Page 1

FormNo.3373-452RevC

G018353

48in,52in,and60inE-ZVac™

TwinSoftBagger

ZMaster

ModelNo.78569—SerialNo.312000001andUp

®

2000SeriesMower

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3373-452*C

Page 2

Introduction

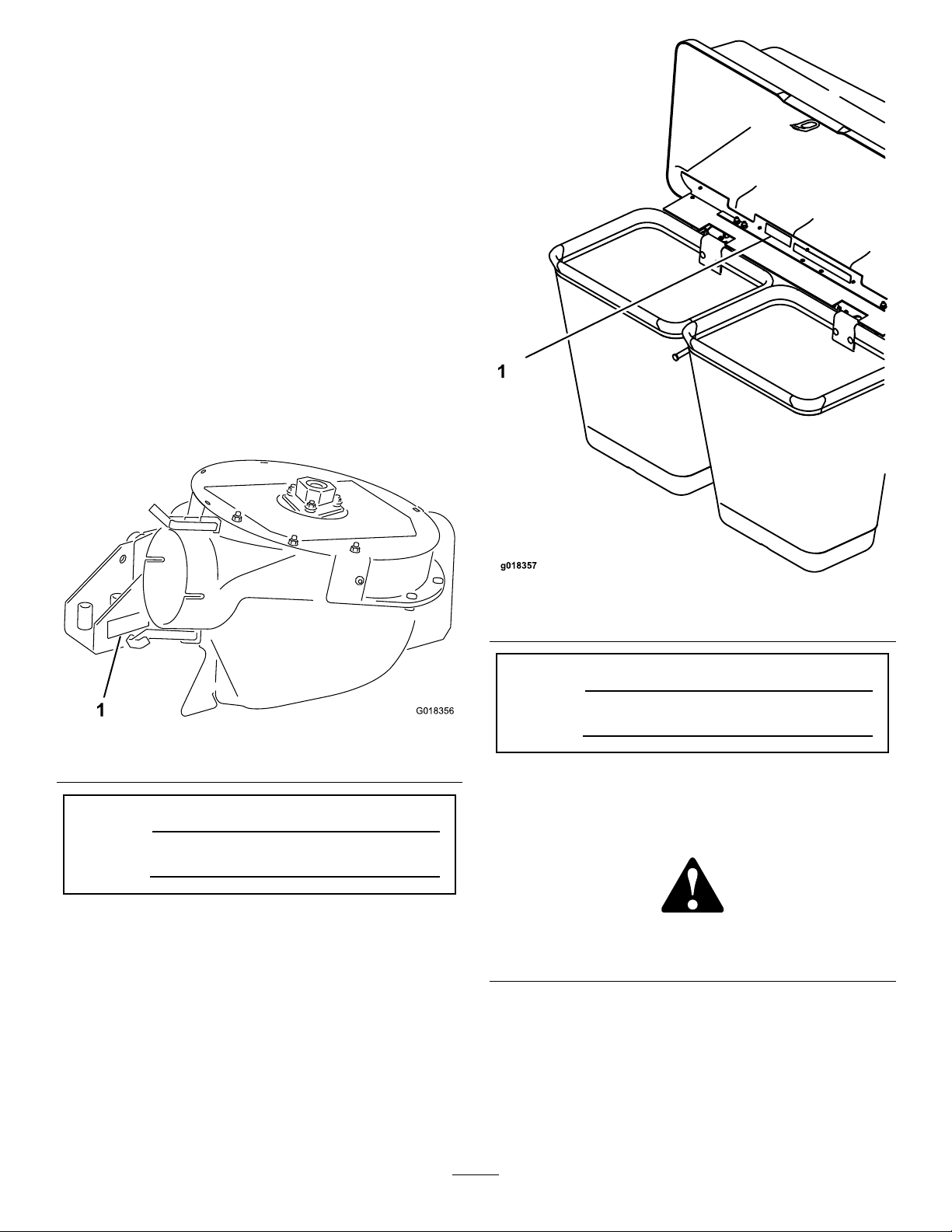

G018356

1

g018357

1

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Figure1,andFigure2identifythe

locationofthemodelnumbersandserialnumbersonthe

product.Writethemodelnumberandserialnumberinthe

spaceprovided.

Figure2

1.Baggermodelandserialnumberlocation

ModelNo.

Figure1

1.Blowermodelandserialnumberlocation

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure3),

ModelNo.

SerialNo.

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure3

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1PreparingtheMower.............................................6

2InstallingtheSideBumpersandSupport

Brackets.............................................................6

3InstallingtheTailpipeExtension.............................7

4DrillingtheExhaust-ShieldMounting

Holes.................................................................9

5InstallingtheExhaustShield..................................11

6InstallingtheHopperSupportFrameandHood

Rod...................................................................12

7InstallingtheHoodBafe.....................................13

8InstallingtheHoodAssemblyandBags...................14

9RoutingtheBlowerBeltintotheBlower

Assembly...........................................................16

10InstallingtheBlowerAssembly.............................17

11InstallingtheBeltCover......................................19

12InstallingtheDischargeTube...............................19

13InstallingtheWeights..........................................23

14CheckingtheTirePressure..................................25

Operation....................................................................25

EmptyingtheGrassBags.........................................26

ClearingObstructionsfromtheBagger

System..............................................................26

RemovingtheBagger..............................................26

UsingtheGrassDeector.......................................27

TransportingMachines............................................27

OperatingTips......................................................27

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

PreparingforMaintenance.......................................29

CleaningtheHoodScreen.......................................29

CleaningtheBaggerandBags...................................29

InspectingtheBlowerBelt.......................................29

ReplacingtheBlowerBelt........................................29

GreasingtheIdlerArm...........................................30

InspectingtheBagger.............................................30

InspectingtheMowerBlades...................................30

ChoosingtheMowerBlades.....................................30

ReplacingtheGrassDeector..................................30

Storage........................................................................31

Troubleshooting...........................................................32

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

•Becomefamiliarwiththesafeoperationoftheequipment,

withtheoperatorcontrols,andsafetysigns.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangetheoperatingcharacteristicsandthe

stabilityofthemachine.

•Followthemanufacturer'srecommendationsforadding

orremovingwheelweightsorcounterweightstoimprove

stability.

•Donotuseagrasscatcheronsteepslopes.Aheavy

grasscatchercouldcauselossofcontroloroverturnthe

machine.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.Useextreme

cautionwhileoperatingneardrop-offs.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeed,directionsorturning.

•Thegrasscatchercanobstructtheviewtotherear.Use

extracarewhenoperatinginreverse.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Keephandsandfeetawayfrommovingparts.Donot

makeadjustmentswiththeenginerunning.

•Stoponlevelground,disengagedrives,chockorblock

wheels,shutofftheenginebeforeleavingtheoperator's

positionforanyreasonincludingemptyingthegrass

catcheroruncloggingthechute.

•Ifyouremovethegrasscatcher,besuretoinstallany

dischargedeectororguardthatmighthavebeen

removedtoinstallthegrasscatcher.Donotoperatethe

mowerwithouteithertheentiregrasscatcherorthegrass

deectorinplace.

•Shutofftheenginebeforeremovingthegrasscatcheror

uncloggingthechute.

•Useastick,notyourhands,toremoveanobstruction

fromtheblowertube.

•Donotleavegrassingrasscatcherforextendedperiods

oftime.

•Grasscatchercomponentsaresubjecttowear,damage

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacewithmanufacturer'srecommendedparts,

whennecessary.

3

Page 4

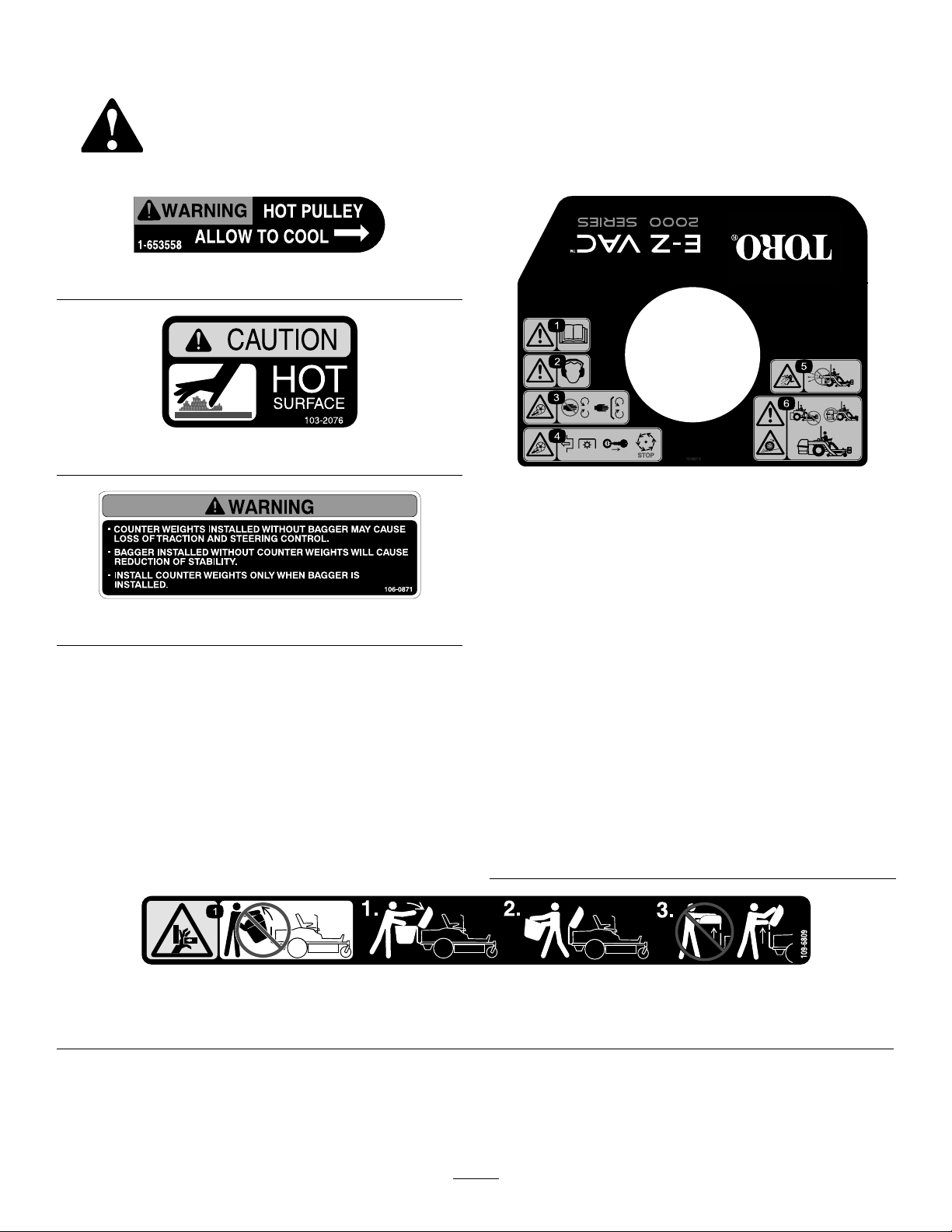

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-653558

103–2076

121–3212

1.Warning—readthe

Operator’sManual.

106-0871

2.Warning—wearhearing

protection.

3.Cutting/dismemberment

hazard,impeller—keep

handsawayfrommoving

parts;keepallguardsin

place.

4.Cutting/dismemberment

hazard,

impeller—disengage

thePTO,removethekey

fromtheignition,waitfor

allmovingpartstostop.

5.Thrownobjecthazard—do

notruntheblowerwithout

thecollectionsystem

installedandlatched.

6.Warning;lossof

traction/control

hazard—ultravac

counterbalanceweight(s)

installedwithoutultravac

maycauselossoftraction

andsteeringcontrol;

ultravacinstalledwithout

ultravaccounterbalance

weight(s)willcause

reducedstability;install

theweight(s)onlywhen

ultravacisinstalled.

109–6809

1.Crushinghazardofhand—donotremovethewholebaggerfromthemachine:1.Openthebaggertop.2.Removethebag(s)

fromthebagger.3.Donotremovethebaggertopwhenitisclosed;openthebaggertopandthenremoveit.

