Page 1

SCAMP AND UTILITY MODELS

SERVICING

4502, 4503, 8602, 8603

WITH

“F”

SERIES ENGINES

SELF-PROPELLED BELT DRIVE

Adjustments

and

servicing of the Scamp and

Utility self-propelled mowers are very different

from

all

previous models of self-propelled

mowers.

SAFETY WARNING

BEFORE

ANY

ADJUSTMENTS OR

REPAIRS ARE ATTEMPTED, DIS-

CONNECT

AND

REMOVE SPARK

PLUG TO PREVENT STARTING.

INSTALLING CONTROL

ROD

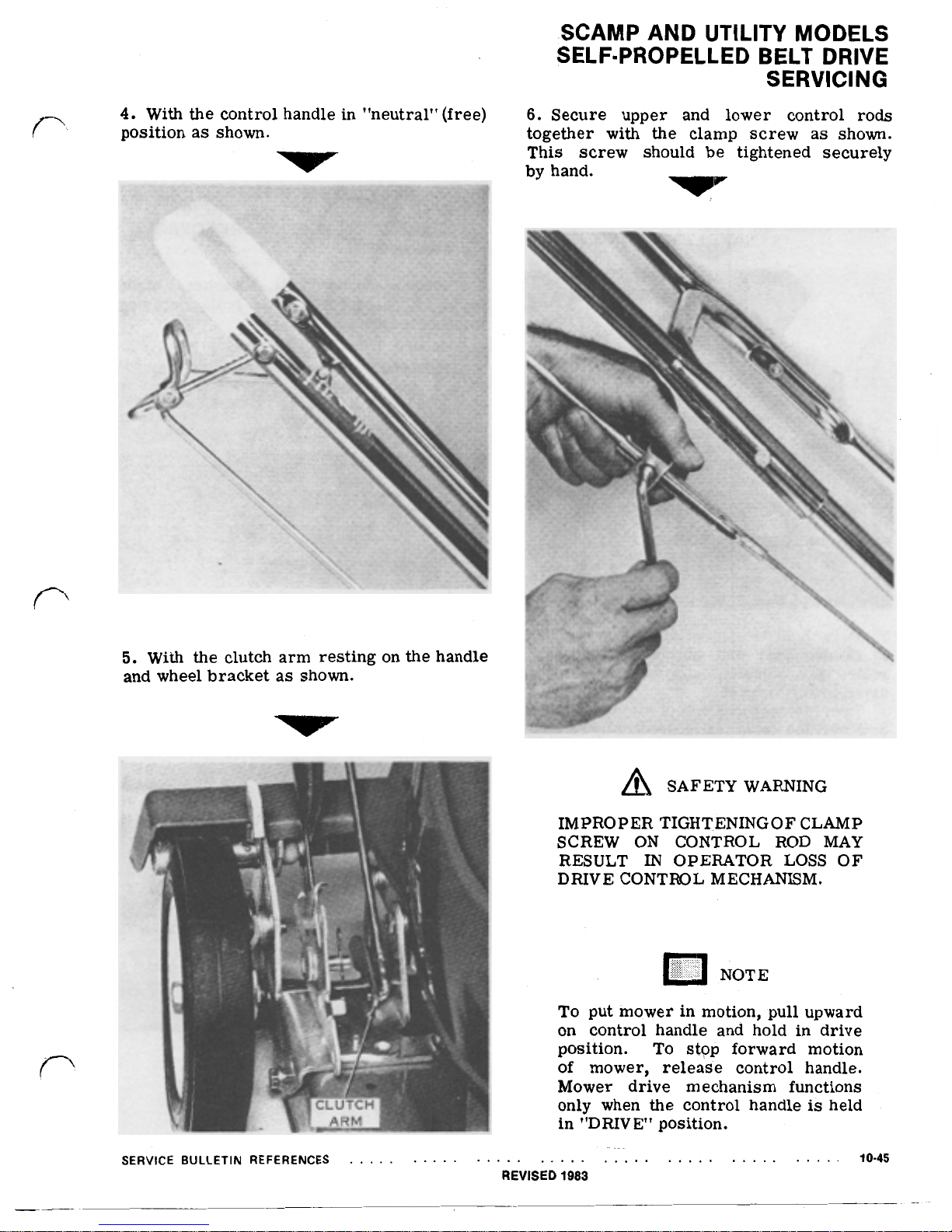

1.

