema ..............................................................................................................22

Información General .................................................................................................................24

Montaje de las Válvulas de Retrolavado Automáticas ...............................................................24

Montaje del Filtro de Control Hidráulico.....................................................................................25

Montaje de los Múltiples ............................................................................................................26

Montaje de Válvulas de Aire/Vacío ............................................................................................28

Conexión de Tubería de Comando Hidráulico……………………………………………………… 29

Funcionamiento de Filtros Automáticos ....................................................................................30

Programación del Controlador de Retrolavado Automático……………………………………… 31

Diagrama de Cableado del Controlador ....................................................................................35

Apéndice 1: Construcción Detallada del Múltiple .......................................................................38

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 21

Page 22

Filtro de Retrolavado Automático

Anexo al Manual de Usuario

Contenido del Sistema

Por favor verifique de inmediato que ha recibido todas las piezas del sistema. Para sistemas con dos

filtros, consulte la Tabla 1. Para sistemas de expansión de un filtro, consulte la tabla 2. Los sistemas

pueden contener paquetes, para verificar el contenido detallado consulte la Tabla 3.

Tabla 1

Tabla 2

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 22

Page 23

de Partes son los siguientes:

Descripción

Cant.

SKU

Manómetro de Salida

2

GPM0100

Tubo Hidráulico 8mm- Bobina 10'

2

B-8MMHYD-10

Disco de Filtro 3/4"

1

ALGD75150-L

Válcula de Escape

2

ARV-BBK1

Buje de Reducción 1/4" x 1/8, Latón

2

28-102

Tee, Plástico [Compresi ón 8 mm x 1/8 NPT)

1

B-FT98-1T

NPT] 1 B-FT28-EL

Tee, Plástico [Compresión 8 mm)

1

B-FT98-T

Bridas Roscadas (2")

2

AC-BHA2

de Partes son los siguientes:

Tubería Ranurada (3")

3

B-DS-V2030

Niples 3 VG03PE

Adaptador de Cubierta de Ventilación

3

T-60403

Contenido del Sistema (continuación)

Tabla 3

Contenido del Kit Hidráulico:

El Kit Hidráulico de AquaClear viene incluido con la

estación del Filtro; el Número

Codo, Plástico [ Compresión 8 mm x 1/8"

Kit de Conectores 3"

El Kit Hidráulico de AquaClear viene incluido con la

estación del Filtro; el Número

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 23

Page 24

Información General

Construya el sistema de múltiples como se muestra en la ilustración de abajo, utilizando

solamente la tubería PVC de cédula 40 y conectores. ES MUY IMPORTANTE asegurarse de

reforzar la tubería de PVC del sistema de múltiples, o cualquier otro tubo de paso para evitar la

acumulación de tensión en las bridas del filtro e inserciones. Considere utilizar tubería PVC tan

corta como sea posible sin agregar conectores o codos adicionales, esto con el fin de mantener

la presión adecuada mejorando así la eficiencia

VÁLVULA

AUTOMÁTICA

DE AIRE/VACÍO

del filtro.

MANÓMETRO DE

SALIDA

FILTRO

BRIDA

ROSCADA

SALIDA DE MÚLTIPLE

MÚLTIPLE DE LAVADO

VÁVULA DE

LAVADO DE 3

VÍAS

MANÓMETRO DE

ENTRADA

ENTRADA DE

MÚLTIPLE

Ilustración 1

Montaje de las Válvulas de Retrolavado Automáticas

1. El modelo de la válvula de retrolavado de 3” cuenta con tubería ranurada. La válvula

debe ser ensamblada a los adaptadores ranurados de PVC, los cuales vienen incluidos.

Vea la ilustración 2 y siga las instrucciones para el Montaje de Tubería Ranurada:

• Utilice una capa de lubricante que no sea derivado de petróleo, y deslice el

empaque de hule hasta la parte central o cuerpo de la válvula.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 24

Page 25

BUJE DE REDUCCIÓN

BUJE DE REDUCCIÓN

COPLE

TEE

• Coloque la conexión de la válvula al

adaptador ranurado de PVC.

• Deslice el empaque hacia el conector de

PVC de modo que se extienda el conector

ranurado en la válvula, y el conector

ranurado al adaptador de PVC.

