Page 1

BlowerKit

FormNo.3424-338RevB

GrandStand

ModelNo.78593—SerialNo.402860000andUp

®

MultiForceMower

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-338*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thisblowerisintendedtobeusedbyprofessional,

hiredoperators.Itisprimarilydesignedtousewind

powertoquicklyclearlargeareasofunwanteddebris

onwell-maintainedlawns,parks,golfcourses,sports

elds,andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

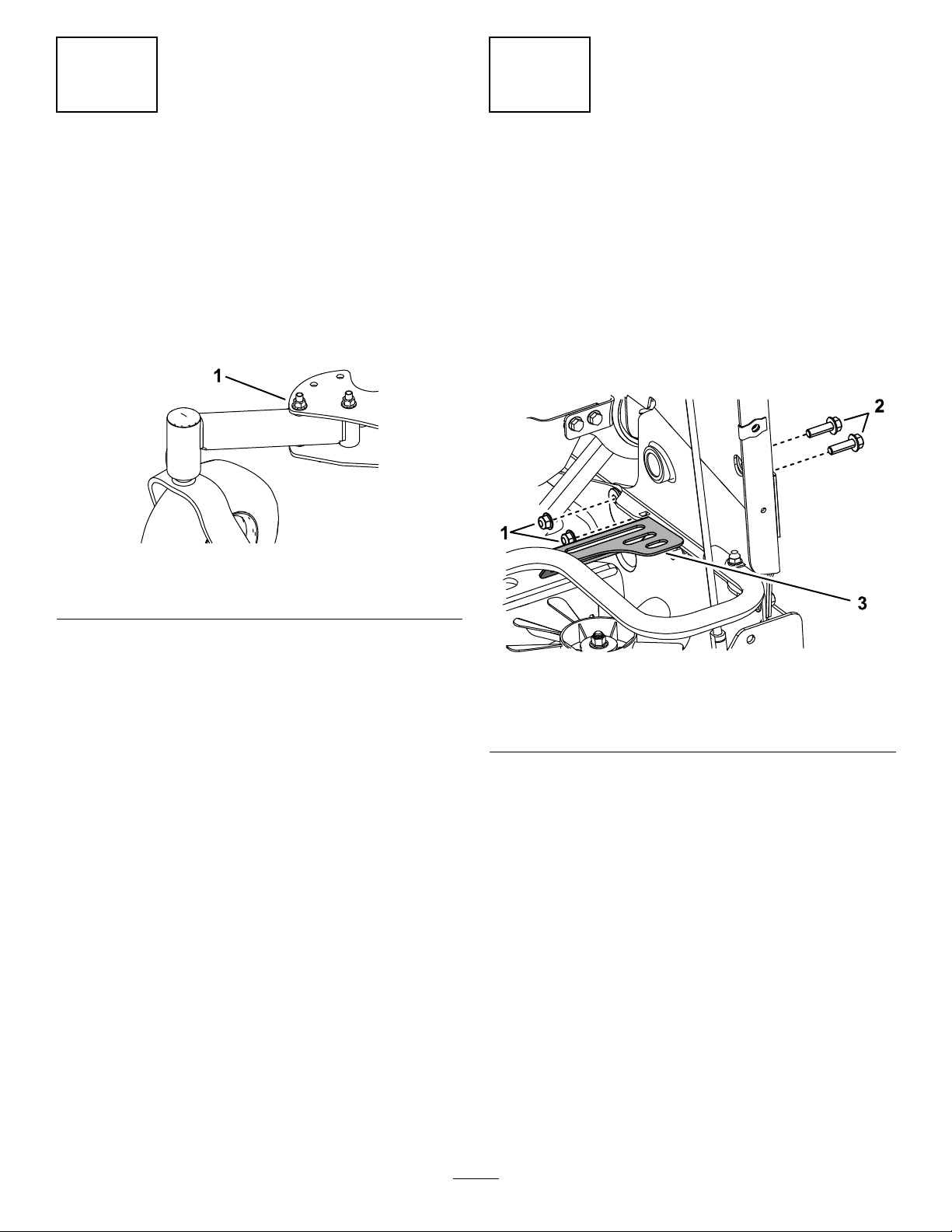

g246145

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1PreparingtheMachine.....................................5

