Page 1

FormNo.3359-401RevA

60inand72inDFSE-ZVac

CollectionSystem

Z500SeriesZMasterMowers

ModelNo.78544—SerialNo.280000001andUp

ModelNo.78545—SerialNo.280000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

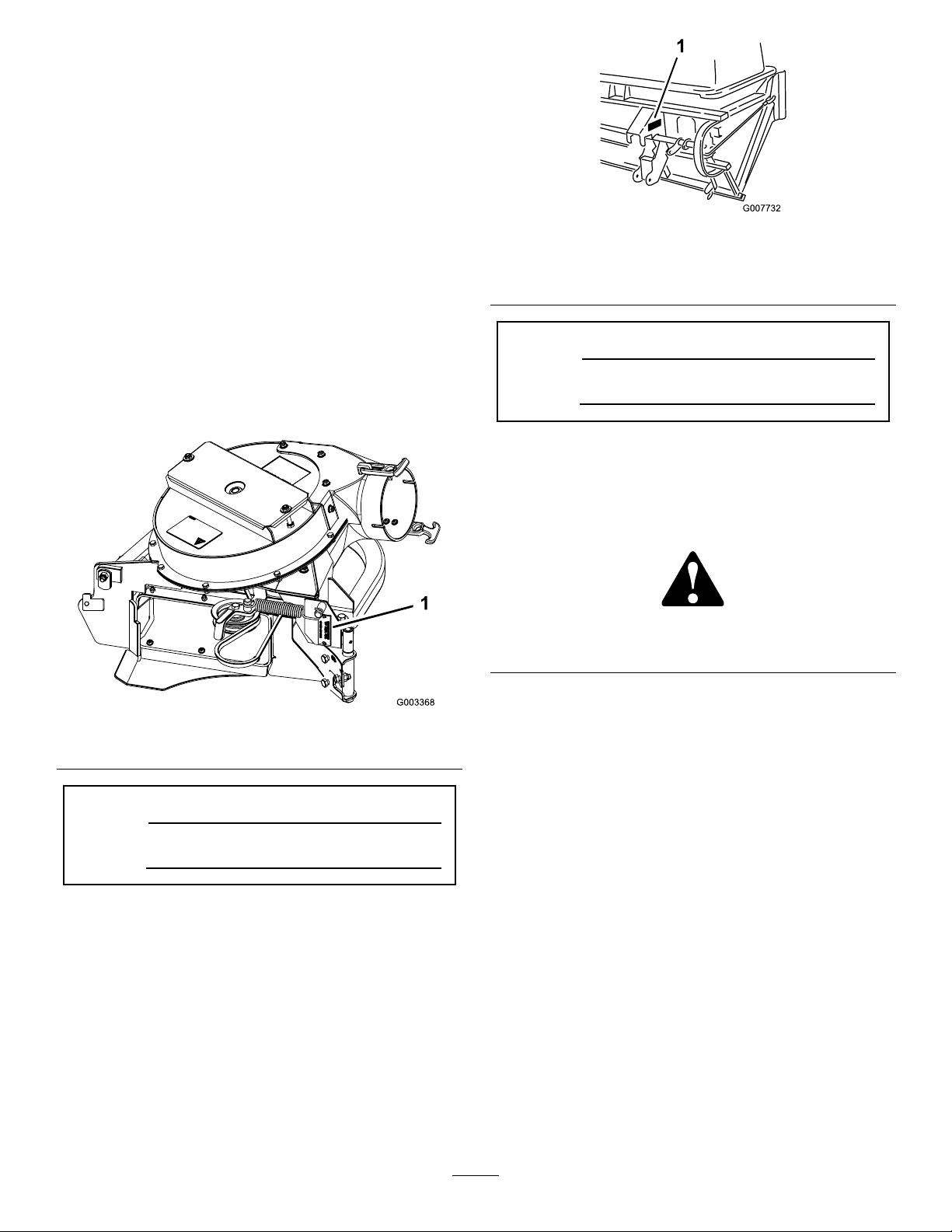

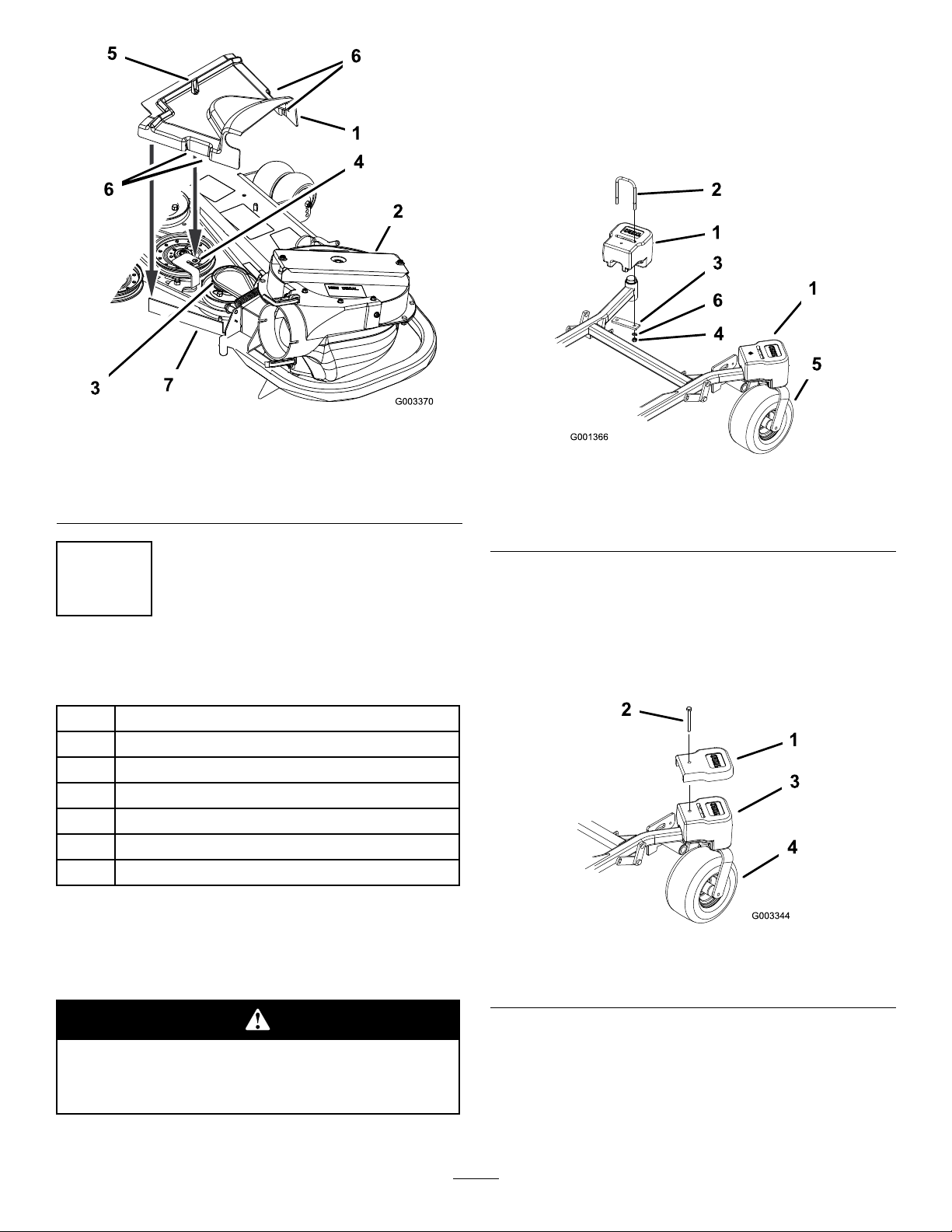

andserialnumbersofyourproductready .Figure1

andFigure2identiesthelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

thespaceprovided.

Figure2

BaggerSerialNumber

1.Baggermodelandserialnumberlocation

ModelNo.

SerialNo.

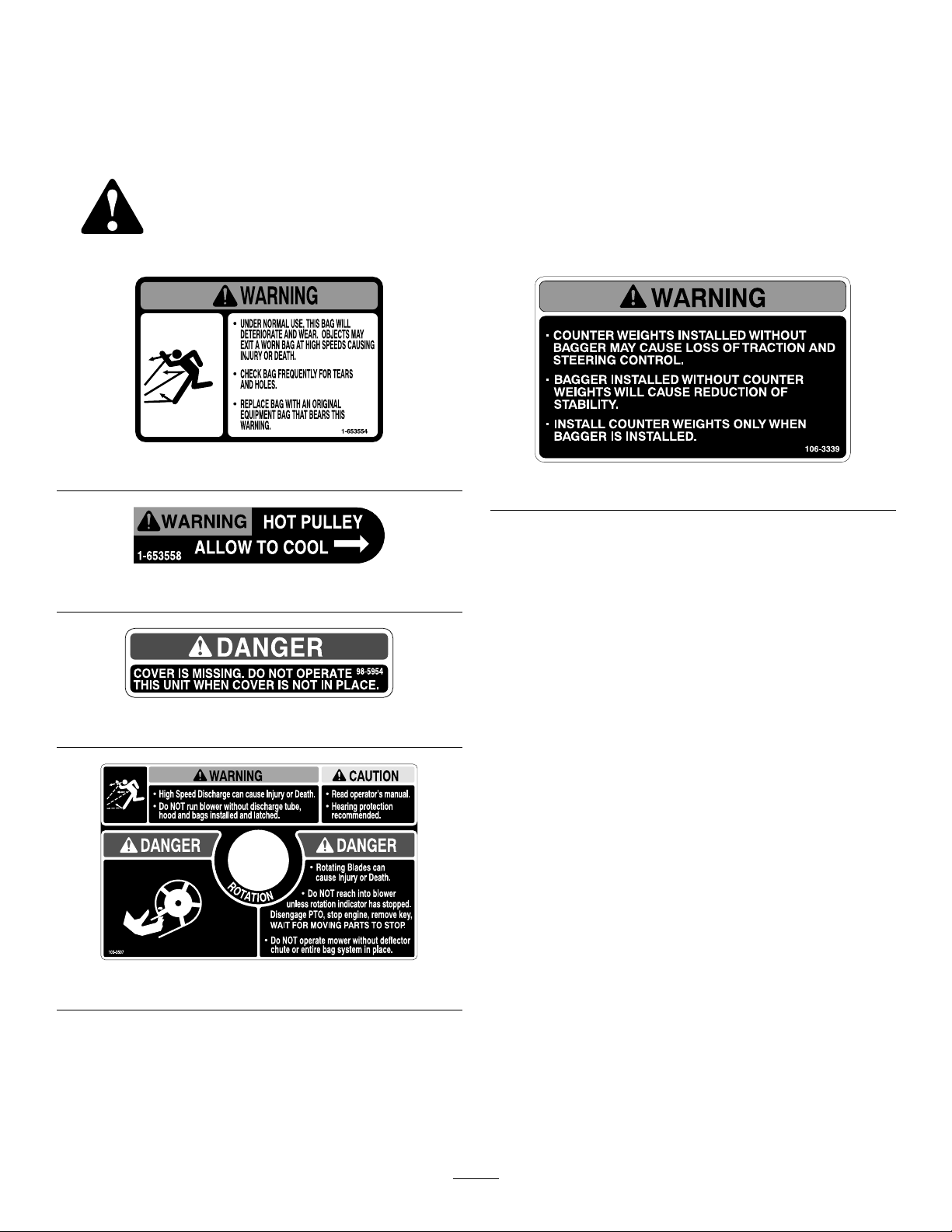

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure3),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure3

