Page 1

Form No. 3353–631 Rev A

44I, 48Iand 52I Twin Soft Bagger

Z100 and Z400 Series Z Master

Model No. 78507—Serial No. 250000351 and Up

Operator’s Manual

Register your product at www.Toro.com

Original Instructions (EN)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 4. . . . . . . . . . . . . . . . .

Setup 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare the Mower 6. . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Flow Baffle (Z400 Mowers only) 6.

Installing the Bagger Bracket (All Z100 Mowers and

Z400 Mowers with 44in and 48in Mower Decks) 6

Installing the Bagger Bracket

(Z400 Mowers with 52in Mower Decks) 9. . . . . . . .

Installing the Blower Assembly 10. . . . . . . . . . . . . . .

Installing the Bagger Belt and Idler Spring 11. . . . . .

Installing the Hood Assembly and Bags 13. . . . . . . .

Installing the Bagger Tube 15. . . . . . . . . . . . . . . . . . .

Checking the Tire Pressure 16. . . . . . . . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Flow Baffle (Z400 Mowers only) 17.

Emptying the Grass Bags 17. . . . . . . . . . . . . . . . . . . .

Clearing Obstructions From the Bagger System 18. .

Removing the Bagger 18. . . . . . . . . . . . . . . . . . . . . . .

Using the Grass Deflector 19. . . . . . . . . . . . . . . . . . .

Transporting Machines 19. . . . . . . . . . . . . . . . . . . . . .

Operating and Bagging Tips 19. . . . . . . . . . . . . . . . .

Maintenance 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 21. . . . . . . . .

Cleaning the Hood Screen 21. . . . . . . . . . . . . . . . . . .

Cleaning the Bagger 21. . . . . . . . . . . . . . . . . . . . . . . .

Checking and Adjusting the Bagger Belt Tension 22.

Checking and Adjusting the Blower Latch 22. . . . . .

Replacing the Blower Belt 23. . . . . . . . . . . . . . . . . . .

Greasing the Idler Arm 24. . . . . . . . . . . . . . . . . . . . .

Checking the Blower Liner 24. . . . . . . . . . . . . . . . . .

Replacing the Blower Liner 24. . . . . . . . . . . . . . . . . .

Inspecting the Bagger 24. . . . . . . . . . . . . . . . . . . . . . .

Inspecting the Mower Blades and Baffles 25. . . . . . .

Installing Mower Blades 25. . . . . . . . . . . . . . . . . . . .

Installing the Grass Deflector 25. . . . . . . . . . . . . . . . .

Storage 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro Total Coverage Guarantee 28. . . . . . . . . . . . . .

Page

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

You may contact Toro directly at www.Toro.com for

product and accessory information, help finding a dealer, or

to register your product.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

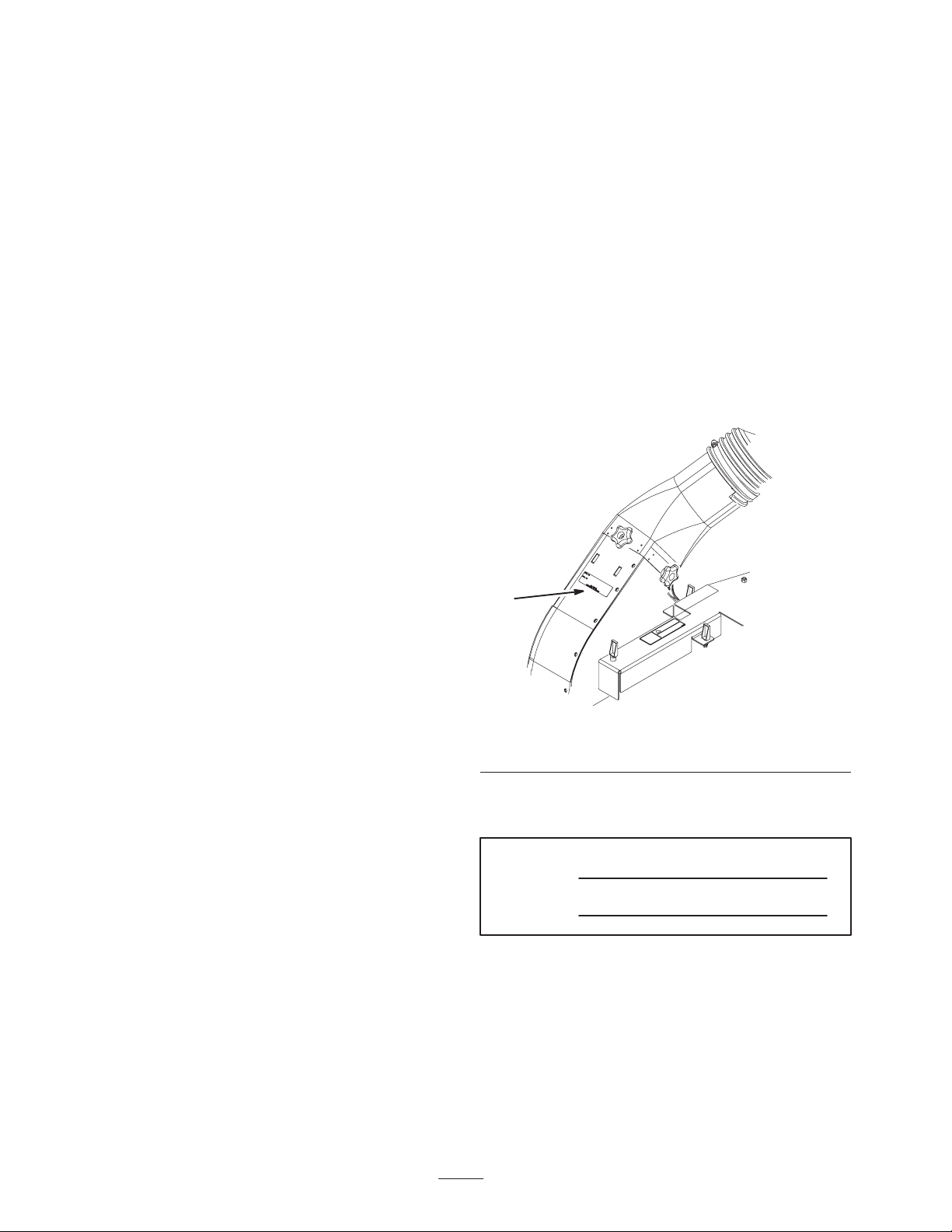

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

m–6231

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

W 2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Contact us at www.Toro.com

All Rights Reserved

2

Printed in the USA

Page 3

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Safety

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

The following list contains safety information specific to

Toro products and other safety information you must know.

• Become familiar with the safe operation of the

equipment, with the operator controls, and safety signs.

• Use extra care with grass catchers or other attachments.

These can change the operating characteristics and the

stability of the machine.

• Do not use a grass catcher on steep slopes. A heavy

grass catcher could cause loss of control or overturn the

machine.

• Slow down and use extra care on hillsides. Be sure to

travel in the recommended direction on hillsides. Turf

conditions can affect the machine’s stability. Use

extreme caution while operating near drop–offs.

• Keep all movement on slopes slow and gradual. Do not

make sudden changes in speed, directions or turning.

• The grass catcher can obstruct the view to the rear. Use

extra care when operating in reverse.

• Use care when loading or unloading the machine into a

trailer or truck

• Never operate with the discharge deflector raised or

removed and never altered, unless using a grass catcher

or mulching baffles.

• Keep hands and feet away from moving parts. Do not

make adjustments with the engine running.

• Stop on level ground, disengage drives, set the parking

brake, shut off the engine before leaving the operator’s

position for any reason including emptying the grass

catcher or unclogging the chute.

• If you remove the grass catcher, be sure to install any

discharge deflector or guard that might have been

removed to install the grass catcher. Do not operate the

mower without either the entire grass catcher or the

grass deflector in place.

• Turn off the engine and wait for all moving parts to

stop before removing the grass catcher or

unclogging the chute.

• Do not use your hands to unclog the chute, blower or

bagger.

• Do not leave grass in grass catcher for extended periods

of time.

• Grass catcher components are subject to wear, damage

and deterioration, which could expose moving parts or

allow objects to be thrown. Frequently check

components and replace with manufacturer’s

recommended parts, when necessary.

