Page 1

FORM NO. 3319–237

BYPASS VALVE KIT

for MIDSIZE HYDRO TRACTION UNITS

PART NO. 95–5861

Loose Parts

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Valve

Decal

Remove Existing By-pass

2

Install valves in hydro pumps

1

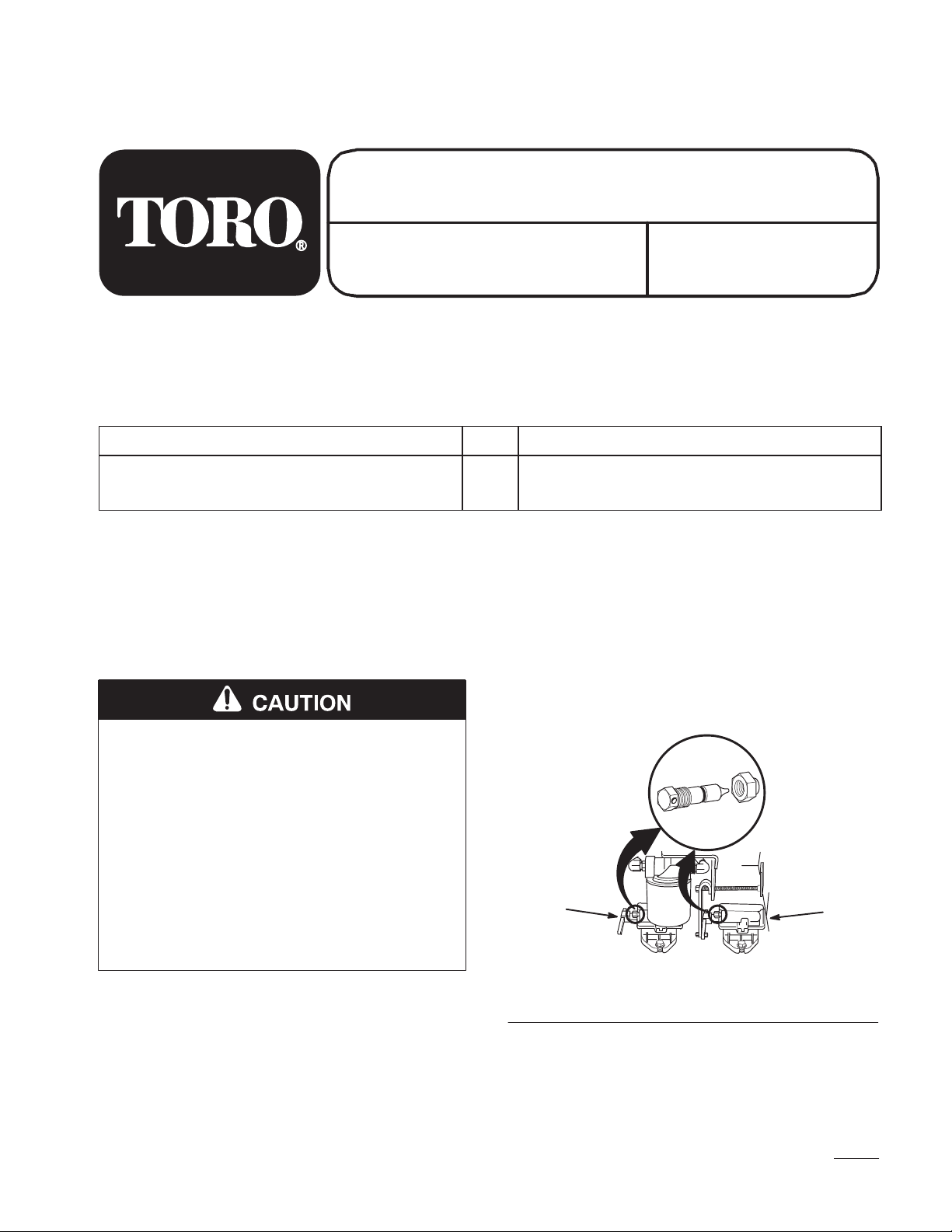

2. Clean area of hydraulic pumps around existing

by-pass valves (Fig. 1).

