Page 1

Installation Procedure ____________________________________________________________

To assure maximum performance from your 800S series sprinklers, read these instructions

completely prior to installation or service.

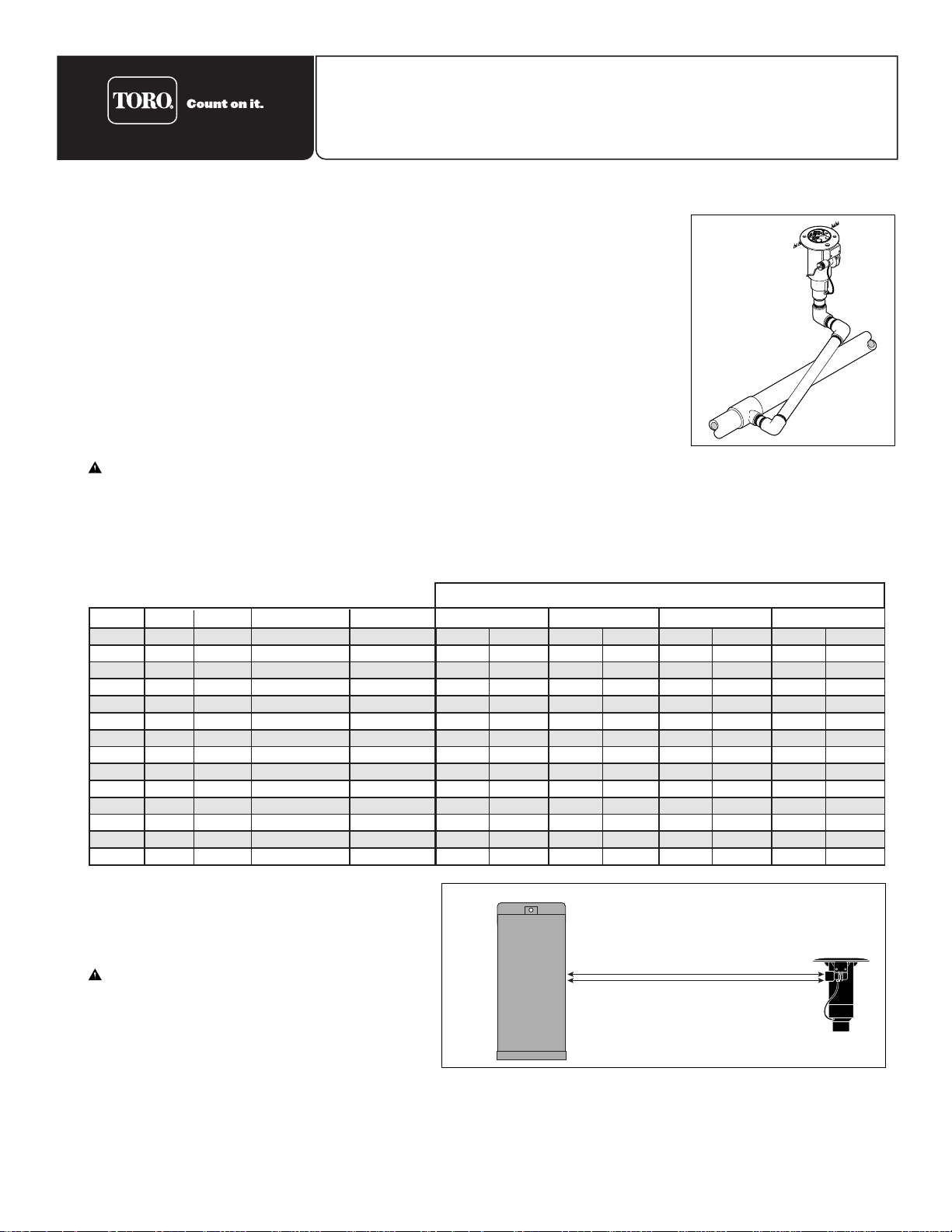

Constructing Swing Joints

1. Construct or provide triple swing joints for each sprinkler as shown in Figure 1. Use PVC or

ABS pipe nipple for the sprinkler connection.

Note: On sites where the possibility of heavy equipment rolling over a sprinkler exists, the

swing joint will flex preventing damage to the lateral or main lines. On a new installation in raw

ground where the sprinklers are to be initially installed above the finished grade and lowered

when new turf is established, the swing joint allows sprinkler repositioning without changing

risers.

