Page 1

FORM NO. 3321–190

GTS 200 CONVERSION KIT

For ProLine BBC Mowers Model Year 1992 and Up and

For ProLine Zone Start Mowers Model Year 1995 and Up

PART NO. 98–9230

PART NO. 98–9240

Loose Parts

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Discharge Chute

Latch Plate

Discharge Door Assembly

Door Retainer

Self-tapping Screw – 1/4-10 x .60

Screw – 3/8-16 x 1.5 3

Engine Decal – 98-2002 1 Replace old engine

ProLine Decal – 84-4960 1

Casing Clamp 1 Install on engine

1

1

1

1

2

Install new discharge chute and door assembly

INSTALLATION

INSTRUCTIONS

Clamp Screw 1

Throttle Control

Throttle Cable

E-Ring

Primer Guard 1 Install on right front quadrant

Cable Tie (Zone Start models only) 2 Fasten cables to lower handle

Cable Tie (BBC models only) 3

Rope Stop 1 Install on recoil rope

Traction Control Decal (Self-propelled zone

start models only)

Control Panel Decal (BBC models only) 1 Replace old decal

Control Bar (BBC models only) 1 Replace old control bar

Printed in USA

The Toro Company – 1998

All Rights Reserved

1

1

2

1 Replace old decal

Replace old throttle cable

Page 2

Installation

DESCRIPTION USEQTY.

Rope Guide (BBC models only) 1

Curved Washer (BBC models only) 1 Install new rope guide

Hex Head Screw – 1/4-20 x 1.5 (BBC models

only)

Hex Lock Nut (BBC models only) 1

Before Installing

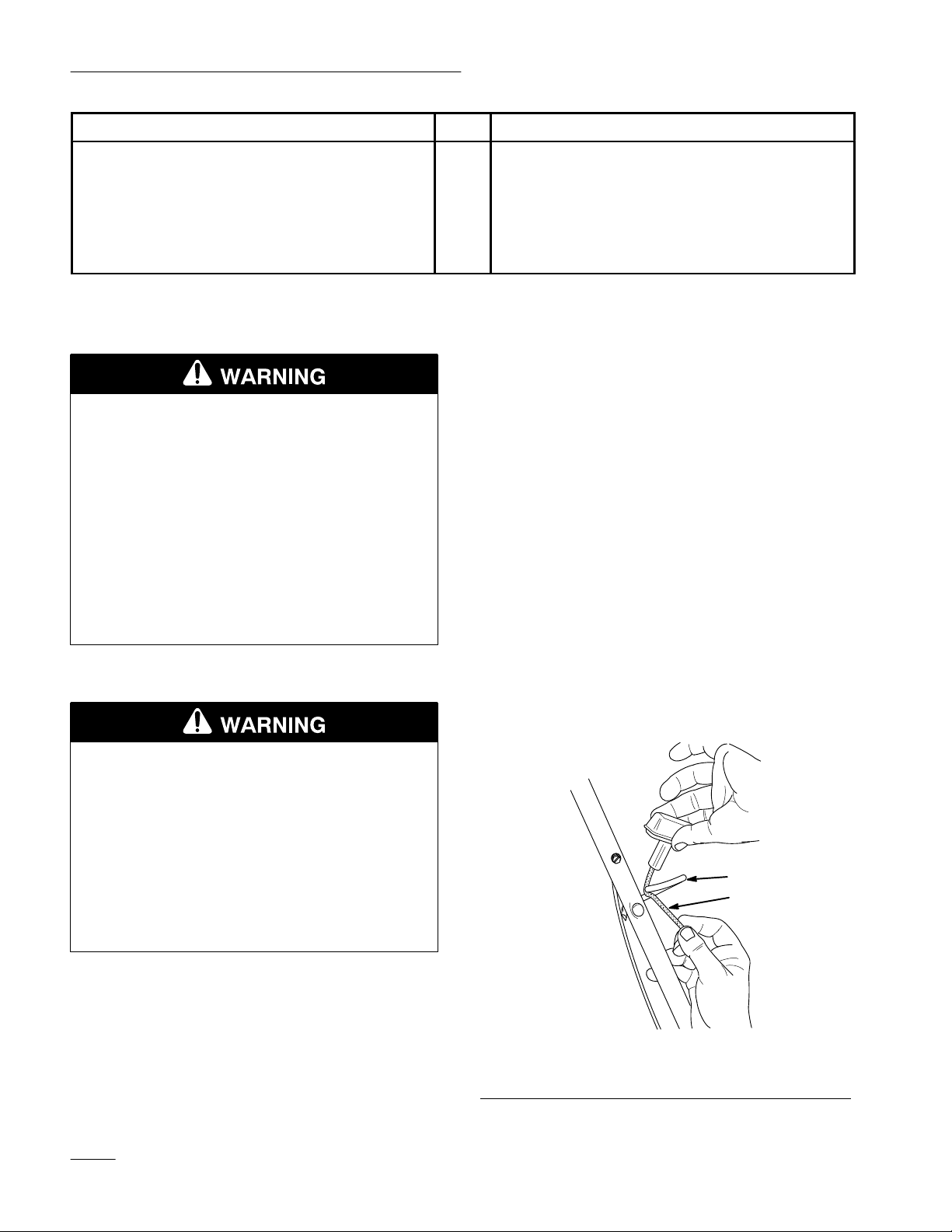

POTENTIAL HAZARD

• If you leave the wire on the spark plug,

someone could accidentally start the engine.

WHAT CAN HAPPEN

• Accidental starting of engine could

seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

• Pull wire off spark plug before you install

kit. Also push wire aside so it does not

accidentally contact spark plug.

1. Disconnect spark plug wire from spark plug.

1

3. Reconnect spark plug wire.

4. Even though the gasoline has been drained from

the engine, enough fuel should be left in the

carburetor bowl and fuel line to start the engine.

Start the engine and let it run until it runs out of

fuel. Briefly running engine will warm up the

oil.

5. Disconnect spark plug wire from spark plug.

6. Drain oil from engine. Refer to your operator’s

manual for proper oil draining procedure.

Disassemble Old Components

Remove Starter Rope

1. Zone Start Models Only – Remove starter rope

from rope guide (Fig. 1).

POTENTIAL HAZARD

• If gasoline is spilled on a hot engine, it

could ignite.

WHAT CAN HAPPEN

• Contact with burning gasoline could cause

serious personal injury.

HOW TO AVOID THE HAZARD

• Drain gasoline from a cold engine only.

2. Make sure engine is cool. Remove cap from fuel

tank and use a pump-type syphon to drain fuel

into a clean gas can.

Note: This is the only procedure

recommended for draining fuel.

