Page 1

FormNo.3375-781RevA

TITANZX4820orZX5420

Zero-Turn-RadiusRidingMower

ModelNo.74920—SerialNo.313000001andUp

ModelNo.74924—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3375-781*A

Page 2

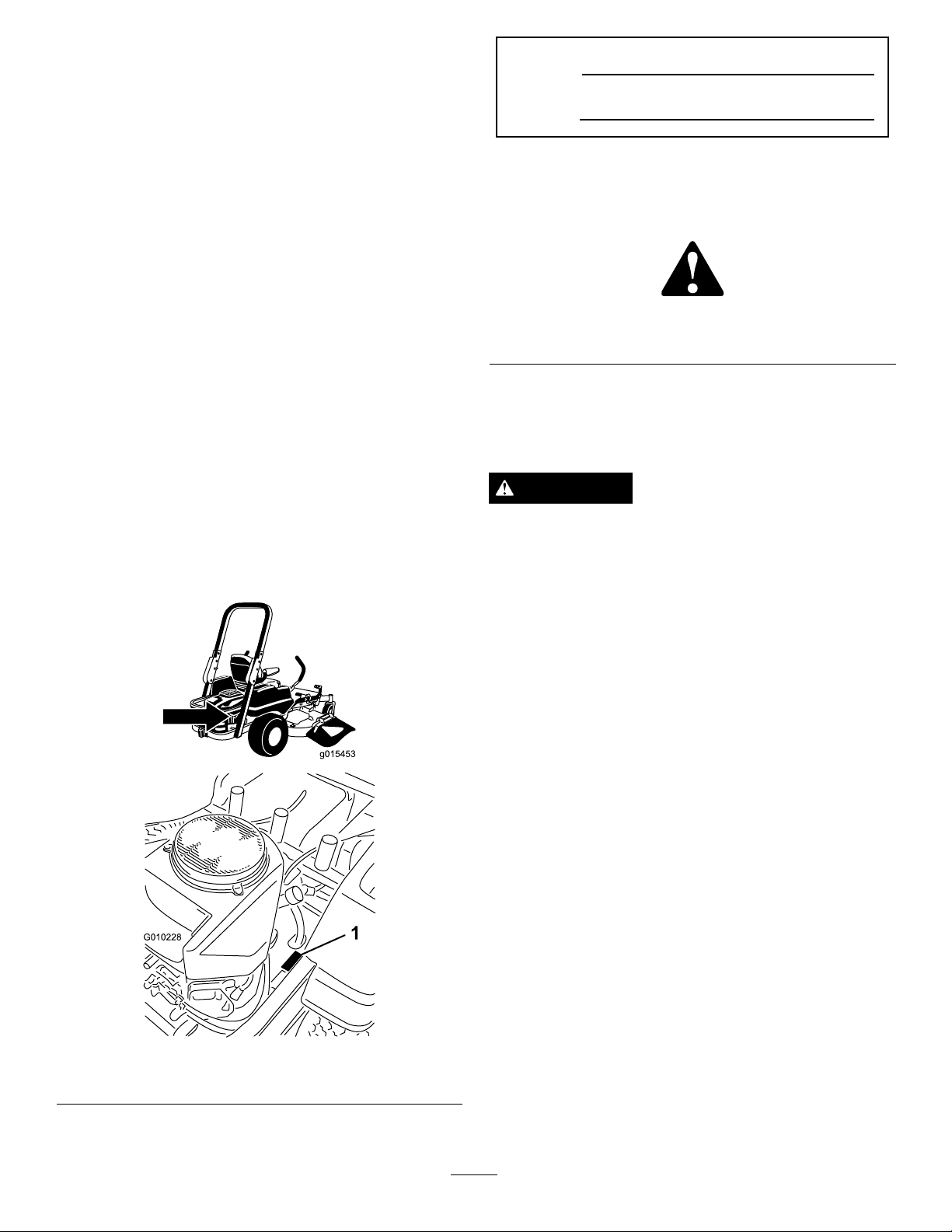

Thismachineisaride-on,rotary-bladelawnmowerintended

G010228

1

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

ModelNo.

SerialNo.

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalT oro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

1.Modelandserialnumberlocation

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1940andratedto

J2723.

