Page 1

TripleBaggingSystem

FormNo.3424-821RevA

ZMaster

®

Professional7500-DSeriesRiding

Mowerwith60inor72inTURBOFORCE

SideDischargeMower

ModelNo.78560—SerialNo.400000000andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-821*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

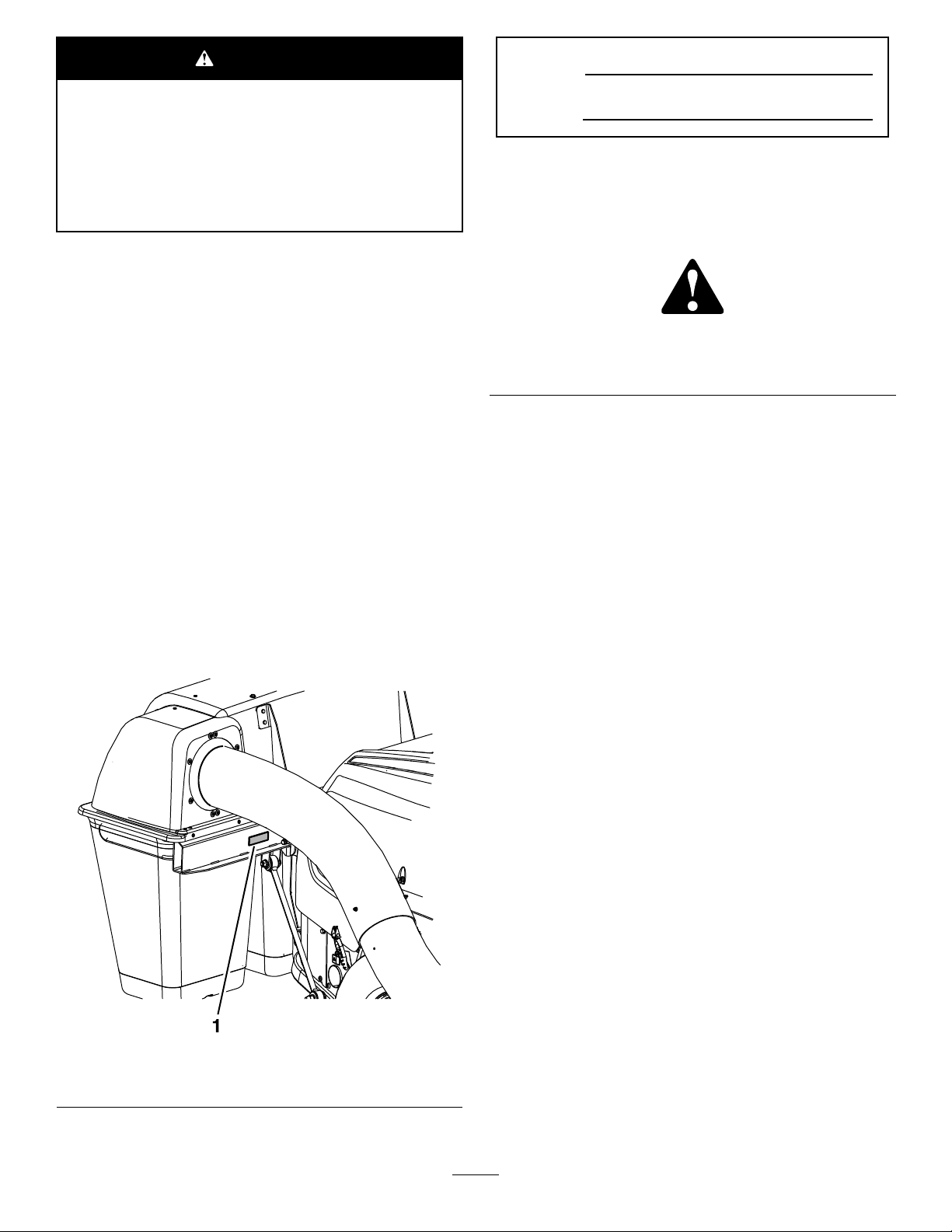

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

1.Modelandserialnumberlocation

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

g241694

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1PreparingtheMachine.....................................6

2InstallingtheWeights.......................................8

3InstallingtheBlowerAssembly.........................9

4InstallingtheMountBrackets..........................11

5InstallingtheHoodAssemblyand

Bags..............................................................12

6InstallingtheDischargeTubes.......................13

7AdjustingtheParkingBrake...........................15

8CheckingtheTirePressure............................15

Operation................................................................15

PositioningtheAdjustableBafe.......................15

EmptyingtheGrassBags.................................16

ClearingObstructionsfromtheBagger

System..........................................................16

RemovingtheCollectionSystemforSide

Discharge......................................................17

UsingtheGrassDeector.................................19

TransportingtheMachine.................................19

OperatingTips.................................................19

Maintenance...........................................................21

RecommendedMaintenanceSchedule(s)...........21

CleaningtheHoodScreen................................21

CleaningtheBaggerandBags.........................22

CheckingtheConditionoftheBelt....................22

InspectingtheBlowerBelt................................22

GreasingtheIdlerArm......................................22

InspectingtheBaggerAttachment....................23

InspectingtheMowerBlades............................23

InstallingtheMowerBlades..............................23

Storage...................................................................23

Troubleshooting......................................................24

DANGER

Theenginecanbecomehotwhenoperating.

Severeburnscanoccurfromcontactinghot

surfaces.

Allowengines,especiallythemufer,tocool

beforetouching.

DANGER

Debris,suchasleaves,grass,orbrushcan

catchre.Areintheengineareacancause

personalinjuryandpropertydamage.

•Keeptheengineandmuferareafreeof

debris.

•Takecarewhenopeningthebaggercover

tokeepdebrisfromfallingontotheengine

andmuferarea.

•Allowthemachinetocoolbeforestoringit.

•Becomefamiliarwiththesafeoperationofthe

equipment,withtheoperatorcontrols,andsafety

signs.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangetheoperating

characteristicsandthestabilityofthemachine.

•Followthemanufacturer'srecommendations

foraddingorremovingwheelweightsor

counterweightstoimprovestability.

•Donotuseagrasscatcheronsteepslopes.A

heavygrasscatchercouldcauselossofcontrol

oroverturnthemachine.

•Slowdownanduseextracareonhillsides.Be

suretotravelintherecommendeddirectionon

hillsides.Turfconditionscanaffectthestabilityof

themachine.Useextremecautionwhileoperating

neardrop-offs.

•Keepallmovementonslopesslowandgradual.

Donotmakesuddenchangesinspeed,directions

orturning.

•Thegrasscatchercanobstructtheviewtothe

rear.Useextracarewhenoperatinginreverse.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Keephandsandfeetawayfrommovingparts.Do

notmakeadjustmentswiththeenginerunning.

•Stopthemachineonlevelground,disengage

thedrives,chockorblockthewheels,shutoff

theengine,andremovethekeybeforeleaving

3

Page 4

theoperator'spositionforanyreason,including

emptyingthegrasscatcheroruncloggingthe

chute.

•Ifyouremovethegrasscatcher,installany

dischargedeectororguardthatmighthavebeen

removedtoinstallthegrasscatcher.Donot

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

112-9028

operatethemachinewithouteithertheentiregrass

catcherorthegrassdeectorinplace.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplace

withmanufacturer'srecommendedparts,when

necessary.

