Page 1

ZMaster

®

RidingMower

ForAllZMaster

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3375-555RevC

®

RidingMowers

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Rearwheels(Woodencrateonly)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

J-bolt2

Wingnut2

Hold-downclamp1

Clamp

Wingnut(1/4inch)

Batteryhold-down2

Nopartsrequired

Seat

Seatplate(xedseatsonly)

Flangenuts(3/8inch)—xedseatsonly

Spacers(3/8inch)—xedseatsonly

Flangenuts(3/8inch)—tiltingseatsonly

Longspacers(tilting,deluxeseatsonly)

Shortspacers(tilting,deluxeseatsonly)

Nopartsrequired

Right-controllever1

Left-controllever

Bolt(3/8x1inch)—2areassembled

Nut(3/8inch)—2areassembled

Carriagebolt(3/8x1-1/2inches)

Flangelocknut(3/8inch)

Air-cleanercap1

Hoseclamp1

Qty.

Use

2

–

–

–

–

–

1

2

–

1

1

8

4

4

2

4

–

1

4

4

1

1

Removethemachinefromacrate.

Addfueltothemachine.

Checktheengine-oillevel.

Checkthetirepressure.

Checkthewheellugnuttorque.

Checkthegrassdeector.

Installabattery(Dieselmachinesonly).

Installabattery(Gasolinemachines

only).

Chargethebattery.

Installtheseat(Internationalmachines

usinggasolineonly).

Checktheseatbelt(International

machinesusinggasolineonly).

Installthemotion-controllevers

(Internationalmachinesusinggasoline

only).

Installthelift-assistpedal(International

machinesusinggasolineonly).

Installtheair-cleanercap(International

machinesusinggasolineonly).

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3375-555*C

Page 2

ProcedureDescription

15

16

17

18

Bolt(1/2x3-1/4inch)

Locknut(1/2inch)

Roll-OverProtectionSystem(ROPS)Kit

Rollbar,rightsection1

Rollbar,leftsection

Rollbar,centersection1

Bolt(3/8x1inch)

Curvedwasher

Flangenut(3/8inch)

Bolt(1/2x3–1/4inch)

Flangenut(1/2inch)

Number2general-purposelithium-base

ormolybdenum-basegrease.(Purchase

separately.)

1tube

Qty.

Use

1

1

1

1

8

8

8

2

2

InstalltheROPShardware(LPG

machinesonly).

InstalltheROPS(International

machinesusinggasolineonly).

InstalltheROPS(Dieselmachines

only).

Checkthemachineforgrease.

19

20

21

Nopartsrequired

Nopartsrequired

Operator'sManual

EngineOwner'sManual

Registrationcard1

Operator-trainingmaterial

Key2

1

RemovingtheMachinefroma

Crate

Partsneededforthisprocedure:

2

Rearwheels(Woodencrateonly)

RemovingaMachinefromaMetalCrate

–

–

1

1

1

Removetheshippingstraps.

Checkthemachinebeforedeliveryto

thecustomer(Allmachines).

Deliveringthemachinetothecustomer

(Allmachines).

Figure1

GasolineMachineShown

Ifremovingthemachinefromametalcrate,refertothe

Dealer/DistributorPortalforfurtherinformation.

RemovingtheMachinefromaWooden

Crate

1.Removethescrewsholdingtherightangleretaining

platetothecrate.