Place retainer clip on clutch arm

with

long side

of

clip on the inside

of

clutch arm.

2.

Align

hole in

clip

with

hole in arm and

assemble lower end

of

the control

rod

in

hole.

3.

Turn (swivel) long end

of

clip up and snap

into position on lower control rod as shown.

SAFETY WARNING

THE LOWER SELF PROPEL CONTROL ROD MUST

BE

ASSEMBLED

TO CLUTCH ARM

AS

SHOWN. IF

NOT THE SELF PROPEL MECHANISM WILL NOT RETURN TO

NEUTRAL WHEN THE CONTROL

LEVER IS RELEASED FROM THE

ENGAGED POSITION.

10-44

REVISED

1983

SERVICE BULLETIN REFERENCES

Page 2

4.

With

the control handle in "neutral" (free)

position as shown.

SCAMP AND UTILITY MODELS

SERVICING

6.

Secure upper and lower control rods

together with the clamp screw as shown.

This screw should be tightened securely

SELF=PROPELLED BELT DRIVE

by hand.

5.

With

the clutch arm resting on the handle

and wheel bracket as shown.

SAFETY WARNING

IMPROPER TIGHT.ENING OF CLAMP

SCREW ON CONTROL ROD MAY

RESULT

IN

OPERATOR LOSS OF

DRIVE CONTROL MECHANISM.

NOTE

To

put mower in motion, pull upward

on control handle and hold in drive

position. To stop forward motion

of

mower, release control handle.

Mower drive mechanism functions

only when the control handle

is

held

in "DRIVE" position.

Page 3

!