2InstallingtheWheelWeightKit

(Optional)........................................................5

3PositioningtheCasterWheels.........................5

4RemovingtheRightFanGuard........................6

5InstallingtheBlower.........................................7

Operation................................................................10

OperationSafety..............................................10

OperatingtheBlower........................................10

UsingtheKickstand...........................................11

RemovingtheBlower........................................13

OperatingTips.................................................15

Maintenance...........................................................16

MaintenanceSafety..........................................16

CheckingtheBelts............................................16

ReplacingtheBlowerBelt.................................16

ReplacingtheClutchBelt..................................17

CheckingtheHydraulicHoses..........................17

RemovingDebrisfromtheMachine..................17

GeneralSafety

Thisproductiscapableofthrowingobjects.Always

followallsafetyinstructionstoavoidseriouspersonal

injury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

,which

3

Page 4

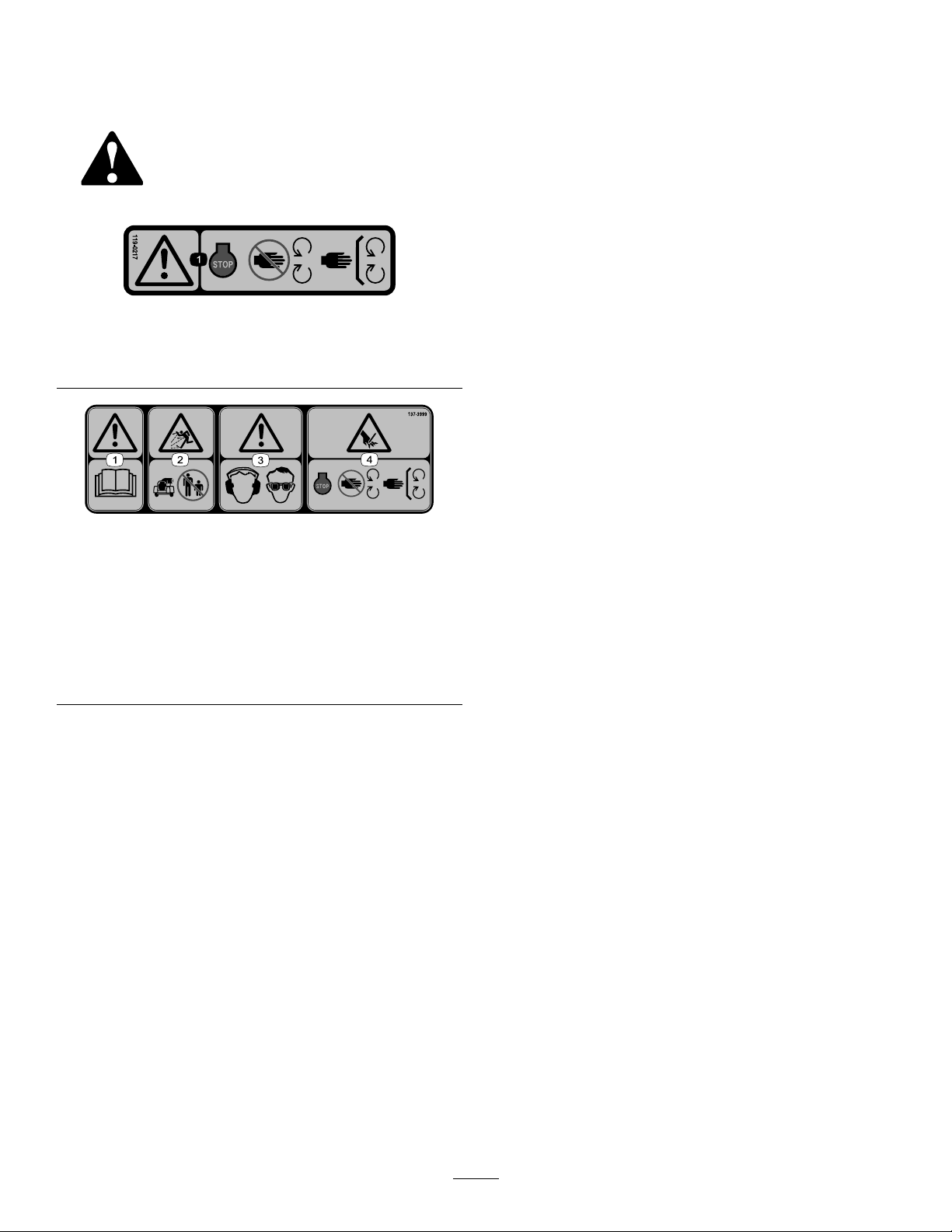

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

119-0217

1.Warning—shutofftheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal119-0217

1.Warning—readthe

Operator’sManual.

2.Thrownobject

hazard—keepbystanders

awayfromthemachine.

decal137-3999

137-3999

3.Warning—wearhearing

andeyeprotection.

4.Cutting/dismemberment

hazardofhands—shut

offtheengine;keep

handsawayfrommoving

parts;keepallguardsand

shieldsinplace.