• Do not leave grass or debris in grass catcher while

transporting the machine.

3

Page 4

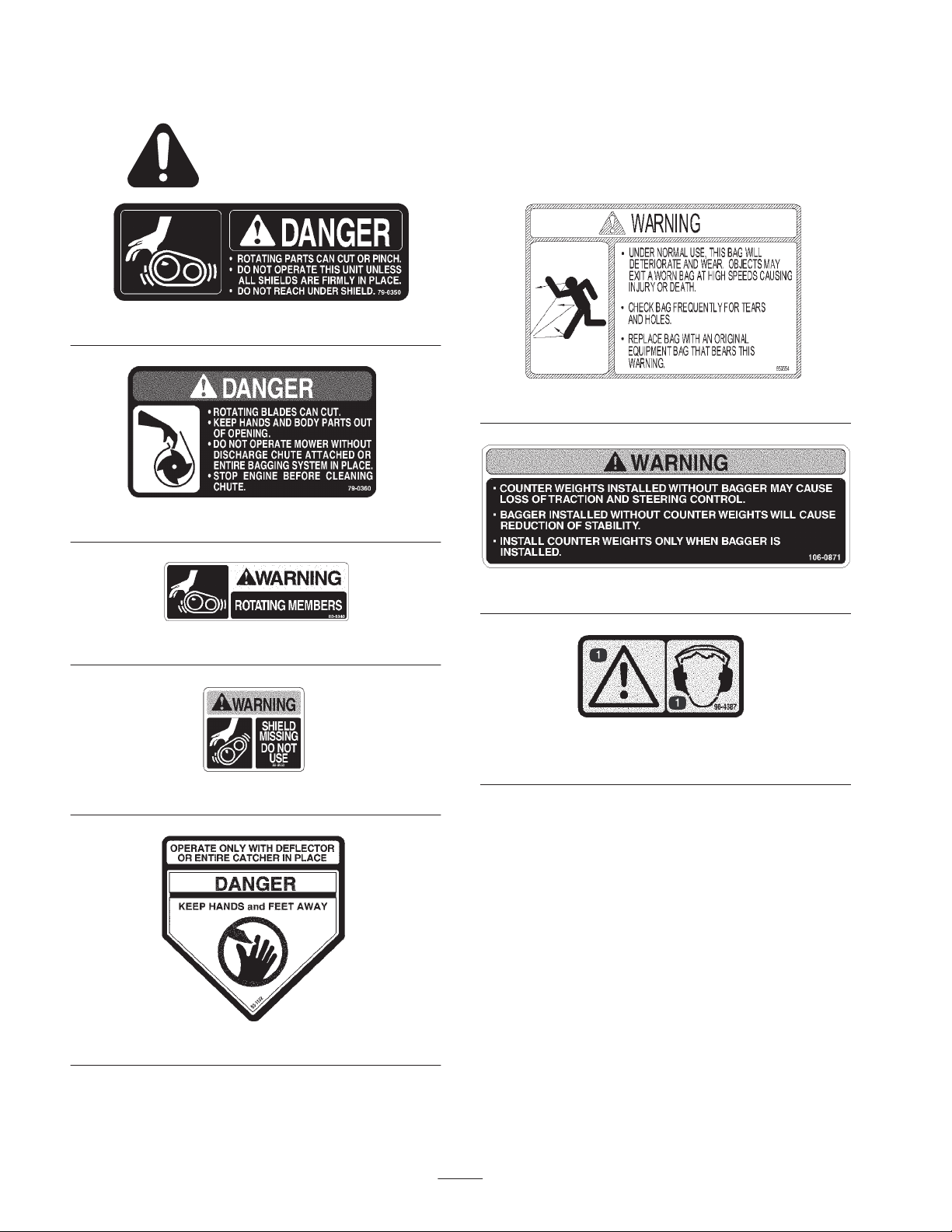

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

79-0350

79-0360

1-653554

80-8040

88-8950

106-0871

98-4387

1. Warning—wear hearing protection.

93-1122

4

Page 5

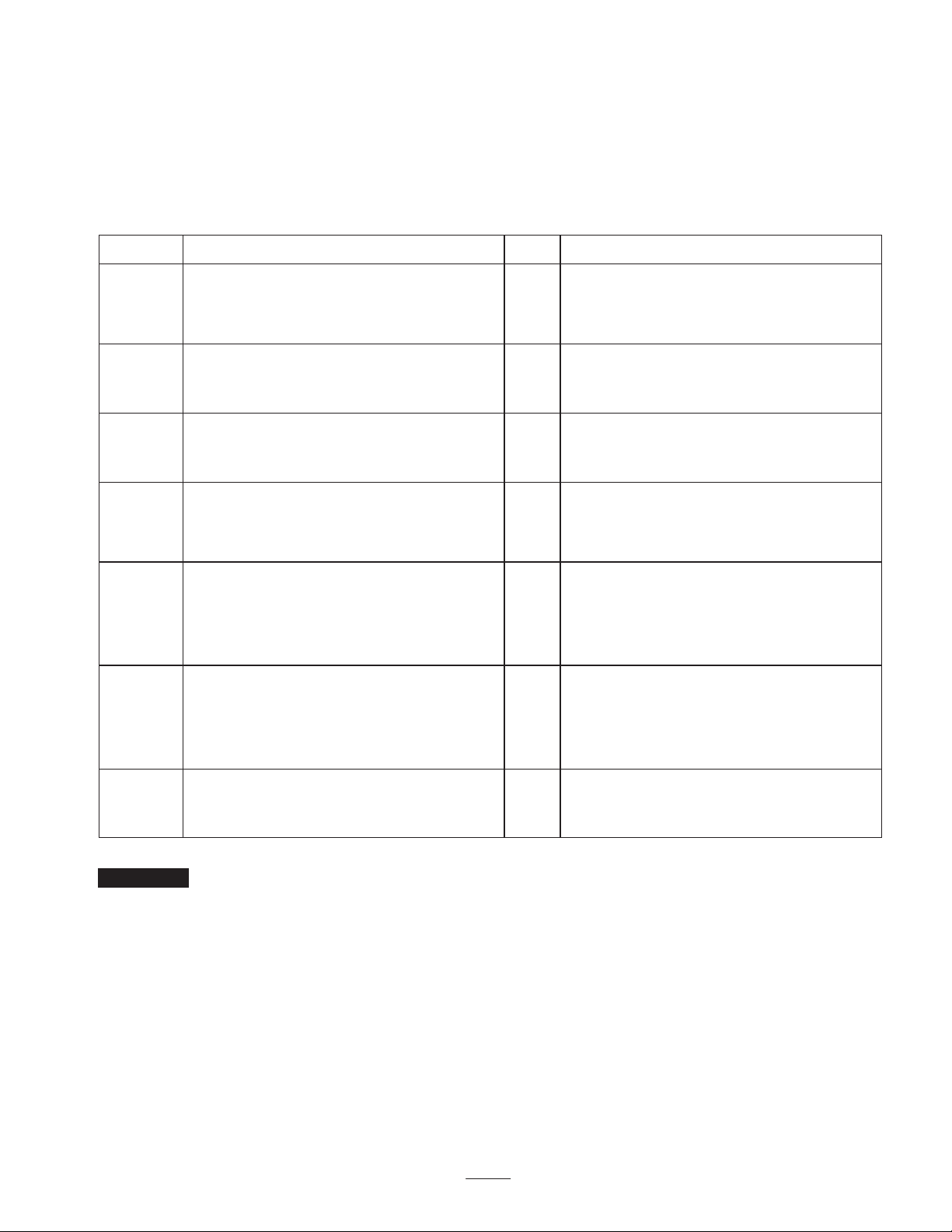

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

Step Description Qty. Use

1

2

3

4

5

6

Bagger bracket

Bolt, 5/16 x 1 inch

Flange nut, 5/16 inch

Bagger bracket 1

Blower assembly 1 Installing the blower assembly

Blower belt cover

Idler spring

Bagger belt

Hood assembly

Bag

Clevis pin

Hairpin cotter

Bagger tube

Clamp

Knob

Blower adapter

1

8

8

1

1

1

1

2

2

2

1

1

2

1

Installing bagger bracket (All Z100

Mowers and Z400 Mowers with 44in and

48in Mower Decks)

Installing bagger bracket (Z400 Mowers

with 52in Mower Decks)

Installing the bagger belt and idler spring

Installing the hood assembly and bags

Installing the bagger tube

7

Important Bagger model 78507 MUST be paired with either model 78508, 78509, 78511, or 78512 finishing kit. Failure

to match the appropriate finishing kit with the appropriate bagger will result in misalignment of the blower assembly relative

to the deck, as well as misalignment of the latch components, and potential interference between the blower inlet shelf and

the deck baffles.

