Page 1

Form No. 3329–565

44 and 52 Finishing Kit

100 Series Z Master 44 Mowers

100 Series Z Master 52 Mowers

Model No. 78508

Model No. 78509

Installation Instructions

Important This kit will require significant time to install the first time. A right angle drill is recommended for

installation.

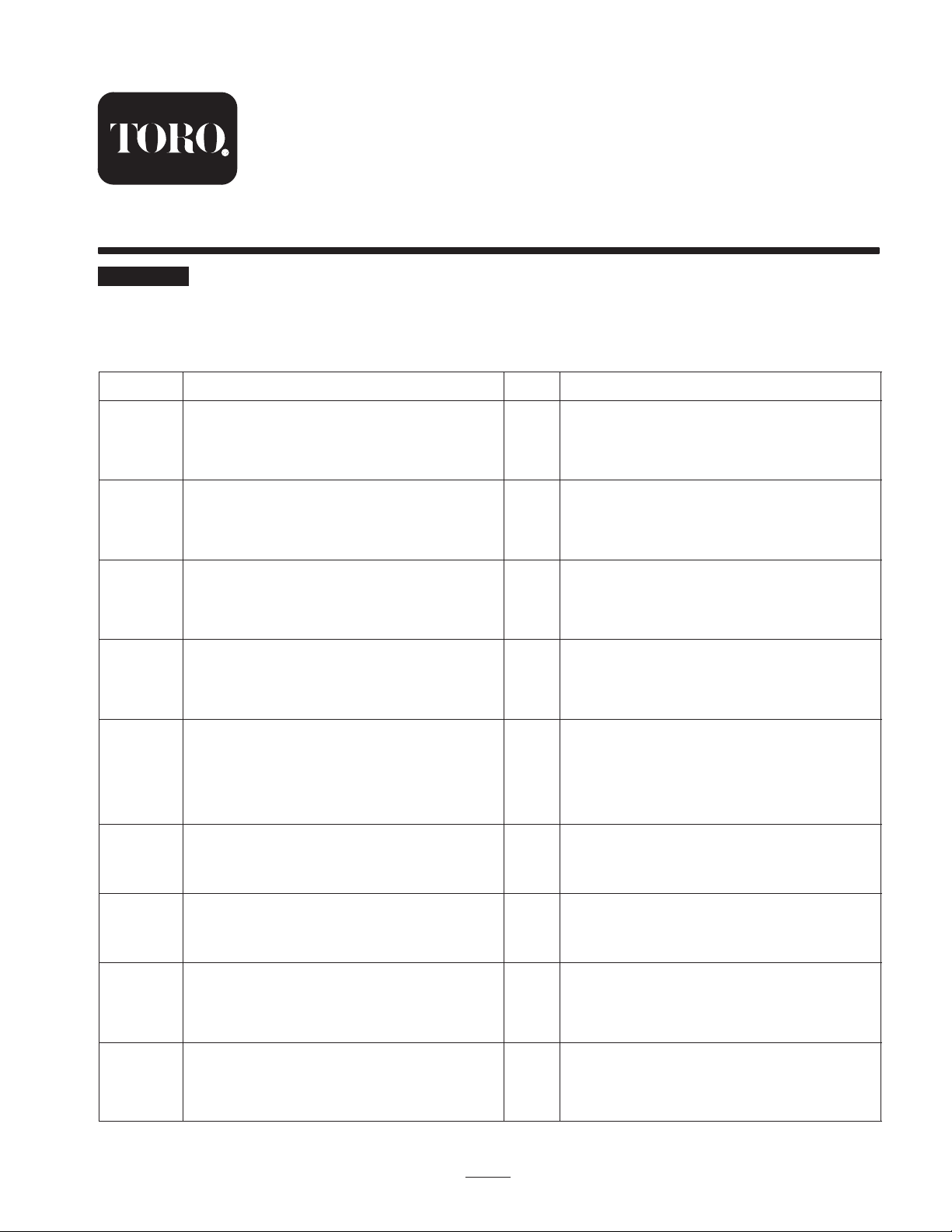

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

Step Description Qty. Use

1

2

3

4

5

6

Tunnel baffle—front

Carriage bolt, 5/16 x 5/8 inch

Flange nut, 5/16 inch

Tunnel baffle—rear

Carriage bolt, 5/16 x 5/8 inch

Flange nut, 5/16 inch

Center rear baffle

Button Head Socket Bolt, 5/16 x 3/4 inch

Flange nut, 5/16 inch

Left rear baffle

Button Head Socket Bolt, 5/16 x 3/4 inch

Flange nut, 5/16 inch

Right rear baffle

Button Head Socket Bolt, 5/16 x 3/4 inch

Carriage bolt, 5/16 x 5/8 inch

Flange nut, 5/16 inch

1

4

4

1

3

3

1

3

3

1

3

3

1

2

1

3

Installing the front tunnel baffle

Installing the rear tunnel baffle

Installing the center rear baffle

Installing the left rear baffle

Installing the right rear baffle

Removing the mower existing pulley

assembly

7

Pulley assembly

8

9

2003 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Bagger Belt

Pulley cover

Mounting plate

Bolt, 3/8 x 1–1/4 inch

Flange nuts, 3/8 inch

Modifying a 44 inch Mower for Belt

Clearance

1

1

1

2

4

4

1

Installing the pulley assembly, belt and

cover

Installing the mounting plate

All Rights Reserved

Printed in the USA

Page 2

Before Installation

Checking the Mower for

Existing Holes

Check for existing holes. Use existing holes in the mower

that align the baffles in their correct positions.