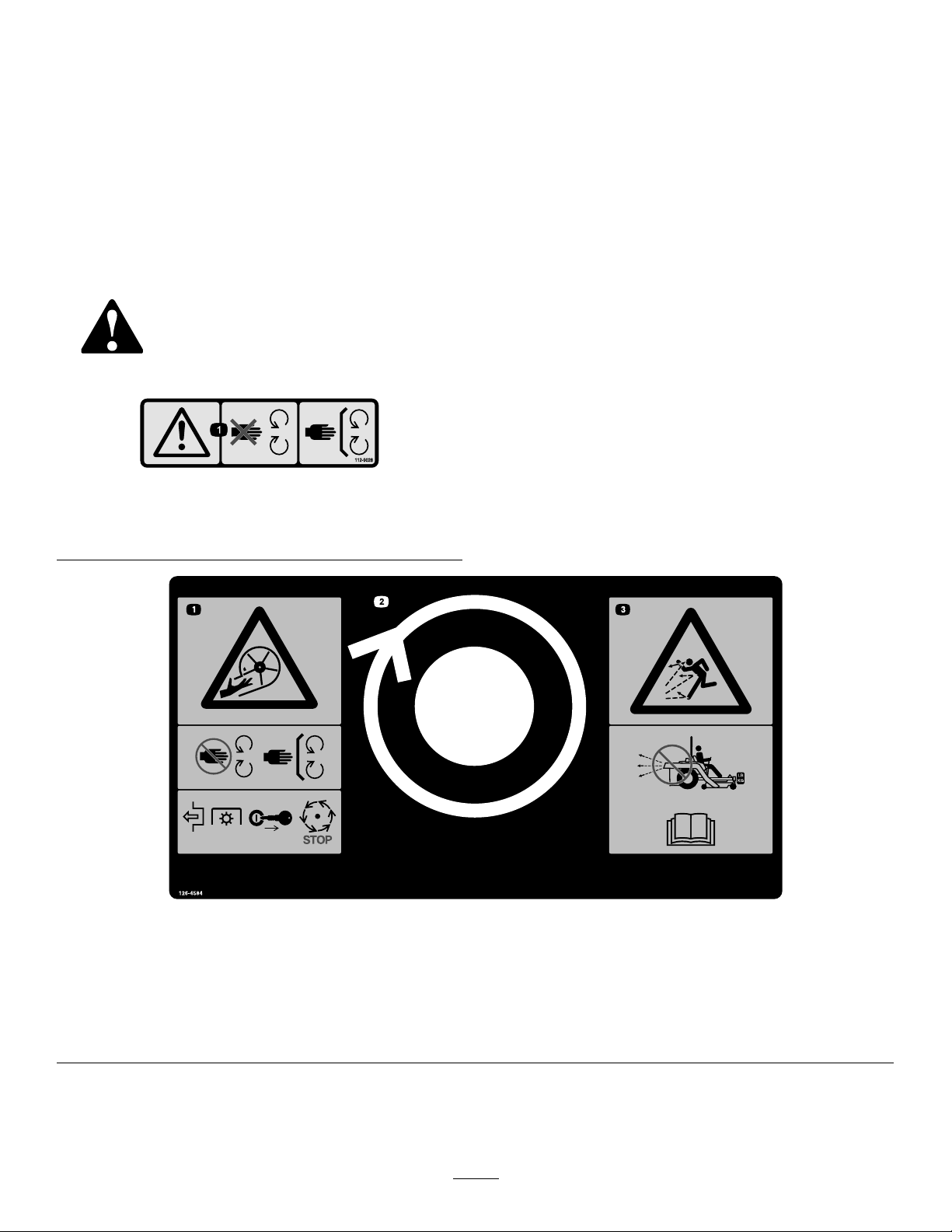

decal112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

126-4584

1.Impeller/Rotatingbladeshazard—keephandsawayfrommovingparts.Keepallsafetydevicesinplaceandworking.Donot

reachintotheblowerunlesstherotationindicatorhasstopped.DisengagethePTO,shutofftheengine,removethekey ,

andwaitforallmovingpartstostop.

2.Rotationindicator

3.Thrownobjectshazard—high-speeddischargecancauseinjuryordeath.Donotruntheblowerwithouttheentirecollection

systeminstalledandlatched.ReadtheOperator’sManual.

decal126-4584

4

Page 5

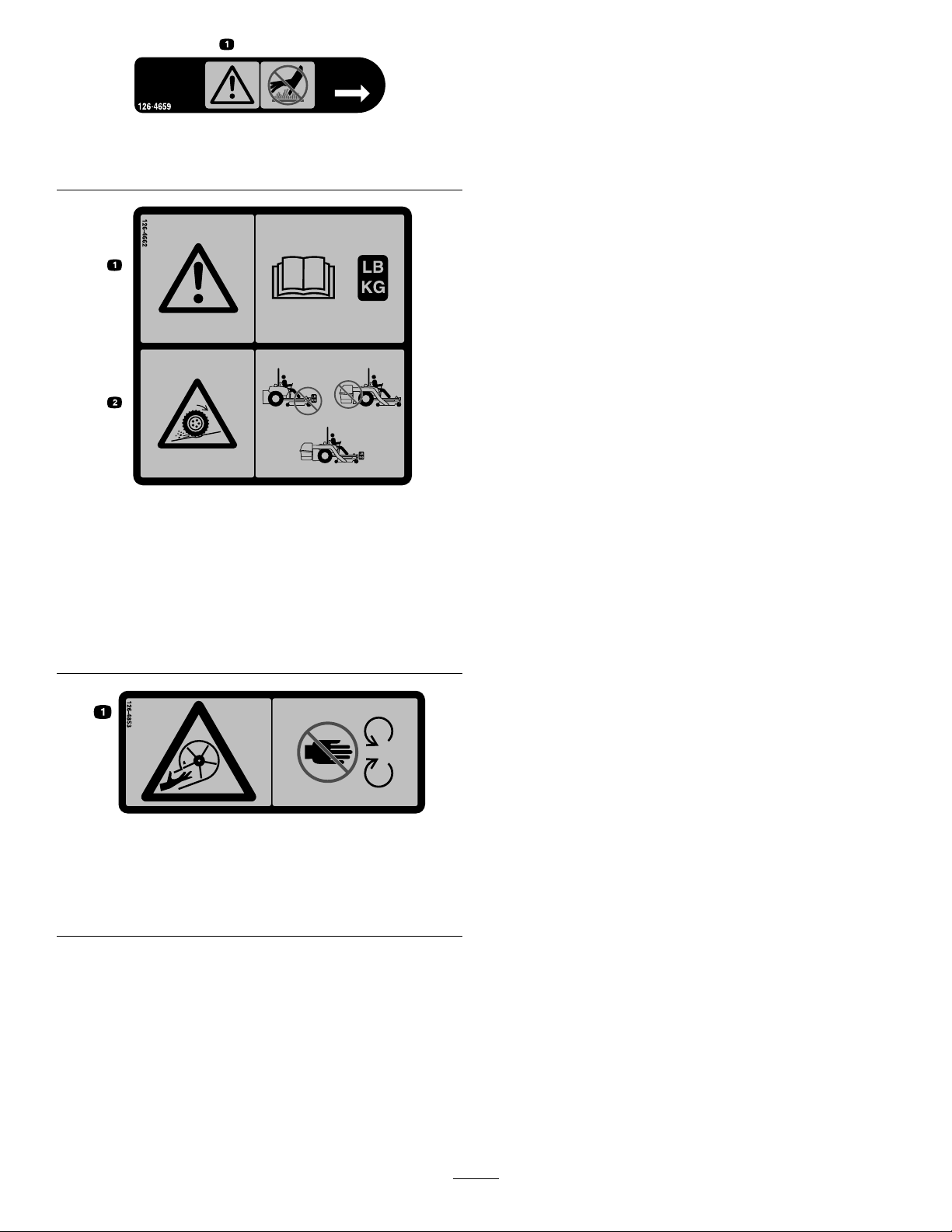

126-4659

1.Warning—hotpulley;allowtocool.