• Sujete el conector ranurado sobre el

empaque de hule, apretando ambos

tornillos.

• La flexibilidad con la que cuenta el ensamble

una vez ya terminado es normal, pues es

una de las ventajas de la conexión de

tubería ranurada.

Montaje del Filtro de Control Hidráulico

Vea la ilustración 3 para seguir las instrucciones precisa s

del Montaje del Filtro de C ont r ol Hidráulico.

Ilustración 2 Montaje de Tubería Ranurada

MANÓMETRO

VÁLVULA

BOLA

TEE

1/8” NPT x COMPRESIÓN 8 MM

NIPLE

34/” NPT

FILTRO- Y

3/4” NPT

TEE

BUJE DE REDUCCIÓN

BUJE DE REDUCCIÓN

CODO

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 25

Page 26

Montaje de los Múltiples

Asegúrese de dejar suficiente espacio para realizar la instalación de los 3 (tres) múltiples (vea

la ilustración 4).

Es muy importante reforzar adecuadamente los múltiples para evitar el exceso de tensión

en la bridas de los filtros, ya que esto puede resultar al fallo del filtro.

Vea la Tabla 4, en la cual encont r ará s ugerencias de conector es as í como longitudes de tubería.

Ilustración 4 Montaje de los Múltiples

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 26

Page 27

Tabla 4 Partes a Conseguir

En el Apéndice 1, encontrará un diagrama detallado de las partes del montaje.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 27