4

Page 5

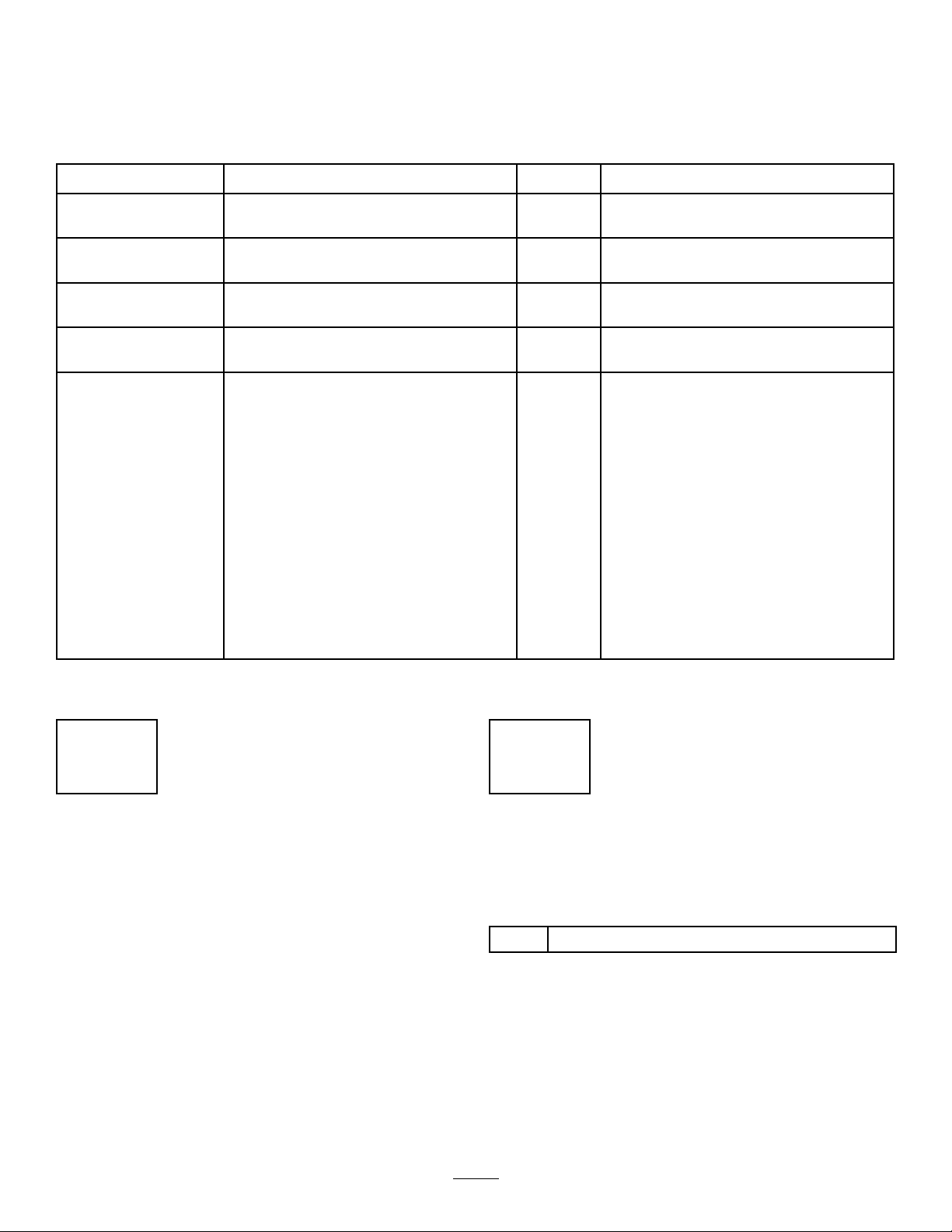

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

WheelWeightKit(soldseparately)

Nopartsrequired

Nopartsrequired

Blowerassembly1

Bushingassembly2

Carriagebolt(3/8x2-1/4inches)

Locknut(3/8inch)

Receiverhitch1

Heatshield1

Bumper2

Thread-formingscrew(1/4x1/2inch)

Stopbracket

Carriagebolt(3/8x1inch)

Nut(3/8inch)

Washer1

Spacer

Thread-formingscrew(1/4x1-1/4inch)

Qty.

Use

–

1

–

–

2

2

2

1

1

1

1

1

Preparethemachine.

InstalltheWheelWeightKit(optional).

Positionthecasterwheels.

Removethefanguard.

Installtheblower.

Important:InstalltheLowFlowHydraulicsKitonyourmachinebeforeinstallingthiskit.

1

PreparingtheMachine

2

InstallingtheWheelWeight Kit(Optional)

NoPartsRequired

Partsneededforthisprocedure:

Procedure

1.Parkthemachineonalevelsurface.

2.LowertheA-frame.

3.DisengagethePTO,engagetheparkingbrake,

andmovethemotion-controlleversoutwardto

theNEUTRAL-LOCKposition.

4.Shutofftheengineandremovethekey.

1

WheelWeightKit(soldseparately)

Procedure

Installingwheelweightscanimprovetractionon

themachinewhenusingtheblower;refertothe

InstallationInstructionsfortheWheelWeightKit.

5

Page 6

3

4

PositioningtheCaster

Wheels

NoPartsRequired

Procedure

Forbothcasters,removethenutandbolt,movethe

castertothefrontposition,andinstallthenutandbolt

(Figure3).Torqueto91to113N∙m(67to83ft-lb).