126-4662

1.Warning—readtheOperator’sManualforthecorrect

quantityofcounterbalanceweight(s).

2.Lossoftractionandsteeringorreducedstabilityhazard—Ez

Vaccounterbalanceweight(s)installedwithouttheEzV ac

maycauselossoftractionandsteeringcontrol.TheEzVac

installedwithouttheEzVaccounterbalanceweight(s)can

causereducedstability.Installweight(s)onlywhentheEz

Vacisinstalled.

decal126-4659

decal126-4662

126-4853

1.Impeller/Rotatingbladeshazard—keephandsawayfrom

movingparts.Keepallsafetydevicesinplaceandworking.

Donotreachintotheblowerunlesstherotationindicator

hasstopped.

decal126-4853

5

Page 6

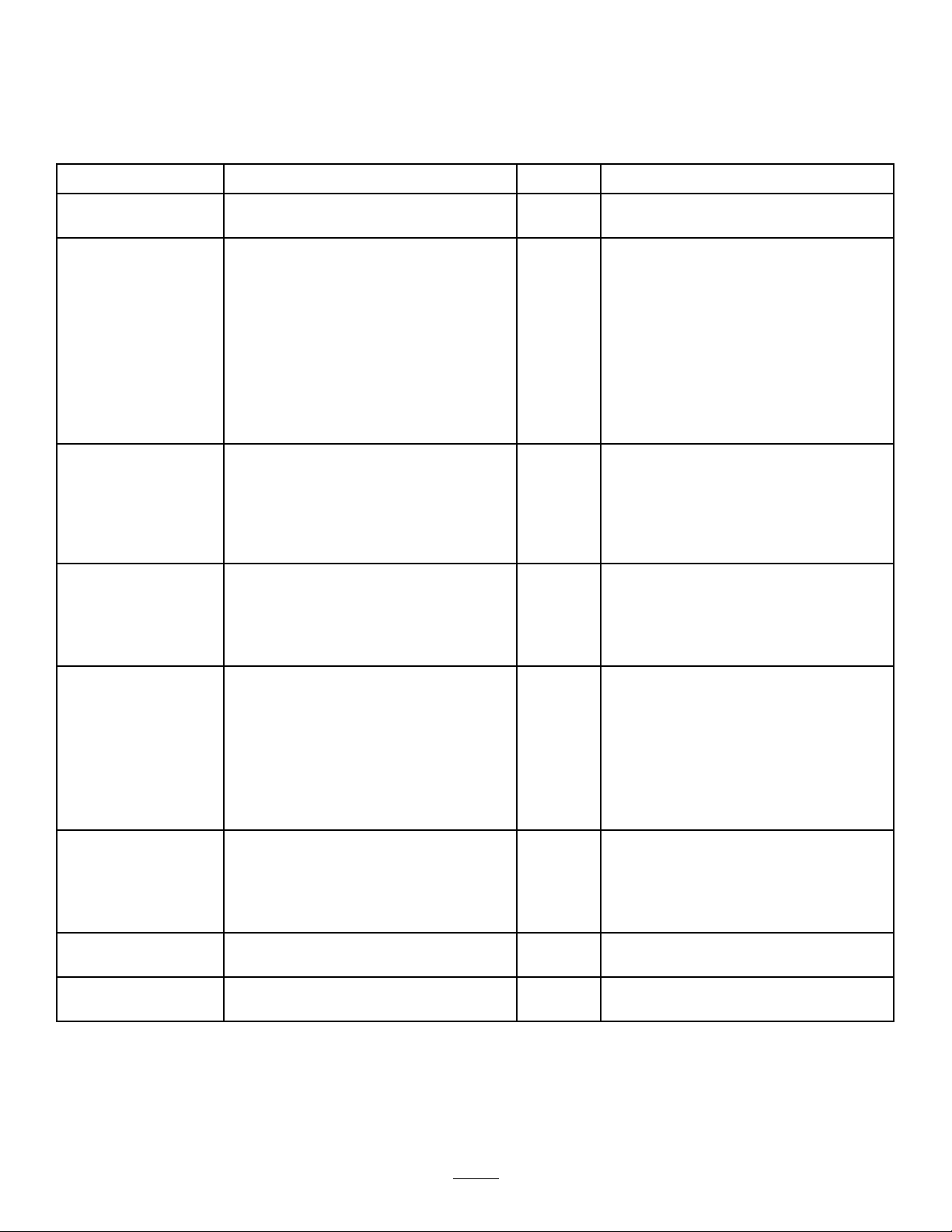

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Weightassembly2

Bolt(3/8x6-1/2inches)

Bracketassembly2

Casterweight—20.4kg(45lb)

Casterweight—9.1kg(20lb)

Clevispin

Hairpincotter2

Locknut(3/8inch)

Washer2

Bolt(3/8x8inches)

Blowerbelt(fromBlowerandDriveKit)

Knob(fromBlowerandDriveKit)

Beltcover(fromBlowerandDriveKit)

Blowerassembly(fromtheBlowerand

DriveKit)

Spring(fromtheBlowerandDriveKit)

Lowermountbracket2

Bolt(3/8x2-1/2inches)

Thickwasher

Locknut(3/8inch)

Carriagebolt(3/8x3inches)

Hoodassembly1

Bag3

Rod-supportassembly2

Thrustwasher4

Baggerpin2

Flatwasher2

Mount-pinlanyard2

Locknut(1/2inch)

Lowertubeasembly1

Uppertube1

Hex-washerheadbolt(#10x3/4inch)

Flatwasher3

Locknut(#10)

Qty.

Use

–

2

2

6

2

4

2

1

1

1

1

1

6

5

8

2

2

3

3

Preparethemachine.

Installtheweights.

Installtheblowerassembly .

Installthemountbrackets.

Installthehoodassemblyandbags.

Installthedischargetubes.

7

8

Nopartsrequired

Nopartsrequired

–

–

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

6

Adjusttheparkingbrake.

Checkthetirepressure.