4

Page 5

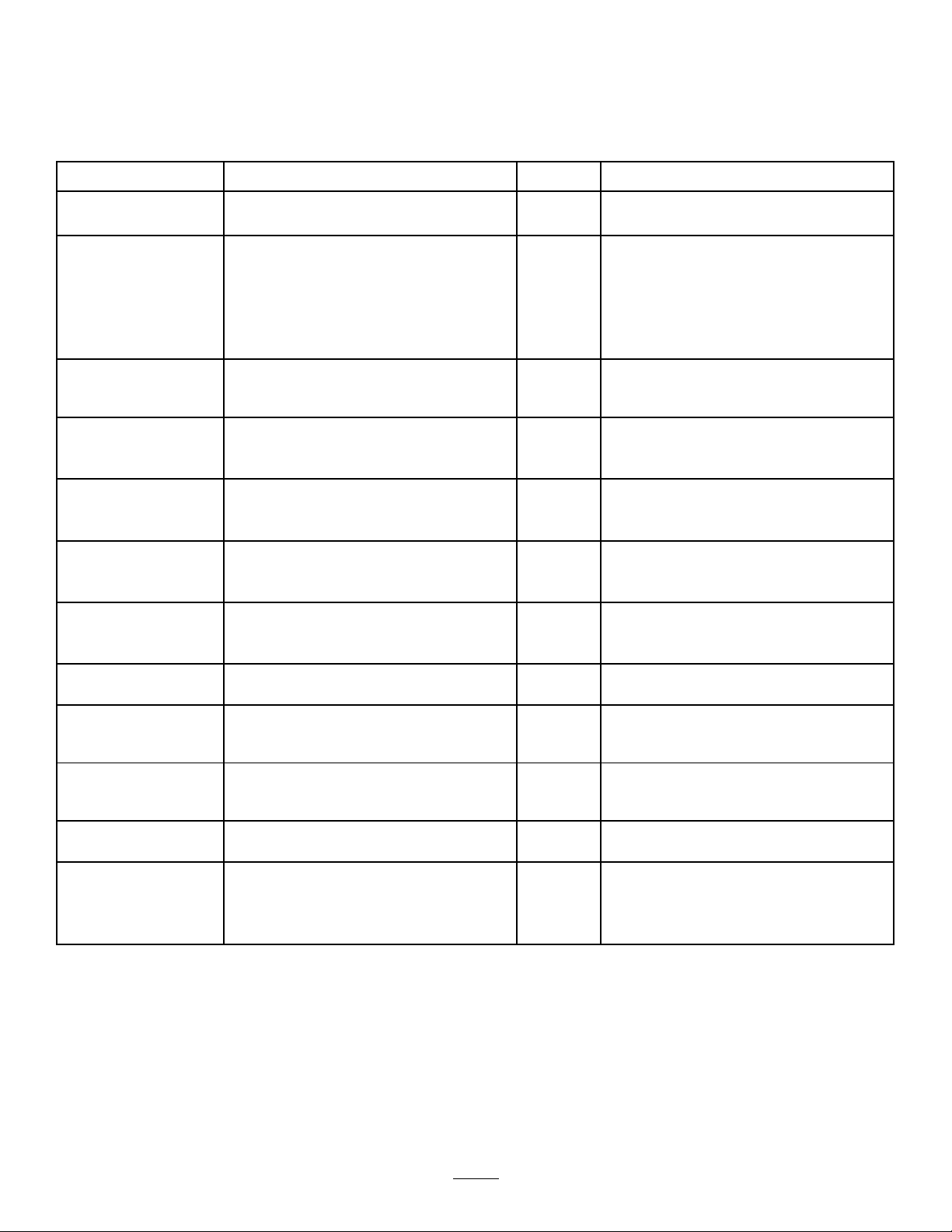

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

12

Nopartsrequired

Leftbumper

Leftframe-supportbracket

Rightbumper1

Rightframe-supportbracket

Carriagebolt(3/8x1-1/4inches)

Flangenut(3/8inch)

Tailpipeextension1

Washer-headscrew(#8x1/2inch,

self-threading)

Exhaustshield1

Flange-hex-headbolt(3/8x1inch)

Nut(3/8inch)

Exhaustshield1

Flange-hex-headbolt(3/8x1inch)

Nut(3/8inch)

Hopper-supportframe

Hairpin2

Hoodhold-downrod1

Baggerhood1

Bafe

Hairpin(small)

Hoodassembly1

Bag2

Blower(fromthebloweranddrivekit)

Blowerbelt(fromthebloweranddrive

kit)

Blowerassembly(fromtheblowerand

drivekit)

Spring(fromthebloweranddrivekit)

Beltcover(fromthebloweranddrivekit)

Coverknob

Upperdischargetube1

Screw(1/4x3/4inch)

Locknut(1/4inch)

Lowerdischargetube1

Qty.

Use

–

1

1

1

6

6

1

2

2

3

3

1

1

2

1

1

1

1

1

1

3

3

Preparethemower.

Installthesidebumpersandsupport

brackets.

Installthemuferextension.

Drilltheexhaust-shieldmountingholes.

Installtheexhaustheatshield.

Installthebaggermountingbrackets.

Installthehoodbafe.

Installthehoodassemblyandbags.

Routetheblowerbeltintotheblower

assembly.

Installtheblowerassembly .

Installthebeltcover.

Installthedischargetubes.

5

Page 6

ProcedureDescription

13

Weight-mountbracket1

Carriagebolt(5/16x3/4inch)

Flangenut(5/16inch)

Frontweight3

Bolt(3/8x1inch)

Lockwasher6

Flatwasher6

Flangenut(3/8inch)

Qty.

Use

2

2

6

3

Installtheweights.

14

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

PreparingtheMower

Nopartsrequired

2

InstallingtheSideBumpers andSupportBrackets

NoPartsRequired

Partsneededforthisprocedure:

Procedure

Performthefollowingproceduretopreparethemowerfor

attachingtheblowerandbaggerkit.

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRALlockedposition,andsettheparking

brake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Repairallbentordamagedareasofthemowerdeck

andreplaceanymissingparts.

4.Cleanthemowerofanydebrisonthedeckorrearpart

ofthemowertoeaseinstallation.

1

1

1Rightbumper

1

6

6

Procedure

1.Removetheleftandrightbumpersasfollows:

A.Removethenutsandboltssecuringtheleftside

–

Leftbumper

Leftframe-supportbracket

Rightframe-supportbracket

Carriagebolt(3/8x1-1/4inches)

Flangenut(3/8inch)

Checkthetirepressure.

bumperandmufershieldtothechassisand

centerengineguardasshowninFigure4.

6

Page 7

G018358

1

3

5

6

7

8

8

7

8

2

4

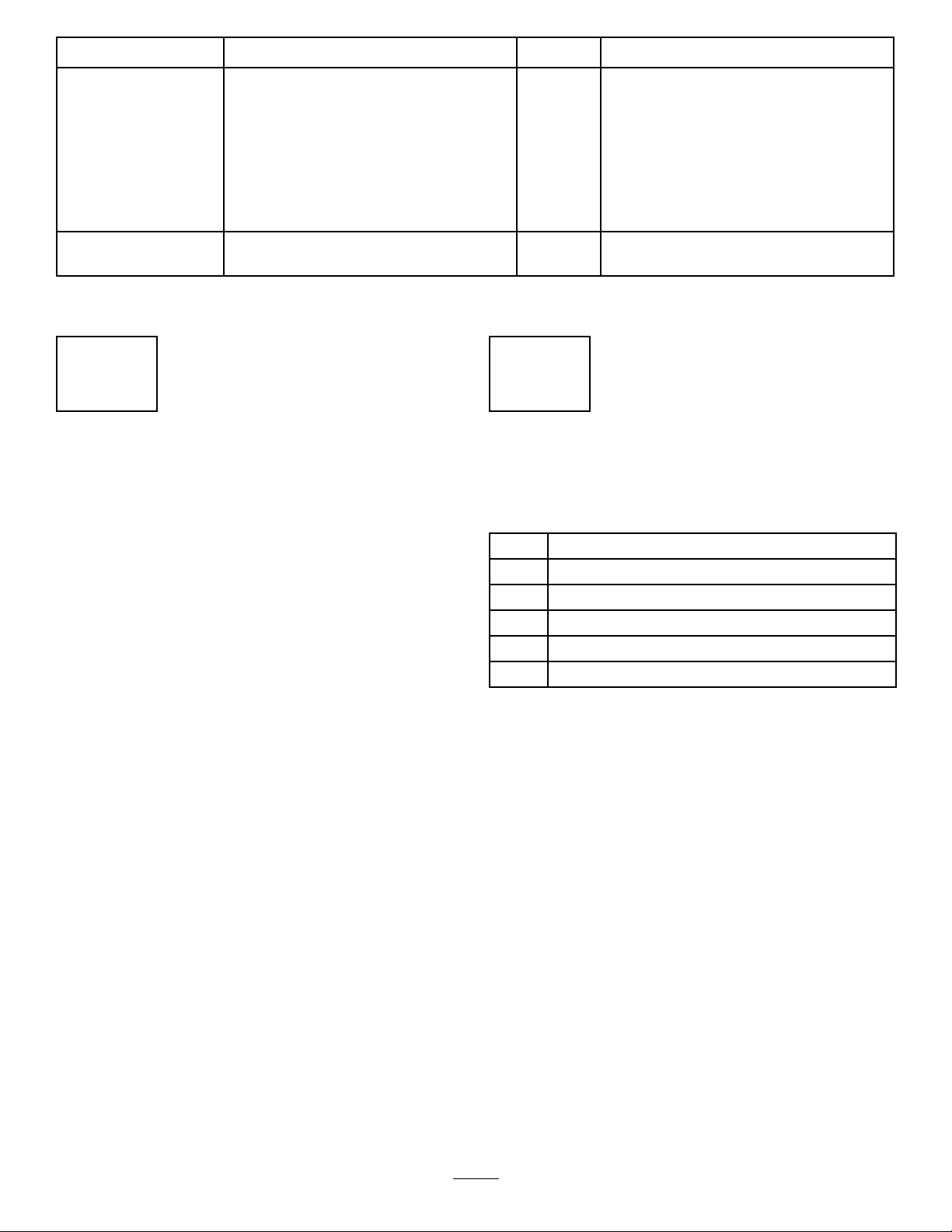

Figure4

SideBumperandBracketInstallation

1.Leftsidebumper

2.Centerengineguard6.Rightframe-support

3.Leftframe-supportbracket7.Carriagebolt(3/8x1-1/4

4.Mufershield8.Flangenut(3/8inch)

5.Rightsidebumper

bracket

inches)

F.Aligntheholesfortheleftframe-supportbracket,

leftsidebumperandmuferguardtotheupper

holeinthecenterengineguard(Figure4).

G.Looselysecurethebracket,bumperandmufer

guardtothecenterengineguardattheupperhole

withacarriagebolts(3/8x1-1/4inches)anda

angenut(3/8inch)(Figure4).

H.Alignthefrontholesintheleftsidebumperand

themuferguardwiththeforward-mounting

pointonthechassis.(Figure4).

I.Securethebumperandguardtothemounting

pointwithacarriagebolt(3/8x1-1/4inches)and

aangenut(3/8inch)(Figure4).

J.Tightenthehardwarethatsecuresthebracket,

bumperandmuferguardtothecenterengine

guard.

3.Installthenewrightsidebumperasfollows:

A.Alignthenewrightsidebumperwiththe

forward-mountingpointonthechassisandthe

bumper-mountingpointsonthecenterengine

guard(Figure4).

B.Alignthemountingange(theangewith2

holes)oftherightframe-supportbrackettothe

leftasshowninFigure4.

B.Removetheleftbumperandmufershieldfrom

themachine.

Note:Retainthemufershieldforinstallation

withthenewleftsidebumper.

C.Removethenutsandboltssecuringtherightside

bumpertothechassisandcenterengineguard.

Note:Discardthecarriageboltsandangenuts

thatsecuretheoriginalleftandrightsidebumpers

tothemachine.

2.Installthenewleftsidebumperasfollows:

A.Alignthenewleftsidebumperwiththe

forward-mountingpointonthechassisandthe

bumper-mountingpointsonthecenterengine

guard(Figure4).

B.Alignthemountingange(theangewith2

holes)oftheleftframe-supportbrackettotheleft

C.Aligntheholesoftherightframe-supportbracket

andbackholesoftherightsidebumperwiththe

back,centerengineguard(Figure4).

D.Looselysecurethebracketandbumpertothe

centerengineguardwith2carriagebolts(3/8x

1-1/4inches)and2angenut(3/8inch)(Figure

4).

E.Alignthefrontholeinthenewrightsidebumper

withtheforwardmountingpointonthechassis

(Figure4).

F.Securethebumpertothemountingpointwith

acarriagebolt(3/8x1-1/4inches)andaange

nut(3/8inch)(Figure4).

G.Tightenthehardwarethatsecuresthebracketand

bumpertothecenterengineguard.

asshowninFigure4.

C.Aligntheholesoftheleftframe-supportbracket

andthebackholesoftheleftsidebumperwith

theholesinthecenterengineguard(Figure4).

D.Looselysecurethebracketandbumpertothe

centerengineguardatthelowerholewitha

carriagebolt(3/8x1-1/4inches)andaangenut

(3/8inch)(Figure4).

E.Positionthemuferheatshieldwiththemounting

angesinsidetheleftsidebumper(Figure4).

