Page 1

FormNo.3371-273RevB

48in,52in,60inor72inE-ZVac™

DFSCollectionSystem

GenIIZMaster

ModelNo.78566—SerialNo.290000001andUp

ModelNo.78567—SerialNo.290000001andUp

ModelNo.78568—SerialNo.290000001andUp

®

Mower

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3371-273*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

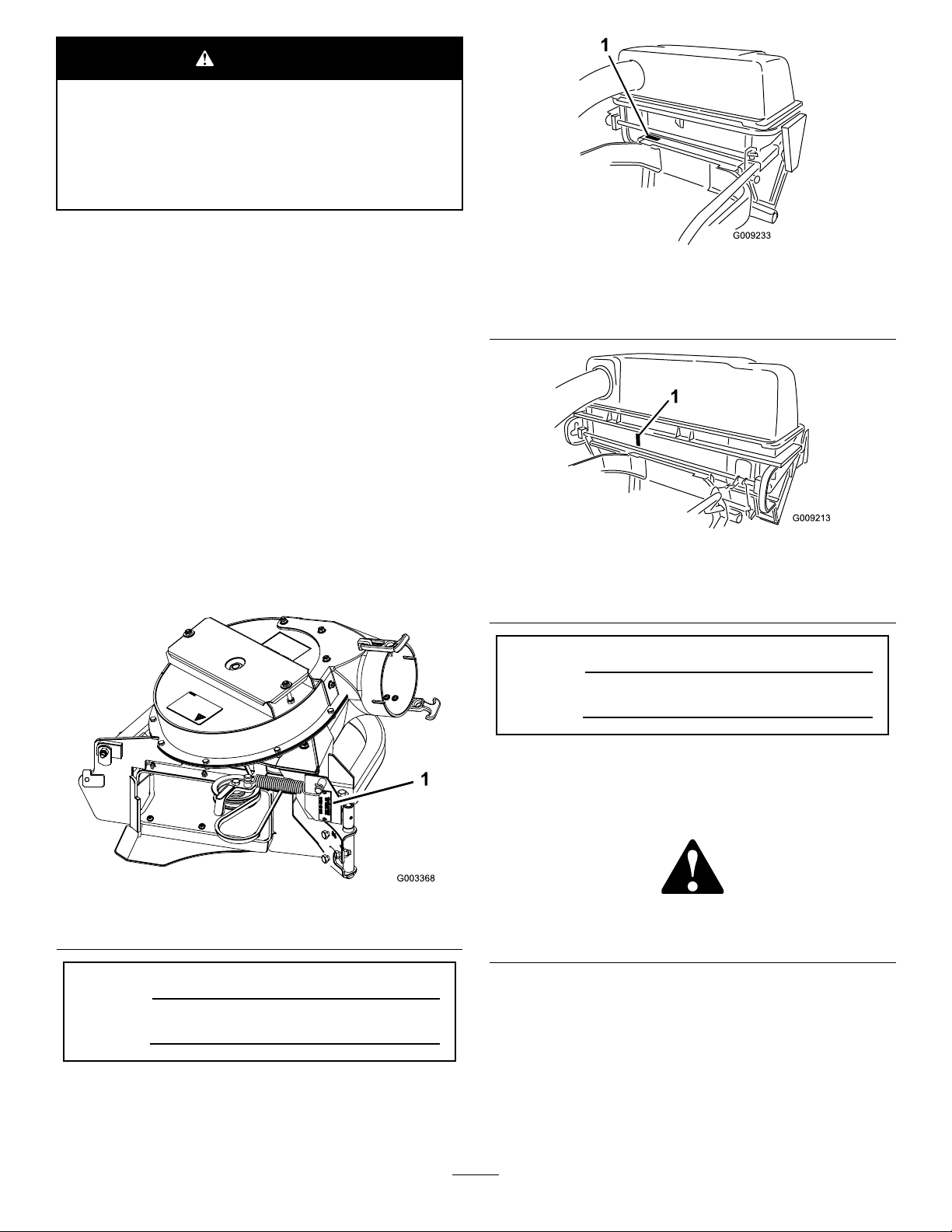

Figure2

48-and52-inchbaggerserialnumber

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1,Figure2andFigure3identies

thelocationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

1.Baggermodelandserialnumberlocation

Figure3

60-and72-inchbaggerserialnumber

1.Baggermodelandserialnumberlocation

ModelNo.

SerialNo.

Figure1

1.Collectionsystemmodelandserialnumberlocation

ModelNo.

SerialNo.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure4),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure4

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1PreparingtheMower.............................................8

2InstallingtheSideBumpers....................................8

3InstallingtheBaggerMountingBrackets...................8

4InstallingtheHandleAssemblyandBracket

.........................................................................9

5InstallingtheHandleAssemblyandBracketfor

48-and52-inchMowers.......................................10

6InstallingtheBaggerAssembly..............................10

7InstallingtheMuferDeector..............................12

8RoutingtheBlowerBeltintotheBlower

Assembly...........................................................12

9InstallingtheBlowerAssembly..............................14

10InstallingtheDischargeTubes.............................16

11InstallingtheBeltCover......................................19

12InstallingtheWeights..........................................19

13InstallingtheBumpers........................................21

14AdjustingtheParkingBrake.................................22

15CheckingtheTirePressure..................................22

Operation....................................................................23

AdjustingtheBafe................................................23

EmptyingtheBagger..............................................24

ClearingObstructionsfromtheCollection

System..............................................................24

RemovingtheBagger..............................................24

UsingtheGrassDeector.......................................25

TransportingMachines............................................25

OperatingTips......................................................25

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

CleaningtheBaggerScreen......................................27

CleaningtheCollectionSystem.................................27

InspectingtheBlowerBelt.......................................28

ReplacingtheBlowerBeltfor60-and72-inch

Mowers.............................................................28

ReplacingtheBlowerBeltfor48-and52-inch

Mowers.............................................................28

CheckingandAdjustingtheBlowerLatch..................29

GreasingtheIdlerArmandHandlePivot...................29

InspectingtheCollectionSystem..............................30

AdjustingtheClosedDoorfor60-and72-inch

Mowers.............................................................30

AdjustingtheOpenDoorfor60-and72-inch

Mowers.............................................................31

AdjustingtheLatchesfor60-and72-inch

Mowers.............................................................31

AdjustingtheArmPositionfor48-and52-inch

Mowers.............................................................31

AdjustingtheClosedDoorfor48-and52-inch

Mowers.............................................................32

AdjustingtheOpenDoorfor48-and52-inch

Mowers.............................................................33

AdjustingtheParkingBrake.....................................34

InspectingtheMowerBlades...................................34

InstallingtheMowerBlades.....................................34

InstallingtheGrassDeector...................................34

Storage........................................................................35

Troubleshooting...........................................................36

3

Page 4

Safety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

•Becomefamiliarwiththesafeoperationoftheequipment,

withtheoperatorcontrols,andsafetysigns.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangetheoperatingcharacteristicsandthe

stabilityofthemachine.

•Followthemanufacturer'srecommendationsforadding

orremovingwheelweightsorcounterweightstoimprove

stability.

•Donotuseagrasscatcheronsteepslopes.Aheavy

grasscatchercouldcauselossofcontroloroverturnthe

machine.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.Useextreme

cautionwhileoperatingneardrop-offs.Refertothe

tractionunitOperator'sManualforoperationnearslopes

anddrop-offs.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeed,directionsorturning.

•Thegrasscatchercanobstructtheviewtotherear.Use

extracarewhenoperatinginreverse.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.Ifthemachineistobedrivenontoatruck

ortrailerwiththehopperfull,alwaysbackuptheramp.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Keephandsandfeetawayfrommovingparts.Donot

makeadjustmentswiththeenginerunning.

•Stoponlevelground,disengagedrives,chockorblock

wheels,shutoffenginebeforeleavingtheoperator's

positionforanyreasonincludingemptyingthegrass

catcheroruncloggingthechute.

•Ifyouremovethegrasscatcher,besuretoinstallany

dischargedeectororguardthatmighthavebeen

removedtoinstallthegrasscatcher.Donotoperatethe

mowerwithouteithertheentiregrasscatcherorthegrass

deectorinplace.

•Stoptheenginebeforeremovingthegrasscatcheror

uncloggingthechute.

•Donotleavegrassingrasscatcherforextendedperiods

oftime.

•Grasscatchercomponentsaresubjecttowear,damage

anddeterioration,whichcouldexposemovingpartsor

allowobjectstobethrown.Frequentlycheckcomponents

andreplacewithmanufacturer'srecommendedparts,

whennecessary.

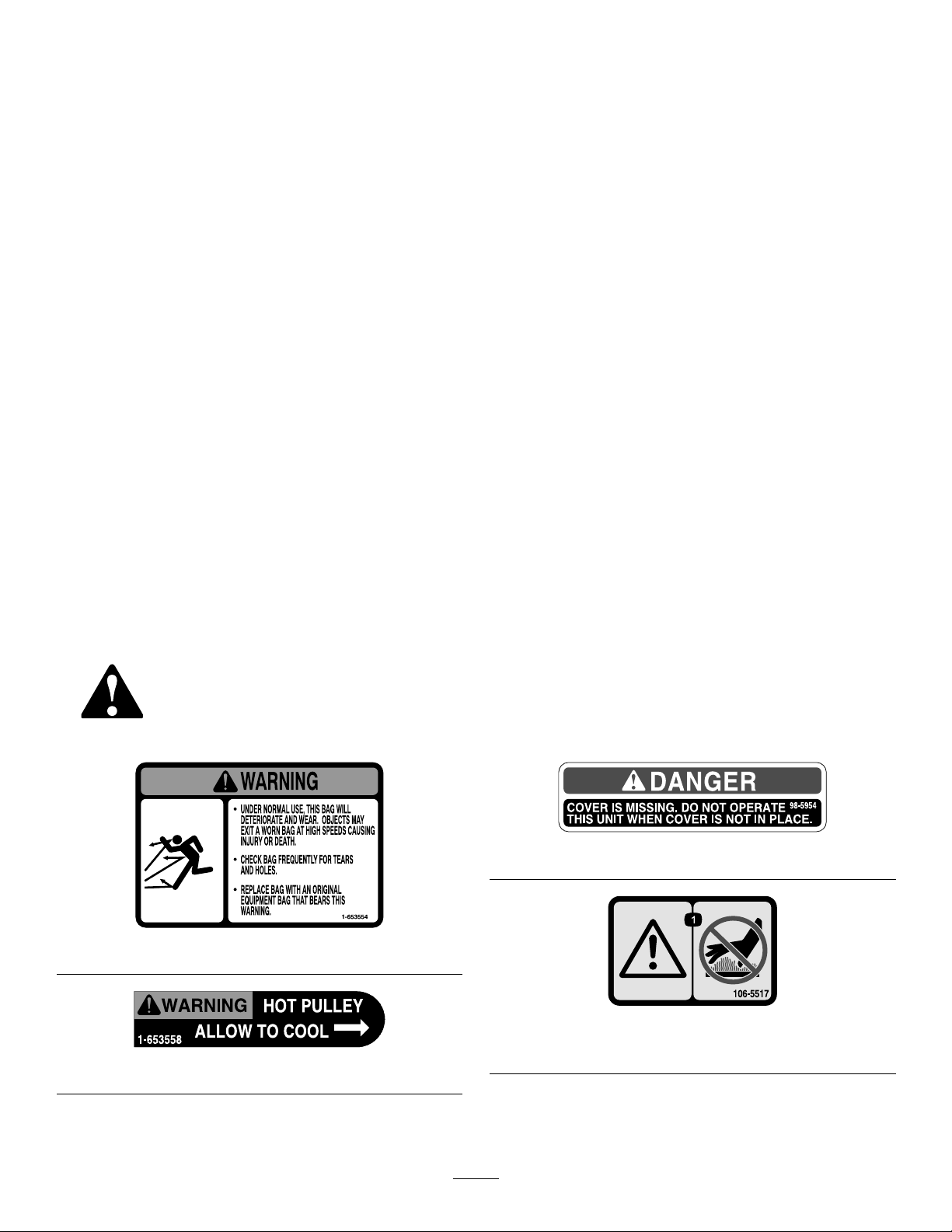

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-653554

1-653558

98-5954

106-5517

1.Warning–Donottouchthehotsurface.