Donottamperwiththeenginecontrolsoralterthegovernor

speed;doingsomaycreateanunsafeconditionresultingin

personalinjury.

Figure1

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperationPracticesforRide-on(riding)

RotaryLawnmowerMachines...............................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

Model74920...........................................................6

Model74924...........................................................6

SlopeIndicator.......................................................7

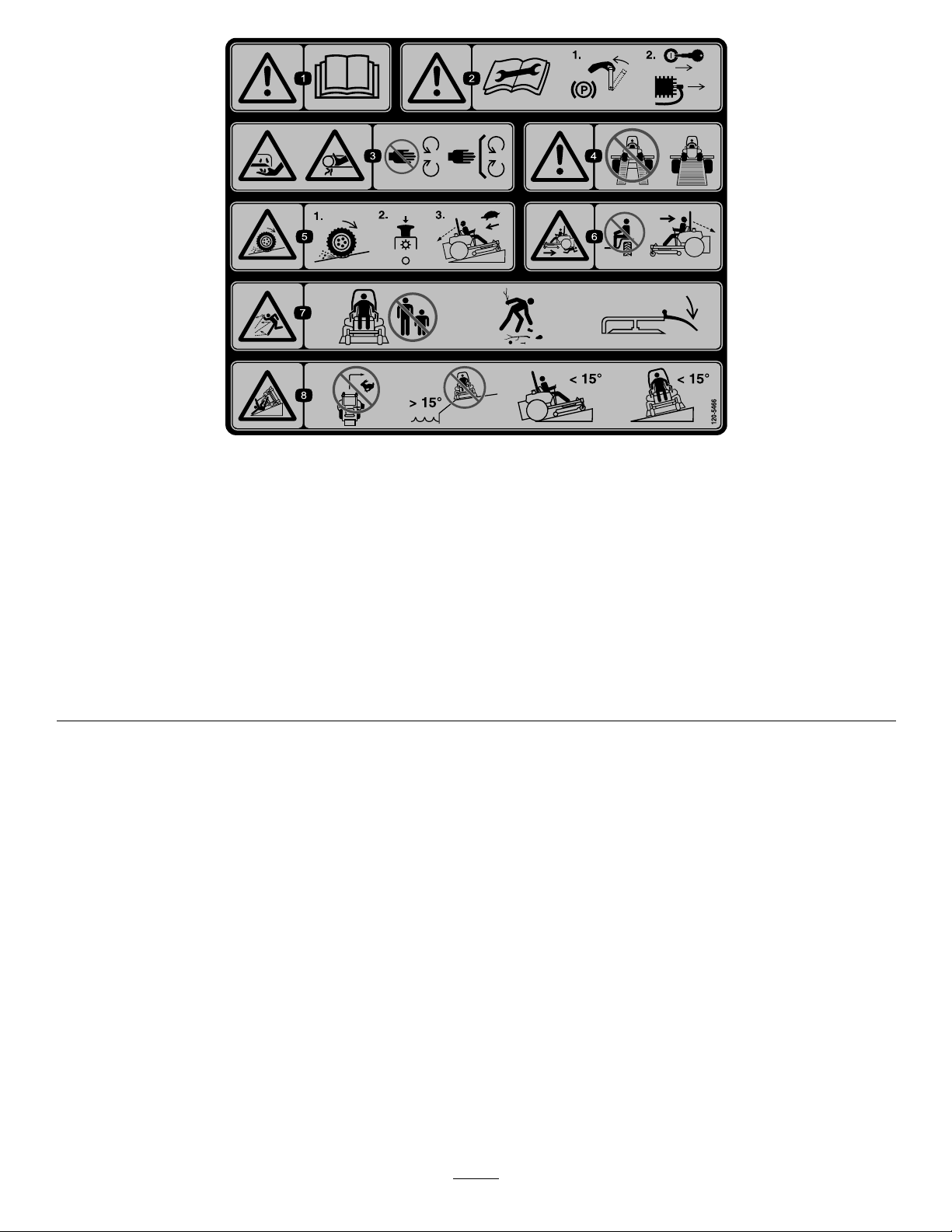

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................14

Controls...............................................................15

Operation....................................................................16

ThinkSafetyFirst...................................................16

UsingtheRolloverProtectionSystem(ROPS)............16

AddingFuel...........................................................17

CheckingtheEngineOilLevel.................................19

OperatingtheParkingBrake....................................19

OperatingtheThrottle............................................19

OperatingtheChoke...............................................19

OperatingtheIgnitionSwitch..................................19

StartingandStoppingtheEngine..............................20

OperatingtheMowerBladeControlSwitch

(PTO)...............................................................21

TheSafetyInterlockSystem.....................................21

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................23

AdjustingtheHeightofCut.....................................23

AdjustingtheAnti-ScalpRollers...............................25

PositioningtheSeat................................................25

AdjustingtheMotionControlLevers........................25

PushingtheMachinebyHand..................................25

Convertingthe48inchMowertoSide

Discharge..........................................................26

Convertingthe54inchMowertoSide

Discharge..........................................................27

UsingtheSideDischarge.........................................29

OperatingTips......................................................30

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

PremaintenanceProcedures........................................33

RaisingtheSeat......................................................33

Lubrication...............................................................33

GreasingtheBearings.............................................33

EngineMaintenance..................................................34

ServicingtheAirCleaner.........................................34

ServicingtheEngineOil..........................................34

ServicingtheSparkPlug..........................................36

CleaningtheCoolingSystem....................................37

FuelSystemMaintenance...........................................38

ReplacingtheFuelFilter..........................................38

ElectricalSystemMaintenance....................................39

ServicingtheBattery...............................................39

ServicingtheFuses.................................................40

DriveSystemMaintenance.........................................41

CheckingtheTirePressure......................................41

HydraulicSystemMaintenance....................................41

CheckingtheHydraulicOilLevel..............................41

