Page 1

HighFlowHydraulicsKit

GrandStand

ModelNo.78601—SerialNo.400000000andUp

Note:RetaintheseinstructionswiththeOperator’sManualforthemachine.

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

®

MultiForceMower

Proposition65Warning

WARNING

CALIFORNIA

FormNo.3415-703RevB

InstallationInstructions

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Safety

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

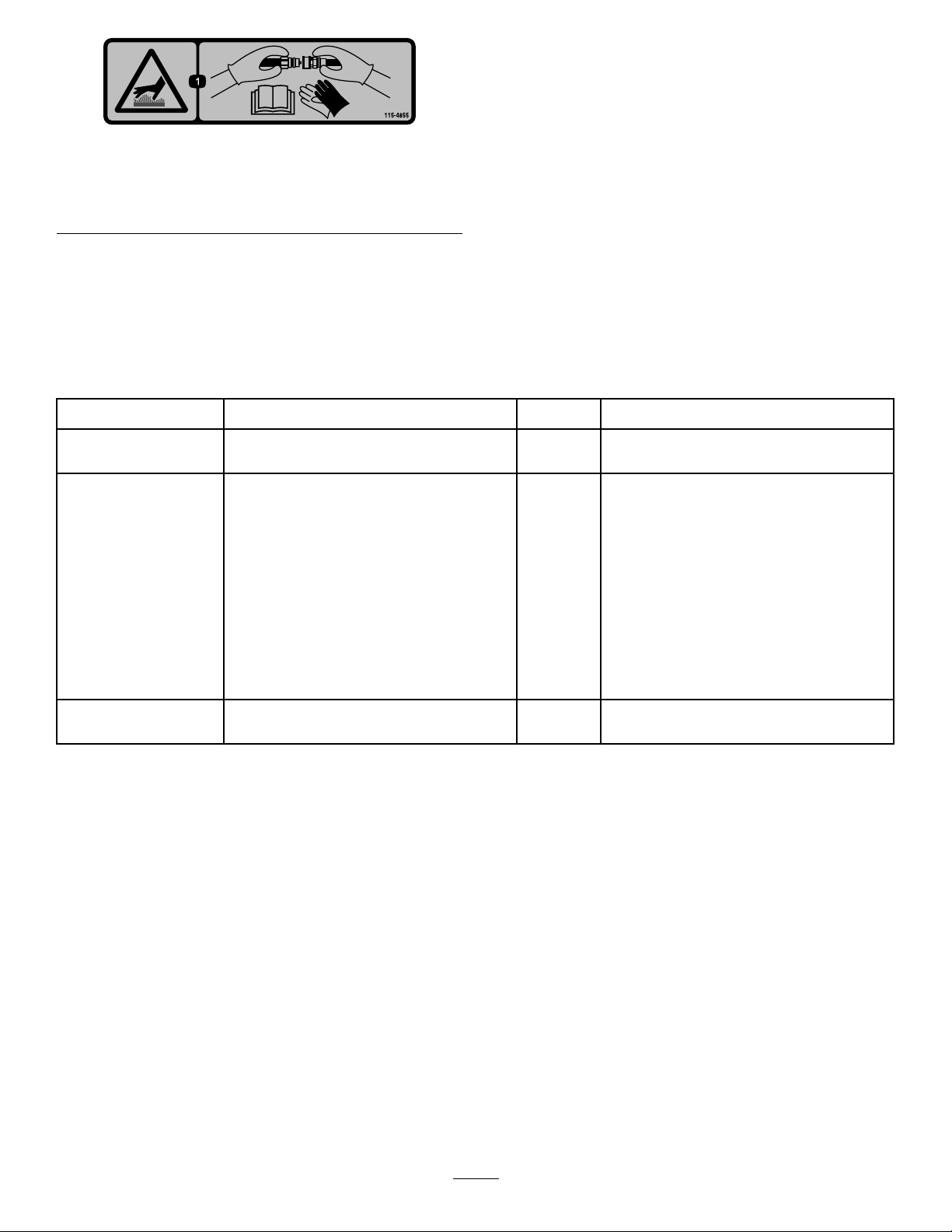

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Registeratwww.T oro.com.

g214500

decal115-4212

115-4212

1.Hydraulic-uidlevel

2.ReadtheOperator's

Manual.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

3.Warning—donottouchthe

hotsurface.