4

Page 5

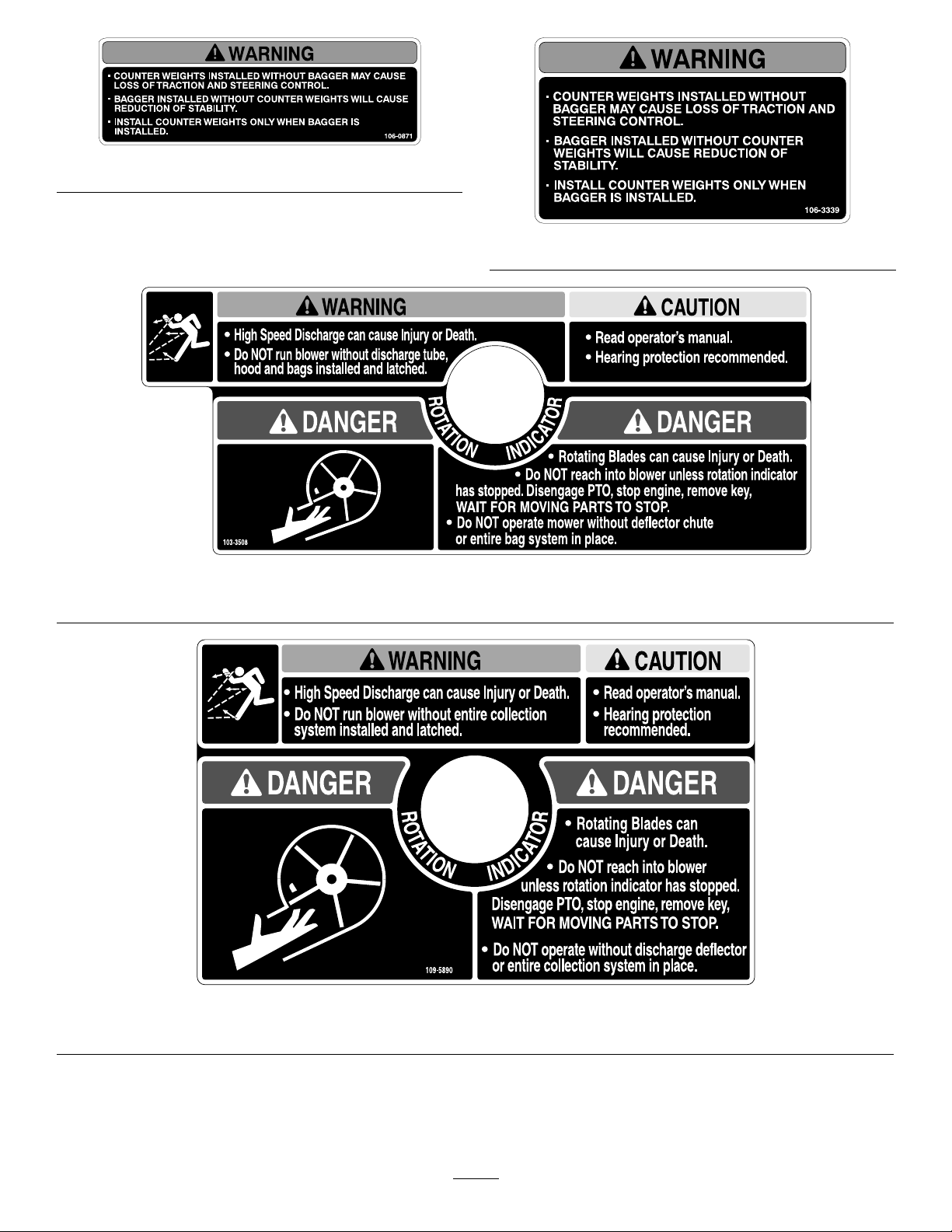

106-0871

106-3339

103-3508

48-inchand52-inchdecksonly

109-5890

60-inchand72-inchdecksonly

5

Page 6

Setup

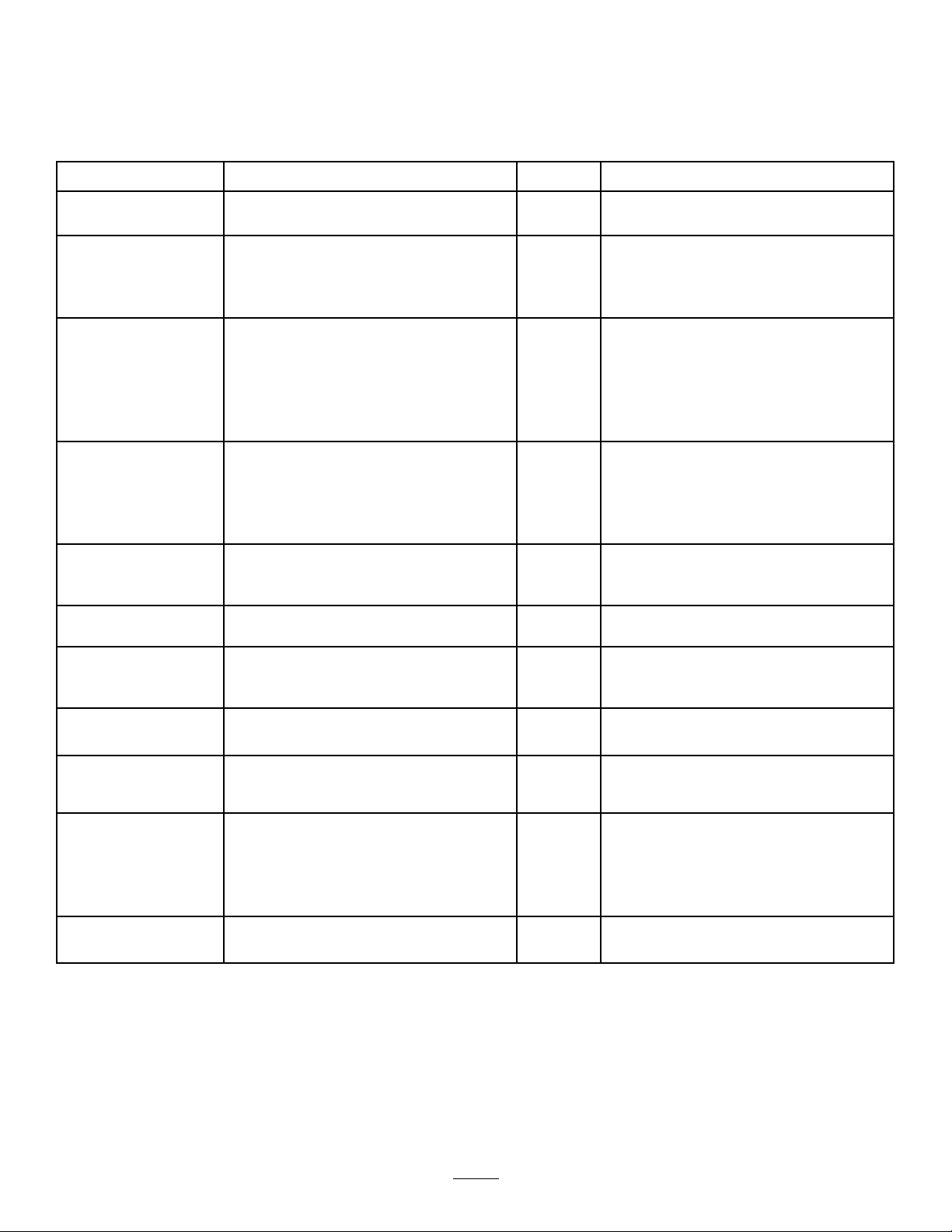

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

Nopartsrequired

Leftbumper

Rightbumper1

Carriagebolt(3/8x1-1/4inches)

Flangenut(largeange–3/8inch)

Uppermountingbracket1

Lowermountingbracket1

Carriagebolt(3/8x1-1/4inches)

Carriagebolt(1/2x2–1/2inches)

Flangenut(largeange–3/8inch)

Flangenut(1/2inch)

Handleassembly1

Handlebracket1

Carriagebolt(3/8x1-1/4inches)

Clevis-pinspring

Flangenut(largeange–3/8inch)

Hoodassembly1

Knob1

Carriagebolt

Baggerassembly1

Pinandhairpincotterassembly2

Muferdeector

Flangenut(smallange–3/8inch)

Carriagebolt(3/8x1-1/4inches)

Blowerbelt(fromtheBlowerandDrive

Kit)

Blowerassembly(fromtheBlowerand

DriveKit)

Spring(fromtheBlowerandDriveKit)

Uppertube1

Lowertube1

Bolt(#10x3/4inches)

Locknut(#10)

Washer(7/32inch)

Beltcover(fromtheBlowerandDrive

Kit)

Qty.

–

1

2

6

4

2

4

2

4

1

4

1

1

2

2

1

1

1

3

3

3

1Installthebeltcover.

Preparethemower.

Installthesidebumpers.

Installthebaggermountingbrackets.

Installthehandleassembly(for60-and

72-inchmowers).

Installthehoodassembly .

Installthebaggerassembly .

Installthemuferdeector.

Routetheblowerbeltintotheblower

assembly.

Installtheblowerassembly .

Installthedischargetubes.

