Page 1

HY13-1521-M2/US

Parker Product

Effective: January, 2010

UHT

Product Series

Service Procedure

Page 2

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS

DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized

distributors provide product and/or system options for further investigation by users having technical expertise. It

is important that you analyze all aspects of your application and review the information concerning the product or

system in the current product catalog. Due to the variety of operating conditions and applications for these

products or systems, the user, through its own analysis and testing, is solely responsible for making the final

selection of the products and systems and assuring that all performance, safety and warning requirements of the

application are met.

The products described herein, including without limitation, product features, specifications, designs, availability

and pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

© Copyright 2009, Parker Hannifin Corporation, All Rights Reserved

2

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 3

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Section 1 General Information

Definitions/Disclaimer 4

Introduction/Design Features 5

Troubleshooting Guide 6

Troubleshooting Checklist 7

Tools & Materials Required for Servicing 8

Flow Test Instructions 9-10

Exploded Views 11-20

Section 2 Reseal & Repair

Disassembly & Assembly - Fan Option 21

Disassembly 22-29

Assembly 30-38

Section 3 Maintenance

System Maintenance Tips 39

Hydraulic Fluids 39

Filtration 39

Oil Temperature 39

3

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 4

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

WARNING A warning describes hazards or unsafe practices which could result in severe

personal injury or death.

CAUTION

A caution describes hazards or unsafe practices which could result in personal injury or

product or property damage.

NOTE A note gives key information to make fo

llowing a procedure easier or quicker.

Disclaimer

This Service Manual has been prepared by Parker Hannifin Corporation for reference and u se by mechanics

who have been trained to repair and service hydraulic pumps on commercial and non-commercial equipment

applications. Parker Hannifin Corporation has exercised reasonable care and diligence to present accurate, clear

and complete information and instructions regarding the techniques and tools required for maintaining, repairing

and servicing the Parker UHT Series. Since this is a general Service Manual, the photographs and illustrations

may not look exactly like the UHT being serviced. The procedures, therefore, must be carefully read and

understood before servicing.

If inspection or testing reveals evidence of abnormal wear or damage to the UHT or if you encounter

circumstances not covered in the Manual, STOP - CONSULT THE EQUIPMENT MANUFACTURER’S SERVICE

MANUAL AND WARRANTY. DO NOT TRY TO REPAIR OR SERVICE A UHT Series WHICH HAS BEEN

DAMAGED OR INCLUDES ANY PART THAT SHOWS EXCESSIVE WEAR UNLESS THE DAMAGED AND

WORN PARTS ARE REPLACED WITH ORIGINAL PARKER REPLACEMENT AND SERVICE PARTS AND

THE UNIT IS RESTORED TO PARKER SPECIFICATIONS FOR THE UHT Series.

It is the responsibility of the mechanic performing the maintenance, repairs or service on a particular UHT Series

to (a) inspect the unit for abnormal wear and damage, (b) choose a repair procedure which will not endanger

his/her safety, the safety of others, the equipment or the safe operation of the UHT Series, and (c) fully inspect

and test the UHT Series and the hydraulic system to ensure that the repair or service of the UHT Series has

been properly performed and that the UHT Series and hydraulic system will function properly.

Conversions

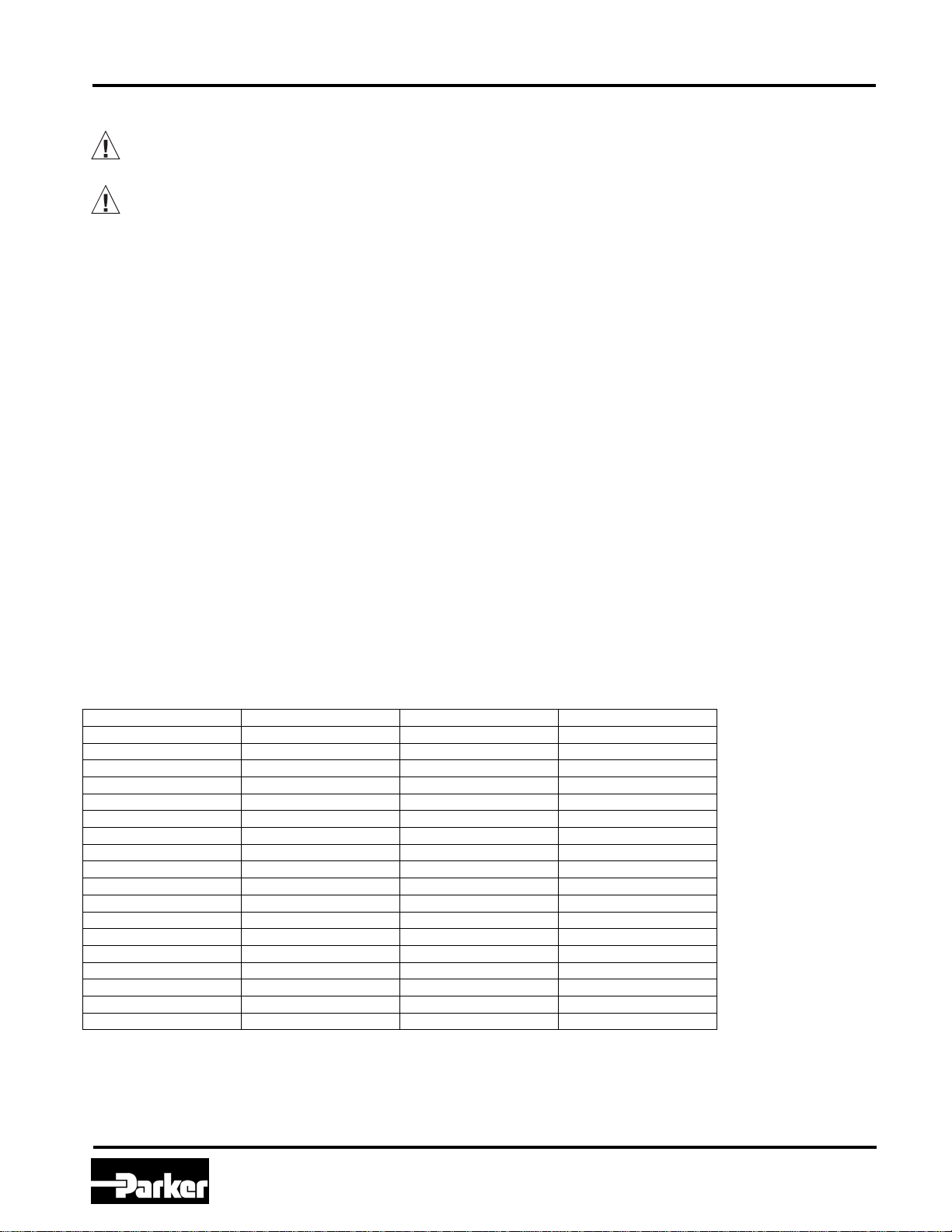

Inches Mm Inches mm

.020 .511 1.060 26.92

.021 .531 1.295 32.89

.029 .741 1.297 32.94

.030 .760 1.396 35.46

.111 2.81 1.398 35.51

.119 3.02 1.620 41.15

.152 3.86 1.622 41.20

.160 4.06 1.983 50.37

.296 7.52 1.985 50.42

.304 7.72 2.120 53.85

.460 11.68 2.122 53.90

.470 11.94 2.233 56.72

.500 12.70 2.235 56.77

.585 14.86 2.483 63.07

.595 15.11 2.485 63.12

.660 16.76 2.500 63.5

.675 17.15 2.88 73.2

1.058 26.87

4

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 5

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Introduction

The three-column format used in this Service Manual will help make it easy for you to service a UHT. Column 1

illustrates the procedure with photographs, Column 2 gives a brief key for each step, and Column 3 explains in

detail the procedure you should follow. Pay special attention to the notes, cautions, and warnings.

This manual contains troubleshooting information and checklists. With them you can diagn ose a hydraulic

system problem without removing the entire assembly the checklists will help you to determine where the

problem may be.