Page 28

Montaje de Válvulas de Aire/Vacío

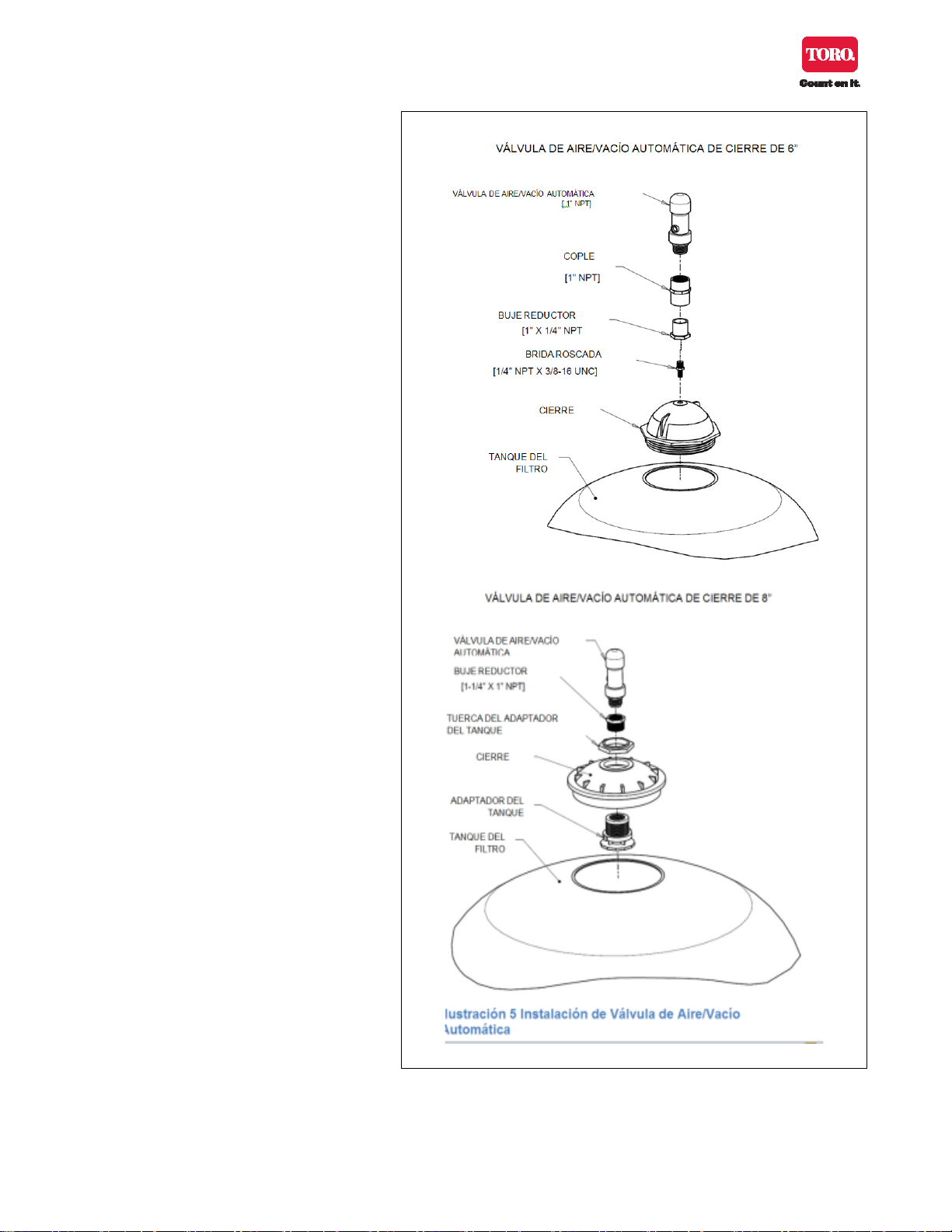

Vea la ilustración 5.

Para los modelos de 18” y 24”, la

válvula de alivio de aire/vacío se

encuentra adherida al niple roscado

de ¼” el cual viene adjunto al

Manual de Ensamble de la unidad

de purga de aire. El resto del

manual de ensamble no es

necesario. Este niple roscado de

¼” será posteriormente instalado en

el cierre de 6” en la parte superior

del filtro.

Para los modelos de 30” y 36”, el

adaptador de aire/vacío debe ser

instalado en el cierre de 8” en la

parte superior del filtro. La Válvula

de aire/vacío puede ser

posteriormente enroscada en el

adaptador. Nota: Este conector es

de rosca inversa, por lo que para

ajustarse debe torcer la tuerca en

sentido contrario a las manijas del

reloj.

Hay un tubo de plástico por donde

escapa el aire (pieza #9 en el

Diagrama de Reemplazo de Piezas

del Manual del Filtro) que está

dentro del filtro, adjunto al Montaje

de Tubería Inferior; el cual tiene un

filtro de pantalla pequeño en el

extremo superior. Este tubo no está

conectado a cualquier parte externa

de la estructura de la Válvula

Aire/Vacío. El tubo con el filtro de

pantalla debe ser colocado dentro

de la cúpula de la cubierta durante

el montaje final.

NOTA: Para todos los conectores roscados, asegúrese de utilizar la cantidad adecuada de

cinta de teflón cerrando firmemente.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 28

Page 29

Ilustración 6

ENTRADA DE MÚLTIPLE

SALIDA DE MÚLTIPLE

Conexión de Tubería de Comando Hidráulico

Al ambiente

Conectar al

Puerto #1 en

Válvulas de

Lavado

CONTROLADOR

BAJO

ALTO

Válvula de

Lavado 2

Válvula de

Lavado 1

MANÓMETRO

VÁLVULA BOLA

FILTRO

Ilustración 7 Conexión de Tubería de Comando Hidráulico

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 29

Page 30

La Tubería de Comando Hidráulico tiene dos propósitos en un sistema de retrolavado

automático:

1. Transmite los niveles de presión al controlador, el cual dirige el retrolavado.

2. Proporciona la presión para abrir y cerrar las válvulas de retrolavado.

Siga el diagrama de circuito

de las ilustraciones 6 y 7 para

conectar la Tubería de

Comando Hidráulico.

El filtro del montaje del

Comando Hidráulico se

asegura de que el agua

utilizada para controlar las

válvulas esté limpia y libre de

residuos. Este filtro se

obstruirá con el tiempo, por lo

tanto debe ser limpiado. El

cierre de la válvula de bola de

agua ascendiente del filtro

permitirá limpiar el filtro,

incluso cuando el sistema

está en funcionamiento. La

limpieza del filtro debe ser

parte de una rutina de

mantenimiento, incluyendo la

detección y resolución de

problemas con el filtro en caso

de que se presenten.

FUNCIONAMIENTO DE AQUA CLEAR™, FILTRO DE ARENA DE FIBRA DE

VIDRIO

FILTRO 2

Agua

limpia

FILTRO 1

Agua de descarga

FUNCIONAMIENTO NORMAL

FILTRO 2

Agua

sucia

Agua

limpia

Funcionamiento de los

FILTRO 1

Agua

sucia

Filtros Automáticos

La imagen superior de la

ilustración 8 muestra el

funcionamiento de los filtros

durante el modo de “filtración”.

