Page 1

FormNo.3358-540RevA

G001412

DFSVacCollectionSystem

foraZ593,Z595orZ589SeriesZMaster

Mower

ModelNo.78514—SerialNo.260000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

1

G001411

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorT oroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Contents

Introduction.................................................................2

Safety..........................................................................3

SafetyandInstructionalDecals...........................4

Setup...........................................................................5

1InstallingtheBaggerMounting

Bracket............................................................7

2TighteningallMountingBolts..........................9

3InstallingtheBaggerDrivePulley....................9

4InstallingtheSpringLoadedIdlerPulley

andSpringAnchor........................................10

5InstallingtheFixedIdlerPulley......................11

6InstallingtheIdlerArmBracket......................12

7InstallingtheBagger.......................................12

8InstallingtheBaggerBelt...............................13

9CheckingandAdjustingtheBaggerBelt

Tension..........................................................14

10InstallingtheWeights...................................14

11InstallingtheBootandDischarge

Tubes.............................................................15

12InstallingtheBaggerDumpHandle..............16

13InstallingtheBaggerDumpLeverStop

Bolt................................................................17

14AdjustingtheBaggerDumpLever................18

15ModifyingtheRadiatorCover......................18

16CheckingtheTirePressure...........................19

Operation...................................................................20

PositioningtheAdjustableBafe......................20

OpeningtheBagger...........................................20

HoldingtheBaggerDoorOpen.........................21

AdjustingtheBaggerDoorOpeningand

Cable.............................................................21

ClearingObstructionsFromtheBagger

System...........................................................21

RemovingtheDischargeTubes.........................22

RemovingtheBagger........................................22

SecuringtheBaggerIdlerPulley.......................23

ReplacingtheGrassDeector...........................23

OperatingTips...................................................24

Maintenance..............................................................26

RecommendedMaintenanceSchedule(s)..............26

CleaningtheScreens.........................................26

CleaningtheBagger..........................................26

CheckingtheBaggerBelt..................................26

GreasingtheIdlerArm......................................26

GreasingtheFanShaftBearings........................26

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

InspectingtheBagger........................................27

InspectingtheMowerBlades............................27

Troubleshooting........................................................28

Safety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsandothersafetyinformationyou

mustknow.

•Becomefamiliarwiththesafeoperationofthe

equipment,withtheoperatorcontrols,andsafety

signs.

•Useextracarewithgrasscatchersorother

attachments.Thesecanchangetheoperating

characteristicsandthestabilityofthemachine.

•Followthemanufacturer’srecommendations

foraddingorremovingwheelweightsor

counterweightstoimprovestability.

•Donotuseagrasscatcheronsteepslopes.A

heavygrasscatchercouldcauselossofcontrolor

overturnthemachine.

•Slowdownanduseextracareonhillsides.Be

suretotravelintherecommendeddirectionon

hillsides.Turfconditionscanaffectthemachine’s

stability.Useextremecautionwhileoperatingnear

drop-offs.

•Keepallmovementonslopesslowandgradual.

Donotmakesuddenchangesinspeed,directions

orturning.

•Thegrasscatchercanobstructtheviewtotherear.

Useextracarewhenoperatinginreverse.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Keephandsandfeetawayfrommovingparts.Do

notmakeadjustmentswiththeenginerunning.

•Stoponlevelground,disengagedrives,chock

orblockwheels,shutoffenginebeforeleaving

theoperator’spositionforanyreasonincluding

emptyingthegrasscatcheroruncloggingthechute.

•Ifyouremovethegrasscatcher,besuretoinstall

anydischargedeectororguardthatmighthave

beenremovedtoinstallthegrasscatcher.Donot

operatethemowerwithouteithertheentiregrass

catcherorthegrassdeectorinplace.

•Stoptheenginebeforeremovingthegrasscatcher

oruncloggingthechute.

•Donotleavegrassingrasscatcherforextended

periodsoftime.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplace

3

Page 4

withmanufacturer’srecommendedparts,when

necessary.

