Page 1

FORM NO. 3321-468

PLENUM KIT

for OFZ GRASS COLLECTOR

PART

NO. 99-0263

Loose

Parts

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Spring bracket – long

Guard bracket

Bolt 3/8–16 x 1-1/4” (32 mm)

Guide strap

Bolt 1/4–24 x 3/4” (19 mm)

Flange locknut 1/4–20

Roller bracket

Bolt 3/8-16 x 3/4” (19 mm)

Flange locknut 3/8–16

Roller

1

1

1

3

3

3

2

8

8

2

Install spring and guard brackets

Install guide straps

Install rear rollers

INSTALLATION

INSTRUCTIONS

Bolt 1/2-13 x 4” (101 mm)

Nut 1/2-13

PT

O cover

Cover support

Bolt 5/16-18 x 3/4” (19 mm)

Flange locknut 5/16-18

Bolt 5/16-18 x 27/64” (1

Chute bumper

Bolt 1/4–20 x 3/4” (19 mm)

Flange locknut 1/4–20

Hinge

Pop rivet

Spring bracket – short

Bolt 1/4–20 x 3/4” (19 mm)

Washer 1/4” (6 mm)

Flange locknut 1/4–20

1 mm)

2

2

1

1

2

4

2

1

2

2

1

9

1

1

1

1

Install PT

Install chute bumper

Install chute hinge, spring and guard brackets

O support and cover

Page 2

DESCRIPTION USEQTY.

Hinge bracket

Screw 10–24 x 1/2” (13 mm)

Locknut 10–24

Locking pin 3/8 x 6” (152 mm)

Spring

Parts Catalog

Unit

Preparation

Install Spring and Guard Brackets

1. Remove the existing spring and spring bracket

from below the traction unit control plate

(Fig. 1). Save the spring bracket for use on the

chute.

2. Attach the new, long spring bracket below the

traction unit control plate with the existing bolt

in the front left hole, down from the top, and

secure it with the existing locknut (Fig. 1). Hook

the chute spring into the bracket.

3. Remove the existing hardware from the left

brake bracket below the traction unit control

plate (Fig. 1).

1

2

2

1

1

1

1. Spring

2.

3.

4. Spring

5.

Install hinge bracket

Install chute

Save for ordering parts

2

1

4

bracket–long

Existing bolt

Existing locknut

Brake bracket

3

Figure 1

6.

Guard bracket

7.

Bolt 3/8-16 x 1-1/4”

(32 mm)

8. Cable

9.

Existing washer

3

9

8

5

6

7

4. Attach the guard, below the brake bracket, with a

new 3/8–16 x 1-1/4” (32 mm) bolt in the front

hole. Include the cable and secure with the

existing washer and locknut above the control

plate. Use the existing rear bolt and locknut

(Fig. 1).

2

Page 3

Install Guides

Note: If you have a right angle drill, you can

drill holes in the blower housing from

the inside, using a guide strap as a

template, and do not need to remove

the housing; skip to step 2. If you

have a regular drill you must complete

step 1 to remove the blower housing

before drilling holes.

1. Remove the blower housing, as follows:

A. Remove (4) locknuts from the front of the

blower housing.

B. Remove (2) 5” capscrews from the upper

part of the housing.

C. Remove (1) 3/8 x 3/4” capscrew from the

inside of blower chute and slide the chute

up and away from lower blower housing.

D. With the blower chute raised, pull the front

blower housing forward and free from the

rest of the housing.