2. Flush lines thoroughly prior to installing sprinkler.

3. Apply Teflon™ tape on riser threads (not required on ACME threads). Install sprinkler to the

riser and tighten.

CAUTION: Use only Teflon tape on riser threads. Use of pipe dope or other types of sealing compounds can cause

deterioration of sprinkler body threads.

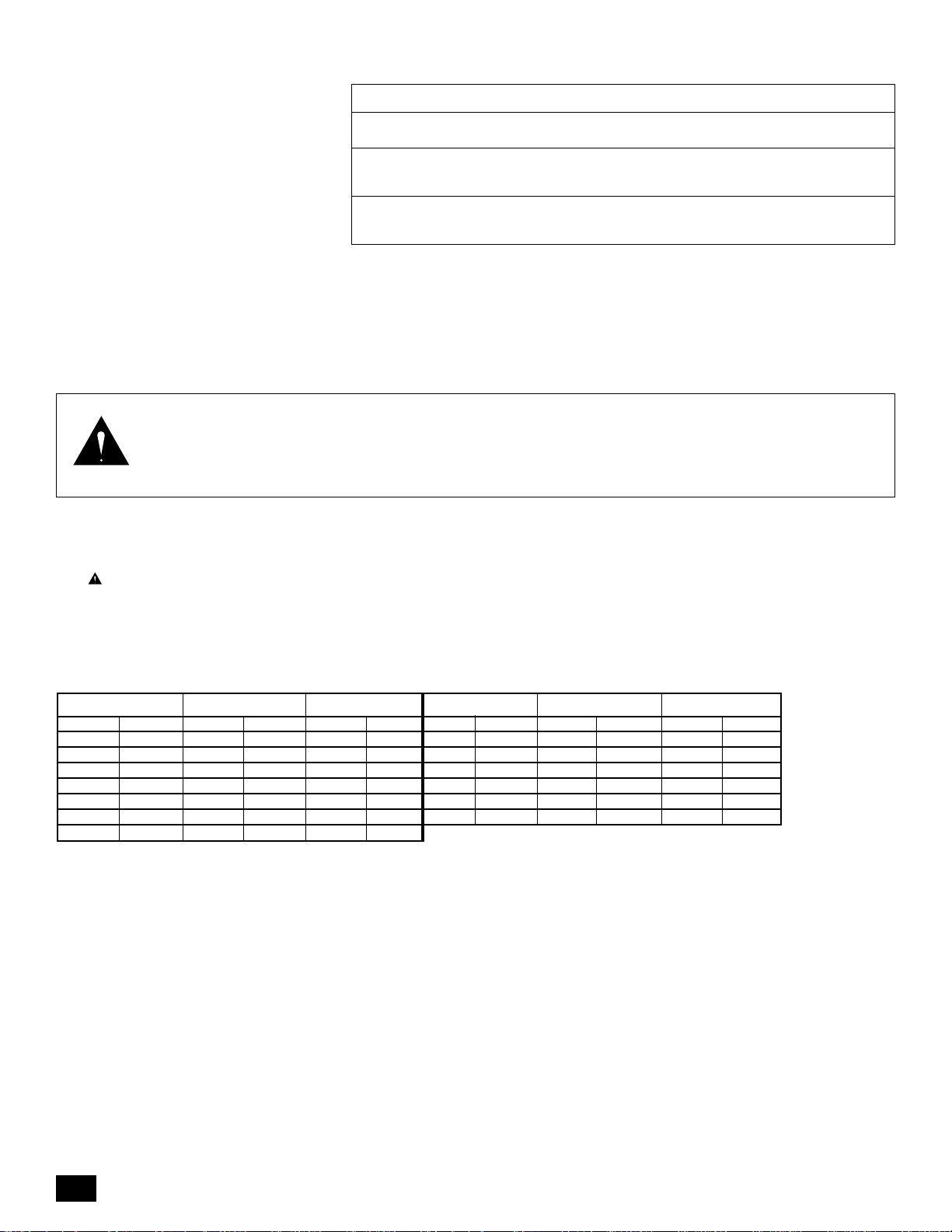

Connecting Control Wires (Electric Models Only)

1. Route control wires to sprinklers. Provide extra wire at sprinkler to allow for height adjustment. One common wire and station wire

is required for each sprinkler. See Wire Sizing Chart, Table 1 for proper application.