7

Page 8

3

4

3

5

3

62

4

3

3

5

61

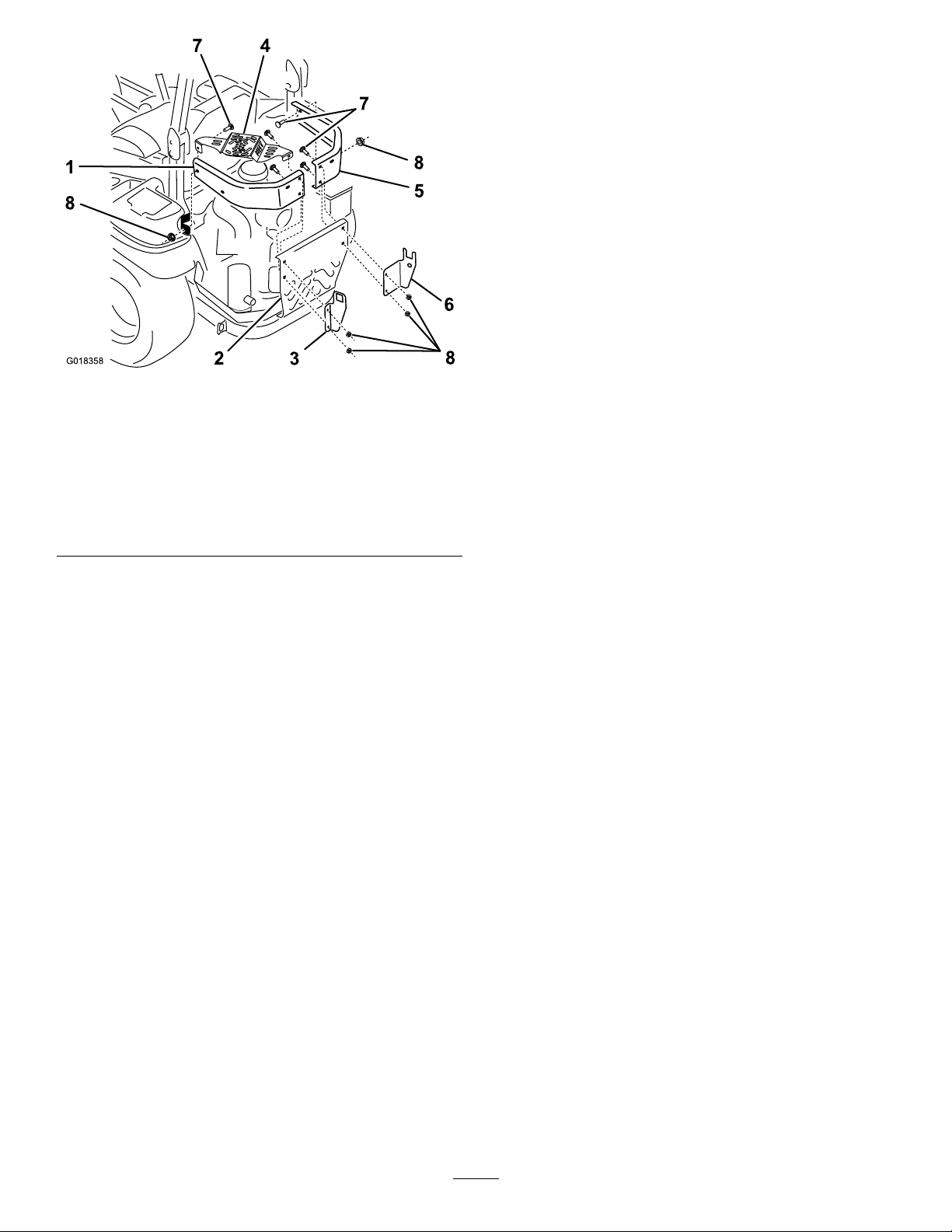

G018372

InstallingtheTailpipe

Extension

Partsneededforthisprocedure:

1Tailpipeextension

1

Washer-headscrew(#8x1/2inch,self-threading)

Procedure

Installthetailpipeextensionasfollows:

1.Locatethemufertailpipeatthelowerleftcornerof

theengine.

Note:Ifyouneedadditionalroomtoinstallthe

tailpipeextension,dothefollowingsteps:

A.Removethe3angenutsthatsecurelower-left

engineguardtothemachine(Figure5).

Note:Retaintheseparts.

Figure5

1.Lower-leftengineguard

(USdomesticmowers)

2.Lower-leftengineguard

(Internationalmowers)

3.Carriagebolt(frontmount

point)

Lower-LeftEngineGuard

4.Flangenut

5.Carriagebolt(center

engineguard)

6.Mufertailpipe

B.Removethe2carriageboltsatthefront-mount

2.Measure19mm(3/4inch)alongtheoutsideofthe

pointandthelower-leftengineguard.(Figure5).

Note:Retaintheseparts.Donotremovethe

carriageboltatthecenterengineguard.

mufertailpipe,fromtheoutletendmovingtowardthe

muferasillustratedinFigure6,andmarkthesurface

ofthetailpipeatthismeasurement.

8

Page 9

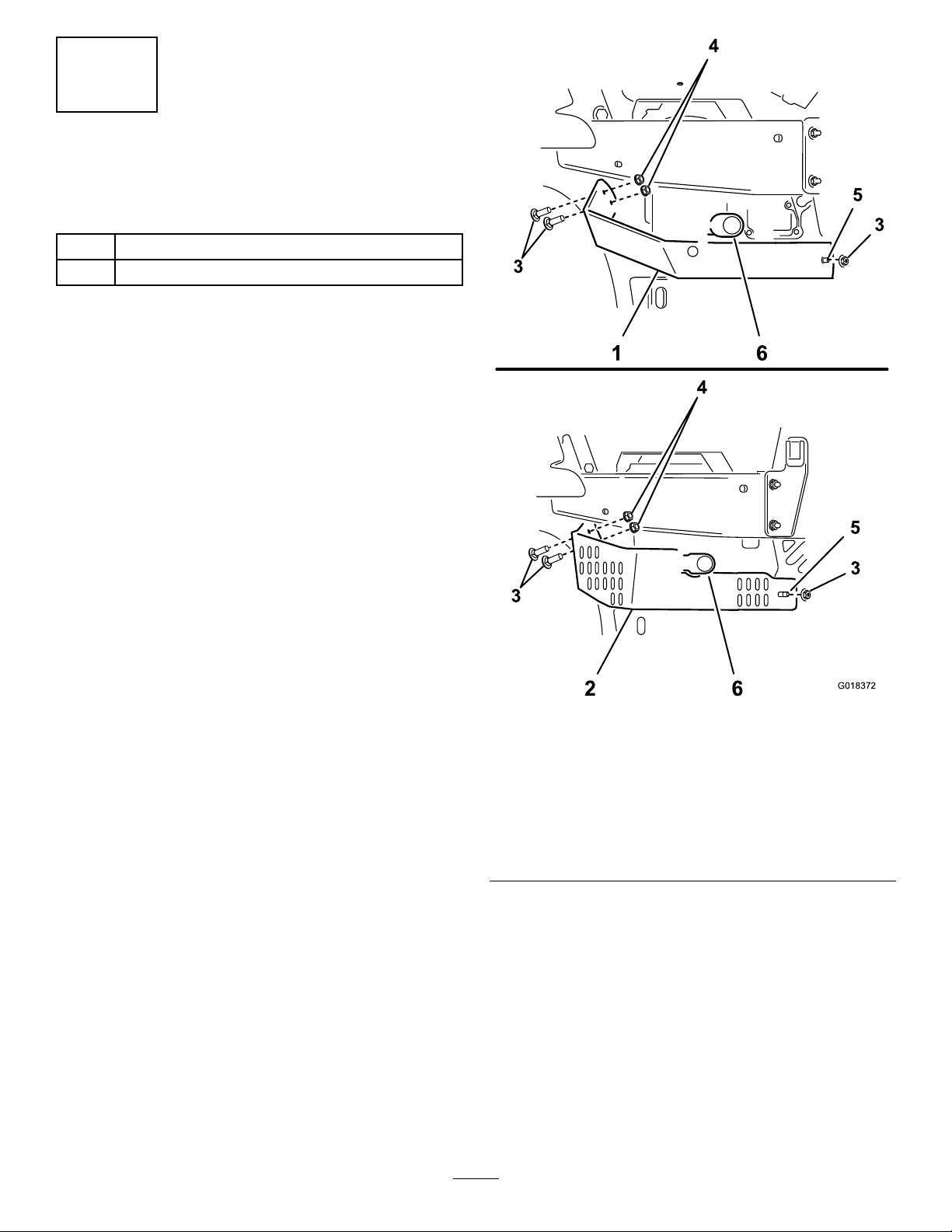

G018366

1

2

3

4

3

4

1

8.Securethetailpipeextensionwiththeself-threading

screw(#8x1/2inch)(Figure6).

Note:Dothefollowingstepstoinstalltheengine

guardifremovedinstep1:

A.Aligntheholesintheguardwithbacksideofthe

front-mountingpointandthecenterengineguard

(Figure5).

B.Looselysecurethelowerengineguardtothe

carriageboltatthecenterengineguardwithone

ofthepreviouslyretainedangenuts(Figure5).

C.Securethelowerengineguardtothefront

mountingpointwiththepreviouslyretained

carriageboltsandangenuts(Figure5).

D.Tightenallthemountinghardwaretosecurethe

lower-leftengineguard.

4

DrillingtheExhaust-Shield

Figure6

TailpipeExtensionInstallation

1.Mufertailpipe

2.3/4inch(19mm)4.Washerheadscrew(#8x

3.Slipthepre-drilledendofthetailpipeextensionover

themufertailpipe,andaligntheendoftheextension

withthemarkcreatedinstep2.Rotatethetailpipe

extensionuntilthepre-drilledholeintheextensionis

alignedoutwardandhorizontal(Figure6).

4.Marktheoutlineoftheholeinthetailpipeextension

ontothemufertailpipe,andremovethetailpipe

extension.

5.Locatethecenterofthemarkonthemufertailpipe

surface,andcenter-punchthelocation.

6.Drilla1.5mm(1/16inch)holeinthemufertailpipe

atthecenter-punchmark.

7.Slipthetailpipeextensiononthemufertailpipeand

aligntheholes.

3.Tailpipeextension

1/2inch,self-threading)

MountingHoles

Partsneededforthisprocedure:

1Exhaustshield

2

Flange-hex-headbolt(3/8x1inch)

2

Nut(3/8inch)

Procedure

Note:Iftheexhaust-shieldmountingholesarepresentin

thelower-leftengineguard,skiptotheinstructionsinsection

5InstallingtheExhaustShield(page11).

Note:Installthetailpipeextensionandthelower-leftengine

guardbeforeinstallingtheexhaust-heatshield.

Drilltheholesinthelower-leftbumperholesfortheexhaust

shieldasfollows:

1.Locatethemufertailpipeandtailpipeextensionatthe

left-rearcorneroftheengine,andlocatethelower-left

engineguard.

2.Aligntheexhaustshieldtothelower-leftengineguard

asfollows:

A.Centerthearchedpartoftheshieldtothetailpipe

extension.

B.Locateandmarktheheat-shieldmountingholes

asfollows:

•ForDomestic(US)Mowers

9

Page 10

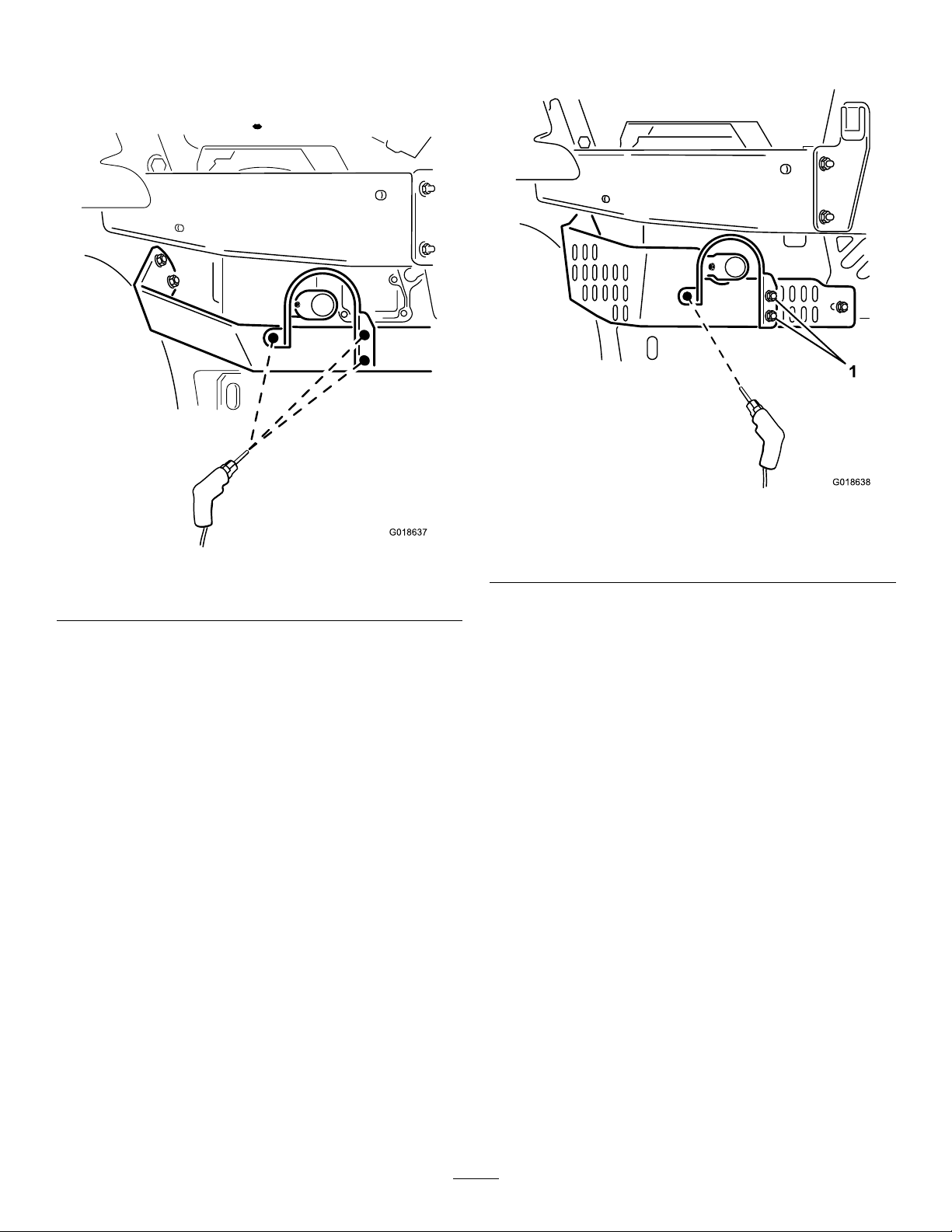

i.Aligntherightangeoftheexhaust

G018637

G018638

1

shield(theangewith2holes)tothe

rearsurfaceofthelower-leftengine

guard(Figure7).

tothetwoleft-most-verticalslotsin

thelower-leftengineguard(Figure8).

Figure7

HeatShieldInstallationonUSDomesticMower

ii.Alignthebottomedgeofthe

exhaust-shieldrightangetothe

bottomedgeoftheengineguard

(Figure7).

iii.Aligntheleftangeoftheexhaust

shield(theangewith1hole)tothe

surfaceofthesmall,angularareaof

thelower-leftengineguard.(Figure7).

