Page 1

Form No. 3355-152 Rev A

Blower and Drive Kit

For 48in E-Z Vac® Bagger for Z400 Series Z Master®

Mowers

Model No. 78536 —Serial No. 260000001 and Up

Installation Instructions

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

1

2

3

4

5

Step

1

Preparing the Mower

No parts required

Template 1

Template 2

Pulley assembly

Pivot bracket

Metal template

Bolt (3/8 x 1 inch)

Nut (3/8 inch)

Blower assembly

Bagger belt

Blower belt cover

Spring

Description

Qty.

–

1

1

1

1

1

3

3

1

1

1

1

Prepare the mower.

Modify the mower deck.

Install the pulley assembly.

Install the pivot bracket.

Install the blower, bagger belt,

spring, and belt cover.

Use

4. Clean the mo w er of any debris on the dec k or

rear par t of the mo w er to ease installation.

Note: Clean the area around the belt co v er

before remo ving .

5. Unlatc h and remo v e the right belt co v er . Sa v e

this hardw are .

No Parts Required

Procedure

P erfor m the follo wing procedure to pre pare the

mo w er for attac hing the blo w er and finishing kit.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. R e pair all bent or damag ed areas of mo w er

dec k and re place any missing par ts .

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

6. Store the right belt co v er for later use . If the

bag g er blo w er and pulley is remo v ed it can be

reused.

Printed in the USA.

All Rights Reserved

Page 2

Step

7. Using a right angle g rinder with a cutting

disk, cut the mo w er dec k as mark ed from the

templates ( Figure 2 ).

2

Modifying the Mower Deck

Parts needed for this step:

1

Template 1

1

Template 2

Procedure

T he use of a right angle g rinder with a cutting

disk and a g rinding disk are recommended for this

procedure . F ollo w all safety r ules and infor mation

that w as included with the right angle g rinder .

1. Lo w er the mo w er dec k to the lo w est

height-of-cut position.

2. Cut out templates 1 and 2 located in the bac k

of the man ual.

3. T ape template n umber 1 into position as sho w

in Figure 1 .

8. Use the right angle g rinder with a g rinding disk

to smooth the rough edg es after the cut outs

are made . Mak e sure to g rind smooth the w eld

that remains after the material is remo v ed.