Note: Wire length data provided in Table 1 is the sum

of the station and common wire legs. See example in

Figure 2.

2. Attach control wires to solenoid leads using an

approved waterproof splicing method.

CAUTION: All wire splices and field connections

must be waterproofed to prevent short circuit to

ground and subsequent controller damage.

A

U

T

O

O

N

O

F

F

Figure 1

Table 1: Wire Sizing Chart

Figure 2

Station Wire = 1095' (334m)

Common Wire = 1095' (334m)

Total Wire Length = 2190' (668m)

835S and 855S Series Rotary Sprinklers

Installation & Service Instructions

2

Voltage AWG mm

23

23

23

23

23

23

23

24 14/14 5 4100 8213' 4107' 2738' 2053'

24 14/12 5 5315

24 14/10 5 7250 14523' 7262'

24

24

24

24

2.5/2.5

14/14

2.5/4.0

14/12

2.5/5.5

14/10

12/12

4.0/4.0

4.0/5.5

12/10

12/8

4.0/7.0

10/10

5.5/5.5

2.5/2.5

2.5/4.0

2.5/5.5

4.0/4.0

12/12

4.0/5.5

12/10

12/8

4.0/5.5

10/10 5.5/5.5

Voltage Drop

4 4100 6571' 2003 m

4 5315

4 7250

4 6530

4 8465

4 11515

4 10400

5 6530 13081' 6540' 4360' 3270'

5 8465 16957' 8479' 5652'

5 11515 23067'

5 10400 20833' 10417' 6944' 5208'

Circular Mils 1 Sprinkler

8518' 4259' 2839' 2129'

11619' 5809' 3873' 2905'

10465' 5232' 3488' 2616'

13566' 6783' 4522' 3391'

18454' 9227' 6151'

16667' 8333' 5556'

10647'

Total Wire Length Between Controller and Sprinkler

2 Sprinklers 3 Sprinklers 4 Sprinklers

2596 m

3541 m

3190 m

4135 m

5625 m

5080 m

2503 m

3245 m

4427 m

3987 m

5168 m

7031 m

6350 m

3285' 2190' 1643'

5324' 3549'

11533'

1001 m

1298 m

1771 m

1595 m

2067 m

2812 m

2540 m

1252 m

1623 m

2213 m

1993 m

2584 m

3515 m

3175 m

4841'

7689'

668 m

865 m

1180 m

1063 m

1378 m

1875 m

1693 m

835 m

1082 m

1476 m

1329 m

1723 m

2344 m

2117 m

4613'

4167'

2662'

3631'

4239'

5767'

501 m

649 m

886 m

798 m

1034 m

1406 m

1270 m

626 m

812 m

1107 m

997 m

1292 m

1758 m

1581 m

Page 2

2

Connecting Hydraulic Control Tubing (Hydraulic Models Only)

1. Route control tubing from the controller

to the sprinkler location(s).

Note: Leave an 18" (45.7 cm) service

loop of tubing at each sprinkler to

facilitate movement of sprinkler and

service operations. Refer to Table 2

for tubing run length and sprinkler

elevation information.

2. Flush tubing thoroughly to remove all

air and debris.

3. Remove the tube retainer and poly cap

from the tubing adapter at the base of

the sprinkler.

4. Slide the tube retainer over the end of the control tubing and attach tubing to adapter.

5. Slide tube retainer over the adapter area to secure tubing.

System Start Up _________________________________________________________________

The following is a recommended procedure that will protect system components during system start-up. The procedure is based on a

velocity fill rate of less than 2' (0.61 m) per second. See Table 3 below.

1. Use jockey pump only to fill the system at a velocity fill rate of less than 2' (0.61 m) per second.

CAUTION: Failure to comply with recommended fill rate will increase line pressure resulting in a water hammer effect

that could damage sprinklers and piping components.

2. Use quick coupler keys at all tees and greens with quick coupler valves to bleed air from the system lines during the filling

process. For best results, do not compress air and then relieve it – bleed the air continuously while filling the system.