No parts needed – Checking the tire pressure

5

Page 6

Before Installation

Prepare the Mower

Step

Perform the following procedure to prepare the mower for

attaching the blower and finishing kit.

1. Disengage the PTO, move the motion control levers to

the neutral locked position and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Clean the mower of any debris on the deck or rear of

mower to ease installation.

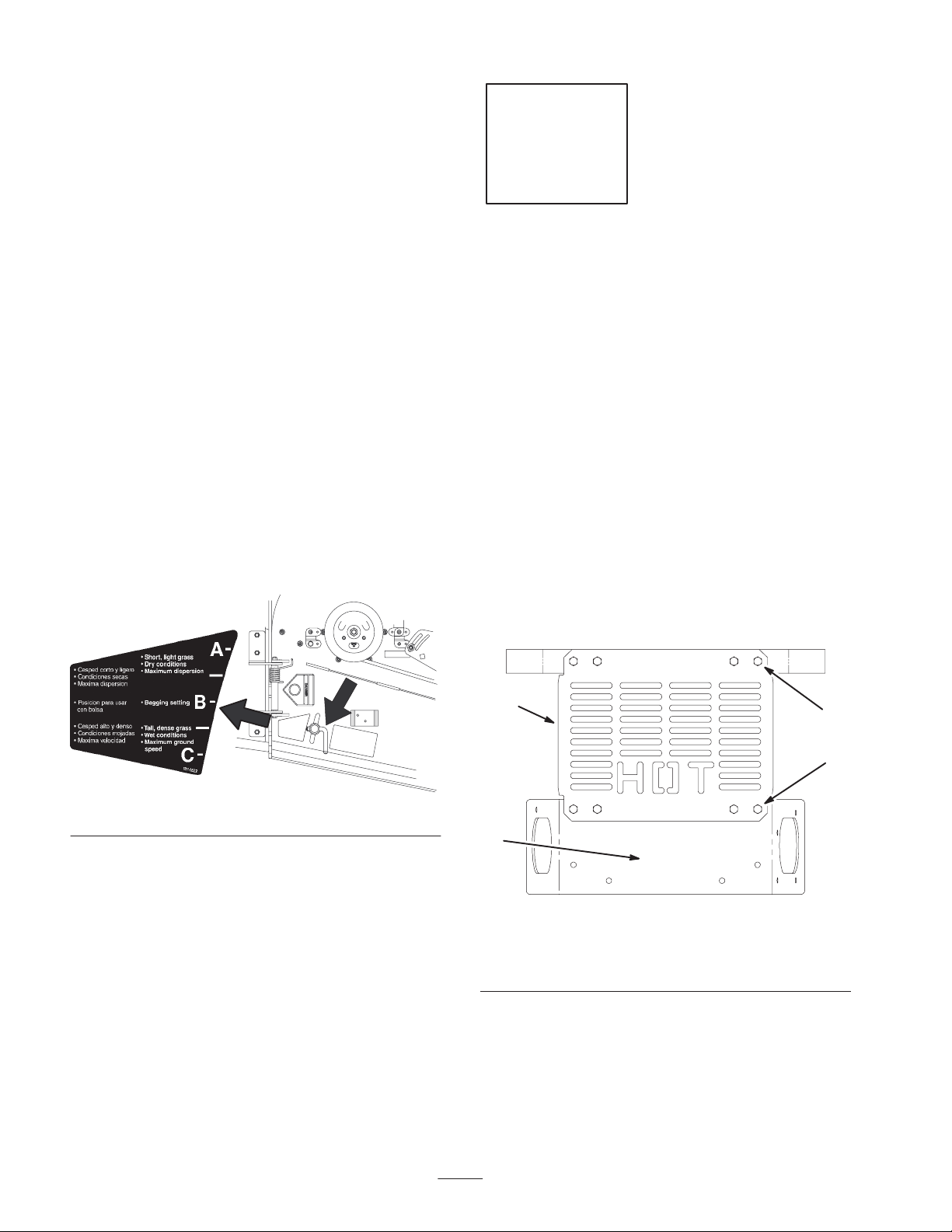

Positioning the Flow Baffle

(Z400 Mowers only)

The middle position or Position B is recommended for

bagging.

Move the adjustable flow baffle to the middle position. To

adjust the baffle refer to your mower Operator’s Manual.

Position B

Middle Position

1

Parts needed for this step:

• 1 Bagger bracket

• 8 Bolts, 5/16 x 1 inch

• 8 Flange nuts, 5/16 inch

Installing the Bagger Bracket

(All Z100 Mowers and Z400

Mowers with 44in and 48in

Mower Decks)

Note: Determine if machine is equipped with a back mount

or back and side mount heat shield. If machine is equipped

with a back mount heat shield (Fig. 4), use steps 1 thru 3. If

machine has a back and side mount heat shield (Fig. 5),

proceed to step 4.

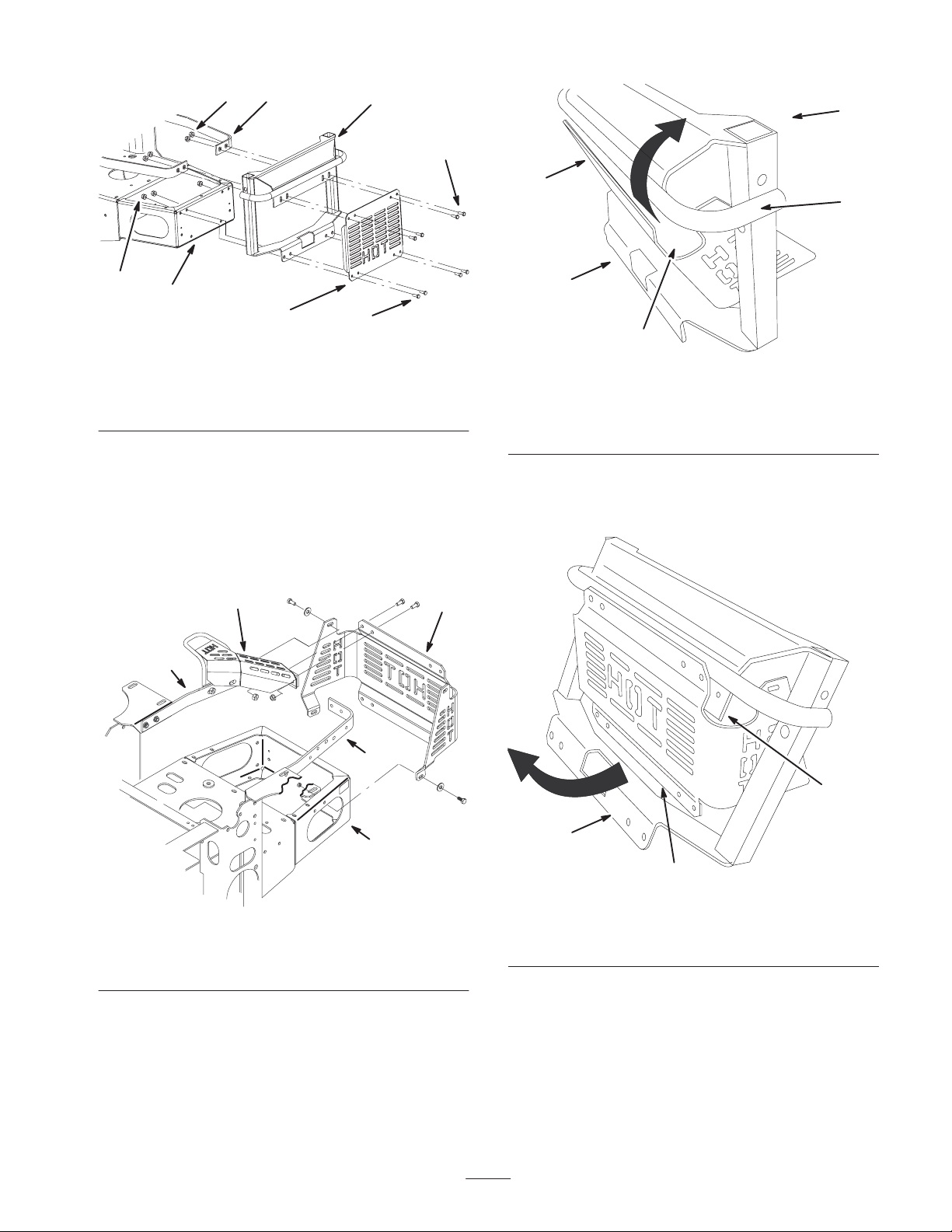

1. Remove the rear heat shield (Fig. 3). Discard the bolts

and nuts.