1.Safetyalertsymbol

Figure1

1.Blowermodelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................4

Setup............................................................................5

1PreparingtheMower.........................................6

2InstallingtheBaggerMountingBracket..............6

3InstallingtheHandleAssembly..........................8

4TighteningallMountingBolts............................9

5InstallingtheBaggerAssembly...........................9

6RoutingtheBlowerBeltintotheBlower

Assembly.......................................................10

7InstallingtheBlowerAssembly.........................10

8SizingtheUpperTubefor60inchMowers

withGasEngines...........................................12

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

9InstallingtheDischargeTubes..........................13

10InstallingtheBeltCover.................................15

11InstallingtheW eights.....................................16

12AdjustingtheParkingBrake...........................16

13CheckingtheTirePressure.............................17

Operation...................................................................18

PositioningtheAdjustableBafe........................18

EmptyingtheBagger..........................................19

ClearingObstructionsfromtheCollection

System............................................................19

RemovingtheBagger.........................................19

UsingtheGrassDeector...................................20

TransportingMachines.......................................20

OperatingTips...................................................20

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

CleaningtheBaggerScreen.................................22

CleaningtheCollectionSystem...........................22

InspectingtheBlowerBelt..................................22

ReplacingtheBlowerBelt...................................22

CheckingandAdjustingtheBlower

Latch..............................................................23

GreasingtheIdlerArmandHandle

Pivot..............................................................23

InspectingtheCollectionSystem........................24

AdjustingtheDoorClosing................................24

AdjustingtheDoorOpening..............................25

AdjustingtheLatches.........................................25

InspectingtheMowerBlades..............................25

InstallingtheMowerBlades................................25

InstallingtheGrassDeector.............................26

Storage.......................................................................26

Troubleshooting.........................................................27

Safety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyoumust

know .

•Becomefamiliarwiththesafeoperationofthe

equipment,withtheoperatorcontrols,andsafety

signs.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangetheoperating

characteristicsandthestabilityofthemachine.

•Followthemanufacturer’srecommendationsfor

addingorremovingwheelweightsorcounterweights

toimprovestability .

•Donotuseagrasscatcheronsteepslopes.Aheavy

grasscatchercouldcauselossofcontroloroverturn

themachine.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

Useextremecautionwhileoperatingneardrop-offs.

•Keepallmovementonslopesslowandgradual.Do

notmakesuddenchangesinspeed,directionsor

turning.

•Thegrasscatchercanobstructtheviewtotherear.

Useextracarewhenoperatinginreverse.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.Ifthemachineistobedriven

ontoatruckortrailerwiththehopperfull,always

backuptheramp.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Keephandsandfeetawayfrommovingparts.Do

notmakeadjustmentswiththeenginerunning.

•Stoponlevelground,disengagedrives,chockor

blockwheels,shutoffenginebeforeleavingthe

operator’spositionforanyreasonincludingemptying

thegrasscatcheroruncloggingthechute.

•Ifyouremovethegrasscatcher,besuretoinstallany

dischargedeectororguardthatmighthavebeen

removedtoinstallthegrasscatcher.Donotoperate

themowerwithouteithertheentiregrasscatcheror

thegrassdeectorinplace.

•Stoptheenginebeforeremovingthegrasscatcher

oruncloggingthechute.

•Donotleavegrassingrasscatcherforextended

periodsoftime.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

3

Page 4

Frequentlycheckcomponentsandreplacewith

manufacturer’srecommendedparts,whennecessary.

