Page 1

P220G Series Plastic Valves

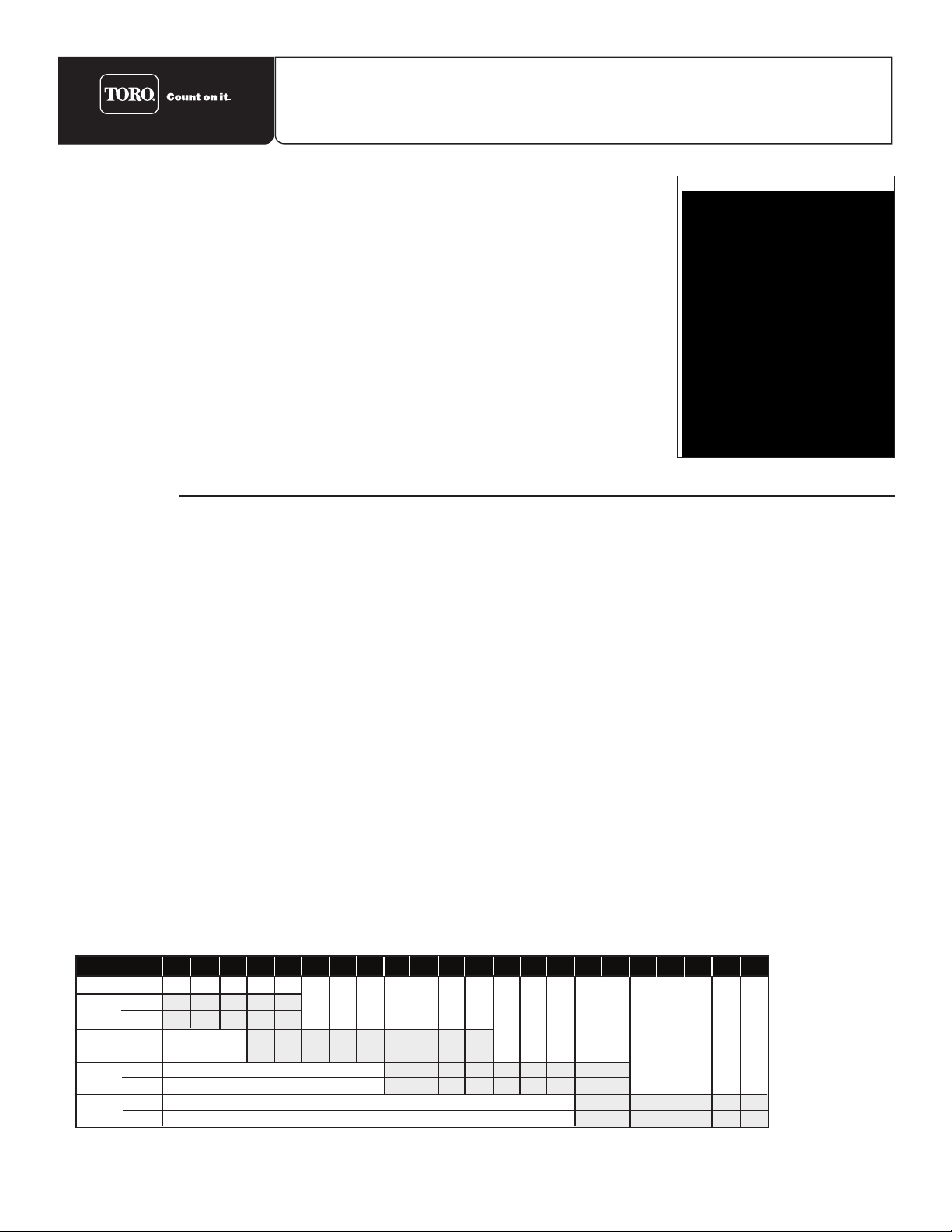

5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 180 200 225 250 275 300

Flow (GPM)

Size – Config.

Globe

Angle

4.0 4.2 3.2 4.1 7.2

2.5 3.0 4.1 5.3 6.7 8.3 10.1

1.9 2.4 3.3 4.3 5.5 6.9 8.5

4.0 4.2 3.1 2.7 4.8

1.6 2.3 3.6 5.2 7.0 9.2 11.7 14.4 17.5

1.3 1.6 2.8 4.0 5.5 7.1 9.0 11.0 13.3

2.1 2.7 3.3 4.0 4.8 5.6 6.5 7.5 8.7

1.2 1.6 2.0 2.4 2.8 3.3 3.9 4.4 5.2

1½"

3"

2"

Globe

Angle

Globe

Angle

Globe

Angle

1"

Installation and Operating Instructions

Introduction

The P220G Series provides a full family of plastic valves are designed specifically to meet

the challenging needs of today’s golf course irrigation systems. Featuring precision pressure

egulation, the P220G Series valve delivers the optimum pressure and flow to every sprinkler

r

on the zone, ensuring maximum uniformity of the water to the turf.