EN–2

1

2

m–2705

Figure 1

1. Rope guide 2. Starter rope

Page 3

Installation

Remove Cable Ties

1. Cut cable ties holding cables to lower handle.

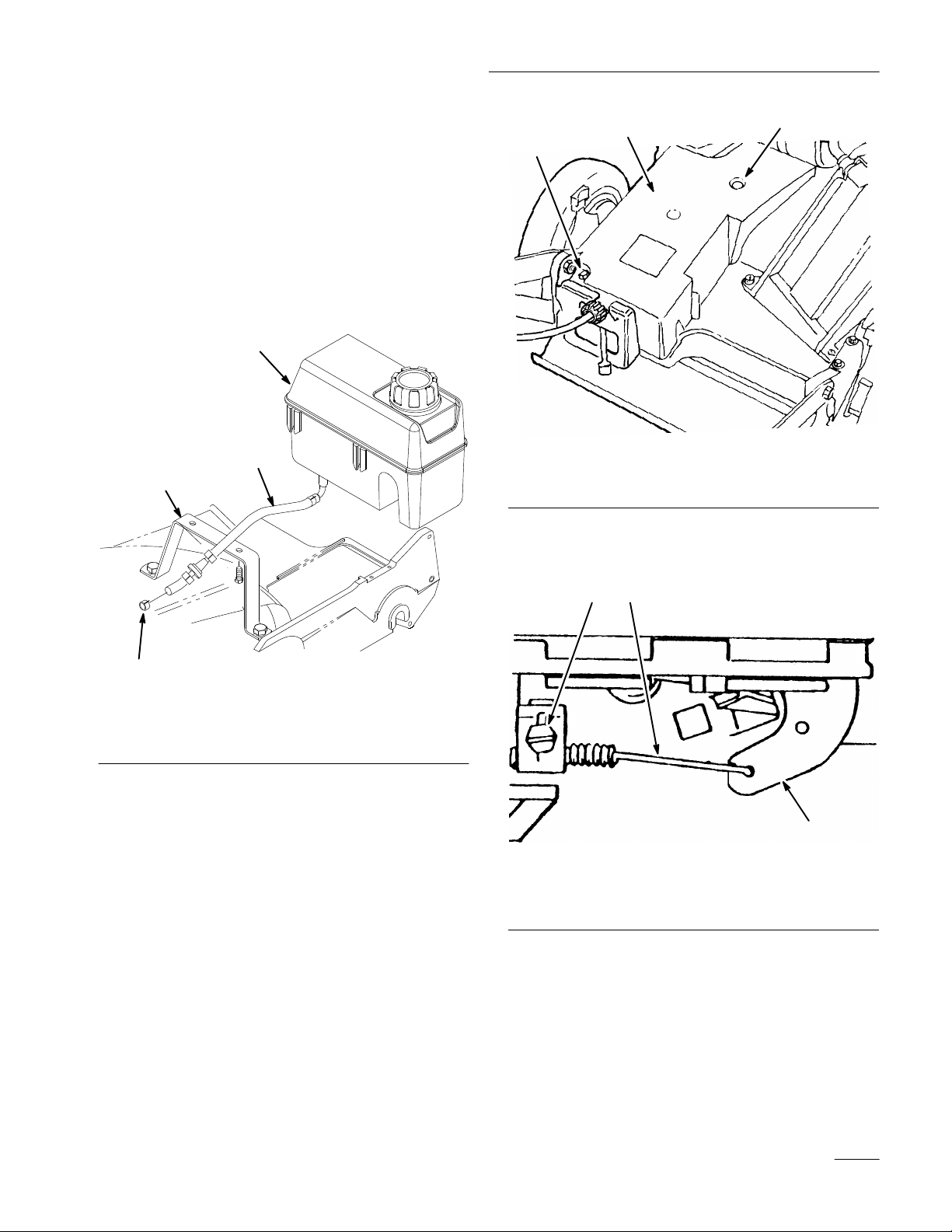

Remove Gas Tank

1. Disconnect fuel line from engine (Fig. 2).

2. Remove gas tank from tank bracket (Fig. 2).

Carefully set tank aside.

4

2

3

Figure 3

1. Belt cover 2. Self-tapping screw (2)

2. Loosen cable clamp screw and disconnect

throttle cable from throttle lever (Fig. 4).

m-224

1

Figure 2

1. Fuel line clamp

2. Fuel line

3. Tank bracket

4. Gas tank

Disconnect Throttle Cable

1. Remove (2) self-tapping screws securing belt

cover to deck (Fig. 3). Set cover and fasteners

aside for reinstallation.

1. Cable clamp screw

2. Throttle cable

Figure 4

3. Throttle lever

m-286

EN–3

Page 4

Installation

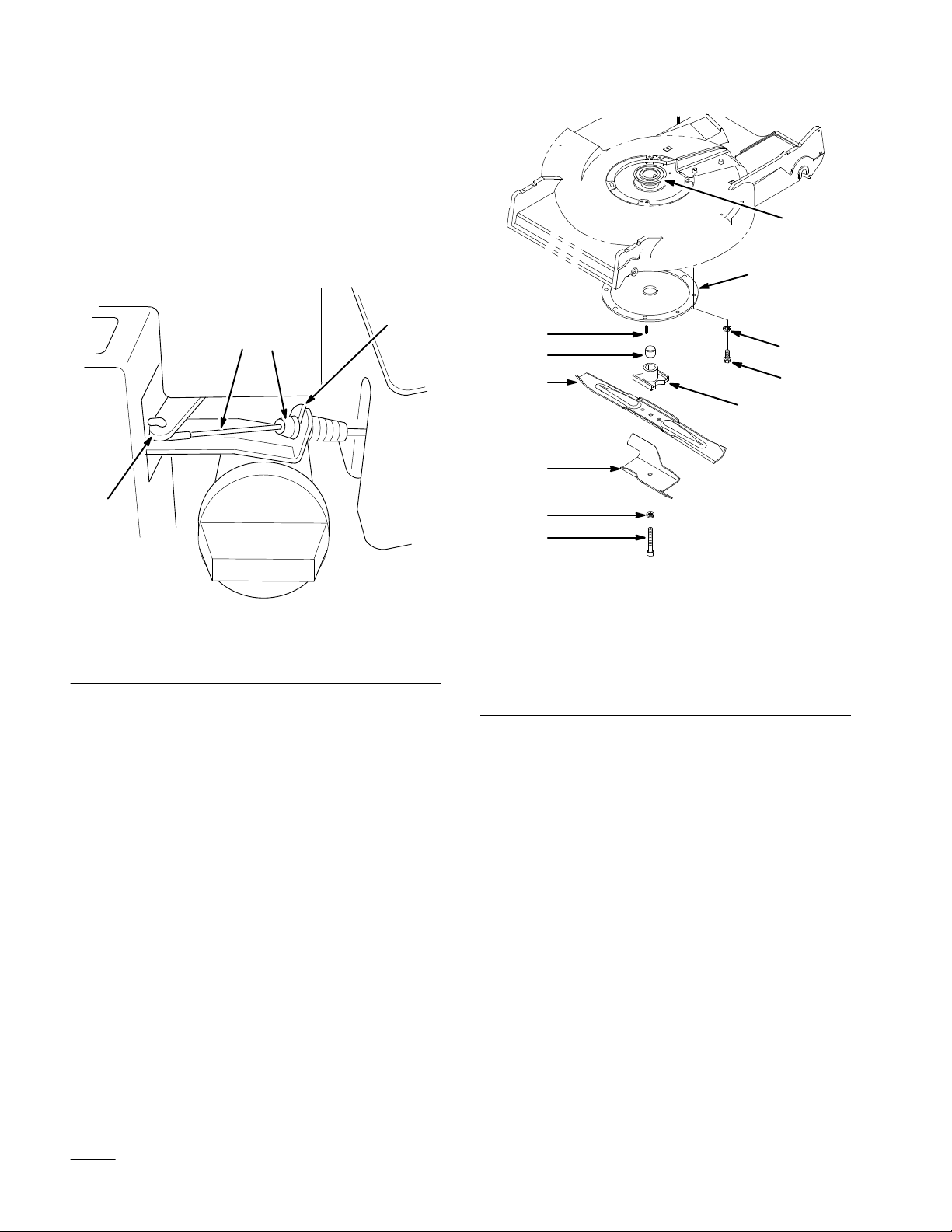

Disconnect Brake Cable

(Zone Start Models Only)

1. Disconnect brake cable from brake arm (Fig. 5).

2. Using a pliers, squeeze tabs on top and bottom

of brake cable fitting, and slide brake cable out

of brake assembly (Fig. 5).