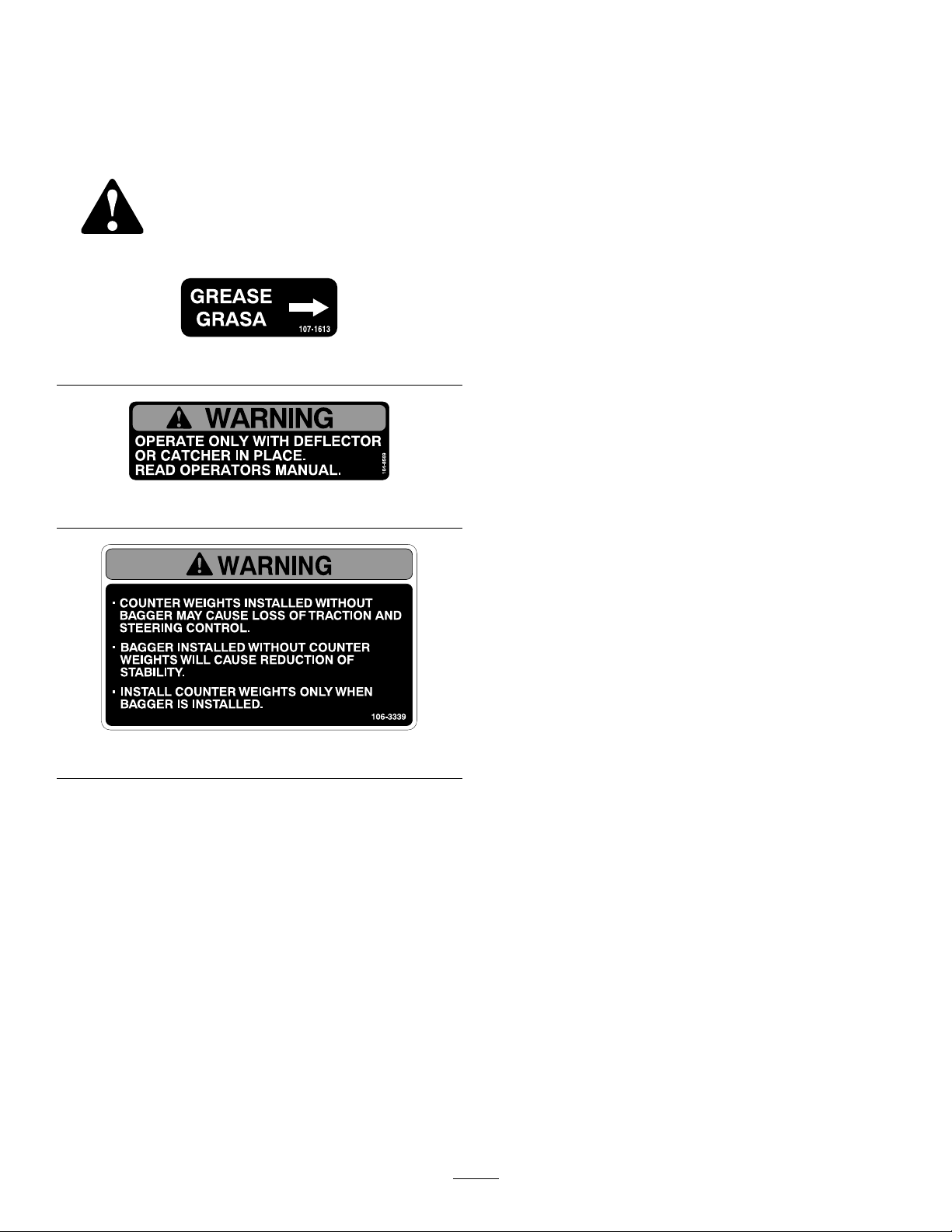

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

107-1613

104-8569

106-3339

4

Page 5

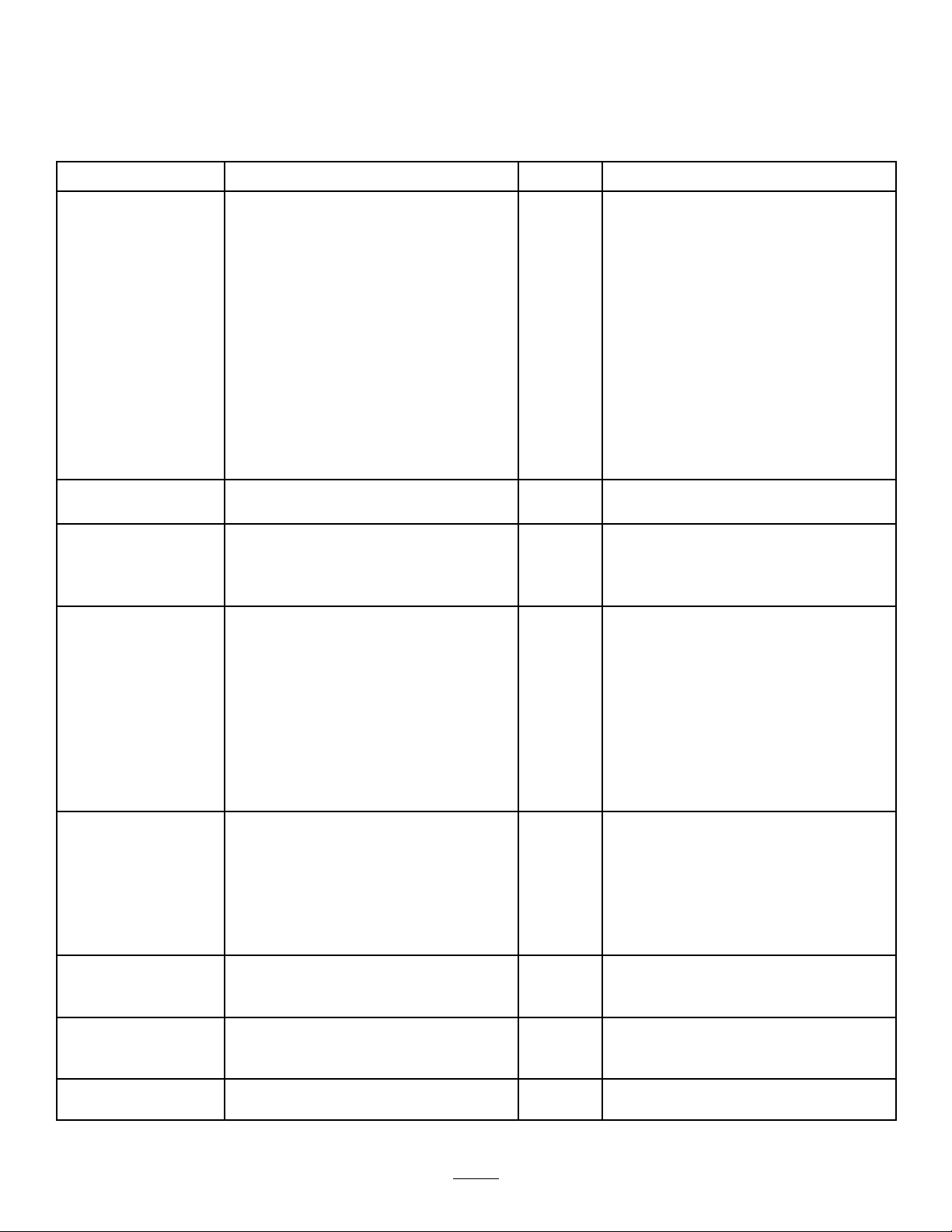

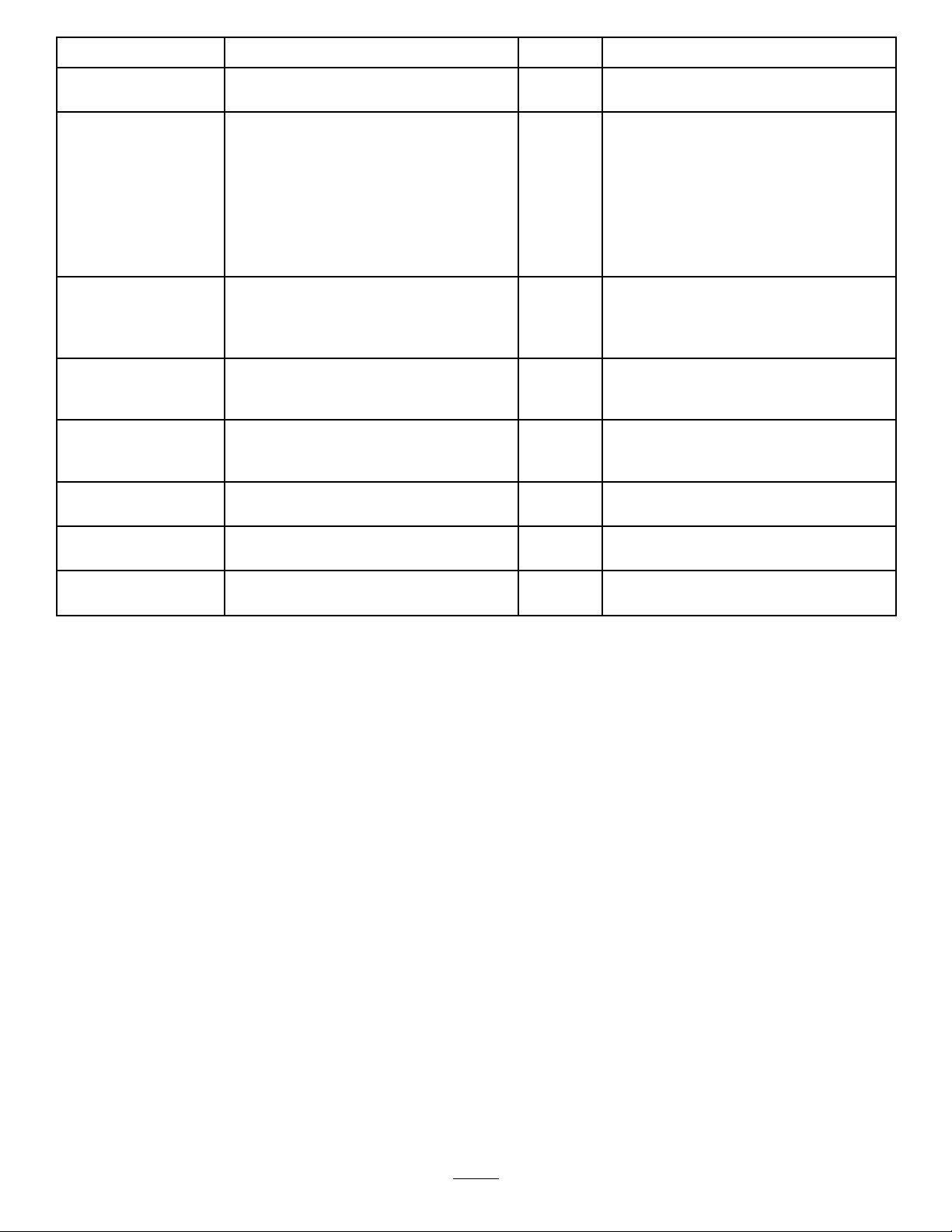

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Baggermountingbracket1

Sidebracket—right

Sidebracket—left

Longframespacer

Shortframespacer

Bolt,(3/8x1-1/2inches)

Bolt,(3/8x1-1/4inches)

Serratedangenut,(3/8inch)

Stiffenerbracket

Bolt,(3/8x3/4inch)

Curvedwasher

Roundspacers2

Bolt,(3/8x1inch)

Sidelocknut,(3/8inch)

Nopartsrequired

Baggerdrivepulley1

Pulleyspacer3

Bolt,(3/8x1-3/4inches)

Flangenut,(3/8inch)

Springloadedidlerpulley

Idlerarm1

Carriagebolt,(3/8x2inches)

Bolt,(3/8x4–1/2inches)

Locknut,(3/8inch)

Washer,7/16inch

Washer,13/32inch

Longroundspacer1

Sidelocknut,(3/8inch)

Springanchor,(3/8inch)

Fixedidlerpulley1

Fixedidlerbracket1

Bolt,(3/8x1-1/2inches)

Bolt,(3/8x3/4inch)

Locknut,(3/8inch)

Flangenut,(3/8inch)

Washer,13/32inch

Idlerarmbracket1

Bolt,(3/8x3/4inch)

Flangenut,(3/8inch)

Bagger1

Clevispin

Hairpincotter2

Baggerbelt1

Spring

Qty.

16

29

14

Use

1

1

2

2

2

2

8

2

1

–

3

3

1

1

1

2

1

1

1

1

1

2

1

2

1

2

2

2

1

Installthebaggermountingbrackets

ontothemachine

Tightenallmountingbolts

Installthebaggerdrivepulley

Installthespringloadedidlerpulley

Installthexedidlerpulley

Installtheidlerarmbracket.

Installthebagger

Installthebaggerbelt

5

Page 6

ProcedureDescription

Qty.

Use

9

10

11

12

13

14

Nopartsrequired

Casterweight

U-bolt2

Nut,(1/2inch)

Lockwasher,(1/2inch)

Plate2

Smalltopweight

Largetopweight1

Bolt,1/2x4inch-fortopweights

Boot1

Middletube1

Uppertube1

Clamp

Dumphandle1

Washers,13/16inch

Cotterpin

Bolt,(1/2x1-3/4inches)

Jamnuts,(1/2inch)

Longcableclevis1

Nopartsrequired

–

2

4

4

2

2

1

2

1

1

2

–

Checkandadjustthebaggerbelt.