The EZ-Reg pressure regulating system, a standard feature on all P220G valves, provides

consistant operating pressure. From low-pressure/flow applications of drip irrigation, to the

high-pressure/flow requirements of high-volume sprinklers, the EZ-Reg adjusts easily with

the micro-adjust dial and indicator, to provided constant downstream pressure 5–100 psi.

Also standard on the P220G series, is the heavy-duty SpikeGuard™ solenoid. Providing

20,000-volt lightning protection – the SpikeGuard solenoid has proven to minimize down

time and service costs, even in the severe lightning-prone regions.

Note: The P220G valve should be installed below grade in a valve box or vault to provide

service access and vandal resistance. The valve installation site should be readily accessible by grounds maintenance personnel and well clear of hardscape features, cart paths

and foot traffic areas.

Specifications

n Configuration:

z Globe/Angle

z Glass-filled nylon and steel construction

1

z 1", 1

⁄2", 2" and 3" NPT female thread models

z 24 VAC electric actuation

z Pressure regulating

3

z 1" - 6

z 1

n Flow Range:

z 1" - 5—60 GPM z 2" - 80—180 GPM

z 1

n Operating Pressure Range:

z Inlet: 10—220 psi

z Outlet: 5—100 ± 3 psi

z Inlet/outlet minimum pressure differential:10 psi

z Burst pressure safety rating: 750 psi

n EZReg Pressure Regulator:

z Compact, precision-dial design

z Regulates during automatic and manual operation

z Serviceable while valve is pressurized

z Schrader-type poppet valve enabling easy

⁄4" H x 33⁄8" W z 2" - 91⁄2" H x 61⁄8" W

1

⁄2" - 71⁄4" H x 35⁄8" W z 3" - 103⁄4" H x 61⁄8" W

1

⁄2" - 30—120 GPM z 3" - 150—300 GPM

verification of downstream pressure

n Friction Loss Chart

n Manual Bleed:

z Manual on/off control

z Internal (downstream) bleed control (below solenoid)

relieves water internally

z External (atmospheric vent) bleed control (on flow control

handle) relieves water to atmosphere

n SpikeGuard Solenoid:

z 24 VAC, 50/60 Hz

z Inrush - 0.12 amps

z Holding - 0.10 amps

n DC-latching Solenoid (optional)

z For Golf Decoder Control (GDC) applications

n Diaphragm:

z Double-beaded, fabric-reinforced

n Filter Screen:

z Stainless steel, 120-mesh

z Self-flushing, contamination resistant and servicable

n Manual Flow Reduction Control:

z Adjustable downstream flow reduction to zero flow (off)

Note: Friction loss values shownn in psi. Operating valve outside indicated flow range is not recommended.