3. After water has filled all lines and all air is removed, remove the quick coupler keys.

Table 3: Recommended System Fill Rate

Table 2: Hydraulic Control Systems

Maximum Distance

Type of System* From Controller Elevation Restrictions

Normally Open (01) Valve elevation should not exceed

with 3/16" Control Tubing 500' 25' ABOVE controller elevation or

70' BELOW controller elevation.

Normally Open (01) Valve elevation should not exceed

with 1/4" Control Tubing 1000' 25' ABOVE controller elevation or

70' BELOW controller elevation

*• All hydraulic connections on Toro valves are 1⁄4" insert type.

• Control line pressure must be equal to or greater than mainline pressure.

• Control line pressure range is 40 to 150 PSI.

Pipe Size Flow Velocity Pipe Size Flow Velocity

in. cm GPM LPM ft/sec m/sec in. cm GPM LPM ft/sec m/sec

1/2 1.3 2 7.6 1.60 0.49 3 7.6 45 170.3 1.86 0.57

3/4 1.9 3 11.4 1.92 0.59 4 10.1 75 283.9 1.87 0.57

1 2.5 5 18.9 1.50 0.46 6 15.2 150 567.8 1.73 0.53

1-1/4 3.1 10 37.9 1.86 0.57 8 20.2 250 946.3 1.70 0.52

1-1/2 3.8 10 37.9 1.41 0.43 10 25.4 450 1703.0 1.97 0.60

2 5.0 20 75.7 1.80 0.55 12 30.5 500 1893.0 1.55 0.47

2-1/2 6.4 30 113.6 1.84 0.56

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIUS INJURY.