Installtheweights

Installthebootanddischargetubes

Installthebaggerdumphandle

Installthebaggerdumpleverstopbolt

Adjustthebaggerdumplever

15

16

Nopartsrequired

Nopartsrequired

–

–

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

ModifytheRadiatorCover

Checkthetirepressure

6

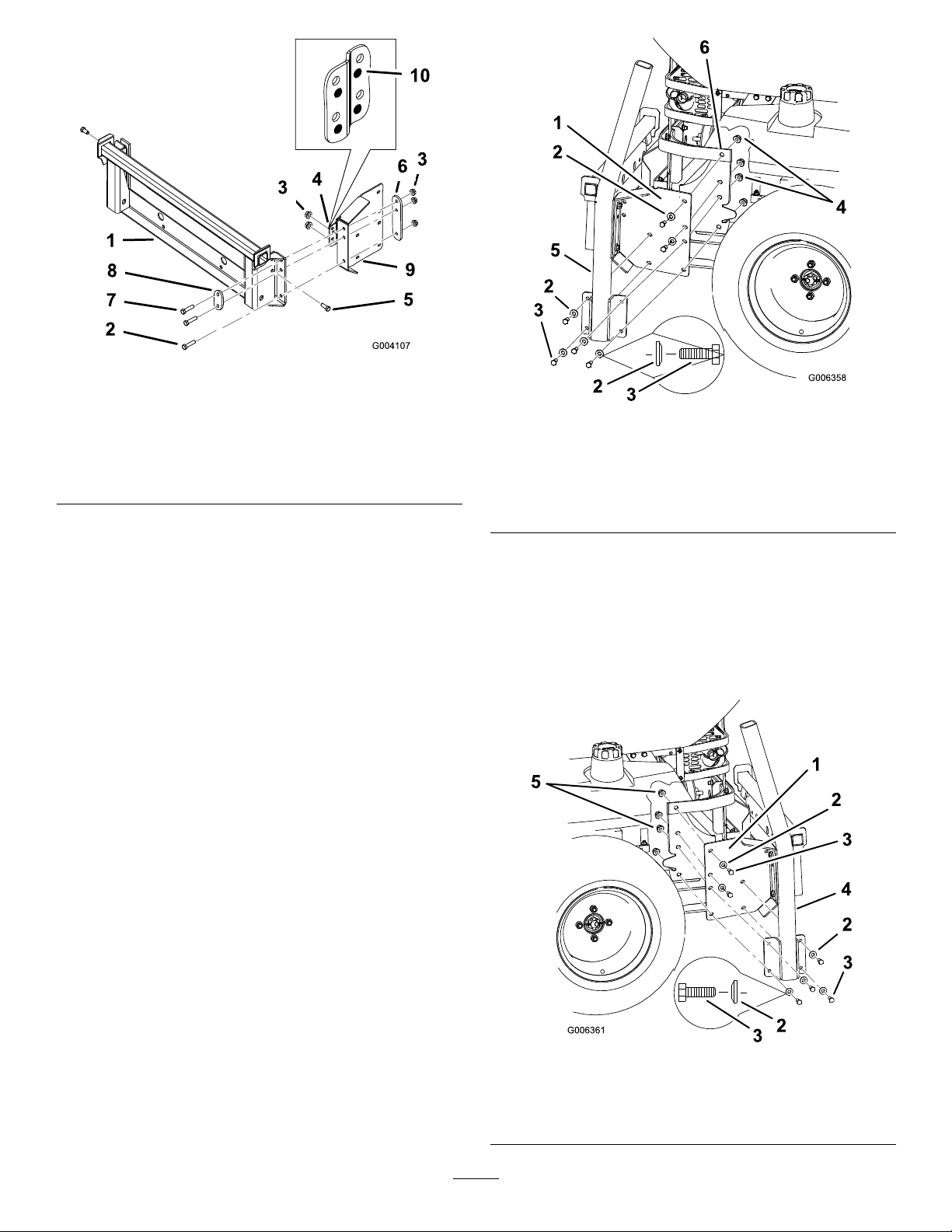

Page 7

1

InstallingtheBaggerMounting

Bracket

Partsneededforthisprocedure:

1Baggermountingbracket

1

Sidebracket—right

1

Sidebracket—left

2

Longframespacer

2

Shortframespacer

16

Bolt,(3/8x1-1/2inches)

2

Bolt,(3/8x1-1/4inches)

29

Serratedangenut,(3/8inch)

2

Stiffenerbracket

8

Bolt,(3/8x3/4inch)

14

Curvedwasher

2Roundspacers

2

Bolt,(3/8x1inch)

1

Sidelocknut,(3/8inch)

Procedure

Important:Donottightenanyboltsuntilbothside

bracketsandbaggermountingbracketaretloose

onthemachine.

RefertoTighteningtheMountingBoltsforthe

correctproceduretotightenthebolts.

Figure3

1.Seratedlocknut2.Sidelocknut

1.Installtherightsidebrackettothebaggermounting

bracket(Figure4).

2.Inthetoptwoholes,install2bolts(3/8x1-1/2

inches),2angenuts(3/8inch),1longframe

spacer,andoneshortframespacer(Figure4).

Note:Makesurethelongframespacerisinstalled

asshowninFigure4).

3.Inthebottomhole,installabolt(3/8x1-1/4

inches)andaangenut(3/8inch)(Figure4).

4.Installabracketstiffenertotherightsidebracket

andbaggermountingbracket.Use4bolts(3/8x

3/4inch)and4angenuts(3/8inch)(Figure4).

UseFigure3fordeterminingthedifferencesbetween

theserratedlocknutsandthesidelocknut.

7

Page 8

Figure4

1.Baggermountingbracket

2.Bolt,(3/8x1-1/4inches)7.Bolt,(3/8x1-1/2inches)

3.Flangenut,(3/8inch)8.Shortframespacer

4.Bracketstiffener

5.Bolt,(3/8x3/4inch)

6.Longframespacer

9.Rightsidebracket

10.Usetheseholesinthe

bracketstiffener

5.Removethebolts,nuts,andwashersholdingthe

rollbartotherightsideofthemachine.Discard

thenuts,bolts,andwashers(Figure5).

6.Removetheexistingboltandnutholdingthe

engineguardasshowninFigure5.

7.Installtherightsidebracketandtherollbarsection

tothesideofthemachineusing6bolts(3/8x1-1/2

inches),6curvedwashers(3/8inch),and6ange

nuts(3/8inch)(Figure5).

Note:Makesurethecurvedwasherareinstalledas

showninFigure5.

Figure5

1.Sidebracket4.Flangenut,(3/8inch)

2.Curvedwasher,(3/8inch)5.ROPS

3.Bolt,(3/8x1-1/2inches)

6.Removetheexistingbolt

fromengineguardand

discard

8.Removethebolts,nuts,andwashersholdingthe

rollbartotheleftsideofthemachine.Discardthe

nuts,bolts,andwashers(Figure6).

9.Installtheleftsidebracketbetweentherollbar

sectionandthesideofthemachineandfastenwith

6bolts(3/8x1-1/2inches),6curvedwashers(3/8

inch),and6angenuts(3/8inch)(Figure6).

Figure6

1.Sidebracket4.ROPS

2.Curvedwasher,(3/8inch)5.Flangenut,(3/8inch)

3.Bolt,(3/8x1-1/2inches)

8

Page 9

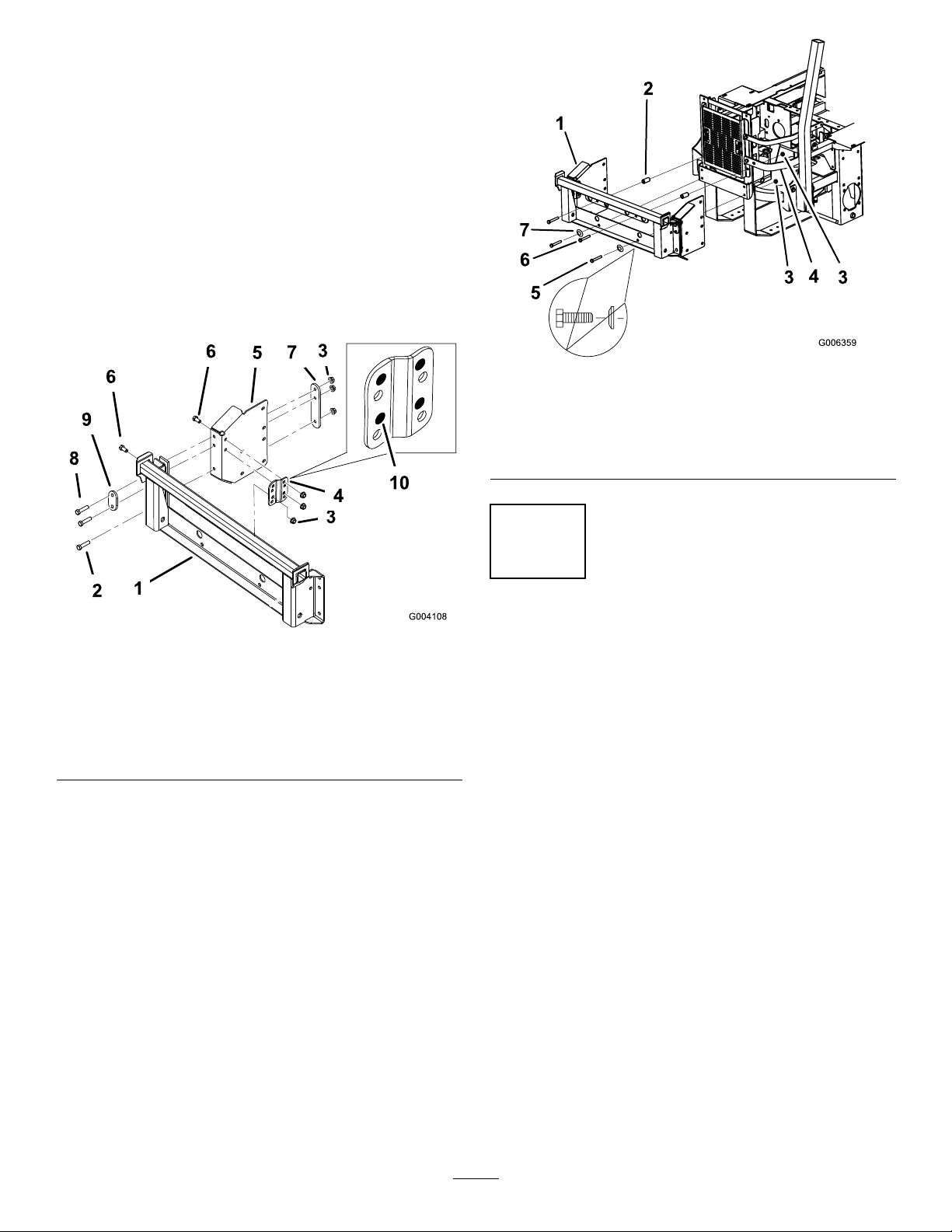

10.Installtheleftsidebrackettothebaggermounting

bracket(Figure7).