Checking the Spindle Shaft for

1999 Models

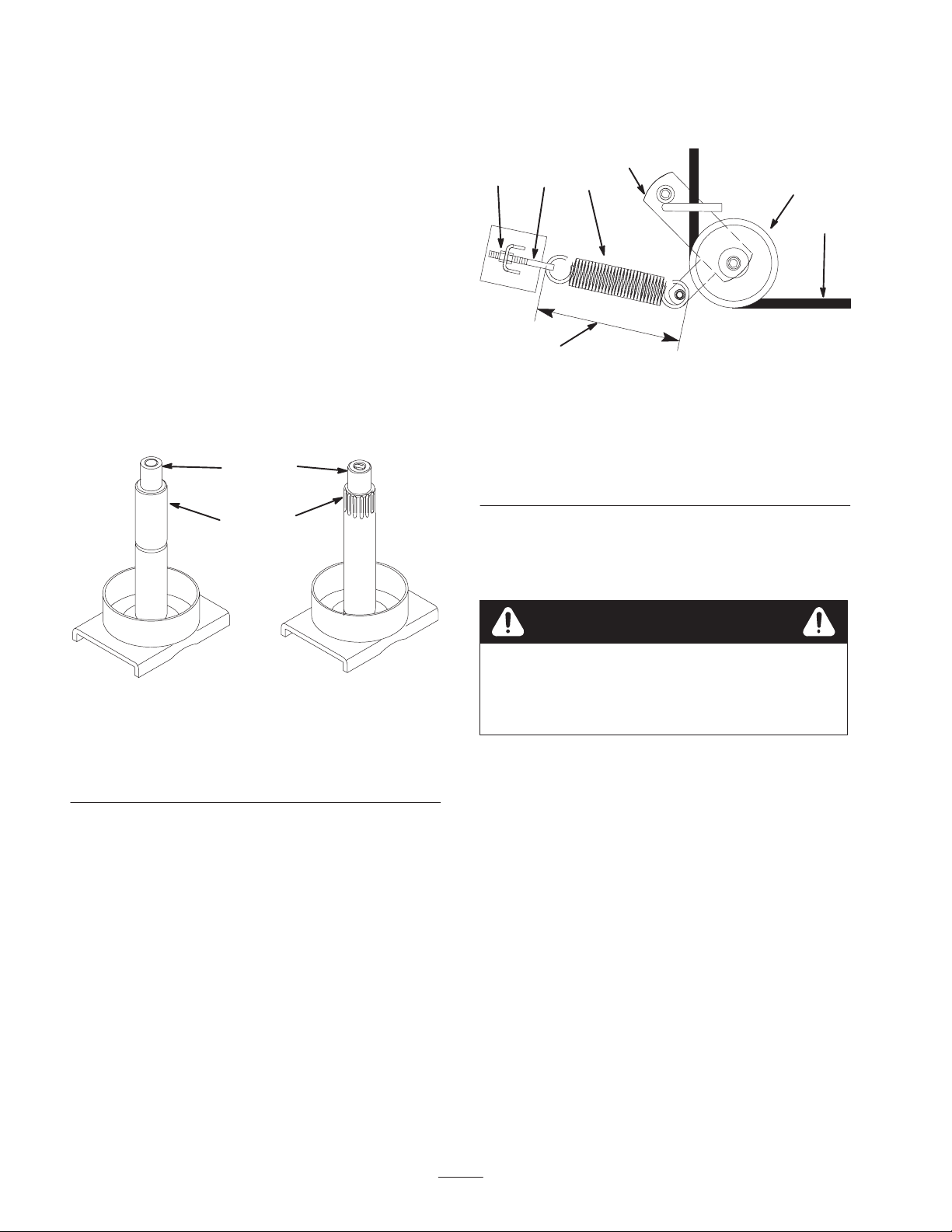

For mowers built in 1999, the right hand blade spindle

shaft may need to be replaced (Fig. 1). Check the right

blade spindle for splines. The splines are needed to install

the pulley assembly shown in Figure 17.

Order a new, year 2000 model, splined spindle shaft from

an Authorized Service Dealer (Fig. 1).

1

2

3

4

14

6

1. Outer nut

2. Idler pulley

3. Idler arm

4. Spring eye bolt

2. Remove the mower belt, starting at the right outside

pulley.

Note: Do not remove the spring.

3

5

Figure 2

Top View

5. Spring

6. 9–3/8 inch ± 1/8 inch

(238 mm ±3 mm)

7. Mower belt

2

M–4197

7

m–6381

Figure 1

Top View

1. Blade spi n d l e

shaft—without splines

2. No splines

3. Year 2000 blade spindle

shaft—with splines

4. Splines

Removing the Mower

Note: If the mower is already level and is removed from

the top bolts, the mower will not need to be leveled.

1. Loosen the outer nut on the spring eye bolt (Fig. 2).

Caution

Spring is under tension when installed and can

cause personal injury.

Do not remove spring from spring eye bolt.

3. Lower the mower onto wood blocks.

Note: If the mower is removed from the top bolts, the

mower will not need to be leveled.

4. Remove the four bolts and nuts at the top of chains

that attached to mower (Fig. 3).

5. Remove the nuts and bolts holding the push arm pins

(Fig. 3).

Note: The gage wheels may need to be removed to allow

the push arm pins to be removed (Fig. 3).