Note:Ensuretheleftange(the

angewith1hole)oftheexhaust

shieldisushwiththeengine-guard

surface.

iv .Alignthetopedgeofthe

exhaust-shieldleftangeand

thetopedgeofthelower-leftengine

guardsothattheangeedgeandthe

guardedgeareparallel(Figure7).

v.Marktheoutlineofallholesinthe

exhaust-shieldangesontothe

lower-leftengineguard,andremove

theexhaustshieldfromtheengine

guard.

•ForInternational(TE)Mowers

i.Aligntheholesoftheexhaust-shield

rightange(theangewith2holes)

Figure8

HeatShieldInstallationonInternational(TE)Mower

1.Flange-hex-headbolt(3/8x1inch)andNut(3/8inch)

ii.Alignthebottomedgeoftheright

angeoftheoftheexhaustshieldto

thebottomedgeoftheengineguard

(Figure8).

iii.Looselysecuretherightangeofthe

exhaustshieldtotheengineguard

with2ange-hex-headbolts(3/8x1

inch)and2angenuts(3/8inch).

iv .Aligntheleftangeoftheexhaust

shield(theangewith1hole)to

angularareaofthelower-leftengine

guard(Figure8).

Note:Ensurethattheleftange

(theangewith1hole)oftheexhaust

shieldisushwiththeengine-guard

surface.

v.Marktheoutlineoftheholeintheleft

angeoftheexhaustshieldontothe

lower-leftengineguard.

vi.Removethefastenersandexhaust

shieldfromtheengineguard.

3.Locatethecenterofthemarksonthelower-left

engine-guardsurface,andcenter-punchthelocations.

4.Drilla10mm(3/8inch)holeintheengineguardat

thecenter-punchmarkcreatedinstep3.

10

Page 11

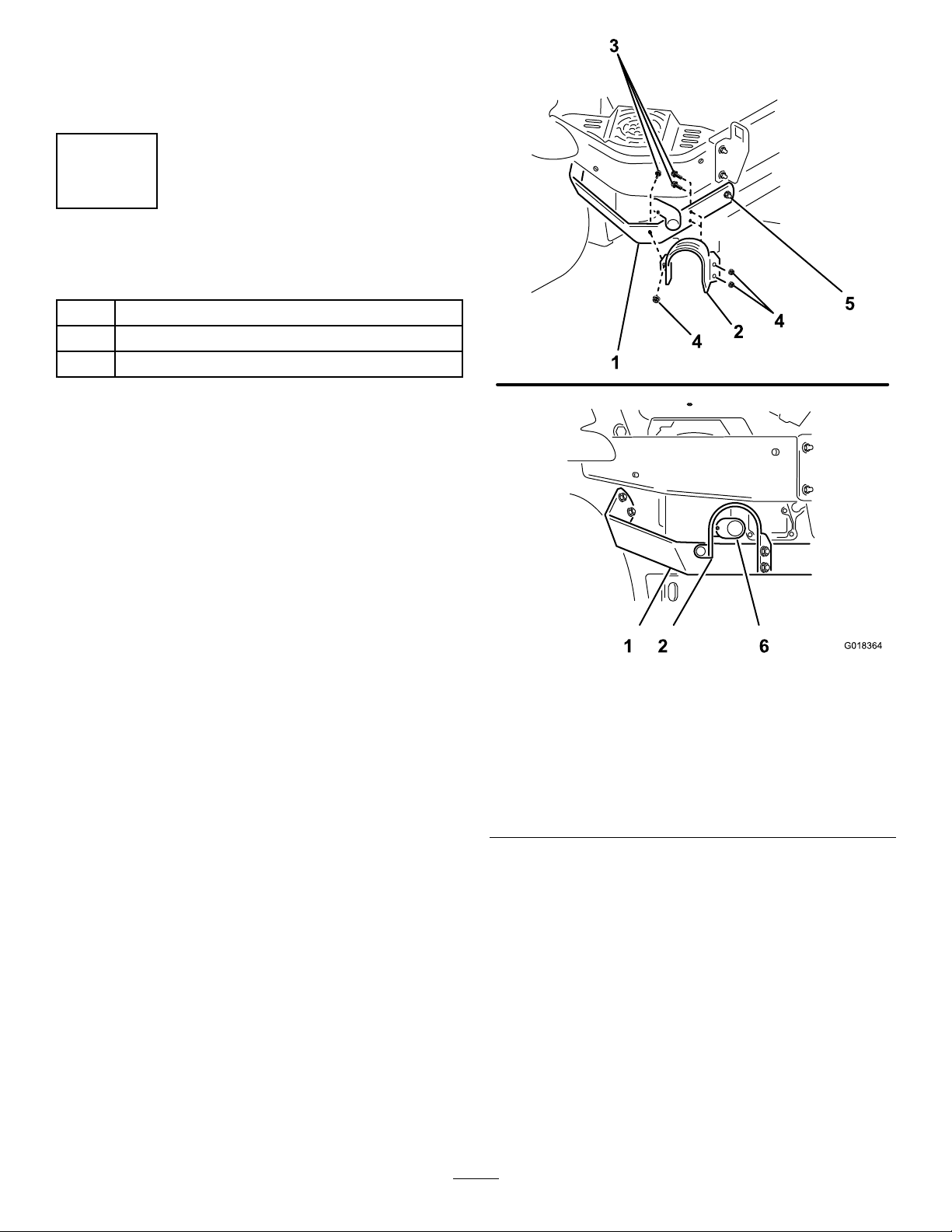

Important:Ensurethatthedrillbitdoes

G018364

621

1

2

3

4

4

5

notcontactthemuferwhendrillingthe

heat-shield-mountingholeinthelower-leftengine

guard.

5

InstallingtheExhaustShield

Partsneededforthisprocedure:

1Exhaustshield

3

Flange-hex-headbolt(3/8x1inch)

3

Nut(3/8inch)

Procedure

Installtheexhaustguardonthelower-leftbumperasfollows:

1.Aligntheholeoftheexhaust-guardleftangetothe

holeinthesmall,angularareaoftheengineguardas

illustratedinFigure9forDomestic(US)mowersor

inFigure10forInternational(TE)mowers.

Figure9

Heat-ShieldInstallationonUSDomesticMower

1.Lower-leftengineguard4.Nut(3/8inch)

2.Exhaustshield

3.Flange-hex-headbolt(3/8

x1inch)

5.Flangenut(lower-left

engineguard,

back-mountingpoint)

6.Tailpipeextension

11

Page 12

G018365

1

2

3

4

4

5

1 2 6

6

g018359

5

1

4

3

6

2

InstallingtheHopperSupport FrameandHoodRod

Partsneededforthisprocedure:

1

Hopper-supportframe

2Hairpin

1Hoodhold-downrod

Procedure

Installthehopper-supportframeasfollows:

1.Alignthehopper-supportframesothatthe2

keyed-hoodpinsonthetopoftheframearepointing

totheright,andthemountingpinonthebottomof

theframeispointingtotheleftasshowninFigure11.

Figure10

Heat-ShieldInstallationonInternational(TE)Mower

1.Lower-leftengineguard4.Nut(3/8inch)

2.Exhaustshield

3.Flange-hex-headbolt(3/8

x1inch)

2.ForDomestic(US)Mowers,aligntheholesinthe

rightangeoftheexhaustguardwiththeholesinthe

backofthelower-leftbumper(Figure9).

5.Flangenut(lower-left

engineguard,

back-mountingpoint)

6.Tailpipeextension

ForInternational(TE)Mowers,aligntheholes

intherightangeoftheexhaustguardwiththe2

left-most-verticalslotsinthebackofthelower-left

engineguard(Figure10).

3.Securetheheatshieldtotheengineguardwiththe3

ange-hex-headbolts(3/8x1inch)and3angenuts

(3/8inch)(Figure9forUSDomestic(US)mowers

orFigure10forInternational(TE)mowers.)

Figure11

Hopper-SupportFrameInstallation

1.Hopper-supportframe4.Leftframe-supportbracket

2.Keyed-hoodpins

3.Mountingpin6.Hairpin

2.Insertthehopper-supportframeintothesquare-shaped

openingoftheleftframe-supportbracket(Figure11).

3.Alignthemountingpintotherightoftheright

frame-supportbracket(Figure11).

4.LowertheframebetweentheU-shapetabsoftheof

therightbracket(Figure11).

5.Rightframe-support

bracket

12

Page 13

5.Slidethehopper-supportframetotheleftuntilthe

g018360

1

2

3

4

G018355

1

2

3

4

5

6

mountingpinpassesthroughtheholeintheright

frame-supportbracket(Figure11).

Note:Thehopper-supportframeandthe

frame-supportbracketsareacloset.Ifnecessary,

useasoft-facedmallettopositionthehopper-frame

supportintheframebrackets.

6.Installthehairpinthroughtheholeofthemounting

pintosecuretheframetothebracket(Figure11).

Installthehoodrodasfollows:

1.Alignthehoodrodsothatthestopangeistowardthe

hopper-supportframe(Figure12).

7

InstallingtheHoodBafe

Partsneededforthisprocedure:

1Baggerhood

1

Bafe

2

Hairpin(small)

InstalltheBafeintheBaggerHood

1.Removeandretainthehairpinsfromthebafe.

2.Locatethebafeslotsinthefrontandbacksidewalls

ofthebaggerhood,andthemountingtabsonthe

hoodbafe(Figure13).

Figure12

HoodRodInstallation

1.Hoodrod

2.Stopange

2.Inserttherodthroughtheholeinthehopper-support

frameuntilthestopangeisagainstthebacksideof

theframe(Figure12).

Note:Ensurethattheholeinthehoodrodis

extendingbeyondtheforwardsideofthehopper-frame

hole.

3.Securethehoodrodtothesupportframebyinserting

thehairpinthroughtheholeinthehoodrod(Figure

12).

3.Hopper-supportframe

4.Hairpin

Figure13

Hood,Bafe,andHairpin

1.Hairpin

2.BaggerHood

3.Bafe-mountingtab

3.Positionthehoodsothattheductsealisonyourleft,

asillustratedinFigure13.

4.Alignthebafesothatthescreenedareaisupand

angledleft(Figure13).

5.Insertthebafeupintothehoodfromthebottom

(Figure13).

4.Bafeslot

5.Bafe

6.Ductseal

13

Page 14

6.Alignthebafe-mountingtabswiththebafeslotsin

g018354

1

2 3 4

6

5

1

2

3

G018608

thehood,andpushthemountingtabsupandthrough

theslots(Figure13).

7.Securethebafetothehoodbyinsertingthehairpins

intotheholesinthebafe-mountingtabsasshown

inFigure14.

Figure15

Air-CleanerCoverRemoval

1.Air-cleanercover3.Air-cleanerlatch

2.Breathervalve

2.Pulltheair-lter-coverbackandremovetheair-lter

cover.

1.Hairpin

2.Baggerhood

3.Bafe-mountingtab

8

InstallingtheHoodAssembly andBags

Partsneededforthisprocedure:

1Hoodassembly

2Bag

BaggerHoodAssembly

Figure14

4.Bafeslot

5.Bafe

6.Ductseal

Installthehoodassemblyasfollows:

1.Onthehood,locatethekeyholeslotintheleftand

right-hoodbrackets(Figure16).

2.Onthehopper-supportframe,locatethe2keyedpins

atthepivotbracketsonthetopofthehopper-support

frame(Figure16).

Procedure

Removetheair-cleanercoverasfollows:

1.Openthe2latchesthatsecuretheair-ltercovertothe

air-lterhousing(Figure15).

14

Page 15

5

2

4

G018361

1

3

1.Positiontheair-cleanercoversothatthebreathervalve

1

3

2

3

G018610

islocatedatapproximately5o’clock(Figure17).

1.Air-cleanercover3.Air-cleanerlatch

1.Hood4.Pivotbracketwith

2.Hoodbracketwithkeyhole

slot

3.Hopper-supportframe

Figure16

HoodInstallation

keyed-pivotpin

5.Hoodinstalled

2.Breathervalve

2.Securethelatches(Figure15).

Installthebagassembliesontothehopper-supportframe

asfollows:

1.Raisethehoodtoexposethenotched-bagbracketson

Figure17

Air-CleanerCover

thehopper-supportframeasshowninFigure18.

3.Rotatethehoodsothatthekeyholeslotisup,andalign

thehoodtotherightofthekeyed-pivotpins(Figure

16).

4.Assemblethehoodtothehopperframebyslidingthe

keyholebracketsoverthekeyedpins(Figure16).

5.Rotatethehooddowntosecurethehoodtothe

hopper-supportframeasshowninFigure16.

Installtheair-cleanercoverasfollows:

Note:Ensurethattheprimaryairlterisfullyseatedby

pushingonitsouterrim.