Figure 2

m–6880

1

3

m–5836

Figure 3

1. Rear heat shield

2. Bolts—remove and

discard

2. Position the bagger bracket behind the engine guard

straps and rear bumper (Fig. 4).

3. Install the bagger bracket and rear heat shield to the

engine guard straps and rear bumper with 8 bolts

(5/16 x 1 inch) and 8 flange nuts (5/16 inch) (Fig. 4).

3. Rear bumper

2

2

6

Page 7

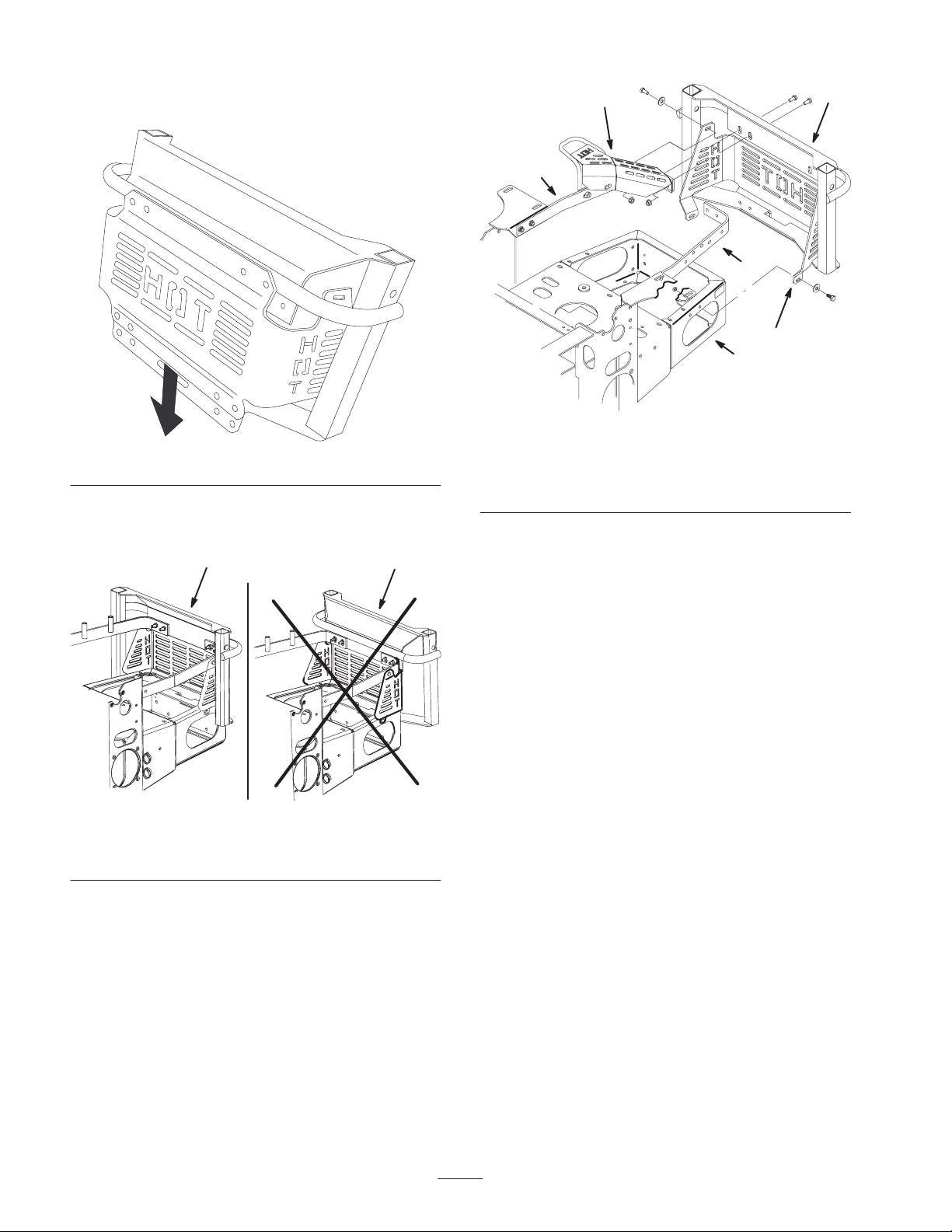

3

5

1

5

2

1

3

3

4

6

2

m–6221

Figure 4

1. Bagger bracket

2. Bolt, 5/16 x 1 inch

3. Flange nut, 5/16 inch

4. Rear bumper

5. Engine guard strap

6. Rear heat shield

4. Remove the 8 bolts and nuts securing the rear of the

heat shield to the engine straps and rear bumper

(Fig. 5). Discard the bolts and nuts.

5. Remove the 4 bolts, washers and nuts securing the sides

of the heat shield to the engine straps, tailpipe guard and

bumper. Retain the heat shield and these bolts, washers

and nuts (Fig. 5).

3

1

2

2

4

m–6812

Figure 6

1. Heat shield

2. Bagger bracket

3. Bar

4. Heat shield notch

5. Front of bagger bracket

7. With the bagger bar in the heat shield notches, push the

bottom of the heat shield towards the rear and past the

back of the bagger bracket (Fig. 7).

2

4

m–6809

Figure 5

1. Heat shield

2. Engine straps

3. Tailpipe guard

4. Rear bumper

Note: Install the heat shield into the bagger bracket from

the front of the bracket.

6. At an angle, insert the top of the heat shield under the

bar of the bagger bracket. Position the bagger bar as far

as possible into the heat shield notches (Fig. 6).

2

1. Heat shield notch

2. Back of bagger

7

3

Figure 7

1

m–6811

3. Bottom of heat shield

Page 8

8. Slide the heat shield down until the holes align with the

bagger bracket holes (Fig. 8).

4

1

2

2

5

3

m–6809

m–6810

Figure 8

Note: Make sure to install the bagger bracket correctly, as

shown in figure 9.

1

2

m–6805

Figure 9

1. Correct position 2. Incorrect position

1. Bagger bracket

2. Engine straps

3. Rear bumper

Figure 10

4. Tailpipe guard

5. Heat shield

9. Install the bagger bracket and heat shield to the engine

straps and rear bumper with 8 new bolts (5/16 x 1 inch)

and 8 new flange nuts (5/16 inch) (Fig. 10).

10. Install the bagger bracket and heat shield to the engine

straps, tailpipe guard and rear bumper with 4 bolts,

4 washers and 4 flange nuts, previously removed

(Fig. 10).