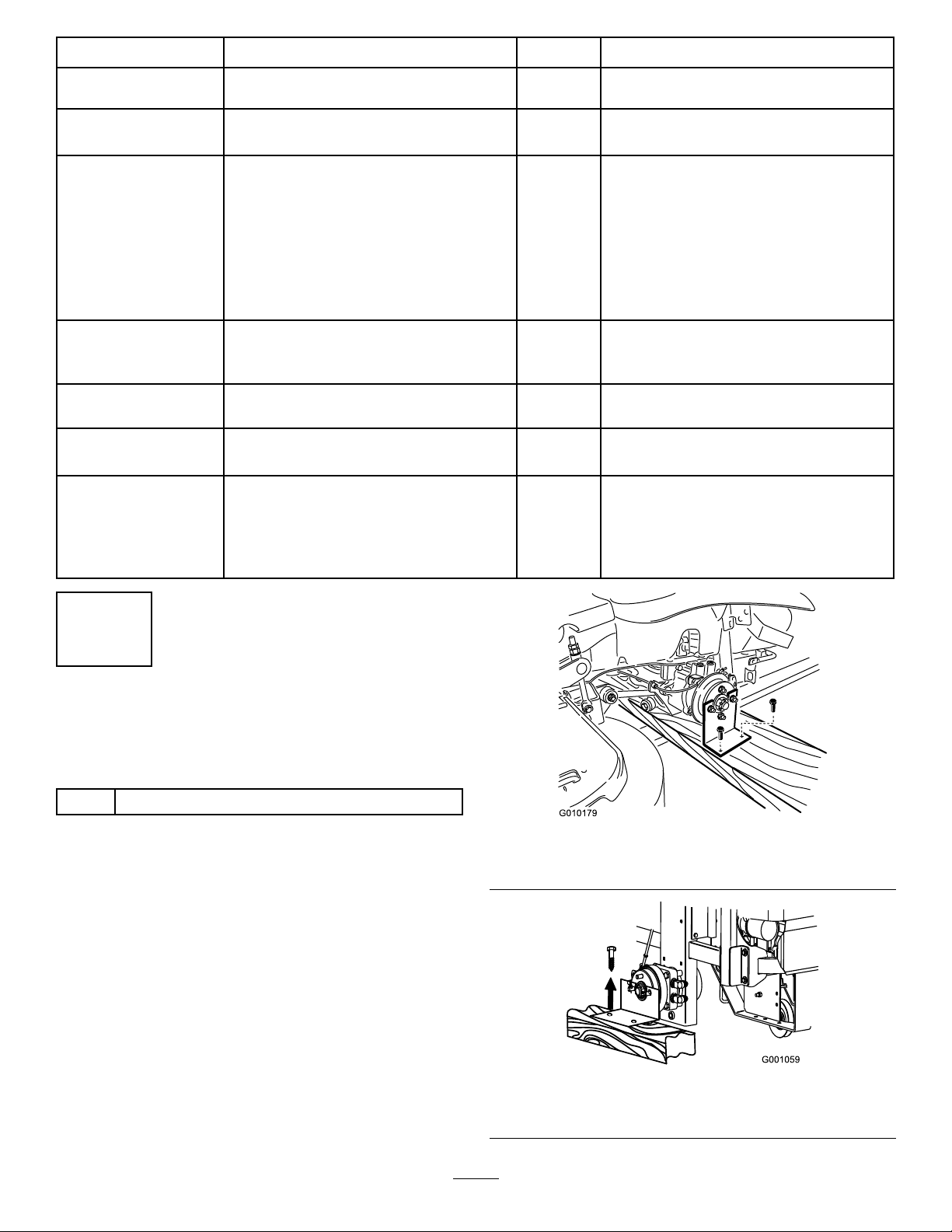

Figure2

DieselMachineShown

2

Page 3

2.Raisethebackofthemachineupandsupportitwith

jack-stands.

Figure3

GasolineMachineShown

Figure6

GasolineMachineShown

Figure7

DieselMachineShown

Figure4

DieselMachineShown

3.Removethewheelnutsfrombothsidesofthevehicle

andremovetherightangleretainingplate.Discardthe

screwsandretainingplate.

Figure5

DieselMachineShown

4.Mountthewheelswiththevalvestemtotheoutside

andsecurethemwiththewheelnutspreviously

removed.

5.Torquethewheelnutsto95ft-lb(128N-m).

6.Removethejackstands.

2

AddingFueltotheMachine

NoPartsRequired

AddingFueltoMachines

Addfueltothemachinebeforestartingit.Refertoyour

Operator’sManualforthecorrectfuelandprocedure.

AddingFueltoLiquidPropaneGas

(LPG)PoweredMachines

CAUTION

Undernocircumstancesshouldyoullpropane

tanksbeyond80%capacity.

Ifyouuseanoverlledtank,itmayresult

inthereleaseofhighlyconcentratedand

extremely-ammableliquidpropane.Refertothe

Safetysectionofthe

1.RemovetheLPG-fueltankfromthefrontofthe.

2.Havethetanklledbytrainedandqualiedpersonnel.

Operator's Man ual

.