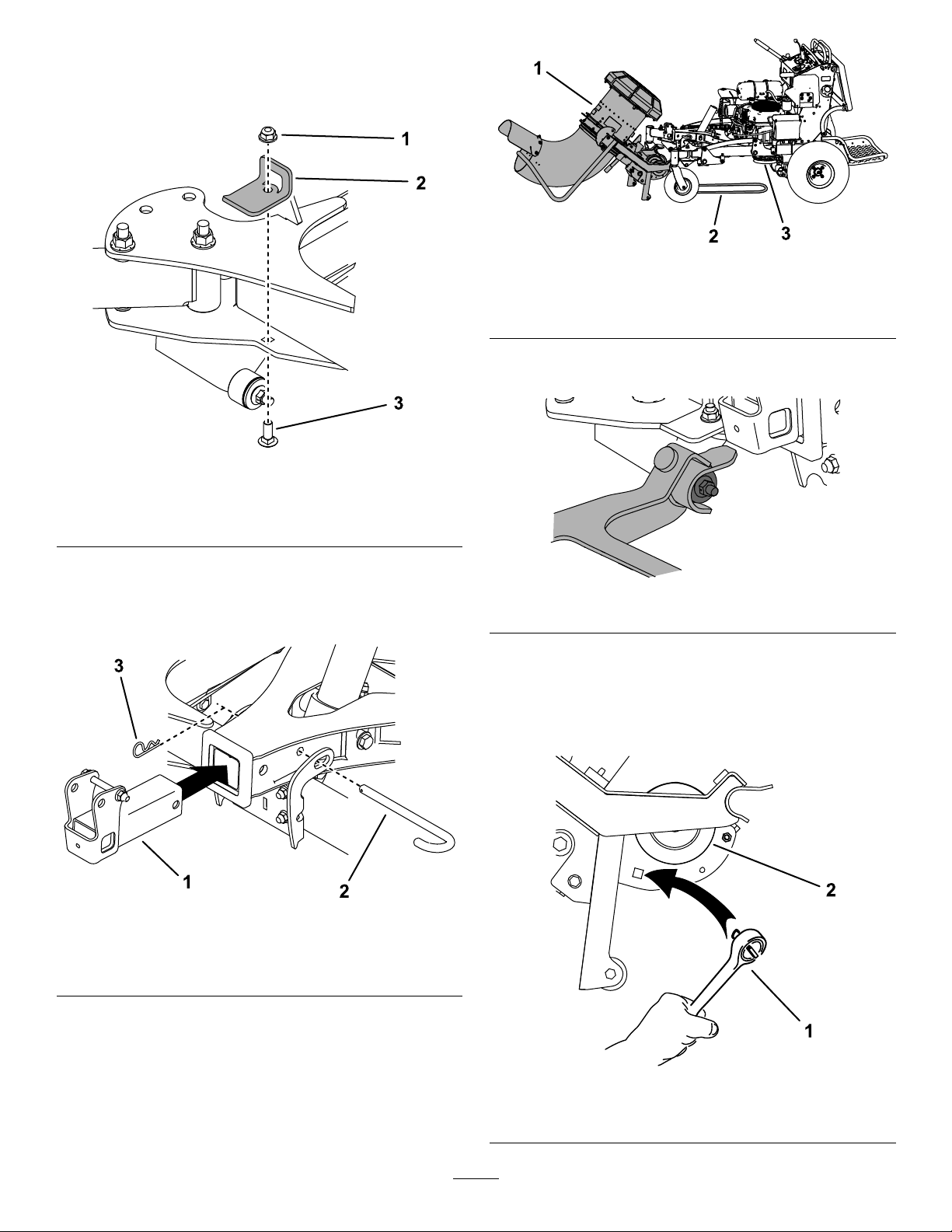

Figure3

RemovingtheRightFan Guard

NoPartsRequired

Procedure

1.Removethefueltank;refertotheOperator’s

Manualforthemachine.

2.Removeandretainthe2bolts,2nuts,andthe

rightfanguard(Figure4).

g230693

1.Nutandbolt

g246823

Figure4

1.Nut(3/8inch)3.Rightfanguard

2.Bolt(3/8x1-1/4inch)

3.Installtheboltsandnutsyouremovedand

torqueto41to49N∙m(30to36ft-lb).

4.Installthefueltank.

6

Page 7

5

InstallingtheBlower

Partsneededforthisprocedure:

1Blowerassembly

2Bushingassembly

2

Carriagebolt(3/8x2-1/4inches)

2

Locknut(3/8inch)

1Receiverhitch

1Heatshield

2Bumper

2

Thread-formingscrew(1/4x1/2inch)

1

Stopbracket

1

Carriagebolt(3/8x1inch)

1

Nut(3/8inch)

1Washer

1

Spacer

1

Thread-formingscrew(1/4x1-1/4inch)