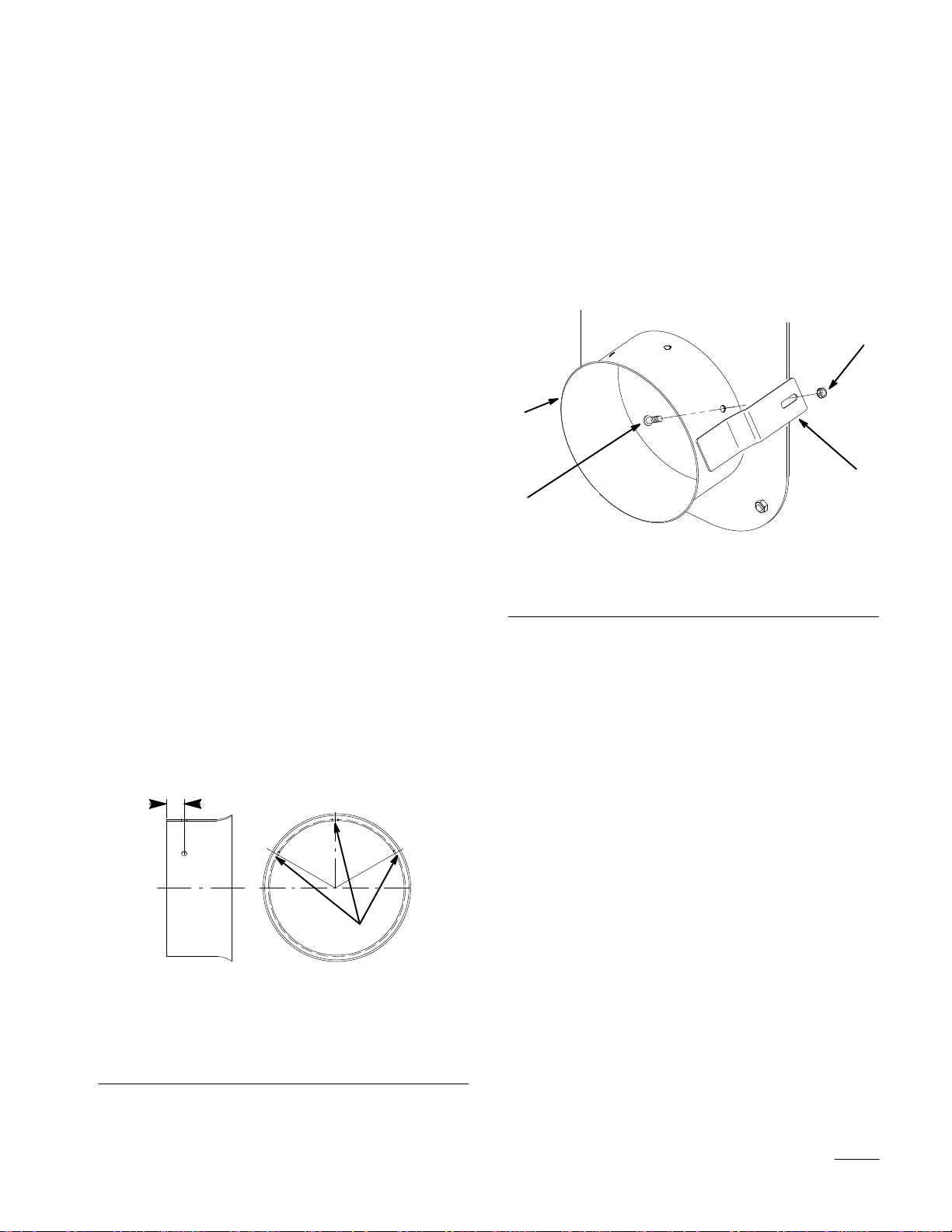

2. Mark, center punch, and drill (3) 9/32” (7.5 mm)

holes in the blower housing, as shown, for

mounting the guides (Fig. 2).

Note: To ensure that the holes are aligned in

the correct position, it is helpful to

position a guide strap on the blower

housing with upset toward blower

opening and against flared flange

(Fig. 3) when marking the holes.

1

2

3

4

3. Place (3) guide straps outside the blower

opening with the upset toward blower opening

and against the flared flange (Fig. 3).

IMPORTANT: The guide straps should be

pulled snug against the flared flange of the

blower housing.

4. Secure each strap to the blower housing with a

1/4–20 x 3/4” (19 mm) bolt, through from the

inside of the housing, and a 1/4-20 flange

locknut (Fig. 3).

1

3

m–3967

Figure 3

1. Blower

2.

housing

Guide strap

3.

Bolt 1/4-20 x 3/4” (19 mm)

4.