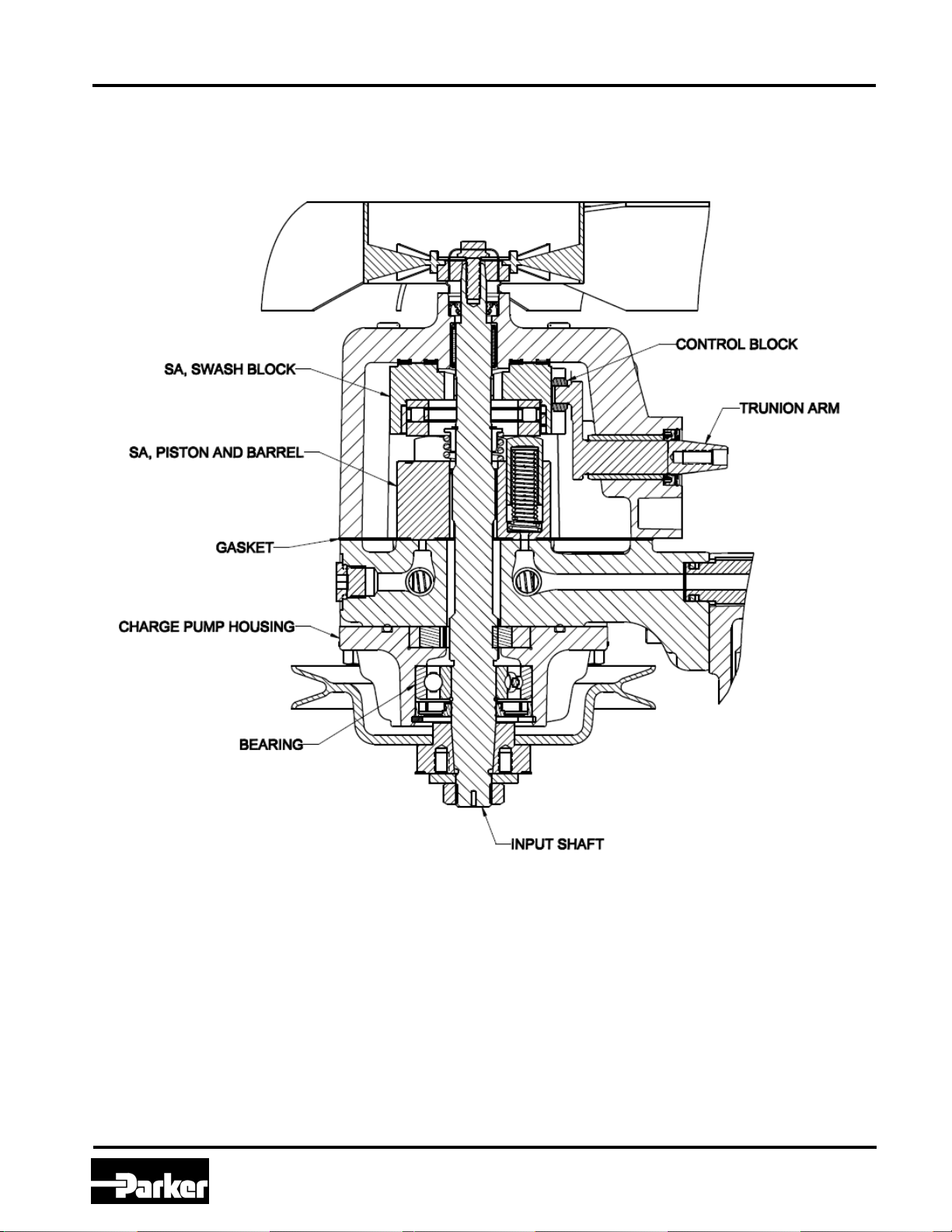

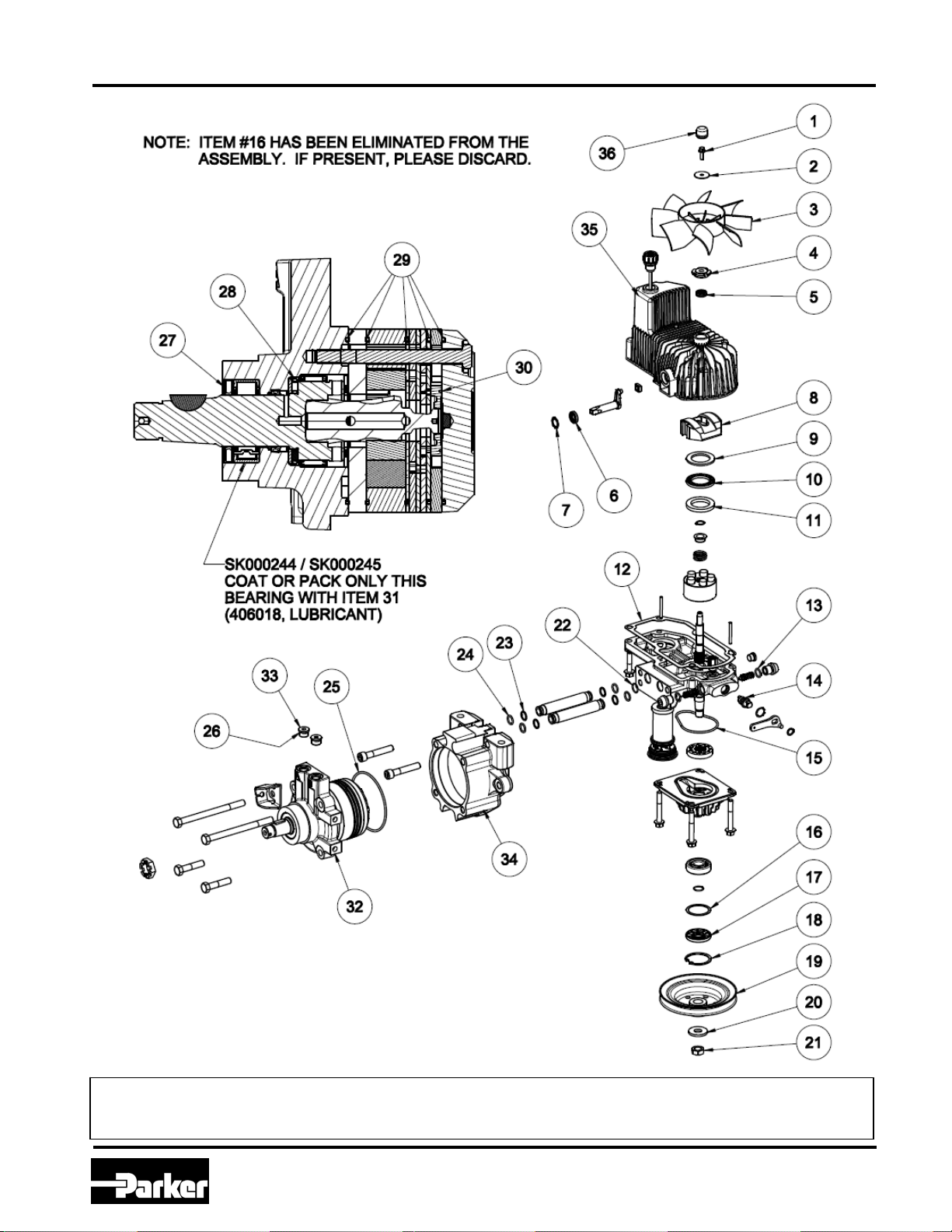

Item numbers on the exploded view correspond with item numbers used throughout the Service Manual.

As you gain experience in servicing UHT Series, you may find that some information in this Service Manual

could be clearer and more complete. If so, let us know about it. Don’t try to second-guess the Service Manual; if

problems occur that you cannot solve, please contact your local OEM approved distributor. Servicing UHT Series

should be safe and productive.

DESIGN FEATURES

UHT

Large area cooling fins result in a cooler running system

Top housing and charge pump cover are sturdy, lightweight aluminum, excellent at

dispersing heat, resulting in an overall cooler system

Forged trunnion shaft increases shaft strength and lengthens pump life

Double caged thrust bearing improve lubrication and vibration absorption, thus

lengthening life of pump

Torqmotor

Roller vane to reduce friction and internal leakage and to maintain efficiency

A patented orbiting commutator system for less wear and longer life

A unique high-pressure shaft seal that eliminates the need for case drain

Manifold designed to improve operating efficiency

Roller vane and sealed commutation assure high volumetric efficiency and smooth low

speed operation

5

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 6

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Troubleshooting Guide

NOTE

Before troubleshooting any system problem, check

service literature published by the equipment and/or

component manufacturers. Follow their instructions, if

given, for checking any component other than the

transmission.

Preparation

Make your troubleshooting easier by preparing as

follows:

• work in a clean, well-lighted place

• have proper tools and materials nearby

• have an air pressure source.

WARNING

Since solvents are flammable, be extremely careful

when using any solvent. Even a small explosion could

cause injury or death.

WARNING

Wear eye protection and be sure to comply with

OSHA and other maximum air pressure

requirements.

Preliminary Checks

Hydraulic systems are often trouble-free. Hence, the

problem an operator complains of could be caused by

something other than the hydraulic components.

Thus, once you have determined that a problem

exists, start with the easy-to-check items, such as:

• Parts damaged from impact that were not properly

repaired, or that should have been replaced

• Improper replacement parts used in previous

servicing

• Mechanical linkage problems such as binding,

broken or loose parts, or slipping belts

Hydraulic Components

If you think the problem is caused by a hydraulic

component, start by checking the easy-to-reach

items.

Check all belts for cracks, hardening or other signs of

wear. Check all pulleys, fans and bolts to make sure

they are tightened to specified torque value. Look for

leaks, especially at coupling shaft, plugs and fittings.

Next, go to the reservoir and filters. Check fluid level

and look for air bubbles. Check external filter(s). A

filter with a maximum of 25 - 30 micron filtration is

recommended for the UHT system.