La imagen inferior muestra el

flujo de agua cuando el Filtro

1 funciona en modo de

“retrolavado”. Una vez que el

Filtro 1 ha sido lavado, el

controlador continuará el con

el Filtro 2.

Ilustración 8 Funcionamiento de Filtros

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 30

Agua de descarga

RETROLAVADO

Page 31

Ilustración 9

Tecla Enter

Programación del Controlador de Retrolavado Automático

Información General

El controlador incluye el manual de usuario con instrucciones precisas para su uso. La información que

se presenta a continuación explica brevemente algunos de los términos que se encuentran en el Manual

de Usuario del controlador.

La función general del controlador de retrolavado es detectar la necesidad de los filtros de ser lavados, y

de administrar el ciclo en el cual cada filtro es lavado individualmente.

A medida que los filtros se ensucian y necesitan lavarse, la pérdida de presión a través de los filtros

aumenta. El controlador detecta la necesidad de los filtros de ser lavados mediante el rastreo de la

presión del sistema, ascendente y descendente de los filtros. El controlador se encuentra físicamente

conectado mediante un tubo hidráulico a dos puntos, ascendente y descendente de los filtros. Esta

diferencia en la presión ascendente y descendente se le llama diferencial de presión, abreviada PD o

DP. El controlador puede ser programado para iniciar una secuencia de lavado cuando la DP llega al

límite especificado, generalmente entre 5 a 7 psi.

El controlador también iniciará una secuencia de retrolavado una vez transcurrido un periodo de tiempo

especificado sin importar si el sensor de DP ha pedido una secuencia de retrolavado o no. De modo que

el sensor de DP funciona generalmente como respaldo, en caso que uno de los sensores falle.

El controlador también realiza un seguimiento del número de ciclos de retrolavado que han ocurrido entre

reinicios, permitiendo al usuario evaluar el funcionamiento del sistema.

Inicio de la Programación

Hay dos etapas durante el proceso de programación. Los Pasos 1 al 4 de esta sección dan

instrucciones en asignar valores que se ajustan frecuentemente: cuánto tiempo, cuándo y con qué

frecuencia se realizará el ciclo de retrolavado; así como el conteo que realiza el controlador de cuántas

veces el filtro ha sido lavado.

Los Pasos 5 al 13 de esta sección se refieren a la Configuración. Le indicará al controlador los valores a

utilizar para las distintas funciones que puede realizar e información acerca del sistema. Típicamente el

sistema es configurado una sola vez ― al inicio del ensamble, sin embargo puede ser reconfigurado en

cualquier momento.

Programación Básica

Para llevar a cabo los Pasos1-4, pulse brevemente la tecla ENTER. Después

de introducir el valor deseado para una función, pulse ENTER para pasar a la

siguiente función a programar. Para cada función las teclas ‘+’ y ‘-‘, se

desplazarán a través de las opciones disponibles para esta función. Siga los

pasos siguientes para la explicación de cada función y ajustes.

Configuración Inicial

Después de realizar la Programación Básica, pulse y mantenga pulsada la tecla ENTER por 3 segundos

para comenzar la fase de Configuración, Pasos 5 al 13. Después de introducir el valor deseado para una

función, pulse ENTER para pasar a la siguiente función a programar. Para cada función las teclas ‘+’ y ‘-‘,

se desplazarán a través de las opciones disponibles para esta función. Siga los pasos siguientes para la

explicación de la función y ajustes.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 31

Page 32

Si durante la programación inicial decide cambiar una variable anteriormente asignada, puede continuar

pasando el resto de las funciones a programar y volver a programar la función deseada.

Cualquier cambio de tiempo que se desee hacer en el ajuste de Configuración, puede realizarse

pulsando y manteniendo presion ada la tecla ENT ER.

Configuración del Programa

A continuación se muestra la secuencia de las funciones del Controlador que aparecerán

después de ingresar el ciclo de programación:

1. Duración del Ciclo de Retrolavado

Define la duración del tiempo de lavado por estación. Puede seleccionar de las siguientes

opciones:

5-20 segundos en pasos de 1 segundo

20-55 segundos en pasos de 5 segundos

1-6 minutos en pasos de 0.5 minutos

La duración de retrolavado generalmente es de 1-2 minutos; puede variar en función de la

carga contaminante del agua, la temporada, y algunos otros factores. Consulte el manual de

instrucciones del filtro general para la orientación sobre cómo ajustar la duración del ciclo de

retrolavado en base a la observación del agua.