3

Page 4

3.Cutthetiessecuringthetankbracketsandmovethem

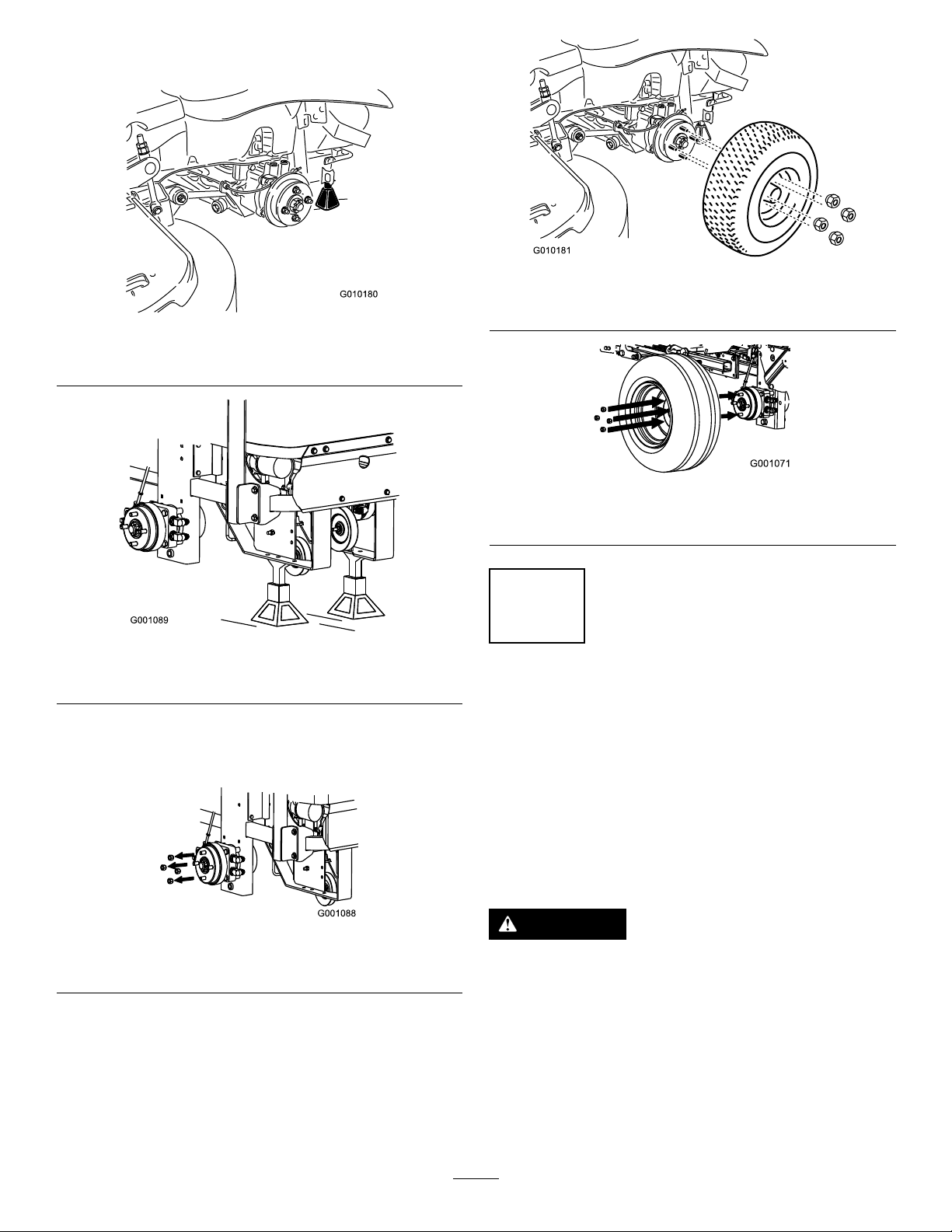

G013619

g030557

1

2

3

outoftheway.

4.Alignthecenterholeoverthemountingpinthatpoints

straightupontheasshowninFigure8.

Figure8

1.Tankcollar

2.Mountingpin

3.Centerhole

8.CheckforleaksasdescribedintheSafetysectionof

theOperator'sManual.

3

CheckingtheEngine-OilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoServicingthe

Engine-OilLevelintheOperator'sManual.

4

CheckingtheTirePressure

Important:IfyoudonotinstalltheLPGtank

correctly,thevalvesandgaugesmaynotfunction

properly.

5.Latchthebracketsandensurethatthetankissecurely

fastenedtothemachine.