4

1 3

2

Figure 5

1. Brake cable

2. Brake arm

3. Brake cable fitting

4. Brake assembly

7

6

4

3

2

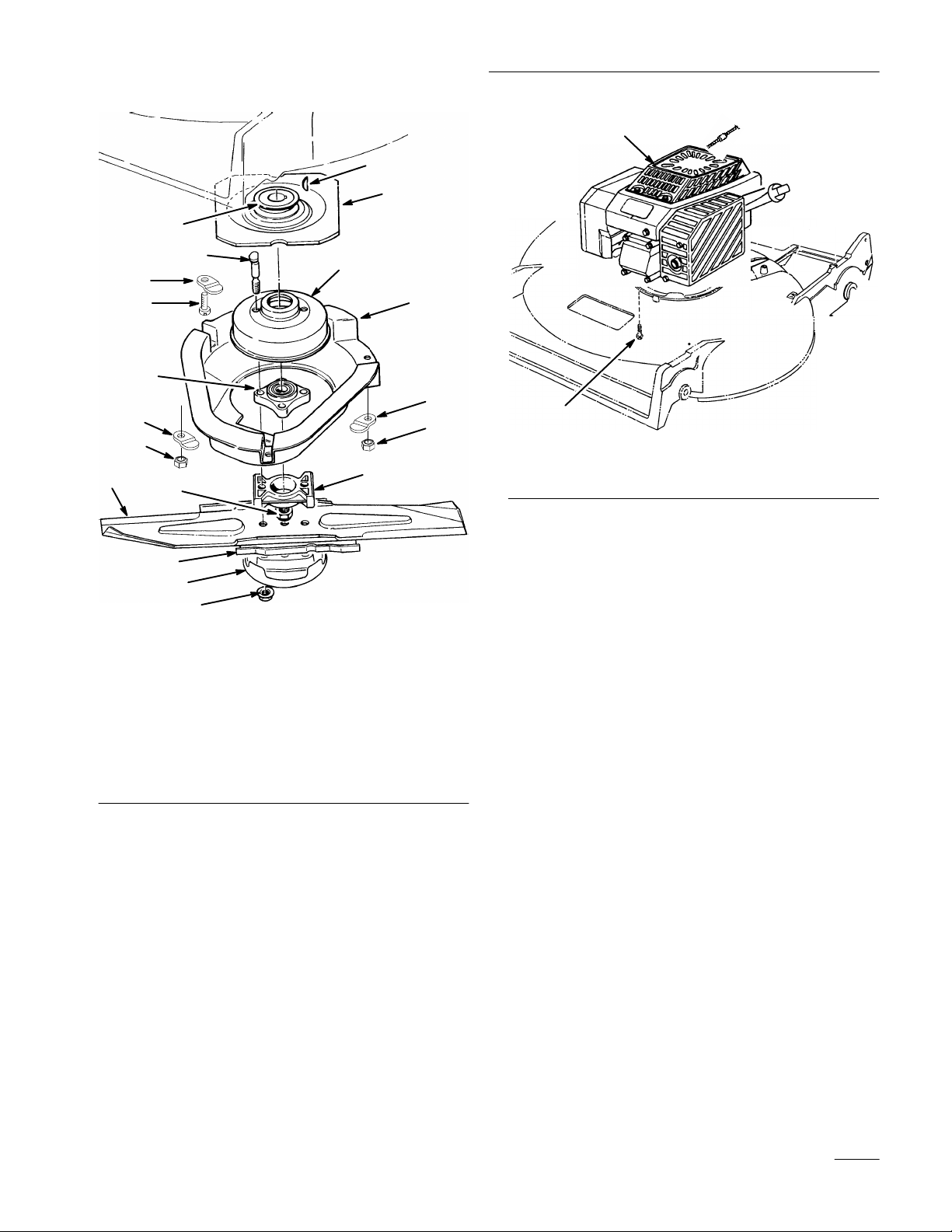

1

1. Blade bolt

2. Lock washer

3. Blade stiffener/accelerator

4. Blade

5. Blade retainer

6. Spacer

11

10

9

8

5

Figure 6

7. Square key

8. Self-tapping screw (3)

9. Internal lock washer (3)

10. Crankshaft protector

11. Engine drive pulley

(self-propelled model only)

Remove Blade Assembly

Zone Start Models

1. Remove blade bolt, lock washer, blade

stiffener/accelerator, blade, blade retainer, spacer,

square key and crankshaft protector (Fig. 6).

To remove the crankshaft protector, remove (3)

self-tapping screws and (3) internal lock

washers. Retain all of these items for

reinstallation.

EN–4

BBC Models

1. Remove (2) blade nuts, anti-scalp cup, blade

stiffener/accelerator, blade, lock nut and blade

spacer. Then loosen tabs securing BBC shield to

housing by loosening nuts or bolts on tabs.

Rotate tabs 180_ out of the way. Remove BBC

shield, hub assembly, brake drum, (2) blade

bolts, flywheel, pulley driver and woodruff key

(Fig. 7). Retain all of these items for

reinstallation.

Page 5

15

Installation

1

16

14

13

8

9

11

8

7

4

5

3

2

1

1. Blade nut (2)

2. Anti-scalp cup

3. Blade stiffener/accelerator

4. Blade

5. Lock nut

6. Blade spacer

7. Lock nut (2)

8. Tab (3)

Figure 7

12

6

9. Screw

10. BBC shield

11. Hub assembly

12. Brake drum

13. Blade bolt (2)

14. Flywheel

15. Pulley driver

16. Woodruff key

10

8

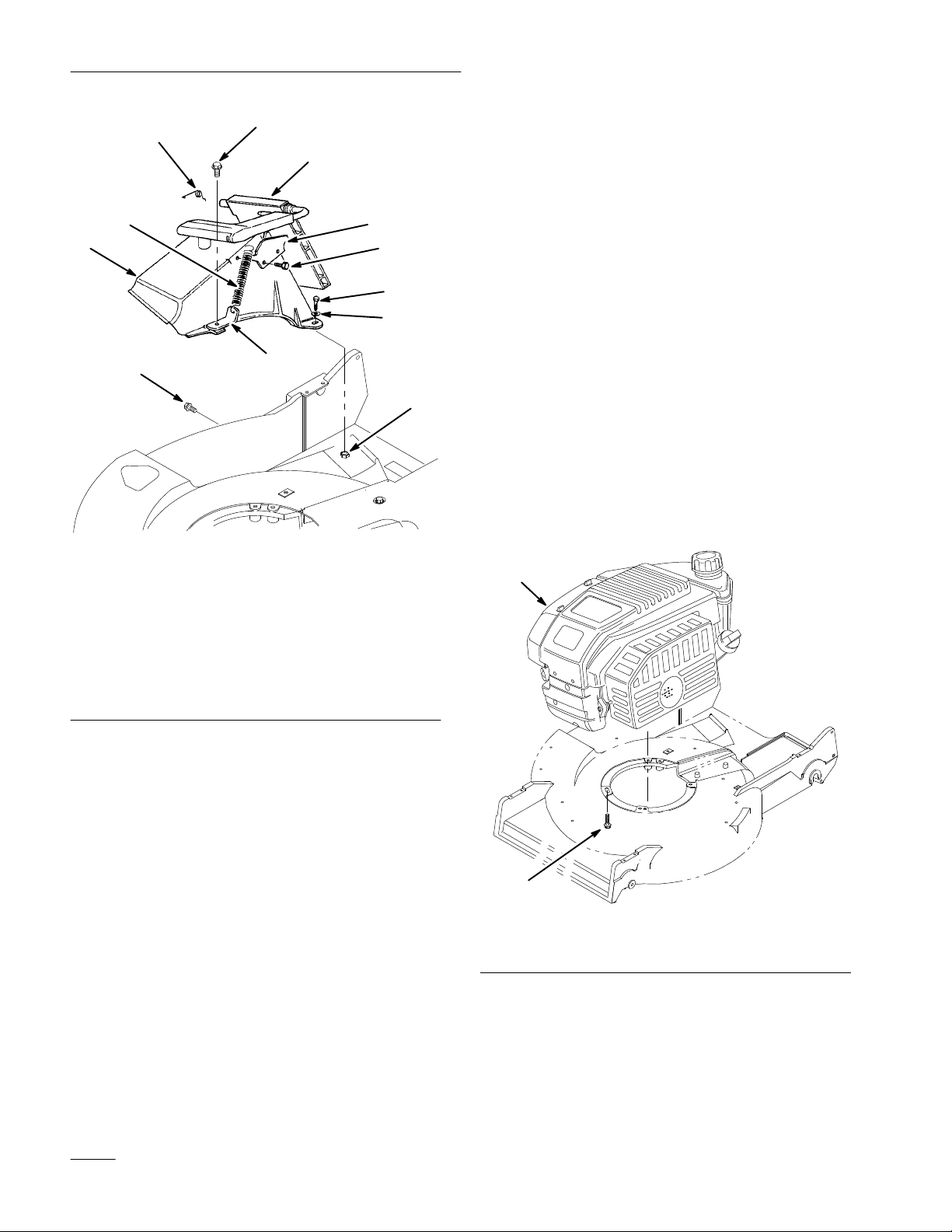

2

7

Figure 8

1. Engine 2. Engine screw (3)

Remove Discharge Tunnel Assembly

(Fig. 9)

1. Remove (2) capscrews, (2) flat washers, (2) lock

nuts, 1/2” hex head washer screw and 3/4” hex

head washer screw securing discharge tunnel

assembly to housing. Retain all of these items

for reinstallation.

2. Lift off discharge tunnel assembly.

3. Remove spring bracket and spring extension.

Retain these items for reinstallation.

Remove Old Engine

1. Remove three (3) engine screws and carefully

lift engine off housing (Fig. 8). Discard screws

and engine.

4. Remove (2) self-tapping screws and latch plate

from old tunnel and discard them.

5. Remove door retainer and discharge door

assembly and discard them.

EN–5

Page 6

Installation

11

8

1

5

1. Discharge tunnel

2. Capscrew (2)

3. Flat washer (2)

4. Lock nut (2)

5. Hex head washer screw

(1/2” long)

6. Hex head washer screw

(3/4” long)

6

Figure 9

12

9

10

2

3

7

4

7. Spring bracket

8. Spring extension

9. Latch plate

10. Self-tapping screw (2)

11. Door retainer

12. Discharge door assembly

3. Install new discharge door assembly and secure

with new door retainer.

4. Install new latch plate to tunnel using (2) new

self-tapping screws.