2. Ajuste de Diferencial de Presión (DP)

Este establece el valor del diferencial de presión en la que iniciará un ciclo de lavado.

Generalmente el ajuste es de 5-7 psi.

3. El Modo de Lavado

Esto establece el método por el cual el controlador comenzará un ciclo de retrolavado.

Generalmente la configuración es “Por tiempo”. En este contexto, tanto el tiempo como el

diferencial de presión pueden comenzar al ciclo de retrolavado; si el sensor del DP da la señal

para el retrolavado antes de que el controlador lo haga, se iniciará el retrolavado, y el

controlador se restablecerá.

El periodo de tiempo a configurar varía dependiendo en cuán sucia el agua esté, del uso de los

filtros, y algunos otros factores. Para optimizar este ajuste, a menudo los productores revisan

con qué frecuencia los filtros funcionan por medio del sensor de DP, y de este modo ajustan el

controlador prolongando el periodo de tiempo en 20% mayor a la frecuencia del sensor del DP.

Generalmente una configuración inicial es de 4-8 horas.

4. Contador de Ciclos

No hay nada qué configurar en este punto. Se lleva a cabo una lectura informativa acerca de la

cantidad de ciclos de retrolavado que se han realizado. Hay tres lecturas consecutivas: DP,

tiempo y manual. Cada paso indica el número de ciclos de retrolavado iniciados por el DP,

tiempo o manual. Revise cada uno de ellos pulsando la tecla ENTER.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 32

Page 33

5. Válvula Principal

El controlador estándar n o se encuentra equipado con esta función; una tarjeta de expansión puede

ser añadida, lo que permite que el controlador ordene a la v álvula principal cuando el ciclo de

retrolavado inicie. Por favor comuníquese con su distribuidor autorizado de Toro, en caso de que

desee agregar esta funció n. Indique ‘No’ en el ajuste estánd ar par a l a válvula principal.

6. Tiempo de Espera

El controlador realiza su f unci ón de r etrolavado con los filtros de uno en uno. El tiempo d e espera es

la pausa entre cada filtro durant e el ciclo de retrolavado. Est e per i odo de tiempo permite al sistema

volver a la presión máxima par a el siguiente ciclo de lavado. G eneralmente el tiempo de espera es

de 30 segundos.

7. Retraso del DP

Este es el retraso durante el cual se espera la lectura del sensor del DP para permanecer es t able

antes de que el controlador inicie un nuevo ciclo de retrolavado. El retraso impide que ini ci e el ciclo

de retrolavado debido a u n pico momentáneo en la presi ón diferencial; si el sensor de presión

diferencial excede el valor de ajuste para el periodo de tiemp o es t ablecido, se iniciará un ciclo de

lavado. Generalmente la configuración es de 10 a 15 segundos.

8. Límite de Ciclos de Lava do

Podría presentarse un fal lo en el sensor de DP, u otro probl ema en el sistema iniciando un ‘bucle

sin fin’ de ciclos de lavado consecutivos. Esto podría crear que se derrame el exceso de agu a, por

lo que se debe establecer un número de ciclos consecutivos de r etrolavado comandados por el

sensor de DP. En caso de que el filt r o comience un ‘bucle sin fin’ de ciclos de lavado consecutivos

comandado por el sensor DP, y una vez que el límite estab lec ido haya sido alcanzado, el sensor DP

será rechazado y el filtro s er á dirigido por el controlador. Cua ndo el sensor de DP regrese

nuevamente a su lectura de ajuste, se reiniciará el límite de bucles y el sensor estará disponible

para iniciar nuevos ciclos de lav ado. Generalmente la conf iguración es de 5.

9. Alarma

El controlador estándar n o se encuentra equipado con esta función; una tarjeta de expansión puede

ser añadida, lo que permite que el controlador cierre el interr uptor y se active una alarma. P or fav or

comuníquese con su distri bui dor aut orizado de Toro, en caso de q ue desee agregar esta función.