6. Remove the push arm pins (Fig. 3).

2

Page 3

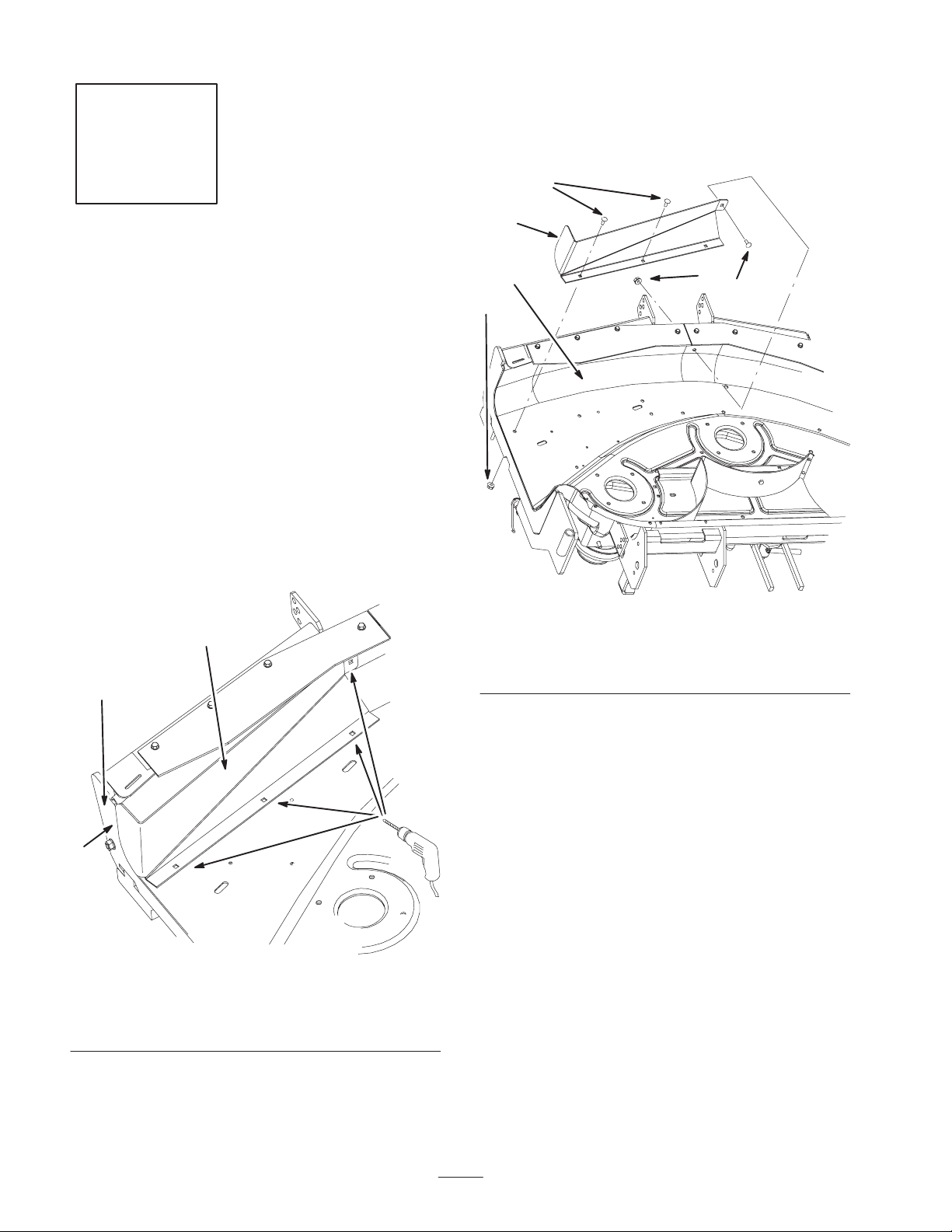

7. Raise the height of cut lever and slide the mower out

(Fig. 3).

Removing the Cutting

Chamber Stiffener

9

5

m–6062

1. Mower

2. Chain

3. Chain Bolt

4. Push Arm

5. Push Arm Bolt

3

2

welded to the cutting chamber (Fig. 4).

1. Remove the cutting chamber stiffener from the mower

(Fig. 4).

Note: This section is only for mowers with a stiffener

3

2

6

7

8

1

4

m–6265

2. Grind the welds flat on rear part of the chamber. This

will allow the correct fit for the cutting chamber

baffle.

Figure 3

6. Push Arm Nut

7. Push Arm Pin

8. Gage wheel

9. Nut

1

2

m–6684

Figure 4

1. Cutting chamber 2. Cutting chamber stiffener

Preparing the Mower

1. Tip the mower upside down and block up ends to ease

installation of components.

2. Thoroughly clean the mower. All debris must be

removed to ensure baffles will fit properly against the

mower.

3. Repair all bent or damaged areas of the mower and

replace any missing parts.

Warning

Contact with sharp blade can cause serious

personal injury.

• Wear gloves or wrap sharp edges of the blade

with a rag.

3

Page 4

Step

5. Remove the clamp.

6. Install the front tunnel baffle to the mower with

4 carriage bolts (5/16 x 5/8 inch) and 4 flange nuts

(5/16 inch) (Fig. 6).

1

Parts needed for this step:

• 1 Tunnel baffle—front

• 4 Carriage bolts, 5/16 x 5/8 inch

• 4 Flange nuts, 5/16 inch

Installing the Front Tunnel

Baffle

Note: Blades and spindles are not shown in the graphics

for clarity.

1. Place the front tunnel baffle against the front wall of

the discharge tunnel (Fig. 5).

2. Align the front baffle, flush with the outside of the

mounting bracket (Fig. 5).

1

3

2

1

3

m–6708

1. Front tunnel baffle

2. Carriage Bolt, 5/16 x

5/8 inch

34

2

Figure 6

3. Flange nut, 5/16 inch

4. Front tunnel wall

2

m–6707

Figure 5

1. Front tunnel baffle

2. Flush edge with outside of

mounting bracket

3. Clamp the baffle in place.

4. Using the baffle as a template, center punch and drill

4 holes (11/32 inch dia.) into the mower (Fig. 5).

3. Outside of mounting

bracket

4. Hole to drill

4

4

Page 5

Step

4. Using the baffle as a template, center punch and drill

3 holes (11/32 inch dia.) into the top of the mower

(Fig. 6).

5. Remove the clamp.

2

Parts needed for this step:

• 1 Tunnel baffle—rear

• 3 Carriage bolt, 5/16 x 5/8 inch

• 3 Flange nut, 5/16 inch

Installing the Rear Tunnel

Baffle

Note: Blades and spindles are not shown in the graphics

for clarity.

1. Place the rear tunnel baffle against the rear wall of the

discharge tunnel (Fig. 7).

Note: The rear tunnel baffle must not extend past the

outside of the mounting bracket.