11.Inthetoptwoholes,install2bolts(3/8x1-1/2

inches),2angenuts(3/8inch),1longframe

spacer,andoneshortframespacer(Figure7).

Note:Makesurethelongframespacerisinstalled

asshowninFigure7.

12.Inthebottomhole,installabolt(3/8x1-1/4

inches)andaangenut(3/8inch)(Figure7).

13.Installabracketstiffenertotheleftsidebracket

andbaggermountingbracket.Use4bolts(3/8x

3/4inch)and4angenuts(3/8inch)(Figure7).

Figure8

1.Baggermountingbracket

2.Roundspacer

3.Flangenut,(3/8inch)7.Curvedwasher,(3/8inch)

4.Bumper

5.Bolt,(3/8x1inch)

6.Bolt,(3/8x1-3/4inches)

Figure7

1.Baggermountingbracket

2.Bolt,(3/8x1-1/4inches)7.Longframespacer

3.Flangenut,(3/8inch)8.Bolt,(3/8x1-1/2inches)

4.Bracketstiffener9.Shortframespacer

5.Leftsidebracket

6.Bolt,(3/8x3/4inch)

10.Usetheseholesinthe

bracketstiffener

14.Inthetoptwoholes,install2bolts(3/8x1-3/4

inches),2roundspacers,and2angenuts(3/8

inch).

15.Inthebottomtwoholes,install2bolts(3/8x1

inch)and2angenuts(3/8inch)(Figure8).

2

TighteningallMountingBolts

NoPartsRequired

Procedure

Thefollowingstepsarethecorrectsequencetotighten

thesidebracketsandthebaggermountingbracket.

All3/8inchmountingboltsneedtobetorquedto

35ft-lb(48N⋅m).

1.Tightenthebaggermountingbrackettotherear

framerst(Figure8).

2.Tightenthebaggermountingbrackettotheside

brackets(Figure4).

3.Tightenthebracketstiffenerstoboththesideplates

andthebaggermountingbracket(Figure4).

4.Tightenthesidebracketstothesideofthemower

(Figure6).

9

Page 10

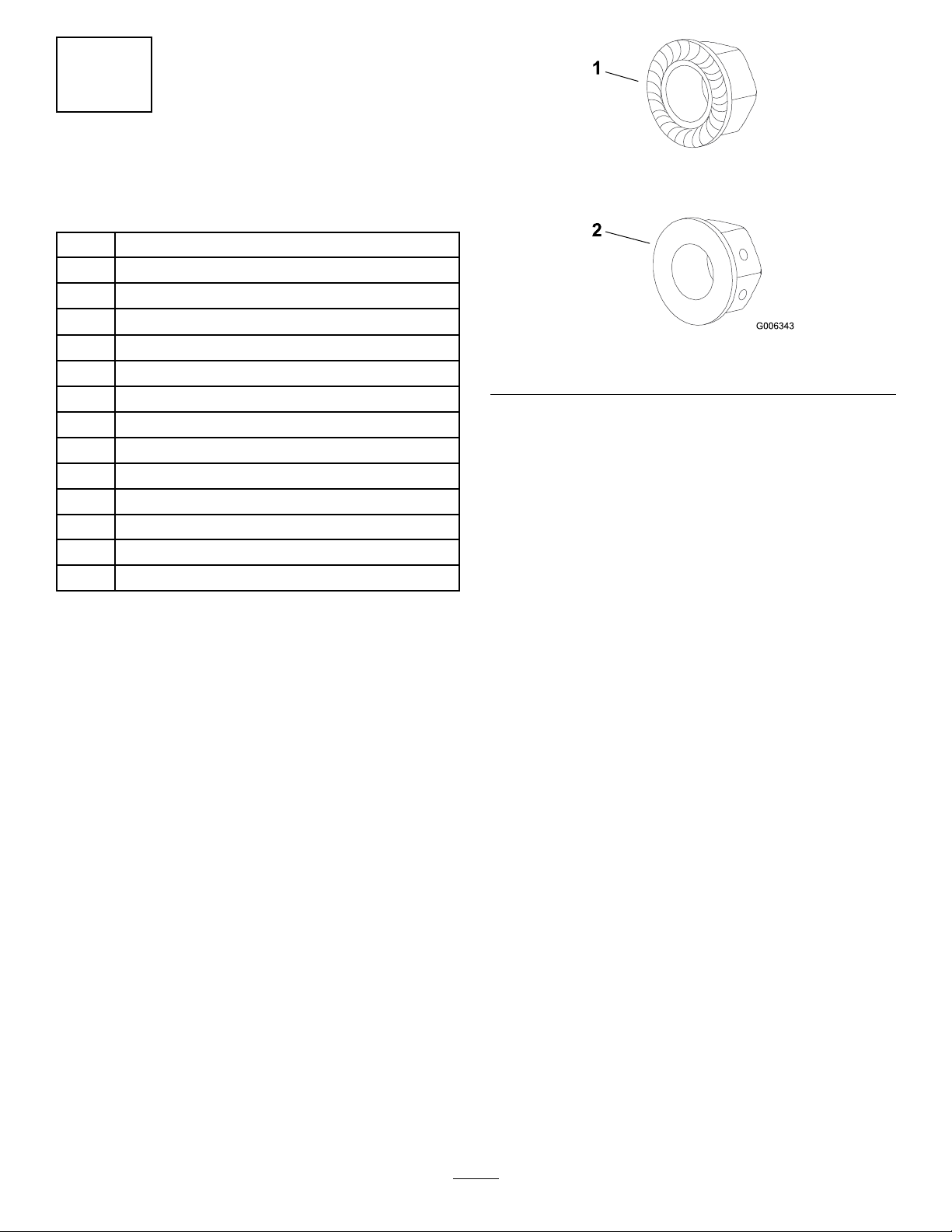

3

InstallingtheBaggerDrive

Pulley

Partsneededforthisprocedure:

1Baggerdrivepulley

3Pulleyspacer

3

Bolt,(3/8x1-3/4inches)

3

Flangenut,(3/8inch)

Procedure

Note:Makesurethegearboxpulleyhas4holesaround

thecenterhole(Figure9).Ifitdoesnot,contactan

AuthorizedServiceDealerforthecorrectpulley.

