Page 1

Axle Retainer Kit

FORM NO. 3321–833

PART

No. 99–5109

INSTRUCTIONS

Loose

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Axle bracket

Screw

Flat washer

Flat washer

Flange locknut, 1/2–13

Installation Instructions

Parts catalog

Description

Parts

, 1/2–13 x 2” (51 mm)

, 17/32” I.D. (13 mm)

, 13/16” I.D. (21 mm)

2

4

8

2

4

1

1

Installation of kit

Read before installing

2. Remove the front wheels to provide access to the

frame where the axle mounts.

INSTALLATION

This kit is designed for use on Dingo Model 22304,

serial no. 890100 to 891033, to provide front axle

retention and alignment.

Installation

1. With the bucket installed, lower and tilt the

bucket onto the ground until the front tires are

off of the ground.

3. Place a safety jack/s under the front of the frame.

4. Remove the chain tensioning bolts with jam nuts

from the axle. Push the axle back against the

end of the frame slot to give added clearance for

drilling the required holes.

5. Using the templates provided, cut out and attach

to each side of the frame locating the edges with

the frame. Center punch each of the holes at the

locations marked on the template.

Page 2

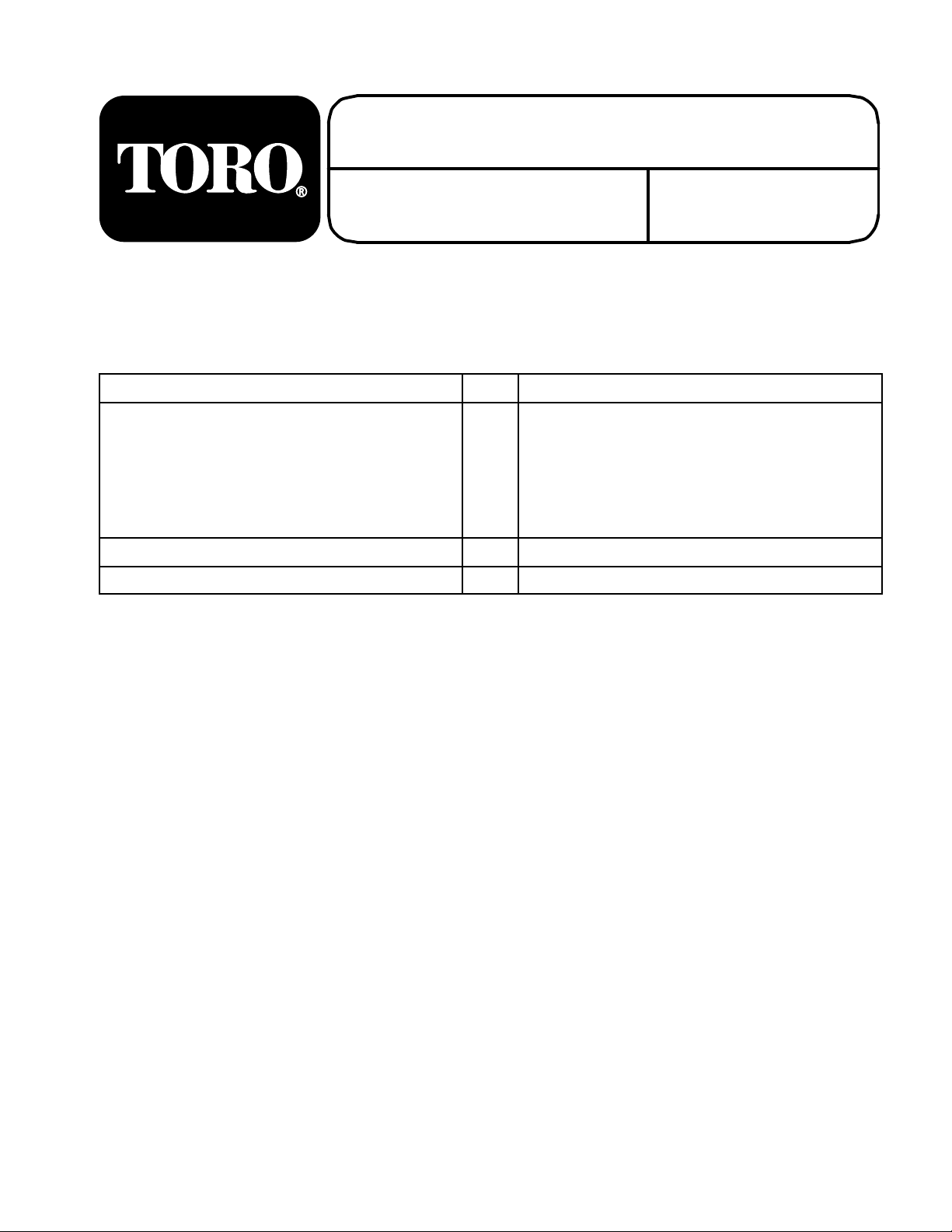

6. Drill a 17/32” hole at each of the four marked

locations (Fig. 1).

