Page 1

Micro-Irrigation

1/2"

Vacuum

Breaker

1" & 2"

Continuous

Acting Air

Release

Valves

1"

Plastic

Air Vent

Air/Vacuum Valves

Air and vacuum control is essential to the safety,

longevity, efficiency, and performance of an

irrigation system. Air must be allowed to exit

pipelines 1) upon startup to prevent water

hammer, 2) during normal operation to prevent

the development of air pockets, and 3) air must be

allowed to enter pipelines and laterals at shut down

to prevent vacuum suction. Various types of valves

and vents are available to perform these functions.

Application:

Removal of Air from Pipelines

• Avoid Water Hammer: Air must be allowed

to escape pipelines at the same rate as water

enters the pipeline during system startup to

avoid dangerous water hammer from

occurring.

• Remove entrained or dissolved air:

Air that has accumulated at high points

during system operation must be allowed to

escape to avoid air pockets which restrict the

flow of water and can cause water hammer.

1" & 2"

Air

Release

and

Vacuum

Relief

Valves

2", 3" & 4" Aluminum Air Vents

Allow the Entry of Air into Pipelines

• Prevent Vacuum Suction in Pipelines:

Air must be allowed to re-enter main and

submain pipelines as water drains during

system shut down to prevent negative

suction from occurring and potential

collapse of the pipelines.

• Prevent Vacuum Suction in Laterals:

Laterals which are buried or submerged in

water may ingest dirty water and/or soil

through the emitters as a result of vacuum

suction if air is not allowed to enter the

laterals during system shut-down and

drainage.