Flange locknut 1/4-20

5. Re–assemble the blower housing, if necessary, as

follows.

A. Assemble the front blower housing to the

main housing and slide the blower chute

down over front of the housing.

B. Fasten the blower chute to the blower

housing with the existing 5” capscrews and

to the traction frame through the inside of

chute. (Remount the hopper sensor when

fastening the blower chute to the frame.)

4

2

1. 57/64”

2.

10 O’clock

3.

12 O’clock

4.

2 O’clock

(22.5 mm)

Figure 2

5

5.

Mark, center punch and

drill (4) 9/32’ (7.5 mm)

holes in blower housing

m–3991

C. Secure the front blower housing with the

existing locknuts.

Note: Do not over torque the fasteners on the

housing, causing binding.

3

Page 4

Mower

Preparation

Change Driveshaft PTO Cover

For ease of performing these modifications, remove

the mower from the carrier frame; refer to Mower

Operator’s Manual for instructions.

Install Rear Rollers

1. Remove the locknut, bolt, and roller from the

mounting bracket.

2. Clamp the roller bracket against the rear of the

mower next to the outer deck weld and flush

with the bottom of the mower (Fig. 4).

3. Using the bracket as a guide, center punch and

pilot drill (4) 1/4” holes, then drill (4) 13/32”

(10.5 mm) holes in the mower (Fig. 4).

4. Insert (4) 3/8–16 x 1” (26 mm) bolts through

from the inside of the mower and secure them

with (4) 3/8-16 locknuts (Fig. 4).

5. Repeat on opposite side for the other roller

bracket.

6. Select the proper hole position for the roller,

depending on height-of-cut to be used; refer to

Adjusting Rollers, page 7.

1. Remove the existing drive shaft, PTO cover, and

cover support, if so equipped. Discard the cover

and support.

2. Place a square along the discharge edge and

align a new drive shaft cover support using the

existing front hole, if present, or align as shown

in Figure 5.

3. Using support as a guide, mark, center punch

and drill (1 or 2), 11/32” (9 mm) hole(s) in the

mower (Fig. 5).

2

1

3

4

m–4004

1. Square

2. Cover

3.

Drill 1

support

1/32” (9 mm) hole

5

Figure 5

4. 3”

5. 2–5/16”

2

1. Roller

2. W

3.

bracket

eld, existing

Center punch, pilot drill,

then drill (4) 13/32”

(10.5 mm) holes

3

5

1

Figure 4

4.

Bolt 3/8-16 x 1” (26 mm)

5.

Locknut 3/8-16

4

m–4002

4. Secure the cover support to the mower with (2)

5/16–18 x 3/4” (19 mm) bolts and (2) 5/16–18

flange locknuts (Fig. 6).

2

1

4

5

1. Cover

2. PTO cover

3.

support

Bolt 5/16-18 x 3/4”

(19 mm)

3

Figure 6

4.

Shoulder bolt 5/16-18 x

27/64” (1

5.

Flange locknut 5/16-16

1 mm)

m–4005

4

Page 5

5. Position the chute bumper against the left inside

of the cover, with the end formed outward as

shown (Fig. 6 and 7).

6. Secure the chute bumper to the cover with (2)

1/4-20 x 3/4” bolts and (2) 1/4-20 flange

locknuts (Fig. 6 and 7).

1

3

2

m-3964

1. PTO

2.

Chute bumper

cover

4

Figure 7

3.

Bolt1/4-20 x 3/4” (19 mm)

4.

Flange locknut 1/4-20

Modify Chute

1. Remove the narrow latch from the chute and

discard.

2. Measure for hole location as shown (Fig. 8).

3. Mark and drill a 9/32” (7.5 mm) hole in the

chute, as shown, for the short spring bracket

(Fig. 8).

4. Place the 1/4” (6 mm) washer and 1/4-20 x 3/4”

(19 mm) bolt through the hole from the inside of

the chute and secure the short spring bracket to

the bolt with a 1/4-20 locknut (Fig. 8).