Visually check other components to see if they are

loosely mounted, show signs of leaks, or other

damage or wear.

Excessive heat in a hydraulic system can create

problems that can easily be overlooked. Every

system has its limitation for the maximum amount of

temperature. After the temperature is attained and

passed, the following can occur:

• oil seal leaks

• pump loss of efficiency (resulting in lower

transmission speeds)

• pump failure

• belts become hard and brittle

• pulley lose

A normal temperature range means an efficient

hydraulic system. Consult the manuals published by

equipment and/or component manufacturers for

maximum allowable temperatures and hydraulic tests

that may be necessary to run on the performance of

the hydraulic components. The UHT is not

recommended for hydraulic systems with maximum

temperatures above 280

o

F (137o C).

6

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 7

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

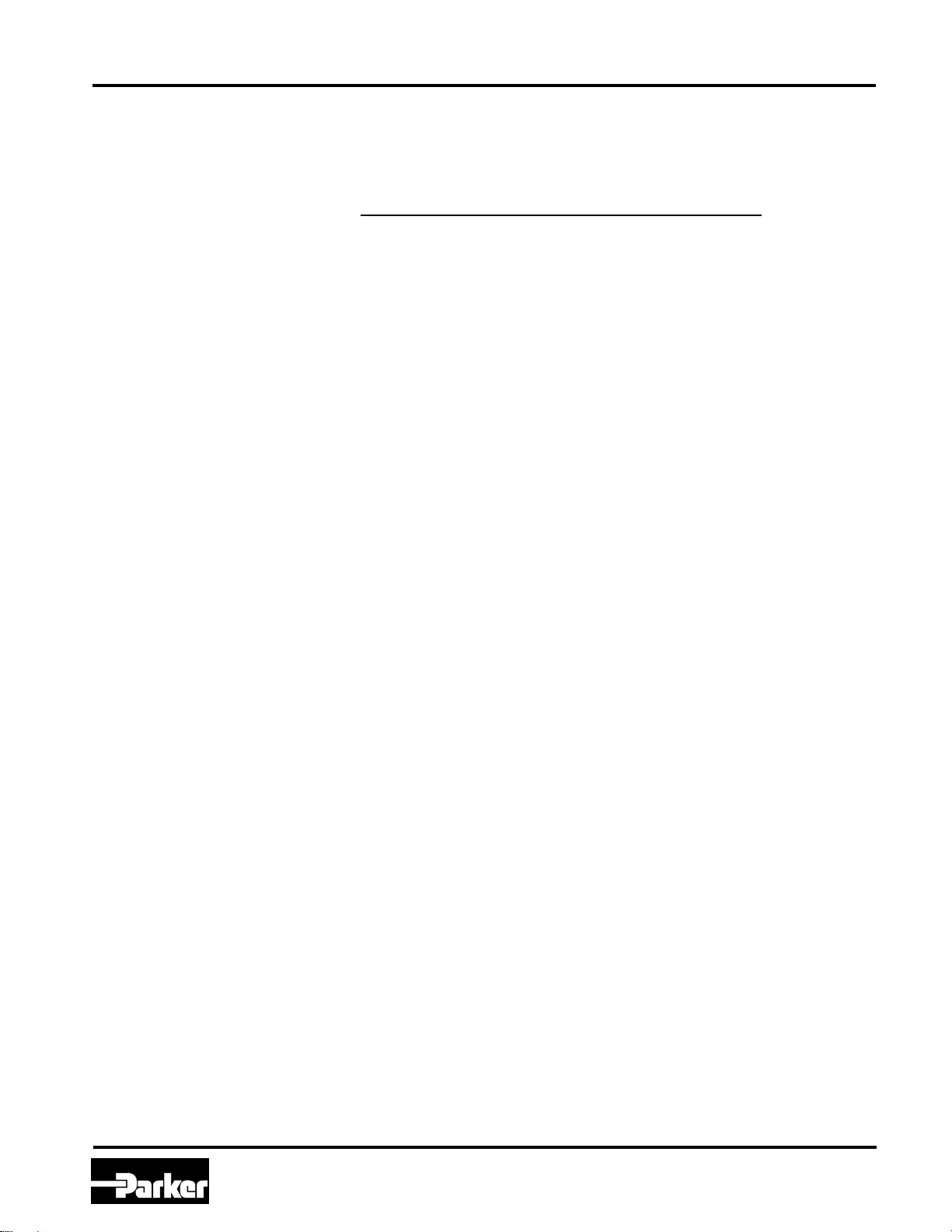

Troubleshooting Checklist

Trouble Cause Remedy

Oil Leakage

Operates Hot

1. Fitting loose, worn or

damaged.

2. Oil seals deteriorated

by excess heat.

1. Debris buildup Remove debris

2. Cooling fan damaged Replace fan

Check & replace damaged fittings or

“O” rings. Torque to manufacturers

specifications.

Replace oil seals by disassembling

unit.

No/Low Power

3. Oil level low or

Fill or change filter

contaminated

4. Excessive loading Reduce vehicle load

5. Air trapped in system

Run vehicle slowly forward and then

reverse several times

6. Mowing conditions Heavy grass or embankments

1. Engine speed low Adjust setting

2. Oil level low or

Fill or change filter

contaminated

3. Bypass turned Turn to closed (horizontal) position

4. Excessive loading Reduce vehicle load

5. Air trapped in system Purge per instructions

6. Suspect internal Disassemble and inspect

7. Pulley or belt loose

Tighten to specifications

Noisy Unit

1. Excessive speed input Adjust input speed above 1800 rpm

and below 3600 rpm

2. Oil level low or

Fill or change filter

contaminated

3. Excessive loading Reduce vehicle load

4. Air trapped in system Run vehicle slowly forward and then

reverse several times

5. Bypass valve open

Turn to closed (horizontal) position

7

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 8

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Tools and Materials Required for Servicing

• Clean, petroleum-based solvent

• Emery paper

• Vise with soft jaws

• Air-pressure source

• Arbor press

• Flat screwdriver

• Grease pencil or paint pen

• Wheel puller

• 1/4" torque wrench : 155-190 in-lbs, 282-342 in-lbs, 90-110 in-lbs, 160-200 in-lbs

• Sockets: 3/8" drive ratchet, 5/16" hex, 1/4” hex, 3/8” hex, 10mm, 14mm, 16mm

• Allen wrenches: 5mm, 6mm, 1/4" and 3/8”

• Combination wrenches:

• Locking pliers

• Internal & external snap ring pliers

• Loctite ™ 242

• Grease – Mobil Mobilith SHC PM 460

• Oil – Recommended OEM Type Oil

• Four inch adjustable spanner wrench (Armstrong 34-157) or three inch fixed spanner (Armstrong 34-

124)

CAUTION

Mixing greases that have different bases can be detrimental to bearing and seal life.