6.Carefullyconnectthefuelhose.Makesurethehoseis

notkinked.

7.Slowlyopenthefuelvalvetoequalizethepressurein

thetank.Ifyouopenthefuelvalvetooquickly,the

pressurereliefvalveisequippedwithabackpressure

checkvalvethatwillshutoffthefuelsupply.Ifthis

happens,closethefuelvalvecompletelyandwaitve

seconds.Slowlyopenthefuelvalve.

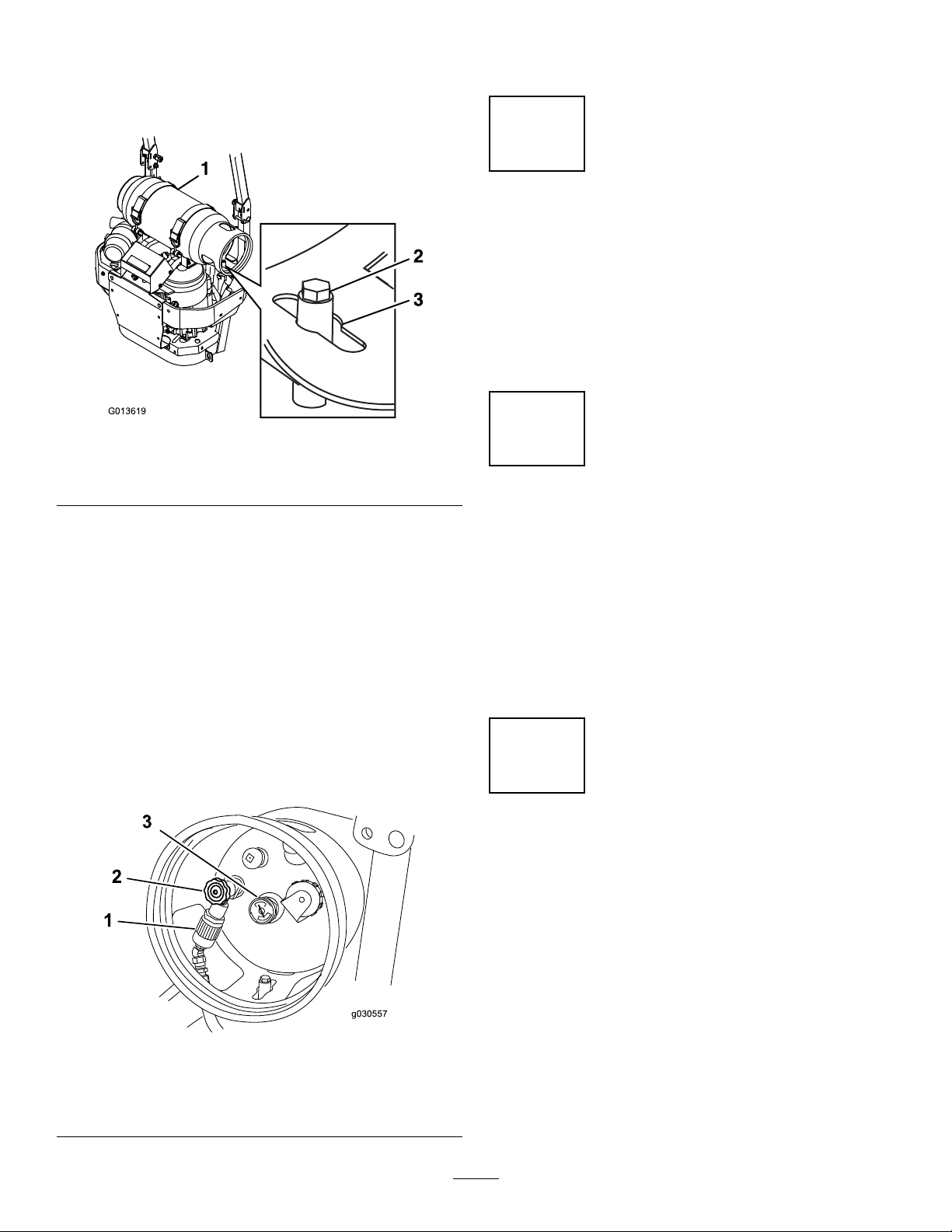

Figure9

NoPartsRequired

Procedure

Pressure:13psi(90kPa)

Note:Checkthetirepressurebeforestartingthemachine.