Indique ‘No’ en el ajuste est ándar para la alarma.

10. Válv ula de Retraso

El controlador estándar n o se encuentra equipado con esta función; una tarjeta de expansión puede

ser añadida, lo que permite al controlador dirigir la válv ula principal cuando un cicl o de l avado inicie,

y además este ajuste dirigirá el ret r aso entre el funcionamiento de la válvula y el ciclo de lavado. Por

favor comuníquese con su distr ibuidor autorizado de Toro, en caso de que desee agregar esta

función. Indique ‘No’ en e l ajust e est ándar para la función de la válvula de retraso.

11. Salidas

Esta función no se utiliza en el controlador estándar; pulse ENTER para saltar la función.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 33

Page 34

Ilustración 10

12. Unidades de Presión

Seleccione las unidades de presión, ‘PSI’ en el estándar norteamericano; o ‘Bar’ en el sistema

métrico.

13. Calibración

Esto calibrará el sensor de DP. Mientras que los puertos del sensor del controlador

permanecen sin conexión con la tubería hidráulica, seleccione ‘SI’ en Calibración. La

calibración se produce rápidamente, y los puertos de los sensores del controlador deben volver

a conectarse después de pasar a través de este paso del programa.

Esto concluye la programación del controlador el cual se encuentra listo para su uso. Si desea

volver a cualquiera de las funciones, simplemente revise cada una de ellas. De igual forma, si

desea volver a cualquier Configuración, desplace y revise cada una. Si desea realizar cambios

en la configuración de los pasos 1-4, pulse brevemente la tecla ENTER; y para realizar

cambios en los pasos 5-13, pulse y mantenga presionada la tecla ENTER durante 3 segundos

Retrolavado Manual

Una secuencia de lavado puede activarse manualmente, pulsando la

tecla MANUAL (tecla con el símbolo de mano, o ‘M’). Pulsando la

tecla MANUAL de nuevo, el ciclo se dará por terminado.

M

Símbolos de la

tecla MANUAL

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 34

Page 35

Diagrama de Cableado del Controlador

Bobinas

Cada una de las bobinas debe estar

conectada a la placa dentro del

controlador, como se muestra en las

ilustraciones 11, 12.

Modelos DC: El cable negro de cada

bobina debe unirse a la terminal común

(C) como los muestra la ilustración 11.

Los cables color rojo deben unirse como lo

muestran las terminales de salida A y B,

respectivamente.

Modelos AC: Los cables de la bobina

serán del mismo color. Un solo cable de

cada bobina debe ser unido a la terminal

común (C), y los otros cables de cada

bobina deben ser conectados a las

terminales de salida A y B como lo

muestra la ilustración 12.

Ilustración 11 Cableado para

Bobina DC

Ilustración 12 Cableado para Bobina AC

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 35

Page 36

Encendido del Controlador

Modelo DC

El modelo DC requiere cuatro baterías

tipo D, las cuales permitirán el

funcionamiento del controlador por un

año. Coloque las baterías, removiendo la

parte superior del controlador y

colocándolas como lo muestras la

ilustración 13.

La unidad cuenta con dos niveles

que indican bacteria baja.

Cuando el voltaje de la batería

desciende hasta el primer nivel, la

señal de batería baja aparecerá

en la pantalla.

Cuando el voltaje de la batería desciende

por debajo del segundo nivel, todas las

Ilustración 13 Coloque las bacterias en la parte

superior del Controlador

salidas se apagarán mientras que en la

pantalla permanecerá solo el icono de batería baja.

El modelo DC siempre se debe utilizar con válvulas bobinas de tipo “Latching" 12v DC.

Modelo AC

El modelo AC está conectado por un transformador a una fuente de energía. El modelo AC

debe utilizarse siempre con válvulas bobina 24v AC.

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 36

Page 37

Ilustración 14 Montaje Final

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 37

Page 38

Apéndice 1: Construcción Detallada de Múltiple

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 38

Page 39

The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue

El Cajon, CA 92020-1523, USA

Tel: +1 (800) 333-8125 or +1 (619) 5622950

Fax: +1 (800 892-1822 or +1 (619) 2589973

Toro.com

ALT 227

Aqua-Clear Automatic Backwash (ENG/SPA) pg. 39

Loading...

Loading...