8

Page 9

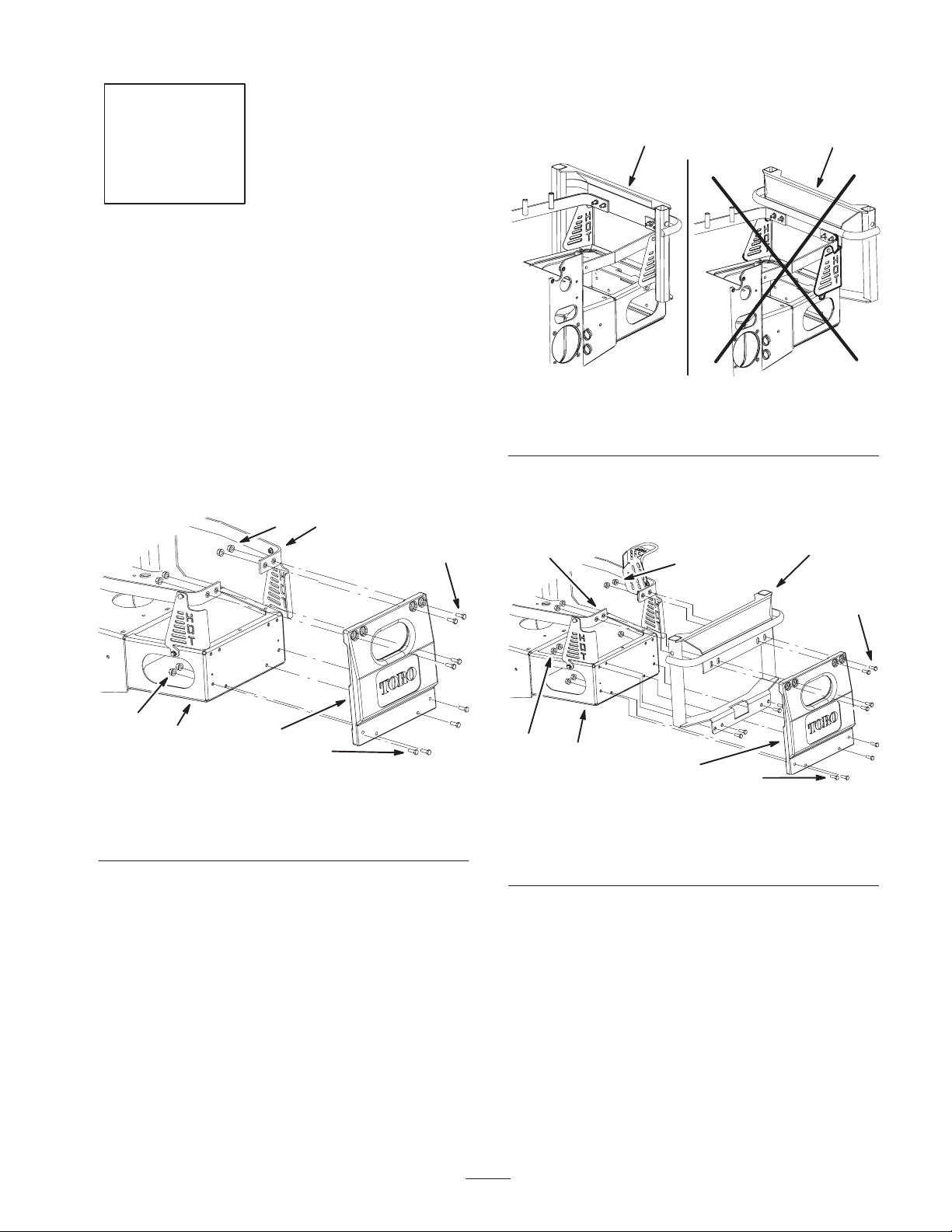

Step

Note: Make sure to install the bagger bracket correctly, as

shown in Figure 12.

2

Parts needed for this step:

• 1 Bagger bracket

Installing the Bagger Bracket

(Z400 Mowers with 52in Mower

Decks)

Note: Use these instructions if machine is equipped with a

rear weight.

1. Remove the rear weight from the back of the machine

(Fig. 11). Save the bolts and flange nuts.

2

4

1

1

Figure 12

1. Correct position 2. Incorrect position

2. Install the bagger bracket and weight to the engine

straps, tailpipe guard, and rear bumper with the 8

existing bolts and nuts previously removed (Fig. 13).

5

3

2

1

m–7782

2

3

m–7783

1. Bolt

2. Flange nut

3. Rear bumper

5

Figure 11

4. Engine guard strap

5. Rear weight

2

1

3

m–7780

1. Bagger bracket

2. Bolt

3. Flange nut

4

6

Figure 13

4. Rear bumper

5. Engine guard strap

6. Rear weight

2

9

Page 10

Step

3

Parts needed for this step:

• 1 Blower assembly

Installing the Blower Assembly

Important Make sure the mounting plate is installed to

the mower. Refer to the Finishing Kit.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Slide the blower assembly peg into the hole on the

mounting plate (Fig. 14).

2

3

1. Mower

2. Blower assembly

3. Blower assembly peg

5

1

4

m–8256

Figure 14

4. Mounting plate hole

5. Mounting plate

4. Close the blower assembly. (Fig. 18).

5. Check if the latch fully engages the front latch peg.

Refer to Checking and Adjusting the Blower Latch on

page 22.

Note: There must not be any gap between the blower

assembly and the mounting plate.

Step

4

Parts needed for this step:

• 1 Blower belt cover

• 1 Idler spring

• 1 Bagger belt

10

Page 11

Installing the Bagger Belt and

Idler Spring

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

Important The idler spring and bagger belt need to be

installed together.

This will create slight tension on both the spring and belt

while installing them.

Installing the Idler Spring

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Open the blower assembly (Fig. 17).

4. Slide the spring into the blower eye bolt (Fig. 15).

5. Install the spring into the idler arm eye bolt (Fig. 15).

6. Close the blower assembly (Fig. 18).

5

4

3. Lower the deck to the 3 inch height–of–cut.

4. Push down on the front latch (colored red) and open the

blower assembly (Fig. 17).

5. For 52 inch mowers only, loosely install the belt cover,

insert the bagger belt under the belt cover and onto the

top mower pulley. Secure the belt cover latch (Fig. 16).

1

4

3

4

1

2

3

1

m–6276

Figure 15

1. Idler spring

2. Blower assembly

3. Idler arm eye bolt

4. Blower eye bolt

5. Idler arm

Installing the Bagger Belt

Note: For 44 inch (112 cm) mowers, make sure the right

rear corner of the cover side plate is modified. Refer to the

mower Finishing Kit.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

3

m–6271

Figure 16

1. 52 inch mower belt cover

2. Blower assembly

3. Top mower pulley

4. Bagger belt

6. Route the bagger belt around the top pulley of the

mower pulley assembly (Fig. 17).

7. Feed the belt between the idler pulleys (Fig. 17).

8. Route the bagger belt around the spring–loaded idler

pulley (Fig. 17). The backside of belt will be touching

the pulley.

9. Route the bagger belt around the fixed idler pulley

(Fig. 17).

10. Route the bagger belt around the blower pulley

(Fig. 17).

2

11

Page 12

3

7

6

4

3 2

1

1

m–8257

5

2

Figure 17

1. Blower pulley

2. Mower

3. Blower assembly

4. Top pulley of mower

pulley assembly

5. Spring loaded idler pulley

(belt back side touching

pulley)

6. Fixed idler pulley

7. Front latch

11. Close the blower assembly and ensure the blower front

latch engages onto the front peg (Fig. 18).

1

m–8259

Figure 19

1. Blower assembly

2. Blower belt cover

3. Latch

14. For 44 inch (112 cm) mowers, install the new belt cover

over the pulley assembly and secure the latch (Fig. 20).

2

3

2

1

2

m–8258

Figure 18

1. Blower latch 2. Front peg

12. Adjust the bagger belt tension. Refer to Adjusting the

Bagger Belt Tension on page 22.

13. Install the belt cover over the pulley assembly and

secure the 3 cover latches into the blower (Fig. 20).

m–6255

1. Mower

2. 44 inch (112 cm) mower

belt cover

12

Figure 20

3. Latch

Page 13

Step

5

Parts needed for this step:

• 1 Hood assembly

• 2 Bags

• 2 Clevis pins

• 2 Hairpin cotter pins

Installing the Hood Assembly

and Bags

Warning

Components around engine will be hot if the

machine has been running. Touching hot

components can cause burns.

• Do not touch engine components when hot.

• Allow engine to cool before performing

maintenance.

1. Install the hood assembly into the bagger bracket

(Fig. 21).

2

1

m–6806

Figure 21

1. Bagger bracket 2. Hood assembly

2. Install clevis pins and hairpin cotters into the bagger

bracket and hood assembly (Fig. 22).

1

1. Hood assembly

2. Bagger bracket

13

3

4

2

Figure 22

3. Clevis pin

4. Hairpin cotter

m–6807

Page 14

3. Install the bag tab into the notch in the hood assembly

(Fig. 23). Do this for both bags.

Note: The bag will rest on the bagger frame (Fig. 23).