Use

6

Page 7

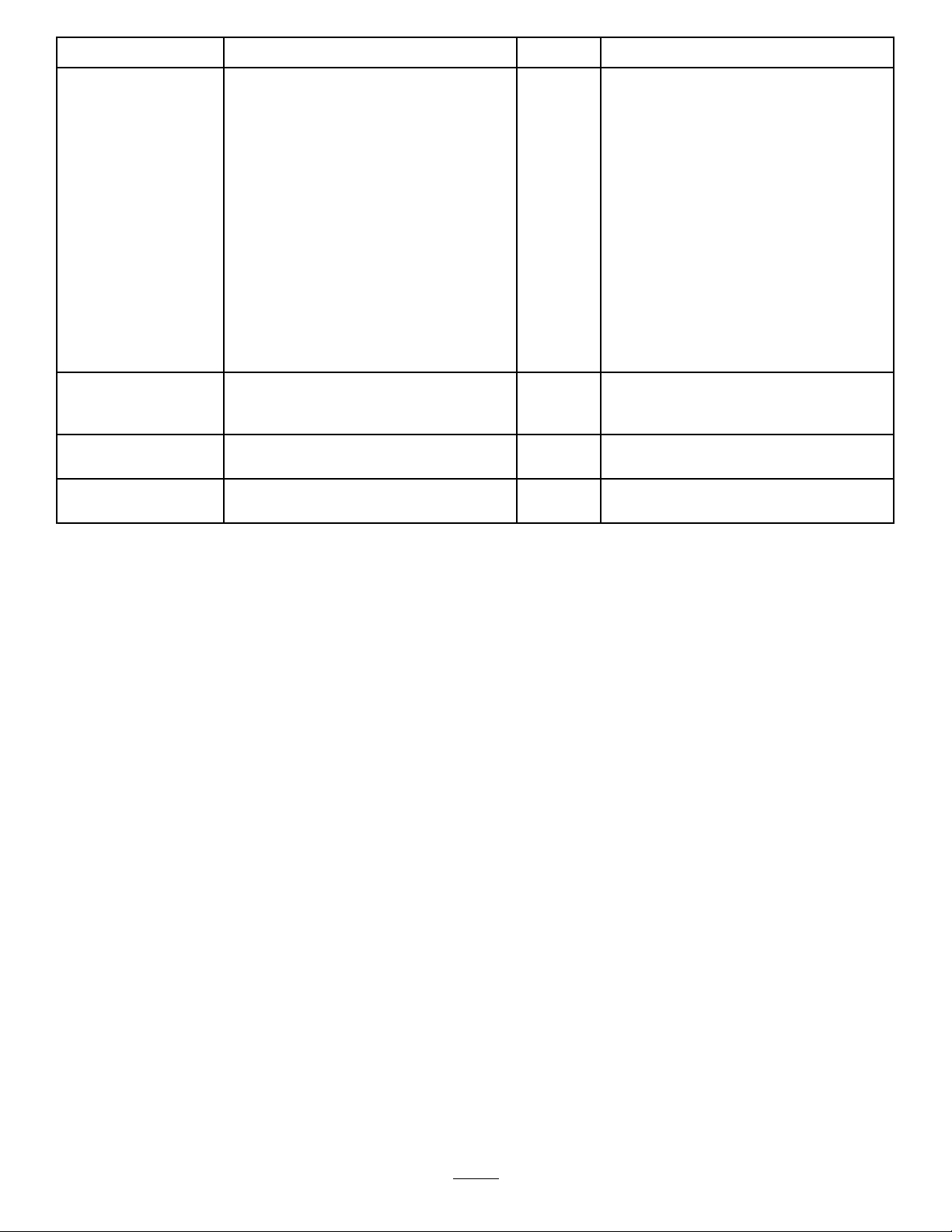

ProcedureDescription

12

13

Casterweight(ifneeded)

Clevispin

Hairpincotter2

Lockwasher(3/8inch)

Weight-mountbracket1

Bolt(3/8x1inch)

Flatwasher(3/8inch)

Flangenut(smallange–3/8inch)

Carriagebolt(5/16x3/4inch)

Flangenut(5/16inch)

Frontweight(48-inch,52-inch,and

60-inchdecks)

Frontweight(72-inchdecks)

Tapbolt(3/8x1-3/4inches)

Nut(3/8inch)

Bumper2

Spacer

Locknut(5/16inch)

Qty.

Use

2

2

6

6

6

3

2

2

3

1

2

2

2

2

Installtheweights.

Installthebumpers(formachineswith

MyRide™suspensionsystem).

14

15

Nopartsrequired

Nopartsrequired

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

–

–

Adjusttheparkingbrake.

Checkthetirepressure.

7

Page 8

1

2

PreparingtheMower

NoPartsRequired

Procedure

Performthefollowingproceduretopreparethemowerfor

attachingtheblowerandnishingkit.

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pullthesparkplugwires.

4.Repairallbentordamagedareasofmowerdeckand

replaceanymissingparts.

5.Cleanthemowerofanydebrisonthedeckorrearpart

ofthemowertoeaseinstallation.

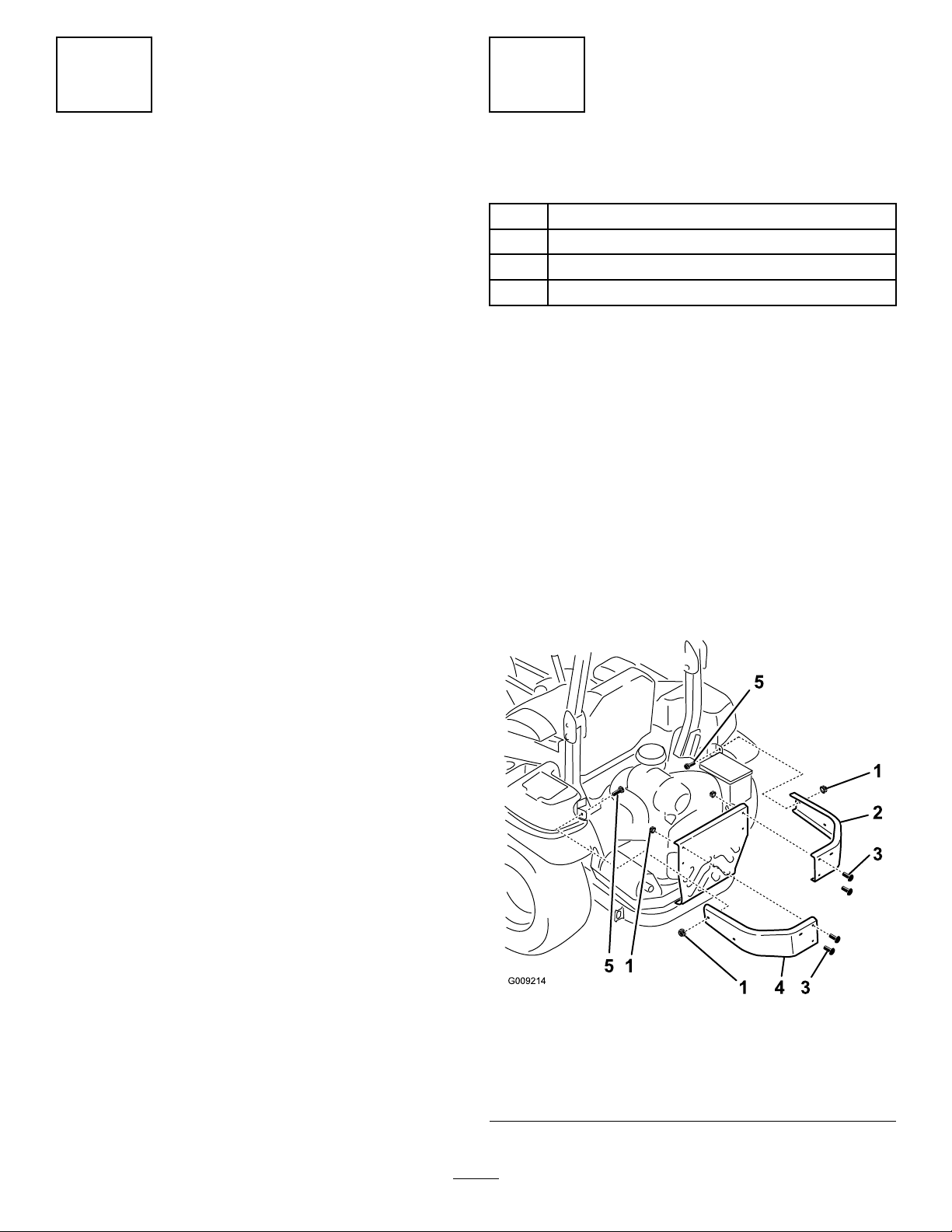

InstallingtheSideBumpers

Partsneededforthisprocedure:

1

Leftbumper

1Rightbumper

2

Carriagebolt(3/8x1-1/4inches)

6

Flangenut(largeange–3/8inch)

Procedure

1.Removethenutsandboltsholdingthesidebumpers

tothemachine(Figure5).

Note:Discardallnutsandonlythe1boltremoved

fromeachside

Note:For60-and72-inchmowers,donotinstallthe

boltandangenutfortheleftbumperneartheROPS.

Youwillinstallthemwhenyouinstallthehandle

bracketinafollowingprocedure.

2.Installthenewleftandrightbumperswith2

carriagebolts(3/8x1-1/4inches),4previously

removedcarriagebolts,and6angenuts(3/8inch)as

showninFigure5.