Page 7

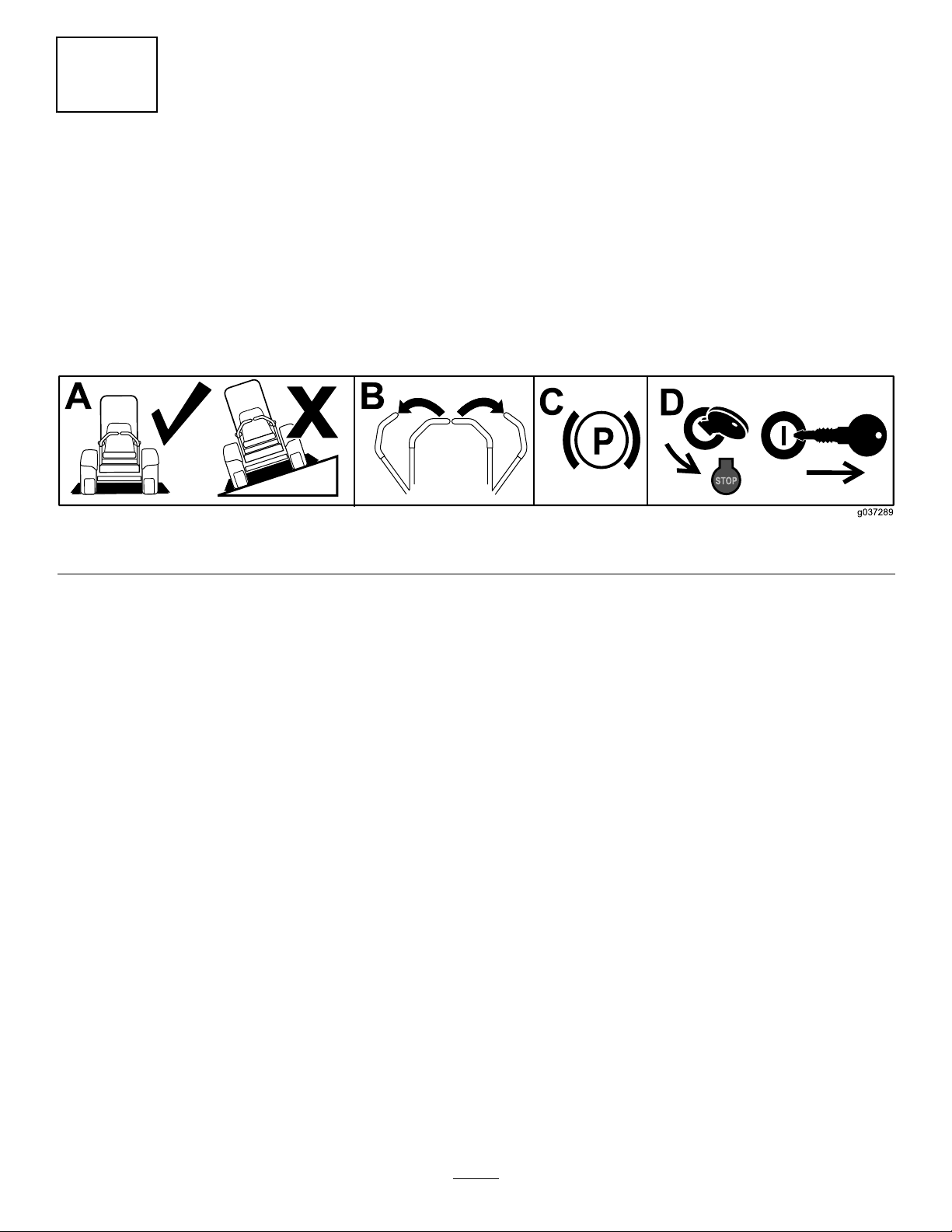

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Movethemotion-controlleverstotheNEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

g037289

Figure3

7

Page 8

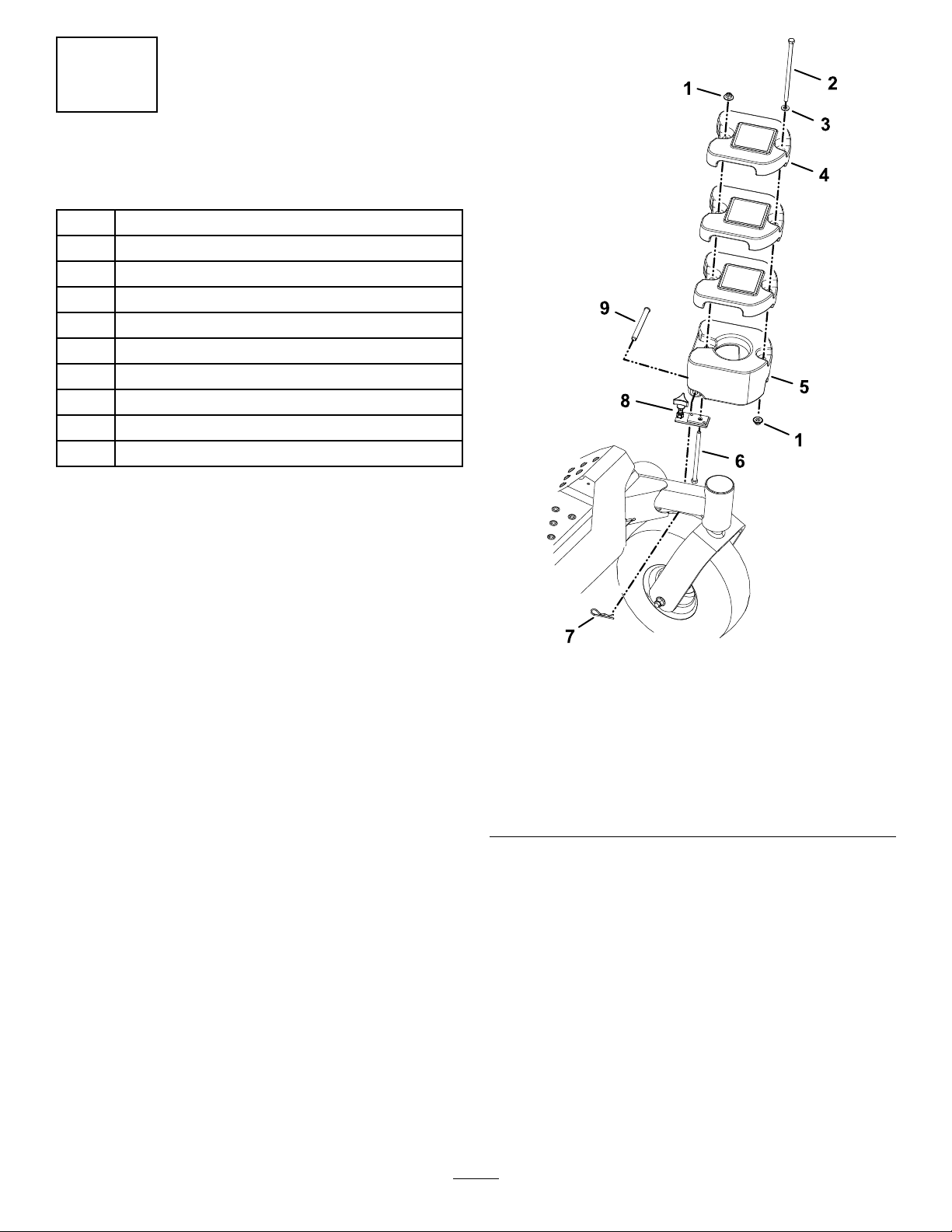

2

InstallingtheWeights

Partsneededforthisprocedure:

2Weightassembly

2

Bolt(3/8x6-1/2inches)

2Bracketassembly

2

Casterweight—20.4kg(45lb)

6

Casterweight—9.1kg(20lb)

2

Clevispin

2Hairpincotter

4

Locknut(3/8inch)

2Washer

2

Bolt(3/8x8inches)

Procedure

1.Insertthebolt(3/8x6-1/2inches)intoholeon

thebottomsideofthebracketandtherearof

theremovable20.4kg(45lb)casterweight

(Figure4).

Carefullyplacetheweightandbracketassembly

ontothecasterarmcenteringtheholeofthe

weightoverthecasterwheel.

2.Securethebottomofthebrackettothecaster

armusingaclevispinandhairpincotter(Figure

4).

3.Tightentheknobontheweightassemblyuntilit

isclampedsecurelytothecasterarm(Figure4).