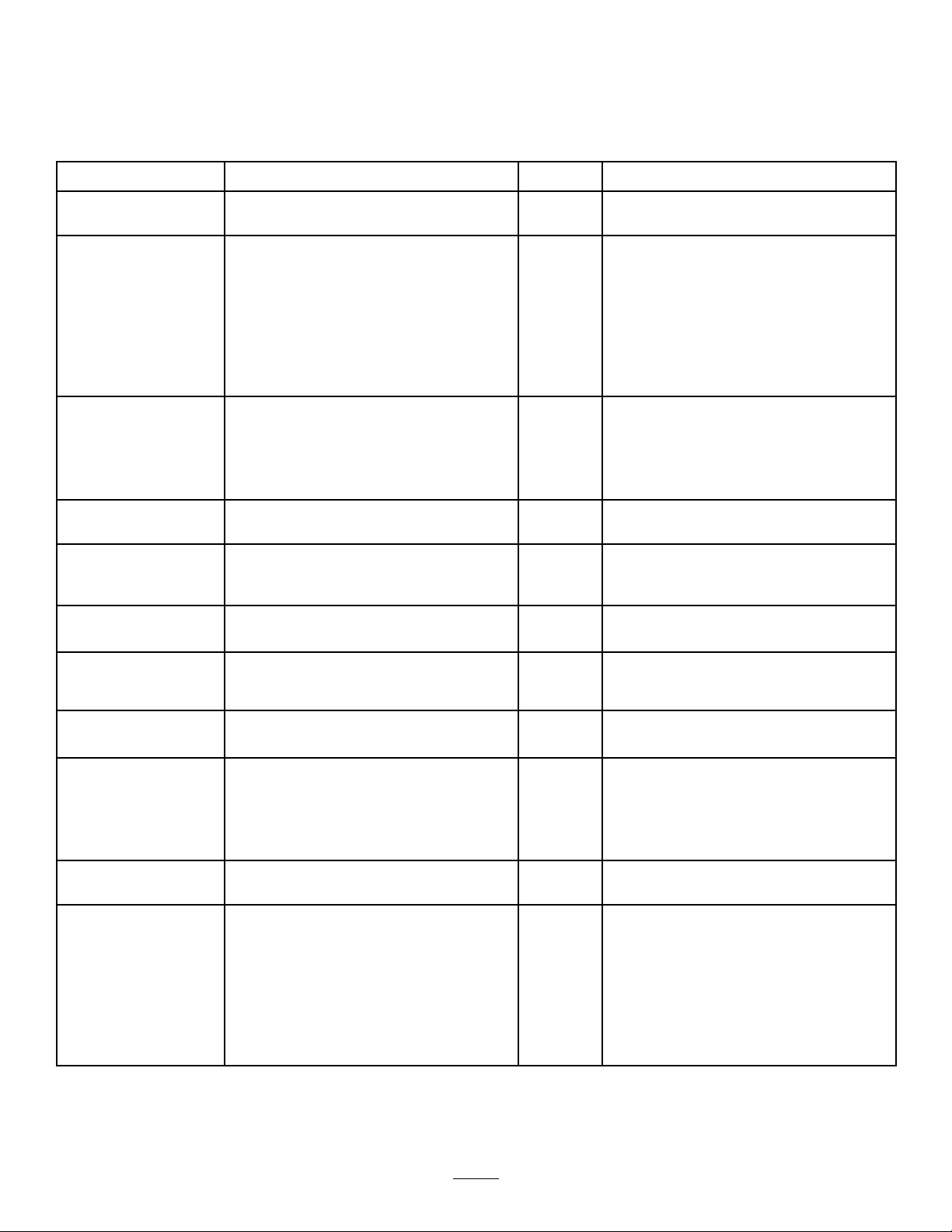

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

1-653554

106-3339

1-653558

98-5954

103-3507

4

Page 5

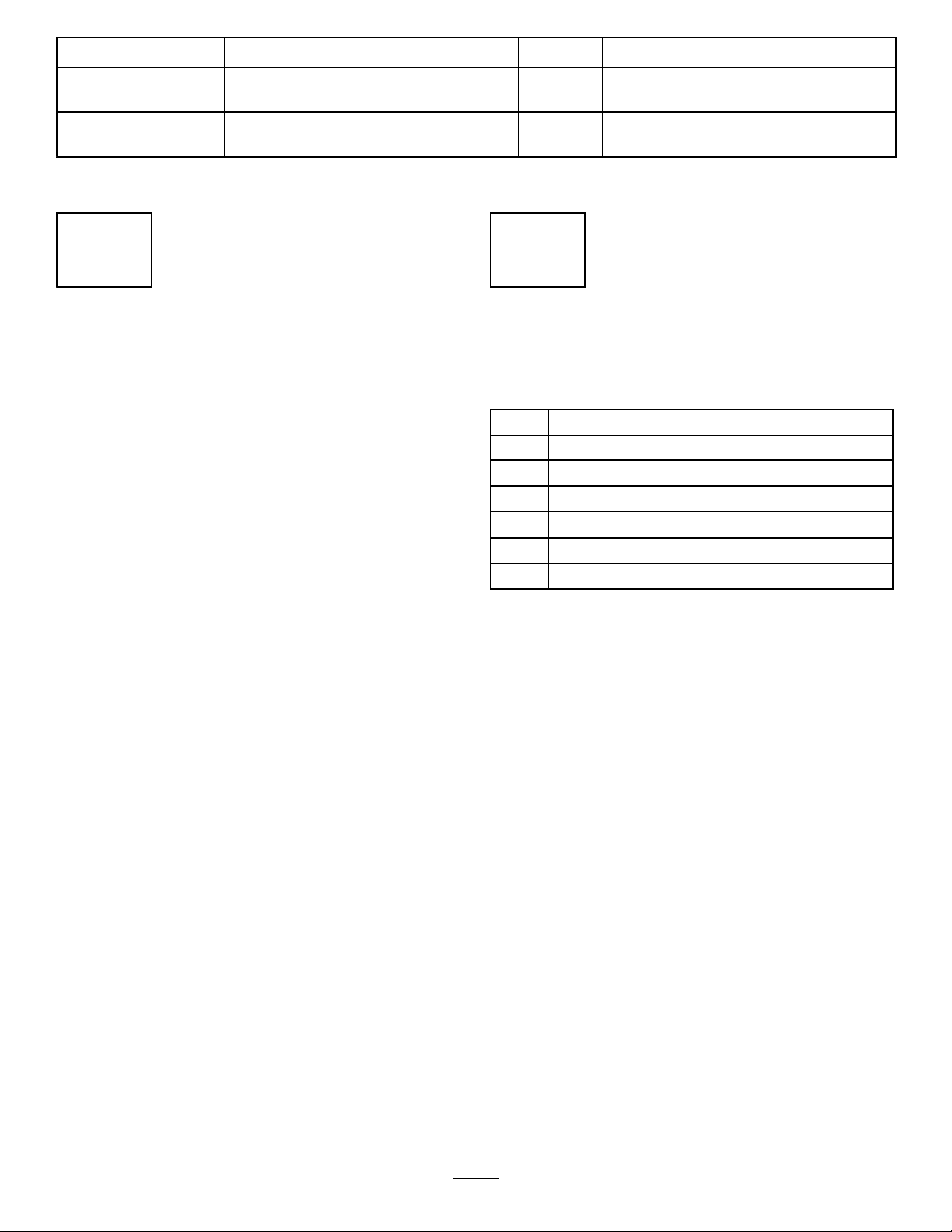

Setup

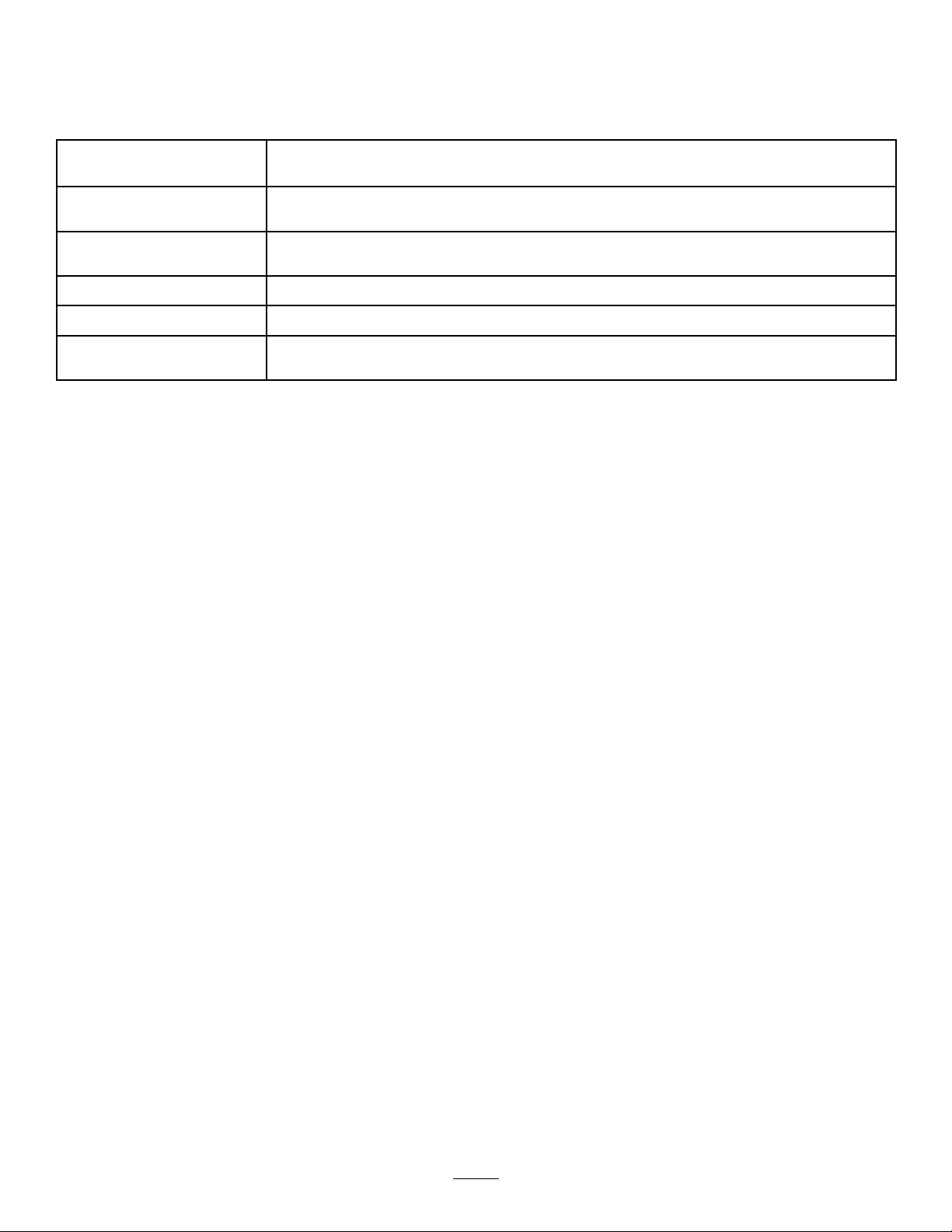

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Nopartsrequired

Baggermountingbracket1

Baggersideplate2

Spacer

Bolt,(3/8x1-1/2inches)

Bolt,(3/8x1inch)(forZ593mowers

only)

FlangeNut,(3/8inch)

Curvedwasher

Handleassembly1

Washer2

Bolt(3/8x1-1/4inches)

Clevispinspring

Locknut(3/8inch)

Nopartsrequired

Baggerassembly1

Clevispin

Hairpincotter2

Blowerbelt(fromBlowerandDriveKit)

Blowerassembly(fromBlowerand

DriveKit)

Spring(fromBlowerandDriveKit)

Uppertube1

Uppertube1

Lowertube1

Bolt,(#10x3/4inches)

Locknut,(#10)

Washer,(7/32inch)

Qty.

14

14

14

Use

–

2

2

3

1

3

–

2

1

1

1

3

3

3

Preparethemower.

Installthebaggermountingbracket

Installthehoodassembly.

Tightenallmountingbolts

Installthebaggerassembly.

Routetheblowerbeltintotheblower

assembly.

Installtheblowerassembly.

Sizetheuppertubefor60inchmowers

withgasengines.

Installthedischargetubes.

10

11

Beltcover(fromBlowerandDriveKit)

Casterweight

U-bolt2

Nut,(1/2inch)

Lockwasher,(1/2inch)

Plate2

Topweight(for60inchmowerdecks

only)

5

2

4

4

2

2

Installthebeltcover .

Installtheweights.

Page 6

ProcedureDescription

Qty.

Use

12

13

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

Nopartsrequired

1

PreparingtheMower

InstallingtheBaggerMounting

–

–

2

Bracket

NoPartsRequired

Partsneededforthisprocedure:

Procedure

Performthefollowingproceduretopreparethemower

forattachingtheblowerandnishingkit.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Repairallbentordamagedareasofmowerdeckand

replaceanymissingparts.

4.Cleanthemowerofanydebrisonthedeckorrear

partofthemowertoeaseinstallation.

1Baggermountingbracket

2Baggersideplate

2

Spacer

14

Bolt,(3/8x1-1/2inches)

2

Bolt,(3/8x1inch)(forZ593mowersonly)

14

FlangeNut,(3/8inch)

14

Curvedwasher

Procedure

Important:Donottightenanyboltsuntilbothside

bracketsandbaggermountingbracketaretloose

onthemachine.

RefertoTighteningtheMountingBoltsforthe

correctproceduretotightenthebolts.

Adjusttheparkingbrake.

Checkthetirepressure.