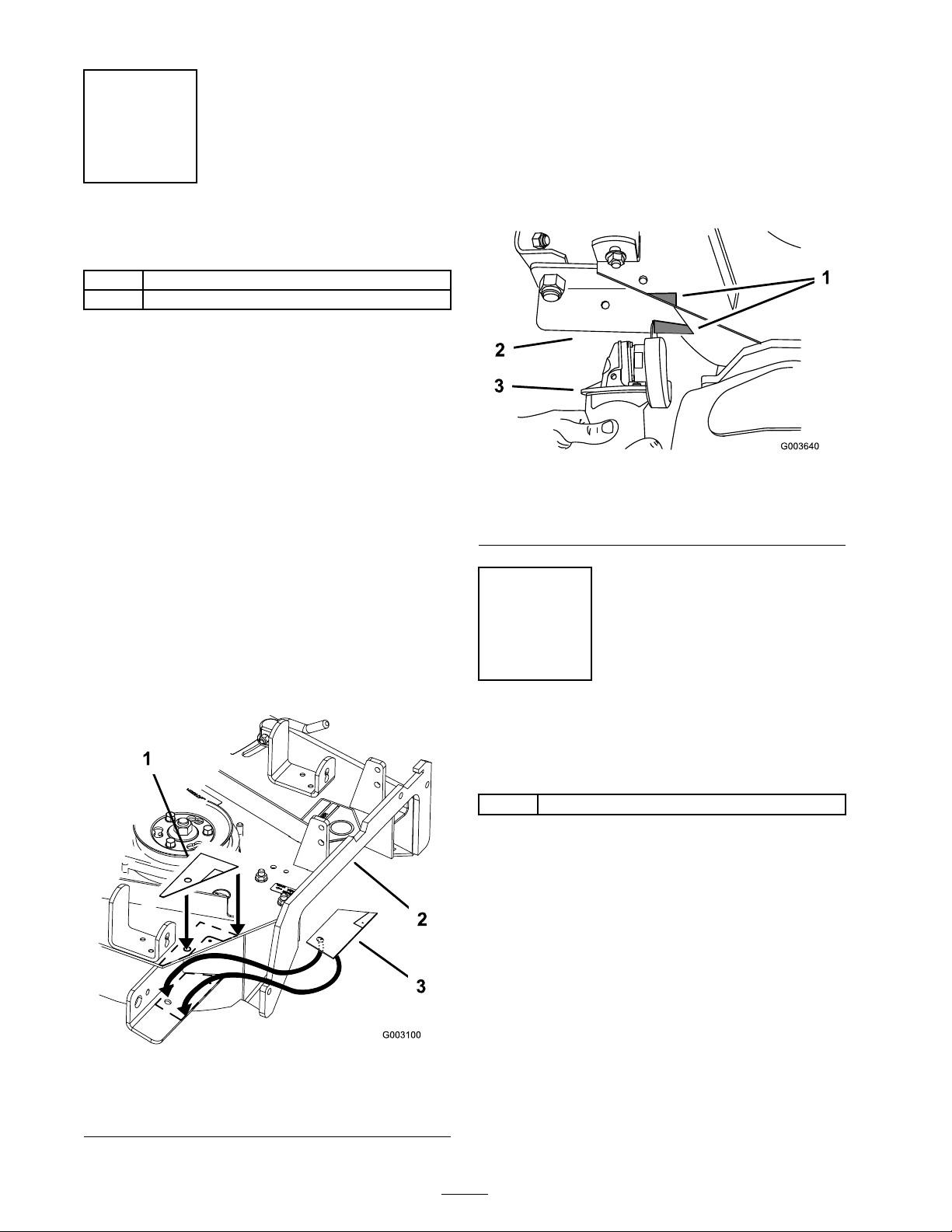

Figure 2

1. Remove material from the

mower deck

2. Mower deck

3. Right angle grinder

Step

4. Mark the edg es sho wn on template n umber 1.

5. T ape template 2 into position as sho w in

Figure 1 .

6. Mark the edg es as sho wn on template 2.

Figure 1

1. Template number 1 3. Template number 2

2. 48 inch (123 cm) mower

deck

3

Installing the Pulley

Assembly

Parts needed for this step:

1

Pulley assembly

Procedure

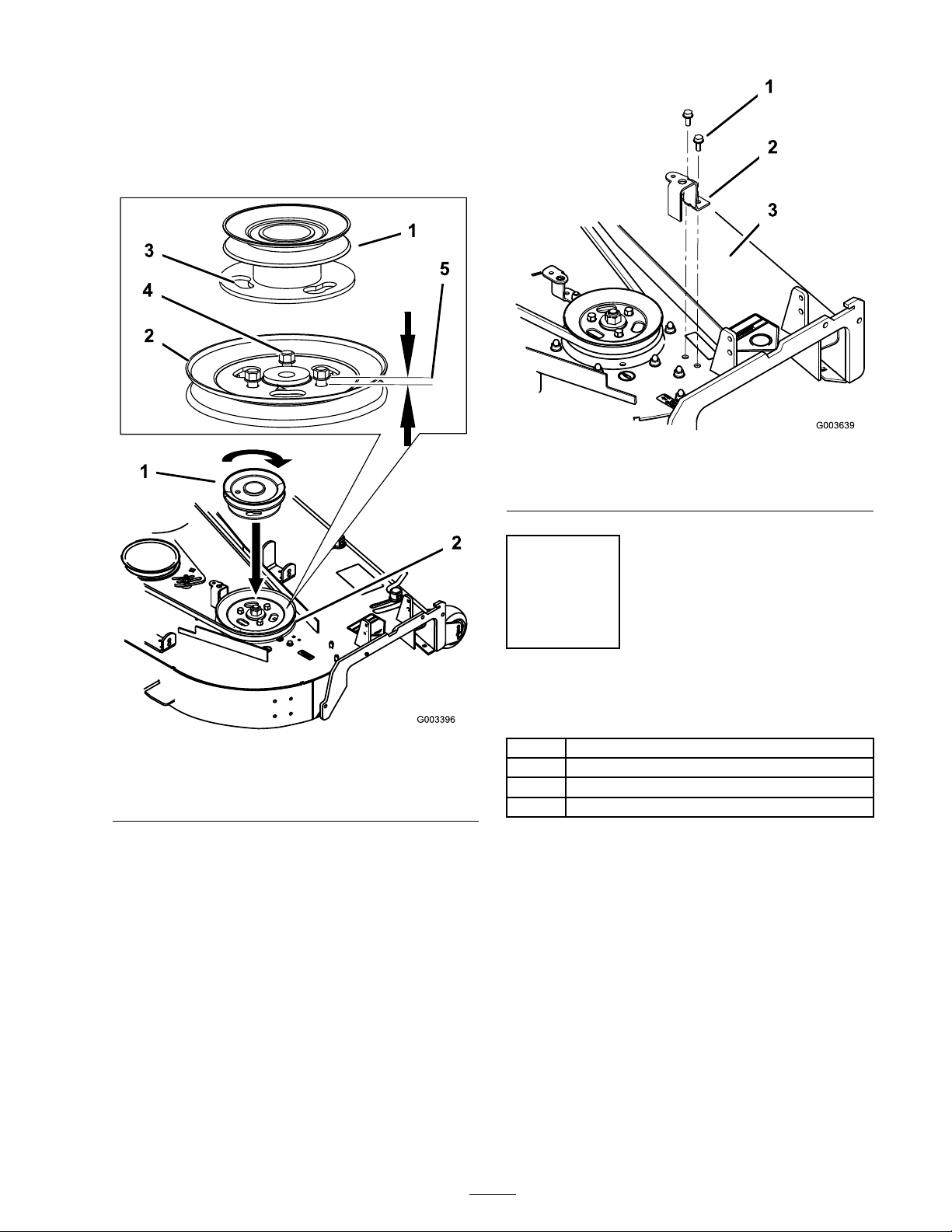

1. Loosen, but do not remo v e , the tapping bolts

on the existing mo w er dec k pulley ( Figure 3 ).

T here should be a 3/16 inc h (5 mm) clearance

betw een the bolt head and pulley .

2. Align the new pulley assembly so that the

openings fit o v er the pulley bolt heads ( Figure

3 ).

3. T ur n the pulley to loc k it into position ( Figure

3 ).

Note: If the pulley does not tur n, loosen

the bolts to raise the bolt heads and allo w the

pulley to loc k into position.

2

Page 3

4. After the new pulley assembly is in position,

tighten the existing bolts to secure new pulley

assembly .

Note: T or que the bolts to 23 ft-lb ± 2 ft-lb

(31 N ⋅ m ± 3 N ⋅ m).

Figure 4

1. Bolt 3. Mower deck

2. Belt cover support bracket

Figure 3

1. Pulley assembly 4. Bolt heads

2. Mower deck pulley

3. Locking slots

5. 3/16 inch (5mm)

5. R emo v e the belt co v er suppor t brac k et from

the mo w er dec k ( Figure 4 ).

Step

4

Installing the Pivot Bracket

Parts needed for this step:

1

Pivot bracket

1

Metal template

3

Bolt (3/8 x 1 inch)

3

Nut (3/8 inch)

Procedure

1. Align the metal template , with the n umber 48

in it, to the mo w er dec k edg e and clamp it

tightly to the mo w er dec k ( Figure 5 ).

2. Center punc h the new mo w er dec k hole

locations using the 3 holes in the template

( Figure 5 ).

3. R emo v e the metal template and drill three , 1/8

inc h diameter , pilot holes with a shar p drill bit

( Figure 5 ).

4. Drill three , 13/32 inc h diameter , holes into the

pilot holes with a shar p drill bit ( Figure 5 ).

3

Page 4

5. R emo v e par t of the metal belt co v er suppor t

on top of the mo w er . R efer to Figure 5 for the

cor rect size and location to remo v e .

1. Mower deck 3. Blower

2. Bolt, (3/8 x 1

inch)

Figure 6

5. Drilled holes

assembly pivot

4. Locknut, (3/8

inch)

Figure 5

1. Cut 1 inch (25 mm) off the

metal belt cover support

here

2. Mower deck 5. Drill three, 1/8 inch pilot

3. Align template with mower

deck edge

4. Template with the number

48 in it

holes and 13/32 inch

diameter holes, here

6. Template location on

mower deck

6. Install the pi v ot brac k et using the 3 bolts (3/8

x 1 inc h) and 3 loc k n uts (3/8 inc h) ( Figure 6 ).

Step

5

Installing the Blower

Assembly, Bagger Belt,

Spring, and Blower Belt

Cover

Parts needed for this step:

1

Blower assembly

1

Bagger belt

1

Blower belt cover

1

Spring

Procedure

R efer to the bag g er Operator’ s Manual for the

cor rect procedure to install the blo w er , bag g er

belt, spring, and blo w er belt co v er .

4

Page 5

Page 6

Page 7

Page 8

Loading...

Loading...