*3415-703*B

Page 2

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

decal115-4855

ProcedureDescription

1

2

3

Qty.

Nopartsrequired

High-owassembly

Rearbracket1

Latchpin1

Smallhairpincotter

Largehairpincotter1

Frontbracket1

Carriagebolt(3/8x2-3/4inches)

Spacer

Nut(3/8inch)

Carriagebolt(3/8x1-1/4inches)

Backplate1

Belt1Routethebelt.

–

1

1

2

2

3

1

Preparethemachine.

Installthehigh-owassembly.

Use

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:IfyouareinstallingthiskitontotheGrandstandMultiForceSnowMachine,youalsoneed

toinstallaclutchontothemachine.ContactyourAuthorizedServiceDealer.

2

Page 3

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.DisengagethePTO,engagetheparkingbrake,

andmovethemotion-controlleversoutwardto

theNEUTRAL-LOCKposition.

3.Shutofftheengineandremovethekey .

g209230

Figure2

2

InstallingtheHigh-Flow Assembly

Partsneededforthisprocedure:

1

High-owassembly

1Rearbracket

1Latchpin

1

Smallhairpincotter

1Largehairpincotter

1Frontbracket

2

Carriagebolt(3/8x2-3/4inches)

2

Spacer

3

Nut(3/8inch)

1

Carriagebolt(3/8x1-1/4inches)