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

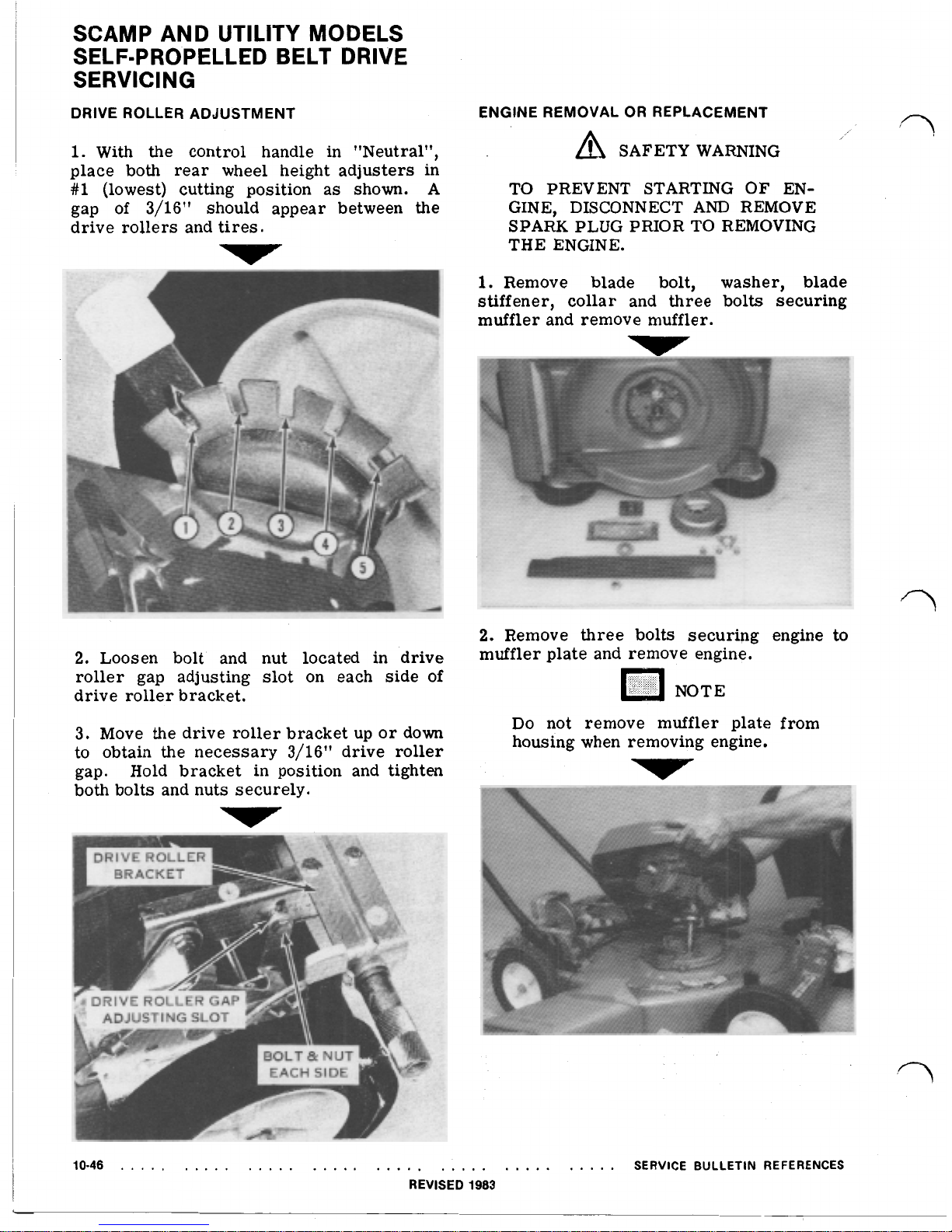

DRIVE ROLLER ADJUSTMENT

1.

With the control handle in "Neutral",

place both rear wheel height adjusters in

#1

(lowest) cutting position as shown.

A

gap of 3/16" should appear between the

drive rollers and tires.

2.

Loosen bolt and nut located in drive

roller gap adjusting slot on each side of

drive roller bracket.

3. Move the drive roller bracket up or down

to obtain the necessary 3/16'' drive roller

gap. Hold bracket

in

position and tighten

both bolts and nuts securely.

ENGINE REMOVAL

OR

REPLACEMENT

SAFETY WARNING

TO PREVENT STARTING OF ENGINE, DISCONNECT

AND

REMOVE

SPARK PLUG PRIOR TO REMOVING

THE ENGINE.

1.

Remove blade bolt, washer, blade

stiffener, collar and three bolts securing

muffler and remove muffler.

n

2.

Remove

three

bolts securing engine to

muffler plate and remove engine.

Do not remove muffler plate from

housing when removing engine.

10-46

SERVICE BULLETIN REFERENCES

REVISED

1983

Page 4

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

V

BELT REMOVAL

OR

REPLACEMENT

SAFETY WARNING

TO PREVENT STARTING ENGINE,

DISCONNECT SPARK PLUG LEAD

AND REMOVE SPARK PLUG.

The

"V"

belt used on the utility self-

propelled model mowers

is

a SPECIAL

BELT.

DO

NOT USE

A

SUBSTITUTE. It

won't work as WELL or as LONG.

To

remove the belt:

1.

Remove

four

belt guard cover screws and

remove cover.

2.

Remove engine

and

remove drive belt from drive

pulley.

SAFETY WARNING

DO

NOT OPERATE MOWER WITH

BELT GUARD REMOVED.

3.

Remove roll pin from left hand drive

roller and remove roller.

4.

Remove belt from driven pulley and slide

shaft assembly to the right. Remove belt

from mower as shown.

SERVICE BULLETIN REFERENCES

10-47

REVISED

1983

Page 5

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

NOTE

After the belt has been removed,

examine for broken, cracked or misaligned pulleys.

The

condition and

the wear pattern of

the

belt

will

provide clues for the above possibilities. Replace damaged or worn

pulleys.

5.

The crankshaft pulley (drive pulley)

is

secured to

the

crankshaft

with

a

SPECIAL

slotted set screw. The end of

this

screw

locates in a hole in the crankshaft. The

correct position and tightness

is

very

IMPORTANT.