3

4. Lower the bagger hood over the bags.

1

3

4

1

1. Hood assembly

2. Bag

3. Bag tab

3

2

Figure 23

4. Notch

5. Bagger frame

4

5

2

m–6761

Figure 24

1. Hood

2. Bags

3. Bagger latch

4. Latch hook

5. Position the bagger latch under the latch hook

(Figures 24 and 25).

6. Push down on bagger latch until it locks into place

(Fig. 25).

m–6760

1

2

Figure 25

1. Bagger latch 2. Latch hook

m–6264

14

Page 15

Step

4

1

6

Parts needed for this step:

• 1 Bagger tube

• 1 Clamp

• 2 Knobs

• 1 Blower adapter

Installing the Bagger Tube

Note: To ease assembly of the bagger tube to the blower

adapter, apply soapy water to both the bagger tube and the

adapter.

1. Install one end of the tube, 4 to 4–1/2 inches (102 to

114 mm) onto the blower adapter and secure it with a

clamp (Fig. 26).

5

3

5

2

Figure 27

1. Tube

2. Blower assembly

3. Top blower stud

Note: There are nubs on the inside of the bagger hood that

hold the upper end of the bagger tube (Fig. 28).

4. Place the upper tube into the bagger hood (Fig. 28).

5. Move the upper tube back and forth, until at least two

ribs engage into the nubs inside the bagger hood

(Fig. 28).

4. Knob

5. Side blower stud

4

m–6252

4

3

2

Figure 26

1. Tube

2. Blower adapter

3. Clamp

4. 4 to 4–1/2 inches (102 to

114 mm)

2. Place the blower adapter over the top blower stud and

slide it into the side stud (Fig. 27).

3. Install the knobs onto the top and side stud (Fig. 27).

This will secure the lower tube end to the blower

assembly.

5. Tube installed onto the

adapter 4 to 4–1/2 inches

(102 to 114 mm)

m–6815

1

1

m–6263

1. Tube

2. Bagger hood

2

3

Figure 28

4

3. Nubs

4. Ribs

15

Page 16

Step

7

Parts needed for this step:

• No parts needed

Checking the Tire Pressure

Note: The tire pressure needs to increase due to the

additional weight.

Check and increase the air pressure in the front caster

wheels and rear tires (Fig. 29).

Pressure: Rear tires—20 psi (138 kPa)

Front caster wheels—25 psi (172 kPa)

1

Figure 29

1. Valve

stem

Check the Level of the Mower

Refer to the mower Operator’s Manual for the correct

procedure.

m–1872

16

Page 17

Operation

Caution

Note: Determine the left and right sides of the machine

from the normal operating position.

Important Set the parking brake when leaving the

machine unattended, even if just for a few minutes.

Warning

To avoid personal injury, follow these procedures:

• Become familiar with all operating and safety

instructions in the operator’s manual for your

mower before using this attachment.

• Never remove the bagger or bagger tubes while

the engine is running.

• Always shut the engine off and wait for all

moving parts to stop before clearing an

obstruction from the bagging system.

• Never do maintenance or repairs while the

engine is running.

• Set the parking brake.

Warning

Children or bystanders may be injured if they

move or attempt to operate the machine while it is

unattended.

Always remove the ignition key, set the parking

brake and chock or block tires when leaving the

machine unattended, even if just for a few minutes.

Positioning the Flow Baffle

(Z400 Mowers only)

The middle position or Position B is recommended for

bagging.

Move the adjustable flow baffle to the middle position. To

adjust the baffle refer to your mower Operator’s Manual.

Position B

Middle Position

Without the grass deflector, bagger tubes or

complete bagger assembly mounted in place, you

and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade(s) and thrown debris will cause injury or

death.

• Always install the grass deflector when

removing the bagger and changing to side

discharge mode.

• If the grass deflector is ever damaged, replace it

immediately. The grass deflector routes material

down toward the turf.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or mower

blades unless you move the power take off

(PTO) to off and rotate the ignition key to off.

Also remove the key and pull the wire off of the

spark plug(s).

• Turn off the engine before unclogging the

discharge chute.

m–6880

Figure 30

Emptying the Grass Bags

Grass bags are heavy when full. Be careful when lifting or

handling a grass bag that is full.

1. Disengage the PTO, set the parking brake, and chock or

block the tires if on a slope.

2. Unlatch the bagger latch (Fig. 25).

3. Open the bagger hood.

4. Compress the debris into the bags. With both hands, lift

up on the bag and unhook it from the bagger bracket.

5. Grab the handle on the bottom of the bag and tip it over

to empty the bag (Fig. 31).

17

Page 18

4. Remove the knobs and then the tube from the blower

assembly (Fig. 27).

5. Remove the tube from the bagger hood (Fig. 28).

6. Using a stick or similar object, not your hands, to

remove and clear the obstruction from the tube

assembly.

1

m–6242

Figure 31

1. Bag 2. Bottom handle

6. Repeat for the other bag.

7. Install the bag tab into the notch in the bagger support

frame (Fig. 23). Do this for both bags.

8. Lower the bagger hood over the bags (Fig. 24).

9. Latch the bagger hood (Fig. 25).

Clearing Obstructions From

the Bagger System

2

Note: In most cases, the debris can be shaken out of the

tube.

7. If the blower assembly is plugged, unlatch the bagger

blower assembly and swing it open (Fig. 17).

8. Using a stick or similar object, not your hands, to

remove and clear the obstruction from the blower

assembly.

9. After you remove the obstruction, install the complete

bagger system and resume operation.

Removing the Bagger

Warning

Components around engine will be hot if the

machine has been running. Touching hot

components can cause burns.

• Do not touch engine components when hot.

• Allow engine to cool before removing the

bagger.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

Danger

When the bagger is in operation, the blower can be

rotating and cut off or injure hands.

• Before adjusting, cleaning, repairing and

inspecting the blower, and before unclogging the

chute, turn off the engine and wait for all moving

parts to stop. Remove the key.

• Use a stick, not your hands, to remove an

obstruction from the blower and tube.

• Keep face, hands, feet, and any other part of

your body or clothing away from concealed,

moving, or rotating parts.

1. Disengage the PTO and set the parking brake.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Empty the bags.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Remove the knobs and then the tube from the blower

assembly (Fig. 27).

4. Remove the tube from the bagger hood (Fig. 28).

5. Unlatch the belt cover over the mower pulley assembly

(Fig. 20).

6. Open the blower assembly to release belt tension and

remove the bagger belt from the mower (Fig. 17).

7. Remove the blower assembly from the the mounting

plate (Fig. 14).

8. If you are changing to side discharge mode, ensure the

grass deflector is installed and can be lowered into

working position.

18

Page 19

Using the Grass Deflector

Transporting Machines

Note: Make sure the grass deflector is installed when the

bagger and tubes are removed.

Warning

Without the grass deflector, bagger tubes or

complete bagger assembly mounted in place, you

and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade(s) and thrown debris will cause injury or

death.

• Always install the grass deflector when

removing the bagger and changing to side

discharge mode.

• If the grass deflector is ever damaged, replace it

immediately. The grass deflector routes material

down toward the turf.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or mower

blades unless you move the power take off

(PTO) to off and rotate the ignition key to off.

Also remove the key and pull the wire off of the

spark plug(s).

Do not leave grass or debris in the bagger while

transporting the machine.

Warning

Transporting the machine with grass or debris in

the bagger can damage the machine.

Do not leave grass or debris in the bagger while

transporting the machine.

Operating and Bagging Tips

Machine Size

Remember that the machine is longer and wider with this

attachment installed. By turning too sharply in confined

places you may damage the attachment or other property.

Trimming

Always trim with the left side of the mower. Do not trim

with the right side of the mower because you could damage

the blower assembly and bagging tube.

1. If the bagger is to be used for a long period of time,

leave the grass deflector off the machine. Install the

grass deflector when changing to side discharge mode.

2. If the bagger is to be used for a short period of time,

leave the grass deflector on the machine. The grass

deflector will rest against the belt cover.

Cutting Height

For optimum bagging performance, set the deck

height–of–cut to remove no more that 2 to 3 inches

(51 to 76 mm) or 1/3 of the grass height, which ever is less.

Cutting off more than this will reduce the capacity of the

vacuum system.