2. Align the rear tunnel baffle, flush with the outside of

the mounting bracket (Fig. 7).

6. Install the rear tunnel baffle with 3 carriage bolts

(5/16 x 5/8 inch) and 3 flange nuts (5/16 inch) (Fig. 8).

Important Make sure the bolt heads are installed on

the inside of the cutting chamber.

2

4

4

1

6

5

4

3

1

3

4

m–6709

1. Rear tunnel baffle

2. Mounting bracket

3. Flush edge with outside of

mounting bracket

2

Figure 7

4. Outside of mounting

bracket

1. Rear tunnel baffle

2. Carriage Bolt, 5/16 x

5/8 inch

3. Flange nut, 5/16 inch

m–6710

Figure 8

4. Hole to drill

5. Tunnel rear wall

6. Mounting bracket

3. Clamp the baffle in place.

5

Page 6

Step

3

Parts needed for this step:

• 1 Center cutting chamber baffle

• 3 Button Head Socket Bolts, 5/16 x 3/4 inch

• 3 Flange nuts, 5/16 inch

4 32

Figure 10

1. Baffle flange

2. Blade

3. Spindle

4. Clamp the center baffle tightly against the cutting

chamber (Fig. 11).

4. Blade clearance,

9/16 to 11/16 inch

(14 mm to 17 mm)

m–62291

Installing the Center Rear

Baffle

A right angle drill is recommended to install this baffle.

1. Place the center rear baffle behind the center cutting

blade chamber (Fig. 11).

2. Align the center rear baffle so the baffle ends are

touching the back mower flange (Fig. 9).

Note: The center baffle ends will rest on the mower flange

(Fig. 9).

3. Align the middle part, of the center rear baffle, 9/16 to

11/16 inch from the blade tip. See Figures 9 and 10

on where to measure.

5

4

5. Using the baffle as a template, mark, center punch and

drill 1/8 inch pilot holes at the 3 locations (Fig. 11).

6. Drill 11/32 inch dia. holes through the pilot holes

(Fig. 11).

7. Install the center baffle with 3 button head socket bolts

(5/16 x 5/8 inch) and 3 flange nuts (5/16 inch)

(Fig. 11).

Important Make sure the bolt heads are installed on

the inside of the cutting chamber (Fig. 11).

53

1

4

5

2

3

Figure 9

1. Mower flange

2. Center baffle

3. Center baffle end touching

mower

Important Make sure the baffle flange is

9/16 to 11/16 inch (14 mm to 17 mm) from the mower

blade (Figures 9 and 10).

4. Blade clearance,

9/16 to 11/16 inch

(14 mm to 17 mm)

5. Center blade

m–6256

1

2

2

m–6176

Figure 11

1. Center Baffle

2. Hole to drill

3. Center cutting blade

chamber

6

4. Flange nuts, 5/16 inch

5. Button head socket bolt,

5/16 x 5/8 inch

Page 7

Step

4

Parts needed for this step:

6. Install the left rear baffle with 3 button head socket

bolts (5/16 x 3/4 inch) and 3 flange nuts (5/16 inch)

(Fig. 13).

Important Make sure the bolt heads are installed on

the inside of the cutting chamber. See figure 13.

6

2

• 1 Left rear baffle

• 3 Button Head Socket Bolts, 5/16 x 3/4 inch

• 3 Flange nuts, 5/16 inch

Installing the Left Rear Baffle

Note: Blades and spindles are not shown in the graphics

for clarity.

1. Place the left rear baffle behind the left cutting

chamber (trim side of mower) (Fig. 12). The tabs will

mount on the outside of the mower.

2. Align the left rear baffle tight against and flush with

the bottom of the center baffle and against the mower

flange (Figures 12 and 13).

3. Clamp the baffle in place.

5

1

8

4

1. Left rear baffle

2. Left side of mower

3. Button head socket bolt,

5/16 x 3/4 inch

4. Flange nut, 5/16 inch

3

7

5

m–6179

Figure 13

5. Hole to drill

6. Rear center baffle

7. Mower flange

8. Tab

6

4

1

3

Figure 12

1. Center Baffle

2. Left rear baffle against

mower flange

3. Flush with bottom of

center baffle

4. Using the baffle as a template, mark, center punch and

drill 1/8 inch pilot holes at the 3 locations (Fig. 13).

5. Drill 11/32 inch dia. holes through the pilot holes

(Fig. 13).