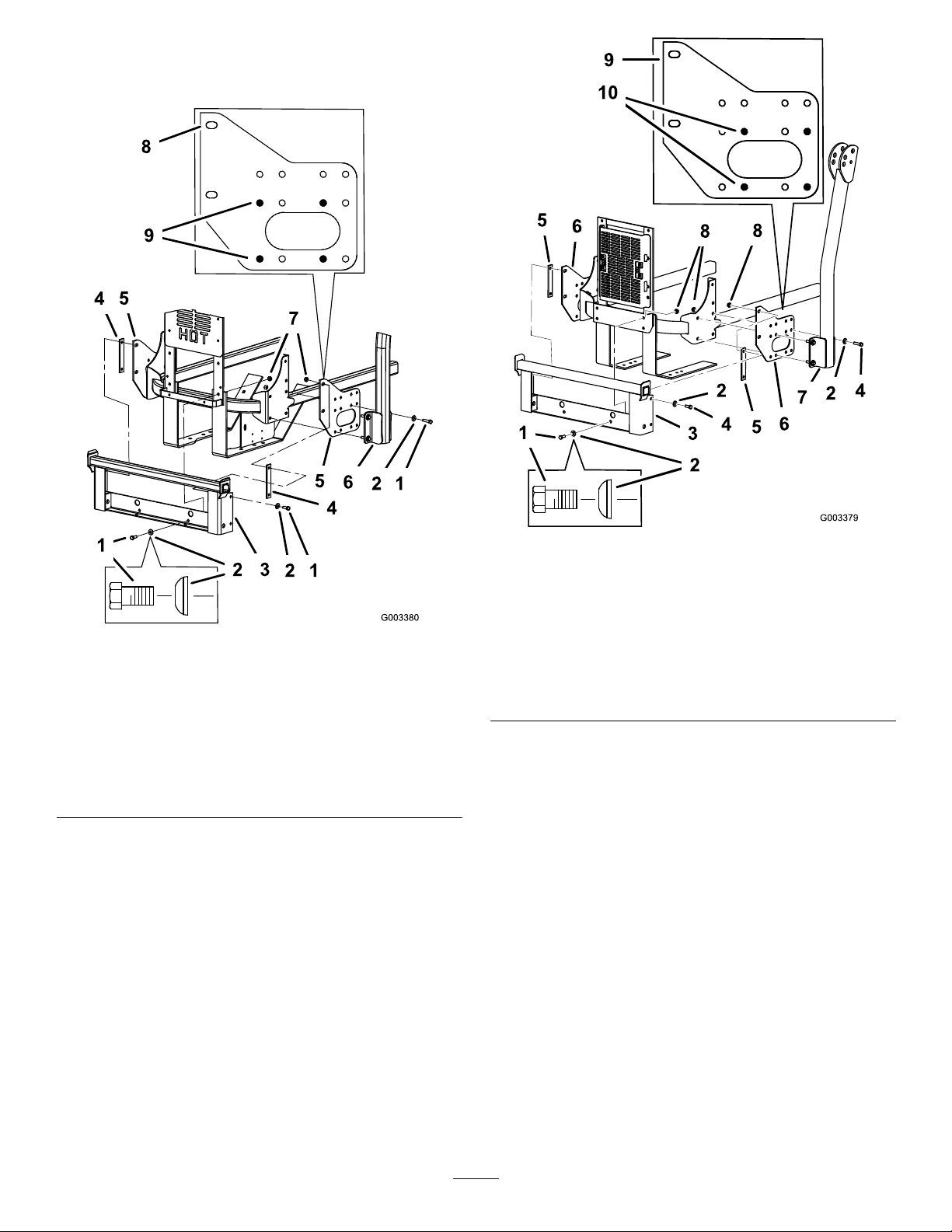

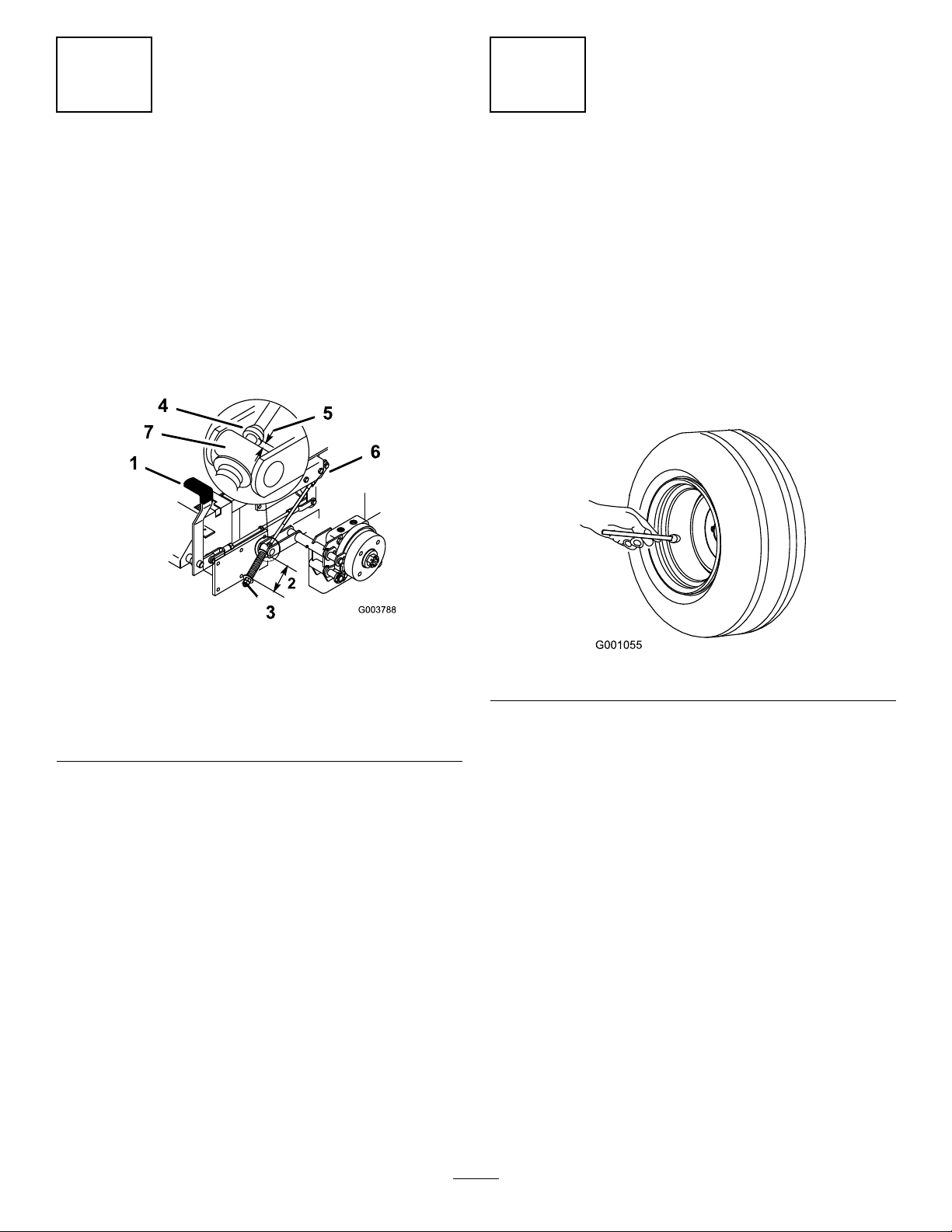

1.Removethebolts,nuts,andwashersholdingtheroll

bartoonesideofthemachine.Discardthenuts,

bolts,andwashers(Figure4,Figure5,andFigure6).

2.Installthebaggersideplateandtherollbarsection

tothesideofthemachineusing4bolts(3/8x1-1/2

inches),4curvedwashers(3/8inch),and4ange

nuts(3/8inch)(Figure4,Figure5,andFigure6).

3.Repeatthestepsabovefortheoppositeside

(Figure4,Figure5,andFigure6).

Note:Makesurethecurvedwashersareinstalledas

showninFigure4,Figure5,andFigure6.

4.Installthebaggermountingbrackettotheleftand

rightsidebaggerbracketswith4bolts(3/8x1-1/2

inches),4curvedwashers(3/8inch),and4ange

nuts(3/8inch)(Figure4,Figure5,andFigure6).

5.Installthebaggermountingbrackettotherearframe

ofthemachinewith2bolts(3/8x1-1/2inches)(use

6

Page 7

2bolts(3/8x1inch)forZ593mowersasshownin

Figure5),2curvedwashers(3/8inch),and2ange

nuts(3/8inch)(Figure4,Figure5,andFigure6).

Figure4

ForZ500GasMowers

1.Bolt,(3/8x1-1/2inches)6.ROPS

2.Curvedwasher,(3/8inch)7.Flangenut,(3/8inch)

3.Baggermountingbracket

4.Spacer

5.Baggersideplate

8.Sideviewofbaggerside

plate

9.Holestowheninstalling

thesidebracket

Figure5

ForKubotaDieselMowers

1.Bolt,(3/8x1inch)

2.Curvedwasher,(3/8inch)7.ROPS

3.Baggermountingbracket

4.Bolt,(3/8x1-1/2inches)9.Sideviewofbaggerside

5.Spacer

6.Baggersideplate

8.Flangenut,(3/8inch)

plate

10.Holestowheninstalling

thesidebracket

7

Page 8

3

InstallingtheHandleAssembly

Partsneededforthisprocedure:

1Handleassembly

2Washer

3

Bolt(3/8x1-1/4inches)

1

Clevispinspring

3

Locknut(3/8inch)

Procedure

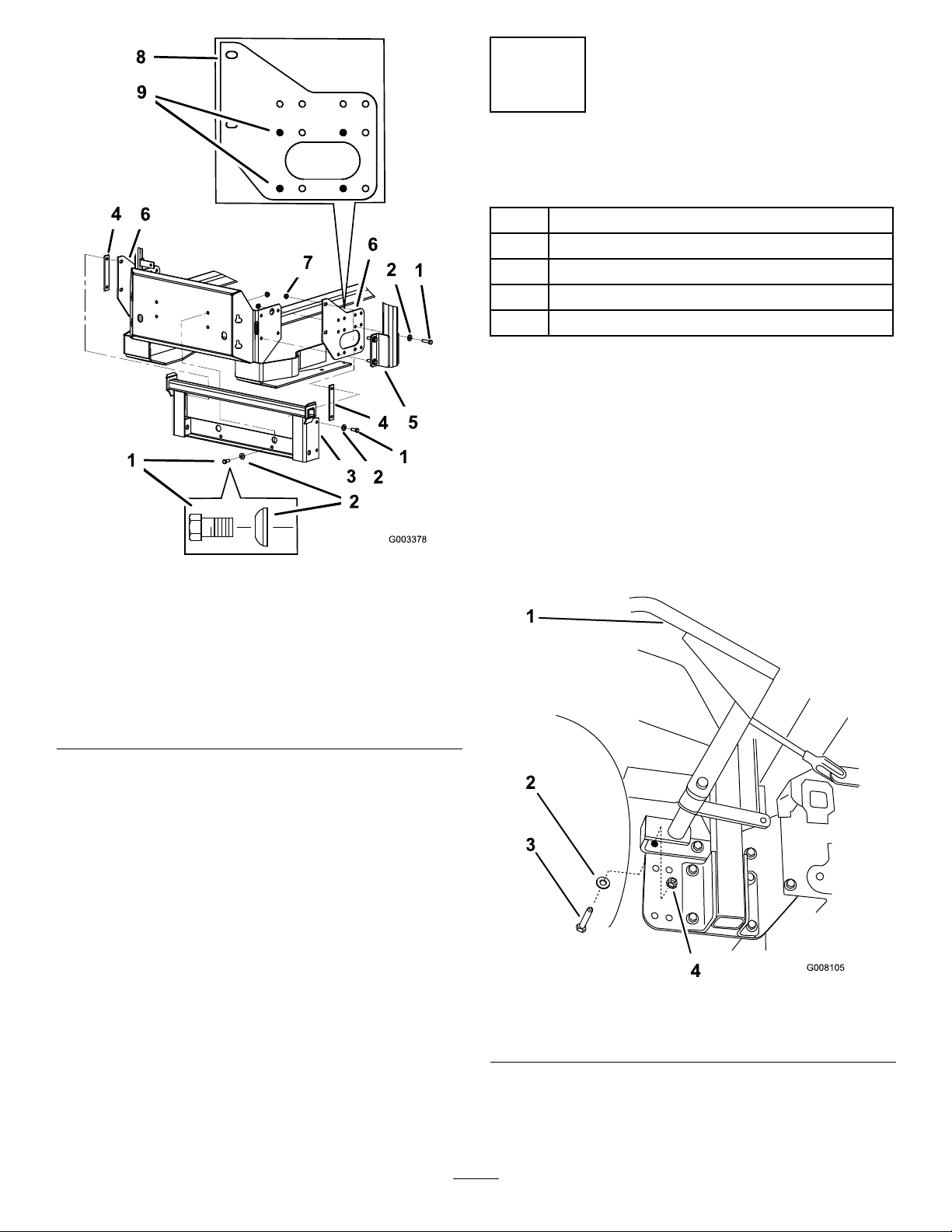

1.PositionthehandleassemblybetweentheROPSroll

barandthebaggermountingbracket(Figure8).

2.Installthehandleassemblytothebaggermounting

bracketandthemachinewith3bolts(3/8x1-1/4

inches)and3locknuts(3/8inch)(Figure7and

Figure8).

Figure6

ForDaihatsuDieselMowers

1.Bolt,(3/8x1-1/2inches)6.ROPS

2.Curvedwasher,(3/8inch)7.Flangenut,(3/8inch)

3.Baggermountingbracket

4.Spacer

5.Baggersideplate

8.Sideviewofbaggerside

plate

9.Holestowheninstalling

thesidebracket

Note:ThemiddleboltisnotusedonKubota

poweredengines(Figure8).

Figure7

1.Handleassembly

2.Washer

3.Bolt(3/8x1-1/4inches)

4.Nut(3/8inch)

8

Page 9

4

TighteningallMountingBolts

NoPartsRequired

Procedure

Thefollowingstepsarethecorrectsequencetotighten

thesidebracketsandthebaggermountingbracket.All

mountingboltsneedtobetorquedto35ft-lb(48N⋅m).

1.Tightenthebaggermountingbrackettotherear

framerst.

2.TightentheROPSandsidebracketstothesideof

themower.

3.Ifthebaggermountingbracketmovessidetosidean

1/8inchormore,installoneorbothofthespacers

betweenthebaggermountingbracketandmounting

plates(Figure4,Figure5,andFigure6).

4.Tightenthebaggermountingbrackettotheside

brackets.

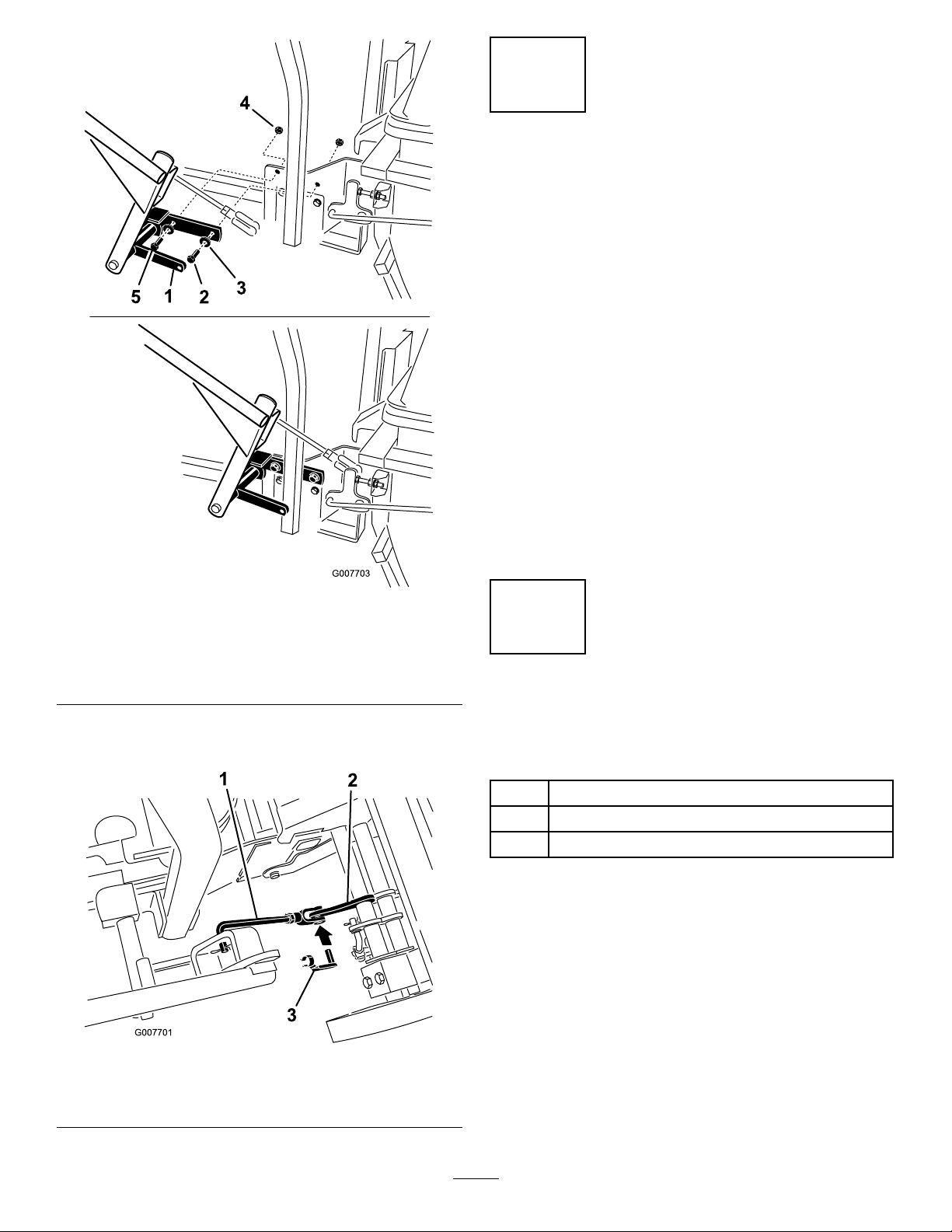

Figure8

1.Handleassembly

2.Bolt(3/8x1-1/4inches)

3.Washer

3.Installthebaggerarmlinkagetothebaggerassembly

withaclevispinspring(Figure9).