Important:Donotpressonthesoftinsideareaofthe

lter

15

Page 16

G018362

1

2

3

5

4

BagInstallation

g018363

1

2

3

G018368

1

2

3

4

Figure18

Figure19

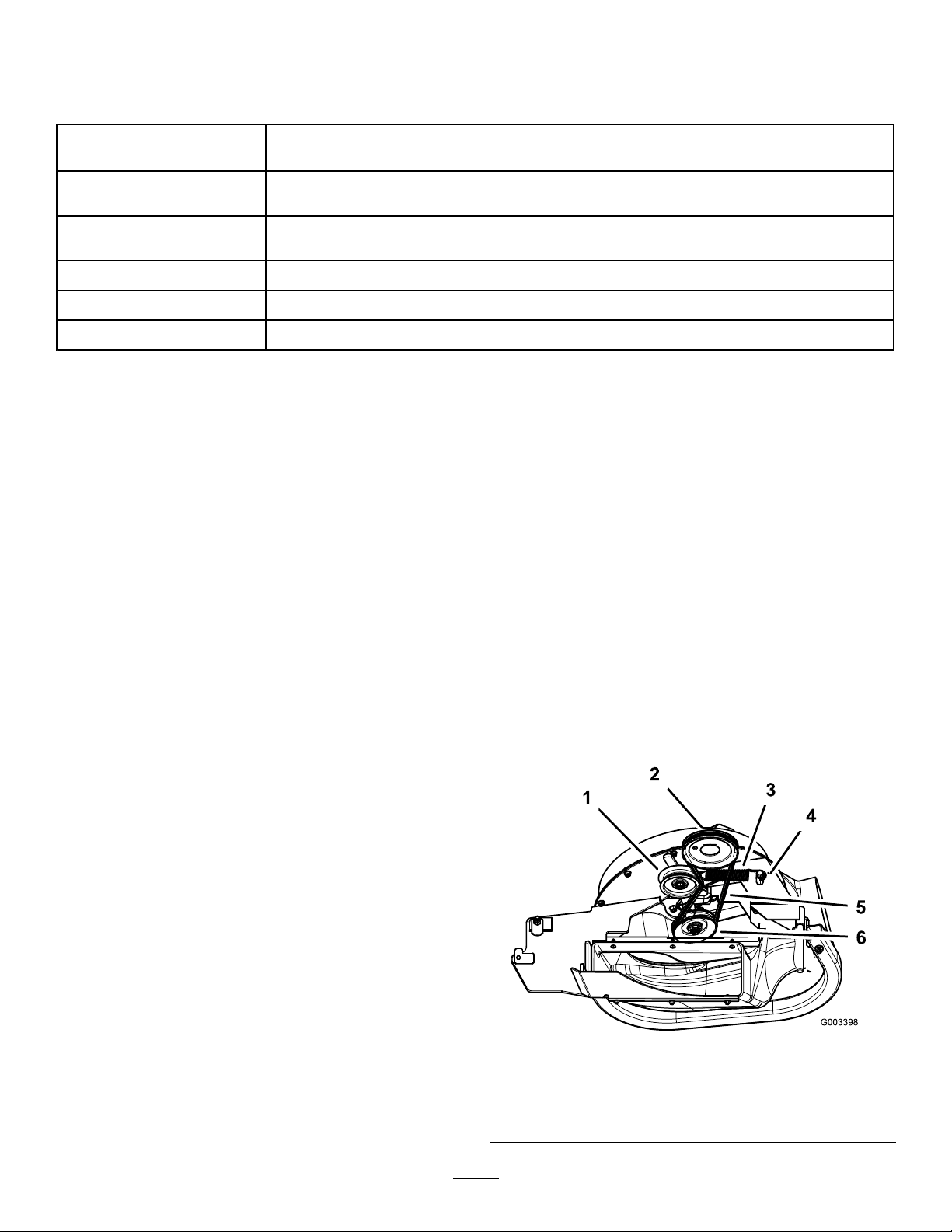

9

RoutingtheBlowerBeltinto theBlowerAssembly

Partsneededforthisprocedure:

1

Blower(fromthebloweranddrivekit)

1

Blowerbelt(fromthebloweranddrivekit)

1.Hood4.Mounttab

2.Notched-bagbracket5.Bag

3.Hopper-supportframe

2.Alignthemounttabofthebagassemblywiththe

notched-bagbracket(Figure18).

3.Lowerthebagassemblyuntilthebagtabisfullyseated

intothenotchedbracket(Figure18).

4.Repeatsteps1and2fortheotherbag(Figure18).

5.Lowerthebaggerhoodoverthebags(Figure18).

6.Aligntheholeinthehoodlatchwiththehood

hold-downrod.(Figure19).

7.Pushthehoodlatchforwarduntiltheendofthehood

rodhaspassedthroughlatchasshowninFigure19.

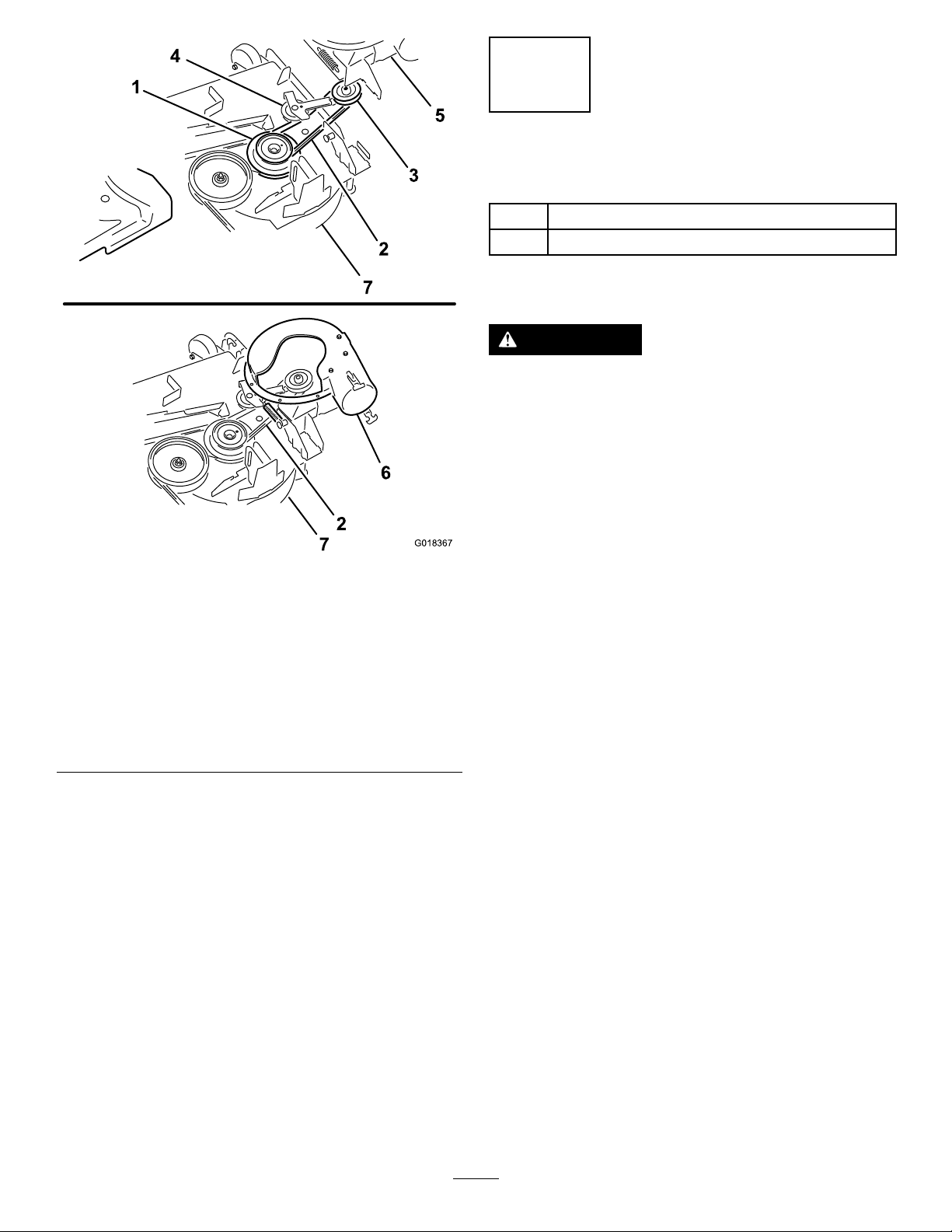

Procedure

1.Installthebeltaroundtheblowerpulley(Figure20and

Figure21).

Figure20

BlowerBeltRouting

1.Drivepulley3.Blowerpulley

2.Blowerbelt

4.Idler/tensionpulley

16

Page 17

G018367

1

2

3

2

4

6

5

7

7

Figure21

BlowerBeltRouting

1.Drivepulley

2.Blowerbelt

3.Blowerpulley7.Mowerdeck

4.Idler/tensionpulley

5.Blower(housing

repositionedforillustrative

purposes)

6.Blowerinposition(housing

portionremovedfor

illustrativepurposes)

2.Ensurethatthebeltremainsalignedtotheblower

pulleywhileyouareinstallingtheblowerassembly.

10

InstallingtheBlowerAssembly

Partsneededforthisprocedure:

1

Blowerassembly(fromthebloweranddrivekit)

1

Spring(fromthebloweranddrivekit)

Procedure

WARNING

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectstowardyouor

bystanders,resultinginseriousinjury.Also,contact

withthebladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

•Ensurethatthegrassdeectorisinstalledwhen

youremovethegrasschuteandcatcher.

Removetheside-dischargechuteasfollows:

Important:Installtheside-dischargechutewhenyou

removethebaggerandblower.

Important:Saveallthehardwareandtheside-discharge

chute.

1.Removethelocknut,bolt,spacer,andspringthatsecure

theside-dischargechutetothemowerdeck(Figure22).

Note:Retaintheremovedhardware.

2.Removethesidedischargechutefromthemowerdeck.

Note:Retainthechute.

17

Page 18

g015594

1

6 2

4

7

3

5

Figure22

4

3

2

1

G018369

G018370

1

2

3

3

4

5

7

6

4

4.Movethelatchpinfromthelockingpositiontothe

openposition(Figure24).

1.Bolt

2.Spacer6.Grassdeector

3.Locknut

4.Spring

5.Springinstalled

7.Jhookendofspring

Installtheblowerassemblyasfollows:

1.Removetheoriginalright-handbeltcoverfromthe

mowerdeck.

Note:Retaintheoriginalbeltcoverforinstallation

whenyouoperatethemowerwiththebagging-kit

blowerremoved.

2.Alignthepivotpinontheblowerwiththepivot-pin

holeinthedeck(Figure23).

3.Lowertheblowerandslidethepivotpinintothepivot

hole(Figure23).

Note:Ensurethatthebeltremainspositionedinthe

blowerpulley .

Figure24

SecuringtheBlowertotheChuteBracket

1.Blowerassembly5.Idlerpivotbracket

2.Latchpin(lockingposition)

3.Latchpin(openposition)7.Belt(beneaththeidler

4.Chutebracket

6.Idlerpulley

pulley)

5.Closetheblowerassemblyandalignthelatchpinwith

theholeinthechutebracket.

6.Movethelatchpintothelockingposition(Figure25).

Note:Ensurethatthelatchpinextendsthroughthe

holeinchutebracket.

Figure23

InstallingBlowertoDeckPivotHole

1.Blowerassembly3.Pivothole

2.Deck4.Blower-pivotpin

18

Page 19

g018371

1

2

3

9

6

8

4

7

5

11

G018445

3

2

1

4

InstallingtheBeltCover

Partsneededforthisprocedure:

1

Beltcover(fromthebloweranddrivekit)

1

Coverknob

Procedure

1.Lowerthemowerdecktothelowestheight-of-cut

position.

Figure25

InstallingtheT ensionSpringandAligningtheBelt

1.Blowerassembly

2.Latchpin(lockingposition)

3.Chutebracket8.Springhookend

4.Idlerpivotbracket

5.Fixedspringpost

Note:Ensurethatthelatchrmlyholdstheblower

assemblyagainstthemowerdeck,butcanbereleased

byhand.

7.Routethebeltaroundthedrivepulleyasillustratedin

Figure20andFigure21.

8.Temporarilyroutethebeltbeneaththeidlerpulley

(Figure25).

9.Movetheidlerpivotbrackettowardthexedspring

post.Installthespringbyaligningthespringhookon

totheidlerspringpost(Figure25).

Note:Ensurethatthespringhooksarecorrectly

positionedonthespringposts.

6.Spring

7.Idlerspringpost

9.Belt(alignedtotheidler

pulley)

2.Alignthenewright-handbeltcoverwiththebelt-cover

bracketandthenotchesinthedeckbracket.

3.Installthenewbeltcoversothatthenotchesonboth

sidesofthecovergooverthebelt-coversupportsand

securethelatch(Figure26).

10.Pullthespringloadedidlerpulleyawayfromthexed

springpost,androutethebeltaroundthemowerdeck

pulley(Figure25).

Note:Ensurethebeltisroutedaroundtheblower

pulleycorrectly.

Figure26

1.Beltcover

2.Belt-coversupport4.Notch

InstallingtheBeltCover

3.Coverknob

4.Securethenewbeltcovertothedeckbyinstallingthe

coverknobfromthebloweranddrivekitthroughthe

coverandthreadedintothebeltcoversupport(Figure

26).