4.Install3casterweights(9.1kg(20lb)overthe

weightassemblyboltandstackthemsecurely

ontothe20.4kg(45lb)casterweight(Figure4).

5.Securetherearoftheweightassemblywitha

locknut(3/8inch)asshowninFigure4.

6.Installthebolt(3/8x8inches)andwasher

throughthetopofthefrontholesoftheweight

assemblyandsecureitusingalocknut(3/8

inch)asshowninFigure4.

7.Repeatthisprocedureontheothersideofthe

machine.

Figure4

1.Locknut(3/8inch)6.Bolt(3/8x6-1/2inches)

2.Bolt(3/8x8inches)

3.Washer8.Bracketassembly

4.Casterweight—9.1kg(20

lb)

5.Casterweight—20.4kg

(45lb)

7.Hairpincotter

9.Clevispin

g260769

8

Page 9

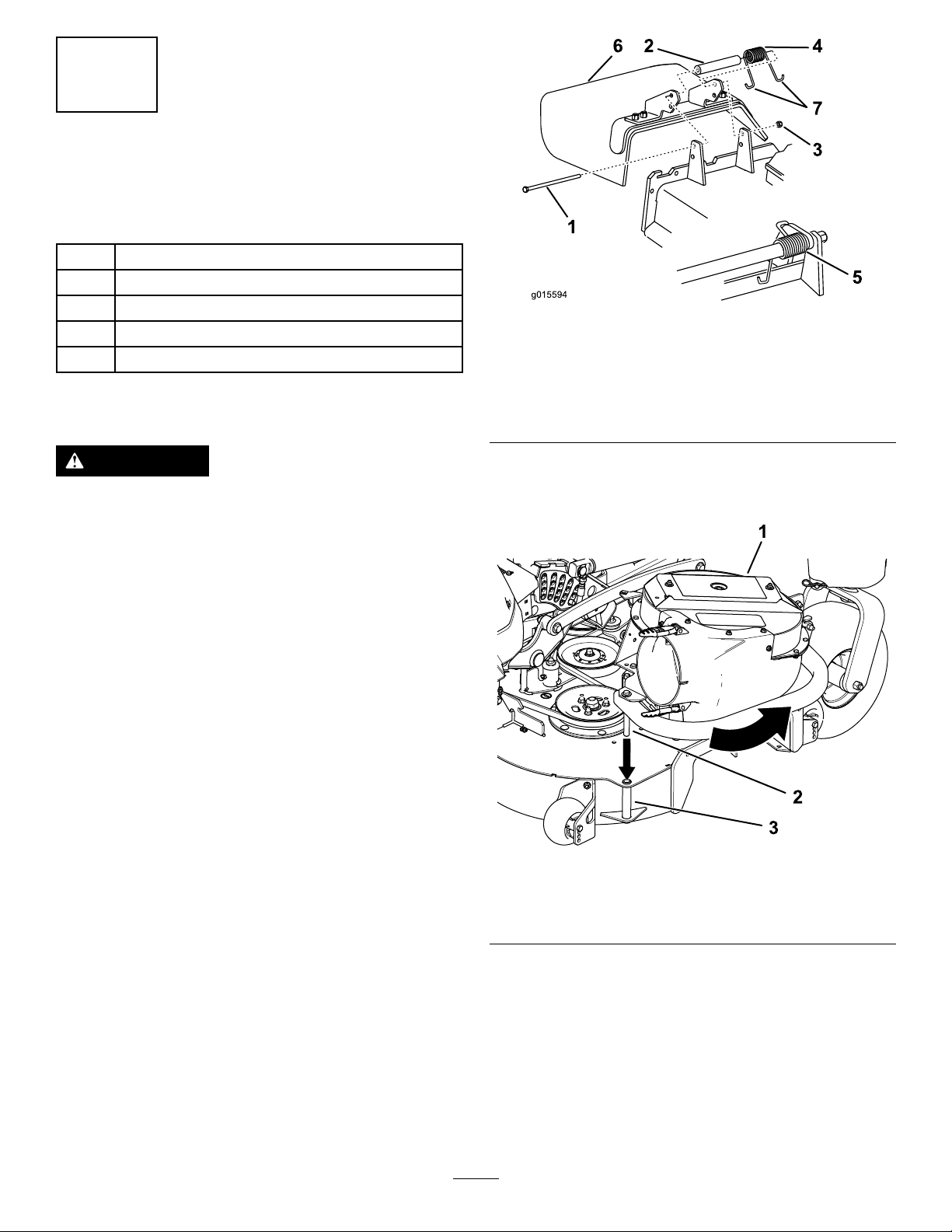

3

InstallingtheBlower Assembly

Partsneededforthisprocedure:

1

Blowerbelt(fromBlowerandDriveKit)

1

Knob(fromBlowerandDriveKit)

1

Beltcover(fromBlowerandDriveKit)

1

Blowerassembly(fromtheBlowerandDriveKit)

1

Spring(fromtheBlowerandDriveKit)

Procedure

Figure5

1.Bolt

2.Spacer6.Grassdeector

3.Locknut

4.Spring

5.Springinstalled

7.J-hookendofspring

g015594

WARNING

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectstowardyou

orbystanders,resultinginseriousinjury .

Also,contactwiththebladecouldoccur.

•Donotoperatethemachineunlessyou

installacoverplate,amulchplate,ora

grasschuteandcatcher.

•Ensurethatyouinstallthegrassdeector

whenthegrasschuteandcatcherare

removed.

1.Removethesidedischargechutefromthe

mowerdeck(Figure5).

Note:Saveallthehardwareandtheside

dischargechute.Installthesidedischargechute

whenthebaggerandblowerareremoved.

2.Inserttheblowerpivotpinintotheblower

supportandrotatetheblowerassemblyinward

towardthemachine(Figure6).

g260773

Figure6

1.Blowerassembly3.Blowersupport

2.Blowerpivotpin

9

Page 10

3.Pullthespring-loadedidlerbackandinstallthe

beltoverthedeckpulleyassembly(Figure7).

Figure7

1.Blowerpulley3.Deckpulley

2.Blowerbelt

4.Spring-loadedidler

4.Positionthebeltcoveratanangleandslideit

underthedeckframe(Figure8).

5.Pushdownontherearofthecoverandslideit

backwardundertheblower.

6.Withthebeltcoverrestingonthedeck,slideit

forwarduntilitseatsunderbothlipsonthedeck

(Figure9).

g260772

g260774

Figure9

1.Blower3.Knob

2.Beltcover4.Decklip

7.Securethebeltcoverusingtheknob(Figure9).

1.Blower

2.Beltcover

g242180

Figure8

3.Mowerframe

10

Page 11

4

InstallingtheMount Brackets

Partsneededforthisprocedure:

2Lowermountbracket

6

Bolt(3/8x2-1/2inches)

5

Thickwasher

8

Locknut(3/8inch)

2

Carriagebolt(3/8x3inches)

3.Looselyinstall1carriagebolt(3/8x3inches),1

thickwasher,and1locknut(3/8inch)intoeach

lowermountbracketthroughthefrontoftherear

bumper(Figure11).

Procedure

1.Looselyinstallalowermountbracketontheleft

andrightsideoftherearbumpercrosstube

(Figure10).

2.Alignthemountingholesandlooselyinstall

thebracketsusing2bolts(3/8x2-1/2inches),

2thickwashers,and2locknuts(3/8inch)as

showninFigure10.

Note:Youdonotinstallathickwasheronthe

left,outerside(Figure10).