1

m–4126

Figure 1

1. 17/32”

Hole

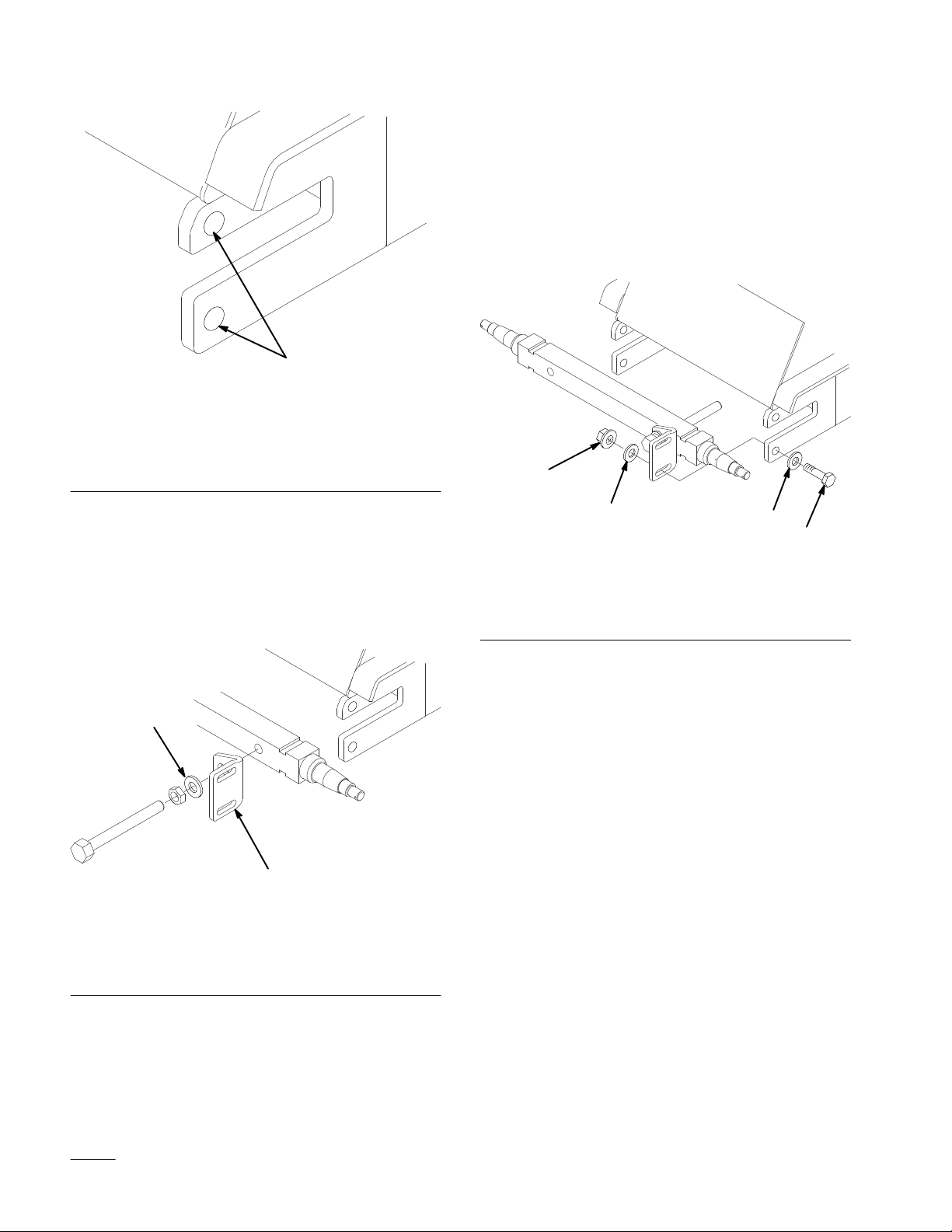

9. Align the axle brackets with the 17/32” holes

drilled in the frame. Install a flat washer (17/32”

I.D.) on each of the 1/2 x 2” screws. Insert the

screws in the holes with the heads to the outside.

Install another flat washer (17/32” I.D.) to each

bolt and loosely secure with 1/2” flange locknuts

(Fig. 3).

3

7. Install a flat washer (13/16” I.D.) and axle

bracket on each tensioning bolt against the jam

nut as shown in Fig. 2.

1

2

m–4127

Figure 2

1. 13/16”

I.D. flat washer

2.

Axle bracket

2

2

1

Figure 3

1. 1/2–13

screw

x 2” (51 mm)

2.

17/32” I.D. flat washer

3.

1/2” Flange locknut

10. Adjust the drive chains, using the tensioning

screws, per instructions in the maintenance

section of the operator manual under “Adjusting

the Tension”. After adjustments have been

made, position the brackets tight against the axle

and the frame. Torque the 1/2” screws to 90

ft–lbs and the the jam nuts on the adjusting

screws to 30 ft–lbs.

11. Reinstall the wheels. Torque the lug nuts to 50

ft–lbs. Start the engine and lower the bucket to

raise the unit off the safety jack/s. Remove safety

jacks and lower unit back to ground with the

bucket.

8. Reinstall each tensioning bolt, with the new

parts installed, back into the axle. Leave the jam

nuts loose.

2

Page 3

Cut

Cut

Cut

Cut

Left Side

Cut

Cut

Cut

Cut

Cut

Right Side

Cut

Loading...

Loading...