1.Flangenut(large

2.Rightbumper

3.Useexistingbolts

8

Figure5

4.Leftbumper

ange–3/8inch)

5.Bolt(3/8x1-1/4inches)

Page 9

3

1

3

6

g017215

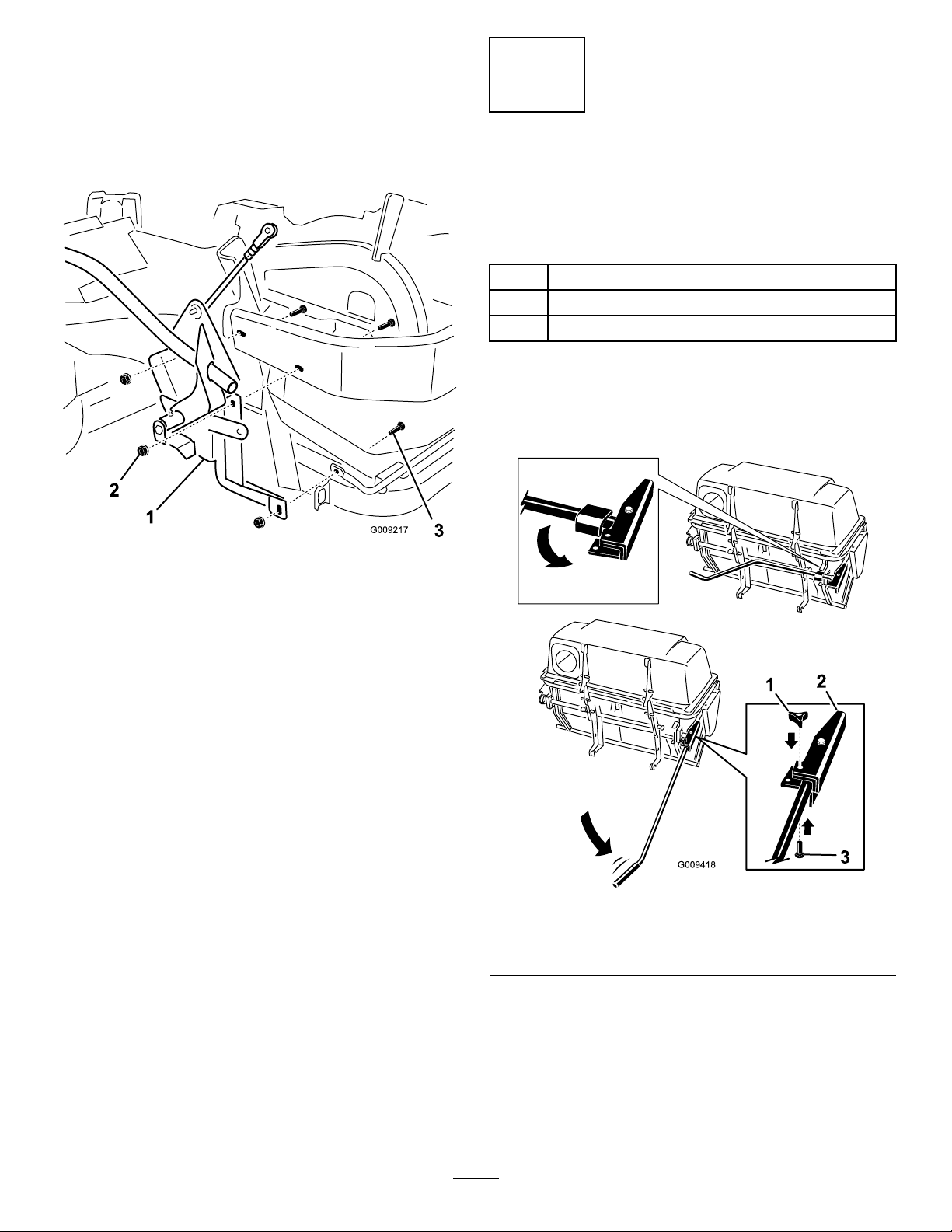

InstallingtheBaggerMounting

2.Installtheuppermountingbrackettotheleftandright

bumperswith2carriagebolts(1/2x2-1/2inches)and

2angenuts(1/2inch)asshowninFigure6.

Brackets

Partsneededforthisprocedure:

1Uppermountingbracket

1Lowermountingbracket

4

Carriagebolt(3/8x1-1/4inches)

2

Carriagebolt(1/2x2–1/2inches)

4

Flangenut(largeange–3/8inch)

2

Flangenut(1/2inch)

Procedure

Note:For60-and72-inchmowers,donotinstallthebolt

andangenutfortheleftsideofthelowermountingbracket.

Thiswillbeinstalledwheninstallingthehandlebracketin

thefollowingprocedure.

1.Installthelowermountingbrackettothemachine

framewith4carriagebolts(3/8x1-1/4inches)and

4angenuts(largeange–3/8inch)asshownin

Figure6.

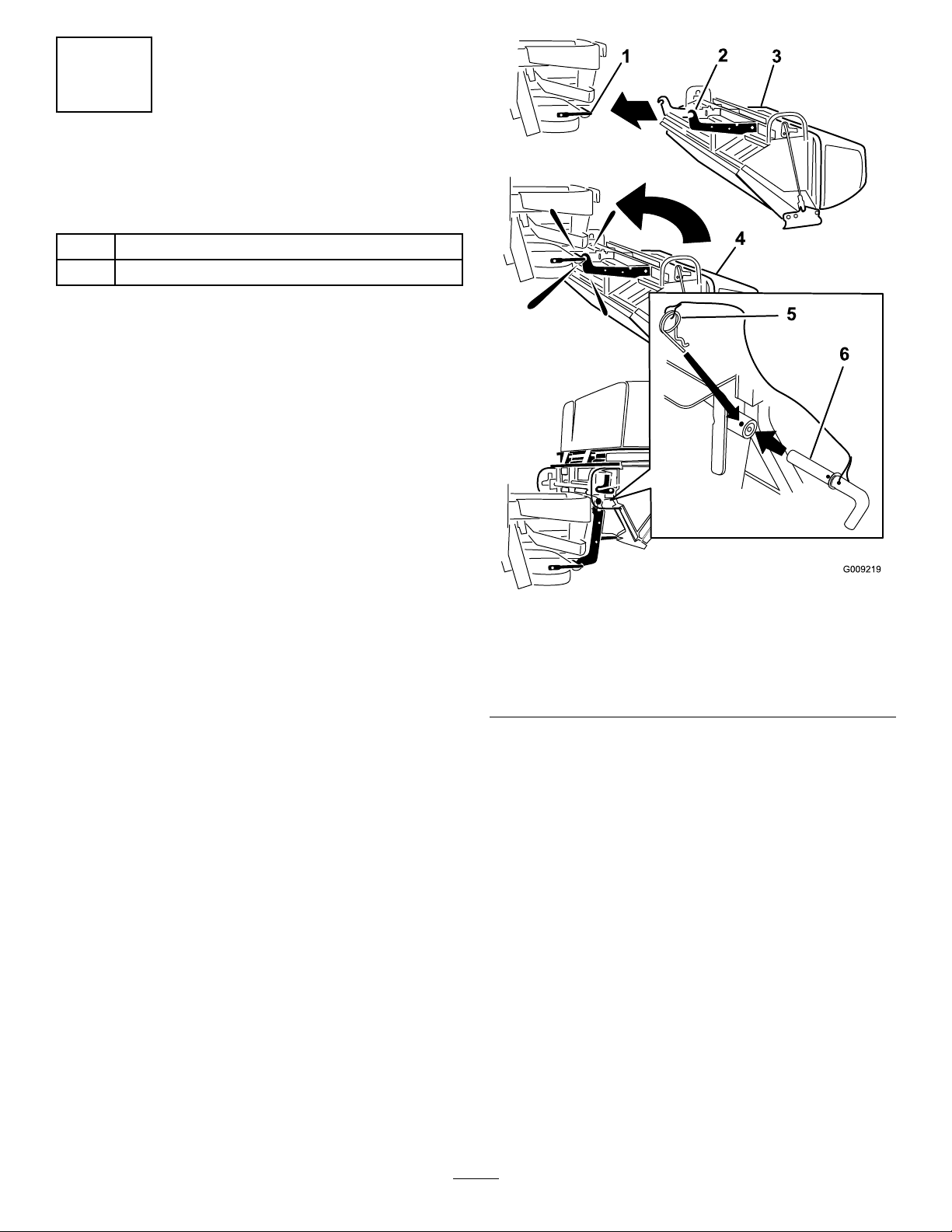

4

InstallingtheHandleAssembly andBracket

60-and72-inchMowers

Partsneededforthisprocedure:

1Handleassembly

1Handlebracket

4

Carriagebolt(3/8x1-1/4inches)

1

Clevis-pinspring

4

Flangenut(largeange–3/8inch)

Procedure

1.Removetheclevis-pinspringfromthebagger-arm

assembly(seeFigure11).

2.Installthehandleassemblypinintothehandlebracket

andconnectthemtogetherwithacarriagebolt(3/8x

1-1/4inches)andaangenut(largeange–3/8inch).

Figure6

1.Carriagebolt(1/2x2-1/2

inches)

2.Uppermountingbracket

3.Flangenut(1/2inch)6.Flangenut(large

4.Lowermountingbracket

5.Carriagebolt(3/8x1-1/4

inches)

ange–3/8inch)

Figure7

1.Bolt(3/8x1-1/4inches)4.Flangenut(large

2.Handlebracket5.Assembledhandleand

3.Handleassembly

9

ange–3/8inch)

bracketassembly

Page 10

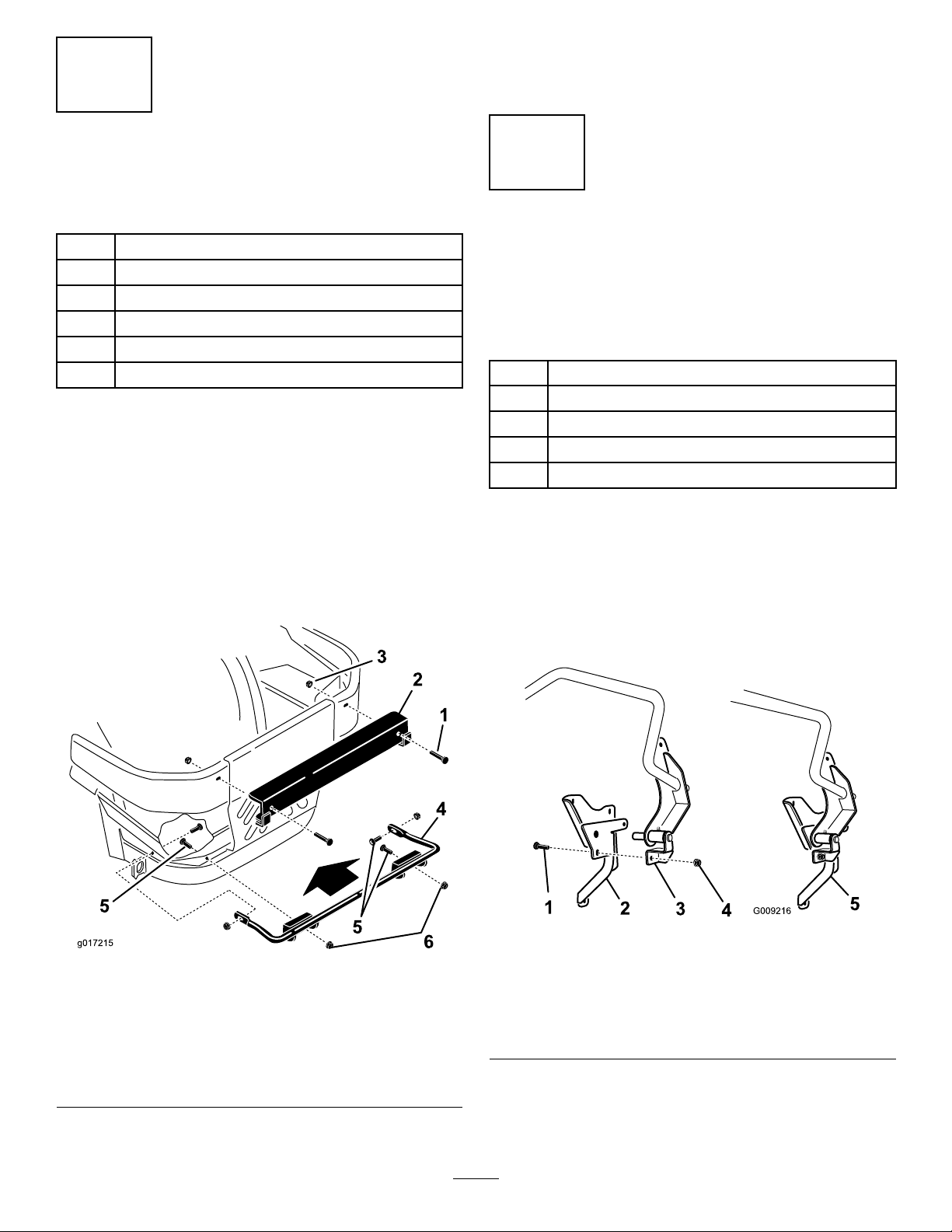

3.Installthehandleandbracketassemblytothesideof

themachinewith3carriagebolts(3/8x1-1/4inches)

and3angenuts(largeange–3/8inch)asshownin

Figure8.