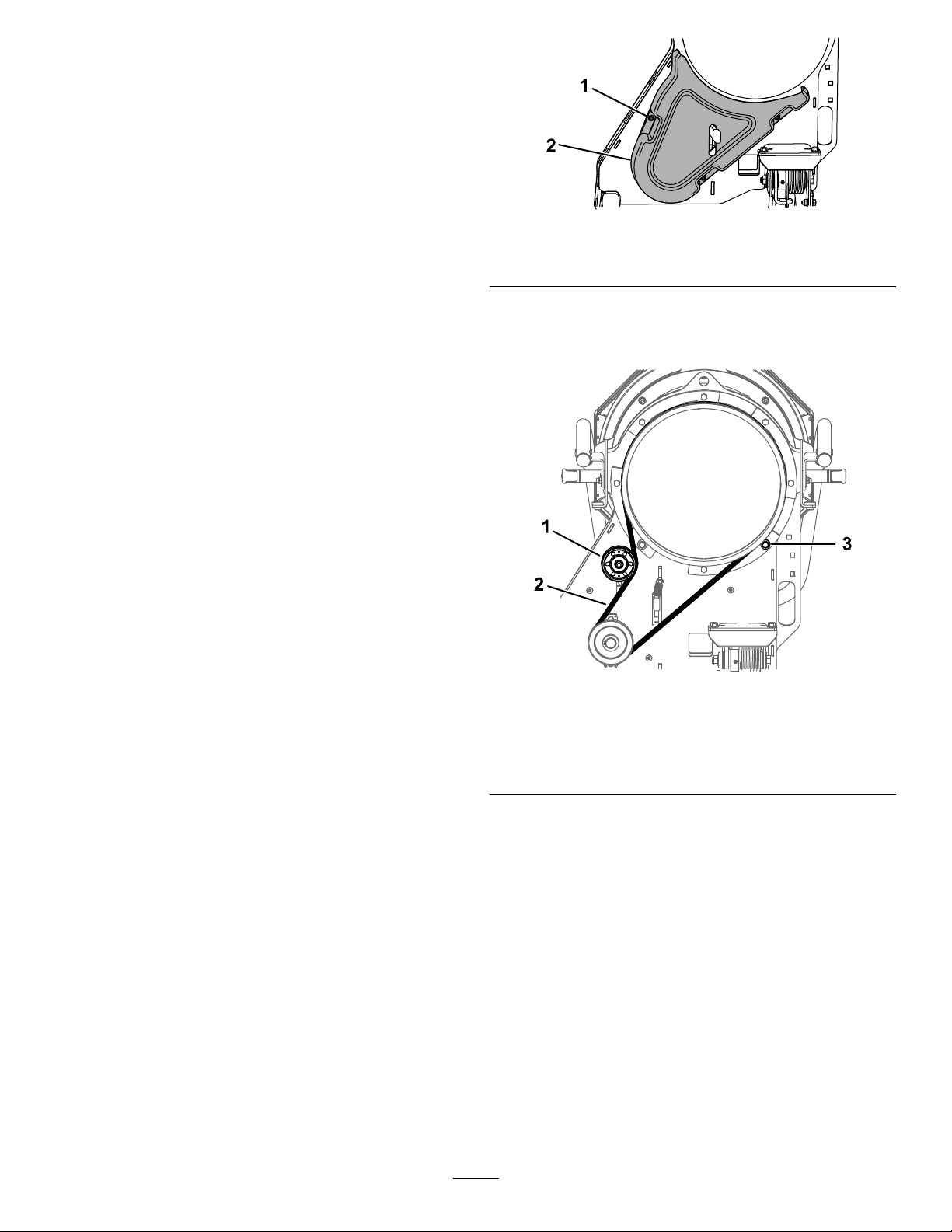

g246215

Figure6

1.Carriagebolt3.Muferguard

2.Nut

4.Looselyinstalltheheatshieldoverthemufer

guard,withthetabsinsidethemuferguardand

totheinsideoftheconsoletower,usingthe2

thread-formingbolts(1/4x1/2inch)andthe

carriageboltandnutyouremovedpreviously

(Figure7).

Important:Tominimizedebrisbuildupon

themufer,installtheheatshieldonthe

machinewhenusingtheblower.

Procedure

1.Removetheair-cleanercoverandlter;referto

theOperator’sManualforthemachine.

2.Installthe2bumpersontheheatshield(Figure

5).

Figure5

1.Heatshield2.Bumper

g256853

Figure7

1.Carriagebolt

g256852

2.Nut

3.Drillhere.

4.Heatshield

5.Thread-formingbolt—1/4

x1/2inch(2)

6.Tab(insidemuferguard)

3.Removethetopcarriageboltandnutsecuring

themuferguardtothemachine(Figure6).

7

Page 8

5.Usingthecenterholeintheheatshieldasa

template,drillahole(7/32inch)intothemufer

guard(Figure7).

6.Usethethread-formingbolt(1/4x1-1/4inch)

andwashertoinstallthespacerbetweenthe

heatshieldandmuferguard(Figure8).

Figure8

9.Useacarriagebolt(3/8x2-1/4inches)andnut

(3/8inch)toinstallthebushingassembliesto

themachine(Figure9).T orquetheboltto37to

45N∙m(27to33ft-lb).

Note:Therubberangeofthebushingshould

facetowardtheinsideofthemachineasshown

inFigure9.

g256854

1.Thread-formingbolt(1/4x

1-1/4)

2.Washer

3.Spacer

7.Torquethe3thread-formingboltsto4.5N∙m

(40in-lb).

Note:Donottorquethecarriageboltatthis

time.

8.Installtheair-cleanerlterandcover.