1Backplate

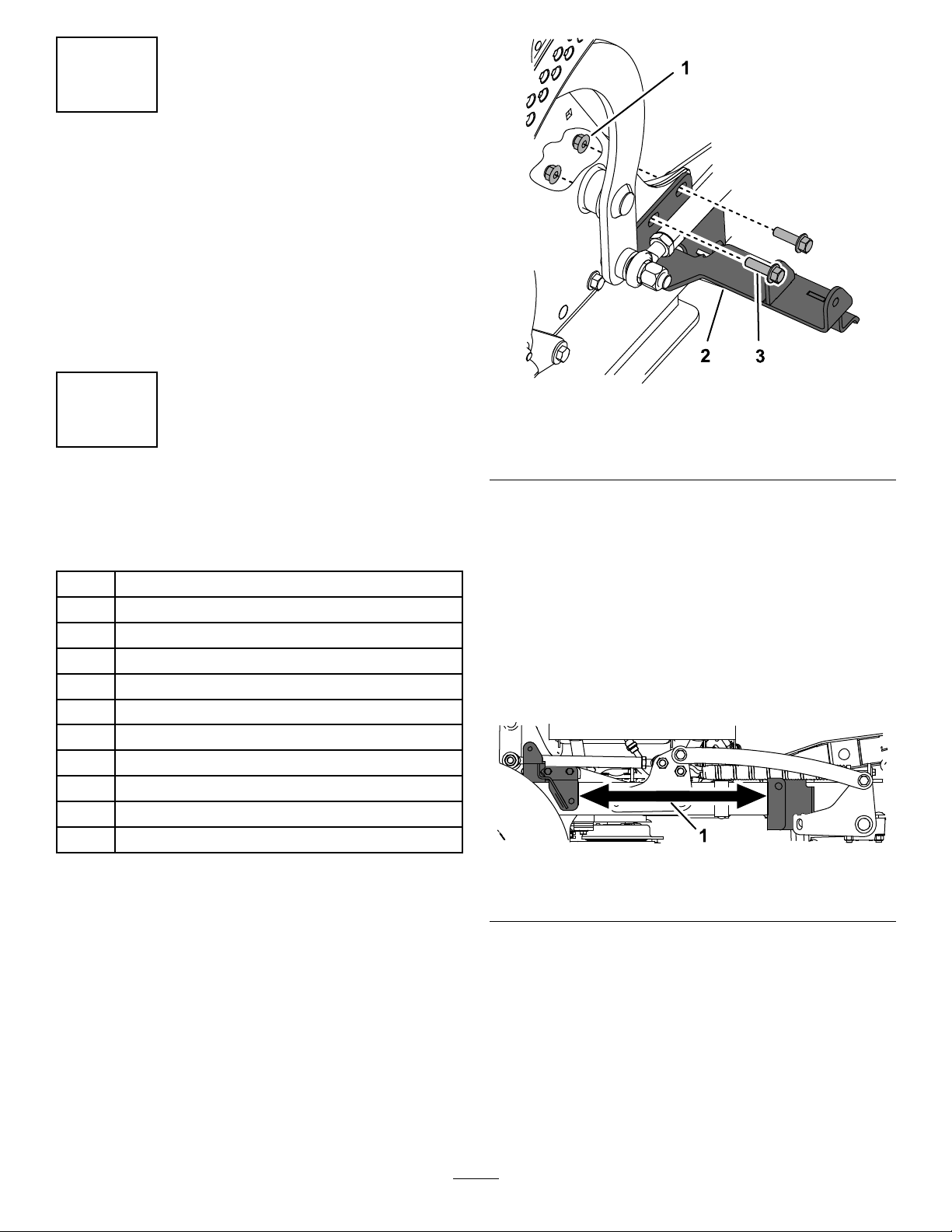

1.Nut(3/8inch)3.Bolt(3/8x1-1/4inches)

2.Rearbracket

3.Usetheboltsandnutsyoujustremovedto

securetherearbracketfromthekitandthefan

shroudtothemachineframe(Figure2).T orque

to41to49N∙m(30to36ft-lb).

4.Looselyinstallthefrontbracketandbackplate

totherighttubeframe,approximately44cm

(17-1/4inches)infrontoftherearbracket

(Figure3),using1carriagebolt(3/8x1-1/4

inches),2carriagebolts(3/8x2-3/4inches),

2spacers,and3nuts(3/8inch)asshownin

(Figure4).

g210668

Figure3

Procedure

Note:Youmayneedasecondpersonorjackstands

toholduptheassemblyasyouinstallittothe

machine.

1.Removethemowerdeck;refertotheOperator’s

Manualforthemachine.

2.Removethe2bolts(3/8x1-1/4inches)and2

nuts(3/8inch)fromtherightsideofthemachine

(Figure2).

Important:Ensurethatthefanshroud

insidetheframedoesnotfallontothe

transaxleasyouremovethehardware.

1.44cm(17-1/4inches)

3

Page 4

Figure4

1.Tubeframe5.Spacer

2.Carriagebolt(3/8x1-1/4

inches)

3.Nut(3/8inch)7.Carriagebolt(3/8x2-3/4

4.Backplate

6.Frontbracket

inches)

5.Installthehigh-owassemblyontothefrontand

rearbrackets,adjustingthefrontbracketas

necessary.Securetheassemblytorearbracket

usingthesmallhairpincotterandlatchpin,and

secureitonthemountpinofthefrontbracket

usingthelargehairpincotter(Figure5).