5

Note:Ensurethattheboltsgothroughtheleft

bumperandthelowerbaggerbracketandconnect

themtothesideofthemachine.

Figure8

1.Handleandbracket

assembly

2.Flangenut(large

ange–3/8inch)

3.Bolt(3/8x1-1/4inches)

InstallingtheHandleAssembly andBracketfor48-and52-inch Mowers

Partsneededforthisprocedure:

1Hoodassembly

1Knob

1

Carriagebolt

Procedure

Pivotthehandleoutintothehandlebracketandsecureit

withacarriageboltandknob(Figure9).

Figure9

1.Knob

2.Handlebracket

10

3.Carriagebolt

Page 11

6

InstallingtheBagger

Assembly

Partsneededforthisprocedure:

1Baggerassembly

2Pinandhairpincotterassembly

Procedure

1.Positionthebaggeronitsback(Figure10).

2.Slidethehooksontothelowermountingbracket

(Figure10).

3.Rotatethebaggeruponthelowerbaggermounting

bracket.

4.Aligntheholeinthebaggerwiththeuppermounting

bracket(Figure10).

5.Installthepinandsecureitwiththehairpincotteron

bothsides(Figure10).

Figure10

1.Lowermountingbracket4.Rotatebaggerup

2.Hook5.Hairpincotterconnected

3.Bagger6.Pinconnectedtolanyard

6.Rotatethebagger-handlelinkageuptothebagger

assemblyandsecureitwithaclevis-pinspring(Figure

11).

Note:Loosenandrotatetheyokeifneededtoalignit

withthebaggerassembly .

tolanyard

11

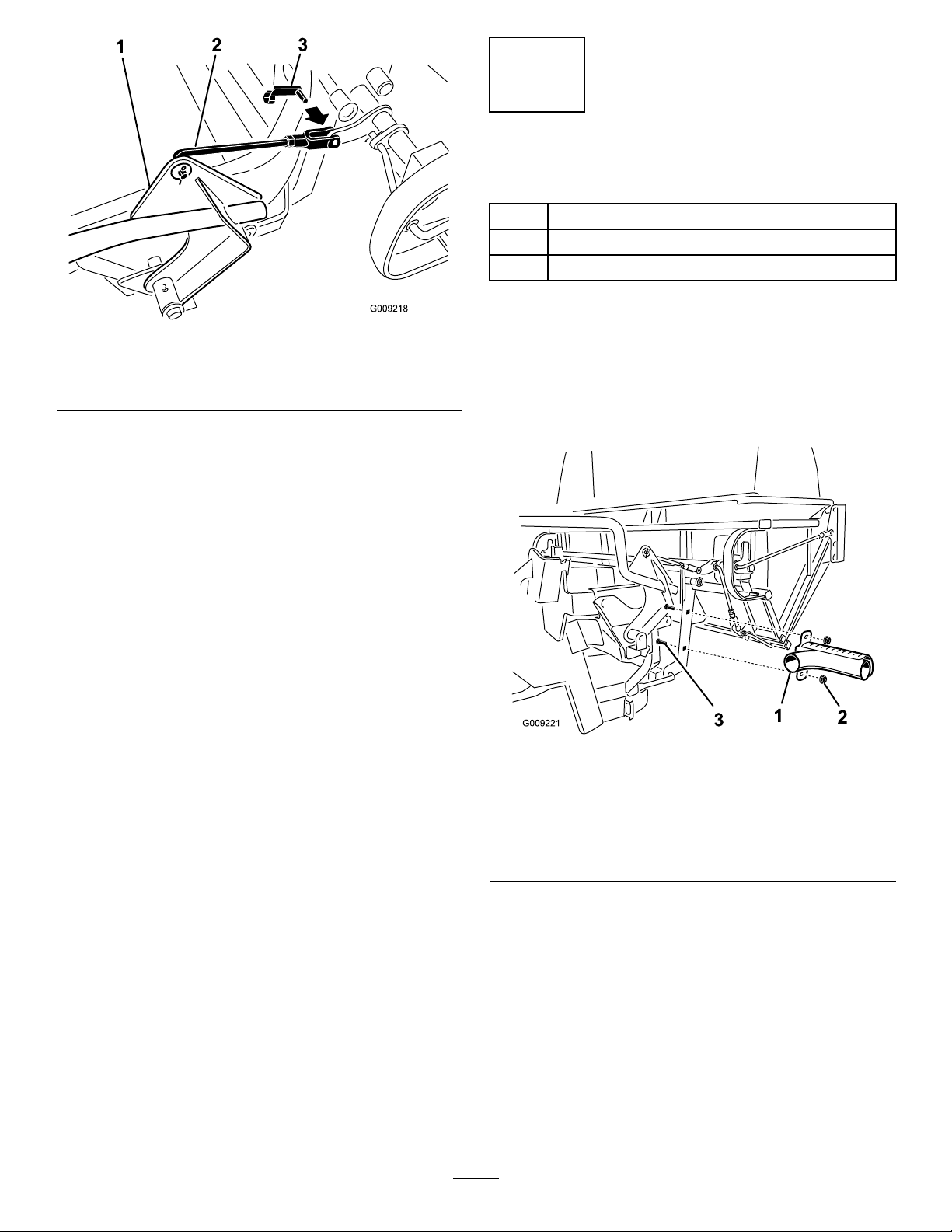

Page 12

7

InstallingtheMuferDeector

Partsneededforthisprocedure:

1

Muferdeector

2

Flangenut(smallange–3/8inch)

2

Carriagebolt(3/8x1-1/4inches)

Figure11

1.Bagger-armassembly

2.Bagger-handlelinkage4.Yoke

3.Clevis-pinspring

Procedure

Installthemuferdeectortothesideofthebaggerframe

(Figure12).

Note:Ensurethatthemuferdeectorispositionedover

thetailpipeonthemufer.

Figure12

60-and72-inchbaggershown

1.Muferdeector3.Carriagebolt(3/8x1-1/4

2.Flangenut(small

ange–3/8inch)

12

inches)

Page 13

8

RoutingtheBlowerBeltinto

theBlowerAssembly

Partsneededforthisprocedure:

1

Blowerbelt(fromtheBlowerandDriveKit)

Procedure

1.For60-and72-inchmowers,installthebeltaroundthe

blowerpulley(Figure13).

Figure13

Blowerfor60-and72-inchMowers

1.Idlerpulley4.Peg

2.Mower-deckpulley5.Belt

3.Spring

6.Blowerpulley

Figure14

Blowerfor48-and52-inchmowers

1.Spring-loadedidlerpulley

2.Mower-deckpulley6.Fixed-idlerpulley

3.Spring

4.Peg8.Belt

5.Beltguide

7.Blowerpulley

2.For48-and52-inchmowers,loosenthebeltguide

(Figure14).

3.Installthebeltaroundtheblowerpulleyandxed-idler

pulley(Figure14).

4.Tightenthebeltguide.

13

Page 14

9

InstallingtheBlowerAssembly

Partsneededforthisprocedure:

1

Blowerassembly(fromtheBlowerandDriveKit)

1

Spring(fromtheBlowerandDriveKit)

Procedure

2.Slidetheblower-assemblypegintothepivothole

(Figure16orFigure17).

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsatyouorbystanders,

resultinginseriousinjury.Also,contactwiththe

bladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

•Makesurethatthegrassdeectorisinstalled

whenyouremovethegrasschuteandcatcher.

1.Removetheside-dischargechutefromthemowerdeck

(Figure15).

Note:Saveallthehardwareandtheside-discharge

chute.Installtheside-dischargechutewhenthebagger

andblowerareremoved.

Figure16

48-and52-inchmowerdeckshown

1.Blowerassembly3.Pivothole

2.Mowerdeck4.Blower-assemblypeg

Figure17

60-and72-inchmowerdeckshown

1.Blowerassembly3.Pivothole

2.Mowerdeck4.Blower-assemblypeg

Figure15

1.Bolt

2.Spacer6.Grassdeector

3.Locknut

4.Spring8.J-hookendofthespring

5.Springinstalled

7.L-endofspring(Place

itbehindthedeckedge

beforeinstallingthebolt)

14

Page 15

3.Closetheblowerassemblytoseeifthelatchesare

adjustedcorrectly(Figure18).

5.Pullthespring-loadedidlerpulleybackandroutethe

beltaroundthemower-deckpulley(Figure20).

Note:Loosenortightentheboltsothelatchesrmly

holdtheblowerassemblyagainstthemowerdeckbut

canbereleasedbyhand

Figure18

1.Latch3.Blowerassembly

2.Bolt

4.InstallthespringasshowninFigure19.

Note:Makesurethatthehooksareinthecorrect

position.

Note:Ensurethatthebeltisroutedaroundtheblower

pulleyscorrectly

Figure20

1.Mower-deckpulley3.Blower

2.Spring-loadedIdlerpulley

1.Spring-loadedidlerpulley

2.Short-hookend

Figure19

3.Long-hookend

15

Page 16

10

InstallingtheDischargeTubes

Partsneededforthisprocedure:

1Uppertube

1Lowertube

3

Bolt(#10x3/4inches)

3

Locknut(#10)

3

Washer(7/32inch)

Procedure

Important:Makesurethatthemowerdeckisin

thelowestheight-of-cutpositionwhileinstallingthe

dischargetubes.

Note:Remembertoreplacethegrassdeectorwhenthe

baggerisremovedfromthemower.RefertoInstallingthe

GrassDeector(page34).

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lowerthemowerdecktothelowestheight-of-cut

position.

4.Installtheuppertubeintothebaggeropeningandpull

itbackoutsothattherubbersealisprotrudingout

(Figure21).

Figure22

1.Hoodplate

2.Uppertube

3.Hoodinthedownposition

6.Oncethe19mm(3/4inch)measurementhasbeen

achieved,marktheuppertubeontheoutsidewhere

therubbersealprotrudesout(Figure23).