4.Nut(3/8inch)

5.Thisboltisnotusedon

Kubotapoweredmachines

5

InstallingtheBagger

Assembly

Partsneededforthisprocedure:

1Baggerassembly

2

Clevispin

2Hairpincotter

Procedure

1.Installthebaggerassemblyontothebagger

mountingbracket(Figure10).

2.Installthe2clevispinsintothebaggerassemblyand

baggermountingbracket.Secureitwith2hairpin

cotters(Figure10).

1.Baggerarmlink

2.Baggerassembly

Figure9

3.Clevispinspring

9

Page 10

Figure10

1.Hoodassembly3.Hairpincotter

2.Clevispin

4.Baggermountingbracket

6

RoutingtheBlowerBeltinto

Figure11

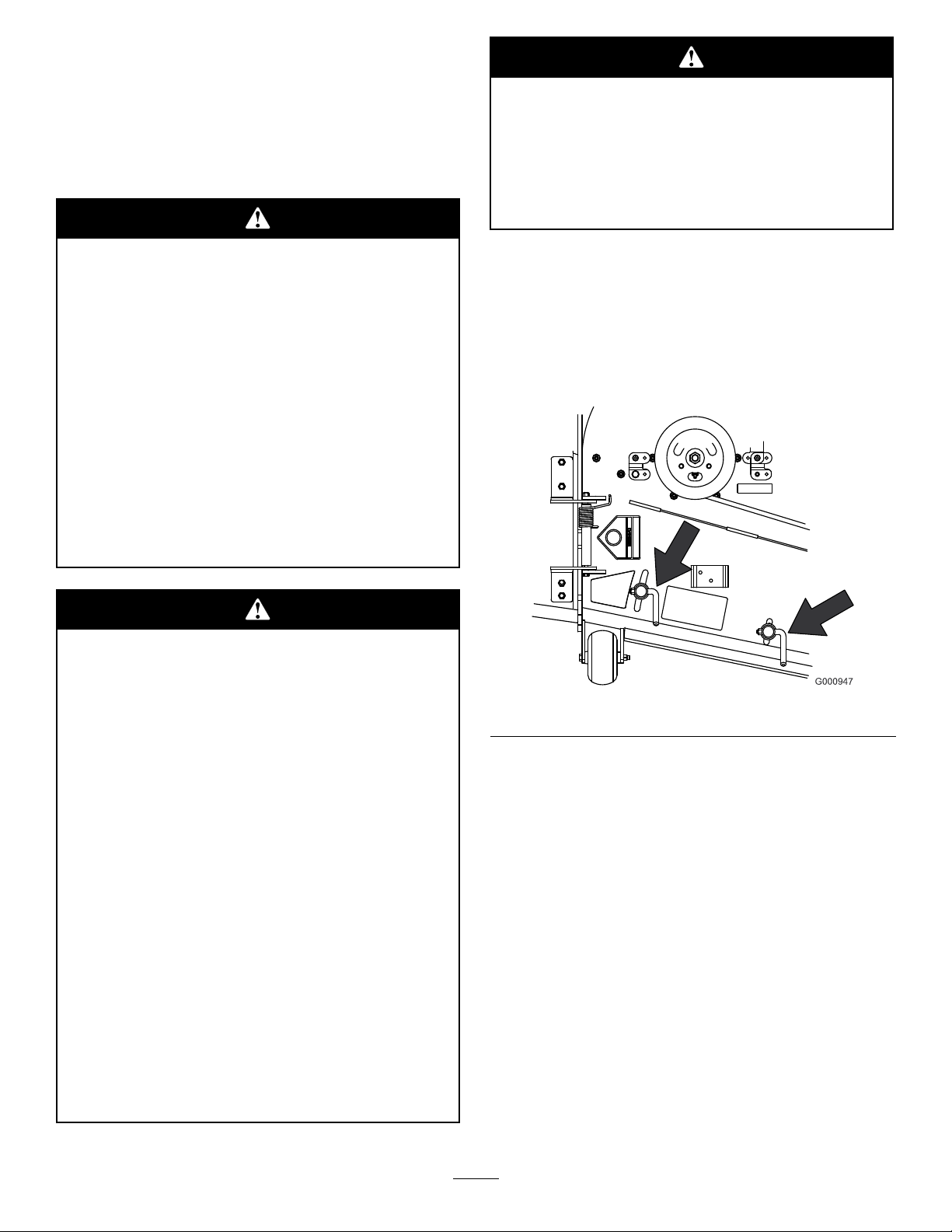

1.Idlerpulley4.Peg

2.Mowerdeckpulley5.Belt

3.Spring

7

InstallingtheBlowerAssembly

6.Blowerpulley

theBlowerAssembly

Partsneededforthisprocedure:

1

Blowerbelt(fromBlowerandDriveKit)

Procedure

1.Installthebeltaroundtheblowerpulley(Figure11).

2.Installthespringtotheidlerarmandthepegonthe

blowerassembly(Figure11).

Partsneededforthisprocedure:

1

Blowerassembly(fromBlowerandDriveKit)

1

Spring(fromBlowerandDriveKit)

Procedure

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

•Neveroperatethelawnmowerunlessyou

installacoverplate,amulchplate,oragrass

chuteandcatcher.

•Makesurethegrassdeectorisinstalled

whenthegrasschuteandcatcherare

removed.

1.Removethesidedischargechutefromthemower

deck(Figure12).

10

Page 11

Figure12

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

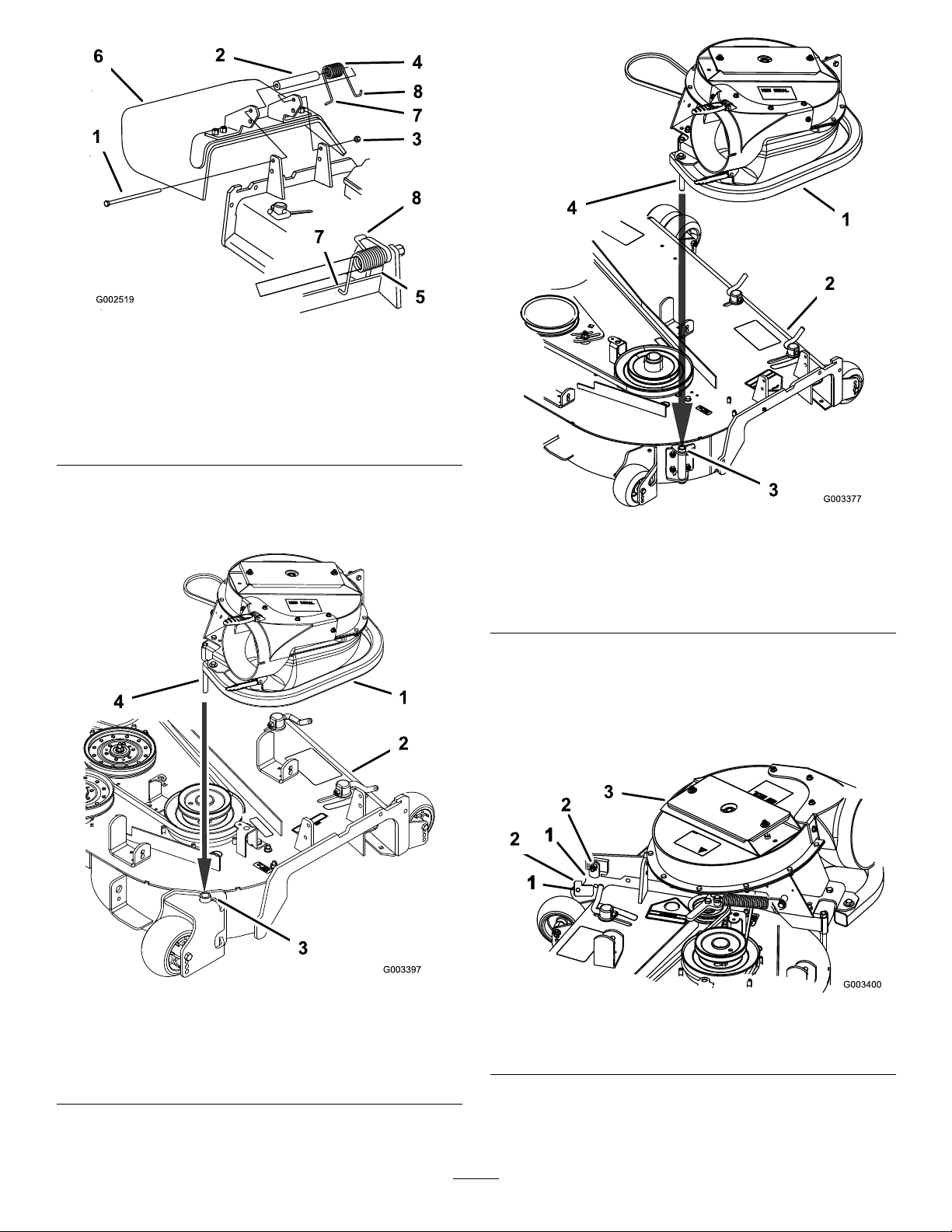

2.Slidetheblowerassemblypegintothepivothole.

For60inchmowersrefertoFigure13andfor72

inchmowersrefertoFigure14.

Figure14

72inchMowerDeck

1.Blowerassembly3.Pivothole

2.Mowerdeck,72inch(183

cm)shown

4.Blowerassemblypeg

3.Closetheblowerassemblytoseeifthelatchesare

adjustedcorrectly.Loosenortightentheboltso

thelatchesrmlyholdtheblowerassemblyagainst

themowerdeck,butcanbereleasedbyhand

(Figure15).

Figure13

60inchMowerDeck

1.Blowerassembly3.Pivothole

2.Mowerdeck,60inch(152

cm)shown

4.Blowerassemblypeg

Figure15

1.Latch3.Blowerassembly

2.Bolt

4.InstallthespringasshowninFigure16.

Makesurethehooksareinthecorrectposition.

