Toro 78478 Parts Catalogue

60 in. Mower

Z–Master 300 Series Attachment

Model No. 78478–210000001 and Up

Form No. 3325-798

Parts Catalog

Ordering Replacement Parts

To order replacement parts, please supply: the part

number, the quantity, and the description of each

part desired.

Understanding Reference Numbers

Each identified part in an illustration has a reference

number. The reference number for a part also appears in

the parts list, along with other information about the part.

This catalog uses two special reference number formats,

one to indicate parts in a service assembly and another

to indicate the quantity of a given part in an illustration.

Service Assembly Reference Numbers

Parts in service assemblies have reference numbers in

the form a:b.

the entire service assembly and the b represents a

sequential number unique to each part within the service

assembly.

The a represents the reference number of

The TORO Company — 2001

All Rights Reserved

For example, a wheel assembly might be identified by

reference number 6, the tire by 6:1, the valve by 6:2,

and the wheel by 6:3. When you order the assembly

identified by reference number 6, you receive all parts

identified by reference numbers 6:1, 6:2, and 6:3.

However, you may also order any part individually.

Reference numbers of this type appear in illustrations

and in part lists.

Reference Numbers Indicating Quantity

In an illustration, if a reference number indicates more

than one part, the reference number has the form nX y.

The n represents the quantity of the part, the X is the

multiplication symbol, and the y represents the reference

number.

For example, in an illustration, the reference number

2X 37 means that two of the parts identified by reference

number 37 are indicated.