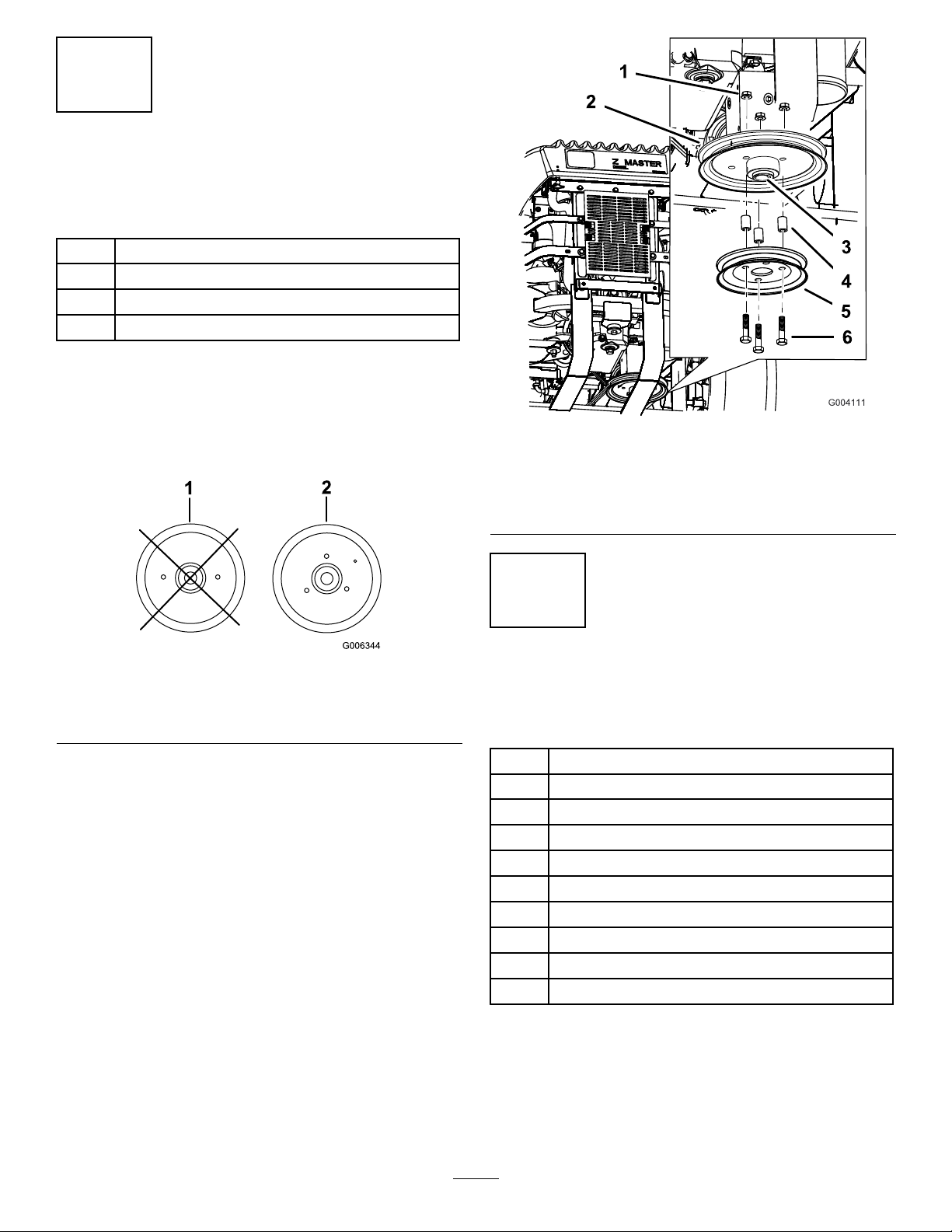

Figure9

1.Donotusethisgearbox

pulley

2.Usethisgearboxpulley

with4holesaroundthe

centerhole

Note:Makesurethegearboxpulleyisushtothe

bottomofthegearboxshaft(Figure10).

Installthebaggerdrivepulleytothegearboxpulley

with3bolts(3/8x1-3/4inches),3spacers,and

3angenuts(3/8inch)(Figure10).

Figure10

1.Flangenut,(3/8inch)4.Spacer

2.Gearboxpulley

3.Gearboxpulleyisush

withgearboxshaft.

4

InstallingtheSpringLoaded

IdlerPulleyandSpringAnchor

Partsneededforthisprocedure:

1

Springloadedidlerpulley

1Idlerarm

1

Carriagebolt,(3/8x2inches)

1

Bolt,(3/8x4–1/2inches)

2

Locknut,(3/8inch)

1

Washer,7/16inch

1

Washer,13/32inch

1Longroundspacer

1

Sidelocknut,(3/8inch)

1

Springanchor,(3/8inch)

5.Baggerdrivepulley

6.Bolt,(1/2x1-3/4inch)

Procedure

Note:InstalltheGussetKitatthesametimeas

installingtheidlerpulleyandthespringanchor.This

willeliminateduplicatesteps.TheGussetKitcanbe

obtainedfromanAuthorizedServiceDealer.

10

Page 11

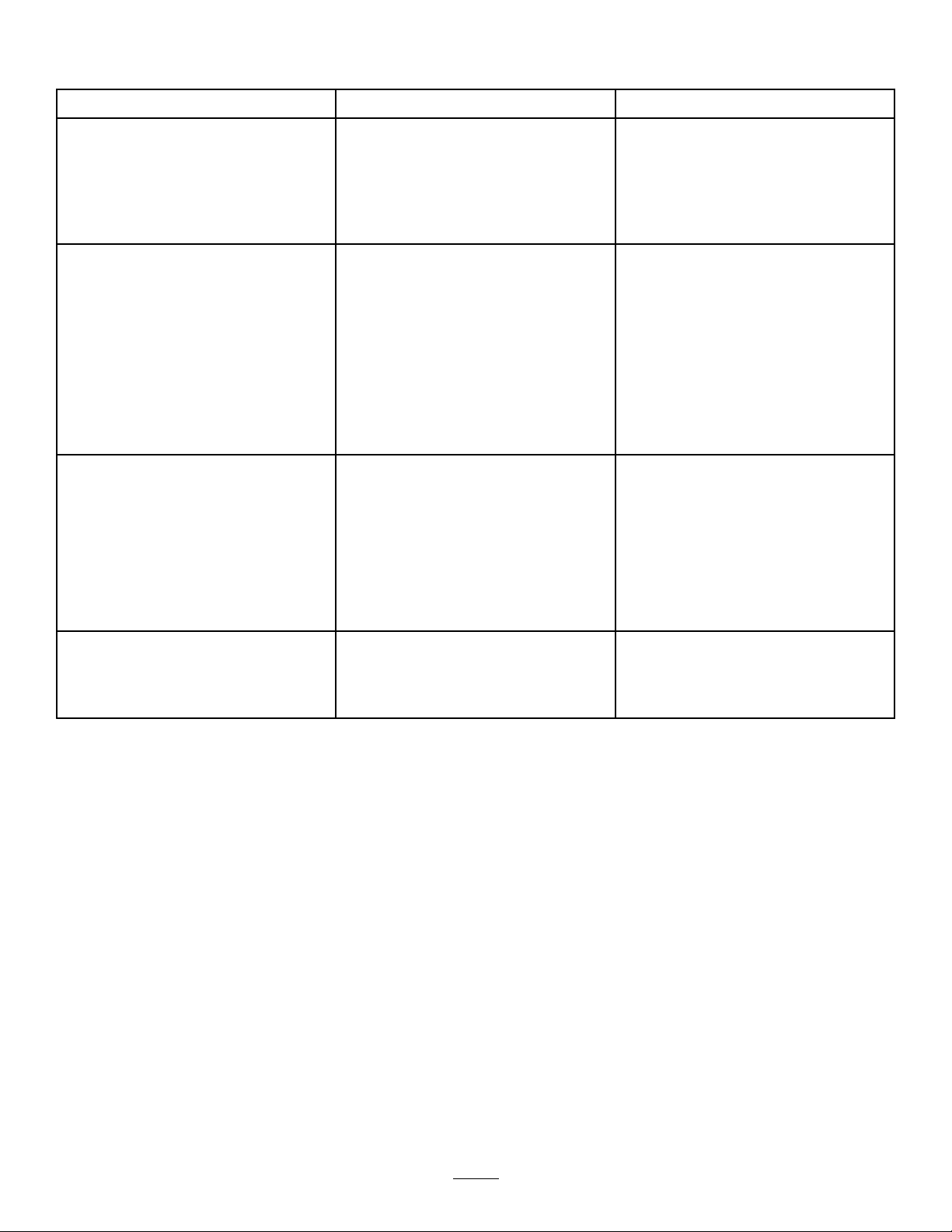

UseFigure11fordeterminingthedifferencesbetween

1

2

3

1

4

5

6

7

8

G001405

9

10

11

12

13

theserratedlocknutsandthesidelocknut.

Figure11

1.Serratedlocknut2.Sidelocknut

1.Installthespringloadedidlerpulleytotheidler

armwithacarriagebolt(3/8x2inches),washer

(13/32inches),andalocknut(3/8inch).

2.Installthespringloadedidlerpulleytotheright

rearbottomframewithabolt(3/8x4inches),long

spacer,washer(7/16inches),andalocknut(3/8

inch)(Figure12).

Figure12

1.Locknut,(3/8inch)8.Rightrearbottomframe

2.Washer,7/16inch9.Springanchor

3.Springloadedidlerpulley10.Sidelocknut,(3/8inch)

4.Washer,13/32inch11.Bolt,(3/8x4–1/2inch

5.Longroundspacer

6.Idlerarm

7.Carriagebolt,(3/8x2

inches)

12.Leftrearbottomframe

13.Rightrearbottomframe

Important:Makesuretheidlerarmandspring

anchorisinstalledinthecorrectholesshown

inFigure12.

5

InstallingtheFixedIdlerPulley

Partsneededforthisprocedure:

1Fixedidlerpulley

1Fixedidlerbracket

1

Bolt,(3/8x1-1/2inches)

2

Bolt,(3/8x3/4inch)

1

Locknut,(3/8inch)

2

Flangenut,(3/8inch)

1

Washer,13/32inch

Procedure

1.Installthexedidlerpulleytothexedidler

bracketwithabolt(3/8x1-1/2inches),washer

(13/32inches),andalocknut(3/8inch).

11

Page 12

2.Installthexedidlerassemblytotheleftrear

G001406

1

2

3

4

5

6

7

8

bottomframewith2bolts(3/8x3/4inch)and2

angenuts(3/8inch)(Figure13).