Valves

3. Loosen jam nuts and unscrew existing by-pass

1. Shut off engine and and wait for all moving parts

to stop. Remove spark plug wire(s).

valves (Fig. 1). Discard valves.

Note: Place a rag under valve area as a small

amount a hydraulic fluid may run out

of opening.

INSTALLATION

INSTRUCTIONS

POTENTIAL HAZARD

• If you leave the wire on the spark plug,

someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of engine could

seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

• Pull wire off spark plug before you do any

maintenance. Also push wire aside so it

does not accidentally contact spark plug.

2

1

Figure 1

1. Hydraulic pump 2. Existing by-pass valve

1

m–3110

1

Page 2

Installation

Install New By-Pass Valve

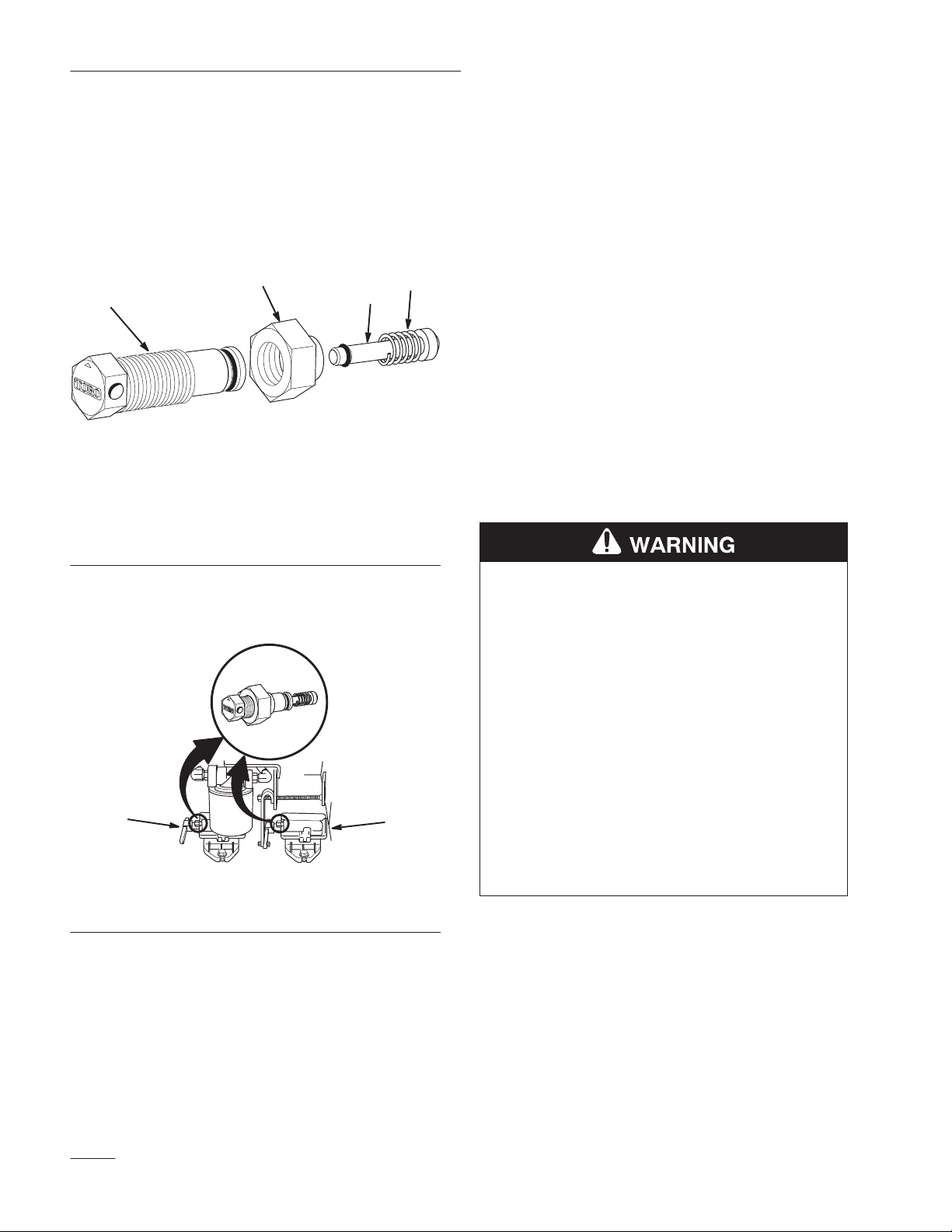

1. Assemble the new by-pass valves, if necessary,

gently rotate and push spring tip into body and

threading jam nut onto body with shoulder

toward tip as shown (Fig. 2).