RefertoyourOperator’sManualforthecorrecttiretype,

correctairpressureneeded,andprocedure.

5

CheckingtheWheelLugNut

Torque

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,checkthe

wheellugnuttorque;refertoCheckingtheWheelLugNuts

intheOperator'sManual

1.LPGfuelhoseconnection

tting

2.Tankvalve

3.Fuelgauge

4

Page 5

6

1

2

3

2

4

G021 181

4

3

3

7

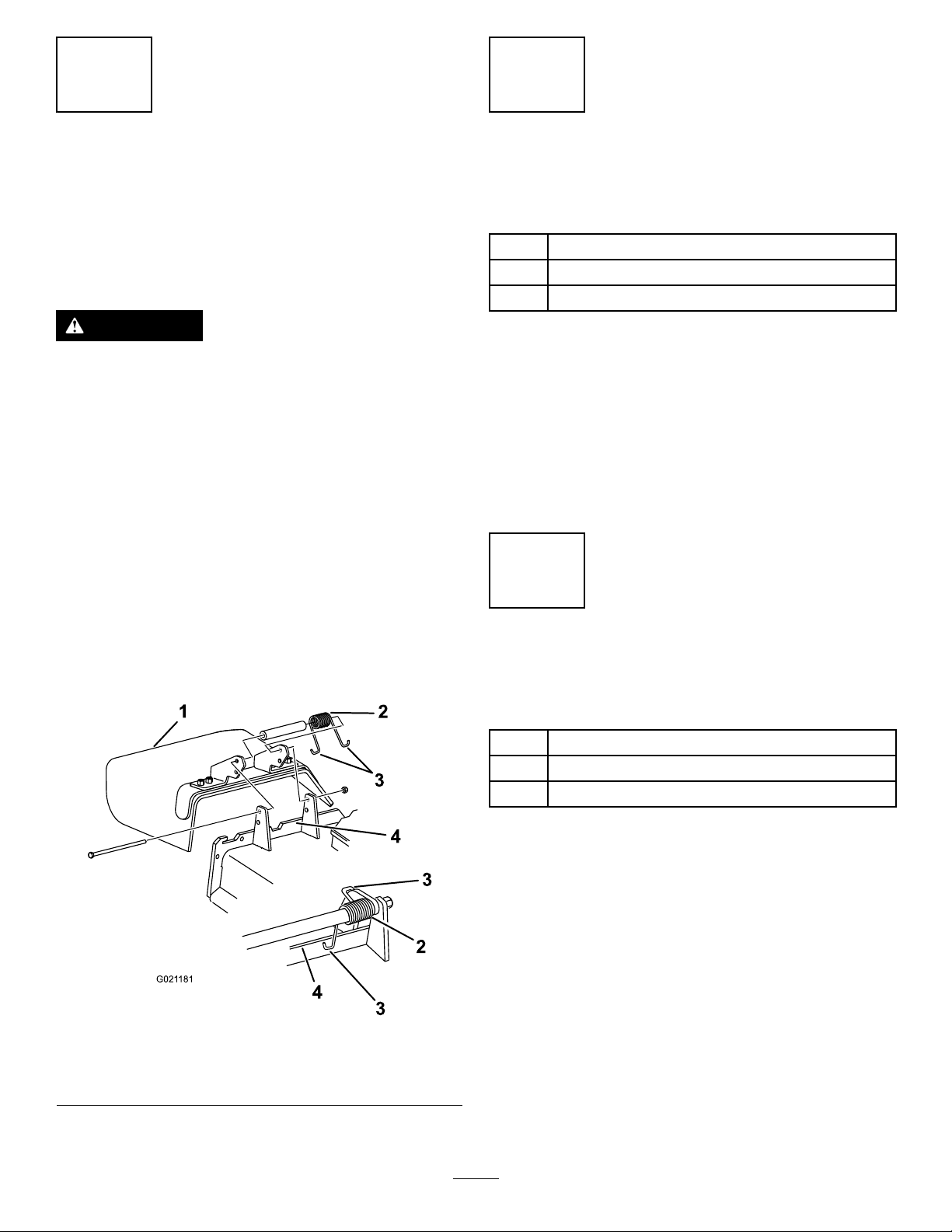

CheckingtheGrassDeector

NoPartsRequired

Procedure

Ifthereareplastictiesholdingthegrassdeectorup,remove

themandlowerthedeectorintoplace.