Figure11

1.Carriagebolt(3/8x3

inches)

2.Thickwasher

4.Looselyinstall2bolts(3/8x2-1/2inches)and

2locknuts(3/8inch)atthefrontoftheframe

brackets(Figure11).

3.Locknut(3/8inch)

4.Bolt(3/8x2-1/2inches)

Note:Theheadoftheboltsshouldface

outwardoneachbracket(Figure1 1).

5.Tightenallthefasteners.

g260786

Figure10

1.Lowermountbracket4.Rearbumpercrosstube

2.Nowasherinstalledhere.

3.Thickwasher

5.Bolt(3/8x2-1/2inches)

6.Locknut(3/8inch)

g260785

11

Page 12

3.Liftthehopperassemblyandpivotitupward

towardtherearofthemachine.

5

InstallingtheHood AssemblyandBags

Partsneededforthisprocedure:

1Hoodassembly

3Bag

2Rod-supportassembly

4Thrustwasher

2Baggerpin

2Flatwasher

2Mount-pinlanyard

2

Locknut(1/2inch)

Procedure

Note:Use2peopleforthisprocedure.

1.Positionthehoodassemblyonitsback.

2.Pickupthebaggerframelegsandhookthe

notchontothelowerbagger-mountbar(Figure

12).

4.Securetherod-supportassemblytoeach

sideoftherearframeusing2baggerpins,2

atwashers,4thrustwashers,2mount-pin

lanyards,and2locknuts(1/2inch)asshownin

Figure13.

Figure13

1.Rod-supportassembly4.Mount-pinlanyard

2.Flatwasher

3.Baggerpin

5.Raisethehoodandinstallthebagassemblies

byslidingthebagframehooksontotheretaining

slotsonthehopperframe.

5.Locknut(1/2inch)

6.Thrustwasher

g260808

Figure12

1.Lowerbagger-mountbar2.Frameleg

6.Closeandlatchthehood.

g242492

12

Page 13

6

InstallingtheDischarge Tubes

Partsneededforthisprocedure:

1Lowertubeasembly

1Uppertube

3

Hex-washerheadbolt(#10x3/4inch)

3Flatwasher

3

Locknut(#10)

Procedure

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Lowerthemachinedecktothelowest

height-of-cutposition.

4.For60-inchdecks,shortentheuppertubeas

follows:

A.Locatethe3holesintheuppertube.

Measure16.5cm(6-1/2inches)upfromthe

endofthetubeandmarkthelocationinall

3areas(Figure14).

5.Installthelowertubeintotheuppertube(Figure

15).

g003424

Figure15

1.Lowertube2.Uppertube

6.Inserttheuppertubeintothehopperseal.

Pushin,thenpullout,sothatthesealis

extendedoutward.

7.Alignthedimpleontheuppertubewiththeend

ofthehoppersealandcenteritbetweenthe2

screws(Figure16).

Figure14

1.Newholelocation

2.Measure16.5cm(6-1/2inches).

3.Measureat3locations—76to89mm(3-1/2inches).

4.Cutthetubehere.

B.Drill3holes(4.8mmor3/16inch)asshown

inFigure14.

C.Measureat3locations—76to89mm(3

to3-1/2inches)fromtheendofthetube,

createthemarks,andapplymaskingtape

aroundthetubeasaguide(Figure14).

D.Carefullycutthetubeanddiscardtheend.

g009351

g007027

Figure16

1.Dimple

8.Slidethelowertubeontothebootandlatch

themtogether(Figure17).

Note:Thereisalatchonthetopandbottom

oftheblowerhousing.

13

Page 14

washers,and3locknuts(#10)asshownin

Figure19.

Installtheboltheadinsidethetubetoprovide

minimumobstructiontoow.Ensurethatthe

upperandthelowerendsareorientedproperly

asyouassemblethetubes(thepartinglines

shouldroughlylineup).

Figure17

1.Blowerassembly

2.Lowertube

3.Latch(triplebagger

shown)

9.Drillthe5.6mm(7/32inch)diameterholesin

thelowertubeusingtheuppertubeholesasthe

reference(Figure18).

g003423

g003392

Figure19

1.Lowertube

2.Uppertube5.Hex-washerheadbolt

3.Flatwasher

4.Locknut(#10)

(#10x3/4inch)

11.Withthebaggerendinrst,installthelower

tubeontotheblowerhousingandsecureitwith

thelatches.

Figure18

1.Drilltheholeshere.

10.Removethetubesfromthemachineand

assembletheupperandlowertubesusing3

hex-washerheadbolts(#10x3/4inch),3at

g007028

14

Page 15

Operation

7

AdjustingtheParking Brake

NoPartsRequired

Procedure

Ensurethattheparkingbrakeisadjustedproperly;

refertoyourOperator’sManual.

8

CheckingtheTirePressure

NoPartsRequired

Procedure

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Engagetheparkingbrakewhenyou

leavethemachineunattended.

WARNING

Toavoidpersonalinjury,followthese

procedures:

•Becomefamiliarwithalloperatingand

safetyinstructionsintheOperator's

Manualforthemowerbeforeusingthis

attachment.

•Neverremovethedischargetube,bags,

baggertop,orthechutewhiletheengine

isrunning.

•Alwaysshutofftheengine,waitforall

movingpartstostop,andremovethekey

beforeclearinganobstructionfromthe

baggingsystem.

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

Note:Increasethetirepressureduetotheadditional

weight.

Checkandincreasetheairpressureinthefrontcaster

wheelsandreartires(Figure20).

Airpressureinthereartires:138kPa(20psi)

Airpressureinthefrontcasterwheels:172kPa

(25psi)

Figure20

PositioningtheAdjustable

Bafe

AdjustthebafetopositionB(middleposition)for

bagging;refertotheOperator’sManualforthe

machine.

g001055

g000947

Figure21

15

Page 16

EmptyingtheGrassBags

ClearingObstructionsfrom

Grassbagsareheavywhenfull.Becarefulwhen

liftingorhandlingagrassbagthatisfull.

1.Parkthemachineonalevelsurface.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Chockthetiresifonaslope.

6.Unlatchthebaggerlatch.

7.Openthebaggerhood.

8.Compressthedebrisintothebags.Withboth

hands,liftuponthebagandunhookitfromthe

baggerbracket.

9.Grabthehandleonthebottomofthebagand

tipitovertoemptythebag(Figure22).

theBaggerSystem

WARNING

Whenthebaggerisinoperation,theblower

canberotatingandcutofforinjurehands.

•Beforeadjusting,cleaning,repairingand

inspectingtheblower,oruncloggingthe

chute,shutofftheengine,waitforall

movingpartstostop,andremovethekey .

•Useastick,notyourhands,toremovean

obstructionfromtheblowerandtube.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

1.Parkthemachineonalevelsurface.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

Figure22

1.Bag2.Bottomhandle

10.Repeatfortheotherbags.

11.Installthebagtabintothenotchinthebagger

supportframe.

Note:Repeatthisstepfortheotherbags.

12.Lowerthebaggerhoodoverthebags.

4.Shutofftheengineandremovethekey.

5.Emptythebags.

6.Unlatchthelowertube.

7.Removethetubesfromthebagger.

8.Useastickorsimilarobject,notyourhands,to

removeandcleartheobstructionfromthetube

assembly.

Note:Inmostcases,thedebriscanbeshaken

outofthetubes.

9.Iftheblowerassemblyisplugged,unlatchthe

g003357

baggerblowerassembly ,removethebelt,and

swingitopen.