ChangingtheHydraulicSystemFilterand

Oil....................................................................41

MowerDeckMaintenance...........................................43

ServicingtheCuttingBlades.....................................43

MowerDeckLeveling.............................................46

InspectingtheBelts................................................47

ReplacingtheMowerBelt........................................47

RemovingtheMower..............................................48

InstallingtheMower...............................................49

ReplacingtheGrassDeector..................................49

Cleaning...................................................................50

WashingtheUndersideoftheMower........................50

WasteDisposal.......................................................51

Storage........................................................................51

CleaningandStorage..............................................51

Troubleshooting...........................................................53

Schematics...................................................................55

3

Page 4

Safety

SafeOperationPractices

forRide-on(riding)Rotary

LawnmowerMachines

ThismachinemeetsorexceedsEuropeanStandardsin

effectatthetimeofproduction.However,improperuseor

maintenancebytheoperatororownercanresultininjury.

Toreducethepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,orDANGER

-“personalsafetyinstruction.”Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheENstandardEN

836:1997.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

Preparation

•Whilemowing,alwayswearsubstantialfootwearandlong

trousers.Donotoperatetheequipmentwhenbarefoot

orwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning-Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulationscan

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan15degrees.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–uselowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Usecarewhenpullingloads.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

4

Page 5

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedcan

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

disconnectthesparkplugwire(s)orremovetheignition

key.

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

lawnmower;

–afterstrikingaforeignobject.Inspectthelawnmower

fordamageandmakerepairsbeforerestartingand

operatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment.

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumescanreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeofgrass,

leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.

•Whenmachineistobeparked,storedorleftunattended,

lowerthecuttingmeans.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyT oro-approvedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanks,orwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

frommowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocksdips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethebladesandproceed

slowlyofftheslope.

5

Page 6

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

UncertaintyValue(K)=0.31m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836(Riding&Stand-Ons).

Model74924

SoundPower

•Keeptherollbarintheraisedandlockedpositionand

usetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Beawarethereisnorolloverprotectionwhentheroll

barisdown.

•ChecktheareatobemowedandneverfoldtheROPSin

areaswherethereareslopes,dropoffsorwater.