5. Hook one end of spring extension through hole

on spring bracket and the other end onto the

discharge door handle.

6. Open and close discharge door to ensure that

discharge tunnel door closes when handle is

released.

Install New Engine

1. Carefully set new engine onto housing.

2. Install and tighten (3) new engine screws

(Fig. 10). Torque the engine screws to 250-400

in-lbs (28-45 NSm).

1

6. Discard discharge tunnel.

Install Conversion Kit

Install New Discharge Tunnel (Fig. 9)

1. Position new discharge tunnel on deck. Align

holes in discharge tunnel with holes in deck.

2. Fasten rear-left and rear-rights corners of tunnel

to deck using (2) capscrews, (2) flat washers and

(2) lock nuts previously removed. Fasten

front-right side of tunnel to deck using 1/2” hex

head washer screw previously removed. Fasten

front-left corner of tunnel and spring bracket to

deck using 3/4” hex head washer screw

previously removed.

EN–6

2

Figure 10

1. Engine 2. Engine screw (3)

Page 7

Installation

Reinstall Blade Assembly

Reinstall blade assembly in reverse order of

disassembly. Refer to Remove Blade Assembly

procedures.

Zone Start Models - When reinstalling crankshaft

protector, install but do not tighten mounting screws.

Insert a shim (a business card works well) between

protector and hub on blade retainer which helps

center protector. Tighten mounting screws and

remove shim. Continue installing blade assembly.

Torque blade bolt to 50 ft.-lbs. (68 Nm).

BBC Models – Torque blade nuts to 15-27 ft.-lbs.

(20-37 Nm).

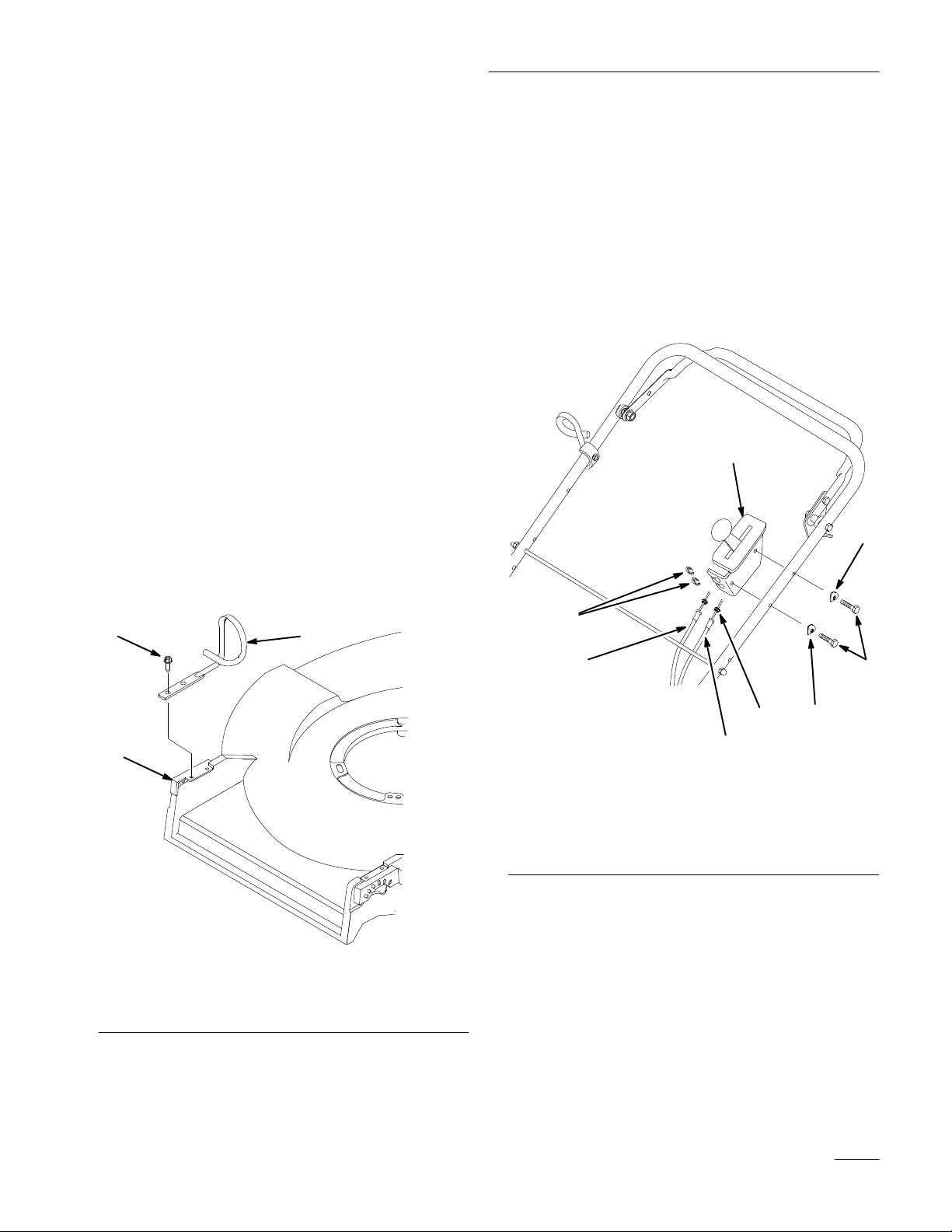

Install Primer Guard

1. Remove (2) hex head screws from right front

quadrant (Fig. 11). Leave quadrant in place.

2. Install new primer guard on top of right front

quadrant with (2) hex head screws (Fig. 11).

Install New Throttle Control

Zone Start Models

1. HP Models Only – Disconnect brake cable from

throttle control by removing E-ring (Fig. 12).

Discard E-ring.

2. SP Models Only - Disconnect traction cable

from throttle control by removing E-ring

(Fig. 12). Discard E-ring.

1

6

2

1

1. Right front quadrant

2. Hex head screw (2)

Figure 11

3. Primer guard

4

3

3

1. Throttle control

2. Brake cable (HP model)

Traction cable (SP model)

3. Throttle cable

Figure 12

4. E-ring

5. Hex head screw (2)

6. Curved washer (2)

7. Seal

7

2

6

5

3. Remove (2) hex head screws and (2) curved

washers securing throttle control to handle

(Fig. 12). Retain screws and washers. Discard

throttle control and throttle cable.

4. Install new throttle control using (2) hex head

screws and (2) curved washers previously

removed.

5. Connect new throttle cable to throttle control

using new E-ring.

EN–7

Page 8

Installation

6. HP Models Only – Reconnect brake cable to

throttle control using new E-ring. Then

reconnect brake cable to engine (Fig. 5).

7. SP Models Only – Reconnect traction cable to

throttle control using new E-ring. Then

reconnect brake cable to engine (Fig. 5).

8. Make sure seals on cables are pushed down tight

(Fig. 12).

9. Route throttle cable across top of transmission

(Fig. 13).

11. Move throttle to (FAST) position.

12. Push throttle arm to rear of engine as far as it

will go.

13. Install new cable clamp and cable clamp screw

to engine (Fig. 14). Tighten cable clamp screw to

lock throttle cable in place.

14. Reinstall belt cover using fasteners previously

removed (Fig. 3).

BBC Models

1. Remove (4) Phillips head screws and (4) lock

nuts securing throttle control to control panel

(Fig. 15). Retain screws and lock nuts. Discard

throttle control, throttle control retainer and

throttle cable.

1

7

1

Figure 13

1. Throttle cable

10. Connect throttle cable to throttle arm on engine

(Fig. 14).

3

1

2

4

m-3638

Figure 14

1. Cable clamp screw

2. Cable clamp

3. Throttle cable

4. Throttle arm

1. Phillips head screw (4)

2. Lock nut (4)

3. Throttle control

4. Throttle control retainer

2

3

4

6

5

Figure 15

5. Throttle cable

6. Seal

7. Decal P/N 98-2003

EN–8

Page 9

Installation

2. Remove and discard old control panel decal.

Install new control panel decal (Fig. 15).

3. Install new throttle control using (4) Phillips

head screws and (4) lock nuts previously

removed. Install new throttle control retainer.

Note: Make sure seal on throttle cable is

pushed down tight.

4. Connect throttle cable to throttle arm on engine.

5. Move throttle to

(FAST) position.

6. Push throttle arm to rear of engine as far as it

will go.

7. Install new cable clamp and cable clamp screw

to engine (Fig. 14). Tighten cable clamp screw to

lock throttle cable in place.