If

not tightened securely,

damage to the pulley, crankshaft and premature wear of the drive belt

will

result.

NOTE

Apply

OMC

Ultra-Lock (part no.

388517)

to

threads

of

set screw prior to installation.

6.

When reinstalling pulley to crankshaft,

the side of the pulley

with

set screw

is

the

lower side.

If

assembled upside

down

(set

screw on top) misalignment and interference

of pulley operation

will

result. Always

check

pulley for damage. Replace

if

necessary.

10.48

REVISED

1983

SERVICE BULLETIN REFERENCES

Page 6

IDLER

PULLEYS TOP STRAND

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

SAFETY

WARNING

INCORRECT DRIVE BELT INSTALLATION MAY ALLOW

MOWER

TO

OPERATE IN REVERSE DIRECTION

TOR OR BYSTANDERS. ASSEMBLE

DRIVE BELT

AS

SHOWN.

CAUSING INJURY

TO

THE OPERA-

DRIVE- BOTTOM STRAND ENGINE

SHAFT DRIVE

PULLEY PULLEY

INSTALL BELT AS SHOWN

FOR PROPER PULLEY ROTATION

8.

Check

the condition of the driveshaft, bronze

bearings, and sleeve. If

signs

of damage or

wear

appear, replace them.

7.

Place belt over left end of drive shaft

as shown.

Do

not assemble

on

driveshaft

pulley.

9.

BUSHING AND BEARING INSTALLA-

TIONS.

NOTE

The sleeve

has

a

flat surface that matches

the flat surface

of

the bracket. When re-

assembling, the flat surfaces must match.

Page 7

SCAMP AND UTILITY MODELS

SERVICING

SELF=PROPELLED BELT DRIVE

10.

Reassemble the drive

shaft

into the bearing

and slide

it

to

the left

as

far

as

possible. Assemble

the washer and drive roller on the drive shaft.

11.

The drive rollers must be properly installed

to

utilize the self-cleaning feature. Proper installation

is

with the vee pointing toward the wheel.

12.

Using a new roll pin, assemble the drive roller

to

the drive shaft. Use

a

5/32”

or larger

drift

punch, drive the roll pin

into

place, flush with the

outer surface. Neither end should protrude beyond

the roller surface.

INSTALL BELT AS SHOWN

FOR

PROPER PULLEY ROTATION

13.

As

you face the front of the mower,

twist

the

forward

end of the belt

1/4

turn counter clockwise

and assemble on the engine drive pulley. Assemble

engine on muffler plate and secure with three bolts.

14.

Release spring tension on idler pulleys and

as-

semble belt on drive shaft pulley. Reassemble idler

pulley spring and rotate the belt several revolutions. Check

to

make sure the belt

is

centered on

the pulleys and TURNING IN RIGHT DIRECTION. Note direction of arrow on large pulley in

illustration above. Check and adjust belt tension

if

necessary. Refer

to

BELT TENSION

ADJUSTMENT.

When replacing either of the belt idler

assemblies, use idler

kit

part no.

682374

for the top and

kit

part no.

682564

on the

bottom.

10.50

SERVICE BULLETIN REFERENCES

REVISED

1983

Page 8

BELT TENSION ADJUSTMENT

1.

Check drive belt installation. Drive belt

must be installed between idler pulleys as

shown.

2.

Drive belt should be checked to insure

that proper tension exists in order to pre-

vent premature belt failure. Lift floating

idler from the upper strand of

"V"

belt.

Belt

will

then become loose. Set floating

idler onto

"V"

belt and check clearance be-

tween the two strands of the

"V"

belt. The

distance between the two strands should not

be less than

1/2"

as shown.

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

3.

To

adjust belt tension; loosen four handle

bracket mounting screws (two on each

bracket) and two screws (one on each side)

located on the sides of rear height adjuster

bracket as shown. Slide entire self-propell-

ing mechanism in direction necessary to

obtain the proper

"V"

belt tension.

4.

Care should be taken to insure that both

sides of the self-propelling mechanism are

positioned equally on the mower housing.