Page 3

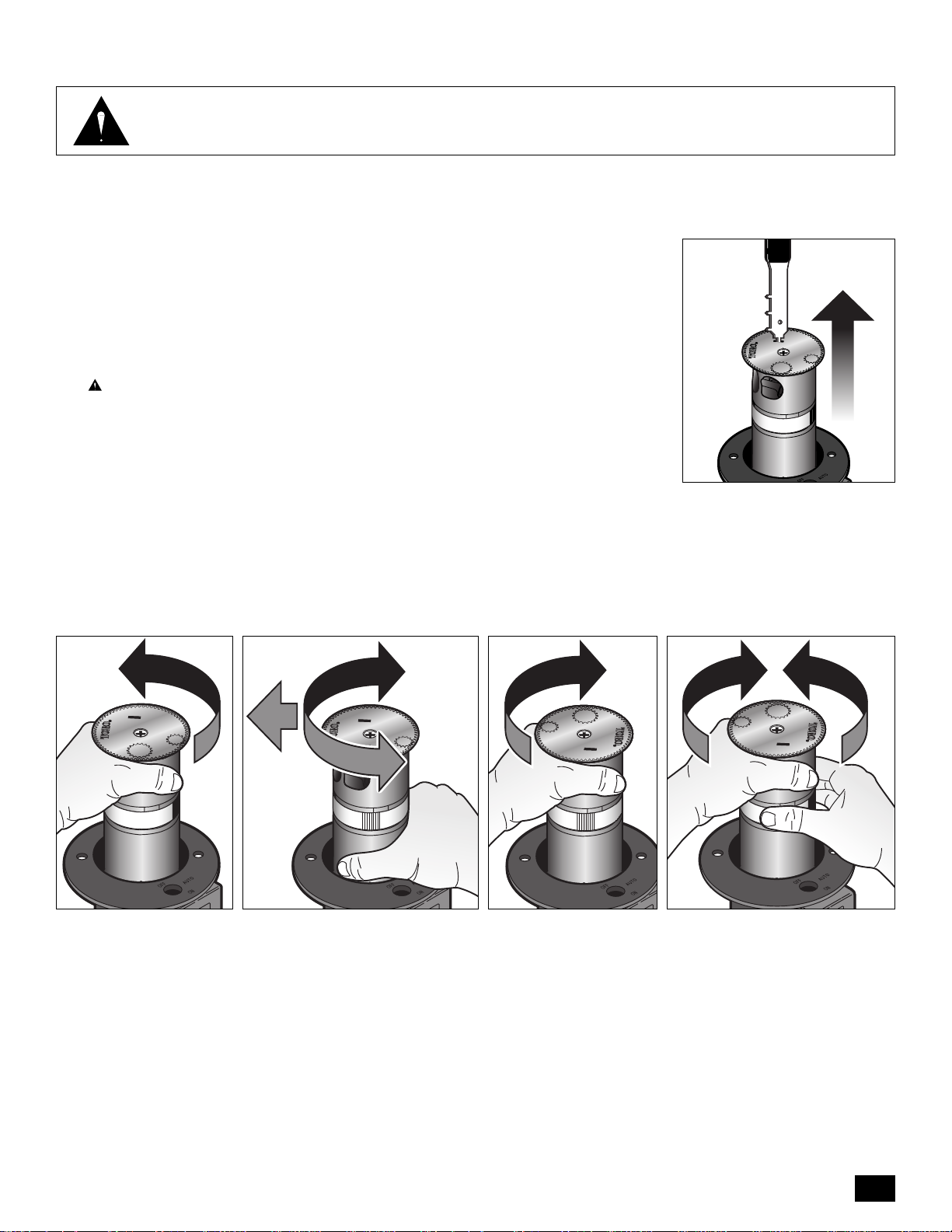

Arc Adjustment Procedure ________________________________________________________

The 835S and 855S sprinkler models can be operated in full-circle or part circle operation. In part-circle operation, the sprinkler arc

can be adjusted from 40°– 330°. When full-circle (360°) operation is selected, the sprinkler will rotate in a clockwise direction only. The

arc is factory preset at 180°. The left side of the arc, located at the end of the counterclockwise rotation, is non-adjustable (fixed).

Therefore, all arc adjustments, whether increasing or decreasing, will change the right side of the arc, located at the end of the

clockwise rotation.

1. Using the sprinkler Multi-Purpose Tool (P/N 995-83), pull the sprinkler riser up from the

body. See Figure 3.

2. Find the sprinkler left stop by rotating the turret counter clockwise until it stops. The left

stop indicates the fixed stop of the arc. See Figure 4.

3. Check the left stop alignment with the left most area being irrigated. Adjust by ratcheting

the riser clockwise or counterclockwise until the sprinkler left stop points to the correct

area. See Figure 5.

CAUTION: The riser can only ratchet when the sprinkler is not operating.

Attempting to ratchet the riser during operation may damage the sprinkler.

The turret can also be used to adjust the left stop. If the left stop falls short of the desired

border, rotate the turret counterclockwise until it is aligned with the left watering border.

See Figure 4.

If the left stop exceeds the border, rotate the turret clockwise until the right stop. Continue

to advance the turret the same distance that the left stop exceeded the border.

See Figure 6.

4. Find the sprinkler right stop by rotating the turret clockwise until it stops. See Figure 6.

Note: If the sprinkler is set at 360° (full-circle), it will rotate clockwise only.

5. Adjust the arc while the turret is pointing at the right stop. Hold the sprinkler riser firmly while pressing the release on the

adjustment band. Rotate the turret counterclockwise or clockwise to the desired right stop. See Figure 7.

6. Activate the sprinkler to check proper arc setting and adjust as necessary.

3

Figure 3

Figure 4 Figure 5 Figure 6 Figure 7

WARNING

DUE TO THE HIGH OPERATING PRESSURE, NEVER STAND OR LEAN DIRECTLY OVER THE TOP OF THE

SPRINKLER OR COME IN CONTACT WITH THE SPRAY. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY.

Page 4

4

Adjustment Band Angle Indicators

The adjustment band of the 835S and 855S have markers at predetermined arcs. By aligning the adjustment band indicators to the

turret arrow, you can set the sprinkler arc to 90°, 180°, 270° or 360°.

Trajectory Adjustment Procedure ___________________________________________________

The 835S and 855S sprinkler models are equipped with the TrujectoryTMnozzle spray angle adjustment feature. The trajectory adjusts

from the top of the sprinkler enabling fine-tuning from 7˚–30˚ to compensate for windy conditions, spraying under low-hanging

obstructions, up bunker faces and along natural habitats.

To adjust the nozzle spray trajectory angle, use a 5/16" socket (Figure 9). Turn the trajectory adjustment clockwise to

decrease (Figure 10) or counter-clockwise to increase (Figure 11).