2

5

4. Left cutting chamber

5. Tab

6. Trim side of mower

m–6178

7

Page 8

Step

5

Parts needed for this step:

• 1 Right rear baffle

• 2 Button Head Socket Bolts, 5/16 x 3/4 inch

• 1 Carriage bolts, 5/16 x 5/8 inch

• 4 Flange nuts, 5/16 inch

Installing the Right Rear Baffle

3. Clamp the baffle in place.

4. Using the baffle as a template, mark, center punch and

drill 1/8 inch pilot holes at the 2 locations (Fig. 15).

5. Drill 11/32 inch dia. holes through the pilot holes

(Fig. 15).

6. Remove the clamp.

7. Install the right rear baffle to the mower with 2 button

head socket bolts (5/16 x 3/4 inch) and 2 flange nuts

(5/16 inch) (Fig. 15).

8. Install the right rear baffle to the rear tunnel baffle

with a carriage bolt (5/16 x 5/8 inch) and a flange nut

(5/16 inch) (Fig. 15).

Important Make sure the button head socket bolt

heads are installed on the inside of the cutting chamber.

See figure 15.

Note: Blades and spindles are not shown in the graphics

for clarity.

1. Place the right rear baffle (side discharge side) behind

the right cutting chamber (Fig. 14). The tabs will

mount on the outside of the mower.

2. Align the right rear baffle tight against and flush with

the bottom of the center baffle and against the mower

flange (Fig. 14 and 15).

4

1

5

2

6

3

m–6712

1. Right rear baffle

2. Right side of mower

3. Carriage Bolt, 5/16 x

5/8 inch

4. Button head socket bolt,

5/16 x 5/8 inch

5

Figure 15

5. Flange nut, 5/16 inch

6. Holes to drill

7. Mower flange

5

4

4

7

15

1. Center Baffle

2. Right rear baffle against

mower flange

3. Flush with bottom of

center baffle

2

Figure 14

4. Right cutting chamber

5. Side discharge opening

3

m–6711

9. Rotate the blades and check if the blades make contact

with the baffles.

10.If contact is made, do not use the mower. Adjust and

make sure all baffles are installed properly.