Page 2

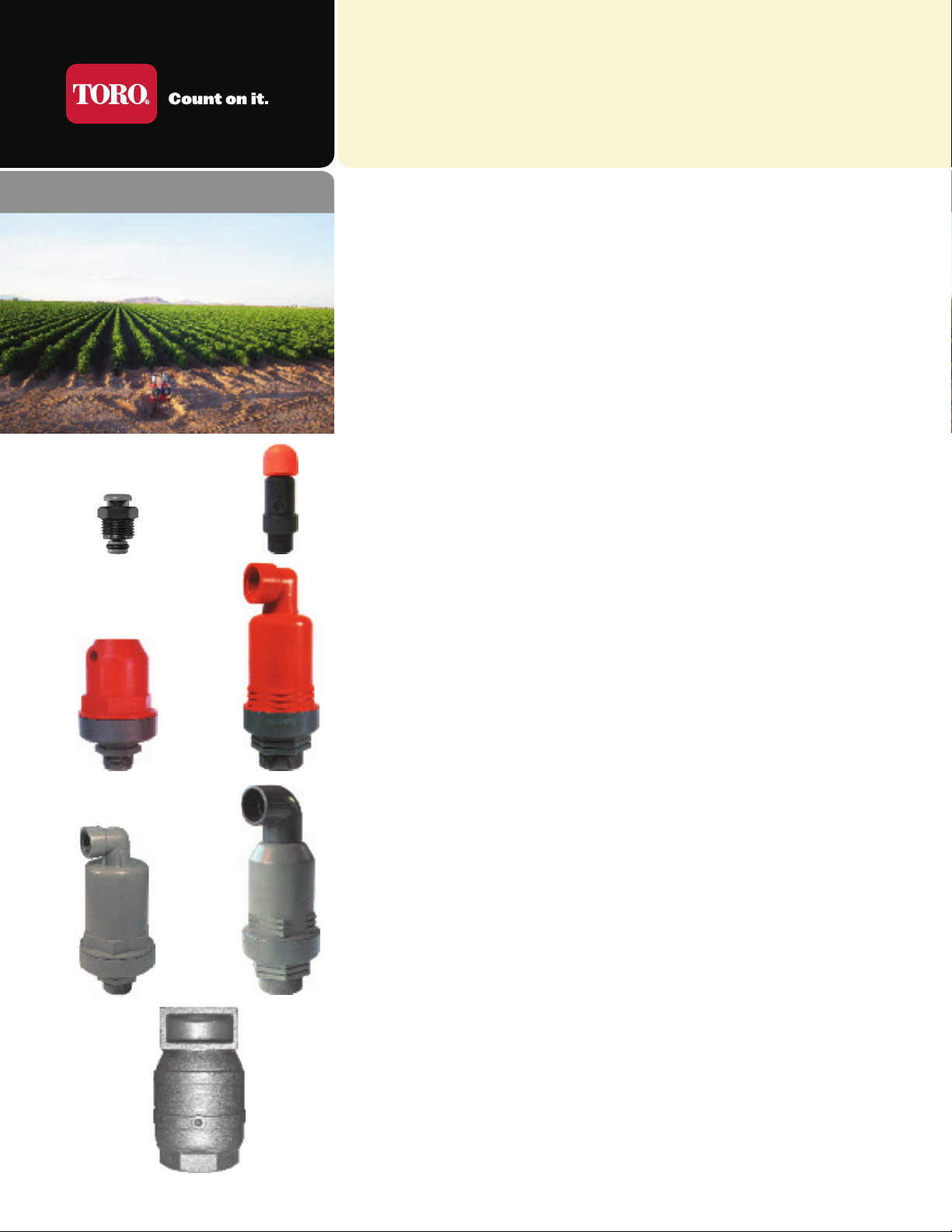

Continuous Acting Air Release Valves

1" & 2" Combination Large Volume Air Relief and Continuous Acting Air Release & Vacuum Relief Valve

• Install at highest points on filter and pump stations to provide both instantaneous and continuous

air relief

• Install on main manifolds every 1000 feet to introduce air into the irrigation system at shutdown to

prevent pipe collapse

• Install at highest point of slope to provide vacuum relief at system shutdown

Model #ARV-1-A

Model #ARV-2-KA

Specifications

Part Number ARV-1-A ARV-2-KA

Valve Type

Connection - male NPT (in) 1 2

Working Pressure (psi) 170 225

Sealing Pressure (psi) 3 3

Volume of air release without valve closing

and without the presence of water (CFM)

Release Air Volume @ 5 psi 8.8 CFM 140 CFM

Units per Box 20 8

Box Weight (lbs) 15 16

Packing Dimensions (in) 15" x 11" x 8"

Single Acting

Continuous

41.2 590

Dual Acting

Continuous

Unit Glossary:

CFM Cubic Feet per Minute

PSI Pounds per Square Inch

m3/h Cubic Meters per Hour

in Inches

1 Cubic Foot of Water = 7.48 Gallons

Page 3

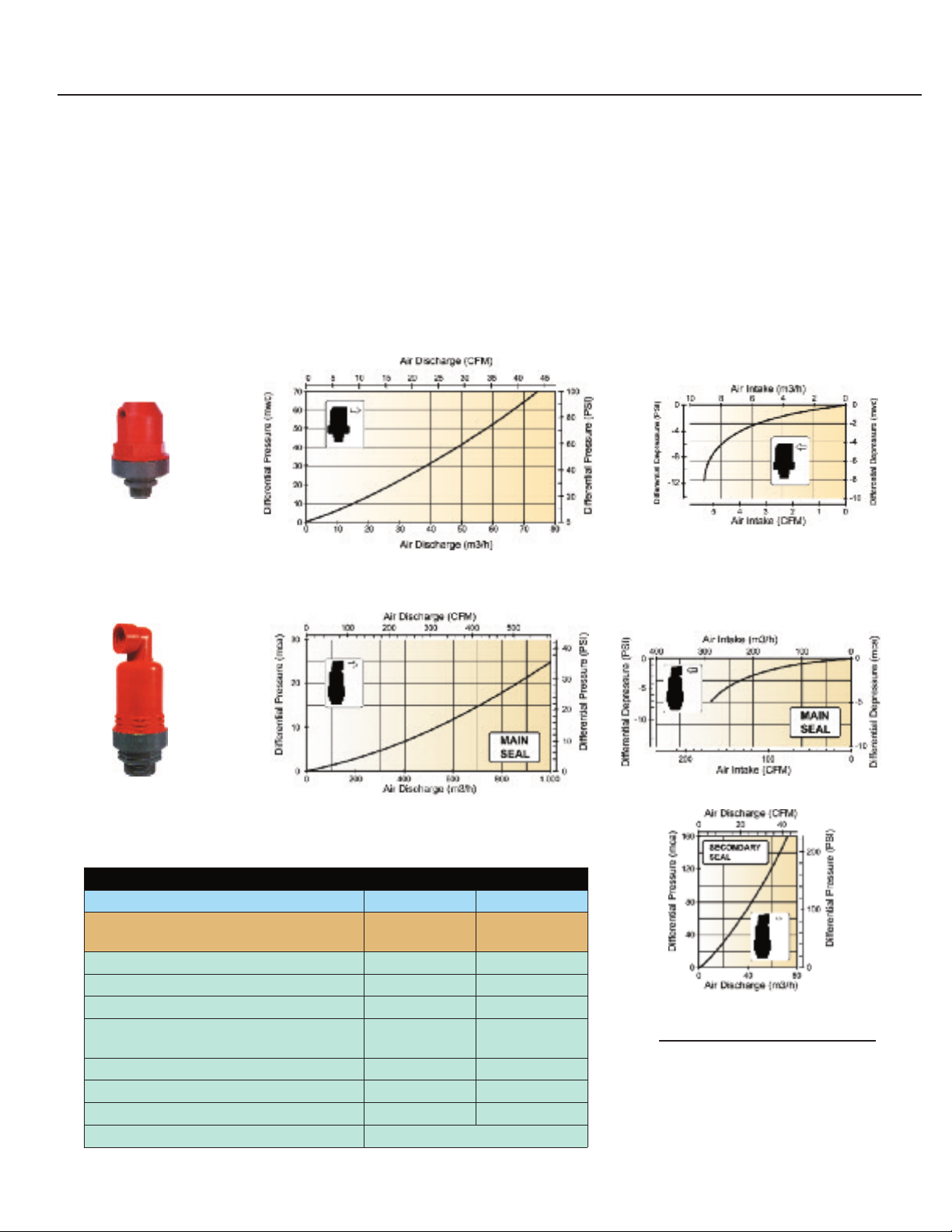

Air Release and Vacuum Relief Valves

1" & 2" Air Release & Vacuum Relief Valves

• Install on manifolds to exhaust air at system start-up

• Install on manifolds to introduce air into the pipeline and provide vacuum relief after system shutdown

• Install downstream of valves to introduce air into the pipeline and provide vacuum relief after

valve shutdown

• Install at highest point of slope to introduce air into the pipeline and provide vacuum relief after

valve shutdown

Model #ARV-1-K

Model #ARV-2-K

Specifications

Part Number ARV-1-K ARV-2-K

Valve Type

Connection - male NPT (in) 1 2

Working Pressure (psi) 225 225

Sealing Pressure (psi) 3 3

Volume of air release without valve closing

and without the presence of water (CFM)

Release Air Volume @ 5 psi 26 CFM 260 CFM

Units Per Box 14 8

Box Weight (lbs) 12 14

Packing Dimensions (in) 15" x 11" x 8"

Air / Vacuum Relief

Non-Continuous

295 590

Page 4

Aluminum Air Vents

Application:

The Aluminum Air Vent series can be

used on gravity or higher pressure

systems, allowing for operation up to 150

psi on the 2" model and 100 psi on 3"

and 4" models. The float and precision ORing provide a tight seal at a very low

pressure, while the strong aluminum alloy

body and full baffle allow for maximum

vent capacity without premature closing.