11

Page 12

8

SizingtheUpperTubefor60

inchMowerswithGasEngines

Partsneededforthisprocedure:

1Uppertube

Procedure

Figure16

1.Springloadedidlerpulley

2.Shorthookend

5.Pullthespringloadedidlerpulleybackandroute

thebeltaroundthemowerdeckpulley .Ensurethe

beltisroutedaroundtheblowerpulleyscorrectly

(Figure17).

3.Longhookend

Note:Thisprocedureisfor60inchmowerswithgas

enginesonly .

1.Measureup3–1/2inches(89mm)fromthebottom

oftheuppertube.Usetheexisting3holesasmarks

andthenmarkitinseveralplacestocreatealine

aroundthetube(Figure18).

2.Cutthe3–1/2inches(89mm)offtheuppertube

(Figure18).

Note:Noticethethreeindentationsinthetube.

Thisiswhereholeswillbedrilledinthefollowing

procedure.

Figure17

1.Mowerdeckpulley3.Blower

2.SpringloadedIdlerpulley

12

Page 13

Figure18

1.Indentationsfordrilling

holes

2.Uppertube5.Linetocuttube

3.Cutoff3–1/2inches(89

mm)for60inchmowers

withgasenginesonly

4.Usetheexistingholesto

createaline

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lowerthemowerdecktothelowestheight-of-cut

position.

4.Installtheuppertubeintothebaggeropeningand

pullitbackoutsotherubbersealisprotrudingout

(Figure19).

Figure19

1.Uppertube3.Baggerhood

2.Baggeropening

5.Measurethedistancethetubeisinsidethehood.

Measurefromthehoodplatetotheedgeofthetube

asshowninFigure20.Thisdistanceneedstobe

3/4inch(19mm).

9

InstallingtheDischargeTubes

Partsneededforthisprocedure:

1Uppertube

1Lowertube

3

Bolt,(#10x3/4inches)

3

Locknut,(#10)

3

Washer,(7/32inch)

Procedure

Important:Makesurethemowerdeckisinthe

lowestheight-of-cutpositionwhileinstallingthe

dischargetubes.

Note:Remembertoreplacethegrassdeectorwhen

thebaggerisremovedfromthemower.Referto

ReplacingtheGrassDeector.

1.DisengagethePTOandsettheparkingbrake.

1.Hoodplate

2.Uppertube

3.Hoodinthedownposition

Figure20

4.3/4inch(19mm)

5.Edgeoftube

13

Page 14

6.Oncethe3/4inch(19mm)measurementhasbeen

achieved,marktheuppertubeontheoutsidewhere

therubbersealprotrudesout.Thisismarkedto

ensurethecorrectpositionfortheuppertubewhen

drillingtheholesandconnectingtheupperand

lowertubes(Figure21).

Note:Therubbersealmustprotrudeoutfromthe

baggerhood.

Figure22

1.Lowertube2.Uppertube

8.Slidethelowertubeontothebootandlatchthem

together(Figure23).

Figure21

1.Uppertube3.Baggerhood

2.Rubbersealprotrudingout4.Markhereagainstthe

rubberseal

7.Installthelowertubeintotheuppertube(Figure22).

Note:Thereisalatchonthetopandbottomof

theblowerhousing.

1.Blowerassembly3.Latch

2.Lowertube

14

Figure23

Page 15

9.Makesurethemowerdeckisinthelowest

height-of-cutpositionandthemarkontheupper

tubeisstillpositionedagainsttheprotrudingrubber

seal.

ChecktomakesurethemarkfromFigure21isstill

inplace.

10.Usingthethreeholesorindentationsintheupper

tubeasatemplate,drillthreeholes(7/32inch

diameter)wheretheupperandlowertubesjoin

together(Figure24).

1.Lowertube

2.Uppertube

3.Flatwasher,(7/32inch)

Figure25

4.Locknut,(#10)

5.Bolt,(#10x3/4inches)

Figure24

1.Baggerhood4.Lowertube

2.Uppertube5.Blowerassembly

3.Drill7/32inchdiameter

holeshere(useupper

tubeasatemplate)

11.Removethelowertubefromtheblower.

12.Jointheupperandlowertubeswith3bolts(#10

x3/4inches),3atwashers(7/32inch),and3

locknuts(#10)(Figure25).

13.Installthelowertubeontotheblowerhousingand

secureitwiththelatches.

10

InstallingtheBeltCover

Partsneededforthisprocedure:

Beltcover(fromBlowerandDriveKit)

Procedure

1.Lowerthemowerdecktothelowestheight-of-cut

position.

2.Installthenewbeltcoversothenotchesonboth

sidesgooverthebeltcoversupportsandsecurethe

latch(Figure26).

15

Page 16

Figure26

1.Beltcover5.Latch

2.Blowerassembly6.Beltcovernotch

3.Pulleyassembly7.Beltcoversupport

4.Beltcoverbracket

2.Installplate,nuts(1/2inch)andlockwasher

(1/2inch)undertheframeandweight(Figure27).

3.Repeatforoppositeside.

Note:AllZMastermowersreceivethecaster

weights.

Figure27

1.Frontcasterweight4.Nut

2.U-bolt5.Frontcaster

3.Plate6.Lockwasher

11

InstallingtheWeights

Partsneededforthisprocedure:

2

Casterweight

2U-bolt

4

Nut,(1/2inch)

4

Lockwasher,(1/2inch)

2Plate

2

Topweight(for60inchmowerdecksonly)

2

Procedure

TocomplywithANSI/OPEIB71.4-2004Standard,

weightsmustbeaddedtothemachine.

Note:OnlyZMastermowerswith60inchmower

decksreceivethetopweights.

4.Installthetopweightsontopofeachcasterweight

for60inchmowerswith2bolts(1/2x2–1/2inches)

(Figure28).

Figure28

1.Topweight3.Frontcasterweight

2.Bolt,(1/2x2–1/2inches)

4.Frontcasterwheel

Thebaggeraddsalotofweighttotherear

ofthemachineandmaycauseanunstable

conditionwhichcouldresultinalossofcontrol.

1.Placecasterweightsonthefrontcasters.

16

Page 17

12

13

AdjustingtheParkingBrake

NoPartsRequired

Procedure

Checktheparkingbrakeforproperadjustment.

1.Disengagebrakelever(leverdown).

2.Measurethelengthofthespring.

Themeasurementshouldbe2-3/4inch(70mm)

betweenwashers(Figure29).

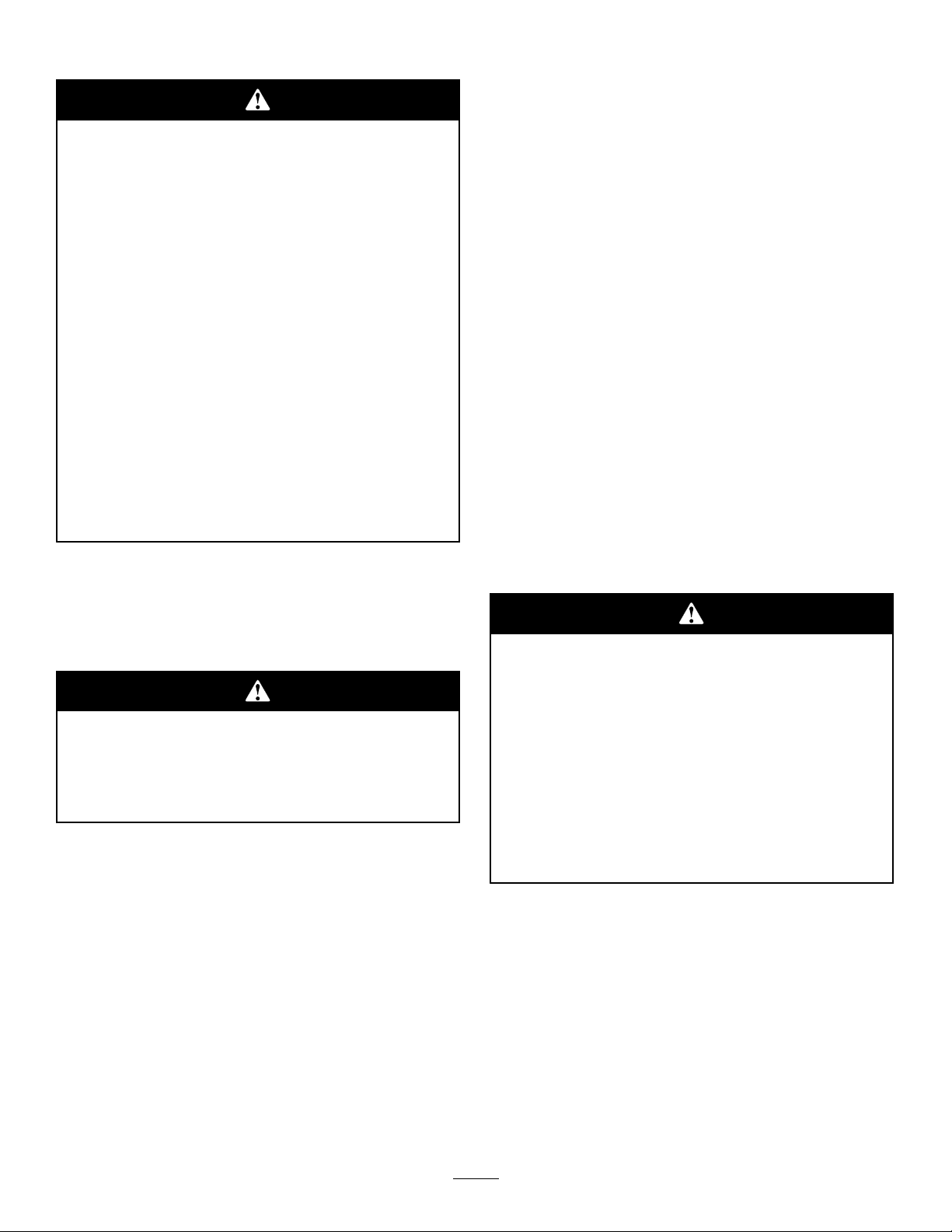

CheckingtheTirePressure

NoPartsRequired

Procedure

Note:Increasethetirepressureduetotheadditional

weight.

Checkandincreasetheairpressureinthefrontcaster

wheelsandreartires(Figure30).

Pressure:Reartires-20psi(138kPa)

Frontcasterwheels-25psi(172kPa)

Figure29

1.Brakelever

2.Spring(2-3/4inches/70

mm)

3.Adjustingnuts7.Trunnionroller

4.Collaronbrakerod

3.Ifadjustmentisnecessary,loosenthejamnutbelow

thespringandtightenthenutdirectlybelowthe

yoke(Figure29).Turnthenutuntilthecorrect

measurementisobtained.Tightenthetwonuts

togetherandrepeatonoppositesideofunit.

4.Turnnutsclockwisetoshortenspringlengthand

turncounter-clockwisetolengthenthespring.

5.Engageparkingbrake,leverup.

6.Measurethedistancebetweenthetrunnionroller

andthecollaronbrakerod.

Themeasurementshouldbe3/16-1/4inch(5-7

mm)(Figure29).

7.Ifadjustmentisnecessary,loosenthejamnut

directlybelowtheyoke.Turnthebottomroduntil

thecorrectmeasurementisobtained(Figure29).

Tightenjamnutatyoke

5.3/16–1/4inch(5–7mm)

6.Jamnutandyoke

Figure30

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Settheparkingbrakewhenleavingthe

machineunattended,evenifjustforafewminutes.