1.Carriagebolt(3/8x2-1/4

inches)

2.Bushingassembly

g250302

Figure9

3.Nut(3/8inch)

4.Rubberange

8

Page 9

10.Useacarriagebolt(3/8x1inch)andalocknut

(3/8inch)toinstallthestopbrackettotheright

sideofthemachine(Figure10).T orquethebolt

to37to45N∙m(27to33ft-lb).

g230767

Figure12

Figure10

1.Locknut(3/8inch)3.Carriagebolt(3/8x1inch)

2.Stopbracket

11.Removethehitchpinandcotterpinfromthe

A-frameanduseittoinstallthehitchreceiver

(Figure11).Ensurethatthepinlocksthe

A-frametothecrosstube.

1.Blowerassembly

2.Belt

3.Clutch

13.Placetheblowerassemblyforksontothe

bushingassemblies(Figure13).

g250341

g250511

Figure13

14.Installthebeltontotheclutch.Verifythatthe

beltisstillroutedontheblowerpulleysandis

seatedproperlyinthepulleygrooves.

Note:Y oucanuseadriveratchet(1/2inch)to

movetheleftidlerpulley(Figure14).

Figure11

1.Hitchreceiver

2.Hitchpin

3.Cotterpin

12.Movetheblowerinfrontofthemachineandlay

thebeltunderneaththemachinesothatitis

linedupwiththeclutch(Figure12).

g230752

g231579

Figure14

1.Driveratchet2.Pulley

9

Page 10

15.RaisetheblowerasdescribedinRaisingthe

Blower(page12).

16.Connectthehydraulichosestothe

quick-disconnectcouplingsontheLowFlow

HydraulicsKit.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.

Fluidinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsare

tightbeforeapplyingpressuretothe

hydraulicsystem.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertond

hydraulicleaks;neveruseyour

hands.

Operation

OperationSafety

•Themachineexceedsnoiselevelsof85dB(A)at

theoperator’sposition.Usehearingprotection

forprolongedexposuretoreducethepotentialof

permanenthearingdamage.

•Wearappropriateclothingincludingeyeprotection;

longpants;substantial,slip-resistantfootwear;

andhearingprotection.Tiebacklonghairanddo

notwearlooseclothingorloosejewelry.

•Stayawayfromthenozzleopeningwhenthe

machineisoperating.Keepallbystandersaway

fromthenozzleopeninganddon’tdirectdischarge

towardbystanders.

•Whenapersonorpetappearsunexpectedlyinor

neartheoperatingarea,stopoperation.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumeoperationuntilthe

areaisclearedofpeopleandpets.

•Shutofftheengine,removethekey,waitforall

movementtostop,andallowthemachinetocool

beforeadjusting,cleaning,storing,orrepairingit.

OperatingtheBlower

Important:Donotoperatetheblowerwithoutthe

heatshieldinstalledonthemachine.

Tooperatetheblower,starttheengine,movethe

motion-controlleverstothecenter,unlockedposition,

movethethrottleleverbetweenhalfandfullthrottle,

andengagethePTO(Figure15).

Figure15

Usetherightswitchforthelowowkittorotatethe

nozzletothedesireddirection(Figure16),anduse

thethrottlelevertoadjusttheblowerspeed.

g009174

Note:Ifyouwouldliketochangethedirectionthe

nozzlerotateswhenyoumovetheswitchaparticular

direction,removethequick-disconnectcouplingsfrom

theLow-FlowHydraulicsKithosesandinstallthemon

theoppositehoses.

10

Page 11

Figure16

1.Notusedwiththiskit2.Rotatetheblowernozzle.

Ensuretocleandebrisfromthemachineregularly.

WARNING

Dischargedairhasconsiderableforceand

couldcauseinjuryorlossoffooting.

•Stayawayfromthenozzleopeningwhen

themachineisoperating.

•Keepbystandersawayfromthenozzle

openingwhenthemachineisoperating.

UsingtheKickstand

LoweringtheBlower

1.Rotatetheblowernozzlesothatitpoints

upward.

g037041

g230843

Figure17

1.Kickstandlockingpinin

theengagedposition

2.Kickstandlockingpinin

thedisengagedposition

3.Kickstandintheblower

operatingposition

4.Kickstandintheblower

storageposition

5.Removethehitchpinandhairpincottersecuring

theblowerassemblytothehitchreceiver(Figure

18).

2.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

NEUTRAL-LOCKposition,andengagetheparking

brake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Pulloutthekickstandlockingpinsonbothsides

ofthemachine,rotatethem90degreessothat

theyaredisengaged,androtatethekickstand

awayfromthemachine(Figure17).Engagethe

pinsandensurethattheysnapintoposition.

g230859

Figure18

1.Hairpincotter2.Hitchpin

11

Page 12

6.Holdthekickstandandpushthereleaselever

down.Slowlylowerthekickstandtotheground.

Note:Oncetheleverdisengagesthehitchpin,

theblowerrotatesdown.

g230770

Figure21

1.Hairpincotter2.Hitchpin

Figure19

1.Releaselever

RaisingtheBlower

1.Raisetheblowersothatitlatchesonthehitch

receiver(Figure20andFigure21).

g230858

2.Securetheassemblytothehitchreceiverusing

thehitchpinandhairpincotterattachedtothe

receiver(Figure21).