8

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 9

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

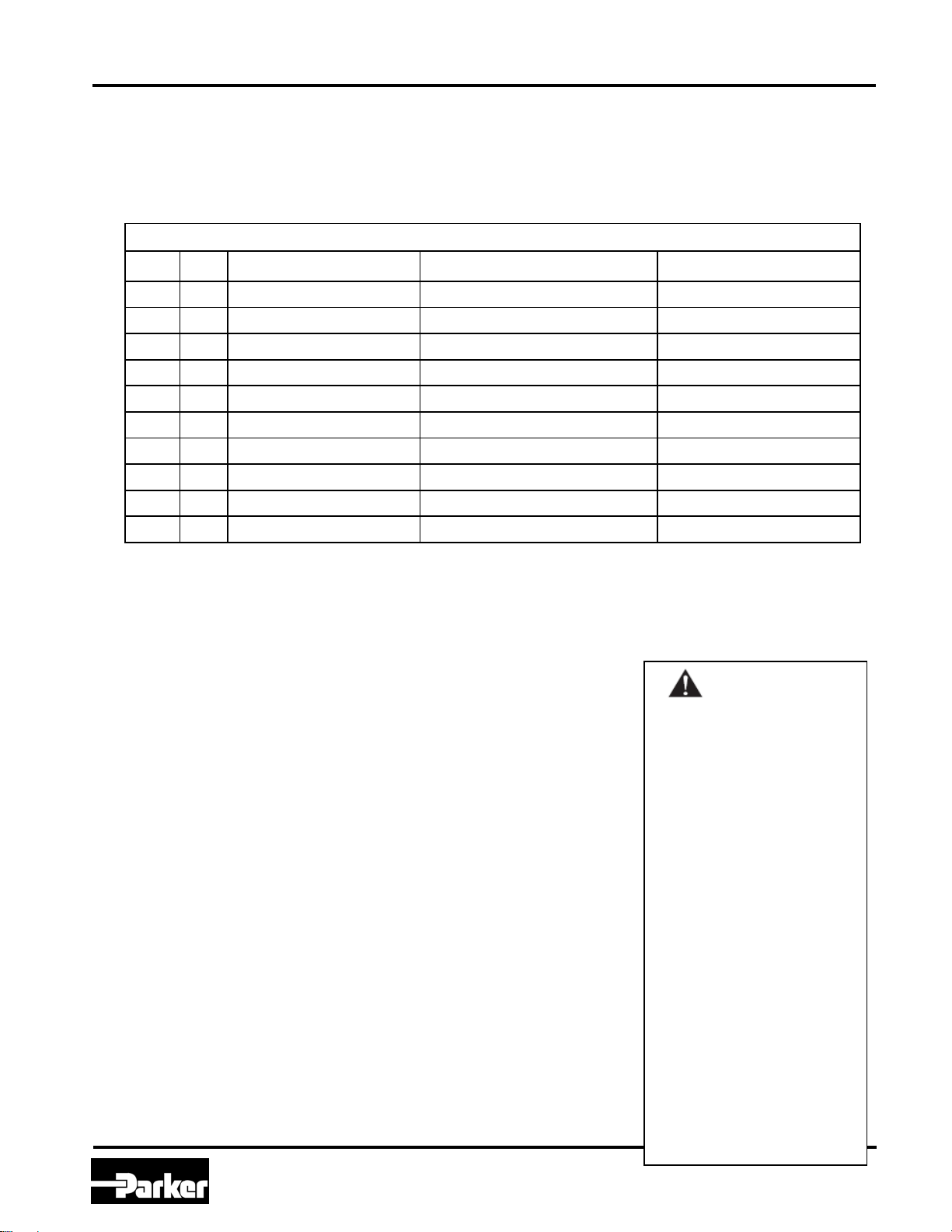

UHT Flow Test Kit Instructions

SK000251

Parts List

Item Qty Part Number

1

2 1 411102 Needle Valve 525 in lbs.

3 2 414003 Gauge Fitting “T” 165-525 in lbs.

4 2 411103 3000 PSI Pressure Gauge 165 in lbs.

5 2 411104 Hose Assembly 525 in lbs.

6 2 414005 Reducer Fitting 525-950 in lbs.

7 1 411105 20 GPM Flow Meter 525 in lbs.

8 1 409350 Diagnostic Plug 525 in lbs.

9 1 SAE-J514-8-8-070120CF Straight Thread Fitting 525 in lbs.

- 1 SK000251 Service Bulletin N/A

1 414002 SAE Swivel Fitting 525 in lbs.

Description

Torque

Overview:

The Flow Test Kit allows the dealer to easily determine if UHT pump is faulty by isolating the

pump section from the wheel motor. The following information describes how to test the pump

by installing the Flow Test Kit and simulating a wheel motor load.

Procedure:

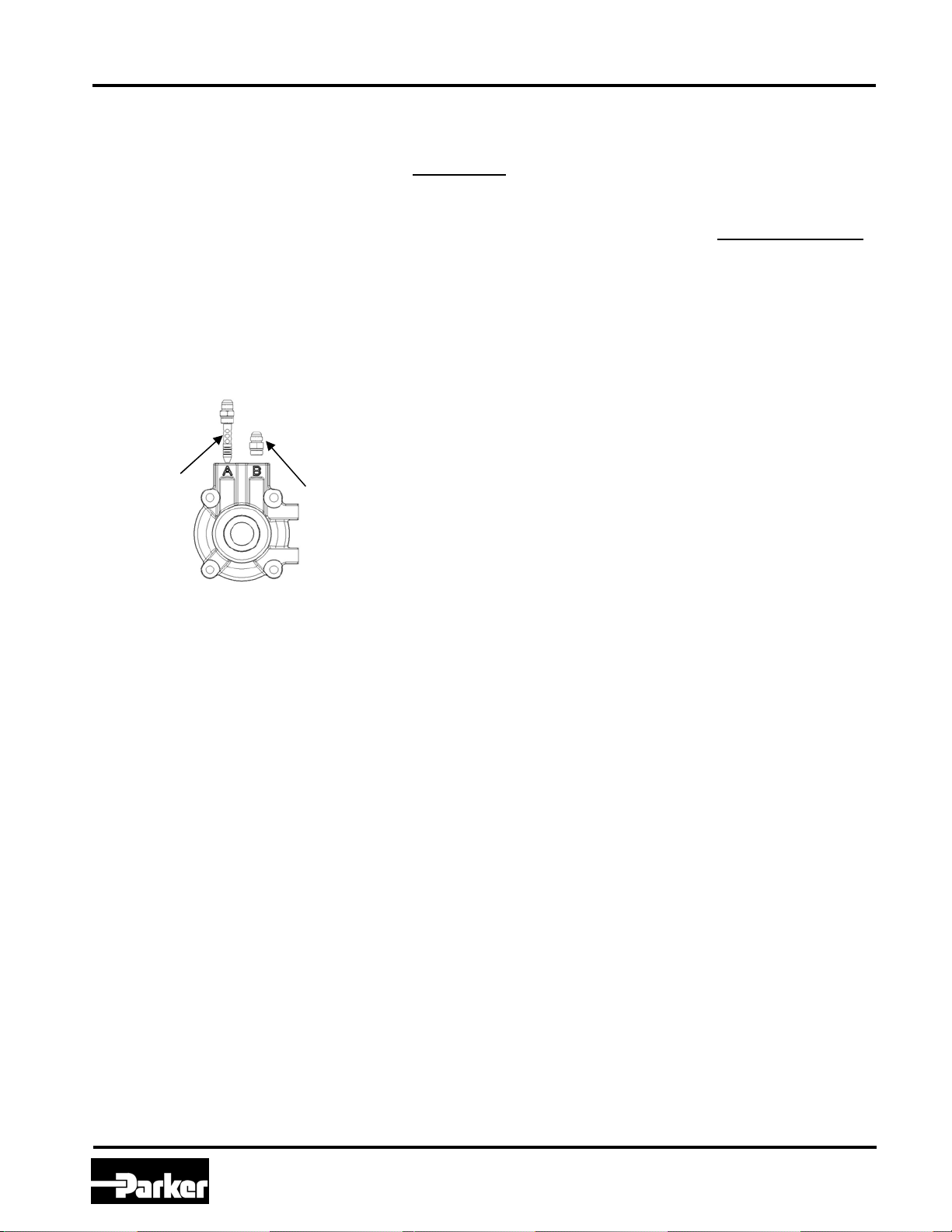

1. Raise the drive tires off the ground and block the remaining

tires to prevent movement of the vehicle during testing.

2. Remove wheel from the hub to gain access to motor.

3. Ensure the pump bypass lever is in the “Closed” position

(horizontal).

4. Isolate the pump from the wheel motor by removing the two

plugs from the top of the wheel motor assembly and installing

the Flow Test Kit. Install the Diagnostic Plug in port “A”, and the

Straight Thread Fitting in port “B”. Take precautions to ensure

no debris gets into the wheel motor system ports.

There is no need to determine the direction of flow with the

Parker flow tester. The flow meter may be connected in either

direction into the high pressure system lines.