Cutting Frequency

Cut the grass often, especially when it grows rapidly. You

will have to cut your grass twice if it gets excessively long

Refer to Bagging Long Grass on page 20.

Cutting Technique

For best lawn appearance, be sure to slightly overlap the

mower into the previously cut area. This helps reduce the

load on the engine and reduces the chance of plugging the

blower assembly and tube.

Bagging Speed

The bagging system may plug if you drive too fast and the

engine speed gets too slow. On hills it may be necessary to

slow the machines ground speed. Mow down hill whenever

possible.

19

Page 20

Caution

As the bagger fills, extra weight is added to the

back of the machine. If you stop and start

suddenly on hills, you may lose steering control or

the machine may tip.

• Do not start or stop suddenly when going uphill

or downhill. Avoid uphill starts.

• If you do stop the machine when going uphill,

disengage the PTO. Then back down the hill

using a slow speed.

• Do not change speeds or stop on slopes.

Bagging Long Grass

If the grass is ever allowed to grow longer than normal, or

if it contains a high degree of moisture, raise the cutting

height higher than usual and cut and bag the grass at this

setting. Then cut and bag the grass again using the lower,

normal setting.

Excessively long grass is heavy and may not be propelled

completely into the bagger. If this happens, the tube and

blower assembly may plug.

Curb Climbing and Loading

Always lift the deck to the highest position when loading

the machine on trailers or ascending/descending a curb.

Leaving the mower in a lower position can cause damage to

mower baffles while loading and going over a curb. If a

curb is higher than 6 inches (152 mm), cross it at a sharp

angle with the deck fully raised. Use extreme caution

when loading onto a trailer.

Front Blowout

A bagging enhancement kit is available to reduce grass

blowout at the front of the mower deck. Excessive dust in

some dry conditions may also be reduced with this kit. This

kit is not available for 44 inch mower decks. Contact an

Authorized Service Dealer for the proper kit.

Bagging Wet Grass

If possible, always try to cut grass when it is dry. Wet grass

can cause plugging.

Reducing Plugging

To avoid plugging the bagging system, reduce ground

speed and mow the grass at a high height-of-cut, then lower

the mower to your normal cutting height and repeat the

bagging process.

Signs of Plugging

As you are bagging, a small amount of grass clippings

normally blow out the front of the mower. An excessive

amount of clipping blow-out indicates that the bagger is

full or the tube is plugged.

Bagging Blades

In most mowing conditions, the standard high lift blades

will provide the best bagging performance.

The Toro Atomic blade is recommended for bagging leaves

in dry conditions. In dry dusty conditions, the medium lift

or low lift blades with reduce dust and dirt blowout while

providing effective bagging air flow.

Contact an Authorized Service Dealer for the proper blades

for different mowing conditions.

20

Page 21

Maintenance

Important If the machine is on a slope, set the parking brake and chock or block the wheels to prevent the machine from

slowly rolling.

Recommended Maintenance Schedule

Maintenance Service

Interval

Each Use • Hood screen—clean

First 8 Hours

8 Hours • Bagger—clean

25 Hours

40 Hours • Blower liner—inspect

100 Hours • Bagger—inspect

Storage Service

Note: Determine the left and right side of the machine from the normal operating position.

Cleaning the Hood Screen

The screen needs to be cleaned before each use. In wet

grass it will need to be cleaned more often.

Maintenance Procedure

• Bagger—inspect

• Bagger belt—check and adjust

• Bagger belt—check and adjust

• Bagger idler arm—grease

• Belt—check for wear/cracks

• Bagger—inspect

• Bagger—clean

Cleaning the Bagger

The screen needs to be cleaned before each use. In wet

grass it will need to be cleaned more often.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Open the bagger and hold the bagger hood open.

4. Clean the debris from the screen.

5. Close the bagger hood.

1. Wash the inside and outside of the bagger hood, tube,

and the underside of the mower. Use a mild automotive

detergent to remove dirt.

2. Make sure you remove matted grass from all parts.

3. After washing all parts, let them dry thoroughly.

Note: With all parts installed, start and run the machine for

a minute to assist in drying.

21

Page 22

Checking and Adjusting the

Bagger Belt Tension

Check the bagger belt tension every 25 hours.

6. Adjust the fixed idler towards the rear to lengthen the

spring and increase belt tension (Fig. 33).

7. Adjust the fixed idler towards the front to shorten the

spring and decrease belt tension (Fig. 33).

Note: When checking the belt tension, the spring length

needs to be between 4 inches and 4–3/4 inches (102 and

121 mm) (Fig. 32).

Important Adjust the bagger belt if the spring length is

4 inches (102 mm) or less or greater than 4–3/4 inches

(121 mm).

1. Disengage the PTO and set the parking brake.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Close the blower assembly and measure between the

spring coil ends. See Figure 32 for measuring the spring

length and eye hook orientation.

5

2

2

8. Tighten the two bolts that hold the fixed idler to the

blower assembly (Fig. 33).

9. Close the blower assembly and measure the spring

length again. Adjust the fixed idler until the correct

spring length is achieved.

5

2

3

4

6

m–7781

Figure 33

1. Fixed idler

2. Blower assembly

3. Adjust idler to the front to

shorten the spring

4. Bolts

5. Adjust idler to the rear to

lengthen the spring

6. Extra holes for adjusting

belt tension

1

3

1

4

m–6275

Figure 32

1. Spring

2. End of spring coils

3. Blower assembly peg

4. Distance between spring

coil ends, 4 to

4–3/4 inches (102 mm to

121 mm)

5. Eye bolt

Note: When adjustment is needed, set the spring length

to 4–3/4 inches (121 mm) +/– 1/4 inch (6 mm) (Fig. 32).

4. If adjustment is needed, open the blower assembly to

remove tension from the bagger belt (Fig. 17).

5. Loosen the two bolts that hold the fixed idler to the

blower assembly (Fig. 33).

Important There are two extra holes in the blower

assembly that can be used to obtain the correct belt tension.

If needed, remove the fixed idler and install it in the extra

holes to get more belt tension adjustment (Fig. 33).

Checking and Adjusting the

Blower Latch

Note: Adjust the blower latch when it is does not engage

the front peg correctly and there is a visible gap between

the mounting plate and blower.

Note: A 9/16 inch thin wall deep socket is recommended

for this procedure.

1. Check that the bagger belt is properly installed and

routed correctly. Refer to the Belt Routing

2. Guide the rod hook onto the front peg and pull up on

the handle to lock the latch. Use the following

procedures to ensure the latch engages properly.

3. There must not be a gap between the mounting plate

and the blower assembly (Fig. 34). If there is a gap,

proceed to item 5 of this procedure and shorten the

latch.

22

Page 23

7. Tighten the lock nut at the end of the rod hook

(Fig. 35).

3

Top view

4

8. Check to make sure the latch locks and unlocks

properly. Repeatadjustments if needed.

Replacing the Blower Belt

Check the bagger belt for wear and cracks after the first

8 hours and then every 25 hours.

2

1

Figure 34

1. Blower assembly

2. Blower front latch (Red)

3. Gap shown

4. Front peg

4. The blower latch must engage the front peg properly. If

it does not, proceed to item 5 of this procedure and

lengthen the latch (Fig. 35).

3

4

m–8261

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Push down on the front latch and open the blower

assembly (Fig. 17). This will automatically remove the

tension from the blower belt.

4. For 52 inch mowers only, remove the bagger belt

between the top mower pulley and the mower belt cover

(Fig. 16).

5. For 44 inch mowers only, remove the mower belt

cover (Fig. 20).

6. Remove the blower belt cover (Fig. 36).

7. Remove the bagger belt from the top pulley of the

mower pulley assembly (Fig. 37).

3 2

1

G000928

2

Figure 35

1. Latch

2. Front peg

3. Locknut

4. Jam nut

5. Adjust the lock nut at the end of the rod hook so the

there is no gap between the blower and mower deck and

that it engages the front peg properly (Fig. 35).

6. Tighten the jam nut up against the block in the handle

(Fig. 35).

1

Figure 36

1. Blower assembly

2. Blower belt cover

3. Latch

8. Remove the bagger belt from the spring–loaded idler

pulley and the fixed idler pulley (Fig. 37).

23

m–8260

Page 24

9. Remove the bagger belt from the blower assembly

6

pulley (Fig. 37).