3.Pulloutthekickstandlockingpinsonbothsides

ofthemachine,rotatethem90degreessothat

theyaredisengaged,andraisethekickstand

(Figure22).Engagetheknobsandensurethat

thepinssnapintoposition.

Figure20

g230769

g230843

Figure22

1.Kickstandlockingpinin

theengagedposition

2.Kickstandlockingpinin

thedisengagedposition

3.Kickstandintheblower

operatingposition

4.Kickstandintheblower

storageposition

12

Page 13

RemovingtheBlower

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,and

movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition.

2.Shutofftheengineandremovethekey.

3.Disconnecttheblowerhydraulichosesfromthe

quick-disconnectcouplingsontheLowFlowKit.

4.Lowertheblower;refertoLoweringtheBlower

(page11).

5.Removethebeltfromtheclutch.

Note:Ifneeded,useadriveratchet(1/2inch)

tomovetheleftidlerpulley(Figure23).

7.Removethehitchpin,cotterpin,andhitch

receiverfromtheA-frame.Installthehitchpin

andcotterpintosecuretheA-frame(Figure24).

g246845

Figure24

Figure23

1.Driveratchet2.Pulley

6.Lifttheblowerassemblyoffthebushing

assembliesonthemachine.

1.Hitchreceiver

2.Hitchpin

3.Cotterpin

8.Removethestopbrackets(Figure25).

g231579

g250341

Figure25

1.Locknut(3/8inch)3.Carriagebolt(3/8x1inch)

2.Stopbracket

9.Removebothbushingassemblies(Figure26).

13

Page 14

Figure26

11.Removethespacer

g230751

1.Bolt3.Nut

2.Bushingassembly

10.Usethefastenerstostorethebushing

assembliesontheleftsideoftheblowerframe

(Figure27).

Figure27

g256854

Figure28

1.Thread-formingbolt(1/4x

1-1/4)

2.Washer

3.Spacer

12.Removetheheatshield(Figure29).

Important:Wheneveryouinstalltheblower

onanothermachine,alsoinstalltheheat

shield.

g246867

1.Bolt3.Nut

2.Bushingassembly

Figure29

1.Carriagebolt

2.Nut

3.Heatshield

4.Thread-formingbolt(2)

13.Installthecarriageboltandnuttosecurethe

muferguard.T orquetheboltto1978to2542

N∙cm(175to225in-lb).

14.Removethefueltank;refertotheOperator’s

Manualforthemachine.

14

g256855

Page 15

15.Removethe2boltsand2nutsfromtheright

sideofthemachineandusethemtoinstallfan

guard(Figure30).T orquetheboltsto37to45

N∙m(27to33ft-lb).

Figure30

OperatingTips

•Practiceoperatingtheblower.Blowthesame

directionthewindisblowingtopreventmaterial

fromblowingbackintotheclearedarea.

•Beawareoftheblowernozzledirectionanddonot

pointitatanyone.

•Adjustthenozzleopeningsothatitblowsunder

thedebris.

•Usecautionwhenblowingaroundnewlyplanted

sodastheforceoftheaircoulddisruptthegrass.

•Thenozzleoutletpositionaffectsthedistance

debriscanbeblown.

•Whenyourotatethenozzle,rotateitupwardand

aroundtopreventblowingdebrisbackintothe

clearedarea.

g246823

1.Nut(3/8inch)

2.Bolt(3/8x1-1/4inches)

16.Installthefueltank.

3.Fanguard

15

Page 16

Maintenance

MaintenanceSafety

•Parkthemachineonalevelsurface.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportthemachinewhen

required.

•Removethekeyfromtheswitchonthetraction

unittopreventaccidentalstartingoftheengine

whenservicing,adjusting,orstoringthemachine.