Note:Thisismarkedtoensurethecorrectposition

fortheuppertubewhendrillingtheholesand

connectingtheupperandlowertubes.

Note:Therubbersealmustprotrudeoutfromthe

baggerhood.

4.3/4inch(19mm)

5.Edgeoftube

Figure21

1.Uppertube3.Baggerhood

2.Baggeropening

5.Measurethedistancethetubeisinsidethehood.

Note:Measurefromthehoodplatetotheedgeof

thetubeasshowninFigure22.Thisdistanceneeds

tobe19mm(3/4inch).

Figure23

1.Uppertube3.Baggerhood

2.Rubbersealprotrudingout4.Markhereagainstthe

rubberseal.

16

Page 17

7.Installthelowertubeintotheuppertube(Figure24).

Figure24

1.Lowertube2.Uppertube

8.Slidethelowertubeontothebootandlatchthem

together(Figure25orFigure26).

Note:Thereisalatchonthetopandbottomofthe

blowerhousing.

Note:Makesurethatthemowerdeckisinthelowest

height-of-cutpositionandthemarkontheuppertube

isstillpositionedagainsttheprotrudingrubberseal.

MakesurethatthemarkfromFigure23isstillinplace.

Figure25

1.Blowerassembly3.Latch

2.Lowertube

17

Page 18

9.Usingthe3holesorindentationsintheuppertubeasa

template,drill3holes(7/32inchdiameter)wherethe

upperandlowertubesjointogether(Figure27).

Figure26

60-and72-inchbaggershown

1.Blowerassembly3.Latch

2.Lowertube

Figure27

1.Baggerhood4.Lowertube

2.Uppertube5.Blowerassembly

3.Drill7/32inchdiameter

holeshere(usetheupper

tubeasatemplate)

10.Removethelowertubefromtheblower.

18

Page 19

11.Jointheupperandlowertubeswith3bolts(#10x

1

2

G009305

G009303

1

2

3/4inches),3atwashers(7/32inch),and3locknuts

(#10)asshowninFigure28.

Figure29

48-and52-inchbaggershown

1.Beltcover3.Notch

2.Belt-coversupport

Figure28

1.Lowertube

2.Uppertube

3.Flatwasher(7/32inch)

12.Installthelowertubeontotheblowerhousingand

secureitwiththelatches.

4.Locknut(#10)

5.Bolt,(#10x3/4inches)

11

InstallingtheBeltCover

Partsneededforthisprocedure:

1

Beltcover(fromtheBlowerandDriveKit)

Procedure

1.Lowerthemowerdecktothelowestheight-of-cut

position.

2.Installthenewbeltcoversothatthenotchesonboth

sidesgooverthebelt-coversupportsandsecurethe

latch(Figure29orFigure30).

Figure30

60-and72-inchbaggershown

1.Beltcover3.Notch

2.Belt-coversupport

19

Page 20

12

InstallingtheWeights

Partsneededforthisprocedure:

2

Casterweight(ifneeded)

2

Clevispin

2Hairpincotter

6

Lockwasher(3/8inch)

1Weight-mountbracket

6

Bolt(3/8x1inch)

6

Flatwasher(3/8inch)

3

Flangenut(smallange–3/8inch)

2

Carriagebolt(5/16x3/4inch)

2

Flangenut(5/16inch)

3

Frontweight(48-inch,52-inch,and60-inchdecks)

1

Frontweight(72-inchdecks)

2

Tapbolt(3/8x1-3/4inches)

2

Nut(3/8inch)

Procedure

3.Tightenthetapboltsothatittouchestheframeand

thentightenthejamnutagainsttheweight.

Figure31

1.Tapbolt(3/8x1-3/4

inches)

2.Nut(3/8inch)5.Clevispin

3.Casterweight

4.Hairpincotter

6.Installthetapboltagainst

theframeandtightenthe

nut.

TocomplywithANSI/OPEIB71.4-2004Standard,youmust

addweightstothemachine.

CAUTION

Thebaggeraddsalotofweighttotherearofthe

machineandmaycauseanunstablecondition,

whichcouldresultinalossofcontrol.

Thefollowingtableshowswhatweightsyouusewhenyou

installabagger.

Frontweights

used

48-inchmower

deckwithbagger

52-inchmower

deckwithbagger

60-inchmower

deckwithbagger

72-inchmower

deckwithbagger

30

30

32

12

1.Installcasterweightsonthefrontcasterswithaclevis

pinandhairpincotter(Figure31).

2.Installthenut(3/8inch)ontoeachtapbolt(3/8x

1-3/4inches)andinstallthetapboltsintoeachweight

(Figure31).

Casterweights

used

4.Installtheweight-mountbracketunderthefootrest

with2carriagebolts(5/16x3/4inch)and2ange

nuts(5/16inch).

Figure32

1.Carriagebolt(5/16x3/4

inch)

2.Weight-mountbracket

3.Flangenut(5/16inch)

5.Installthefrontweightsontopofthefootrest(Figure

33).

20

Page 21

6.Securethefrontweightsontopofthefootrestandto

theweight-mountbracketwith6bolts(3/8x1inch),

6lockwashers(3/8inch),3angenuts(smallange)

(3/8inch)and6atwashers(3/8inch)(Figure33).

13

InstallingtheBumpers

MachineswithMyRide™Suspension

System

Partsneededforthisprocedure:

2Bumper

2

Spacer

2

Locknut(5/16inch)

Procedure

For48-inch,52-inch,and60-inchdecks,installthebumpers

tothe2outsideholesofthetoeboard(Figure35).

Figure33

1.Frontweight

2.Flatwasher(3/8inch)5.Holeinfootrest

3.Lockwasher(3/8inch)6.Flangenut(small

4.Bolt(3/8x1inch)

ange–3/8inch)

1.Locknut(5/16inch)

2.Spacer

Figure35

3.Bumper

Figure34

1.Weight-mountbracket

2.Flatwasher(3/8inch)4.Bolt(3/8x1inch)

3.Lockwasher(3/8inch)

21

Page 22

For72-inchdecks,installthebumperstothe2insideholes

ofthetoeboard(Figure36).

Figure36

15

CheckingtheTirePressure

NoPartsRequired

Procedure

Note:Increasethetirepressureduetotheadditionalweight.

Checkandincreasetheairpressureinthefrontcasterwheels

andthereartires(Figure37).

Pressure:Reartires:138kPa(20psi)

Frontcasterwheels:172kPa(25psi)

1.Locknut(5/16inch)

2.Spacer

3.Bumper

14

AdjustingtheParkingBrake

NoPartsRequired

Procedure

Makesurethatthebrakeisadjustedproperly;refertothe

Operator’sManualforthemachine.

Figure37

22

Page 23

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Settheparkingbrakewhenyouleavethe

machine,evenifjustforafewminutes.

WARNING

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Toavoidpersonalinjury,followtheseprocedures:

•Becomefamiliarwithalloperatingandsafety

instructionsinthe

machinebeforeusingthisattachment.

•Neverremovethebaggerorbaggertubeswhile

theengineisrunning.

•Alwaysshuttheengineoffandwaitforall

movingpartstostopbeforeclearingan

obstructionfromthebaggingsystem.

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

•Settheparkingbrake.

Operator's Man ual

foryour

WARNING

Withoutthegrassdeector,baggertubesor

completecollectionsystemmountedinplace,you

andothersareexposedtobladecontactandthrown

debris.Contactwiththerotatingmowerblade(s)

andthrowndebriswillcauseinjuryordeath.

AdjustingtheBafe

AdjustthebafetopositionB(middleposition)forbagging.

RefertotheOperator’sManualforthemachineforthebafe

adjustmentprocedure.

Figure38

•Alwaysinstallthegrassdeectorwhenyou

removethecollectionsystemandchangeto

side-dischargemode.

•Ifthegrassdeectoriseverdamaged,replaceit

immediately.Thegrassdeectorroutesmaterial

downtowardtheturf.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(PTO)tooffandrotatetheignitionkeytooff.

Alsoremovethekeyandpullthewireoffthe

sparkplug(s).

•Turnofftheenginebeforeuncloggingthe

dischargechute.

•Neveruseyourhandstounclogthedischarge

chute,useastickorsimilarobject.

23

Page 24

EmptyingtheBagger

1.DisengagethePTOandsettheparkingbrake.

2.Liftthehandletoopenthedoorandemptythehopper.

3.Pushthehandledowntoclosethedoor(Figure39).

7.Iftheblowerassemblyisplugged,unlatchtheblower

assembly,removethebelt,andswingitopen.

Important:Useastickorsimilarobject,notyour

hands,toremoveandcleartheobstructionfrom

theblowerassembly.

Note:Ifyoudrivethemachineontoatruckortrailer

whilethehopperisfull,alwaysbackuptheramp.This

willreducethechanceofrearwardtip.

Figure39

ClearingObstructionsfrom theCollectionSystem

WARNING

Whenyouoperatecollectionsystem,theblower

rotatesandcancutofforinjurehands.

•Beforeadjusting,cleaning,repairingand

inspectingtheblower,andbeforeunclogging

thechute,turnofftheengineandwaitforall

movingpartstostop.Removethekey.

•Useastick,notyourhands,toremovean

obstructionfromtheblowerandtube.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

1.DisengagethePTOandsettheparkingbrake.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

8.Afteryouremovetheobstruction,installthecomplete

collectionsystemandresumeoperation.

RemovingtheBagger

WARNING

Componentsaroundenginewillbehotifthe

machinehasbeenrunning.Touchinghot

componentscancauseburns.

•Donottouchenginecomponentswhenthey

arehot.

•Allowenginetocoolbeforeremovingthebagger.

1.DisengagethePTO,settheparkingbrake,andchock

orblockthetires.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchthelowertubefromtheblowerandremove

thetubefromtheblowerassembly.

4.Removethetubefromthebaggerhood.

5.Lowerthemowerdecktothelowestheight-of-cut

position.

6.Unlatchthebeltcoveroverthemower-pulleyassembly.

7.Removetheblowerbeltfromthemower-pulley

assembly.

8.Opentheblowerassembly .

9.Removetheblowerassemblyfromthepivothole.

10.Ifyouarechangingtoside-dischargemode,ensurethat

thegrassdeectorisinstalledandcanbeloweredinto

workingposition.

11.Removethecollectionsystemassembly .

3.Emptythebagger.

4.Unlatchthelowertube.

5.Removethetubesfromthebagger.

6.Useastickorsimilarobject,notyourhands,toremove

andcleartheobstructionfromthetubeassembly .

Note:Inmostcases,thedebriscanbeshakenoutof

thetubes.

24

Page 25

UsingtheGrassDeector

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Alwaysinstallthegrassdeectorwhenremoving

thecollectionsystemandchangingtoside

dischargemode.