Figure 8

90° 180° 270° 360°

Figure 9 Figure 10

Figure 11

Increase

Trajection

Decrease

Trajection

Page 5

Pilot Valve Operation (Electric Models Only) __________________________________________

The main function of the pilot valve is to control the operation of the main

valve located in the base of the sprinkler body. The main valve is operated

by the release of water metered through the pilot valve when it is activated

either manually at the sprinkler or by the irrigation system controller.

Another important function of the pilot valve is to regulate the water

pressure to the sprinkler nozzle. Pressure regulation compensates for large

variations within the system and maintains a constant pressure for optimum

sprinkler operation. The pilot valve is factory set to regulate one of four

pressure levels 50 psi (3.4 bar), 65 psi (4.5 bar), 80 psi (5.5 bar) or 100

PSI (6.9 bar).

Change the pilot valve operating pressure by loosening the thumb screw

that secures the selector lever. Position the selector lever to the desired

operating pressure and hand-tighten the nut. See Figure 12.

Troubleshooting__________________________________________________________________

Pilot Valve

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

Sprinkler will (a) No 24 VAC to solenoid assembly. (Electric Models)

not turn on – Measure voltage with a Digital Volt Meter (DVM). Check wiring and controller program.

– Refer to Controller Operating Instructions.

(b) Selector cam in "OFF" position.

– Set to "AUTO" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 12.)

(d) Insufficient pressure in controller supply line and/or sprinkler control tube. (N.C. Models)

– Check pressure.

Sprinkler will (a) Constant 24 VAC from controller. (Electric Models)

not shut off – Check for voltage using a DVM. If voltage is present, disconnect wire.

If sprinkler closes, service controller. Refer to Controller Service Manual.

(b) Selector cam in manual "ON" position.

– Set to "AUTO" or "OFF" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 12.)

(d) Constant pressure from controller. (N.C. Models)

– Check pilot valve at controller for constant flow.

– Check elevation differential. Valve elevation should not exceed 0' above

controller elevation or 70' (21.3 m) below controller elevation.

Sprinkler Mechanism

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

Sprinkler won't rotate (a) Debris wedged between stator and turbine.

– Remove obstruction.

(b) Drive assembly defective.

– Replace drive assembly.

(c) Nozzle base assembly defective.

– Replace nozzle base assembly.

Head sticks up (a) Dirt in riser assembly.

– Flush out. (See Flushing Procedure on page 12.)

(b) Damaged or missing return spring.

– Replace.

(c) Damaged riser.

– Replace.

Poor distribution pattern (a) Nozzle plugged with debris.

– Clean or replace nozzle.

(b) Nozzle orifice damaged.

– Replace nozzle.

(c) Low operating pressure.

– Determine why system overloaded and correct.

5

Figure 12

100 PSI

(7.0 kg/cm

2

)

80 PSI

(5.6 kg/cm

2

)

65 PSI

(4.6 kg/cm

2

)

50 PSI (3.5 kg/cm

2

)

O

T

U

A

O N

Page 6

Main Valve

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

Valve won't close (a) Continuous 24 VAC to sprinkler.

(Electric ) – Check controller for voltage source.

(b) Leak in pilot valve assembly.

– Replace pilot valve assembly.

(c) Plugged supply screen on piston.

– Clean or replace screen.

(d) Manual control selector on pilot valve assembly turned to "ON" position.

– Turn to "AUTO" position.

(e) Plunger movement restricted.

– Inspect and clean or replace.

(f) Valve cylinder misaligned with sprinkler body communication tube.

– Remove valve assembly and install correctly.

(g) Foreign object keeping valve from seating.

– Remove, clean and check valve for damage. Replace if necessary.

(h) Damaged piston seal or piston assembly.

– Replace valve assembly.

Valve won't close (a) Leak in control tubing.

(Hydraulic) – Isolate and repair.

(b) Pilot valve leak in controller.

– Confirm by observing constant dripping from discharge line of controller.

Refer to Controller Service Manual.

(c) Valve cylinder misaligned with sprinkler body communication tube.

– Remove valve assembly and install correctly.

(d) Foreign object keeping valve from seating.

– Remove, clean and check valve for damage. Replace if necessary.

(e) Damaged piston seal or piston assembly.

– Replace valve assembly.