WARNING

Anuncovereddischargeopeningcouldallowthe

machinetothrowobjectsintheoperator'sor

bystander'sdirectionandresultinseriousinjuryor

death.Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstalla

coverplate,amulchplate,grassdeectororbagger.

1.Makesurethatoneendofthespringisinstalledbehind

thedeckedgebeforeinstallingtheboltasshownin

Figure10.

2.Placetheotherendofthespringaroundgrassdeector

(Figure10).

InstallingaBattery(Diesel

MachinesOnly)

Partsneededforthisprocedure:

2J-bolt

2Wingnut

1Hold-downclamp

Procedure

Important:Thisprocedureonlyappliestomachines

thatdonotcomewithabatteryinstalled.

Purchasea12Vbatteryandinstallitintothemachine.The

enginerequiresaminimumof540CCA.

Usethehardwareincludedtoinstallthenewbattery.Referto

InstallingtheBatteryintheOperator'sManual.

8

Important:Thegrassdeectormustbefreeto

rotatewithdownwardtension.Liftthedeectorup

tothefullopenpositionandensurethatitrotates

freely,withoutbindingintothefulldownposition.

Figure10

1.GrassDeector3.Endofspring

2.Spring

4.Deckedge

InstallingaBattery(Gasoline

MachinesOnly)

Partsneededforthisprocedure:

1

Clamp

2

Wingnut(1/4inch)

2Batteryhold-down

Procedure

Important:Thisprocedureappliesonlytomachines

thatdonotcomewithabatteryinstalled.

1.Purchasea12Vbattery.

Modelswitha29hpengineandbelowrequireabattery

withaminimumof260CCA.

Modelswitha30hpengineandhigherrequireabattery

withaminimumof340CCA.

2.Locatethebattery-mountinghardwareandinstallit

intothemachine.RefertoInstallingtheBatteryinthe

Operator'sManual.

5

Page 6

9

10

ChargingtheBattery

NoPartsRequired

Procedure

WARNING

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjury.

•Keepcigarettes,sparksandamesawayfrom

thebattery .

•Makesuretheignitionswitchisoff.

•Ventilatewhenchargingorusingthebatteryin

anenclosedspace.

Important:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccurtothe

engine.

Chargethebattery.RefertotheOperator'sManualfor

instructions.

InstallingtheSeat

(InternationalMachines

UsingGasolineOnly)

Partsneededforthisprocedure:

1

Seat

1

Seatplate(xedseatsonly)

8

Flangenuts(3/8inch)—xedseatsonly

4

Spacers(3/8inch)—xedseatsonly

4

Flangenuts(3/8inch)—tiltingseatsonly

2

Longspacers(tilting,deluxeseatsonly)

4

Shortspacers(tilting,deluxeseatsonly)

InstallingtheSeatonModelswitha

FixedSeat

1.Removethehydraulic-unitshroudfromthemachine.

Figure11

Figure12

1.Hydraulic-unitshroud2.Bolts

2.Removethe4nutsholdingtheseatplatetothe

machine.Discardthesenuts,theyareusedforshipping

only.

6

Page 7

Figure13

g030558

3.Securetheseatplatetotheseatwith4spacersand4

angenuts(3/8inch).

Figure14

4.Plugtheharnessconnectorintotheseatswitchlocated

undertheseattowardsthefront.

5.Installtheseattothemachineframewith4angenuts

(3/8inch).

Figure15

1.Harnessconnector2.Flangenuts

InstallingtheSeatonModelswitha

TiltingSeat

1.Tilttheseatframeup.

2.Fordeluxeseatsonly,installthespacersasshownin

Figure16.

Figure16

Formachineswithadeluxeseatonly

1.Deluxeseat

2.Longspacer

3.Seatframe

4.Shortspacers

3.Installtheseattotheseatframewith4angenuts(3/8

inch)—Figure17.

7

Page 8

4.Plugtheharnessconnectorintotheseatswitchlocated

3

2

1

g014862

undertheseattowardsthefront.

Figure17

1.Seatswitch

2.Flangenuts

3.Harnessconnector

11

CheckingtheSeatBelt

(InternationalMachinesUsing

GasolineOnly)

NoPartsRequired

Procedure

Important:Ensurethebolttorqueissetbetween49

to61ft-lb(67to83N-m).