•Ifthegrassdeectoriseverdamaged,replaceit

immediately.Thegrassdeectorroutesmaterial

downtowardtheturf.

•Neverputyourhandsorfeetunderthemower.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.You

needtocutyourgrasstwiceifitgetsexcessivelylong(referto

BaggingLongGrassBaggingLongGrass(page25)).

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlapthe

mowerintothepreviouslycutarea.Thishelpsreducethe

loadontheengineandreducesthechanceofpluggingthe

blowerassemblyandtubes.

BaggingSpeed

Thebaggingsystemmayplugifyoudrivetoofastandthe

enginespeedgetstooslow .Onhills,youmayneedtoslow

thegroundspeedofthemachine.Mowdownhillwhenever

possible.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(PTO)totheoffposition,rotatetheignitionkey

tooffandremovethekey .

TransportingMachines

DANGER

Transportingthemachinewithgrassordebrisin

thebaggercandamagethemachine.

Donotleavegrassordebrisinthebaggerwhile

transportingthemachineonatrailerortruck.

OperatingTips

MachineSize

Rememberthatthemachineislongerandwiderwiththis

attachmentinstalled.Ifyouturntoosharplyinconned

places,youmaydamagetheattachmentorotherproperty.

Trimming

Alwaystrimwiththeleftsideofthemower.Donottrim

withtherightsideofthemowerbecauseyoucoulddamage

thebaggingtubes.

CuttingHeight

CAUTION

Asthebaggerlls,extraweightisaddedtotheback

ofthemachine.Ifyoustopandstartsuddenlyon

hills,youmaylosesteeringcontrolorthemachine

maytip.

•Donotstartorstopsuddenlywhengoinguphill

ordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoinguphill,

disengagethePTO.Thenbackdownthehill

usingaslowspeed.

•Donotchangespeedsorstoponslopes.

BaggingLongGrass

Ifthegrassgrowslongerthannormal,orifitcontainsahigh

degreeofmoisture,raisethecuttingheighthigherthanusual

andcutandbagthegrassatthissetting.Thencutandbagthe

grassagainusingthelower,normalsetting.

Excessivelylonggrassisheavyandmaynotbepropelled

completelyintothebagger.Ifthishappens,thetubeand

blowermayplug.Toavoidpluggingthebaggingsystem,mow

thegrassatahighheight-of-cut,thenlowerthemowerto

yournormalcuttingheightandrepeatthebaggingprocess.

BaggingWetGrass

Ifpossible,alwaystrytocutgrasswhenitisdry.W etgrass

cancauseplugging.

Foroptimumbaggingperformance,setthedeckheight-of-cut

toremovenomorethan2to3inches(51to76mm)or

1/3ofthegrassheight,whicheverisless.Cuttingoffmore

thanthiswillreducethecapacityofthevacuumsystem.

25

Page 26

ReducingPlugging

Toavoidpluggingthebaggingsystem,reducetheground

speedandmowthegrassatahighheight-of-cut,thenlower

themowertoyournormalcuttingheightandrepeatthe

baggingprocess.

SignsofPlugging

Asyouusethebagger,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.Anexcessive

amountofclippingblow-outindicatesthatthebaggerisfull

orthetubeisplugged.

BaggingBlades

Inmostmowingconditions,thestandardhighliftblades

providesthebestbaggingperformance.

TheToroAtomicbladeisrecommendedforbaggingleaves

indryconditions.Indry,dustyconditions,themediumliftor

lowliftbladesreducesdustanddirtblowoutwhileproviding

effectivebaggingairow.

ContactanAuthorizedServiceDealerfortheproperblades

fordifferentmowingconditions.

CurbClimbingandLoading

Alwaysliftthedecktothehighestpositionwhenloadingthe

machineontrailersorascending/descendingacurb.Leaving

themowerinalowerpositionwhileloadingorgoingovera

curbcancausedamagetothemower.Ifacurbishigherthan

152mm(6inches),crossitatasharpanglewiththedeck

fullyraised.Useextremecautionwhenloadingontoatrailer.

Useafull-widthramp;therampshouldbelongenoughso

thattheangledoesnotexceed15degrees.

26

Page 27

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Inspecttheblowerbelt.

•Inspectthecollectionsystem.

•Adjusttheparkingbrake(alsowhenreplacingorremovingabrakecomponent).

•Cleanthehoodscreen.

•Cleanthecollectionsystem.

•Inspecttheblowerbelt.

•Greasetheidlerarm.

•Greasethehandlepivot.

•Inspectthecollectionsystem.

CleaningtheBaggerScreen

ServiceInterval:Beforeeachuseordaily

Cleanthescreenbeforeeachuse(moreofteninwetgrass).

1.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Openthebagger.

4.Cleanthedebrisfromthescreen.

5.Closethebagger.

CleaningtheCollection System

ServiceInterval:Beforeeachuseordaily

1.Washtheinsideandoutsideofthebaggerhood,tube,

andtheundersideofthemower.Useamildautomotive

detergenttoremovedirt.

2.Makesureyouremovemattedgrassfromallparts.

3.Afterwashingallparts,letthemdrythoroughly.

Note:Withallpartsinstalled,startandrunthemachinefor

aminutetoassistindrying.

27

Page 28

InspectingtheBlowerBelt

ServiceInterval:Aftertherst8hours

Every25hours

Checkthebeltsforcracks,frayededges,burnmarks,orany

otherdamage.Replacedamagedbelts.

ReplacingtheBlowerBeltfor 60-and72-inchMowers

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pullbackonthespring-loadedidlerpulleytorelieve

thebelttension(Figure40).

4.Removetheexistingbaggerbeltfromthemower-deck

pulleyandthentheblowerpulleys.

5.Installthenewbeltaroundtheblowerpulleysandthe

mower-deckpulley(Figure40).

6.InstallthespringasshowninFigure41.

Figure41

1.Spring-loadedidlerpulley

2.Short-hookend

7.Pullbackonthespring-loadedidlerpulleyandinstall

thebeltontothespring-loadedidlerpulley(Figure40).

3.Long-hookend

Figure40

1.Idlerpulley

2.Mower-deckpulley5.Belt

3.Spring

4.Springpeg

6.Blowerpulley

ReplacingtheBlowerBeltfor 48-and52-inchMowers

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Loosenthebeltguidebolt(Figure42).

4.Removetheexistingblowerbelt.

5.Installthenewbeltaroundtheblowerpulley(Figure

42).

6.Installthebeltbetweenthexed-idlerpulleyandthe

belt-guidebolt.

7.Tightenthebeltguidebolt(Figure42).

28

Page 29

Figure42

1.Idlerpulley5.Belt

2.Mower-deckpulley6.Belt-guidebolt

3.Spring

4.Springpeg

8.InstallthespringasshowninFigure43.

7.Fixed-idlerpulley

8.Blowerpulley

CheckingandAdjustingthe BlowerLatch

Closetheblowerassemblytoseeifthelatchesareadjusted

correctly.Loosenortightentheboltssothelatchesrmly

holdtheblowerassemblyagainstthemowerdeckbutcanbe

releasedbyhand.

Figure44

1.Latch3.Blowerassembly

2.Bolt

Figure43

1.Spring-loadedidlerpulley

2.Short-hookend

9.Installthebeltontothespring-loadedidlerpulley

(Figure42).

3.Long-hookend

GreasingtheIdlerArmand HandlePivot

ServiceInterval:Every50hours—Greasetheidlerarm.

Every100hours—Greasethehandlepivot.

Greasetheblowerbeltidlerarm(Figure45).

Figure45

29

Page 30

For60-and72-inchmowersonly,greasethehandlepivot

(Figure46).

Figure46

AdjustingtheClosedDoorfor 60-and72-inchMowers

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Withthedoorclosed,loosenthenutsandadjustthe

stopboltssothatthecontactarmisstraightupand

down(Figure47).

4.Adjustthelengthofthehingelinkstosothatthedoor

completelyclosesandreasonableforceisonthehandle

(Figure47).

Note:Lengthenthelinkstoreducetheforce.Shorten

thelinkstoincreasetheforce

Note:Makesurethatboththeleftandrightsidesare

adjustedthesamedistance.Withthedoorclosed,the

linksshouldbeslightlytighttominimizerattling.

5.Tightenthenuts.

InspectingtheCollection System

ServiceInterval:Aftertherst8hours

Every100hours

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Checktheuppertube,lowertube,bagger,andthe

blowerassembly .

Note:Replacethesepartsiftheyarecrackedor

broken.

4.Checkthebaggerframe.

Note:Replaceanypartsthatarecrackedorbroken.

5.Tightenallnutsboltsandscrews.

1.Contactarm—straightup

anddown

2.Stopbolt

Figure47

3.Hingelinks

30

Page 31

AdjustingtheOpenDoorfor

AdjustingtheLatchesfor60-

60-and72-inchMowers

Note:Performthisprocedureafteradjustingthedoorto

completelyclose.

Adjustthehandlelinktosothatthedooropensasmuchas

possible(Figure48andFigure49).

Note:Lengthenthehandlelinktoopenthedoorfarther.

Shortenthehandlelinktoopenthedoorless

Note:Howfarthedooropensiscontrolledbythecontact

armhittingthestop.Thestopisnotadjustableandprevents

thedoorfrombeingopenedtoofar.

and72-inchMowers

Note:Adjusttheopendoorandcloseddoorpositions

beforeadjustingthelatches.

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closethedoor.

4.Ensurethatthelatchescompletelyengageandcontacts

thelatchrodweldedtothedoor(Figure50).

Note:Thelatchesneedtobetightagainstthelatch

rod.Theyneedtobelooseenoughtomoveorwiggle.

1.Handle

2.Handlelink

1.Handleassembly

2.Bagger-handlelink

Figure48

Figure49

3.Stop

3.Clevis-pinspring

Figure50

1.Latchlink2.Latchrod

AdjustingtheArmPositionfor 48-and52-inchMowers

Theleftandrightbellcrankarmsneedtobeequallypositioned

fromtheupperframetubeforproperuse.

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethesideplatefrombothsidesofthebagger

(Figure51).

31

Page 32

Figure51

1.Bolt

2.Washer

3.Sideplate

4.Checkthedistancebetweentheleftandrightbellcranks

andtheupperframetube.

AdjustingtheClosedDoorfor 48-and52-inchMowers

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKEDposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Withthedoorclosed,checkandensurethatitisslightly

tightagainsttheframewhenclosed.

4.Ifadjustmentisneeded,adjustthenuts.

Note:Lengthenthelinkstoreducetheforce.Shorten

thelinkstoincreasetheforce.

Note:Makesurethatboththeleftandrightsidesare

adjustedthesamedistance.Withthedoorclosed,the

linksshouldbeslightlytighttominimizerattling.

5.Tightenthenuts.

Note:Thesedimensionsneedtobethesameonboth

sides.

5.Tomakethedistancesequal,loosentheAllen-head

boltonthehuboftherightbellcrank(Figure52).