3325–798

Contents

Description Page Description Page

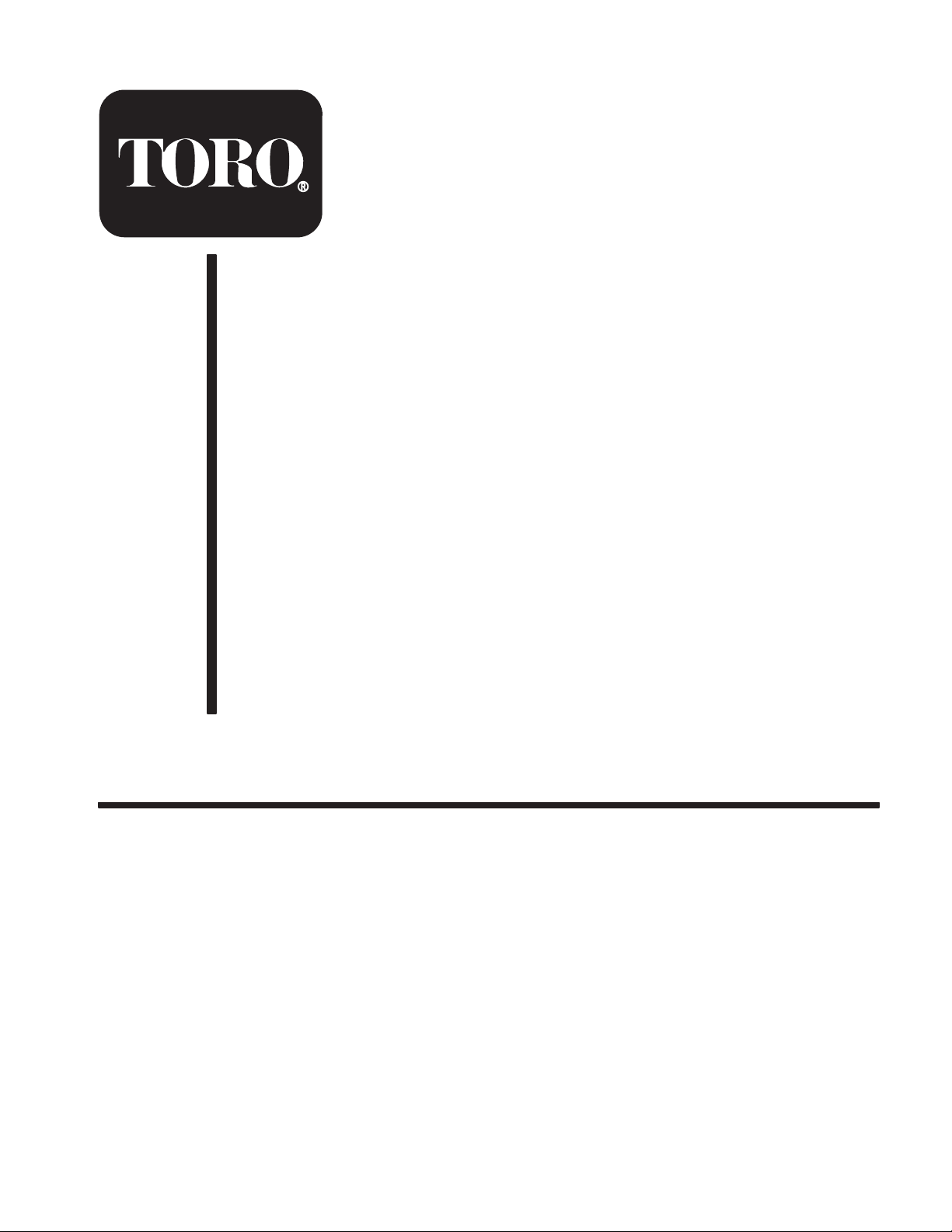

Deck Assembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

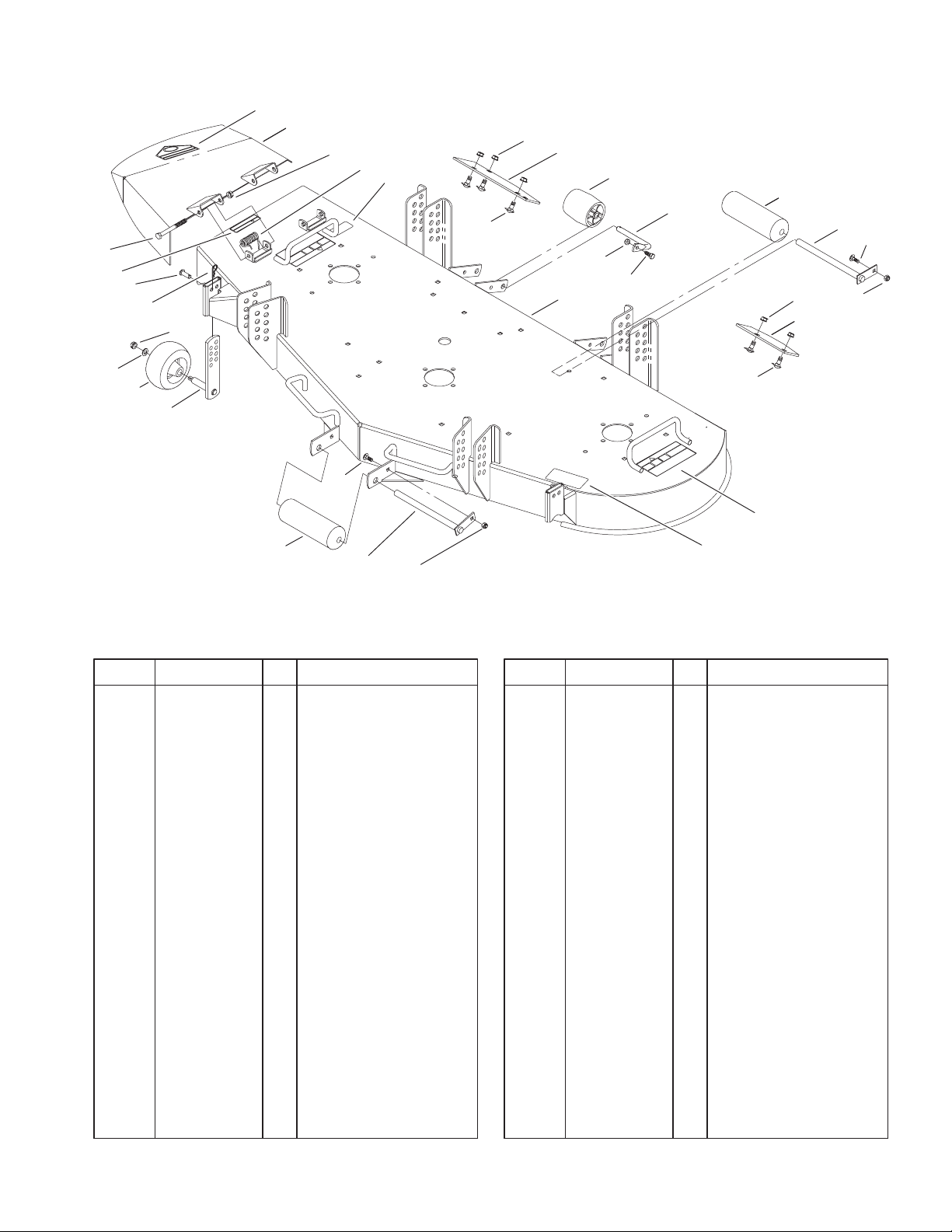

Deck Plate, Spindle and Blade Assembly 4. . . . .

Drive and Idler Assembly 5. . . . . . . . . . . . . . . . . . .

Gearbox Assembly No. 100–5846 6. . . . . . . . . . .

Carrier Frame Assembly 7. . . . . . . . . . . . . . . . . . .

Footrest Assembly 8. . . . . . . . . . . . . . . . . . . . . . . .

Part Description Abbreviations

Part descriptions in this catalog may include the following abbreviations.

Abbreviation Meaning Abbreviation Meaning

AR as required. . . . . . . . . . . . . . . . .