Figure13

1.Fixedidlerpulley

2.Washer,(13/32inch)

3.Locknut,(3/8inch)7.Leftrearbottomframe

4.Flangenut,(3/8inch)8.Bolt,(3/8x3/4inch)

5.Bolt,(3/8x1-1/2inches)

6.FixedIdlerpulleybracket

Figure14

1.Bolt,(3/8x3/4inch)3.Nut,(3/8inch)

2.idlerarmbracket4.Idlerpulley

7

6

InstallingtheIdlerArmBracket

Partsneededforthisprocedure:

1Idlerarmbracket

2

Bolt,(3/8x3/4inch)

2

Flangenut,(3/8inch)

Procedure

Installtheidlerarmbrackettotherightrearbottom

framewith2bolts(3/8x3/4inch)and2angenuts

(3/8inch)(Figure14).

InstallingtheBagger

Partsneededforthisprocedure:

1Bagger

2

Clevispin

2Hairpincotter

Procedure

1.Installthebaggerontothebaggermounting

bracketFigure15

2.Installthe2clevispinsintothebaggerandbagger

mountingbracket.Securethemwith2hairpin

cottersFigure15

12

Page 13

G001402

2

3

4

1

Figure15

1

2

3

4

5

6

G001407

1.Bagger3.Hairpincotter

2.Baggermountingbracket

4.Clevispin

3.Removethecableguideandboltfromtheframeof

thebagger(Figure16).

4.Installthecableguide,bolt,andnutwiththecable

behindthecableguide(Figure16).

8

InstallingtheBaggerBelt

Partsneededforthisprocedure:

1Baggerbelt

1

Spring

Procedure

1.Routethebaggerbeltaroundthedrivepulleyand

thebaggerpulley(Figure17).

Note:Makesurethecableguidecanrotate.

Figure16

1.Cable3.Cableclevis

2.Cablebehindthecable

guide

Figure17

1.Drivepulley4.Fixedidlerpulley

2.Baggerpulley

3.Springloadedidlerpulley

5.Skidplate

6.Baggerbelt

2.Installthespringontotheidlerarm(Figure18).

3.Routethebaggerbeltaroundthespringloaded

idlerpulleyandthexedidlerpulley(Figure18).

4.Installthespringontothespringanchorattached

totheleftrearbottomframe(Figure18).

13

Page 14

G001408

1

2

3

4

5

Figure18

1

2

3

4

5

G001886

6

G001365

1

2

3

1.Springloadedidlerpulley4.SpringAnchor

2.Fixedidlerpulley5.Belt

3.Spring

9

Figure19

1.Drivepulley4.Fixedidlerpulley

2.Baggerpulley5.Baggerbelt

3.Springloadedidlerpulley6.1–1/8inch±1/8inch(29

mm±3mm)

2.Ifthegapisnotcorrect,removethespring.

3.Toadjustthebelttensioncompletethefollowing:

A.Loosenthe2nutsonthelowerfanshaftpillow

block(Figure20).

B.Insertaspacerbehindthepillowblock

(Figure20).

C.Tightenthenuts.

CheckingandAdjustingthe

BaggerBeltTension

NoPartsRequired

Procedure

1.Measurethegap,atthebaggertensionerpulley,

betweenthetightandslacksideofthebeltwhen

thebaggertensionerpulleyandspringareinstalled

(Figure18).Thereneedstobeagapof1-1/8inch

±1/8inch(29mm±3mm)betweenthebelt

strands(Figure19).

D.Checkthebeltgapandrepeatprocedureas

required.

Figure20

1.Pillowblock

2.Fanshaft

3.Spacer

14

Page 15

10

1

2

3

4

6

1

5

G001366

2

1

3

4

5

G001409

InstallingtheWeights

Partsneededforthisprocedure:

2

Casterweight

2U-bolt

4

Nut,(1/2inch)

4

Lockwasher,(1/2inch)

2Plate

2

Smalltopweight

1Largetopweight

2

Bolt,1/2x4inch-fortopweights

Figure21

1.Frontcasterweight4.Nut

2.U-bolt5.Frontcaster

3.Plate6.Lockwasher

Procedure

TocomplywithANSI/OPEIB71.4-2004Standard,

topweightsmustbeaddedtothemachine.

Thebaggeraddsalotofweighttotherear

ofthemachineandmaycauseanunstable

conditionwhichcouldresultinalossofcontrol.

1.Placecasterweightsonthefrontcasters.

2.Installplate,nuts(1/2inch)andlockwasher

(1/2inch)undertheframeandweight(Figure21).

3.Repeatforoppositeside.

Note:ZMastermowerswith52inchmowerdecks

requireadditionalweightifnoZStand®isinstalled.

ContactyourAuthorizedServiceDealerforthe

weightkit.

4.Installthealargetopweightsontopofeachcaster

weight(Figure22).

5.Installthe2smalltopweightsontopofeachlarge

topweightandsecurethemwithabolt(1/2x4

inches)(Figure22).

1.Topweight3.Frontcasterweight

2.Bolt,(1/2x4inches)

Figure22

4.Frontcasterwheel

15

Page 16

6.Placetherearhookovertherearofthemounting

G001369

1

2

3

4

5

6

7

8

9

10

11

bracket(Figure24).

11

InstallingtheBootand

DischargeTubes

Partsneededforthisprocedure:

1Boot

1Middletube

1Uppertube

1

Clamp

Procedure

Note:RemembertoreplacetheLorthestraightend

ofthespringwheninsidedischargemode.Referto

ReplacingtheGrassDeector.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

7.Installtheuppertubeintothebagger(Figure24).

8.Slidetheclampontothemiddletube(Figure24).

9.Aligntheknobonthemiddletubewiththenotch

intheuppertube.Slidethemiddletubeintothe

uppertubeandtwistthemiddletube60degrees

(Figure24).

10.Tightentheclamparoundtheupperandmiddle

tubeconnection(Figure24).

11.Slidethemiddletubeontothebootandlatchthem

together(Figure24).

3.Torelievethespringtensiononthegrassdeector,

placetheLorthestraightendofthespringinfront

ofthemountingbracket.

4.Liftthegrassdeectorallthewayback.

5.Positiontheboot’sfronthookintothefrontsloton

themountingbracket(Figure24).

Note:Ifthegrassdeectorinterfereswiththe

boot,grindoffpartofthegrassdeectorframe.See

Figure23forthecorrectparttogrindoff.

Figure24

1.Boot7.Mountingbracket

2.Middletube8.Frontslot

3.Knob9.Rearhook

4.Uppertube10.Fronthook

5.Latch

6.Notchinuppertube

11.Clamp

Figure23

1.Grassdeectorframe2.Grindthispartoff

16

Page 17

12

1

2

3

4

5

G001372

6

7

8

13

InstallingtheBaggerDump

Handle

Partsneededforthisprocedure:

1Dumphandle

2

Washers,13/16inch

1

Cotterpin

Procedure

1.Unfastenthedumphandlefromthecrate.

2.Installawasherontothebaggerdumphandleand

installthebaggerdumphandleintothebagger

frame(Figure25).

3.Fastenthebaggerhandlewithawasher(13/16

inches)andacotterpin(Figure25).

InstallingtheBaggerDump

LeverStopBolt

Partsneededforthisprocedure:

1

Bolt,(1/2x1-3/4inches)

2

Jamnuts,(1/2inch)

1Longcableclevis

Procedure

1.Removethecotterpinandclevispinsecuringthe

baggercableclevistothebaggerdumphandle

(Figure26).

2.Threadajamnut(1/2inch)allthewayontothe

bolt(1/2x1-3/4inches)(Figure26).

3.Movethebaggerdumpleverforwardtomovethe

bottomoftheleverawayfromthestopbracket

(Figure26).

4.Inserttheboltintothestopbracketholeandthread

anotherjamnut(1/2inch)ontothebolt.Donot

tighten.

5.Securethebaggercableclevistothebaggerdump

handlewiththeclevispinandcotterpinpreviously

removed(Figure26).

Figure25

1.Dumphandle

2.Washer

3.Cotterpin

4.Baggerframe

Figure26

1.Baggerdumplever

2.Baggercable

3.Longcableclevis

4.Bolt,(1/2x1-3/4inches)8.Cotterpin

5.Jamnut,(1/2inch)

6.Stopbracket

7.Clevispin

17

Page 18

6.Installthebaggercableintothecableclevis

G001373

1

2

3

4

5

5

1

(Figure26).

7.Adjustthehandlestop,refertoAdjustingthe

BaggerDumpLever.

14

AdjustingtheBaggerDump

Lever

NoPartsRequired

Procedure

Thebaggerleverneedstobeadjustedtoremoveslack

inthebaggercable.

Important:Makesurethebaggerdoorislatched

beforeadjustingthelever.

1.Loosenthenutsonbothsidesofthestopbracket

(Figure27).

2.Adjustthestopboltuntilthereisnoslackinthe

baggercable(Figure27).

3.Tightenthenutsonbothsidesofthestopbracket

(Figure27).

15

ModifyingtheRadiatorCover

NoPartsRequired

Procedure

1.Locatetemplatenumber1inthebackofthis

manual.Cutouttemplatenumber1asindicatedon

thetemplate(Figure28).

2.Positionthetemplateontheright-handsideofthe

radiatorcover(Figure28).