1

1. Body

2. Tip

3

Figure 2

3. Jam nut

4. Spring

4

2

m–3107

Bleeding Hydraulic System

The traction system is self bleeding, however, it may

be necessary to bleed the system after changing the

valve

1. Raise the rear of machine until wheels are off the

floor and support with jack stands.

2. Start the engine and run at idle speed. Engage

traction on one side and spin the wheel by hand.

3. When the wheel begins to spin on its own, keep

it engaged until wheel drives smoothly.

(minimum 2 minute)

4. Check hydraulic fluid level as it drops and add

as required to maintain level.

5. Repeat procedure on opposite wheel.

2. Thread new by-pass valves into hydraulic pumps

(Fig.3 ).

2

1

Figure 3

1. Hydraulic pump 2. New valve

1

m–3111

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

HOW TO AVOID THE HAZARD

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks.

2

Page 3

Installation

Adjusting By-pass Valve

The by–pass valve is adjustable to ensure easy

operation with a variety of deck sizes. If the front of

the deck lifts off the ground when the upper control

bar is quickly pushed forward or the machine is

unable to drive up hills, an adjustment may be

needed.

Test Procedure

1. Start engine and run for 5 minutes at 3/4 throttle,

to warm hydraulic fluid.

2. Drive the machine to a clear and level open area

such as a driveway.

IMPORTANT: There should be at least 10

feet of clear area in front of the machine.

3. Loosen the quick release levers and push the

reference bar forward to the “FAST” position.

Lock the quick release levers to secure the

reference bar.

8. If the machine accelerates slowly, and the front

caster wheels do not lift off the ground, the

machine is too un–responsive. Adjustment is

required.

Adjustment Procedure

The by–pass valve should be adjusted to deliver best

performance for the size (weight) mower you have.

The by–pass valve factory setting is 1/2 turn out.

The following values can be used as initial settings

for different size mowers:

62” 1/6 turn out

52” 1/2 turn out

44” 1 turn out

36” 1 turn out

9. Loosen large jam nut several turns (Fig. 4).

10. Gently close by–pass valve (Fig. 4).

IMPORTANT: Do not over–tighten valve or

needle and seat may be damaged. Do not

exceed 50 inch pounds to close valve.

4. Move throttle control to 3/4 throttle.

5. Quickly push the upper control bar against the

reference bar. The front caster wheels should

almost lift off the ground. If front caster wheels

lift the off the ground , the machine is too

aggressive and adjustment is required.

6. Move the engine throttle to the “FAST” position.

7. Quickly push the upper control bar against the

reference bar. The front caster wheels should lift

1 to 3 inches off the ground. If front caster

wheels lift the off the ground more than 3

inches, the machine is too aggressive.

Adjustment is required.

11. Open by–pass valve 1/2 turn (Fig. 4).

12. Tighten jam nut to lock the adjustment (Fig. 4).

13. Repeat “Test Procedure” to check for proper

operation.

IMPORTANT: By–pass valve adjustment is

very sensitive, do not adjust more than 1/6

turn (one flat) at a time.

14. If the machine is too aggressive, the valve needs

to be open further.

15. If the machine is un–responsive, the valve needs

to be closed further.

3

Page 4

Installation

16. Repeat “Test Procedure” to check for proper

operation. Re-adjust the by–pass valves until

proper performance is achieved.

1

1

Figure 4

1. By-pass valve 2. Jam nut

2

m–3098

Install Decal

1. Install decal for by-pass valve adjustment to rear

frame (Fig. 5).

m–3107

Figure 5

1. Decal

4

Loading...

Loading...