ASM assembly. . . . . . . . . . . . . . . .

CARR carriage. . . . . . . . . . . . . .

DEG degrees. . . . . . . . . . . . . . . .

FH flat head. . . . . . . . . . . . . . . . .

GA gauge. . . . . . . . . . . . . . . . .

HF hex flange. . . . . . . . . . . . . . . . .

HH hex head. . . . . . . . . . . . . . . . .

HHF hex head flange. . . . . . . . . . . . . . . .

HLH hex lag head. . . . . . . . . . . . . . . .

HJ hex jam. . . . . . . . . . . . . . . . . .

HOC height-of-cut. . . . . . . . . . . . . . . .

HS hex socket. . . . . . . . . . . . . . . . .

HSBH hex socket button head. . . . . . . . . . . . . .

HSFH hex socket flat head. . . . . . . . . . . . . . .

HSH hex socket head. . . . . . . . . . . . . . . .

HWH hex washer head. . . . . . . . . . . . . . .

HWHTF hex washer head. . . . . . . . . . . . .

thread forming

HYD hydraulic. . . . . . . . . . . . . . . .

INC incorporated. . . . . . . . . . . . . . . . .

LH left hand. . . . . . . . . . . . . . . . .

NI nylon insert. . . . . . . . . . . . . . . . . .

PPH Phillips pan head. . . . . . . . . . . . . . . .

PTH Phillips truss head. . . . . . . . . . . . . . . .

PTO power take off. . . . . . . . . . . . . . . .

RH right hand. . . . . . . . . . . . . . . . .

SFH slotted fillister head. . . . . . . . . . . . . . . .

SHH slotted hex head. . . . . . . . . . . . . . . .

SQH square head. . . . . . . . . . . . . . . .

SHWH slotted hex washer head. . . . . . . . . . . . . .

SPH slotted pan head. . . . . . . . . . . . . . . .

SRH slotted round head. . . . . . . . . . . . . . . .

STD standard. . . . . . . . . . . . . . . .

TAP self tapping. . . . . . . . . . . . . . . .

TTH Torx truss head. . . . . . . . . . . . . . . .

WH wing head. . . . . . . . . . . . . . . . .

2

28

12:2

26

25

3325–798

2:1

2

2

3

4

4

12:4

3

3

6

11

7

9

12

8

10

13

13

3

16

14

15

9

23

22

21

15

13

14

DescriptionPart No. Qty.Ref. No. DescriptionPart No. Qty.Ref. No.

2 94–9589 1 Chute ASM

2:1 93–1122 1 Decal–Danger

3 3296–39 9 Nut–Lock, NI

4 40–6230 2 Spring

6 94–9510–01 1 Plate–Wear, RH

7 3231–2 5 Screw–CARR

8 322–4 2 Screw–HH

9 3296–29 4 Nut–Lock

10 110847 2 Roller–Shaft

11 108798 2 Roller

12 98–4364 1 Deck ASM

12:1 66–1340 2 Decal–Danger

12:2 66–6380 1 Decal–Danger

12:3 68–3380 1 Decal – Wheel

Adjustment

12:4 105–2625 1 Decal–Safety STD

13 113349 2 Roller–Anti Scalp

14 113603 2 Roller–Shaft

15 3230–1 2 Screw–CARR

16 79–1290–01 1 Plate–Wear, LH

21 68–2350 2 Gage–Wheel

22 68–2730 2 Gage–Wheel

23 3256–24 2 Washer–Flat

25 3290–467 2 Pin–Hair

26 283–2 2 Pin–Clevis

28 323–42 2 Screw–HH

7

12:1

12:3

9

Sheet No.:2

Deck Assembly

3

3325–798

1

2

3

4

9

5

6

7

16

9

14:1

14

14:1

12

11

Deck Plate, Spindle and Blade Assembly

DescriptionPart No. Qty.Ref. No. DescriptionPart No. Qty.Ref. No.

1 302–2 3 Fitting–Grease

2 3296–60 3 Nut–Lock, NI

3 94–9534 3 Pulley – Spindle

4 3235–22 12 Screw–HH

5 94–9547 1 Decal – Belt

Installation

6 68–8340 1 Decal–Torque

7 3296–39 10 Nut–Lock, NI

8 3231–2 10 Screw–CARR

9 88–8950 3 Decal–Warning

10 327–6 3 Screw–HH

11 920260 6 Washer–Special

12 112947 3 Blade

13 113512 3 Cup–Spindle

14 17–8359 3 Spindle Housing ASM

14:1 113514 2 Bearing

14:3 94–2315 1 Shaft–Spindle

15 3256–24 A/R Washer–Flat

16 98–4359–01 1 Plate–Top

8

9

15

14:3

13

10

Sheet No.:3

4

Loading...

Loading...