Toavoidpersonalinjury,followthese

procedures:

•Becomefamiliarwithalloperatingand

safetyinstructionsintheoperator’smanual

foryourmowerbeforeusingthisattachment.

•Neverremovethebaggerorbaggertubes

whiletheengineisrunning.

•Alwaysshuttheengineoffandwaitforall

movingpartstostopbeforeclearingan

obstructionfromthebaggingsystem.

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileit

isunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

PositioningtheAdjustable

Bafe

AdjustthebafetopositionB(middleposition)for

bagging.RefertothemachinesOperatorManualfor

thebafeadjustmentprocedure.

•Settheparkingbrake.

Withoutthegrassdeector,baggertubesor

completecollectionsystemmountedinplace,

youandothersareexposedtobladecontact

andthrowndebris.Contactwiththerotating

mowerblade(s)andthrowndebriswillcause

injuryordeath.

•Alwaysinstallthegrassdeectorwhen

removingthecollectionsystemand

changingtosidedischargemode.

•Ifthegrassdeectoriseverdamaged,

replaceitimmediately.Thegrassdeector

routesmaterialdowntowardtheturf.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(PTO)tooffandrotatetheignition

keytooff.Alsoremovethekeyandpullthe

wireoffofthesparkplug(s).

Figure31

•Turnofftheenginebeforeuncloggingthe

dischargechute.

18

Page 19

EmptyingtheBagger

1.DisengagethePTOandsettheparkingbrake.

2.Liftuponthehandletoopenthedoorandempty

thehopper.

3.Pushthehandledowntoclosethedoor(Figure32).

Note:Ifthemachineistobedrivenontoatruck

ortrailerwiththehopperfull,alwaysbackupthe

ramp.Thiswillreducethechanceofrearwardtip.

Figure32

Note:Inmostcases,thedebriscanbeshakenout

ofthetubes.

7.Iftheblowerassemblyisplugged,unlatchthe

blowerassembly,removethebelt,andswingitopen.

8.Usingastickorsimilarobject,notyourhands,to

removeandcleartheobstructionfromtheblower

assembly.

9.Afteryouremovetheobstruction,installthe

completecollectionsystemandresumeoperation.

RemovingtheBagger

Componentsaroundenginewillbehotifthe

machinehasbeenrunning.Touchinghot

componentscancauseburns.

•Donottouchenginecomponentswhenhot.

ClearingObstructionsfrom

theCollectionSystem

Whenthecollectionsystemisinoperation,the

blowercanberotatingandcutofforinjure

hands.

•Beforeadjusting,cleaning,repairing

andinspectingtheblower,andbefore

uncloggingthechute,turnofftheengine

andwaitforallmovingpartstostop.

Removethekey .

•Useastick,notyourhands,toremovean

obstructionfromtheblowerandtube.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

1.DisengagethePTOandsettheparkingbrake.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Emptythebagger.

4.Unlatchthelowertube.

5.Removethetubesfromthebagger.

6.Usingastickorsimilarobject,notyourhands,to

removeandcleartheobstructionfromthetube

assembly.

•Allowenginetocoolbeforeremovingthe

bagger.

1.DisengagethePTO ,settheparkingbrake,and

chockorblockthetires.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchthelowertubefromtheblowerandremove

thetubefromtheblowerassembly.

4.Removethetubefromthebaggerhood.

5.Lowerthemowerdecktothelowestheight-of-cut

position.

6.Unlatchthebeltcoveroverthemowerpulley

assembly.

7.Removetheblowerbeltfromthemowerpulley

assembly.

8.Opentheblowerassembly .

9.Removetheblowerassemblyfromthepivothole.

10.Ifyouarechangingtosidedischargemode,ensure

thegrassdeectorisinstalledandcanbelowered

intoworkingposition.

11.Removethecollectionsystemassembly.

19

Page 20

UsingtheGrassDeector

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebriswill

causeinjuryordeath.

•Alwaysinstallthegrassdeectorwhen

removingthecollectionsystemand

changingtosidedischargemode.

•Ifthegrassdeectoriseverdamaged,

replaceitimmediately.Thegrassdeector

routesmaterialdowntowardtheturf.

•Neverputyourhandsorfeetunderthe

mower.

CuttingHeight

Foroptimumbaggingperformance,setthedeck

height-of-cuttoremovenomorethat2to3inches(51

to76mm)or1/3ofthegrassheight,whicheverisless.

Cuttingoffmorethanthiswillreducethecapacityof

thevacuumsystem.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.

Youwillhavetocutyourgrasstwiceifitgetsexcessively

long(refertoBaggingLongGrass).

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlap

themowerintothepreviouslycutarea.Thishelps

reducetheloadontheengineandreducesthechance

ofpluggingtheblowerassemblyandtubes.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(PTO)totheoffposition,rotatethe

ignitionkeytooffandremovethekey .

TransportingMachines

Donotleavegrassordebrisinthebaggerwhile

transportingthemachineonatrailerortruck.

Transportingthemachinewithgrassordebris

inthebaggercandamagethemachine.

Donotleavegrassordebrisinthebaggerwhile

transportingthemachineonatrailerortruck.

OperatingTips

BaggingSpeed

Thebaggingsystemmayplugifyoudrivetoofastand

theenginespeedgetstooslow .Onhillsitmaybe

necessarytoslowthemachinesgroundspeed.Mow

downhillwheneverpossible.

Asthebaggerlls,extraweightisaddedto

thebackofthemachine.Ifyoustopandstart

suddenlyonhills,youmaylosesteeringcontrol

orthemachinemaytip.

•Donotstartorstopsuddenlywhengoing

uphillordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoing

uphill,disengagethePTO.Thenbackdown

thehillusingaslowspeed.

•Donotchangespeedsorstoponslopes.

MachineSize

Rememberthatthemachineislongerandwiderwith

thisattachmentinstalled.Byturningtoosharplyin

connedplacesyoumaydamagetheattachmentor

otherproperty.

Trimming

Alwaystrimwiththeleftsideofthemower.Donot

trimwiththerightsideofthemowerbecauseyoucould

damagethebaggingtubes.

BaggingLongGrass

Ifthegrassiseverallowedtogrowlongerthannormal,

orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutandbagthe

grassatthissetting.Thencutandbagthegrassagain

usingthelower,normalsetting.

Excessivelylonggrassisheavyandmaynotbe

propelledcompletelyintothebagger.Ifthishappens,

thetubeandblowermayplug.Toavoidpluggingthe

baggingsystem,mowthegrassatahighheight-of-cut,

20

Page 21

thenlowerthemowertoyournormalcuttingheight

andrepeatthebaggingprocess.

BaggingWetGrass

Ifpossible,alwaystrytocutgrasswhenitisdry.Wet

grasscancauseplugging.

ReducingPlugging

Toavoidpluggingthebaggingsystem,reduceground

speedandmowthegrassatahighheight-of-cut,then

lowerthemowertoyournormalcuttingheightand

repeatthebaggingprocess.

SignsofPlugging

Asyouarebagging,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.Anexcessive

amountofclippingblow-outindicatesthatthebagger

isfullorthetubeisplugged.

BaggingBlades

Inmostmowingconditions,thestandardhighlift

bladeswillprovidethebestbaggingperformance.

TheT oroAtomicbladeisrecommendedforbagging

leavesindryconditions.Indrydustyconditions,the

mediumliftorlowliftbladeswillreducedustanddirt

blowoutwhileprovidingeffectivebaggingairow .

ContactanAuthorizedServiceDealerfortheproper

bladesfordifferentmowingconditions.

CurbClimbingandLoading

Alwaysliftthedecktothehighestpositionwhenloading

themachineontrailersorascending/descendinga

curb.Leavingthemowerinalowerpositioncancause

damagetothemowerwhileloadingandgoingovera

curb.Ifacurbishigherthan6inches(152mm),crossit

atasharpanglewiththedeckfullyraised.Useextreme

cautionwhenloadingontoatrailer.

21

Page 22

Maintenance

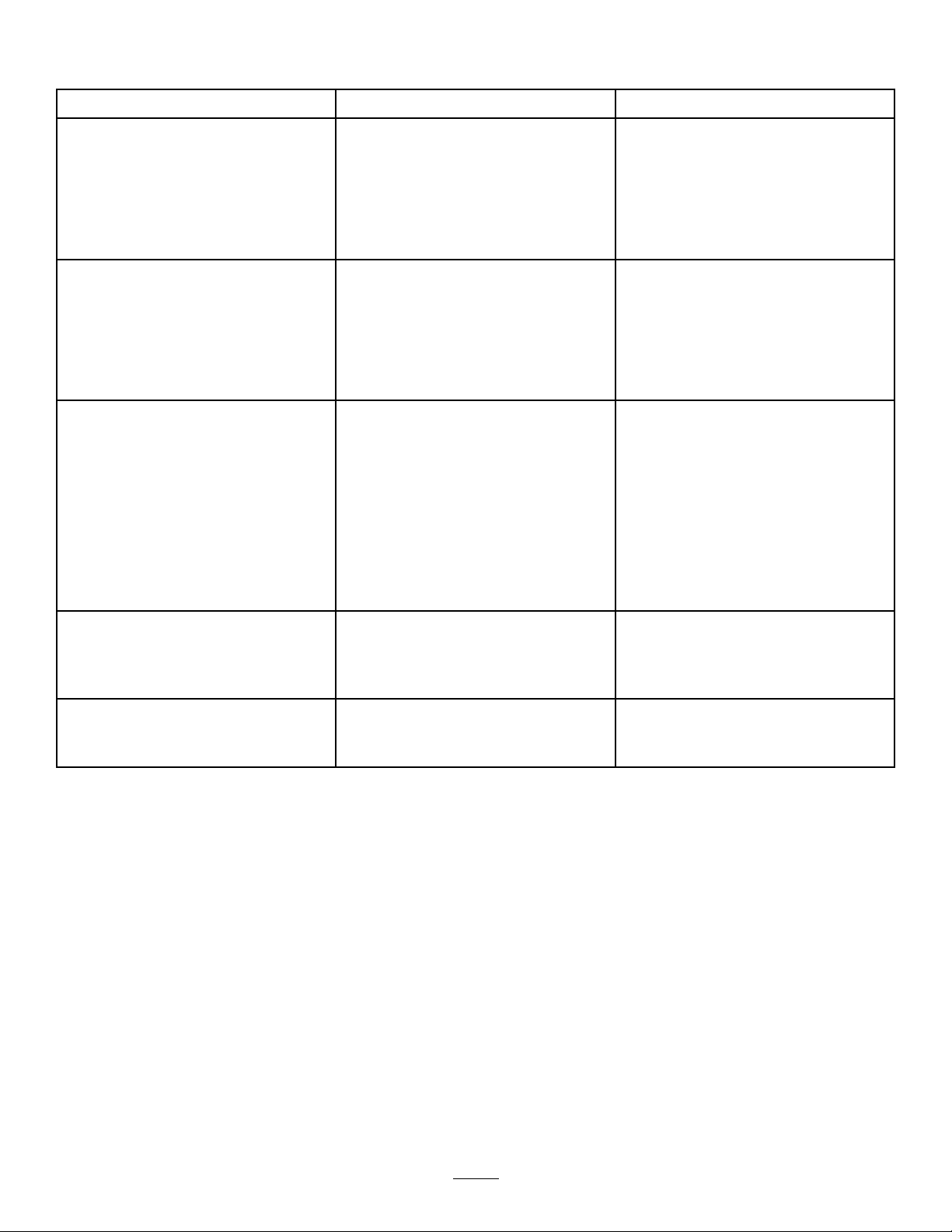

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Inspecttheblowerbelt.