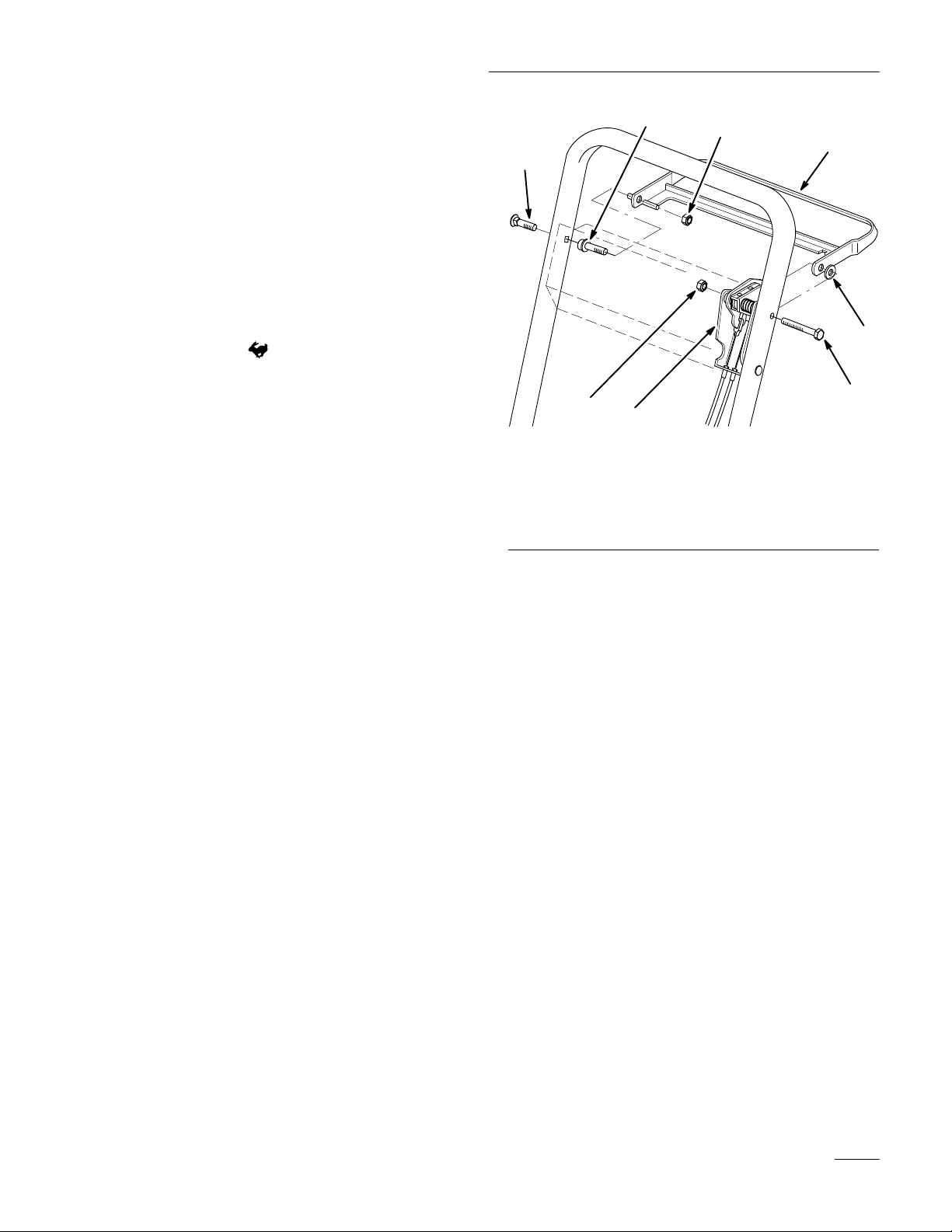

Install New Control Bar

(BBC Models Only)

2

7

1. Control bar

2. Handle screw

3. Support spacer

4. Hex flange nut

3

8

4

1

6

5

Figure 16

5. Hex head cap screw

6. Spacer

7. Lock nut

8. Control bracket

1. Remove handle screw, support spacer and hex

flange nut securing right side of control bar to

handle (Fig. 16). Retain these items for

reinstallation.

2. Carefully remove hex head cap screw, spacer and

lock nut securing left side of control bar and top

portion of control bracket to handle (Fig. 16).

Retain these items for reinstallation. Leave other

parts loosely assembled in control bracket for

reinstallation.

3. Remove and discard old control bar.

4. Attach new control bar by reversing order of

disassembly.

Reinstall Gas Tank

Reinstall gas tank in reverse order of disassembly

(Fig. 2). Connect fuel line to engine.

EN–9

Page 10

Installation

Adjust Brake Cable

POTENTIAL HAZARD

• BBC Models Only – Do not over–tighten

blade brake cable. Over–tightening could

cause blade brake to be pulled off brake

drum. If brake does not contact drum,

blade will not stop rotating when control

bar is released.

WHAT CAN HAPPEN

• A rotating blade could cause serious

personal injury.

HOW TO AVOID THE HAZARD

• Check the blade brake mechanism each

time brake cable is adjusted to ensure

brake is stopping blade in 3 seconds or less.

• If blade does not stop rotating in 3 seconds

or less, bring unit to your local Authorized

Toro Service Dealer for inspection and

repair.

Hand Push Model

1. Handle

2. Brake lever

3. 3/16”-1/4”

1

2

3

4

5

6

483

Figure 17

4. Cable adjuster

5. Jam nut

6. Cable conduit

1

1. Zone Start Models Only – CHECK

ADJUSTMENT (Fig. 17 & 18)—Move control

bar toward handle until slack in wire is removed.

Gap between brake lever and handle must be

3/16”–1/4”. See step 2 for adjustment.

2. ADJUST CABLE CONDUIT

• Hand Push Models (Fig. 17)–Loosen jam

nut on brake cable. Insert 3/16”-1/4” object

between brake lever and handle. Turn cable

adjuster on brake cable until slack is

removed. Then tighten nut.

• Self-propelled Models (Fig. 18)–Loosen

nut on cable bracket. Insert 3/16”-1/4”

object between brake lever and handle. Pull

down on cable conduit until all slack is

removed from wire. Then tighten nut.

Self-propelled Model

1. Handle

2. Brake lever

2

Figure 18

3

4

3. 3/16”-1/4”

4. Cable bracket

EN–10

Page 11

• BBC Models (Fig. 19) – Loosen cable

clamp screw until brake cable conduit

slides. Pull cable to remove slack, but do

not put tension on spring. Tighten screw to

lock adjustment in place.

2

Installation

2

6-8”