8

Page 9

Step

2

3

5

6

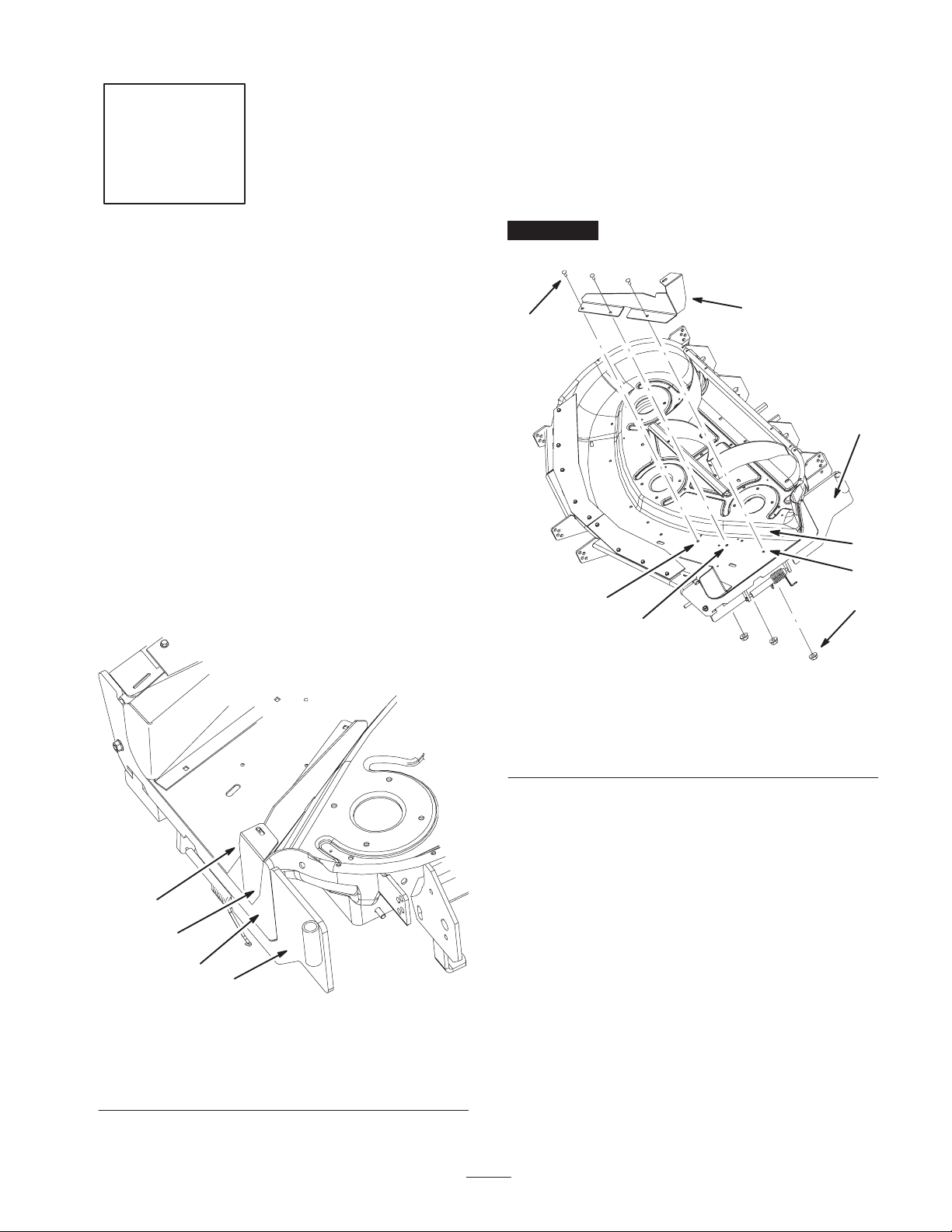

No Parts needed for this step.

Removing the Existing Mower

Pulley

Note: Clean the area around pulley before removing

pulley assembly. Hold spindle up from underneath the

deck. It can fall when nut and washer are removed.

1. Turn the mower over.

2. Remove the right belt cover from the mower and

discard.

3. Remove the nut and washer on top of the spindle

(Fig. 17). Save the nut and washer.

4. Remove the existing pulley assembly.

Step

1

1. 44 inch mower

2. Remove this corner

3. 3–1/4 inches

4

4

m–6713

Figure 16

4. 1 inch

5. Pulley cover stud

7

No Parts needed for this step.

Modifying a 44 inch Mower for

Belt Clearance

Note: This section is only for 44 inch mowers that do not

have a belt clearance notch.

1. Remove the right rear corner of the pulley cover plate

(Fig. 16). This will give clearance for the blower belt.

2. Refer to Figure 16 for the correct dimensions of the

cutout.

Note: Do not cut out the stud in the back of the pulley

cover plate. The stud is needed for the pulley cover.

9

Page 10

Step

8

Parts needed for this step:

• 1 Pulley assembly

• 1 Bagger Belt

• 1 Pulley cover

Installing the Pulley Assembly

Note: For mowers built in 1999, check the right blade

spindle for splines. Refer to Checking the Spindle for

1999 Models on page 2.

1. Install new pulley assembly onto the spindle. Install it

so the large pulley is on the bottom (Fig. 17).

2. Install the washer and nut (Fig. 17).

Installing the Belt Cover and Bagger Belt

Refer to the bagger Operator ’s Manual for installing the

belt cover and bagger belt.

Important Tighten the nut to 115 ft–lb ± 15 ft–lb

torque.

3. Grease the spindle to fill bearings with grease.

1

2

3

4

5

Figure 17

1. Nut

2. Washer

3. Pulley Assembly

4. Blade spindle

5. Mower

6. Lower pulley

7. Upper pulley

7

6

m–6714

10

Page 11

Step

9

Parts needed for this step:

• 2 Mounting plates

• 1 Template

• 4 Bolts, 3/8 x 1–1/4 inch

• 4 Flange nuts, 3/8 inch

Installing the Mounting Plates

Drilling the Holes into the Mounting

Bracket

This kit contains a metal template for locating the

mounting bracket holes to drill.

Installing the Mounting Plates

1. Install the mounting plates to the inside of the

mounting bracket with 4 bolts (3/8 x 1–1/4 inch) and

4 flange nuts (3/8 inch) (Fig. 19).

1

1

5

2

4

3

m–6683

1. Remove the grass deflector from the mower (Fig. 22).

2. Position the template onto the the mounting bracket

and align with the top and sides of the mounting

bracket. (Fig. 18).

3. Clamp the template to the mounting bracket (Fig. 18).

4. Mark and center punch the 4 holes and remove the

template (Fig. 18).

5. Drill 1/8 inch pilot holes at the 4 marked locations and

then drill 7/16 inch dia. holes.