3

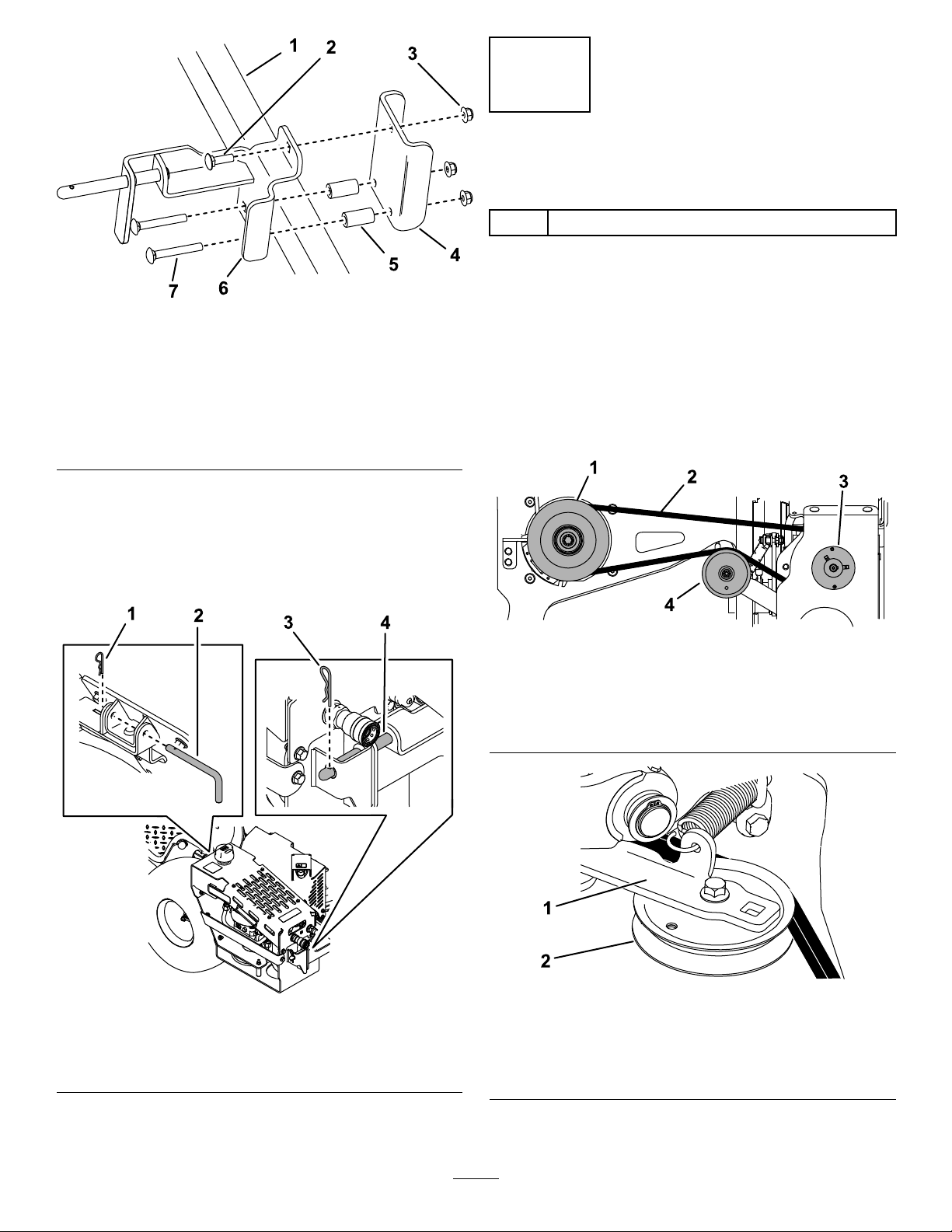

RoutingtheBelt

Partsneededforthisprocedure:

1Belt

Procedure

g209229

Routethebeltaroundthemachineclutchpulleyand

idlerpulley(Figure6).

Note:Thebeltcomesfromthefactoryalready

attachedtothehigh-owpumppulley.Usearatchet

topullbacktheidlerarmtorelievetensiononthe

spring;youdonotneedtoremovethespringfrom

theidlerpulley(Figure7)

Figure5

1.Smallhairpincotter

2.Latchpin4.Mountpin

3.Largehairpincotter

g209259

Figure6

Viewbelowthemachine

1.Clutchpulley3.High-owpumppulley

2.Belt4.Idlerpulley

g209503

Figure7

Topview

1.Idlerarm2.Idlerpulley

g214199

6.Torquetheboltsonthefrontandrearbrackets

to37to45N∙m(27to33ft-lb).

4

Page 5

Operation

ConnectinganAttachment

Important:DonotengagethemachinePTO

withoutanattachmentconnectedtothehigh-ow

assembly.

Important:Checkthehydraulic-uidlevelbefore

engagingtheattachment;refertoCheckingthe

HydraulicFluid(page6).

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey .

3.Connecttheattachmenthosestothehigh-ow

assemblyquick-disconnectcouplers(Figure8).

Note:Wipeanydirtandcontaminantsfrom

thecouplersbeforeconnectingthemtothe

attachmenthoses.

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey .

3.Disconnectanyattachmentsfromthe

quick-disconnectcouplers.Coverthecouplers.

4.Removethebelt(Figure6).

5.Removethesmallhairpincotterandlatchpin

fromtherearoftheassembly(Figure9).

Figure8

1.Femaleconnector2.Maleconnector

4.Starttheengine.

5.Movetheenginethrottlebetween1/2and3/4

throttleandengagethePTO.

Note:Incoldweather,allowtheattachment

torunforafewminutesbeforeincreasingthe

throttletofullthrottle.

6.Ensurethattheattachmentrunssmoothlyprior

tooperationundernormalworkconditions.

RemovingtheAssembly

g209503

Figure9

1.Smallhairpincotter

2.Latchpin4.Mountpin

6.Removethelargehairpincotterfromthemount

pinonthefrontoftheassembly(Figure9).

g209505

7.Lifttheassemblyoffthefrontandrearbrackets

attachedtothemachine.