19

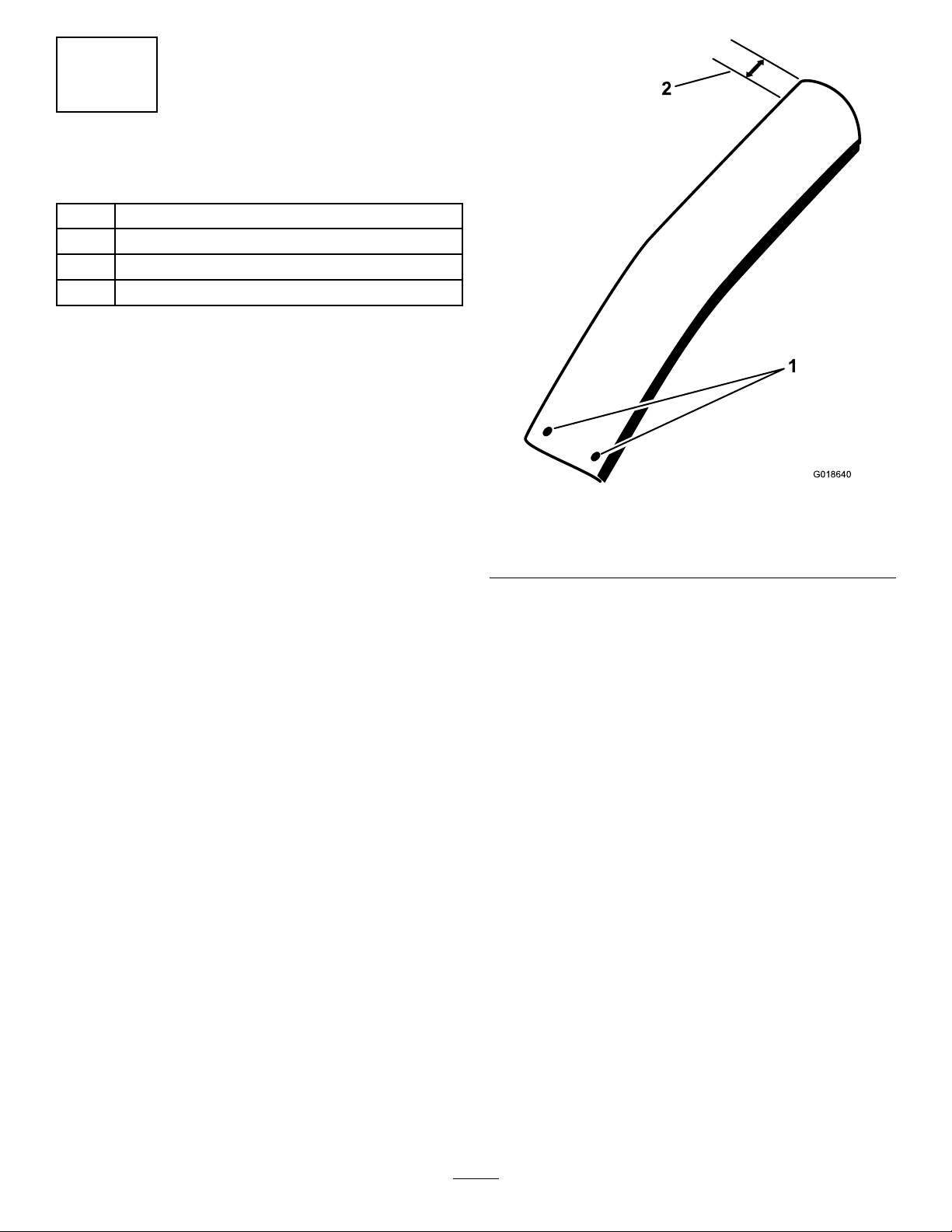

Page 20

12

G018640

2

1

InstallingtheDischargeTube

Partsneededforthisprocedure:

1Upperdischargetube

3

Screw(1/4x3/4inch)

3

Locknut(1/4inch)

1Lowerdischargetube

Procedure

Important:Ensurethatthemowerdeckisinthelowest

height-of-cutpositionbeforeinstallingthedischarge

tubes.

Note:Remembertoinstallthegrassdeectorwhenyou

removethebaggerfromthemower;refertoReplacingthe

GrassDeector(page30).

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lowerthemowerdecktothelowestheight-of-cut

position.

4.Removethebagsforviewingthetubeunderthehood.

5.Lowerandlatchthehoodforthehopper.

6.Forabaggerkitinstalledona52-inchmowerora

60-inchmower,skiptotheinstructionsforstep8.

7.Forabaggerkitinstalledona48-inchmower,cut

theupperdischargetubeasfollows:

A.Locatetheupperendoftheupperdischargetube

(Figure27).

Note:Thelowerendoftheupperdischargetube

haspre-drilledholes.

Figure27

UpperDischargeTube

1.Pre-drilledholes

B.Measure17.8cm(7inches)fromtheendofthe

tube,andmarkthetubeatthislocation(Figure

27).

C.Applymaskingtapearoundthecircumferenceof

theupperdischargetubealignedwiththemarkon

thetubecreatedinstepB(Figure27).

D.Usingtapeasaguide,carefullycutoffanddiscard

theexcesslengthoftube(Figure27).

8.Drilltheholesforthelowerdischargetubeasfollows:

A.Locatethewhitedotattheupperendofthelower

dischargetube.

B.Drillthelowerdischargetubewitha1/4inch(6.5

mm)drillbitatthecenter-punchmark(Figure28).

2.17.8cm(7inches)

20

Page 21

G018439

4

2

3

3

1

6

5

F.Usingtheremainingholesinthelowerendofthe

G018440

1

2

3

uppertubeasatemplate,drillthe2remaining

holesintheupperendofthelowerdischargetube

(Figure28).

G.Removethescrewusedtoaligntheupperand

lowertubes.

9.Installtheupperandlowerdischargetubesasfollows:

Note:Ensurethatthemowerdeckisatthelowest

cuttingpositionandthehopperbagsareremoved.

A.Inserttheupperend(noholes)oftheupper

dischargetubethroughthetubesealinthehood

bypushingthetubeinuntilthetubecontactsthe

insideofthehood,thenpullthetubeoutslightly

sothatthesealextendsoutward(Figure29).

Figure29

UpperDischargeTubeandBaggerHood

Figure28

DrillingLowerDischargeTube

1.Whitedot4.Upperdischargetube

2.Lowerdischargetube

3.Drill6.5mm(1/4inch)

diameterhole

5.Screw(1/4x3/4inch)

6.Upperdischarge-tubehole

1.Uppertube3.Baggerhood

2.Rubbersealprotrudingout

B.Alignlowerendofthelowerdischargetubewith

theblower-dischargeport.

C.Alignthenotchinthelowerdischargetubeto

lowerlatchadjacenttotheblower-dischargeport.

D.Slipthedischargetubeontheblowerportand

C.Removeandretainthehardwareinthelowerend

oftheupperdischargetube.

Note:Theholesinthelowerendoftheupper

attachthelatches.

E.Sliptheupperandlowerdischargetubestogether

(Figure30).

dischargetubearespacedanequaldistance

aroundthetubecircumference.

D.Alignoneofthepre-drilledholesatthelowerend

oftheupperdischargetubewiththeholeinthe

upperendofthelowerdischargetubethatwas

drilledinstepB(Figure28).

E.Insertascrew(1/4x3/4inches)throughoneof

theholestomaintainthealignmentoftheupper

andlowertubes(Figure28).

21

Page 22

5

G018442

3

4

1

2

3

1.Upperdischargetube

4

4

5

G01861 1

1

2

3

2.Lowerdischargetube

3.Tape(marker)

F.Rotatetheuppertubesothattheendinthehood

Figure30

TapeMarkingtheAlignedHoles

4.Hole(1/4inch)

5.Screw(1/4x3/4inches)

pointstowardsthecenterofthehood(Figure30).

Note:Thepartinglinesonthetubewillbe

approximatelyhorizontalatthehoodseal(Figure

31).

Figure31

UpperDischargeTubeandBaggerHood

1.Lowerdischargetube4.Partingline

2.Upperdischargetube

3.Baggerhood

5.Projectingendofupper

dischargetube

G.Whilemaintainingtheapproximatepositionof

theupperdischargetube,aligntheholesinthe

upperandlowerduct(Figure30).

H.Insertascrew(1/4x3/4inch)throughoneofthe

holestomaintainthealignmentoftheupperand

lowertubes(Figure30).

I.Markeachtubeontheareaadjacenttothescrew

withapieceoftape(Figure30).

Note:Accomplishmeasurementandmarking

theupperdischargetubewiththehoodclosed

andaccessedfrombeneaththehood.

J.Withthedeckinthelowestpositionandthehood

closed,lookunderneaththehoodandmeasure

thelengthoftheupperdischargetubeprotruding

intothehopper.Ifthedischargetubeextends

morethan7.6cm(3inches),removetheexcess

tubelength(Figure33).

22

Page 23

G018443

2

1 3

UpperDischargeTubeMeasurement

3

G018444

1

2

Figure32

1.7.6cm(3inches)

2.Excesstubelength

Ifnecessary,shortentheupperdischargeductas

follows:

i.Measure7.6cm(3inches)alongtheupper

dischargetubefromthetubesealtoward

theendofthetubeandmarkthetubeat

thislocation(Figure32).

ii.Removethescrewthatisaligningthe

upperandlowerdischargetubes,and

removeuppertubefromthehoodandthe

lowertubefromtheblower.

i.Applymaskingtapearoundthe

circumferenceoftheupperdischargetube

alignedwiththemarkonthetubecreated

instepi(Figure32).

ii.Usingtapeasaguide,carefullycutoffand

discardtheexcesslengthoftube.

K.Locatethetapemarkingtheholesonthelower

andupperdischargetubesappliedinstepI.

3.Tubeseal

Figure33

LowerDischargeTubeLatch

10.Unlatchthehood,installthehopperbags,andlatchthe

hood(Figure18andFigure19);referto8Installingthe

HoodAssemblyandBags(page14).

13

L.Slipthetubestogetherandaligntheholesmarked

withthetape(Figure30).

M.Securethetubesatalltheholeswiththescrews

(1/4x3/4inch)andlocknuts(1/4inch)(Figure

30).

N.Inserttheupperdischargetubethroughthetube

sealinthehoodbypushingthetubeinuntilthe

tubecontactstheinsideofthehood(Figure29).

O.Pullthetubeoutslightlysothatthesealis

extendedoutward(Figure29).

P .Sliplowerendofthelowerdischargetubeover

theblowerdischargeport,andalignthenotchin

thetubewiththelowerlatch,andsecurethelower

dischargetubethelatches(Figure33).

InstallingtheWeights

Partsneededforthisprocedure:

1Weight-mountbracket

2

Carriagebolt(5/16x3/4inch)

2

Flangenut(5/16inch)

3Frontweight

6

Bolt(3/8x1inch)

6Lockwasher

6Flatwasher

3

Flangenut(3/8inch)

Procedure

InstalltheweightstocomplywithANSI/OPEI

B71.4-2012Standard.

23

Page 24

CAUTION

Thebaggeraddsweighttotherearofthemachine

andmaycauseanunstableconditionwhichcould

resultinalossofcontrol.

1.Installtheweight-mountbracketunderthefootrest

with2carriagebolts(5/16x3/4inch)and2ange

nuts(5/16inch).

Figure34

1.Carriagebolt(5/16x3/4

inch)

2.Weight-mountbracket

3.Flangenut(5/16inch)

1.Frontweight

2.Flatwasher

3.Lockwasher

Figure35

4.Bolt(3/8x1inch)

5.Holeinfootrest

6.Flangenut(3/8inch)

2.Installthefrontweightsontopofthefootrest(Figure

35).

3.Securethefrontweightsontopofthefootrestandto

theweight-mountbracketwith6bolts(3/8x1inch),

6lockwashers,6atwashers,and3angenuts(3/8

inch)(Figure35).

Figure36

1.Weight-mountbracket3.Lockwasher

2.Flatwasher

4.Bolt(3/8x1inch)

24

Page 25

Operation

14

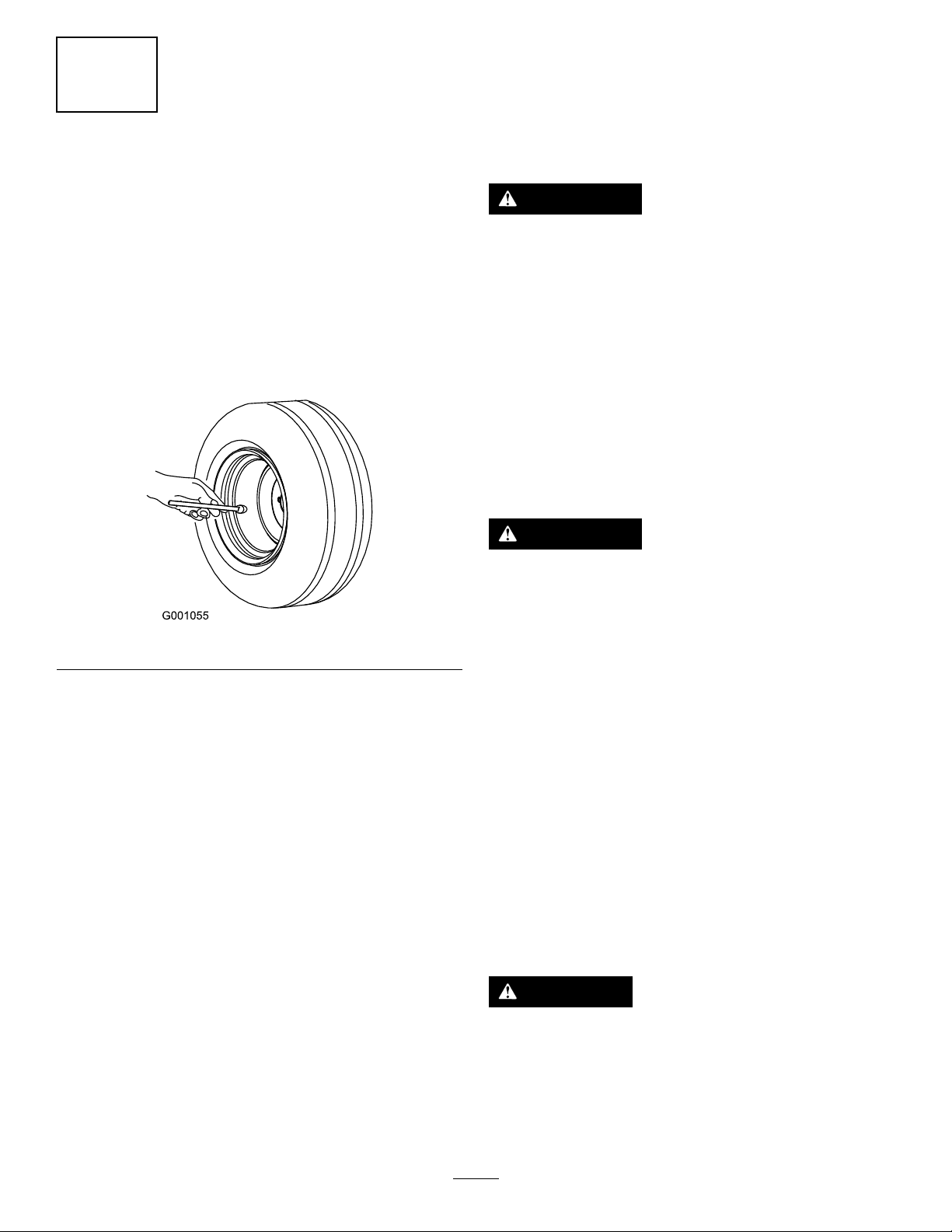

CheckingtheTirePressure

NoPartsRequired

Procedure

Note:Increasethetirepressureduetotheadditionalweight.