3

6

4

3

1

Figure 19

1. Spring

2. Cable clamp screw

3. Cable conduit

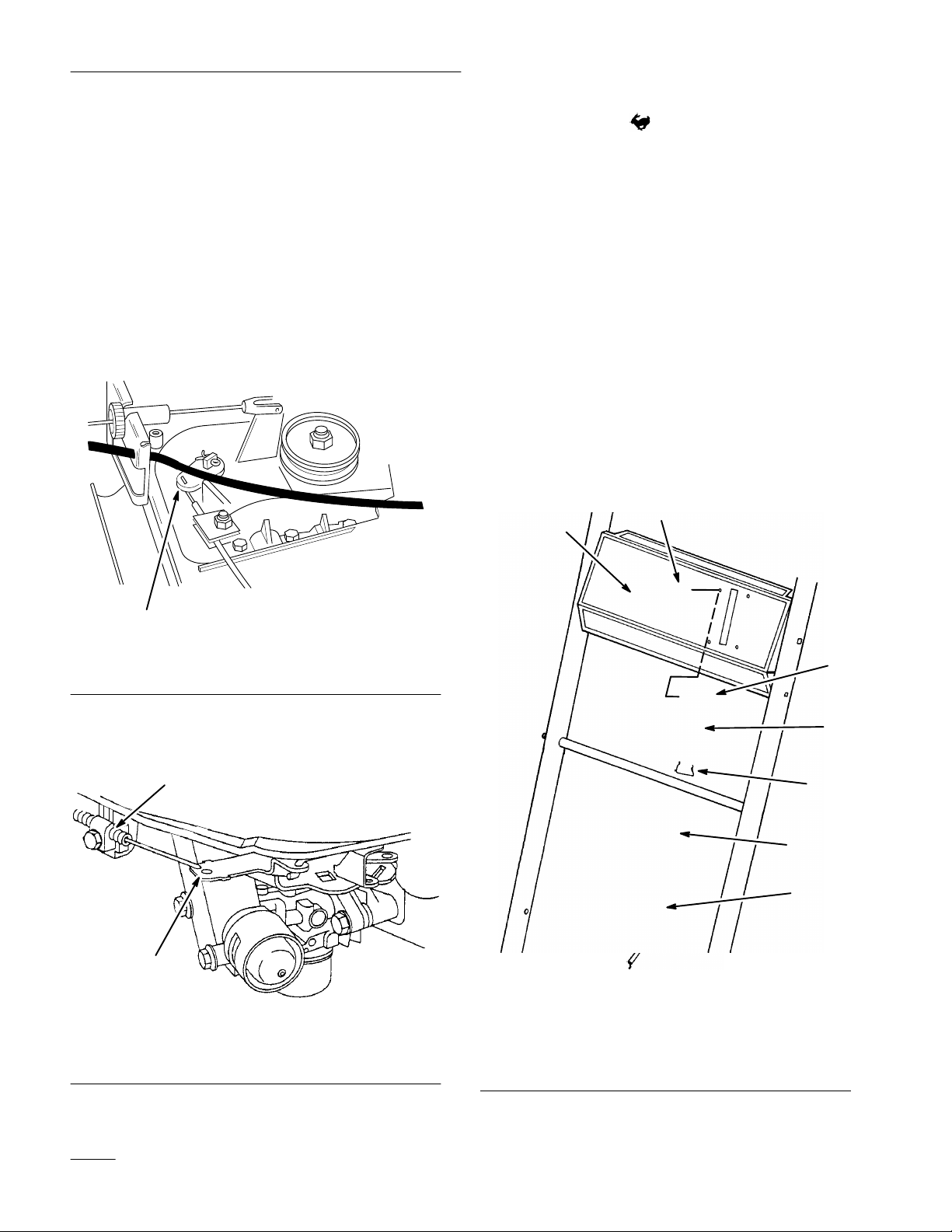

Install Starter Rope in Rope Guide

Zone Start Models

1. Reinstall starter rope in rope guide (Fig. 1).

BBC Models

1. Drill a 9/32” hole for rope guide approximately

6-8” down from control bar hole (Fig. 20).

2. Install new rope guide using hex head capscrew,

curved washer and hex lock nut (Fig. 20).

278

5

1

Figure 20

1. 9/32” hole

2. Control bar hole

3. Rope guide

4. Hex head capscrew

5. Curved washer

6. Hex lock nut

Install New Rope Stop

1. Crimp rope stop onto starter rope approximately

2” from recoil opening on engine (Fig. 21).

1

2”

3. Install starter rope in rope guide (Fig. 1).

Figure 21

1. Rope stop

EN–11

Page 12

Installation

Install New Cable Ties

1. Reattach cables to lower handle using new cable

ties.

Install New Decals

1. Install new decals on engine (Fig. 22).

2

1

Figure 22

1. Decal P/N 84-4960 2. Decal P/N 98-2002

2. Zone Start Self-propelled Model Only –

Remove and discard old decal from control bar.

Install new decal on control bar (Fig. 23).

Figure 23

1. Decal P/N 98-7116

1

EN–12

Page 13

FORM NO 3321–190

KIT DE CONVERSIÓN GTS 200

Para las cortadoras de césped ProLine BBC del año 1992

y posteriores y para las cortadoras de césped ProLine Zone Start

del año 1995 y posteriores

REF. PIEZA 98–9230

REF. PIEZA 98–9240

INSTALACIÓN

INSTRUCCIONES

Piezas sueltas

Nota: Utilice el cuadro siguiente para identificar las piezas que se utilizarán durante el montaje.

DESCRIPCIÓN CANT. USO

Rampa de descarga

Placa del pestillo

Conjunto de la puerta de descarga

Retén de la puerta

Tornillo autorroscante – 1/4-10 x .60

Tornillo – 3/8–16 x 1.5 3

Calcomanía del motor – 98–2002 1 Reemplaza al viejo motor

Calcomanía ProLine – 84–4960 1

Abrazadera de la funda 1 Instalar en el motor

1

1

1

1

2

Instale la rampa de descarga y el conjunto

de la puerta nuevos

Tornillo de fijación 1

Control del acelerador

Cable del acelerador

Anillo en E

Guarda del cebador 1 Instalar en el cuadrante delantero derecho

Atadura para cables

(modelos Zone Start únicamente)

Atadura para cables (modelos BBC únicamente) 3

Tope para cuerda 1 Instalar en la cuerda de recuperación

Calcomanía del control de tracción (modelos

autopropulsados Zone Start únicamente)

Calcomanía del panel de control

(modelos BBC únicamente)

Barra de control (modelos BBC únicamente) 1 Reemplaza a la barra de control vieja

Printed in USA

The Toro Company – 1998

All Rights Reserved

1

1

2

2 Sujeta los cables al manillar inferior

1 Reemplaza a la calcomanía vieja

1 Reemplaza a la calcomanía vieja

Reemplaza al viejo cable del acelerador

Page 14

Instalación

DESCRIPCIÓN USOCANT.

Guía para cuerda (modelos BBC únicamente) 1

Arandela curvada (modelos BBC únicamente) 1 Instalar la nueva guía para cuerda

Tornillo de cabeza hexagonal – 1/4-20 x 1.5

(modelos BBC únicamente)

Contratuerca hexagonal (modelos BBC

únicamente)

Antes de la instalación

PELIGRO POTENCIAL

• Si deja el cable en la bujía, alguien podría

hacer arrancar el motor accidentalmente.

LO QUE PUEDE SUCEDER

• El arrancado accidental del motor puede

lesionar gravemente al operador o a los

espectadores.

COMO EVITAR EL PELIGRO

• Desconecte el cable de la bujía antes de

instalar el kit. Más aún, sepárelo

completamente para que no pueda tocar

accidentalmente la bujía.

1

1

2. Cerciórese de que el motor esté frío. Saque la

tapa del depósito de combustible y utilice un

sifón de tipo bomba para drenar el combustible

hasta una lata de gasolina vacía.

Nota: Este es el único procedimiento

recomendado para vaciar el

combustible.

3. Vuelva a conectar el cable de la bujía.

4. Incluso cuando se haya drenado la gasolina del

motor, debe quedar suficiente combustible en el

carburador y en la línea de combustible como

para arrancar el motor. Arranque el motor y

déjelo funcionar hasta que se agote la gasolina.

Haciendo funcionar brevemente el motor se

calentará el aceite.

5. Desconecte el cable de la bujía.

1. Desconecte el cable de la bujía.

PELIGRO POTENCIAL

• Si la gasolina se derrama sobre un motor

caliente, podría inflamarse.

LO QUE PUEDE SUCEDER

• El contacto con gasolina ardiendo podría

causar graves heridas.

COMO EVITAR EL PELIGRO

• Vacíe la gasolina solamente de un motor en

frío.

ES–2

6. Drene el aceite del motor. Consulte en el manual

del operario el procedimiento de drenaje

correcto.

Page 15

Instalación

Desmontaje de los

componentes viejos

Desmontaje de la cuerda de arranque

1. Modelos Zone Start únicamente – Desmonte

la cuerda de arranque de la guía para cuerda

(Fig. 1).

1

2

Retire las ataduras para cables

1. Corte las ataduras para cables que sujetan los

cables al manillar inferior.

Desmontaje del depósito de combustible

1. Desconecte la línea de gasolina del motor

(Fig. 2).

2. Desmonte el depósito de gasolina de su ménsula

(Fig. 2). Coloque cuidadosamente el depósito a

un lado.

4

2

3

Figura 1

1. Guía para cuerda 2. Cuerda de arranque

m–2705

1

1. Abrazadera de la línea de

combustible

2. Tubo de combustible

Figura 2

3. Abrazadera del depósito

4. Depósito de gasolina

ES–3

Page 16

Instalación

Desconexión del cable del acelerador

1. Saque los (2) tornillos autorroscantes que sujetan

la cubierta de la correa a la plataforma (Fig. 3).

Coloque a un lado la cubierta y las piezas de

sujeción para volver a utilizarlas más adelante.

m-224

Desconexión del cable del freno

(modelos Zone Start únicamente)

1. Desconecte el cable del freno del brazo del freno

(Fig. 5).

2. Utilizando unos alicates, apriete las lengüetas de

la parte superior e inferior de la pieza de

conexión del cable del freno, y deslice éste fuera

de la ménsula (Fig. 5).

4

1 3

2

Figura 3

1. Cubierta de la correa 2. Tornillo autorroscante (2)

2. Afloje el tornillo de la abrazadera del cable y

desconecte el cable del acelerador de la palanca

del acelerador (Fig. 4).

m-286

Figura 4

1. Tornillo de la abrazadera

del cable

2. Cable del acelerador

3. Palanca del acelerador

Figura 5

1. Cable del freno

2. Brazo del freno

3. Pieza de sujeción del

cable del freno

4. Conjunto del freno

Desmontaje del conjunto del freno

Modelos Zone Start

1. Saque el perno de la cuchilla, la arandela de

seguridad, el refuerzo/acelerador de la cuchilla,

la cuchilla, el retén de la cuchilla, el espaciador,

la llave cuadrada y el protector del cigüeñal

(Fig. 6).