10.Useastickorsimilarobject,notyourhands,

toremoveandcleartheobstructionfromthe

blowerassembly.

11.Afteryouremovetheobstruction,installthe

completebaggersystemandresumeoperation.

13.Latchthebaggerhood.

16

Page 17

RemovingtheCollection SystemforSideDischarge

CAUTION

Failingtoremovethefrontbaggerweights

andoperatingthemachinewithoutthebagger

attachmentmaycauseanunstablecondition

whichcouldresultinalossofcontrol.

•Alwaysremovethefrontweightswhen

removingthebaggerattachment.

•Neveroperatethemachinewithoutthe

baggerattachmentandthefrontweights

stillinstalled.

1.Parkthemachineonalevelsurface.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Chockthetiresandemptythehopper.

6.Removethedischargetubebyreleasingthe

latchesattheblower.Slidethetubeoffthe

bloweroutletandremovetheupperendfrom

thehopper(Figure23).

g242158

Figure24

1.Belt-coverbracket4.Belt

2.Beltcover5.Decksheave

3.Knob

CAUTION

Thedecksheavebecomeshot.Touching

ahotdecksheavecancausesevere

burns.

Allowthedecksheavetocoolcompletely

beforeremovingthebelt.

Figure23

1.Hopper5.Beltcover

2.Clevispin

3.Casterarmweight

4.Hairpin8.Bag

6.Blower

7.Tubes

7.Removetheknobfromthebelt-coverbracket

andtakeoffthebeltcover(Figure24).

8.Pulltheidler-releasehandleandremovethebelt

fromtheuppergrooveofthedecksheave.

9.Unlatchthefrontendoftheblower,pivotthe

blowerback,andliftitoffthedeck(Figure25).

g242330

g242410

Figure25

1.Blowerlatch

2.Pivottheblowerawayfromthedeck.

17

Page 18

10.Installthedischargedeectorusingtheparts

showninFigure26.

Figure26

E.Removethebracketassemblyandall

mountinghardwarefromthecasterarm.

F.Repeatthisprocedureontheothersideof

themachine.

g015594

1.Bolt

2.Spacer6.Grassdeector

3.Locknut

4.Spring

5.Springinstalled

7.J-hookendofspring

WARNING

Anuncovereddischargeopeningcould

allowthelawnmowertothrowobjectsat

youorbystanders,resultinginserious

injury.Also,contactwiththebladecould

occur.

•Neveroperatethelawnmowerunless

youinstallacoverplate,amulch

plate,oragrasschuteandcatcher.

•Ensurethatthegrassdeectorisin

thedownposition.

11.Installtheplasticbeltcoverandtightenthe

knobs.

12.Removethebagsfromthehopperassemblyby

openingthehopperandliftinguptherearofthe

bagandunhookingthefrontclip.

13.Removethehopperassembly.

Figure27

1.Bolt(3/8x6-1/2inches)

2.Knob

3.Bracket

4.Casterweight—20.4kg

(45lb)

5.Clevispin10.Bolt(3/8x8inches)

6.Hairpincotter

7.Casterweight—9.1kg(20

lb)

8.Locknut(3/8inch)

9.Washer

g242048

14.Removethecasterweightsasfollows:

A.Removethelocknut(3/8inch)fromthe

bottomofthe20.4kg(45lb)weight

mountedtothecasterarm(Figure27).

B.Removethebolt(3/8x8inches)and

washer(Figure27).

C.Removethelocknut(3/8inch)fromthetop

9.1kg(20lb)casterweight(Figure27).

D.Carefullyliftandremoveeachweightfrom

thecasterarms.

15.Removethecasterweightsbylooseningthe

clampingknobsuntilyoucanmovetheweight

relativetothecasterarm.Removethehairpin

cottersandclevispinsthatsecuretheweights

tothecasterarms.Carefullylifttheweightsoff

ofthecasterarms.

18

Page 19

UsingtheGrassDeector

DANGER

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Alwaysinstallthegrassdeectorwhen

removingthebaggerandchangingtoside

dischargemode.

•Ifthegrassdeectoriseverdamaged,

replaceitimmediately.Thegrassdeector

routesmaterialdowntowardtheturf.

•Neverputyourhandsorfeetunderthe

mowerdeck.

CuttingHeight

Donotsetthemowercuttingheighttoolowbecause

longgrasssurroundingthemowercanpreventair

fromgettingunderthemowerandenteringthe

baggingsystem.Ifenoughairdoesnotgetunderthe

mower,thebaggingsystemwillplug.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.

Youwillhavetocutyourgrasstwiceifitgets

excessivelylong.

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlap

themowerintothepreviouslycutarea.Thishelps

reducetheloadontheengineandreducesthechance

ofpluggingthechuteanddischargetube.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

take-off(PTO)totheOFFposition,rotate

theignitionkeytooffandremovethekey.

•Neveruseyourhandstoclearthe

dischargearea.Useastickorsimilar

objecttoclearthedischargearea.

TransportingtheMachine

Donotleavegrassordebrisinthebaggerwhile

transportingthemachine.

DANGER

Transportingthemachinewithgrassordebris

inthebaggercandamagethemachine.

Donotleavegrassordebrisinthebagger

whiletransportingthemachine.

OperatingTips

TipsforBagging

RememberingtheSize

Rememberthatthemachineislongerandwiderwith

thisattachmentinstalled.Byturningtoosharplyin

connedplacesyoumaydamagetheattachment.

BaggingSpeed

Mostoftenyouwillbagwiththemowerthrottleinthe

Fastpositionanddriveatanormalgroundspeed.

However,inextremelydryanddustygrass,youmay

wanttoslightlyreducethethrottlespeedandincrease

thegroundspeedofthemower.Thebaggingsystem

mayplugifyoudrivetoofastandtheenginespeed

getstooslow.Onhillsitmaybenecessarytoslow

themowergroundspeed.Thishelpsmaintainthe

enginespeedandbaggingefciency.Mowdownhill

wheneverpossible.

CAUTION

Asthebaggerlls,extraweightisaddedto

thebackofthemachine.Ifyoustopand

startsuddenlyonhills,youmaylosesteering

controlorthemachinemaytip.

•Donotstartorstopsuddenlywhengoing

uphillordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoing

uphill,disengagethebladecontrol.Then

backdownthehillusingaslowspeed.

•Avoidsuddenturnsorrapidspeed

changesonslopes.

•Donotoperatethemachinewithoutthe

baggerattachmentandthefrontweights

stillinstalled.

Trimming

Alwaystrimwiththeleftsideofthemower.Donottrim

withtherightsideofthemowerbecauseyoucould

damagethebaggerchuteanddischargetube.

BaggingLongGrass

Excessivelylonggrassisheavyandmaynotbe

propelledcompletelyintothegrassbags.Ifthis

happens,thedischargetubeandchutemayplug.T o

avoidpluggingthebaggingsystem,mowthegrass

19

Page 20

atahighheightofcut,thenlowerthemowertoyour

normalcuttingheightandrepeatthebaggingprocess.

BaggingWetGrass

Alwaystrytocutgrasswhenitisdrybecauseyour

lawnwillhaveaneatappearance.Ifyoumustcutwet

grass,usetheconventionalsidedischargefeatureof

themower.Severalhourslater,whentheclippings

aredry,installthecompletebaggerattachmentand

vacuumupthegrassclippings.

SignsofPlugging

Asyouarebagging,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.Anexcessive

amountofclippingsblowingoutindicatesthatthe

bagsarefullorthesystemisplugged.