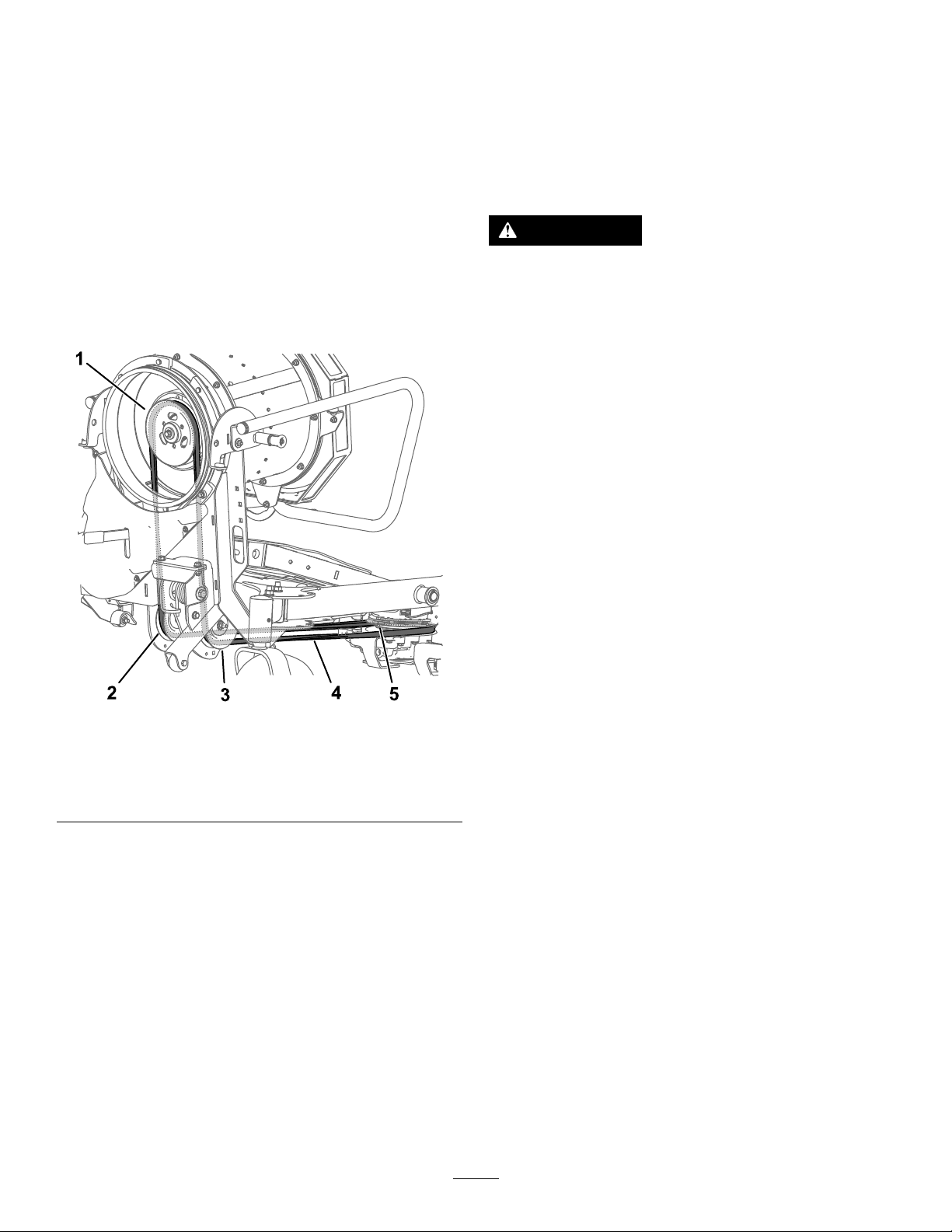

1.Bolt(3)

g246599

Figure31

2.Beltcover

•Performonlythosemaintenanceinstructions

describedinthismanual.Iftheblowerrequiresa

majorrepair,contactanauthorizedT orodistributor.

•Ensurethatthemachineisinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Keepyourhandsandfeetawayfrommovingparts.

Donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

CheckingtheBelts

ServiceInterval:Every300hours

Checkthebeltsforcracks,frayededges,burnmarks,

oranyotherdamage.Replacedamagedbelts.

4.Loosenthenutonthetoppulleyandslidethe

pulleyuptoreleasetensiononthebelt(Figure

32).

g250730

Figure32

Blowernozzlenotshownforclarity

1.Toppulley3.Rollerbearing

2.Belt

ReplacingtheBlowerBelt

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethebeltcover(Figure31).

5.Removetherollerbearing(Figure32).

6.Removethebeltandinstallanewbelt(Figure

32).

7.Installtherollerbearing(Figure32)

8.Slidethetoppulleydownuntilthebeltdeection

is5mm(0.19inch)atthecenterofthelargest

spanandtightenthenut(Figure32).

16

Page 17

ReplacingtheClutchBelt

CheckingtheHydraulic

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowertheblower.

4.Loosenthenozzleclampandremovethenozzle.

5.Removethebeltfromthemachineclutch.

Note:Y oucanuseadriveratchet(1/2inch)to

movetheleftidlerpulley(Figure14).

6.Removethebeltfromthefanpulley(Figure33).

Hoses

ServiceInterval:Every100hours

Checkthehydraulichosesforleaks,loosettings,

kinkedlines,loosemountingsupports,wear,weather,

andchemicaldeterioration.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

Figure33

1.Fanpulley4.Belt

2.Rightidlerpulley

3.Leftidlerpulley

7.Routethebeltdownthroughthedriveadapter

assembly,aroundtheidlerpulleys,andaround

theclutchpulley(Figure33).Ensurethatthe

beltisseatedproperlyinthepulleygrooves.

5.Clutchpulley

Note:Ifneeded,youmayuseadriveratchet

(1/2inch)tomovetheleftidlerpulley(Figure14).

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

RemovingDebrisfromthe Machine

g246640

ServiceInterval:Aftereachuse

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleandebrisfromthedrives,mufer,andengine

aftereachuse.

17

Page 18

Notes:

Page 19

Notes:

Page 20

Loading...

Loading...