9

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

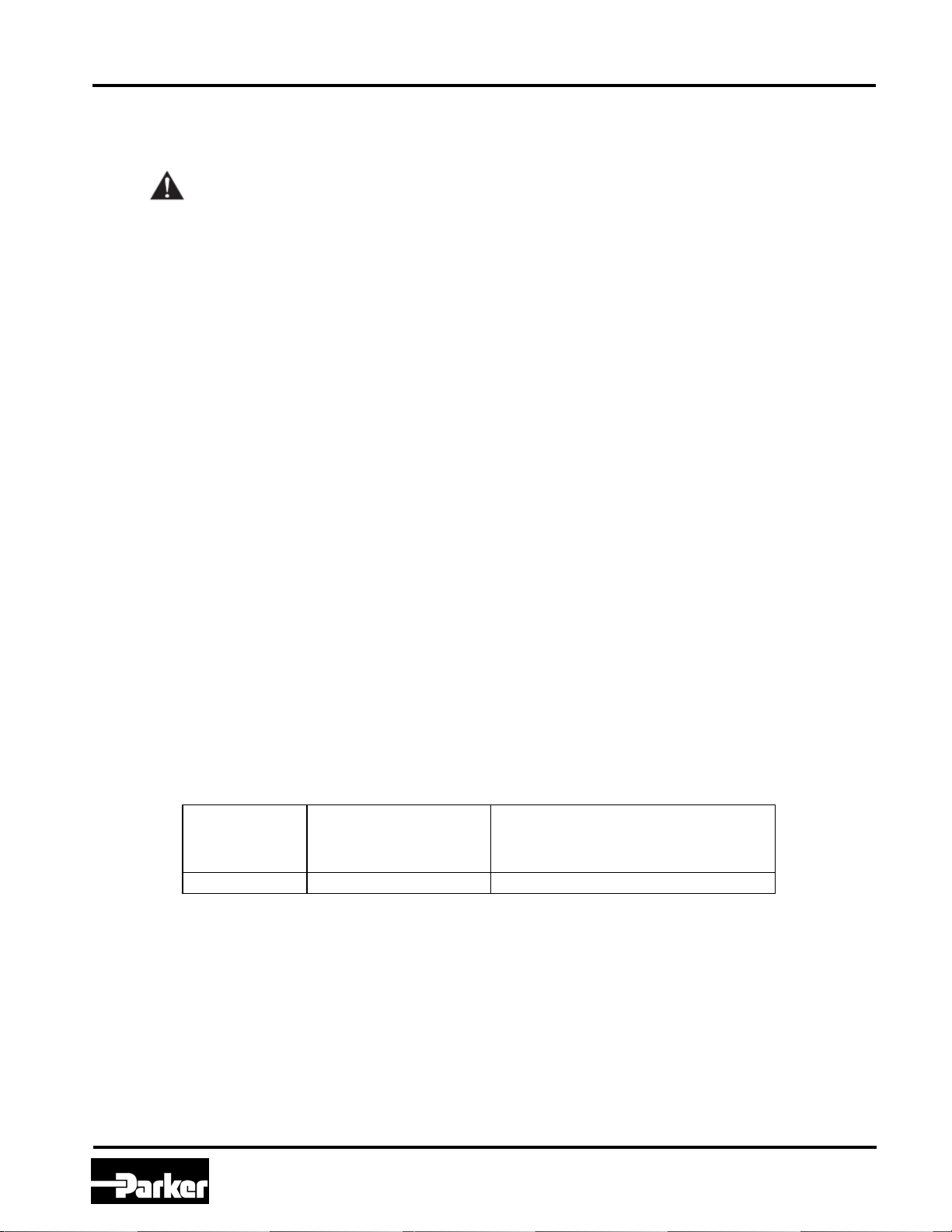

WARNINGS

Portions of this procedure

require testing while the

vehicle is operated in an

elevated position.

Ensure vehicle is properly

secured to prevent injury

to the service technician

or bystanders.

Do not attempt any adjustments with the engine

running. When working

around vehicle linkages,

use extreme caution.

High temperatures can be

generated.

Follow all safety procedures in the vehicle owner’s manual.

Page 10

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

CAUTION: All fittings and hoses must be securely attached. The test is

accomplished using the vehicle’s high pressure system lines. Failure to secure

connections could result in bodily injury.

5. Completely open the restriction valve.

6. Start the engine and, if required, engage the drive pulley.

7. Slowly bring engine up to maximum operating speed.

8. Move the vehicle’s directional control lever on the pump being tested all the way into the

forward position. Lock the control arm into position to prevent false readings.

9. Continue to operate without any load to allow the system oil temperature to rise.

NOTE: Raising the temperature of the oil will make a difference in your readings. To complete

the test accurately, the oil temperature should fall between 110˚ and 140˚ F.

10. Tighten the restriction valve until the difference between the pressure gauge readings is

300 psi (21 bar). Record the flow reading from the bi-directional flow meter.

11. Tighten the restriction valve until the difference between the pressure gauge readings is

1000 psi (69 bar) and record the flow reading again.

12. The maximum allowable flow rate change is shown below. If the difference exceeds this

level, the pump is unacceptable.

13. When testing is complete, re-install the motor port plugs. Torque to 35 to 50 ft-lb.

Displacement

Series

cc/rev

(nominal)

UHT 12 to 16 1.0

* Max. Allowable Flow Rate Change is equal to the flow rate at 300 psi minus the flow rate at 1000 psi.

Max. Allowable Flow Rate

Change* (gpm)

10

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

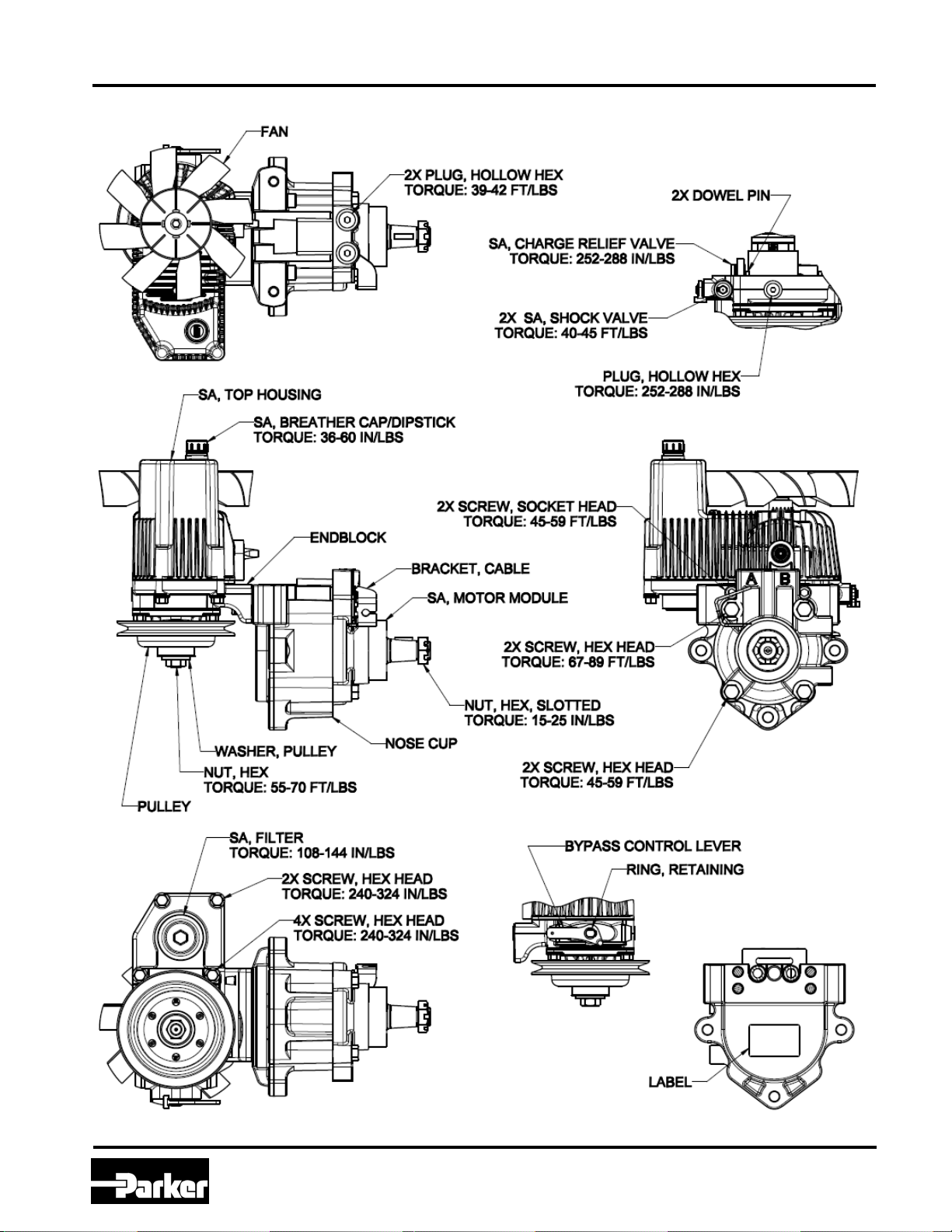

Page 11

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

EXAMPLE:

First Reading 300 psi (21 bar) 5 gpm (19 l/min)

Second Reading 1000 psi (69 bar) - 3 gpm (11 l/min)

Difference 2 gpm (8 l/min)

By subtracting the second reading from the first, a

defective pump can be identified. In the example

above, 2 gpm indicates a defective pump.

11

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 12

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

12

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 13

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

13

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 14

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Note: When servicing UHT assemblies with a serial number code of 09256 or earlier, item 29 is not req uired.

When servicing UHT assemblies with a serial number code of 09257 or after, item 25 is not required. Though item 22 is

provided in the seal kit, it can be discarded if the endblock does not include a machined seal groove.