3.Largehairpincotter

Note:Ifyouareinstallingthemowerdeck,you

donotneedtoremovethebrackets.

8.Ifyouwillbeinstallingabaggertothemachine,

removethefrontandrearbrackets(seeFigure

2andFigure4).Installtheboltsandnutsfrom

therearbrackettothesecurethefanshroudto

themachine.

Important:Ensurethatthefanshroud

insidetheframedoesnotfallontothe

transaxleasyouremovethehardware.

Note:T oinstalltheassemblyonthemachineagain,

referto2InstallingtheHigh-FlowAssembly(page3).

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

5

Page 6

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst75hours

Beforeeachuseordaily

Every100hours

Every250hours

MaintenanceProcedure

•Changethehydraulicuid,lter,andscreentting.

•Checkthehydraulic-uidlevel.

•Cleandebrisfromthecooler.

•Checkthebelt.

•Changethehydraulicuid,lter,andscreentting.

CheckingtheHydraulic Fluid

ServiceInterval:Beforeeachuseordaily

HydraulicFluidType:T oro®HYPR-OIL™500

hydraulicoil

HydraulicFluidCapacity:4.7L(1.25USgallons)

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey.Allow

themachinetocool.

3.Removethebreathercapandwipeoffthe

dipstickwithacleanrag(Figure10).

4.Insertthedipstickintothetank,butdonotthread

thecap;thenremoveitandchecktheuidlevel

(Figure10).

Note:Theuidlevelshouldbebetweenthe

upperandlowerlinesonthedipstick.

g209517

Figure10

1.Breathercap2.Fluidlevel

5.Iftheuidlevelislow,addhydraulicuidtothe

tankuntilthelevelisbetweentheupperand

lowerlinesonthedipstick(Figure10).

6.Installthebreathercap.

6

Page 7

ChangingtheHydraulic Fluid,Filter,andScreen Fitting

ServiceInterval:Aftertherst75hours

Every250hours/Yearly(whichevercomesrst)

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey.Allow

themachinetocool.

WARNING

Hothydraulicuidcancausesevere

burns.

Allowthehydraulicuidtocoolbefore

performinganymaintenanceonthe

hydraulicsystem.

3.Placeadrainpanunderthe90-degreetting

(Figure1 1).

Figure12

1.Screentting

7.Installthenewscreenttingtothetank(Figure

12).T orquethettingto79to98N∙m(58to72

ft-lb)

8.Installthetubetothescreenttingandpump

(Figure12).

2.Tube

g209573

Figure11

Viewfromtheleftsideoftheassembly

1.90-degreetting2.Hydrauliclter

4.Removethehosefromthettingandallowthe

uidtodrain.

5.Installthehosetothetting.

9.Torquetheendsofthetubeto45to56N∙m(33

to41ft-lb).

10.Removethehydrauliclter(Figure1 1).

11.Lubricatethenewltergasketandllthelter

withhydraulicuid.

12.Ensurethatthelter-mountingareaisclean

andscrewthelteronuntilthegasketcontacts

themountingplate;thentightenthelteran

additional1/10to1/4turn(Figure11).

13.Fillthehydraulictankwithuid;refertoChecking

theHydraulicFluid(page6).

g209562

14.Starttheengineandletitrunwithanattachment

connectedforabout2minutestopurgeairfrom

thesystem.

15.Shutofftheengineandcheckforleaks.

6.Removethetubeandscreenttingfromthetank

andpump(Figure12).Discardthescreentting.

7

Page 8

WARNING

ReplacingtheBelt

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.

Fluidinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertond

hydraulicleaks;neveruseyour

hands.

CleaningDebrisfromthe HydraulicCooler

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey .

3.Removeanydebrisbuildupfromthehydraulic

coolerandpumpfanshroud(Figure13).

Note:Youmayusepressurizedairtohelp

removedebristhataredifculttoreach.

ServiceInterval:Every100hours

Signsofawornbeltincludesqueakingwhenthebelt

isrotating,afrayedbeltedge,burnmarks,andcracks.

Replacethedeckbeltifanyoftheseconditionsare

evident.

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey .

3.Removethebeltfromthepulleys(Figure14).

g209259

Figure14

1.Clutchpulley3.High-owpumppulley

2.Belt4.Idlerpulley

4.Installthenewbeltaroundthemachineclutch

pulley,idlerpulley,andhigh-owpumppulley

(Figure14).