Para sacar el protector del cigüeñal, saque los (3)

tornillos autorroscantes y las (3) arandelas de

seguridad internas. Conserve estas piezas para

volver a utilizarlas durante el montaje.

ES–4

Page 17

Instalación

16

14

11

10

7

6

4

9

8

5

3

2

1

Figura 6

1. Perno de la cuchilla

2. Arandela de seguridad

3. Refuerzo/acelerador de la

cuchilla

4. Cuchilla

5. Retén de la cuchilla

6. Espaciador

7. Llave cuadrada

8. Tornillo autorroscante (3)

9. Arandela de seguridad

interna (3)

10. Protector del cigüeñal

11. Polea de accionamiento

del motor (modelo

autopropulsado

únicamente)

Modelos BBC

1. Saque las (2) tuercas de la cuchilla, la cubeta

antipelusa, el refuerzo/acelerador de la cuchilla,

la cuchilla, la tuerca de seguridad y el espaciador

de la cuchilla. Afloje después las lengüetas que

sujetan la guarda del BBC (Blade Brake Clutch Embrague del freno de la cuchilla) al

alojamiento, aflojando las tuercas o los pernos de

las lengüetas. Gire las lengüetas 180_ para

despejar el camino. Saque la guarda del BBC, el

conjunto del cubo, el tambor del freno, (2)

pernos de la cuchilla, el volante, el accionador de

la polea y la llave woodruff (Fig. 7). Conserve

estas piezas para volver a utilizarlas durante el

montaje.

15

13

8

9

11

8

7

4

5

3

2

1

1. Tuerca de la cuchilla (2)

2. Cubeta antipelusa

3. Refuerzo/acelerador de la

cuchilla

4. Cuchilla

5. Contratuerca

6. Espaciador de la cuchilla

7. Contratuerca (2)

8. Lengüeta (3)

12

10

8

7

6

Figura 7

9. Tornillo

10. Guarda del BBC

11. Conjunto del cubo

12. Tambor del freno

13. Perno de la cuchilla (2)

14. Volante

15. Accionamiento de la polea

16. Llave Woodruff

ES–5

Page 18

Instalación

Desmontaje del motor viejo

1. Saque los tres (3) tornillos del motor y levante

éste cuidadosamente para sacarlo del alojamiento

(Fig. 8). Deseche los tornillos y el motor.

1

2

Figura 8

1. Motor 2. Tornillo del motor (3)

Desmontaje del conjunto del túnel de

descarga (Fig. 9)

1. Saque los (2) tornillos de cabeza, las (2)

arandelas lisas, las (2) contratuercas, el tornillo

de cabeza hexagonal con arandela de 1/2”, y el

tornillo de cabeza hexagonal con arandela de

3/4” que sujetan el conjunto del túnel de

descarga al alojamiento. Conserve estas piezas

para volver a utilizarlas durante el montaje.

11

8

1

5

1. Túnel de descarga

2. Tornillo de cabeza (2)

3. Arandela lisa (2)

4. Contratuerca (2)

5. Tornillo de cabeza

hexagonal, con arandela

(1/2” long.)

6. Tornillo de cabeza

hexagonal, con

arandela(3/4” long.)

6

7

Figura 9

7. Ménsula del muelle

8. Extensión del muelle

9. Placa del pestillo

10. Tornillo autorroscante (2)

11. Retén de la puerta

12. Conjunto de la puerta de

descarga

6. Deseche el túnel de descarga.

Instalación del kit de

12

9

10

2

3

4

2. Levante el conjunto del túnel de descarga.

3. Saque la ménsula del muelle y la extensión del

muelle. Conserve estas piezas para volver a

utilizarlas durante el montaje.

4. Saque los (2) tornillos autorroscantes y la placa

del pestillo del túnel viejo y deséchelos.

5. Saque el retén de la puerta y el conjunto de la

puerta de descarga y deséchelos.

ES–6

conversión

Instale el nuevo túnel de descarga

(Fig. 9)

1. Coloque el nuevo túnel de descarga en la

plataforma. Alinee los orificios del túnel de

descarga con los orificios de la plataforma.

2. Sujete las esquinas trasera-izquierda y

trasera-derecha del túnel a la plataforma usando

los (2) tornillos de cabeza, las (2) arandelas lisas

Page 19

y las (2) tuercas de seguridad desmontadas

previamente. Sujete el lado delantero-derecho

del túnel a la plataforma usando el tornillo de

cabeza hexagonal con arandela de 1/2” retirado

previamente. Sujete la esquina delanteraizquierda del túnel y la ménsula del muelle a la

plataforma usando el tornillo de cabeza

hexagonal con arandela de 3/4” retirado

previamente.

3. Instale el nuevo conjunto de la puerta de

descarga y sujételo con el nuevo retén de la

puerta.

4. Instale la nueva placa del pestillo en el túnel

usando (2) tornillos autorroscantes nuevos.

Instalación

1

5. Enganche un extremo de la extensión del muelle

a través del orificio de la ménsula del muelle y el

otro extremo en el asa de la puerta de descarga.

6. Abra y cierre la puerta de descarga para

comprobar que se cierra cuando se suelta el asa.

Instalación del nuevo motor

1. Coloque cuidadosamente el nuevo motor en el

alojamiento.

2. Instale y apriete los (3) tornillos del motor

nuevos (Fig. 10). Apriete los tornillos del motor

a un par de 28–45 NSm (250–400 in-lbs).

2

Figura 10

1. Motor 2. Tornillo del motor (3)

Reinstalación del conjunto de la cuchilla

Vuelva a instalar el conjunto de la cuchilla siguiendo

el orden inverso al desmontaje. Consulte los

procedimientos de la sección Desmontaje del

conjunto de la cuchilla.

Modelos Zone Start - Cuando vuelva a instalar el

protector del cigüeñal, coloque, pero no apriete, los

tornillos de montaje. Introduzca un calzo (una tarjeta

de visita puede servir) entre el protector y el cubo del

retén de la cuchilla que ayuda a centrar el protector.

Apriete los tornillos de montaje y retire el calzo.

Continúe con la instalación del conjunto de la

cuchilla. Apriete el perno de la cuchilla a un par de

68 NSm (50 ft.-lbs.).

Modelos BBC - Apriete las tuercas de la cuchilla a

un par de 20–37 NSm (15–27 ft.-lbs.).

ES–7

Page 20

Instalación

Instalación de la guarda del cebador

1. Saque los (2) tornillos de cabeza hexagonal del

cuadrante delantero derecho (Fig. 11). Deje

colocado el cuadrante.

2

1

Figura 11

1. Cuadrante delantero

derecho

2. Tornillo de cabeza

hexagonal (2)

2. Instale la nueva guarda del cebador encima del

cuadrante delantero derecho con los (2) dos

tornillos de cabeza hexagonal (Fig. 11).

3

3. Guarda del cebador

3. Saque los (2) tornillos de cabeza hexagonal y las

(2) arandelas curvadas que sujetan el control del

acelerador al manillar (Fig. 12). Guarde los

tornillos y las arandelas. Deseche el control del

acelerador y el cable del acelerador.

1

4

3

6

1. Control del acelerador

2. Cable del freno

(modelo HP)

Cable de tracción

(modelo SP)

3. Cable del acelerador

7

2

Figura 12

4. Anillo en E

5. Tornillo de cabeza

hexagonal (2)

6. Arandela curvada (2)

7. Junta

6

5

Instalación del nuevo control del

acelerador

Modelos Zone Start

1. Modelos HP únicamente – Retire el anillo en E

para desconectar el cable del freno del control

del acelerador (Fig. 12). Deseche el anillo en E.

2. Modelos SP únicamente – Retire el anillo en E

para desconectar el cable de tracción del control

del acelerador (Fig. 12). Deseche el anillo en E.

ES–8

4. Instale el nuevo control del acelerador usando

los (2) tornillos de cabeza hexagonal y las (2)

arandelas curvadas retiradas previamente.

5. Conecte el nuevo cable del acelerador al control

del acelerador usando un nuevo anillo en E.

6. Modelos HP únicamente – Vuelva a conectar el

cable del freno al control del acelerador usando

un anillo en E nuevo. Después conecte el cable

del freno al motor (Fig. 5).