Valve won't open (a) Control (field) wires severed.

(Electric) – Isolate and repair.

(b) No power to controller.

– Establish controller power.

(c) No power from controller to solenoid.

– Check for blown fuse and replace.

(d) Manual control selector on pilot valve assembly turned to "OFF" position.

– Turn to "AUTO" position.

(e) Pilot valve solenoid inoperative.

– Remove and replace.

(f) Pilot valve plunger movement restricted.

– Inspect, clean and/or replace.

(g) No supply from main valve.

– Debris in control tube, main valve assembly and/or communication

passages in body. Flush thoroughly.

Valve won't open (a) Plugged controller discharge line or discharge port in pilot valve.

(Hydraulic) – Verify by checking for discharge at discharge line when station is

activated. If no discharge, refer to Controller Service Manual.

Sprinkler Weeping (a) Damaged or blocked valve seat.

(Slow leak in valve) – Remove blockage and, if necessary, replace valve assembly.

(b) Damaged piston seal or piston assembly.

– Replace valve assembly.

(c) Low pressure on supply line .

– Check for low pressure reason and correct.

(d) Elevation of normally closed sprinkler exceeds 75' (22.9 m) differential.

Several valves on different (a) Control tubing leak which lowers supply pressure to other stations.

stations fail to close – Turn controller from station to station until a station is reached where

(Hydraulic) only valves on that station stay open. The leak would be in the tubing

on that station. Isolate and repair.

(b) Leak in supply line to controller.

– Verify by checking pressure in all control lines.

(c) Leak in controller pilot valve.

– Verify by constant discharge from controller.

(d) Plugged supply line filter.

– Replace filter if more than 3 psi (0.21 bar) differential exists.

6

Page 7

7

Service Procedures ______________________________________________________________

Servicing Sprinkler Mechanism

Note: Refer to Figure 13 for the following procedure.

1. Remove the cap screw (1) and cap (2).

Note: During reassembly, ensure the cap is correctly installed with the Toro Logo positioned over the main nozzle (10).

2. Insert the hooked end of the multi-purpose tool (P/N 995-83) into the snap ring slot (3). Pull the snap ring inward towards the

sprinkler assembly, then upward to remove from the groove in body.

Note: During reassembly, ensure the snap ring is correctly installed and fully seated in the sprinkler body.

3. Insert the hooked end of the tool into the slot provided in the nozzle base above the right intermediate nozzle (9). Pull the riser

assembly until enough clearance to handle. Hold onto the riser body (13) and carefully extract it from the sprinkler body.

CAUTION: The seal/retainer (4) will eject (caused by the decompressing spring [5]) as it clears the sprinkler body.

4. Three small tabs are provided on the edge of the multi-purpose tool. Insert tabs into the debris filter screen (17). Holding the

plastic base of riser assembly, turn the screen counterclockwise to remove.

5. Remove the variable stator (16) from riser assembly.

6. Loosen the drive assembly retaining screw (14) 6–7 turns and pull the drive assembly (15) using a pair of pliers. See Figure 14.

Note: Do not remove the retaining screw completely as it is easily misplaced.

CAUTION: When removing or installing the drive assembly, do not use the turbine to pull the drive assembly. Use the

drive assembly body to extract it out. Failure to comply may cause separation of the drive assembly components.

Note: During reassembly, ensure drive assembly is properly aligned with the retaining screw.

7. Using a 5/8" nut driver (P/N 995-99), unscrew main nozzle (10) from nozzle base assembly.

8. Using a 5/16" nut driver (P/N 995-105), unscrew the inner (8) and intermediate (9) nozzles.

9. Thoroughly clean and inspect all parts and replace as necessary. Reassemble in reverse order.

10. When installing the riser assembly to the sprinkler body, align the ratchet ring with the inside body rib. Use the indicator on top of

the sprinkler body to center the ratchet ring. See Figure 15.

Figure 13

Figure 14

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIOUS INJURY.

Figure 15

3

4

6

1

2

5

8

10

9

11

14

7

12

13

15

16

17

Page 8

Servicing Main Valve

1. See Warning above. To remove valve assembly, squeeze

snap ring ears together with snap ring pliers (P/N 995-100)

and remove snap ring from sprinkler body. See Figure 16.