1.Hydrauliccooler

Note:Usecarenottocutortwistthebeltas

youslideitunderthepumppulleyandframe.

Youdonotneedtoremovethespringfromthe

idlerpulley .

g209576

Figure13

2.Pumpfanshroud

8

Page 9

Notes:

Page 10

Notes:

Page 11

Notes:

Page 12

TheToroWarranty

ALimitedW arranty(seewarrantyperiodsbelow)Contractor

Landscape

Equipment(LCE)

RidingProduct

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,ToroW arrantyCompany ,pursuanttoanagreement

betweenthem,jointlypromisetorepairtheT oroProductslistedbelowifdefectivein

materialsorworkmanship.

Thefollowingtimeperiodsapplyfromtheoriginaldateofpurchase:

ProductsWarrantyPeriod

GrandStand

•Engines

ZMaster

•Engines

ZMaster

•Engines

ZMaster

•Engines

ZMaster

•Engines

ZMaster

•Engines

TITANHD1500Series

3

®

3

®

3

®

3

®

3

®

3

®

3000SeriesMowers

5000SeriesMowers

6000SeriesMowers

7000SeriesMowers

8000SeriesMowers

Mowers

5yearsor1,200hours

3years

5yearsor1,200hours

3years

5yearsor1,200hours

3years

5yearsor1,400hours

3years

4yearsor1,200hours

2years

2years

3years

4yearsor500Hours

2

2

2

2

2

2

•EnginesToro–4yearsor500hours

TITANHD2000Series

•Engines

TITANHD2500Series

•Engines

3

Kohler–3years

4yearsor1000Hours

4yearsor750Hours

3

Kawasaki–3years

2

2

AllMowers

•Battery90daysPartsandLabor

1yearPartsonly

•BeltsandTires90days

•Attachments1year

1

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialwarrantywouldapply.

2

Whicheveroccursrst.

3

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer.

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenanceprocedures

describedintheOperator'sManual.Suchroutinemaintenance,whetherperformedby

adealerorbyyou,isatyourexpense.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsorworkmanship,

followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.T olocateadealerconvenienttoyou,accessourwebsiteat

www.T oro.com.Youmayalsocallthenumberslistedinitem#3tousethe

24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)totheService

Dealer.Thedealerwilldiagnosetheproblemanddetermineifitiscovered

underwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’sanalysisorwith

theassistanceprovided,contactusat:

ToroWarrantyCompany

CustomerCareDepartment,RLCDivision

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

888-865-5676(U.S.Customers)

888-865-5691(Canadacustomers)

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystemcoverage

andenginewarrantycoverageonsomeproducts.Thisexpresswarrantydoesnot

coverthefollowing:

•Costofregularmaintenanceserviceorparts,suchaslters,fuel,lubricants,oil

changes,sparkplugs,airlters,bladesharpeningorwornblades,cable/linkage

adjustments,orbrakeandclutchadjustments

•Componentsfailingduetonormalwear

•Anyproductorpartwhichhasbeenaltered,misused,neglected,orrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Pickupanddeliverycharges

•RepairsorattemptedrepairsbyanyoneotherthananAuthorizedToroService

Dealer

•Repairsnecessaryduetofailuretofollowrecommendedfuelprocedure(consult

Operator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontainsmorethan

10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-useoverone

month

GeneralConditions

AllrepairscoveredbythesewarrantiesmustbeperformedbyanAuthorizedToro

ServiceDealerusingT oroapprovedreplacementparts.

NeitherTheToroCompanynorT oroWarrantyCompanyisliableforindirect,

incidentalorconsequentialdamagesinconnectionwiththeuseoftheToro

Productscoveredbythiswarranty,includinganycostorexpenseofproviding

substituteequipmentorserviceduringreasonableperiodsofmalfunctionor

non-usependingcompletionofrepairsunderthiswarranty .

Allimpliedwarrantiesofmerchantability(thattheproductistforordinaryuse)

andtnessforuse(thattheproductistforaparticularpurpose)arelimitedto

thedurationoftheexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequentialdamages,

orlimitationsonhowlonganimpliedwarrantylasts,sotheaboveexclusions

andlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveotherrights

whichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry ,

province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheT oroimporter.Ifallother

remediesfail,youmaycontactusatT oroWarrantyCompany .

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0252RevK

Loading...

Loading...