7. Modelos SP únicamente – Vuelva a conectar el

cable de tracción al control del acelerador usando

un anillo en E nuevo. Después conecte el cable

del freno al motor (Fig. 5).

Page 21

Instalación

8. Asegúrese de que las juntas de los cables están

firmemente introducidas (Fig. 12).

9. Pase el cable del acelerador sobre la parte

superior de la transmisión (Fig. 13).

1

Figura 13

1. Cable del acelerador

10. Conecte el cable del acelerador al brazo del

acelerador del motor (Fig. 14).

13. Instale un tornillo y una abrazadera de cable

nuevos en el motor (Fig. 14). Apriete el tornillo

de la abrazadera para inmovilizar el cable del

acelerador.

14. Vuelva a instalar la cubierta de la correa usando

las piezas de sujeción que había retirado

previamente (Fig. 3).

Modelos BBC

1. Saque los (4) tornillos de cabeza Phillips y las

(4) contratuercas que sujetan el control del

acelerador al panel de control (Fig. 15). Guarde

los tornillo y las contratuercas. Deseche el

control del acelerador, el retén del cable del

acelerador y el cable del acelerador.

1

7

3

1

2

4

m-3638

Figura 14

1. Tornillo de la abrazadera

del cable

2. Abrazadera del cable

3. Cable del acelerador

4. Brazo del acelerador

11. Mueva el acelerador hasta la posición

RÁPIDO (FAST).

12. Empuje al máximo el brazo del acelerador hacia

la parte de atrás del motor.

1. Tornillo con cabeza

Phillips (4)

2. Contratuerca (4)

3. Control del acelerador

4. Retén del control del

acelerador

2

3

4

6

5

Figura 15

5. Cable del acelerador

6. Junta

7. Calcomanía ref.

pieza 98-2003

ES–9

Page 22

Instalación

2. Retire y deseche la vieja calcomanía del panel de

control. Instale una nueva calcomanía en el panel

de control (Fig. 15).

3. Instale el nuevo control del acelerador usando

los (4) tornillos de cabeza Phillips y las (4)

contratuercas que había retirado previamente.

Instale el nuevo retén del control del acelerador.

Nota: Cerciórese de que la junta del cable del

acelerador está firmemente introducida.

4. Conecte el cable del acelerador al brazo del

acelerador del motor.

5. Coloque el acelerador en la posición

RÁPIDO (FAST).

6. Empuje al máximo el brazo del acelerador hacia

la parte de atrás del motor.

7. Instale un tornillo y una abrazadera de cable

nuevos en el motor (Fig. 14). Apriete el tornillo

de la abrazadera para inmovilizar el cable del

acelerador.

Instalación de la nueva barra de control

(modelos BBC únicamente)

1. Saque el tornillo del manillar, el espaciador del

soporte y la tuerca con brida hexagonal que

sujetan el lado derecho de la barra de control al

manillar (Fig. 16). Conserve estas piezas para

volver a utilizarlas durante el montaje.

2. Saque cuidadosamente el tornillo de cabeza

hexagonal, el espaciador y la contratuerca que

sujetan el lado izquierdo de la barra de control a

la parte superior de la ménsula de control del

manillar (Fig. 16). Conserve estas piezas para

volver a utilizarlas durante el montaje. Deje las

demás piezas de la ménsula de control sin

apretar.

2

7

1. Barra de control

2. Tornillo del manillar

3. Espaciador del soporte

4. Tuerca con brida

hexagonal

8

3

Figura 16

4

1

5

5. Tornillo con cabeza

hexagonal

6. Espaciador

7. Contratuerca

8. Ménsula de control

3. Saque y deseche la vieja barra de control.

4. Coloque la nueva barra de control invirtiendo el

orden de desmontaje.

Instalación del depósito de gasolina

Vuelva a instalar el depósito de gasolina siguiendo el

orden inverso al desmontaje (Fig. 2). Conecte la línea

de combustible al motor.

6

ES–10

Page 23

Instalación

Ajuste del cable del freno

PELIGRO POTENCIAL

• Modelos BBC únicamente – No apriete

excesivamente el cable del freno de la

cuchilla. Si lo aprieta en exceso, el freno de

la cuchilla podría salirse del tambor del

freno. Si el freno no toca el tambor, cuando

se suelta la barra de control la cuchilla

seguirá girando.

LO QUE PUEDE SUCEDER

• La cuchilla en rotación podría causar

graves lesiones personales.

COMO EVITAR EL PELIGRO

• Revise el mecanismo del freno de la cuchilla

cada vez que ajusta el cable del freno para

garantizar que el freno se detiene en menos

de 3 segundos.

• Si la cuchilla no deja de girar en menos

de 3 segundos, póngase en contacto con un

concesionario de servicio autorizado de

Toro para que inspeccionen y reparen la

máquina.

(3/16”–1/4”) entre la palanca del freno y el

manillar. Tire hacia abajo del conducto del

cable hasta que se elimine cualquier

flojedad del alambre, y después apriete la

tuerca.

1

Modelo empujado a mano

1. Manillar

2. Palanca del freno

3. 3/16”-1/4”

4

5

6

Figura 17

4. Pieza de ajuste del cable

5. Contratuerca

6. Conducto del cable

2

3

483

1. Modelos Zone Start únicamente –

COMPROBACIÓN DEL AJUSTE (Fig. 17 &

18)– Mueva la barra de control hacia el manillar,

hasta que desaparezca la flojedad del cable. La

holgura entre la palanca del freno y el manillar

debe ser de 4,7 – 6,3 mm (3/16”–1/4”). Para el

ajuste, consulte el paso 2.

2. AJUSTE DEL CONDUCTO DEL CABLE

• Modelos empujados a mano (Fig. 17) –

Afloje la contratuerca del cable del freno.

Introduzca un objeto de 4,7 – 6,3 mm

(3/16”–1/4”) entre la palanca del freno y el

manillar. Gire la pieza de ajuste del cable

del freno hasta eliminar cualquier flojedad,

y después apriete la tuerca.

• Modelos autopropulsados (Fig. 18) –

Afloje la tuerca de la ménsula del cable.

Introduzca un objeto de 4,7 – 6,3 mm

Modelo autopropulsado

1. Manillar

2. Palanca del freno

2

Figura 18

1

3

4

3. 3/16”-1/4”

4. Ménsula del cable

ES–11

Page 24

Instalación

• Modelos BBC (Fig. 19) - Afloje el tornillo

de la ménsula del cable hasta que el

conducto del cable del freno comience a

deslizarse. Tire del cable para eliminar la

flojedad, pero sin aplicar tensión en el

muelle. Apriete el tornillo para bloquear el

ajuste.

2

3

1

Figura 19

1. Muelle

2. Tornillo de la abrazadera

del cable

3. Conducto del cable

278

Modelos BBC

1. Taladre un orificio de 7 mm (9/32”), para pasar

la guía para cuerda, a aproximadamente 15 –

20 cm (6–8”) por debajo del orificio de la barra

de control (Fig. 20).

2. Instale la guía para cuerda usando el tornillo de

cabeza hexagonal, la arandela curvada y la

contratuerca hexagonal (Fig. 20).

3. Instale la cuerda de arranque en la guía para

cuerda (Fig. 1).

2

6-8”

3

6

4

Instalación de la cuerda de arranque y de

la guía para cuerda

Modelos Zone Start

1. Vuelva a colocar la cuerda de arranque y la guía

para cuerda (Fig. 1).

5

1

1. Orificio de 7 mm (9/32”)

2. Orificio de la barra de

control

3. Guía para cuerda

Figura 20

4. Tornillo de cabeza

hexagonal

5. Arandela curvada

6. Contratuerca hexagonal

ES–12

Page 25

Instalación del nuevo tope para cuerda

Instalación

1. Coloque el tope alrededor de la cuerda de

arranque a aproximadamente 5 cm de la abertura

para el retroceso de la cuerda del motor

(Fig. 21).

1

2”

Figura 21

1. Tope de la cuerda

2

1

Figura 22

1. Calcomanía ref.

pieza 84-4960

2. Calcomanía ref.

pieza 98-2002

2. Modelo autopropulsado Zone Start

únicamente – Retire y deseche la vieja

calcomanía de la barra de control. Instale la

nueva calcomanía (Fig. 23).

1

Instalación de la nueva atadura para

cables

1. Vuelva a sujetar los cables al manillar inferior

utilizando la nueva atadura para cables.

Instalación de las nuevas calcomanías

1. Instale las nuevas calcomanías en el motor

(Fig. 22).

Figura 23

1. Calcomanía ref.

pieza 98-7116

ES–13

Page 26

Page 27

Page 28

Loading...

Loading...