14

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 15

Service Manual

Series HB Hydrostatic Transmission

HY13-1521-M2/US

General Information

15

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

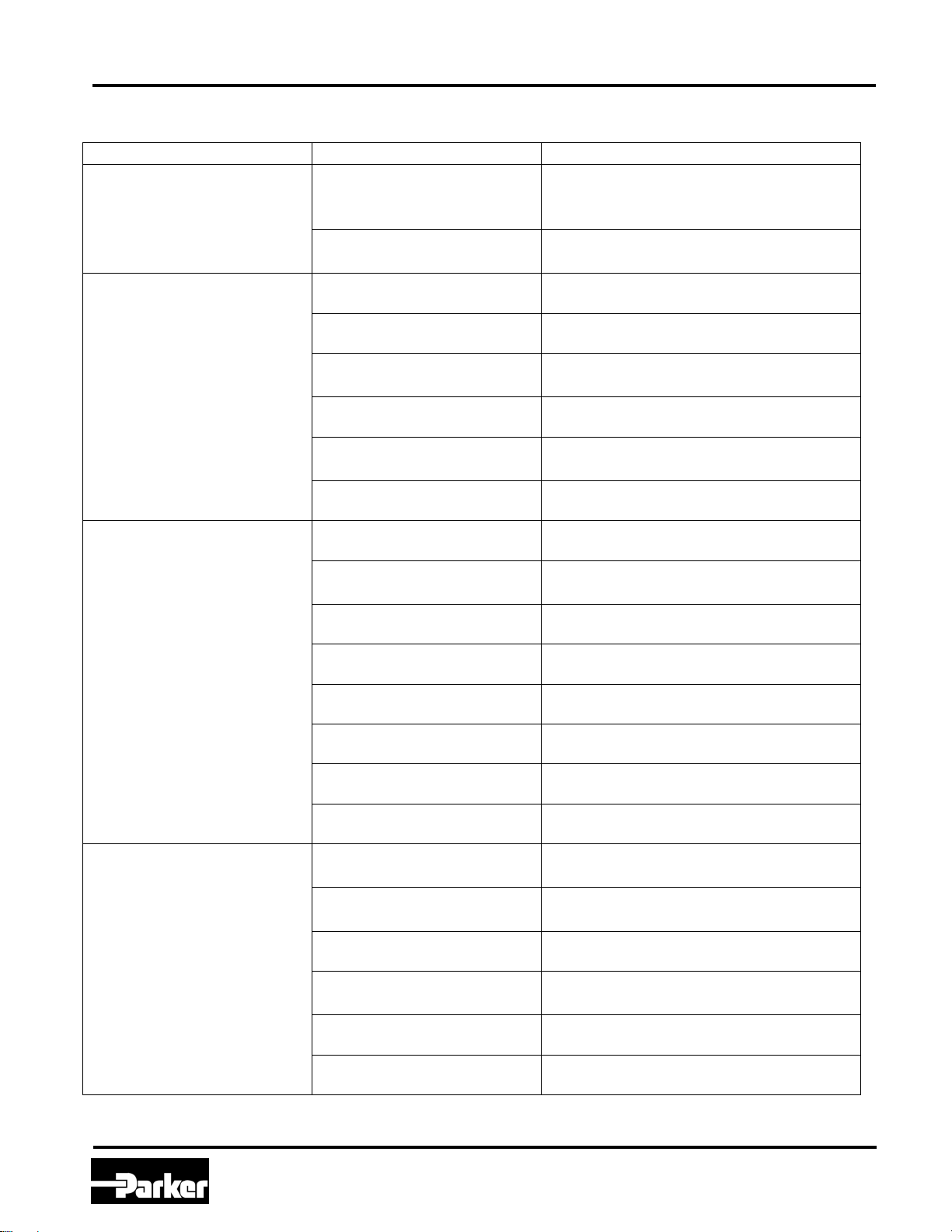

SK000243 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

22 4 032202-017

PACKING, PREFORMED, O-RING SEAL

23 4

032860-001

RETAINER, PACKING BACKUP

24 1

032203-114

PACKING, PREFORMED, O-RING SEAL

SK000244 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

27 1

478035

SEAL

28 1

032818

SEAL, SHAFT

31 1

406018

LUBRICANT PACK SK000245 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

22 1 032202-017

PACKING, PREFORMED, O-RING SEAL

23 4 032860-001

RETAINER, PACKING BACKUP

24 4 032203-114

PACKING, PREFORMED, O-RING SEAL

25 1

032203-249

PACKING, PREFORMED, O-RING SEAL

26 2 032206-018

PACKING, PREFORMED, O-RING SEAL

27 1 478035

SEAL, (DIRT & WATER)

28 1

032818

SEAL, SHAFT

29 6 032820

O-RING SEALS

30

1 032439

SEAL, COMMUTATOR

31 1

406018

LUBRICANT PACK SK000246- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

8 1 HP2013000-A1

SA, SWASH BLOCK

9 1 069010

WASHER, THRUST

10 1

063048

BEARING, THRUST

11 1

069011

WASHER, THRUST

SK000247 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

5

1 032090

SEAL, FAN DRIVE

6 1

478087

SEAL, TRUNNION ARM

7 1

401303

RING, RETAINING

12

1 034001

GASKET

13 2 032203-114

PACKING, PREFORMED, O-RING SEAL

14 1

032202-111

PACKING, PREFORMED, O-RING SEAL

15

1 032202-239

PACKING, PREFORMED, O-RING SEAL

16

** WASHER, SEAL (NOT REQUIRED) **

17 1

478086

SEAL, SHAFT

18 1

401114

RING, RETAINING

22 1 032202-017

PACKING, PREFORMED, O-RING SEAL

23

4 032860-001

RETAINER, PACKING BACKUP

24 4 032203-114

PACKING, PREFORMED, O-RING SEAL

SK000249 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

19 1 403855

PULLEY

20 1

028413

WASHER

21 1

025164

NUT SK000250- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

1 1

100000025-038

SCREW, HEX FLANGE UNRC

2 1

028020

WASHER, FAN DRIVE

3 1

420066

FAN, 8.3 INCH

4 1

100000032

SPACER, FAN

Page 16

Service Manual

Series HB Hydrostatic Transmission

HY13-1521-M2/US

General Information

16

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

SK000257 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240ZF080UHTA

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

25 1 032203-249

PACKING, PREFORMED, O-RING SEAL

1 SK000243

SERVICE KIT, SEALS

SK000258 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240ZF081UHTA

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

25 1 032203-249

PACKING, PREFORMED, O-RING SEAL

1 SK000243

SERVICE KIT, SEALS

SK000259 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0280ZF080UHTB

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

25 1 032203-249

PACKING, PREFORMED, O-RING SEAL

1 SK000243

SERVICE KIT, SEALS

SK000260- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0280ZF081UHTB

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

25 1 032203-249

PACKING, PREFORMED, O-RING SEAL

1 SK000243

SERVICE KIT, SEALS

SK000261- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240YF080UHTC

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

SK000262 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240YF081UHTC

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

SK000263- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0280YF080UHTD

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

SK000264 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0280YF081UHTD

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

SK000265- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240YF080UHTE

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

SK000266 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

32 1 TL0240YF081UHTE

SA, MOTOR

33 2 036016-008

PLUG, HOLLOW HEX

1 SK000243

SERVICE KIT, SEALS

Page 17

Service Manual

Series HB Hydrostatic Transmission

HY13-1521-M2/US

General Information

17

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

SK000267- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

34 1 HB011002

NOSE CUP, MACHINED

1 SK000243

SERVICE KIT, SEALS

SK000268 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

34 1 HB011003

NOSE CUP, MACHINED

25 1 032203-249

PACKING, PREFORMED, O-RING SEAL

1 SK000243

SERVICE KIT, SEALS

SK000271- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

35 1 HB012002-A1

SA, TOP HOUSING

12 1 034001

GASKET

SK000272 - PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

35 1 HB012003-A1

SA, TOP HOUSING

12 1 034001

GASKET

SK000273- PART LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

36 1 478088

DUST CAP

Page 18

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Before you disassemble the UHT or any of its components, read this entire manual. It provides important

information on parts and procedures you will need to know to service the UHT Unit.

The UHT will have a six cross member bolts and four frame mounting bolts.

Remove fan from shaft prior to servicing any portion of UHT unit to prevent from breaking.

Thoroughly clean off all outside dirt, especially from around fittings before disconnecting and removing the UHT

transmission. Remove rust or corrosion from the coupling shaft.

Remove shaft connections and immediately plug port holes and fluid lines.

Remove the UHT from the system, drain it of fluid and take it to a clean work surface.

Clean and dry the UHT before you start to disassemble it.

As you disassemble the UHT, clean all parts, except seals, in clean, OSHA approved solvent, and air blow them

dry.

WARNING

Solvents are flammable, be extremely careful when using them. Even a small explosion or fire could

cause injury or death.

WARNIN

Wear eye protection and be sure to comply with OSHA and other maximum air pressure requirements.

ARN

W

Never steam or high pressure wash hydraulic components. Do not force or abuse closely fitted parts.

Keep parts separate to avoid nicks and burrs.

rd all seals and seal rings as they are removed from the UHT Unit. Replace all seal rings and any damaged

Disca

or worn parts with genuine Parker Hannifin Corporation or OEM approved service parts.

G

G

IN

18

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 19

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Clean unit of grass and other

debris; let dry.

Remove unit from vehicle

Drain the oil from the unit

Remove the breather/dipstick

assembly.

Place an oil pan under the

unit for oil collection.

Remove the filter and

position the unit as

necessary to drain oil into the

Remove the fan and fan

spacer

Inspect drive fingers for

wear

Note: Some units may not

pan.

Remove the ¼-20UNC bolt

securing the fan to the shaft

using a 3/8” socket. Remove

the fan washer and fan.

Using a small pry bar or flat

head screwdriver, gently pry

the fan spacer from the taper

on the pump shaft.

have a fan. If fan is not

present, skip to next step.