Checkandincreasetheairpressureinthefrontcasterwheels

andreartires(Figure37).

Pressureinthereartires:138kPa(20psi)

Pressureinthefrontcasterwheels:172kPa(25psi)

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Settheparkingbrakewhenleavingthe

machineunattended,evenifjustforafewminutes.

WARNING

Toavoidpersonalinjury,followtheseprocedures:

•Becomefamiliarwithalloperatingandsafety

instructionsinthe

mowerbeforeusingthisattachment.

•Neverremovethebaggerorbaggertubeswhile

theengineisrunning.

•Alwaysshutofftheengineandwaitforall

movingpartstostopbeforeclearingan

obstructionfromthebaggingsystem.

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

•Settheparkingbrake.

Operator's Man ual

foryour

WARNING

Figure37

Withoutthegrassdeector,baggertubes,ora

completebaggerassemblymountedinplace,you

andothersareexposedtobladecontactandthrown

debris.Contactwiththerotatingmowerblade(s)

andthrowndebriswillcauseinjuryordeath.

•Alwaysinstallthegrassdeectorwhenremoving

thebaggerandchangingtoside-discharge

mode.

•Ifthegrassdeectoriseverdamaged,replaceit

immediately.Thegrassdeectorroutesmaterial

downtowardtheturf.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff(PTO)

toOFF,shutofftheengine,andremovethekey.

Disconnectthesparkplug(s)wires.

•Shutofftheenginebeforeuncloggingthe

dischargechute.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

25

Page 26

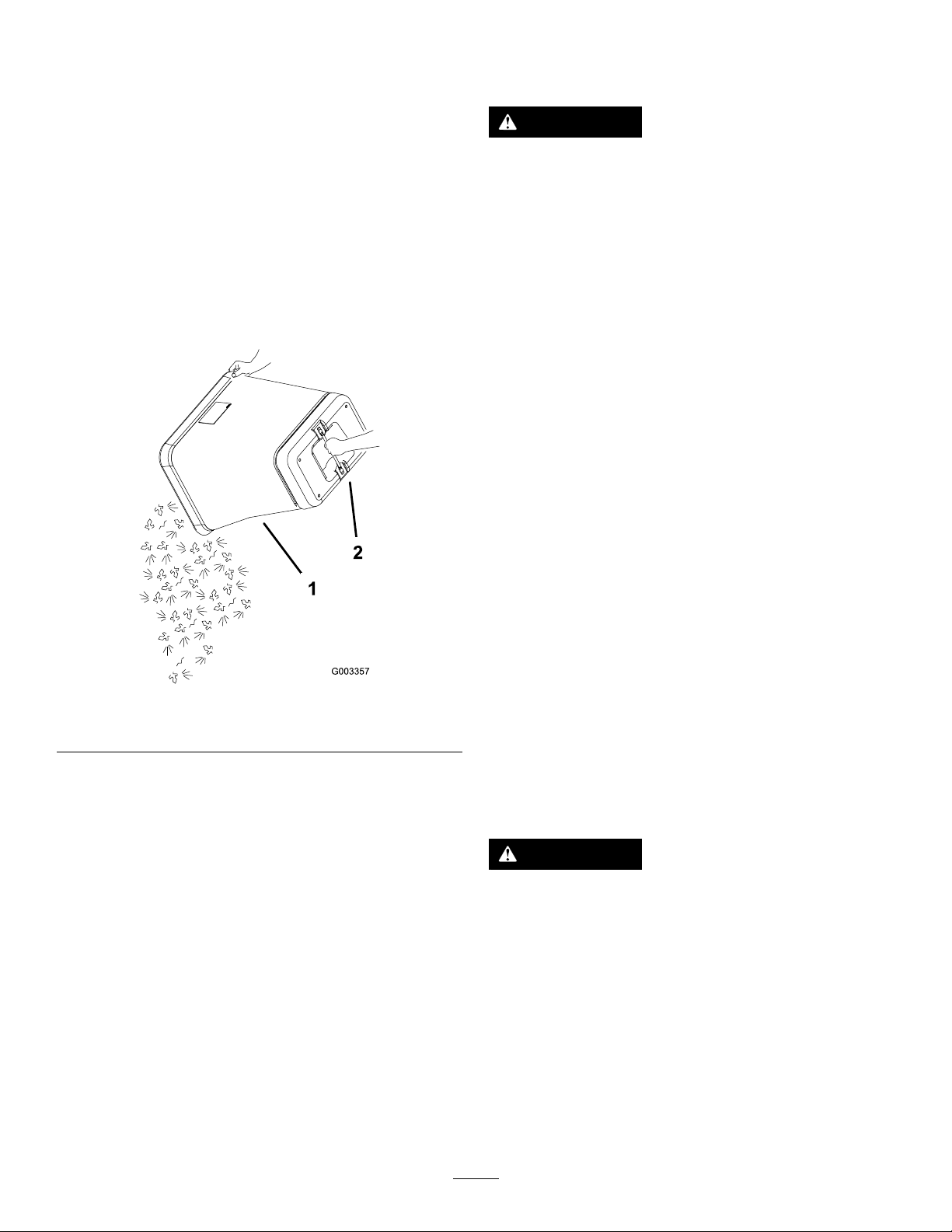

EmptyingtheGrassBags

ClearingObstructionsfrom

Grassbagsareheavywhenfull.Becarefulwhenliftingor

handlingagrassbagthatisfull.

1.DisengagethePTO,settheparkingbrake,andchock

orblockthetiresifthemachineisonaslope.

2.Unlatchthebaggerlatch.

3.Openthebaggerhood.

4.Compressthedebrisintothebags.

5.Usebothhandstoliftuponthebagandunhookit

fromthebaggerbracket.

6.Grabthehandleonthebottomofthebagandtipit

overtoemptythebag(Figure38).

theBaggerSystem

WARNING

Whenthebaggerisinoperation,theblowercanbe

rotatingandcutofforinjurehands.

•Beforeadjusting,cleaning,repairingand

inspectingtheblower,andbeforeunclogging

thechute,shutofftheengine,andwaitforall

movingpartstostop.Removethekey .

•Useastick,notyourhands,toremovean

obstructionfromtheblowerandtube.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Emptythebags.

4.Unlatchthelowertube.

5.Removethetubesfromthebagger.

6.Useastickorsimilarobject,notyourhands,toremove

andcleartheobstructionfromthetubeassembly .

Figure38

1.Bag2.Bottomhandle

7.Repeatstep5andstep6theotherbag.

8.Installthebagtabofeachbagintothenotchinthe

bagger-supportframe.

9.Lowerthebaggerhoodoverthebags.

10.Latchthebaggerhood.

Note:Inmostcases,youcanshakethedebrisoutof

thetubes.

7.Iftheblowerassemblyisplugged,unlatchthebagger

blowerassembly,removethebelt,andswingitopen.

8.Useastickorsimilarobject,notyourhands,toremove

andcleartheobstructionfromtheblowerassembly.

9.Afteryouremovetheobstruction,installthecomplete

baggersystemandresumeoperation.

RemovingtheBagger

WARNING

Componentsaroundenginewillbehotifthe

machinehasbeenrunning.Touchinghot

componentscancauseburns.

•Donottouchenginecomponentswhenhot.

•Allowenginetocoolbeforeremovingthebagger.

1.DisengagethePTO,settheparkingbrake,andchock

orblockthetires.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchthelowertubefromtheblowerandremove

thetubefromtheblowerassembly.

26

Page 27

4.Removethetubefromthebaggerhood.

5.Lowerthemowerdecktothelowestheight-of-cut

position.

OperatingTips

MachineSize

6.Removetheknobandthebeltcoveroverthemower

pulleyassembly.

7.Removethebaggerbeltfromthemowerpulley

assembly.

8.Opentheblowerassembly.

9.Removetheblowerassemblyfromthepivothole.

10.Ifyouarechangingtoside-dischargemode,ensurethat

thegrassdeectorisinstalledandcanbeloweredinto

workingposition.

11.Removethehoodandbagassembly.

UsingtheGrassDeector

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Alwaysinstallthegrassdeectorwhenremoving

thebaggerandchangingtoside-discharge

mode.

Rememberthatthemachineislongerandwiderwiththis

attachmentinstalled.Byturningtoosharplyinconned

placesyoumaydamagetheattachmentorotherproperty.

Trimming

Alwaystrimwiththeleftsideofthemower.Donottrim

withtherightsideofthemowerbecauseyoucoulddamage

thebaggingtubes.

CuttingHeight

Foroptimumbaggingperformance,setthedeckheight-of-cut

toremovenomorethat51to76mm(2to3inches)or1/3of

thegrassheight,whicheverisless.Cuttingoffmorethanthis

willreducethecapacityofthevacuumsystem.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.Youwill

havetocutyourgrasstwiceifitgetsexcessivelylong(referto

BaggingLongGrass).

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlapthe

mowerintothepreviouslycutarea.Thishelpsreducethe

loadontheengineandreducesthechanceofpluggingthe

blowerassemblyandtubes.

•Ifthegrassdeectoriseverdamaged,replaceit

immediately.Thegrassdeectorroutesmaterial

downtowardtheturf.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(PTO)totheOFFposition,rotatetheignition

keytoOFFandremovethekey.

TransportingMachines

Donotleavegrassordebrisinthebaggerwhiletransporting

themachine.

DANGER

Transportingthemachinewithgrassordebrisin

thebaggercandamagethemachine.

Donotleavegrassordebrisinthebaggerwhile

transportingthemachine.

BaggingSpeed

Thebaggingsystemmayplugifyoudrivetoofastandthe

enginespeedgetstooslow .Onhills,itmaybenecessary

toslowthegroundspeedofthemachine.Mowdownhill

wheneverpossible.

CAUTION

Asthebaggerlls,extraweightisaddedtotheback

ofthemachine.Ifyoustopandstartsuddenlyon

hills,youmaylosesteeringcontrolorthemachine

maytip.

•Donotstartorstopsuddenlywhengoinguphill

ordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoinguphill,

disengagethePTO.Thenbackdownthehill

usingaslowspeed.

•Donotchangespeedsorstoponslopes.

BaggingLongGrass

Ifthegrassisallowedtogrowlongerthannormal,orifit

containsahighdegreeofmoisture,raisethecuttingheight

higherthanusualandcutandbagthegrassatthissetting.

27

Page 28

Thencutandbagthegrassagainusingthelower,normal

setting.

Excessivelylonggrassisheavyandmaynotbepropelled

completelyintothebagger.Ifthishappens,thetubeand

blowermayplug.Toavoidpluggingthebaggingsystem,mow

thegrassatahighheight-of-cut,thenlowerthemowerto

yournormalcuttingheightandrepeatthebaggingprocess.

BaggingWetGrass

Ifpossible,alwaystrytocutgrasswhenitisdry.Wetgrass

cancauseplugging.

ReducingPlugging

Toavoidpluggingthebaggingsystem,reducegroundspeed

andmowthegrassatahighheight-of-cut,thenlowerthe

mowertoyournormalcuttingheightandrepeatthebagging

process.

SignsofPlugging

Asyouarebagging,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.Anexcessive

amountofclippingblow-outindicatesthatthebaggerisfull

orthetubeisplugged.

BaggingBlades

Formostmowingconditions,thestandardhighliftbladeswill

providethebestbaggingperformance.

TheToroAtomicbladeisrecommendedforbaggingleaves

indryconditions.Indrydustyconditions,themediumlift

orlowliftbladeswillreducedustanddirtblowoutwhile

providingeffectivebaggingairow .

ContactanAuthorizedServiceDealerfortheproperblades

fordifferentmowingconditions.

CurbClimbingandLoading

Alwaysliftthedecktothehighestpositionwhenloadingthe

machineontrailersorascending/descendingacurb.Leaving

themowerinalowerpositioncandamagethemachinewhile

loadingandgoingoveracurb.Ifacurbishigherthan152mm

(6inches),crossitatasharpanglewiththedeckfullyraised.

Useextremecautionwhenloadingthemachineontoatrailer.