•Inspectthecollectionsystem.

•Cleanthehoodscreen.

•Cleanthecollectionsystem.

•Inspecttheblowerbelt.

•Greasetheidlerarm.

•Greasethehandlepivot.

•Inspectthecollectionsystem.

CleaningtheBaggerScreen

ServiceInterval:Beforeeachuseordaily

Thescreensneedtobecleanedbeforeeachuse.Inwet

grasstheywillneedtobecleanedmoreoften.

1.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Openthebagger.

4.Cleanthedebrisfromthescreen.

5.Closethebagger.

ReplacingtheBlowerBelt

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pullbackonthespringloadedidlerpulleytorelieve

thebelttension(Figure33).

4.Removetheexistingblowerbeltfromthemower

deckpulleyandthentheblowerpulleys.

5.Installthenewbeltaroundtheblowerpulleysand

themowerdeckpulley(Figure33).

CleaningtheCollection

System

ServiceInterval:Beforeeachuseordaily

1.Washtheinsideandoutsideofthebaggerhood,

tube,andtheundersideofthemower.Useamild

automotivedetergenttoremovedirt.

2.Makesureyouremovemattedgrassfromallparts.

3.Afterwashingallparts,letthemdrythoroughly.

Note:Withallpartsinstalled,startandrunthemachine

foraminutetoassistindrying.

InspectingtheBlowerBelt

ServiceInterval:Aftertherst8hours

Every25hours

Checkbeltsforcracks,frayededges,burnmarksorany

otherdamage.Replacedamagedbelts.

22

Page 23

Figure33

1.Idlerpulley4.Peg

2.Mowerdeckpulley5.Belt

3.Spring

Figure35

1.Latch3.Blowerassembly

2.Bolt

6.Blowerpulley

GreasingtheIdlerArmand

6.InstallthespringasshowninFigure34.

Figure34

1.Springloadedidlerpulley

2.Shorthookend

3.Longhookend

7.Pullbackonthespringloadedidlerpulleyand

installthebeltontothespringloadedidlerpulley

(Figure33).

HandlePivot

ServiceInterval:Every50hours—Greasetheidler

arm.

Every100hours—Greasethehandle

pivot.

Greasetheblowerbeltidlerarm(Figure36).

Figure36

CheckingandAdjustingthe

BlowerLatch

Closetheblowerassemblytoseeifthelatchesare

adjustedcorrectly.Loosenortightentheboltssothe

latchesrmlyholdtheblowerassemblyagainstthe

mowerdeck,butcanbereleasedbyhand.

23

Page 24

Greasethehandlepivot(Figure37).

Figure37

InspectingtheCollection

System

ServiceInterval:Aftertherst8hours

Every100hours

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Checktheuppertube,lowertube,bagger,andthe

blowerassembly.Replacethesepartsiftheyare

crackedorbroken.

4.Checkthebaggerframe.Replaceanypartsthatare

crackedorbroken.

5.Tightenallnutsboltsandscrews.

5.Afterthestopboltshavebeenadjusted,thelengthof

thehingelinkscanbeadjustedtoprovidecomplete

closingofthedoorandreasonableforceonthe

handle.Lengthenthelinkstoreducetheforce.

Shortenthelinkstoincreasetheforce(Figure38

andFigure39).

6.Makesureboththeleftandrightsidesareadjusted

thesamedistance.Withthedoorclosed,thelinks

shouldbeslightlytighttominimizerattling.

7.Tightenthenuts.

Figure38

1.Contactarmstraightup

anddown

2.Stopbolt

3.Hingelinks

AdjustingtheDoorClosing

Thetwohingelinksandtwostopscrewscanbeadjusted

toprovidecompleteclosingofthedoor.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Withthedoorclosed,thestopboltsneedtobe

adjustedsothatthecontactarmisstraightupand

down(Figure38andFigure39).

4.Ifadjustmentisneed,loosenthenutsandadjustthe

stopbolts(Figure38andFigure39).

24

1.Contactarm

2.Stopbolt

Figure39

3.Hingelinks

Page 25

AdjustingtheDoorOpening

Performthisafteradjustingthedoorclosing.

Adjustthehandlelinktoobtainthemaximumdoor

opening.Lengthenthehandlelinktoopenthedoor

farther.Shortenthehandlelinktoopenthedoorless

(Figure40).

Note:Themaximumdooropeningiscontrolledbythe

contactarmhittingthestop.Thestopisnotadjustable

andpreventsthedoorfrombeingopenedtoofar.

Figure40

1.Handle

2.Handlelink

3.Stop

Figure41

1.Latchlink2.Latchrod

InspectingtheMowerBlades

1.Inspectthemowerbladesregularlyandwhenevera

bladestrikesaforeignobject.

2.Ifbladesarebadlywornordamaged,installnew

blades.RefertoyourmowerOperator’ sManualfor

completeblademaintenance.

InstallingtheMowerBlades

AdjustingtheLatches

Thelatchescanbeadjustaftertheopenandcloseddoor

positionshavebeenset.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Closethedoor.

4.Checkthetoensurethelatchescompletelyengage

andcontactsthelatchrodweldedtothedoor

(Figure41).

5.Thelatchesneedtobetightagainstthelatchrod.

Theyneedtobelooseenoughtomoveorwiggle.

Inmostmowingconditions,thestandardhighliftblades

willprovidethebestbaggingperformance.

TheToroAtomicbladeisrecommendedforbagging

leavesindryconditions.Indrydustyconditions,the

mediumliftorlowliftbladeswillreducedustanddirt

blowoutwhileprovidingeffectivebaggingairow .

ContactanAuthorizedServiceDealerfortheproper

bladesfordifferentmowingconditions.

RefertothemowerOperator’ sManualformore

informationoninstallingblades.

25

Page 26

InstallingtheGrassDeector

Storage

1.Cleanthebagger.RefertoCleaningtheBagger.

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

•Neveroperatethelawnmowerunlessyou

installacoverplate,amulchplate,oragrass

chuteandcatcher.

•Makesurethegrassdeectorisinthedown

position.

1.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(Figure42).

2.Removethedamagedorworngrassdeector.

3.Placethespacerandspringontothegrassdeector.

PlacetheLendofthespringbehindthedeckedge.

Note:MakesuretheLendofthespringisinstalled

behindthedeckedgebeforeinstallingtheboltas

showninFigure42

4.Installtheboltandnut.

5.PlacetheJhookendofthespringaroundthegrass

deector(Figure42).

2.Inspectthebaggerfordamage.RefertoInspecting

theCollectionSystem.

3.Makesurethebaggerisemptyandthoroughlydry.

4.Checkthebeltforwearorcracks.

5.Storethemachineinaclean,dryplace,outofdirect

sunlight.Ifyoumuststorethemachineoutside,

coveritwithaweatherproofcover.Thisprotectsthe

plasticpartsandextendsthelifeofthemachine.

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

Figure42

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

26

Page 27

Troubleshooting

Problem

Abnormalvibration.

Reducedbaggingperformance.

Blowerandtubesplugtoofrequently.

PossibleCauseCorrectiveAction

1.Cuttingblade(s)is/arebentor

unbalanced.

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Looseblowerpulleyorpulleyassembly.3.Tightentheappropriatepulley.

4.Wornblowerbelt.4.Replacebelt.

5.Blowerfanblade(s)is/arebentor

unbalanced.

1.Lowenginespeed.1.Alwaysoperatethecollectionsystem

2.Pluggedscreeninbaggerhood.2.Removedebris,leavesorgrass

3.Looseblowerbelt.3.Replacetheblowerbelt.

4.Apluggedtubeorblower.4.Locateandremovepluggeddebris.

5.Fullbagger .5.Emptythebagger.

1.Baggeristoofull.1.Dumpmorefrequently.

2.Lowenginespeed.2.Alwaysoperatethecollectionsystem

3.Grassistoowet.3.Cutgrasswhenitisdry.

4.Grassistoolong.4.Cutnomorethan2-3inches(51-76

5.Pluggedscreeninhood.5.Removedebris,leavesorgrass

6.Groundspeedistoofast.6.Drivesloweratfullthrottle.

7.Wornblowerbelt.7.Replacebelt.

1.Installnewcuttingblade(s).

5.ContactanAuthorizedServiceDealer.

atfullthrottle.

clippingsfromthescreen.

atfullthrottle.

mm)or1/3ofthegrassheight,which

everisless.

clippingsfromthescreen.

Debrisblowout.

Blowerimpellerdoesnotspinfreely .

1.Baggeristoofull.1.Dumpmorefrequently.

2.Groundspeedistoofast.2.Drivesloweratfullthrottle.

3.Mowerdeckisnotleveled.

1.Pluggedblower .1.Removedebris,leavesorgrass

2.Impellernotaligned.

3.Seethemoweroperator’smanualfor

levelingthemowerdeck.

clippingsfromtheblowerimpeller.

2.ContactanAuthorizedServiceDealer.

27

Page 28

Landscape

Contractor

Equipment (LCE)

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant to an

agreement between them, jointly promise to repair the listed Toro Products if

defective in materials or workmanship. The following time periods apply from

the date of purchase:

This warranty applies to:

•

ProLine Mid-Size Mowers and Attachments

•

Z Master Mid-Mount ZRTs and Attachments

Components

Traction Unit Frame and Carrier Frame

All Spindles

Engines* and /Hydraulic System

Deck Shells (34 ″ -72 ″ )

Z500 Series Electric Clutch

Remaining Components

* S o m e e n g i n e s u s e d o n T o r o L C E P r o d u c t s a r e w a r r a n t e d b y t h e e n g i n e m a n u f a c t u r e r .

This warranty includes the cost of parts and labor, but you must pay

transportation costs.

Warranty Period

1 year

1 year

2 year

3 years Parts

2 years Labor

2 years

2 years

2 years

1 year

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you, access our website at

www.Toro.com. You may also call our Toro Customer Care Department

toll free at 888–865–5676 (U.S. Customers) or 888–865–5691 (Canada

customers).

2. Bring the product and your proof of purchase (sales receipt) to the Service

Dealer.

If for any reason you are dissatised with the Service Dealer’s analysis or with

the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures

described in the operator’s manual. Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

Items and Conditions Not Covered

There is no other express warranty except for special emission system coverage

on some products. This express warranty does not cover the following:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants,

tune-up parts, blade sharpening, brake and clutch adjustments.

• Any product or part which has been altered or misused or required

replacement or repair due to normal wear, accidents, or lack of proper

maintenance.

• Repairs necessary due to improper fuel, contaminants in the fuel system, or

failure to properly prepare the fuel system prior to any period of non-use

over three months.

• Pickup and delivery charges.

General Conditions

All repairs covered by this warranty must be performed by an Authorized Toro

Service Dealer using Toro approved replacement parts.

Neither The Toro® Company nor Toro Warranty Company is liable for

indirect, incidental or consequential damages in connection with the

use of the Toro Products covered by this warranty, including any

cost or expense of providing substitute equipment or service during

reasonable periods of malfunction or non-use pending completion

of repairs under this warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

All implied warranties of merchantability (that the product is t

for ordinary use) and tness for use (that the product is t for

a particular purpose) are limited to the duration of the express

warranty.

This warranty gives you specic legal rights, and you may also have

other rights which vary from state to state.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee

policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information,

contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

374-0037 Rev F

Loading...

Loading...