3.Lineupthemarkonthetemplatewherethe

baggercableclevishitstheradiatorcoverandthe

templatebottomisushwiththebottomofcover

(Figure28).

4.Tapethetemplatetotheradiatorcover.Markthe

outeredgeofthetemplate(Figure28).

5.Cuttheradiatorcoveratthemarkedline.Thiswill

preventdamagetotheradiatorcoverwhileusing

thebaggerdumplever(Figure28).

Note:Makesuretofollowthetemplateoutline.Do

notcreateanysharpcorners.

Figure27

1.Baggerdumplever4.Baggercable

2.Stopbracket

3.Stopbolt

5.Nut

18

Page 19

Figure28

G001055

1.Cable

2.Cableguide

3.Nosharpcorners7.Baggercableclevis

4.Radiatorcover8.Markontemplatealigned

5.Baggerdumplever

6.Templatealignedwith

coverbottom

withclevis

Figure29

1.Valvestem

16

CheckingtheTirePressure

NoPartsRequired

Procedure

Note:Increasethetirepressureduetotheadditional

weight.

Checkandincreasetheairpressureinthefrontcaster

wheelsandreartires(Figure29).

Pressure:Reartires-20psi(90kPa)

Frontcasterwheels-25psi(90kPa)

19

Page 20

Operation

G000947

1

2

G001374

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Ifthemachineisonaslope,chock

orblockthewheelstopreventthemachinefrom

slowlyrolling.

Toavoidpersonalinjury,followthese

procedures:

•Becomefamiliarwithalloperatingand

safetyinstructionsintheoperator’smanual

foryourmowerbeforeusingthisattachment.

•Neverremovethebaggerorbaggertubes

whiletheengineisrunning.

•Alwaysshuttheengineoffandwaitforall

movingpartstostopbeforeclearingan

obstructionfromthebaggingsystem.

PositioningtheAdjustable

Bafe

AdjustthebafetopositionB(middleposition)for

bagging.RefertothemachinesOperatorManualfor

thebafeadjustmentprocedure.

Figure30

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

Withoutthegrassdeector,baggertubesor

completebaggerassemblymountedinplace,

youandothersareexposedtobladecontact

andthrowndebris.Contactwiththerotating

mowerblade(s)andthrowndebriswillcause

injuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(PTO)tooffandrotatetheignition

keytooff.Alsoremovethekeyandpullthe

wireoffofthesparkplug(s).

OpeningtheBagger

1.DisengagethePTO.

2.Reachback,squeezeandreleasethelatchlever

againstthebaggerlever(Figure31).Thiswill

openthelatchthatsecuresthebaggerdoor.

3.Pulldownonthebaggerarmtoallowthegrassto

falloutofthebagger(Figure31).

4.Returnthebaggerarmtouprightpositioninone

quickmotion.Makesurethebaggerdoorfully

engagesintothelatch(Figure31).

Note:Makesurethebaggerlatchisfullyengaged

beforecollectinggrass.

Figure31

1.Baggerlever2.Latchlever

20

Page 21

HoldingtheBaggerDoorOpen

G001375

1

3

2

4

G001376

1

5

3

4

6

7

2

Hands,ngersandarmscangetpinched

betweenthebackandfrontsectionsofthe

collector.

•Keeppeopleawayfromcollectorwhile

emptyingit.

•Ifworkingontheinside,usetheholdingpin

toholdthecollectordooropen.

1.DisengagethePTO,settheparkingbrake,and

chockorblockthetires.

2.Turnofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Openthebagger;refertoOpeningtheBagger.

4.Withthebaggeropen,pullouttheholdingpinand

insertintotheholeinthehinge(Figure32).

2.Turnofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethebagger.

4.Removethecotterpinandclevispin(Figure33).

5.Adjustthebaggercabletothedesiredholeposition

(Figure33).

Note:Thelowerholewillallowthedoortoopen

higher.Theupperholewillallowlessforcetoopen

thedoorwhileusingthehandle.

6.Installtheclevispinandcotterpinintothebagger

andcableend(Figure33).

Figure32

1.Holdingpin

2.Holeinhinge(open)

3.Holeinhinge(storage)

4.Hinge

AdjustingtheBaggerDoor

OpeningandCable

Adjustingthecableatthetopofthebagger,canallow

thedoortoopenfartherforyourdesireconditions.

1.DisengagethePTO,settheparkingbrake,and

chockorblockthetires.

Figure33

1.Baggercable

2.Holesinbaggerdoor

hinge

3.Clevispin

4.Hinge

5.Cotterpin

6.Lowerhole-allowsdoorto

openhigher

7.Upperhole-allowsless

forcetoopendoor

ClearingObstructionsFrom

theBaggerSystem

1.Emptythebagger.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Removethecompletetubeassemblyfromthe

baggerandboot.

5.Removethebootfromthemower.

21

Page 22

6.Usingastickorsimilarobject,carefullyremove

G001369

1

2

3

4

5

6

7

8

9

10

11

andcleartheobstructionfromthemower,upper

tube,middletube,orbootassembly.

7.Afteryouremovetheobstruction,installthe

completebaggersystemandresumeoperation.

RefertoInstallingtheDischargeTubes.

RemovingtheDischarge

Tubes

Note:RemembertoreplacetheLendofthespring

wheninsidedischargemode.RefertoReplacingthe

GrassDeector.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Unlatchthemiddletubefromthebootandslide

apart(Figure34).

4.Removethetubeassemblyfromthebagger

(Figure34).

5.Removethebootfromthemountingbracket

(Figure34).

Figure34

1.Boot7.Mountingbracket

2.Middletube8.Frontslot

3.Knob9.Rearhook

4.Uppertube10.Fronthook

5.Latch

6.Notchinuppertube

11.Clamp

6.Lowerthegrassdeectorbackintoplace.

7.Ifyouarechangingtosidedischargemode,install

thegrassdeectorspring.RefertoReplacingthe

GrassDeector.

RemovingtheBagger

Ifyouoperatemowerwithoutthebagger

installedorwiththedischargetubesandboot

removed,youandothersmaybeinjuredby

throwndebrisorcutbytheblade.

Alwaysoperatethemowerwitheitherthe

completebaggermountedinplaceorusethe

mowerinsidedischarge.

1.Disengagethepowertakeoff(PTO),setthe

parkingbrake,turntheignitionkeytooffand

removethekey.

2.Removethedischargetubes.RefertoRemoving

theDischargeTubes.

3.Removehairpincottersandclevispinsfromthe

baggerandbaggerbracket.

4.Removetheskidplate.

5.Removethebaggerbeltandbaggeridlerpulley.

6.Removethebaggerfromthebaggermounting

bracket.

22

Page 23

7.Installtheskidplate.

G000977

1

2

3

4

5

6

7

8

8.Replacethegrassdeectorspring;referto

ReplacingtheGrassDeectorSpring.

ReplacingtheGrassDeector

9.Removeboththetopweightsandcasterweights.

SecuringtheBaggerIdler

Pulley

Forthisprocedure,useoneoftheclevispinsand

hairpincotterpinsusedtoattachthebaggertothe

baggermountingbracket.

Note:Onlysecurethebaggeridlerpulleywhenyou

areremovingthebagger.

1.Tosecuretheidlerarm,inserttheclevispinthrough

theidlerarmandidlerarmbracket(Figure35).

2.Installthehairpincotterpintosecuretheclevis

pin(Figure35).

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresult

inseriousinjury.Also,contactwiththeblade

couldoccur.

Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschute

andcatcher.

1.Removethelocknut,bolt,springandspacer

holdingthedeectortothepivotbrackets

(Figure36).Removedamagedorworngrass

deector.

2.Placespacerandspringontograssdeector.Place

theLendofspringbehinddeckedge.

Note:MakesuretheLendofspringisinstalled

behinddeckedgebeforeinstallingtheboltasshown

inFigure36.

3.Installboltandnut.PlaceJhookendofspring

aroundgrassdeector(Figure36).

1.Clevispin

2.Baggeridlerarm4.Hairpincotterpin

Figure35

3.Idlerarmbracket

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

Figure36

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

23

Page 24

OperatingTips

MachineSize

Rememberthatthemachineislongerandwiderwith

thisattachmentinstalled.Byturningtoosharplyin

connedplacesyoumaydamagetheattachmentor

otherproperty.

Trimming

Alwaystrimwiththeleftsideofthemower.Donot

trimwiththerightsideofthemowerbecauseyou

coulddamagethebaggingtubes.

CuttingHeight

Foroptimumbaggingperformance,setthedeck

height-of-cuttoremovenomorethat2to3inches

(51to76mm)or1/3ofthegrassheight,whichever

isless.Cuttingoffmorethanthiswillreducethe

capacityofthevacuumsystem.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.

Youwillhavetocutyourgrasstwiceifitgets

excessivelylong(refertoBaggingLongGrass).

Asthebaggerlls,extraweightisaddedto

thebackofthemachine.Ifyoustopandstart

suddenlyonhills,youmaylosesteeringcontrol

orthemachinemaytip.

•Donotstartorstopsuddenlywhengoing

uphillordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoing

uphill,disengagethePTO.Thenbackdown

thehillusingaslowspeed.