This can be accomplished by measuring the

distance from

the

front edge on the height

adjuster brackets to the' 1/4" diameter gage

holes located directly in front of these

brackets as shown. This distance must be

the same for both sides. Before tightening

screws make sure the distance between the

strands of

the

"V"

belt

is

not

less

than

1/2".

Tighten the four handle bracket

screws and the two side screws securely.

Reassemble belt guard to self-propel

mechanism using screws previously

removed.

SAFETY WARNING

DO

NOT

OPERATE MOWER WITH

BELT

GUARD REMOVED.

SERVICE BULLETIN REFERENCES

10.51

REVISED

1983

Page 9

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

LUBRICATION

10

HOURS

1.

DRIVE ROLLER BEARINGS-Disassemble

rotating shaft cover from self-propel mechanism by

removing four screws. Unscrew plug from end of

each drive roller (Point

“A”).

Fill exposed cavity

610721

OR EQUIVALENT. Replace plug and

tighten until snug. Repeat procedure until lubricant appears on cross-shaft at Point

“B”.

Reas-

semble rotating shaft cover to self-propel assembly.

with LAWN-BOY

“A”

GREASE, PART NO.

FLOATING IDLER PULLEY-Do not immerse

the idler pulley in solvent.

Use

a rag containing

solvent, clean the hole in the idler pulley and the

shoulder

bolt

thoroughly. Useing a small amount of

LAWN-BOY

A

GREASE or EQUIVALENT, relubricate the shoulder bolt and remount idler

pulley assembly in the same order it

was

originally.

AS REQUIRED

1.

CLUTCH LINKAGE-Apply several drops

of

light machine oil on clutch mechanism

at

all

pivoting points.

10-52

NEW STYLE

LOWER IDLER ASSEMBLY

PART

#682564

BOLT-PULLEY-ARM-NUT

LOWER IDLER PULLEY Permanently lubri-

cated.

No lubrication required.

SERVICE BULLETIN REFERENCES

REVISED

1983

Page 10

UTILITY

MODELS

4502 AND 8602

SCAMP MODELS 4503 AND 8603

SELF-PROPELLED SERVICING

On

4502,4503,8602,8603

models of Utility and

Scamp mowers, a blade nut has replaced the

blade bolt previously used on earlier models.

SAFETY WARNING

THE BLADE

NUT

MUST BE REPLACED AFTER BEING REMOVED

AND REINSTALLED FOUR

(4)

TIMES. THE LOCKING FEATURE OF

THE BLADE NUT WILL HAVE

DECREASED AND BLADE COULD

LOOSEN IF REPLACEMENT

IS

NOT

MADE.

1.

Collar

4.

Blade

2.

Stiffener

5.

Nut

3.

Washer

(20

and

21

inch

models only)

Before assembling collar on crankshaft, check to

be sure it did not get bent or distorted when be

ing

removed.

If

so,

replace it.

Do

not use,

because, it will cause vibration.

If

the blade nut

is

to

be

reused, clean the threads

thoroughly. Also clean threads on crank shaft.

Apply OMC Ultra-Lock

Part

No.

388517

on the

threads.

NOTE

When installing blade after sharpening

and balance, torque blade nut

to

45-50

ft.

1bS.

SAFETY WARNING

ALWAYS USE ORIGINAL EQUIPMENT REPLACEMENT BLADE AND

ATTACHMENT HARDWARE TO

IN-

SURE COMPLIANCE WITH SAFETY

STALLING BLADE, BE SURE PARTS

QUENCE IN WHICH THEY WERE

REMOVED. ALWAYS REPLACE

BLADE WITH CURVED EDGE UP

(TOWARD HOUSING).

SPECIFICATIONS. WHEN REINARE REPLACED IN THE SAME SE-

A

blade collar that

was

damaged

and

bent when

being removed from crankshaft should always be

replaced.

If

not replaced, a vibration in the mower

and a rough, uneven

or

ragged cutting may

result.

KEEP

BLADE SHARP AND BALANCED

REVISED

1983 10-53

Loading...

Loading...