6. File the metal burrs from the drilled holes.

3

1

3

1. Template

2. Mounting bracket

Figure 18

3. Mark and center punch

holes

m–6225

2

1. Mounting plate

2. Bolt, 3/8 x 1–1/4 inch

3. Flange nut, 3/8 inch

Figure 19

4. Mounting bracket

5. 7/16 inch holes to drill

11

Page 12

Installing the Blades

Installing the Mower and

Note: In certain mowing conditions, improved bagging

performance can be achieved by using bagging blades.

Contact an Authorized Service Dealer for the proper

blades for different mowing conditions.

1. Install the blade onto the spindle shaft (Fig. 20).

Important The curved part of the blade must be

pointing upward toward the inside of the mower to ensure

proper cutting.

2. Install the spring disk and blade bolt (Fig. 20). Torque

the blade bolt to 85–110 ft-lb (115–150 Nm).

3. Rotate the blades to ensure there is clearance between

the blade tips and the baffles.

4. If contact is made, do not use the mower. Adjust and

make sure the baffles are installed properly.

Important Do not use the mower if blades contact the

baffles.

3

5

4

2

Mower Belt

1. Install the mower to the machine. Reverse the

instructions in Removing the Mower on page 2.

Note: If the mower was already level and was removed

from the top bolts, the mower will not need to be leveled.

Refer to the mower Operator ’s Manual if the mower

needs to be leveled.

2. Route the mower belt onto the lower pulley (Fig. 17)

and idler pulley (Fig. 21).

3. Route the mower belt. Refer to the mower Operator ’s

Manual.

4. Tighten the outer nut on spring eye bolt (Fig. 21).

Note: Check the spring length. The spring should measure

9–3/8 inch ± 1/8 inch (238 mm ± 3 mm) when installed.

Adjust if it does not (Fig. 21).

5. Tighten the inner nut on spring eye bolt (Fig. 21).

14

3

5

2

7

1

4

1. Sail Area of Blade

2. Blade

3. Spring Disk

Figure 20

4. Blade Bolt

5. Cone T owards Bolt Head

3

M–4226

6

M–4197

Figure 21

Top View

1. Outer nut

2. Idler pulley

3. Idler arm

4. Spring eye bolt

5. Spring

6. 9–3/8 inch ± 1/8 inch

(238 mm ±3 mm)

7. Mower belt

12

Page 13

Using the Grass Deflector

Installing the Grass Deflector

Important Make sure the grass deflector is installed

when the bagger and tubes are removed.

Warning

Without the grass deflector, bagger tubes or

complete bagger assembly mounted in place, you

and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade(s) and thrown debris will cause injury or

death.

• Always install the grass deflector when

removing the bagger and changing to side

discharge mode.

• If the grass deflector is ever damaged, replace

it immediately. The grass deflector routes

material down toward the turf.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or mower

blades unless you move the power take off

(PTO) to off and rotate the ignition key to off.

Also remove the key and pull the wire off of the

spark plug(s).

1. When the bagger is to be used for dedicated bagging,

leave the grass deflector off the machine.

• Remember to install the grass deflector when

changing to side discharge mode.

2. When the mower is switched between bagging and

side discharge frequently, leave the grass deflector on

the machine. The grass deflector will rest against the

blower belt cover.

Important Make sure the grass deflector is installed

when the bagger and tubes are removed.

The grass deflector spring will have either an L end or a

straight end (Fig. 22).

Warning

An uncovered discharge opening could allow the

lawn mower to throw objects in the operator’s or

bystander’s direction and result in serious injury.

Also, contact with the blade could occur.

Never operate the lawn mower unless you install a

cover plate, a mulch plate, grass deflector or a

grass chute and catcher.

1. Place spacer and spring onto grass deflector. Place the

L or the straight end of spring behind deck edge.

Note: Make sure the L or the straight end of spring is

installed behind deck edge before installing the bolt as

shown in figure 22.

2. Install bolt and nut. Place J hook end of spring around

grass deflector (Fig. 22).

Important The grass deflector must be lowered down

into position. Lift the deflector up to test that it lowers

into the full down position.

8

6

1

4

2

3

5

10

1. Bolt

2. Spacer

3. Locknut

4. Spring

5. Spring installed

6. Grass Deflector

13

7

m–6085

Figure 22

7. L end of spring, place

behind mounting bracket

before installing bolt

8. J hook end of spring

9. Mounting bracket

10. Straight end—possible

style of spring

Page 14

141516

Page 15

Page 16

Loading...

Loading...