•Donotchangespeedsorstoponslopes.

BaggingLongGrass

Excessivelylonggrassisheavyandmaynotbe

propelledcompletelyintothebagger.Ifthishappens,

thetubeandbootmayplug.Toavoidpluggingthe

baggingsystem,mowthegrassatahighheight-of-cut,

thenlowerthemowertoyournormalcuttingheight

andrepeatthebaggingprocess.

BaggingWetGrass

Ifpossible,alwaystrytocutgrasswhenitisdry.

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlap

themowerintothepreviouslycutarea.Thishelps

reducetheloadontheengineandreducesthechance

ofpluggingthebootandtube.

BaggingSpeed

Thebaggingsystemmayplugifyoudrivetoofast

andtheenginespeedgetstooslow.Onhillsitmaybe

necessarytoslowthemachinesgroundspeed.Mow

downhillwheneverpossible.

SignsofPlugging

Asyouarebagging,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.An

excessiveamountofclippingblow-outindicatesthat

thebaggerisfullorthebootisplugged.

24

Page 25

Withoutthegrassdeector,baggertubesor

completebaggerassemblymountedinplace,

youandothersareexposedtobladecontact

andthrowndebris.Contactwiththerotating

mowerblade(s)andthrowndebriswillcause

injuryordeath.

•Neverremovethegrassdeectorfrom

themowerbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(PTO)tooffandrotatetheignition

keytooff.Alsoremovethekeyandpullthe

wireoffofthesparkplug(s).

FanVacuum

Thebaggingsystemoperatesbyvacuumcreatedby

arotatingfanmountedinthetopofthehopper.If

thevacuumactionisreduced,baggingperformance

willdiminish.RefertoTroubleshootingforcauses

ofreducedperformance.

CurbClimbingandLoading

Alwaysliftthedecktothehighestposition

whenloadingthemachineontrailersor

ascending/descendingacurb.Leavingthemowerina

lowerpositioncancausedamagetothemowerwhile

loadingandgoingoveracurb.Ifacurbishigherthan

6inches(152mm),crossitatasharpanglewiththe

deckfullyraised.Useextremecautionwhenloading

ontoatrailer.

25

Page 26

Maintenance

G001410

G001377

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10operating

hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Checkthebaggerbelt.

•Inspectthebagger.

•Cleanthescreens.

•Cleanthebagger.

•Greasetheidlerarm.

•Greasethefanshaftbearings.

•Inspectthebagger.

CleaningtheScreens

Thescreensneedtobecleanedbeforeeachuse.Inwet

grasstheywillneedtobecleanedmoreoften.

1.Disengagethepowertakeoff(PTO),setthe

parkingbrake,turntheignitionkeytooffand

removethekey.

2.Openthebaggerandholdthebaggerdooropen.

RefertoHoldingtheBaggerDoorOpen.

3.Cleanthedebrisfromthescreens.

4.Closethebaggerdoor.

CleaningtheBagger

Thebaggerneedstobecleaneddaily.

1.Washtheinsideandoutsideofthebagger,upper

tube,lowertube,bootassemblyandtheunderside

ofthemower.Useamildautomotivedetergent

toremovedirt.

2.Makesureyouremovemattedgrassfromallparts.

3.Afterwashingallparts,letthemdrythoroughly.

CheckingtheBaggerBelt

Thebaggerbelttensionneedstobecheckedafterthe

rst10hours.

Checkthebelttension.RefertoAdjustingtheBagger

Belt.

GreasingtheIdlerArm

Figure37

GreasingtheFanShaft

Bearings

Greasetheupperandlowerbaggerfanshaftbearings

(Figure38&Figure39)every100hours.

Figure38

Greasethebaggerbeltidlerarm(Figure37)every

50hours.

Removerubberplugtoexposegreasetting.

26

Page 27

G001378

Figure39

InspectingtheBagger

Inspectthebaggerattachmentafterthersttenhours

ofoperation,and100hoursthereafter.

1.Disengagethepowertakeoff(PTO),setthe

parkingbrake,turntheignitionkeytooffand

removethekey.

2.Checktheuppertube,lowertube,andtheboot

assembly.Replacethesepartsiftheyarecracked

orbroken.

3.Checkthebagger,baggerframe,andscreens.

Replaceanypartsthatarecrackedorbroken.

4.Tightenallnutsboltsandscrews.

InspectingtheMowerBlades

1.Inspectthemowerbladesregularlyandwhenever

abladestrikesaforeignobject.

2.Ifbladesarebadlywornordamaged,installnew

blades.Refertoyourmoweroperator’smanualfor

completeblademaintenance.

27

Page 28

Troubleshooting

Problem

Abnormalvibration.

Reducedbaggingperformance.

Bootandtubesplugtoofrequently .

PossibleCauseCorrectiveAction

1.Cuttingblade(s)is/arebentor

unbalanced.

2.Blademountingboltisloose.2.Tightentheblademountingbolt.

3.Enginemountingboltsareloose.3.Tightentheenginemountingbolts.

4.Loosebaggerorpulleyassembly.4.Tightentheappropriatepulley.

5.Baggerbeltiswornordamaged.

1.Lowenginespeed.

2.Pluggedfanscreen.

3.Loosebaggerbelt.3.Tightenthebaggerbelt.

4.Brokensealbetweenthehopperand

reardoor.

5.Apluggedboot.5.Locateandremovepluggeddebris.

6.Impropersealaroundtheuppertube

goingintothehopper.

7.Fullhopper .7.Emptythehopper.

1.Hopperistoofull.1.Dumpmorefrequently.

2.Lowenginespeed.

3.Grassistoowet.3.Cutgrasswhenitisdry.

4.Grassistoolong.4.Cutnomorethan2-3inchesor1/3of

5.Pluggedfanscreen.

6.Groundspeedistoofast.6.Drivesloweratfullthrottle.

1.Installnewcuttingblade(s).

5.ContactanAuthorizedServiceDealer.

1.Alwaysoperatethebaggeratfull

throttle.

2.Removedebris,leavesorgrass

clippingsfromthefansscreen..

4.Ensurethereardoorislatched.

6.Ensurethatthereisagoodsealatthe

hopper.

2.Alwaysoperatethebaggeratfull

throttle.

thegrassheight,whicheverisless.

5.Removedebris,leavesorgrass

clippingsfromthefanscreen.

Debrisblowout.

1.Hopperistoofull.1.Dumpmorefrequently.

2.Groundspeedistoofast.2.Drivesloweratfullthrottle.

3.Mowerdeckisnotleveled.

3.Seethemoweroperator’smanualfor

levelingthemowerdeck.

28

Page 29

29

Page 30

Page 31

Page 32

Landscape

Contractor

Equipment (LCE)

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant to an

agreement between them, jointly promise to repair the listed Toro Products if

defective in materials or workmanship. The following time periods apply from

the date of purchase:

This warranty applies to:

•

ProLine Mid-Size Mowers and Attachments

•

Z Master Mid-Mount ZRTs and Attachments

Components

Traction Unit Frame and Carrier Frame

All Spindles

Engines* and /Hydraulic System

Deck Shells (34 ″ -72 ″ )

Z500 Series Electric Clutch

Remaining Components

* S o m e e n g i n e s u s e d o n T o r o L C E P r o d u c t s a r e w a r r a n t e d b y t h e e n g i n e m a n u f a c t u r e r .

This warranty includes the cost of parts and labor, but you must pay

transportation costs.

Warranty Period

1 year

1 year

2 year

3 years Parts

2 years Labor

2 years

2 years

2 years

1 year

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you, access our website at

www.Toro.com. You may also call our Toro Customer Care Department

toll free at 888–865–5676 (U.S. Customers) or 888–865–5691 (Canada

customers).

2. Bring the product and your proof of purchase (sales receipt) to the Service

Dealer.

If for any reason you are dissatised with the Service Dealer’s analysis or with

the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures

described in the operator’s manual. Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

Items and Conditions Not Covered

There is no other express warranty except for special emission system coverage

on some products. This express warranty does not cover the following:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants,

tune-up parts, blade sharpening, brake and clutch adjustments.

• Any product or part which has been altered or misused or required

replacement or repair due to normal wear, accidents, or lack of proper

maintenance.

• Repairs necessary due to improper fuel, contaminants in the fuel system, or

failure to properly prepare the fuel system prior to any period of non-use

over three months.

• Pickup and delivery charges.

General Conditions

All repairs covered by this warranty must be performed by an Authorized Toro

Service Dealer using Toro approved replacement parts.

Neither The Toro® Company nor Toro Warranty Company is liable for

indirect, incidental or consequential damages in connection with the

use of the Toro Products covered by this warranty, including any

cost or expense of providing substitute equipment or service during

reasonable periods of malfunction or non-use pending completion

of repairs under this warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

All implied warranties of merchantability (that the product is t

for ordinary use) and tness for use (that the product is t for

a particular purpose) are limited to the duration of the express

warranty.

This warranty gives you specic legal rights, and you may also have

other rights which vary from state to state.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee

policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information,

contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

374-0037 Rev F

Loading...

Loading...