10. Install the new bagger belt. Refer to Installing the

Bagger Belt on page 11.

7

m–8257

3

1

5

2

4

Figure 37

1. Blower pulley

2. Mower

3. Blower assembly

4. Top pulley of mower

pulley assembly

5. Spring loaded idler pulley

6. Fixed idler pulley

7. Front latch

Greasing the Idler Arm

Grease the bagger belt idler arm every 25 hours (Fig. 38).

2

1

m–6251

Figure 38

1. Bagger idler arm 2. Grease zerk

Checking the Blower Liner

Check the blower liner inside the blower every 40 hours

and more often in extreme mowing and bagging conditions.

1. Remove the blower adapter and tube from the blower

(Fig. 27).

2. Check the liner for any excessive wear. Do not use your

hands to check the liner or remove debris.

3. Replace the liner if any excessive wear is noticed.

Replacing the Blower Liner

Contact an Authorized Service Dealer for replacing the

blower liner.

Inspecting the Bagger

Inspect the bagger attachment after the first 8 hours of

operation and 100 hours thereafter.

1. Disengage the PTO, set the parking brake, and chock or

block the drive wheels.

2. Turn off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

24

Page 25

3. Check the tube, blower assembly, and the bagger hood.

Replace these parts if they are cracked or broken.

2. Install bolt and nut. Place J hook end of spring around

grass deflector (Fig. 39).

4. Check the bags, bagger frame, and screen. Replace any

parts that are cracked, worn or broken.

5. Tighten all nuts, bolts and screws.

Inspecting the Mower Blades

and Baffles

1. Inspect the mower blades and baffles regularly and

whenever a blade strikes a foreign object.

2. If blades or baffles are badly worn or damaged, install

new blades or baffles. Refer to your mower operator’s

manual for complete blade maintenance.

Installing Mower Blades

In most mowing conditions, the standard high lift blades

will provide the best bagging performance.

The Toro Atomic blade is recommended for bagging leaves

in dry conditions. In dry dusty conditions, the medium lift

or low lift blades with reduce dust and dirt blowout while

providing effective bagging air flow.

Contact an Authorized Service Dealer for the proper blades

for different mowing conditions.

Important The grass deflector must be lowered down

into position. Lift the deflector up to test that it lowers into

the full down position.

8

6

1

Figure 39

1. Bolt

2. Spacer

3. Locknut

4. Spring

5. Spring installed

6. Grass Deflector

4

2

3

5

10

m–6085

7. L end of spring, place

behind mounting bracket

before installing bolt

8. J hook end of spring

9. Mounting bracket

10. Straight end—possible

style of spring

7

Refer to the mower Operator’s Manual for more

information on installing blades.

Installing the Grass Deflector

The grass deflector spring will have either an L end or a

straight end (Fig. 39).

Note: Make sure the grass deflector is installed when the

bagger and tubes are removed.

Warning

An uncovered discharge opening could allow the

lawn mower to throw objects in the operator’s or

bystander’s direction and result in serious injury.

Also, contact with the blade could occur.

Never operate the lawn mower unless you install a

cover plate, a mulch plate, grass deflector or a

grass chute and catcher.

1. Place spacer and spring onto grass deflector. Place the L

or the straight end of spring behind deck edge.

Storage

1. Clean the bagger attachment. Refer to Cleaning the

Bagger on page 21.

2. Inspect the bagger attachment for damage. Refer to

Inspecting the Bagger on page 21.

3. Make sure the bags are empty and thoroughly dry.

4. Check the belt for wear or cracks.

5. Store the machine in a clean, dry place, out of direct

sunlight. If you must store the machine outside, cover it

with a weatherproof cover. This protects the plastic

parts and extends the life of the machine.

Note: Make sure the L or the straight end of spring is

installed behind deck edge before installing the bolt as

shown in figure 39.

25

Page 26

Troubleshooting

pg

Problem Possible Causes Corrective Action

Abnormal vibration.

Reduced bagging performance.

Blower and tube plug too

frequently.

1. Cutting blade(s) bent or

unbalanced.

2. Blade mounting bolt is loose. 2. Tighten blade mounting bolt.

3. Loose blower pulley or pulley

assembly.

4. Blower belt is worn or

damaged.

5. Blower impeller is out of

balance.

6. Blower impeller is bent. 6. Do not use machine. Replace

1. Low engine speed. 1. Always operate the bagger at

2. Plugged screen. 2. Remove debris, leaves or grass

3. Loose blower belt. 3. Adjust the blower belt tension.

4. A plugged tube. 4. Locate and remove plugged

5. Full bags. 5. Empty bags.

1. Bags are too full. 1. Dump more frequently.

2. Low engine speed. 2. Always operate the bagger at

1. Install new cutting blade(s).

3. Tighten the appropriate pulley.

4. Replace the blower belt.

5. Contact Authorized Service

Dealer.

bent impeller.

full throttle.

clippings from the screen.

debris.

full throttle.

Debris blowout.

Blower impeller does not spin

freely.

3. Grass is too wet. 3. Cut grass when dry.

4. Grass is too long. 4. Cut no more that 2 to 3 inches

(51 to 76 mm) or 1/3 of the

grass height, which ever is

less.

5. Plugged screen. 5. Remove debris, leaves or grass

clippings from the screen.

6. Ground speed is too fast. 6. Drive slower at full throttle.

7. Worn blower belt. 7. Replace belt.

1. Bags are too full. 1. Dump more frequently.

2. Ground speed is too fast. 2. Drive slower at full throttle.

3. Mower is not leveled. 3. See the mower operator’s

manual for leveling the mower.

1. Plugged blower. 1. Remove debris, leaves or grass

clippings from the blower

impeller.

2. Impeller not aligned. 2. Contact Authorized Service

Dealer.

26

Page 27

Page 28

Landscape Contractor

Equipment (LCE)

The Toro Total Coverage Guarantee

A Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly promise to repair

the listed Toro product if defective in materials or workmanship.

This warranty applies to:

• ProLine Mid-Size Walk Power Mowers and Accessories

• Z Master Mid-Mount ZRTs and Accessories

The following time periods apply from the date of purchase:

Components

• Engines* 2 years

• Hydraulic Systems 2 years

• Traction Unit Frame 2 years

• Carrier Frame 2 years

• Deck Shells 2 years

• Deck Spindles 3 years Parts, 2 years Labor

• Z500 Series Clutches 2 years

• Remaining Components 1 year

This warranty includes the cost of parts and labor, but you must

pay transportation costs.

* Some engines used on Toro LCE products are warranted by the

engine manufacturer.

Warranty Period

Instructions for Obtaining Warranty Service

If you think that your Toro LCE product contains a defect in

materials or workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to

arrange service at their dealership. To locate a dealer

convenient to you, access our website at www.Toro.com. You

may also call our Toro Customer Care Department toll free at

888-865–5676 (U.S. customers) or 888-865–5691 (Canada

customers).

2. Bring the product and your proof of purchase (sales receipt) to

the Service Dealer.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, call us toll free at the

numbers above or write us at:

LCE Customer Care Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

You must maintain your Toro product by following the maintenance

procedures described in the Operator’s Manual. Such routine

maintenance, whether performed by a dealer or by you, is at your

expense.

There is no other express warranty except for special emission

system coverage on some products. This express warranty does

not cover the following:

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, blade sharpening, brake and

clutch adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear, accidents,

or lack of proper maintenance.

• Repairs necessary due to improper fuel, contaminants in the

fuel system, or failure to properly prepare the fuel system prior

to any period of non-use over three months.

• Pickup and delivery charges.

• Operational misuse, neglect, or accidents.

• Repairs or attempted repairs by anyone other than an

Authorized Toro Service Dealer using Toro approved parts.

All repairs covered by this warranty must be performed by an

Authorized Toro Service Dealer using Toro approved replacement

parts.

Repair by an Authorized Toro Service Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty.

Some states do not allow exclusions of incidental or

consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and

limitations may not apply to you.

All implied warranties of merchantability (that the product is

fit for ordinary use) and fitness for use (that the product is fit

for a particular purpose) are limited to the duration of the

express warranty.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Owner Responsibilities

Items and Conditions Not Covered

General Conditions

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0037 Rev. E

Loading...

Loading...