Checktheseatbeltangleandtheseatbeltbolttorquebefore

operating.

1.Sideofseat

2.Seatbeltbolt,Settorque

between49to61ft-lb(67

to83N-m)

12

InstallingtheMotion-Control

Levers(InternationalMachines

UsingGasolineOnly)

Partsneededforthisprocedure:

1Right-controllever

1

Left-controllever

4

Bolt(3/8x1inch)—2areassembled

4

Nut(3/8inch)—2areassembled

Figure18

3.47degrees

1.Checktheangleoftheseatbeltcomparedtothe

bottomoftheseat.Theangleneedstobe47degrees.

See(Figure18)

2.Ifneeded,settheseatbelttothecorrectangle.

3.Checkandsetthebolttorquebetween49to61ft-lb

(67to83N-m).

Procedure

1.Rotatethemotion-controlleverstotheupright

position.

2.Looselyinstallthecontrolleversontheinsideofthe

posts,using4boltsand4nuts.

Note:Installthecontrolleversinthetopandmiddle

holesforthehighpositionorthemiddleandbottom

holesforthelowposition,asdesired.

8

Page 9

Figure19

1 2

3

g016346

1.Bolt(3/8x1inch)3.Controllever

2.Handle

4.Nut(3/8inch)

13

InstallingtheLift-AssistPedal

(InternationalMachinesUsing

GasolineOnly)

Partsneededforthisprocedure:

1

Carriagebolt(3/8x1-1/2inches)

1

Flangelocknut(3/8inch)

Procedure

3.Raisetheleversandalignthemtogetherintheneutral

positionandtightenthebolts.

Figure20

1.Ifneeded,loosentheexistingboltandnutforthe

lift-assistpedal.

2.Rotatethelift-assistpedaltothecorrectposition

andinstallthecarriagebolt(3/8x1-1/2inches)and

locknut(3/8inch)(Figure21).Tightenbothbolts.

Note:Ifthemachineisnotproperlytracking,referto

AdjustingtheTrackinginyourOperator'sManual.

Figure21

1.Lift-assistpedal3.Carriagebolt(3/8x1-1/2

inches)

2.Flangelocknut(3/8inch)

9

Page 10

14

InstallingtheAir-CleanerCap

(InternationalMachinesUsing

GasolineOnly)

Partsneededforthisprocedure:

1Air-cleanercap

1Hoseclamp

Procedure

Note:Notallunitscomewithaheavydutyaircleaner.This

procedureonlyappliestomodelsthathaveaheavydutyair

cleaner.

1.Removetheplasticplugortapecoveringtheaircleaner.

Figure23

3.Installtheair-cleanercapontotheaircleanerand

secureitwiththehoseclamp.

Figure22

2.Installthehoseclampontotheair-cleanercap.

Figure24

10

Page 11

15

G013506

1

2 3

16

InstallingtheROPSHardware

(LPGMachinesOnly)

Partsneededforthisprocedure:

1

Bolt(1/2x3-1/4inch)

1

Locknut(1/2inch)

Procedure

Installthebolt(1/2x3-1/4inch)andlocknut(1/2inch)

intotheopenholeintheRoll-OverProtectionSystem

(ROPS)—Figure25.Thiswillpreventtherollbarfrom

hittingthecylinderwhenloweredtothedownposition.

InstallingtheROPS

(InternationalMachines

UsingGasolineOnly)

Partsneededforthisprocedure:

1

Roll-OverProtectionSystem(ROPS)Kit

Procedure

InstalltheRoll-OverProtectionSystem(ROPS)Kit.Follow

theinstructionsincludedwiththeROPSKit.

17

InstallingtheROPS(Diesel

MachinesOnly)

1.Locknut(1/2inch)3.Bolt(1/2x3-1/4inch)

2.ROPS

Figure25

Partsneededforthisprocedure:

1Rollbar,rightsection

1

Rollbar,leftsection

1Rollbar,centersection

8

Bolt(3/8x1inch)

8

Curvedwasher

8

Flangenut(3/8inch)

2

Bolt(1/2x3–1/4inch)

2

Flangenut(1/2inch)

Procedure

1.Looselyinstalltherightandleftrollbarsectiontothe

frame,with8bolts(3/8x1inch),8curvedwashers,

and8angenuts(3/8inch).