Air Intake Flow Chart

Hg

Air Discharge Flow Chart

Features and Benefits:

• Cast Aluminum body

combines lightweight strength

and corrosion resistance

• Synthetic rubber O-ring

assures a positive seal even

with low head applications

• Simple design ensures troublefree performance

• Available in 2", 3", & 4"

Female NPT inlet

Specifications

Part Number ARV-2AV ARV-3AV ARV-4AV

Valve Type

Connection - female NPT (in) 2 3 4

Working Pressure (psi) Max. 150 Max. 100 Max. 100

Units per Box 25 10 4

*Conversion: 1 cubic foot of water = 7.48 gallons

Aluminum

Air Vent

Aluminum

Air Vent

Aluminum

Air Vent

Page 5

1/2" Vacuum Breaker

1-3/4" (43 mm)

1

" (25 mm)

20 40 60

80

100

– 0.4

– 0.2

– 0.1

– 0.3

1

/2" Vacuum Breaker (ARV)

)rab( e

r

usser

P

evitag

e

N

-7

-6

-5

-4

-3

-2

-1

0

1

-50 -40 -30 -20 -10 0 10 20 30 40

Vacuum Relief CFM Air Release

Pressure(psi)

Application:

The 1/2" Air & Vacuum Relief Valve (ARV) is

specifically designed to prevent soil ingestion

of emitters from back siphoning.

Closed Open

Model #YD-500-34

Features:

• Large Air Passage

• High resistance to chemicals

• Smooth, reliable operation

• Easy to handle and maintain

• Plastic construction

Specifications

Part Number YD-500-34

Valve Type 1/2" Vacuum Breaker

Connection - male NPT (in) 0.5

Working Pressure (psi) Max. 150

Temperature (°F) Max. 180

Units per Bag 10

Weight (lbs ; grams) 0.024 ; 11

• Buna-N Seal

Air Intake Flow Chart

ote: 1 bar = 14.5 psi

N

1" Plastic Air Vent

Application:

The 1" Plastic Air Vent provides instant air and vacuum

relief. The brightly colored cap allows for easy visibility

and is removable for easy maintenance.

Specifications

Model #ARV-BBK1

Part Number ARV-BBK1

Valve Type Plastic Air Vent

Connection - male NPT (in) 1

Sealing Pressure (psi) 80

Totally sealed from (psi) 5

Units per box 25

Box weight (lbs) 5

Performance Graph of ARV-BBK1

*Performance Data Tested and Verified at CIT, Fresno, California.

**Conversion: 1 cubic foot of water = 7.48 gallons

Page 6

Installation*

The simplest method for selecting the proper size of air/vacuum relief valves is called the

"four-to-one" rule. This rule specifies that the clear opening diameter of the air/vacuum

relief valve be no less than 1/4 the inner diameter of the pipe. Thus, for an 8-inch pipe,

the air/vacuum relief valve should have a clear opening diameter of no less than 2 inches.**

Air vents (vacuum relief) should be installed

1

2

3

4

downstream of all shut-off valves.

Air vents (vacuum relief) should ideally be installed

at or near all high points in manifolds (both inlet

and flushing manifolds).

Air vents (vacuum relief) can be damaged by

field equipment, so some designs consolidate

control valves and vacuum relief valves for

several blocks in one location.

Air vents must be installed so that they do not

become sources of contaminants for the drip

system. Most air vents open up if the system is not

operating, and dirt can fall into the pipelines.

Solutions include:

• High enough installation to prevent soil

particles from entering the manifolds

• Horizontal (rather than vertical)

positioning of some types of vacuum

relief valves. In particular, this deals with

the common use of various check valves

for vacuum relief. Those check valves

have typically been installed vertically.

Some growers use spring-loaded check

valves as dual vacuum/relief and

fertilizer injection ports, and the same

cautions apply.

On very steep ground, some systems have many air

5

* Source: Irrigation and Training Research Center (ITRC), BioResource and

Agricultural Engineering (BRAE) Dept., California Polytechnic State University (CalPoly)

** Source: Toro Micro-Irrigation Design Manual

vents along manifolds to break the vacuum quickly.

©2014 The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue, El Cajon, CA 92020-1523, USA

Tel: +1(800) 333-8125 or +1 (619) 562-2950

Fax: +1 (800) 892-1822 or +1 (619) 258-9973

toro.com

ALT087 06/14

Loading...

Loading...