28

Page 29

Maintenance

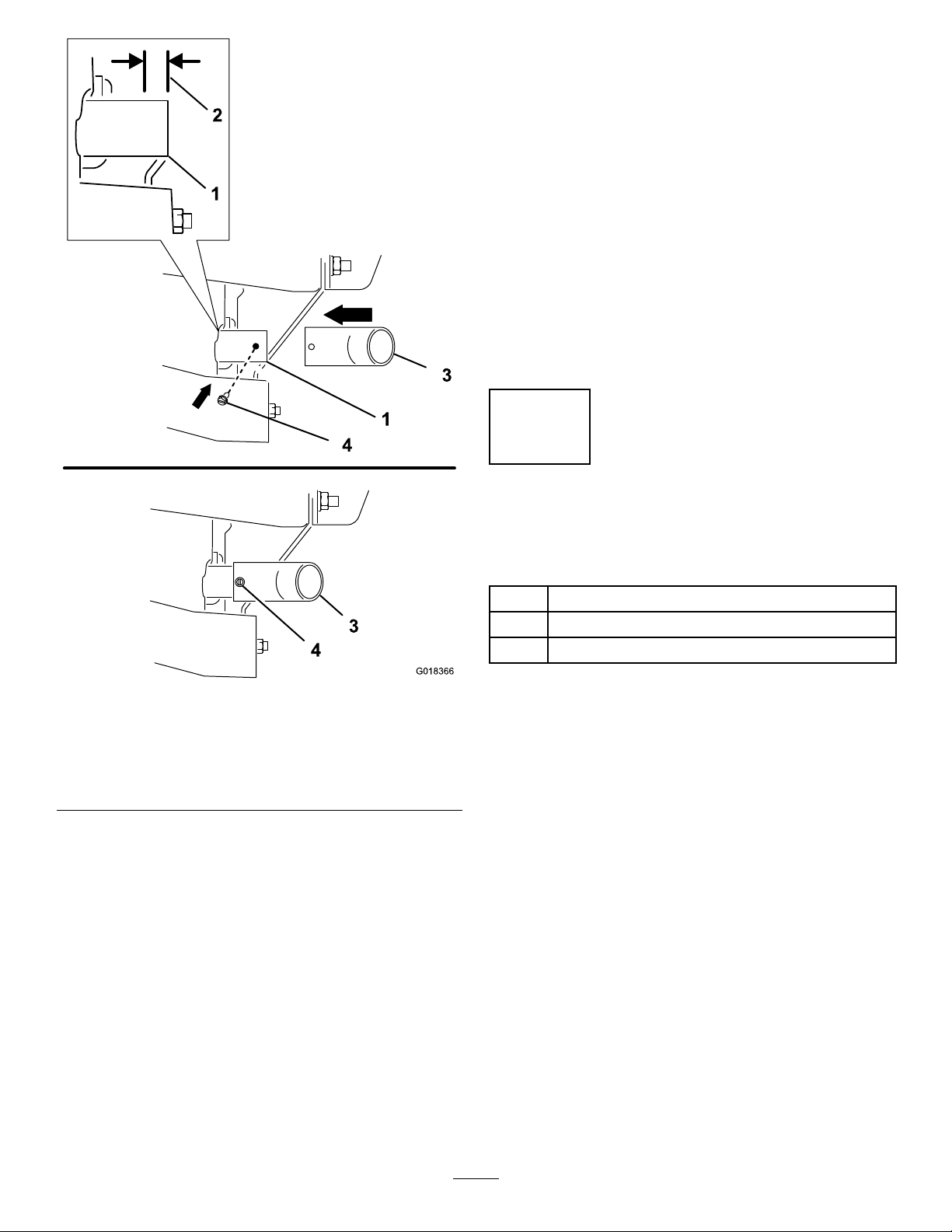

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Inspecttheblowerbelt.

•Inspectthebagger.

•Cleanthehoodscreen.

•Cleanthebagger.

•Inspecttheblowerbelt.

•Greasetheidlerarm.

•Inspectthebagger.

PreparingforMaintenance

Dothefollowingstepsbeforepreformingmaintenanceon

themachine:

1.Parkthemachineonalevelsurface.

2.DisengagethePTO,movethemotioncontrollevers

totheNEUTRALlockedposition,andsettheparking

brake.

3.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanthemowerofanydebrisonthedeckorrearpart

ofthemowertoeasemaintenance.

CleaningtheHoodScreen

ServiceInterval:Beforeeachuseordaily

1.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Openthebaggerhood.

4.Cleanthedebrisfromthescreen.

5.Closethebaggerhood.

InspectingtheBlowerBelt

ServiceInterval:Aftertherst8hours

Every25hours

Checkbeltsforcracks,frayededges,burnmarksoranyother

damage.Replacedamagedbelts.

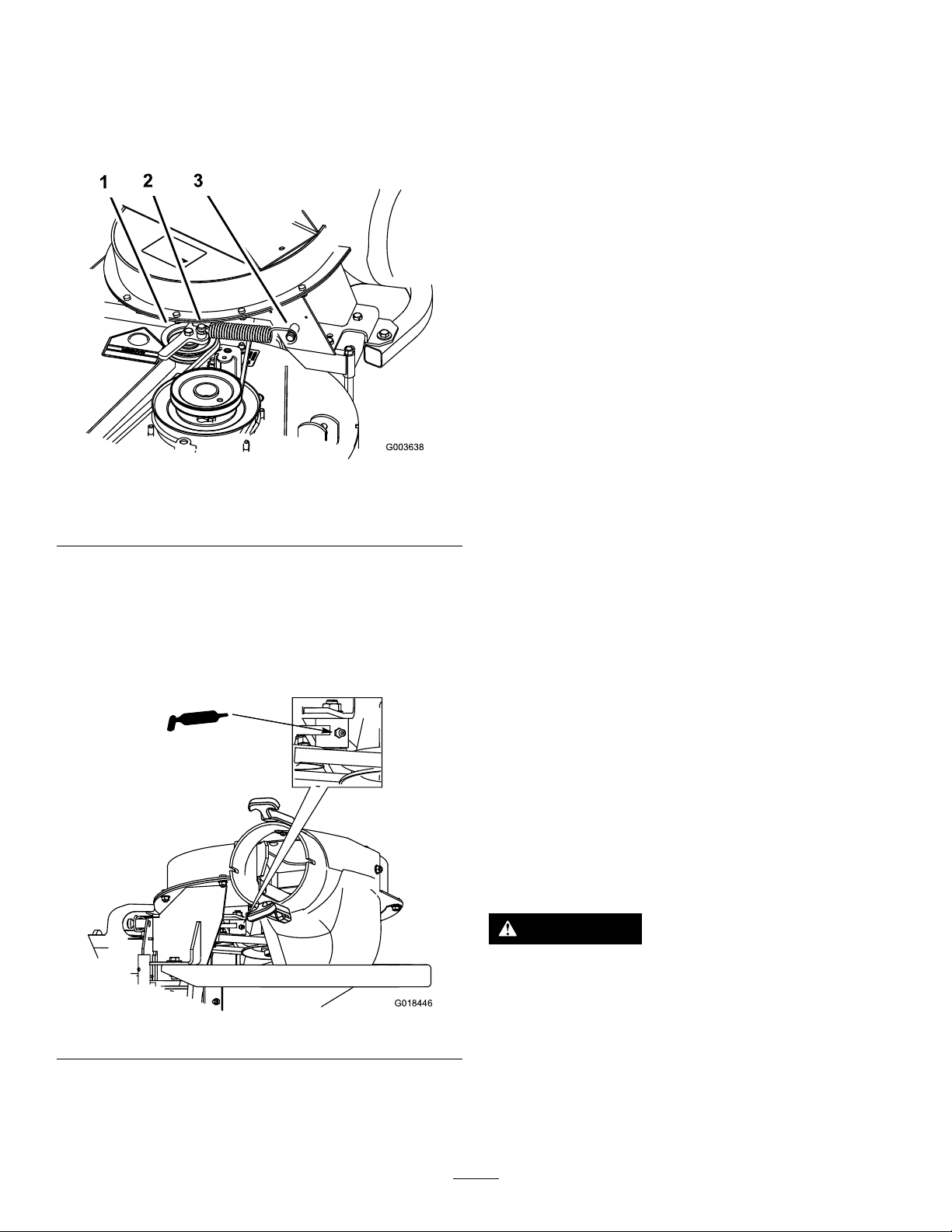

ReplacingtheBlowerBelt

1.DisengagethePTO,movethemotioncontrollevers

totheNEUTRALlockedposition,andsettheparking

brake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pullbackonthespring-loadedidlerpulleytorelieve

thebelttension(Figure39).

CleaningtheBaggerandBags

ServiceInterval:Beforeeachuseordaily

1.Washtheinsideandoutsideofthebaggerhood,bags,

tube,andtheundersideofthemower.

Note:Useamildautomotivedetergenttoremovedirt.

2.Ensurethatyouremovemattedgrassfromallparts.

3.Afterwashingallparts,letthemdrythoroughly.

Note:Withallpartsinstalled,startandrunthemachinefor

aminutetoassistindrying.

1.Idlerpulley

2.Mower-deckpulley5.Belt

3.Spring

29

Figure39

4.Springpeg

6.Blowerpulley

Page 30

4.Removetheexistingbaggerbeltfromthemower-deck

G018446

pulleyandthentheblowerpulleys.

5.Installthenewbeltaroundtheblowerpulleysandthe

mower-deckpulley(Figure39).

6.InstallthespringasshowninFigure40.

Figure40

1.Spring-loadedidlerpulley

2.Shorthookend

7.Pullbackonthespringloadedidlerpulleyandinstall

thebeltontothespringloadedidlerpulley(Figure39).

3.Longhookend

InspectingtheBagger

ServiceInterval:Every100hours

Aftertherst8hours

1.DisengagethePTO,movethemotioncontrollevers

totheNEUTRALlockedposition,andsettheparking

brake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Checktheuppertube,lowertube,baggerhood,and

theblowerassembly.

Note:Replacethesepartsiftheyarecrackedor

broken.

4.Checkthebags,baggerframe,andscreen.

Note:Replaceanypartsthatarecrackedorbroken.

5.Tightenallnutsboltsandscrews.

InspectingtheMowerBlades

1.Inspectthemowerbladesregularlyandwhenevera

bladestrikesaforeignobject.

2.Ifbladesarebadlywornordamaged,installnewblades.

RefertoyourmachineOperator'sManualforcomplete

blademaintenance.

ChoosingtheMowerBlades

GreasingtheIdlerArm

ServiceInterval:Every50hours

Figure41

Inmostmowingconditions,thestandardhighliftbladeswill

providethebestbaggingperformance.

UseaToroAtomicbladeforbaggingleavesindryconditions.

Indrydustyconditions,themediumliftorlowliftblades

willreducedustanddirtblowoutwhileprovidingeffective

baggingairow .

ContactanAuthorizedServiceDealerfortheproperblades

fordifferentmowingconditions.

RefertothemowerOperator'sManualformoreinformation

oninstallingblades.

ReplacingtheGrassDeector

WARNING

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectstowardyouor

bystanders,resultinginseriousinjury.Also,contact

withthebladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrassdeector

andabagger.

•Ensurethatthegrassdeectorisinthedown

position.

30

Page 31

1.Removethelocknut,bolt,spring,and

g015594

1

6 2

4

7

3

5

spacerthatsecurethegrassdeectorto

thepivotbracketsonthedeck(Figure42).

Removethedamagedorworngrassdeector.

Figure42

Storage

1.Cleanthebaggerattachment;refertoCleaningthe

BaggerandBags(page29).

2.Inspectthebaggerattachmentfordamage;referto

InspectingtheBagger(page30).

3.Ensurethatthebagsareemptyandthoroughlydry.

4.Checkthebeltforwearorcracks.

5.Storethemachineinaclean,dryplace,outofdirect

sunlight.Ifyoumuststorethemachineoutside,cover

itwithaweatherproofcover.Thisprotectstheplastic

partsandextendsthelifeofthemachine.

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring

5.Springinstalled

7.J-hookendofthespring

2.Placethespacerandspringontothegrassdeector.

Place1J-hookendofthespringbehindthedeckedge.

Note:Ensurethat1J-hookendofthespringis

installedbehindthedeckedgebeforeinstallingthebolt

showninFigure42.

3.Installtheboltandnut.Place1J-hookendofthe

springaroundthegrassdeector(Figure42).

Important:Thegrassdeectormustbeable

torotate.Liftthedeectoruptothefullopen

positionandensurethatitrotatestothefulldown

position.

31

Page 32

Troubleshooting

Problem

Abnormalvibration.

Reducedbaggingperformance.

Blowerandtubesplugtoofrequently .

PossibleCauseCorrectiveAction

1.Cuttingblade(s)is/arebentor

unbalanced.

2.Blade-mountingboltisloose.2.Tightentheblade-mountingbolt.

3.Looseblowerpulleyorpulley

assembly.

4.Wornbaggerbelt.4.Replacethebelt.

5.Blowerfanblade(s)is/arebentor

unbalanced.

1.Lowenginespeed.

2.Pluggedscreeninbaggerhood.2.Removedebris,leavesorgrass

3.Loosebaggerbelt.3.Replacethebaggerbelt.

4.Apluggedtubeorblower.4.Locateandremovepluggeddebris.

5.Fullbags.5.Emptythehopper.

1.Bagsaretoofull.1.Dumpmorefrequently.

2.Lowenginespeed.

3.Grassistoowet.3.Cutgrasswhenitisdry.

4.Grassistoolong.4.Cutnomorethan51-76mm(2-3

5.Pluggedscreeninhood.5.Removedebris,leavesorgrass

6.Groundspeedistoofast.6.Drivesloweratfullthrottle.

7.Wornbaggerbelt.7.Replacebelt.

1.Installnewcuttingblade(s).

3.Tightentheappropriatepulley.

5.ContactanAuthorizedServiceDealer.

1.Alwaysoperatetheengineatfull

throttle.

clippingsfromthescreen.

2.Alwaysoperatetheengineatfull

throttle.

inches)or1/3ofthegrassheight,

whicheverisless.

clippingsfromthescreen.

Debrisblowout.

Blowerimpellerdoesnotspinfreely .

1.Bagsaretoofull.1.Dumpmorefrequently.

2.Groundspeedistoofast.

3.Mowerdeckisnotleveled.

1.Pluggedblower.1.Removedebris,leavesorgrass

2.Impellernotaligned.

2.Drivethemachineatslowground

speedwhileoperatingtheengineat

fullthrottle.

3.SeethemachineOperator'sManual

forlevelingthemowerdeck.

clippingsfromtheblowerimpeller .

2.ContactanAuthorizedServiceDealer.

32

Loading...

Loading...