Note:Installthecurvedwasherconetowardthebolt

head.

11

Page 12

Figure26

g030555

2.Installthelanyardclipsontothelongbolts(1/2x

3-1/4inch).

Note:Makesurethebenttabpointstowardthehead

ofthebolt.

Figure27

3.Lightlyoiltheendsofthecenterrollbarsection.

4.Looselyinstallthecenterrollbarsectionusing2bolts

(1/2x3-1/4inch)and2angenuts(1/2inch).

Note:Installtheboltsfromtheoutsideoftherollbar.

Note:Installthelanyardtaborientedasshownin

Figure28andpointingforward.

Figure28

5.Raisetherollbarintotheuprightpositionandsecure

itwiththepinsandhairpincotterpinsfastenedtothe

lanyards.

Figure29

6.Torqueallofthelowerfasteners,attachedtothe

machineframe,to30ft-lb(40.7N-m).

7.Tightenthecenterroll-barbolts(1/2x3-1/4inch)so

itrotatesfreelywithsomeresistance.

Note:Nomorethanonethreadshouldbeexposed

outsidethenut.

12

Page 13

19

g030083

RemovingtheShippingStraps

NoPartsRequired

Procedure

Figure30

18

CheckingtheMachinefor

Grease

Partsneededforthisprocedure:

Note:ThisprocedureisonlyformachineswithaMyRide

suspensionsystem.

WARNING

Thespringsarecompressedbytheshippingstraps.

Whenthestrapsarecut,theseatwillraiseup

quicklybyapproximately8.9cm(3-1/2inches).

Note:Ensurethestrapsareremovedbeforeoperatingthe

machine.

™

1tube

Procedure

Beforeyouusethemachine,checkthemachineforgrease;

refertoLubricationintheOperator'sManual.

Number2general-purposelithium-baseor

molybdenum-basegrease.(Purchaseseparately.)

Figure31

13

Page 14

20

CheckingtheMachineBeforeDeliverytotheCustomer(All

Machines)

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouperformorhaveperformedtheprocedureslistedinthe

followingtableandinitialeachwhennished.RefertotheOperator'sManualforinstructionsonperformingtheseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemachine.

Checkthatallspindlesaregreased.

Checktheengine-oillevel.

Checkthehydraulic-uidlevel.

CheckROPSissecure.

Onliquidcooledmachines,checkthelevelofthecoolantintheradiatorandoverowbottle.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator'sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator'sManual.

EnsurethatthePTOworks.

Checkallfastenersthatyouinstalledtoensurethattheyaretight.

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:

CheckProcedure

Date:

14

Page 15

21

DeliveringtheMachinetotheCustomer(AllMachines)

Partsneededforthisprocedure:

1

Operator'sManual

1

EngineOwner'sManual

1Registrationcard

1

Operator-trainingmaterial

2Key

Procedure

Atdelivery,llinthemodelandserialnumber,completetheitemslistedinthefollowingtable,andinitialeachwhennished.

ModelNo.

SerialNo.

15

Page 16

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Fueltank

•

Oilllcap/Oildipstick

•

Sparkplug(s)

•

Engine-oillter

•

Engine-oildrain

•

Fuelgauge,valveandhose

•

Airlter

•

Radiatorcoolant(ifapplicable)

•

Hydraulic-uidreservoir

•

Hydrauliclter

•

Battery

•

Ignitionswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoffswitch(PTO)

•

Motion-controllevers

•

Parkingbrake

•

Height-of-cut

•

Lift-assistlever(ifapplicable)

•

ZStand®(ifapplicable)

•

Adjustableseat

•

Hydraulic-bypassvalves

•

RolloverProtectionSystem(ROPS)

•

Deck-owbafe

RefertotheOperator'sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator'sManual.

Describethepostsaleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronlineat

www.T oro.com

MakesurethatthecustomerreceivestheOperator'sManual,EngineOwner'sManual,

SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthePartsCatalogisavailableatwww.T oro.com.

Assistthecustomerinloadingthemachine.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signanddateinthespace

providebelowandkeepacopyofthispagefordealerrecords.Also,thedealermustremindthecustomertouseafull-width

trailerramptoloadthemachine.

Signature:

Signature:Date:

Date:

16

Loading...

Loading...