Remove the pulley

Inspect the pulley for

damage or abnormal wear

While holding the pulley from

turning, remove the 5/818UNF nut. Remove the flat

pulley washer. Use puller

with ¼-20 bolts of

appropriate length threaded

into the face of pulley to

remove from shaft.

Remove the motor bolts

Using a ¾” socket remove

the (4) ½-20 bolts securing

the motor and parking brake

cable anchor. The lower two

bolts are 2 ¼ “long and the

two top bolts are 6 ½” long.

19

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 20

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove the complete drive

motor

Remove the motor from the

nosecup by tapping cast iron

housing with a soft-face

mallet and gently prying on

the flange surface of the

motor taking care not to

damage the aluminum

nosecup.

Remove the nosecup

Remove the nosecup from

the endblock by removing the

two (2) ½-20 x 2 ¾” long

socket head caps screws

with a 5/16” allen head

socket.

Remove the transfer tubes

Remove the transfer tubes

by gently pulling the tubes

out of the endblock. It may

be necessary to rotate the

tubes while pulling.

Remove the charge pump

Using snap ring pliers

remove the charge pump

cover snap ring.

cover seal snap ring

20

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 21

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Disassemble the pump

section

Note: Two left bolts

measure 1 ¾” long the

other four are 2 ¾” long.

Using a 9/16” socket remove

the (6) 3/8-16UNC bolts

securing the top housing to

the endblock. Note two (2) of

the bolts are shorter than the

other four (4) that secures

the charge pump cover to

endblock and top housing.

Disassemble the pump

section

Note: Before completely

removing the top housing,

lay pump section on its side

so that pistons do not fall out

of the bores.

Disassemble the pump

section

Remove the top housing

from the endblock assembly.

Note that the swash block

and trunnion arm will remain

in the top housing when it is

removed from the end block

assembly.

Remove the swash block

assembly

Remove the swash block

assembly from the top

housing by lifting it out.

21

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 22

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove bearing cage and

thrust washers

Note: Washers should be

re-installed in the same

orientation/position they

were found – Do not Flip

Remove the trunnion arm

and control block

Caution:

Do not remove the two

cradle bushings!

Remove the bearing cage

and thrust washers from the

swash block by lifting them

out. Check both washers and

bearing for excess wear or

pitting damage.

Remove the trunnion arm

and the control block by

sliding the trunnion arm

toward the center of the top

housing and removing it from

the bore.

The bushings can have light

wear pattern but no other

damage. Both bushings must

be tight and seated flat

against radius.

Trunnion arm seal

Inspect trunnion arm seal for

any damage or leakage at or

around trunnion arm seal.

If replacing the trunnion seal

remove retainer clip then

trunnion arm seal with a flat

head screw driver.

22

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 23

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove the cylinder block

Remove spring retainer

Remove the cylinder block

assembly

Inspect pistons, bores and

both running surfaces

Remove the snap ring from

the pump shaft with external

snap ring pliers. Use care

not to over-stretch snap ring.

Take special notice not to

scratch sealing zone on shaft

while removing and replacing

snap ring.

Remove the spring retainer

and the cylinder block spring

from the shaft.

Remove the cylinder block

from the pump shaft by

sliding the cylinder block off

the splines on the pump

shaft. It may be necessary

to rotate the cylinder block

by hand while lifting.

Check for excessive wear

Check surface of rotating

group and sides of pistons

for excessive wear, indicated

by scoring. Remove pistons

and check bores and springs

for signs of scoring. Check

top of OD of pistons for

pitting or scratch marks.

Parts must be replaced if the

scoring is deep enough to

23

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

catch a fingernail.

Page 24

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove the charge pump

cover and shaft bearing

sub-assembly from end

block

Remove charge pump seal

Remove shaft bearing subassembly from charge

pump cover

Remove the charge pump

cover assembly and shaft

bearing sub-assembly by

sliding the pump shaft

through the central hole in

the end block.

Push out charge pump seal

with shaft.

Pull shaft bearing subassembly from charge pump

cover.

Pump shaft and bearing

sub-assembly

Inspect shaft and bearing

assembly for any heavy

scoring or damage around

seal area. Do not attempt to

remove bearing from shaft

this is a sub-assembly.

24

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 25

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove charge pump

rotor and stator

Remove two dowel pins

Remove the charge pump

pressure relief valve

Remove charge pump rotor,

stator and o-ring. Inspect for

scoring or any damage to

rotor and stator. Inspect the

O-ring, it should be flexible

and conform to the o-ring

groove in the charge pump

cover.

Remove the dowel pins by

sliding the pins out of the

bores in the end block.

Remove with ¼” allen head

socket or appropriate hex

wrench as necessary.

Orifice Plug

Do not remove the orifice

plug! Make sure the orifice is

free from debris by blowing

low pressure shop air

through orifice to ensure

clean passage.

25

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 26

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove the bypass valve

snap ring

Remove the bypass valve

Remove the shock / check

valves

Remove the snap ring

securing the bypass valve in

the bore with internal snap

ring pliers.

Remove the bypass valve

from the bore by pulling the

valve directly out of the bore

in the end block.

Remove shock valve with

3/8” allen head socket

16cc – 280 will have 241

number on the outside of

shock valve.

12cc – 240 will have 275

number on the outside of

shock valve.

Shock Valves

16cc – 280 will have 241

number on the outside of

shock valve.

12cc – 240 will have 275

number on the outside of

shock valve.

26

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 27

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Check Valves

Remove check valve with

5/16” allen head socket .

Check valves will not have

any numbers on the outside.

Please refer to picture to

determine if you have either

check or shock valves.

27

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 28

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

End block assembly

Key factor in the successful

repair is cleanliness. Prior to

assembly make sure all

exposed surfaces are

thoroughly clean and free of

foreign material and

chemicals. Replace all seals,

o-rings, oils and gaskets with

original OEM parts.

Orifice plug is clean

Do not remove the orifice

plug! Make sure the orifice is

free from debris by blowing

low pressure shop air through

orifice to ensure clean

passage.

Install the shock /

check valves

16cc – 280 will have 241

number on the outside of

shock valve

12cc – 240 will have 275

number on the outside of

shock valve

Engage threads manually

hand start several threads to

prevent cross threading.

Torque shock valve to

specifications 480 - 540 in.

lbs.

Torque check valves to 252 –

288 in lbs.

Lube the bypass valve O-ring

and position in bypass port.

Install the bypass valve

28

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 29

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install bypass valves

Install the bypass valve

retaining ring, pliers

required

Install the bypass valve

snap ring

Install the bypass valve. Push

valve directly in the bore of

the end block as far as it will

go.

Install the snap ring securing

the bypass valve in the bore.

Place retaining ring on bypass

valve shaft and position into

the groove on the inside of

the bypass valve port.

Use the tip on the pliers to

make sure the retaining ring is

seated in the groove around

the entire circumference of

hole.

Install two dowel pins

Install the dowel pins by

sliding the pins into the bores

in the end block.

29

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 30

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install ¼ SAE hex plug

into port on side of end

block

Torque to

specifications

Install charge relief

cartridge

Install O-ring

Install the ¼ SAE hex plug.

Hand start several threads to

prevent cross threading.

Torque ¼ SAE hex plug on

side of end block 252 – 288 in

lbs.

Install the charge relief

cartridge hand start several

threads to prevent cross

threading. Using a ¼ “ allen

head socket torque to 252 –

288 in lbs.

*If a hex type valve is present,

use an 11/16“hex socket to

apply torque.

Lube case drain O-ring and

install in end block.

Note: Certain models may or

may not have this o ring.

If your end block has this Oring replace if end block does

not have this o ring then it will

not be required.

30

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 31

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Polish I.D. with emery

cloth paper

Replacement Trunnion

seal

Remove any burrs with emery

cloth paper from the I.D. of

trunnion seal area. Clean

area with a lint free cloth after

polishing I.D.

With the flat side of seal

facing up push seal in flush to

top housing.

Place socket on top of

seal

Tap seal into place

Place 11/16 deep well socket

over seal.

Gently tap socket with rubber

hammer driving seal into

place.

31

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 32

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install retainer clip

eat retainer clip

S

isual check

V

Place retainer clip with the

tongs pointed away from seal.

ently tap socket with rubber

G

hammer driving retainer clip.

See that the seal retainer is

ush with the top of the

fl

housing.

octite ™ 242

L

hreadlocker

T

Apply Loctite ™ 242

Threadlocker to the O.D. of

seal bore

Use of Loc

liminates the need for a snap

e

tite ™ 242

ring.

32

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 33

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Apply Loctite ™ 242

Threadlocker to the

O.D. of the fan seal

Press fan seal into top

housing bore

Look for rubber

scraped off by snap

ring groove replace

seal if it has been

damaged

Top housing in now

complete sub assembly

Note: Loctite ™ 242 should

not contact rubber I.D. on

seal.