6.Positionthebellcrankarmsthesamedistancefrom

theupperframetube.

7.TightentheAllen-headboltandinstallthesideplates.

Figure53

1.Door3.Nut

2.Hingelink

1.Rightbellcrankarm

2.Allen-headbolt

Figure52

3.Distancefromthe

bellcrankarmandupper

frametubeisthesameon

bothsides.

4.Upperframetube

32

Page 33

AdjustingtheOpenDoorfor 48-and52-inchMowers

Performthisafteradjustingthecloseddoor.

1.Removethesideplatefrombothsidesofthebagger

(Figure54).

Figure55

Figure54

1.Bolt

2.Washer

3.Sideplate

2.Openthedoor.

3.Checkthedistancebetweentheuppertubeofthedoor

frameandthelowerlipofthemoldedhood(Figure55).

Note:Thedistanceshouldbebetween3.2mm(1/8

inch)and9.6mm(3/8inch).

1.Lowerlipofthemolded

hood

2.Themeasurementis

betweenan3.2mm(1/8

inch)and9.6mm(3/8

inch).

3.Uppertubeofthedoor

frame

4.Ifadjustmentisneeded,adjustthehingestopsonboth

sidessothatthedistancebetweentheuppertubeof

thedoorframeandthelowerlipofthemoldedhoodis

betweenan3.2mm(1/8inch)and9.6mm(3/8inch).

Note:Makesurethatboththeleftandrighthinge

stopsareadjustedthesamedistance.

5.Tightenthenutsandinstallthesideplates.

1.Hingestop2.Nut

33

Figure56

Page 34

AdjustingtheParkingBrake

InstallingtheGrassDeector

ServiceInterval:Aftertherst100hours

RefertotheOperator’sManualforthemachinetoadjustthe

parkingbrake.

InspectingtheMowerBlades

1.Inspectthemowerbladesregularlyandwhenevera

bladestrikesaforeignobject.

2.Ifbladesarebadlywornordamaged,installnewblades.

RefertoyourmowerOperator'sManualforcomplete

blademaintenance.

InstallingtheMowerBlades

Inmostmowingconditions,thestandardhigh-liftbladeswill

providethebestbaggingperformance.

TheToroAtomicbladeisrecommendedforbaggingleaves

indryconditions.Indrydustyconditions,themedium-liftor

low-liftbladesreducesdustanddirtblowoutwhileproviding

effectivebaggingairow.

ContactanAuthorizedServiceDealerfortheproperblades

fordifferentmowingconditions.

RefertothemowerOperator'sManualformoreinformation

oninstallingblades.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsatyouorothersand

resultinseriousinjury.Also,contactwiththeblade

couldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

•Makesurethatthegrassdeectorisinthedown

position.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure57).

2.Removethedamagedorworngrassdeector.

3.Placethespacerandspringontothegrassdeector.

Note:PlacetheLendofthespringbehindthedeck

edge.

Note:MakesurethattheLendofthespringis

installedbehindthedeckedgebeforeinstallingthebolt

asshowninFigure57

4.Installtheboltandnut.

5.PlacetheJ-hookendofthespringaroundthegrass

deector(Figure57).

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorupto

testthatitlowersintothefulldownposition.

Figure57

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.J-hookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

34

Page 35

Storage

1.Cleanthebagger.RefertoCleaningtheBaggerScreen

(page27)andCleaningtheCollectionSystem(page27).

2.Inspectthebaggerfordamage.RefertoInspectingthe

CollectionSystem(page30).

3.Makesurethatthebaggerisemptyandthoroughlydry.

4.Checkthebeltforwearorcracks.

5.Storethemachineinaclean,dryplace,outofdirect

sunlight.Ifyoumuststorethemachineoutside,cover

itwithaweatherproofcover.Thisprotectstheplastic

partsandextendsthelifeofthemachine.

35

Page 36

Troubleshooting

Problem

Thereisabnormalvibration.

Baggingperformanceisreduced.

Blowerandtubesplugtoofrequently .

PossibleCauseCorrectiveAction

1.Cuttingblade(s)is/arebentor

unbalanced.

2.Ablade-mountingboltisloose.2.Tightentheblade-mountingbolt.

3.Ablowerpulleyorpulleyassemblyis

loose.

4.Ablowerbeltisworn.4.Replacetheblowerbelt.

5.Blowerfanblade(s)is/arebentor

unbalanced.

1.Theenginespeedislow.1.Alwaysoperatethecollectionsystem

2.Thescreeninthebaggerhoodis

plugged.

3.Ablowerbeltisloose.3.Replacetheblowerbelt.

4.Atubeorblowerisplugged.4.Locateandremovethepluggeddebris.

5.Thebaggerisfull.

1.Thebaggeristoofull.1.Dumpthebaggermorefrequently.

2.Theenginespeedislow.2.Alwaysoperatethecollectionsystem

3.Grassistoowet.3.Cutgrasswhenitisdry .

4.Grassistoolong.4.Cutnomorethan51-76mm(2-3

5.Thescreeninthebaggerhoodis

plugged.

6.Thegroundspeedistoofast.6.Drivesloweratfullthrottle.

7.Ablowerbeltisworn.7.Replacetheblowerbelt.

1.Installnewcuttingblade(s).

3.Tightentheappropriatepulley .

5.ContactanAuthorizedServiceDealer.

atfullthrottle.

2.Removedebris,leavesorgrass

clippingsfromthescreen.

5.Emptythebagger.

atfullthrottle.

inches)or1/3ofthegrassheight,

whicheverisless.

5.Removedebris,leavesorgrass

clippingsfromthescreen.

Debrisblowout.

Theblowerimpellerdoesnotspinfreely.

1.Thebaggeristoofull.1.Dumpthebaggermorefrequently.

2.Thegroundspeedistoofast.2.Drivesloweratfullthrottle.

3.Themowerdeckisnotlevel.

1.Theblowerisplugged.1.Removedebris,leavesorgrass

2.Theimpellernotaligned.

3.SeetheOperator'sManualforthe

machineforlevelingthemowerdeck.

clippingsfromtheblowerimpeller .

2.ContactanAuthorizedServiceDealer.

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

Notes:

39

Page 40

TheToroTotalCoverageWarranty

ALimitedWarranty(seewarrantyperiodsbelow)Contractor

Landscape

Equipment

(LCE)

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany ,pursuanttoanagreement

betweenthem,jointlypromisetotheoriginalpurchasertorepairtheT oroProducts

listedbelowifdefectiveinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchasebytheoriginalowner:

ProductsWarrantyPeriod

21in.Mowers2yearsResidentialUse

1yearCommercialUse

4

•Engines

Honda–2years

Kawasaki–3years

30in.Mowers2yearsResidentialUse

1yearCommercialUse

4

•Engines

Mid-SizeWalk-BehindMowers

4

•Engines

GrandStand

4

•Engines

•Frame

®

ZMaster

•Engines

2000SeriesMowers

4

•Frame

®

ZMaster

•Engines

•Frame

ZMaster

•Engines

®

4

4

3000SeriesMowers

5000SeriesMowers

®

Mowers

Kawasaki–3years

2years

Kawasaki–3years

5yearsor1,200hours

3years

Lifetime(originalowneronly)

4yearsor500hours

3years

Lifetime(originalowneronly)

5yearsor1,200hours

3years

Lifetime(originalowneronly)

5yearsor1,200hours

KohlerCommand–2years

KohlerEFI–3years

•Frame

®

ZMaster

•Engines

6000SeriesMowers

4

•Frame

®

ZMaster

•Engines

7000SeriesMowers

4

•Frame

®

ZMaster

•Engines

8000SeriesMowers

4

•Frame

Lifetime(originalowneronly)

5yearsor1,200hours

Kawasaki–3years

Lifetime(originalowneronly)

5yearsor1,200hours

2years

Lifetime(originalowneronly)

2yearsor1,200hours

2years

Lifetime(originalowneronly)

AllMowers

•Battery90daysPartsandLabor

1yearPartsonly

•BeltsandTires90days

•Attachments1year

1

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialwarrantywouldapply.

2

Whicheveroccursrst.

3

LifetimeFrameW arranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthe

tractorstructurethatothercomponentssuchastheenginearesecuredto,cracksorbreaksin

normaluse,itwillberepairedorreplaced,atToro'soption,underwarrantyatnocostforpartsand

labor.Framefailureduetomisuseorabuseandfailureorrepairrequiredduetorustorcorrosion

arenotcovered.

4

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer .

1

1

2

3

2

3

2

3

2

3

2

3

2

3

2

3

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsorworkmanship,

followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.T olocateadealerconvenienttoyou,refertotheYellowPagesof

yourtelephonedirectory(lookunder“LawnMowers”)oraccessourwebsite

atwww.Toro.com.Y oumayalsocallthenumberslistedinitem#3tousethe

24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)totheService

Dealer.Thedealerwilldiagnosetheproblemanddetermineifitiscovered

underwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’sanalysisorwith

theassistanceprovided,contactusat:

RLCCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

888-865-5676(U.S.Customers)

888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenanceprocedures

describedintheOperator'sManual.Suchroutinemaintenance,whetherperformedby

adealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystemcoverage

andenginewarrantycoverageonsomeproducts.Thisexpresswarrantydoesnot

coverthefollowing:

•Costofregularmaintenanceserviceorparts,suchaslters,fuel,lubricants,oil

changes,sparkplugs,airltersbladesharpeningorwornblades,cable/linkage

adjustments,orbrakeandclutchadjustments

•Componentsfailingduetonormalwear

•Anyproductorpartwhichhasbeenalteredormisusedorneglectedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Pickupanddeliverycharges

•RepairsorattemptedrepairsbyanyoneotherthananAuthorizedT oroService

Dealer

•Repairsnecessaryduetofailuretofollowrecommendedfuelprocedure(consult

Operator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontainsmorethan

10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-useoverone

month

GeneralConditions

AllrepairscoveredbythesewarrantiesmustbeperformedbyanAuthorizedT oro

ServiceDealerusingT oroapprovedreplacementparts.

NeitherTheToroCompanynorToroWarrantyCompanyisliableforindirect,

incidentalorconsequentialdamagesinconnectionwiththeuseoftheT oro

Productscoveredbythiswarranty ,includinganycostorexpenseofproviding

substituteequipmentorserviceduringreasonableperiodsofmalfunctionor

non-usependingcompletionofrepairsunderthiswarranty.

Allimpliedwarrantiesofmerchantability(thattheproductistforordinaryuse)

andtnessforuse(thattheproductistforaparticularpurpose)arelimitedto

thedurationoftheexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequentialdamages,

orlimitationsonhowlonganimpliedwarrantylasts,sotheaboveexclusions

andlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveotherrights

whichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry,

province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheToroimporter .Ifallother

remediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0252RevG

Loading...

Loading...