2. Use valve removal tool P/N 995-08 for 835S or 995-09 for

855S to remove valve assembly from base of sprinkler body.

Valve removal tool is inserted into sprinkler body and pushed

through valve ribs. A slight twist will catch tool under ribs

enabling valve removal by pulling straight up and out. See

Figure 17.

Note: If valve removal tool is not available, use snap ring

pliers to grasp rib of valve cylinder assembly and pull up and

out of sprinkler body.

3. Reinstall valve assembly using valve insertion tool P/N 995-76

for 835S or 995-101 for 855S as follows:

• Load snap ring onto insertion tool carrier with stepped side

against carrier as shown in Figure 18. While holding snap

ring in compressed position, slide retainer clip in to hold snap

ring ears

• Load valve assembly on carrier as shown.

• Locate position of communication tube in bottom of sprinkler body and orient insertion tool accordingly.

• Insert tool straight down into sprinkler body aligning bosses on t-handle with holes on sprinkler body flange. When valve

assembly clears vertical side wall ribs inside body, pull up on snap ring release mechanism (855 models only) and press valve

assembly into position. Snap ring will lock into groove when properly installed. Remove insertion tool and check snap ring to

confirm that it is fully seated in groove

WARNING

IF THE VALVE SNAP RING IS DIFFICULT TO REMOVE, RESIDUAL WATER PRESSURE MAY BE REMAINING IN

THE SYSTEM. TO PREVENT POSSIBLE SERIOUS INJURY DUE TO VALVE BEING EJECTED UPWARD UNDER

PRESSURE, CONFIRM THE FOLLOWING CONDITIONS EXIST PRIOR TO REMOVING THE SNAP RING AND

VALV E.

A. WATER SUPPLY TO SPRINKLER IS SHUT OFF AT SOURCE.

B. ALL PRESSURE IS BLED FROM SYSTEM, INCLUDING CONTROL TUBES.

C. AC POWER IS DISCONNECTED AT SOURCE.

Figure 17Figure 16

Figure 18

Snap Ring Release

Mechanism

Stepped Side

of Snap Ring

Snap Ring In

Retainer Clip

Valve Assembly

Orientation In Carrier

Snap Ring

Released

Press Valve Assembly

Into Position

Page 9

Servicing Pilot Valve

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIOUS INJURY.

WARNING

Note: Refer to Figure 19 for the following procedure.

Figure 19

1. Make sure that the water supply to sprinkler is positively

shut off and any residual pressure has been bled off. If the

sprinkler is pressurized, main valve will open when the pilot

valve is disconnected from control tube.

2. Carefully remove turf and soil from the side of the sprinkler

to expose pilot valve and control tubing.

3. Remove the two retaining screws from the pilot valve

housing.

4. Pull the pilot valve assembly away from the sprinkler body

and cut the control tubing just below tube retainer. Unless

pilot valve has been previously removed, control tubing

length will be sufficient for re-connection.

5. Remove tube retainer and remaining piece of control tubing

1

4

2

8

7

6

3

9

11

10

5

13

12

from valve body fitting.

6. Remove the solenoid (1 or 2) by turning it counterclockwise.

7. Remove the retaining nut (17) and washer (18) from the

pressure adjuster (10) and pull the pilot valve body

assembly out of housing (14).

8. Remove diaphragm assembly (14), piston (13), spring (12), traveling adjuster (11), pressure adjuster (10) and o-ring (6).

9. Remove selector shaft assembly (8) and plunger assembly (4).

Note: The selector shaft retains the plunger in the valve body.

10. Thoroughly clean and inspect all parts. Replace damaged parts as necessary and reassemble in reverse order.

Note: Refer to Illustrated Parts Breakout Book, form number 490-3043 for service part numbers.

14

15

16

17

Flushing Sprinkler ________________________________________________________________

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIOUS INJURY.

1. With sprinkler operating, carefully step down on center of cap several times. Water will flow around riser and flush out debris.

2. Cycle sprinkler on and off several times to check for proper retraction. Cap should be even with top of body flange when fully

retracted. If riser sticks in up position, check for debris lodged between riser and body. Flush out all debris. Remove sprinkler

mechanism if necessary.

© 2005 The Toro Company, Irrigation Division Form Number 373-0380 Rev. A

Loading...

Loading...