Place a rubber hammer on

top of seal. Use second

rubber hammer drive seal into

cavity flush. Place a 5/8

socket over seal using rubber

hammer drive seal either

below snap ring groove in

bore or .200” deep.

Note: By adding Loctite to the

O.D. of fan seal the snap ring

will not be required.

Install trunnion arm

Install control block

Lubricate trunnion arm shaft

and insert into and through

the trunnion arm seal.

Install control block onto

trunnion arm inside of top

housing.

33

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 34

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Apply Oil

Install swash block

Apply Oil into swash

block

Apply OEM recommended oil

to cradle bushings.

Install swash block

subassembly onto cradle

bearing in top housing. Verify

that swash block moves freely

back and forth on bushing

without binding or dragging

Apply OEM recommended oil

prior to installing thin washer

into swash block

Install thrust washer

Install thrust bearing

Install thin (.143”) thrust

washer into swash block.

Install thrust bearing on top of

thrust washer.

34

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 35

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install top washer

Apply Oil to top washer

Install charge pump

shaft and bearing

assembly into charge

pump cover.

Install thick (.261”) thrust

washer into swash block.

Apply OEM recommended oil

to top of thrust washer.

Place charge pump cover

face down with the extended

shaft through hole in table.

Be careful as you insert shaft

assembly into charge pump

cover not to damage I.D. of

cover.

fter bearing

A

installation en

sure

there is room for the

seal.

ote: Flat washer not

N

ush shaft and bearing

P

assembly to the bottom o

cover.

ote: Flat washer not

N

required if present.

f the

used after mid 2009 in

production.

35

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 36

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install charge pump

seal

stall snap ring

In

stall charge pump O-

In

ng

ri

Place seal over output shaft

requires pushing down on

seal below snap ring groove

of cover. Ade of a socket that

fits flush to the face of seal

lightly tap until seal is below

snap ring groove.

se internal snap ring pliers

U

and insert snap ring into

groove of charge pump co

ver.

Lightly oil O-ring, flip charge

ump cover over and install

p

O-ring into charge pump

cover groove.

Install charge pump

stator and rotor

Lightly oil both parts, place

the stator into charge pump

over followed by the rotor c

inside of stator.

36

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 37

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install charge pump

shaft into end block

emporarily bolt charge

T

pump cover to end

block

Rotating group

ssembly

a

With the end block sitting on

edge insert the charge pump

shaft until face of charge

pump cover mates to end

block.

se two charge pump cover

U

bolts, flat washers and nuts,

finger tighten to temporarily

hold the charge pump cover

to end block.

Install rotating group

over the charge pump

haft

s

Flip end block over with

charge pump shaft up.

ightly oil face of end block

L

place rotating group over

shaft resting on face of e

nd

block.

37

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 38

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Central spring and

bushing

Place central spring and

bushing onto pump shaft on

top of barrel.

Install snap ring onto

shaft

Using internal snap ring

pliers, put retaining snap ring

over pump shaft and place on

top of the central spring

bushing.

Place 16mm socket

over shaft

Place a 16mm deep well

socket 3 ½” long over shaft

resting on the snap ring.

Compress snap ring

By pushing down on socket

compress the central spring

until snap ring locks into snap

ring groove of shaft.

38

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 39

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Remove two nuts and

washers

Install face gasket

Install all six bolts

Remove the two nuts and

washers.

Install gasket onto sealing

surface of top of end block.

Install the two hex bolts that

are (1.75”) long in the end

block install the other four hex

head bolts that are (2.75”)

long through charge pump

cover and through end block.

Carefully position top

housing to end block

Take special care not to allow

the swash block or the

internal bearing and washers

to fall out of position.

39

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 40

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Carefully assembly top

housing to end block

Slip pump shaft through the

center hole of swash block

Hand tighten bolts

While holding the top housing

level to end block hand start

each of the six bolts with

socket to secure both the top

housing and end block

together.

Torque all six hex head

bolts

Going diagonal from each bolt

torque to 300 – 336 in lbs.

Install filter

Torque filter

Lightly oil filter O- ring and

insert into end block hand

start until snug.

Torque filter to 108 – 114 in

lbs.

40

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 41

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install both pipe tubes

Inspect interface for

slivers of backup ring

replace if sheared

Install O-Ring if hole is

present

stall nose cup

In

Oil all O-rings on both ends of

pipe tubes. First slightly rotate

pipe into end block tube

holes. With the palm of your

hand slightly compress tubes

down pass O-rings.

Oil O-ring and place into

position.

osition nose cup over both

P

tube pipes.

stall both allen head

In

screws

Install motor O-ring

Note:

When servicing UHT assembli

erial number code of

with a s

09257 or earlier, this O-ring (item

25) is not required.

and start each one of the

H

two allen head screws that

measure 2.750” long, torque

to 540 – 708 in lbs.

Slip O-ring over the end cover

of motor down to the O.D. of

motor housing base. Then

install motor into nose cup.

es

Press down on motor

mounting flange to seat the

pipes in the ports until

ends of the pipes rest on the

oil port shoulders.

oil

the

41

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 42

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Oil nose cup ID

Note: If assembly does

not have motor o-ring

skip this process.

Install wheel motor into

nose cup

Install pump pulley

Use OEM recommended oil to

lube the ID of the nose cup

where the motor O-ring will be

located.

Position the motor tube holes

of the wheel motor casting

over the two oil pipes. Press

down on motor mounting

flange to seat the oil pipes in

the ports until the ends of the

pipes rest on the oil port

shoulders.

Place pulley onto pump shaft

as shown.

Washer

Lock nut

Place washer on top of pulley.

Use Loctite ™ 242 on threads

of nut. Hand start the lock nut

onto shaft.

42

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 43

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Torque nut

Install brake cable

bracket nearest to “A”

port as shown.

Position brake cable

Fill with OEM

recommend oil capacity

level of 2.7 quarts

While holding the pulley in

place with a adjustable

spanner wrench tighten the

nut to 55-70 ft lbs.

Orient the slot opening

towards “A” & “B” ports. Insert

long hex head bolt

through brake cable bracket

motor flange hole and nose

cup install the other three

large hex head bolts.

While holding the brake cable

bracket in position tighten the

hex nut to specification.

Visually inspect bracket

through-hole flange is flat

against the housing and bolt

head. Tighten the other three

bolts to specification.

Add 2.7 quarts of OEM

recommend oil. Secure

dipstick hand tight. Fill to

correct height on dipstick.

Hand tighten to 36 – 60 in lbs.

Install pump fan spacer

Place spacer over pump shaft

with the taper of washer to fit

the taper of the pump shaft

43

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 44

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Install fan

Note: If assembly does

not have Fan. Install

shaft cover by applying

Loctite ™ 242 to bottom

edge and tap (gently) into

top housing bore until

seated.

Install fan washer

Install bolt to secure

fan

Place fan on top of pump

washer with the blades face

down as shown in picture.

Place fan washer with the

tangs in-between fan tabs

Apply Loctite ™ 242 to the

threads of bolt. Start fan bolt

by hand and torque to 108 –

144 in lbs.

By pass lever

Install snap ring

Slide the by pass lever over

the by pass valve knob

handle pointing towards the

motor out put shaft

Place snap ring over the by

pass arm and release snap

ring into groove

44

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 45

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Secure snap ring in

groove

Make sure snap ring is secure

in groove keep the by pass

lever position towards output

shaft of drive motor

Assembly complete

With the rear tires jacked up

Start up and purge

vehicle

off the ground cycle

transmissions full speed for

30 seconds each direction.

Recheck reservoir dipstick to

make sure reservoir level is

full.

45

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Page 46

System Maintenance Tips

Adjust fluid level in reservoir as necessary.

Encourage all operators to report any malfunction or accident that may have damaged the hydraulic

system or component.

Do not attempt to weld any broken component. Replace the component with original OEM equipment

only.

Do not cold straighten, hot straighten, or bend any part.

Prevent dirt or other foreign matter from entering the hydraulic system. Clean the area around the oil

dipstick cap before checking oil level.

Investigate and correct any external leak in the hydraulic system, no matter how minor the leak.

Comply with manufacturer’s specifications for cleaning or replacing the filter.

CAUTION

CA

UTION

CAUTION

during operation or in an accident. Replace any component that is damaged or that is questionable.

CAUTION

internally.

CAUTION

Maintain the proper fluid level in the reservoir. When changing fluid, completely drain old oil from the system. It is

suggested also that you flush the system with clean oil.

Do not weld, braze, solder or in any way alter any UHT component.

Maximum operating pressure must not exceed recommended pressure capacity.

Always carefully inspect any system component that may have been struck or damaged

Do not force any coupling onto the UHT coupling shaft as this could damage the unit

Do not mix oil types. Any mixture, or an unapproved oil could deteriorate the seals.

Parker Hann

Hydraulic Pu

2745 Snapps Ferry Road

Greeneville, TN 37745 USA

ifin Corporation

mp/Motor Division

Loading...

Loading...