7

3

6

7. Install the PTO cover onto the cover support

with (2) 5/16–18 x 27/64” (11 mm) shoulder

bolts and (2) 5/16–18 flange locknuts (Fig. 6).

2

1. 2-5/8”

2.

3.

(57 mm)

5-7/8” (149 mm)

Mark and drill 9/32” (7.5

mm) hole in chute

1

Figure 8

5

4

4.

Bolt 1/4-20 x 3/4” (19 mm)

5. W

asher 1/4” (6 mm)

6.

Spring bracket–short

7.

Locknut 1/4-20

m–4000

5

Page 6

Install Hinge Bracket

1. Center the wide chute bracket across the front of

the chute with the rear edge of the bracket

aligned with the angle change on the chute

(Fig. 9) and clamp it on top of the chute.

2. Using the wide chute bracket as a guide, drill (9)

#20 holes in chute, as shown (Fig. 9).

3. Secure the wide chute bracket to chute with (9)

5/32” pop rivets, inserted up through the chute

opening (Fig. 9).

1 2

7. Mark, center punch, and drill (2) 17/64”

(6.5 mm) holes on top of mower, using the hinge

bracket as a template.

8. Secure the hinge bracket to the mower with (2)

10–24 x 1/2” (13 mm) screws, through from the

bottom of mower, and (2) 10–24 locknuts

(Fig. 11).

Note: The mounting holes on the hinge

bracket are slotted. Ensure that you

slide the bracket as far forward as

possible.

3

1

3

4

m–4001

Figure 9

1. Wide

2.

chute bracket

Drill (9) #20 holes

3.

Pop rivet 5/32”

4.

Change of angle

4. Attach the wide hinge bracket to the chute with

the locking pin (Fig. 10).

1

2

m–4044

Figure 10

1. Wide

hinge bracket

2.

Locking pin

m–4007

1. Wide

2.

2

hinge bracket

Bolt 10-24 x 1/2” (13 mm)

Figure 1

1

3.

Locknut 10-24

9. Remove the locking pin securing the chute to the

mower and remove the chute.

5. Remove the narrow hinge plate from the mower

and discard.

6. Tilt the mower up on its nose and slide the chute

into position against the rear of the mower over

the discharge area (Fig. 11).

6

Page 7

Install Chute

Adjusting Rollers

1. Install the mower; refer to the Mower Operator’s

Manual

2. Raise the mower and slide the chute into the

blower inlet, below the guide straps (Fig. 12).

3. Lower the mower and slide the chute forward

against the rear of the mower. Secure the chute

to the mower with the locking pin (Fig. 12).

4. Hook the free end of the spring you installed on

the traction unit previously (Fig. 1) to the

bracket on the top of the chute as shown in

Figure 12.

1

6

4

3

2

The rollers must be adjusted to set the height-of-cut.

To set a height–of–cut above 2” (51 mm), the rollers

must be adjusted to the lower hole location. To set the

height-of-cut to the 1” or 1–1/2” (25 or 39 mm)

position, the rollers must be adjusted to the upper

hole location.

1. After adjusting height-of-cut, tilt the mower to

adjust the front roller, refer to; Tilting Mower.

2. Remove the locknut and bolt to change the hole

location (Fig. 13).

3. Select the proper hole position for the

height-of-cut to be used (Fig. 13).

4. Insert the 1/2-13 x 4” (101 mm) bolt through the

roller and secure it with the 1/2-13 locknut

(Fig. 13).

Note: Do not overtighten the roller mounting

bolt; rollers must turn freely.

5. Lower the mower, refer to; Tilting Mower, then

repeat the adjustment on the rear rollers.

1. Chute

2. Blower

3.

Guide strap

4. Latch

5

inlet

Figure 12

5.

6.

Locking pin 3/8 x 6”

(152 mm)

Spring and bracket

3

1

1. Roller

2. Bolt

1/2-13 x 4” (101 mm)

3.

Locknut 1/2-13

3

1

2

3

1

5

5

2

2

4

m–3940

Figure 13

4. Spacer

5. Holes

7

Page 8

Loading...

Loading...