20

Page 21

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst10hours

Beforeeachuseordaily

Every25hours

Every50hours

Beforestorage

MaintenanceProcedure

•Inspecttheblowerbelt.

•Inspectthebagger.

•Cleanthehoodscreen.

•Cleanthebagger.

•Inspecttheblowerbelt.

•Greasetheidlerarm.

•Checktheconditionofthebelt.

•Inspectthebagger.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

DANGER

Enginescanbecomehotwhentheyareoperating.Severeburnscanoccurfromcontactinghot

surfaces.

Allowengines,especiallythemufer,tocoolbeforetouching.

DANGER

Debris,suchasleaves,grass,orbrushcancatchre.Areintheengineareacancause

personalinjuryandpropertydamage.

•Keeptheengineandmuferareafreeofdebrisaccumulation.

•Takecarewhenopeningthebaggercovertokeepdebrisfromfallingontotheengineand

muferarea.

•Allowthemachinetocoolbeforestoringit.

CleaningtheHoodScreen

ServiceInterval:Beforeeachuseordaily

Thescreensneedtobecleanedbeforeeachuse.In

wetgrasstheywillneedtobecleanedmoreoften.

1.Parkthemachineonalevelsurface.

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Openthebaggerhood.

6.Cleanthedebrisfromthescreen.

7.Closethebaggerhood.

21

Page 22

CleaningtheBaggerand

GreasingtheIdlerArm

Bags

ServiceInterval:Beforeeachuseordaily

Cleanthebaggerdaily.

1.Washtheinsideandoutsideofthebagger

hood,bags,tube,andtheundersideofthe

mowerdeck.Useamildautomotivedetergent

toremovedirt.

2.Removemattedgrassfromallparts.

3.Afterwashingalltheparts,letthemdry

thoroughly.

Note:Withallpartsinstalled,startandrunthe

machineforaminutetodrythem.

CheckingtheConditionof theBelt

ServiceInterval:Every50hours

1.Parkthemachineonalevelsurface.

ServiceInterval:Every25hours

Greasethebaggerbeltidlerarm(Figure28)every

25hours.

g003455

Figure28

2.Movethemotion-controlleverstothe

NEUTRAL-LOCKposition.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Inspectthebeltfordamageorwear.Replace

thebeltwithoneofthefollowing:

DeckPartNo.

60-inchdeck103-0866

72-inchdeck103-0867

InspectingtheBlowerBelt

ServiceInterval:Aftertherst8hours

Every25hours

Checkbeltsforcracks,frayededges,burnmarksor

anyotherdamage.Replacedamagedbelts.

22

Page 23

InspectingtheBagger

Storage

Attachment

ServiceInterval:Aftertherst10hours

Beforestorage

1.Checkthechute,dischargetube,andthebagger

top.Replacethesepartsiftheyarecrackedor

broken.

2.Tightenallnuts,bolts,andscrews.

3.Inspectallthefastenersandlatches;replace

anythataremissingordamaged.

4.Inspectthegrassbagsfordeterioration.

WARNING

Youorbystanderscouldbeseverely

injuredbyyingdebrisorthrownobjects

thatmaypassthroughtorn,worn,or

deterioratedgrassbags.

•Checkthegrassbagsforholes,rips,

wear,andotherdeterioration.

•Ifthebaghasdeteriorated,install

newgrassbagssuppliedby

themanufacturerofthisbagger

attachment.

1.Cleanthebaggerattachment;refertoCleaning

theBaggerandBags(page22).

2.Inspectthebaggerattachmentfordamage;refer

toInspectingtheBaggerAttachment(page23).

3.Ensurethatthebagsareemptyandthoroughly

dry.

4.Checkthebeltforwearorcracks.

5.Storethemachineinaclean,dryplace,outof

directsunlight.Ifyoumuststorethemachine

outside,coveritwithaweatherproofcover.This

protectstheplasticpartsandextendsthelifeof

themachine.

InspectingtheMower Blades

1.Inspectthemowerbladesregularlyand

wheneverabladestrikesaforeignobject.

2.Ifbladesarebadlywornordamaged,install

newblades.RefertoyourmachineOperator's

Manualforcompleteblademaintenance.

InstallingtheMowerBlades

Inmostmowingconditions,thestandardhigh-lift

bladesprovidethebestbaggingperformance.

TheT oroAtomicbladeisrecommendedforbagging

leavesindryconditions.Indrydustyconditions,the

mediumliftorlowliftbladeswillreducedustanddirt

blowoutwhileprovidingeffectivebaggingairow.

ContactanAuthorizedServiceDealerfortheproper

bladesfordifferentmowingconditions.

RefertothemachinesOperator'sManualformore

informationoninstallingblades.

23

Page 24

Troubleshooting

Problem

Thereisabnormalvibration.

Thereisreducedbaggingperformance.

Theblowerandtubesplugtoofrequently.

PossibleCauseCorrectiveAction

1.Thecuttingblade(s)is/arebentor

unbalanced.

2.Theblade-mountingboltisloose.2.Tightentheblade-mountingbolt.

3.Theblowerpulleyorpulleyassembly

isloose.

4.Thebaggerbeltisworn.4.Replacethebelt.

5.Theblowerfanblade(s)is/arebentor

unbalanced.

1.Theenginespeedislow.

2.Thebagger-hoodscreenisplugged.2.Removethedebris,leavesorgrass

3.Loosebaggerbelt.3.Replacethebaggerbelt.

4.Theblowerortubeisplugged.4.Locateandremovethepluggeddebris.

5.Thebagsarefull.

1.Thebagsaretoofull.1.Dumpthebagsmorefrequently.

2.Theenginespeedislow.

3.Thegrassistoowet.

4.Thegrassistoolong.

5.Thescreeninthehoodisplugged.5.Removethedebris,leavesorgrass

6.Thegroundspeedistoofast.6.Drivesloweratfullthrottle.

7.Thebaggerbeltisworn.7.Replacethebelt.

1.Installnewcuttingblade(s).

3.Tightentheappropriatepulley.

5.ContactanAuthorizedServiceDealer.

1.Alwaysoperatethebaggeratfull

throttle.

clippingsfromthescreen.

5.Emptythebags.

2.Alwaysoperatethebaggeratfull

throttle.

3.Cutthegrasswhenitisdry.

4.Cutnomorethan51to76mm(2to

3inches)or1/3ofthegrassheight,

whicheverisless.

clippingsfromthescreen.

Thereisdebrisblowout.

Theblowerimpellerdoesnotspinfreely.

1.Thebagsaretoofull.1.Dumpthebagsmorefrequently.

2.Thegroundspeedistoofast.2.Drivesloweratfullthrottle.

3.Themowerdeckisnotleveled.

1.Theblowerisplugged.1.Removethedebris,leavesorgrass

2.Theimpellerisnotaligned.

3.Seethemoweroperator'smanualfor

levelingthemowerdeck.

clippingsfromtheblowerimpeller .

2.ContactanAuthorizedServiceDealer.

24

Page 25

Notes:

Page 26

Notes:

Page 27

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

SerialNo.

78560

400000000andup

andUp

ProductDescriptionInvoiceDescription

TripleBaggingSystem,Z

MasterProfessional7500-D

SeriesRidingMowerwith

60inor72inTURBOFORCE

SideDischargeMower

TRIPLEBAGASSEMBLY

GeneralDescription

Bagger

Directive

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHurst

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

July10,2018

Tel.+3216386659

Page 28

Loading...

Loading...