Page 2

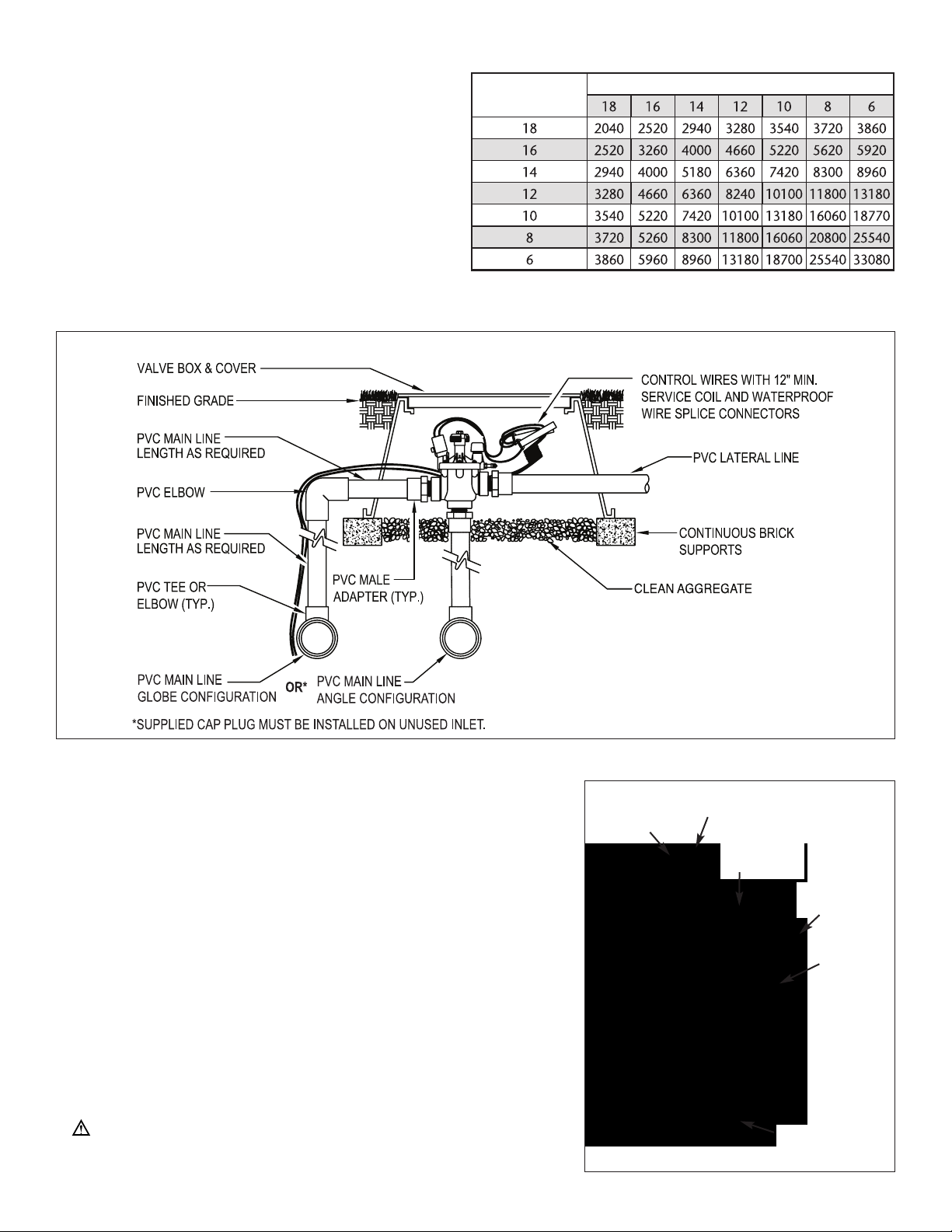

nstallation Guidelines

I

• Note the flow direction arrow in the side of the valve body

and install accordingly.

• The valve can be installed at any angle without affecting

operation.

• Use direct-burial irrigation control wire for connection from

the controller to valves.

• Leave a 12" wire expansion loop at each valve location on

long-run wire lengths.

• Waterproof wire splice connectors are absolutely essential

for proper electric control system operation. Follow the

installation instructions provided by the connector

manufacturer for optimum performance.

Typical Installation Detail

Common Wire

Gauge Size

Note: Values indicate maximum. one-way distance ( in feet) between controller

and valve solenoid under the followig conditions: minimum voltage - 20 VAC,

maximum amperage - 0.12A and operating pressure - 150 psi.

Control Wire Gauge Size

Valve Adjustment Procedures

• Close the valve by turning the Flow Control Handle fully clockwise, just until

resistance is felt - do not overtighten!

• Remove the EZReg dial protective cover (if installed). Turn the control dial

until the pointer indicates the desired downstream pressure (5 to 100 psi).

Flow Control

Handle

Note: One revolution of the control dial adjusts the pressure setting

approximately 10 psi. A minimum of 10 psi pressure differential between

the valve inlet and outlet is required for proper EZReg operation.

• Pressurize the main supply line to the valve. Confirm that all pipe connections

are properly sealed.

• Actuate the valve either electrically at the controller, or manually by turning

the Internal Bleed Handle counterclockwise to the ON position.

Note: EZReg operation is bypassed when the valve is manually actuated

using the External Bleed Cap.

• Turn the Flow Control Handle slowly counterclockwise to adjust sprinkler

operation.

• To confirm outlet pressure, remove the poppet valve cap, located directly

below the EZReg. Attach a water-pressure test gauge to the poppet valve

for a direct reading. Adjust pressure as preferred.

Important: The EZReg assembly can be removed for service while

the valve is pressurized. However, the valve must not be operated with

the EZReg assembly removed.

© 2009 The Toro Company, Irrigation Division • www.toro.com Form Number 373-0545 Rev. A

External Bleed Cap

w/Metering Rod

EZReg

Control Dial

Internal

Bleed Handle

Poppet

Valve

Inlet Cap Plug

Loading...

Loading...