•Lowertherollbaronlywhenabsolutelynecessary.Donot

weartheseatbeltwiththerollbarfoldeddown.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

Model74920

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof93

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

Hand-ArmVibration

Measuredvibrationlevelforlefthand=3.1m/s2

Measuredvibrationlevelforrighthand=2.7m/s2

UncertaintyValue(K)=1.5m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof93

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

Hand-ArmVibration

Measuredvibrationlevelforlefthand=2.4m/s2

Measuredvibrationlevelforrighthand=2.6m/s2

UncertaintyValue(K)=1.3m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBodyVibration

Measuredvibrationlevel=0.63m/s2

WholeBodyVibration

Measuredvibrationlevel=0.71m/s2

UncertaintyValue(K)=0.35m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836(Riding&Stand-Ons).

6

Page 7

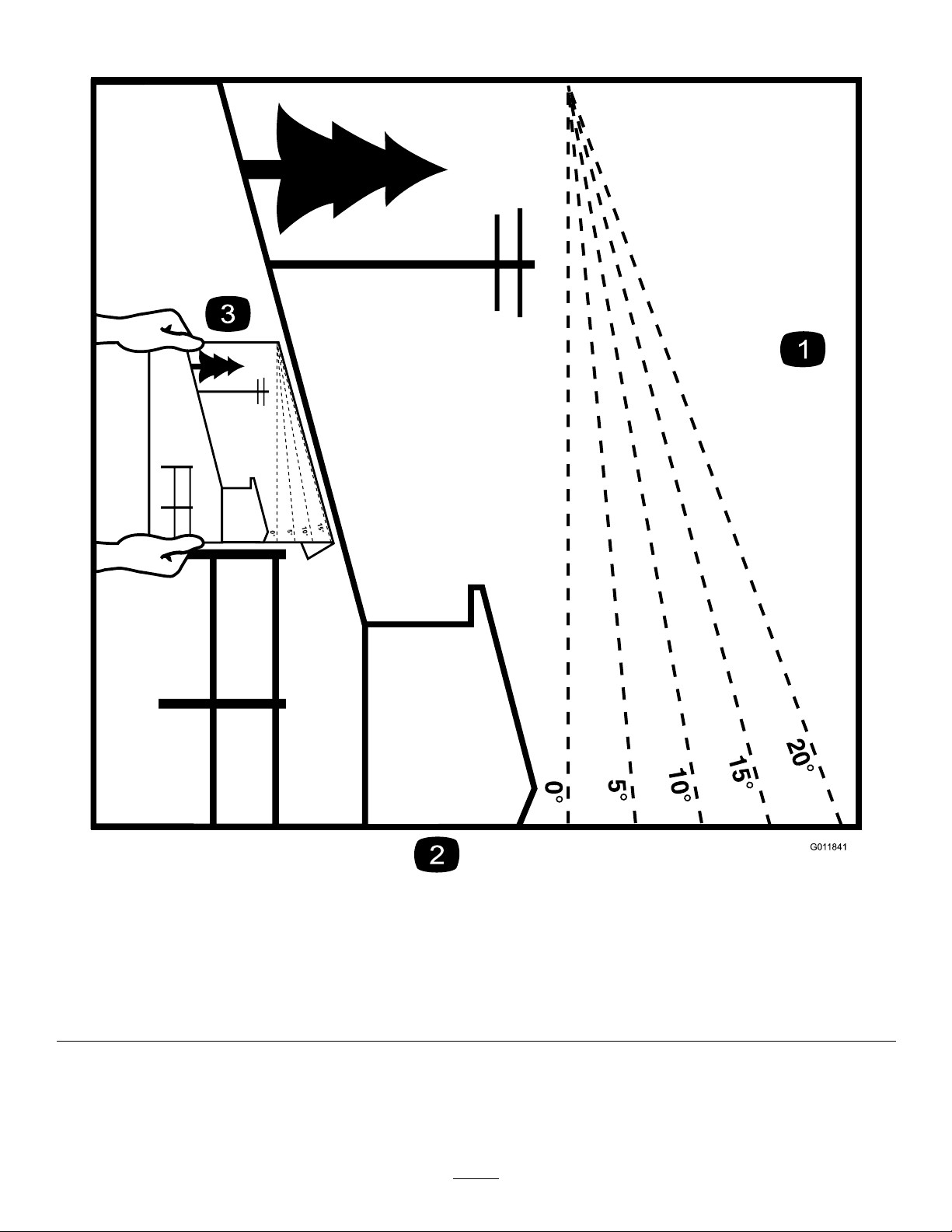

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

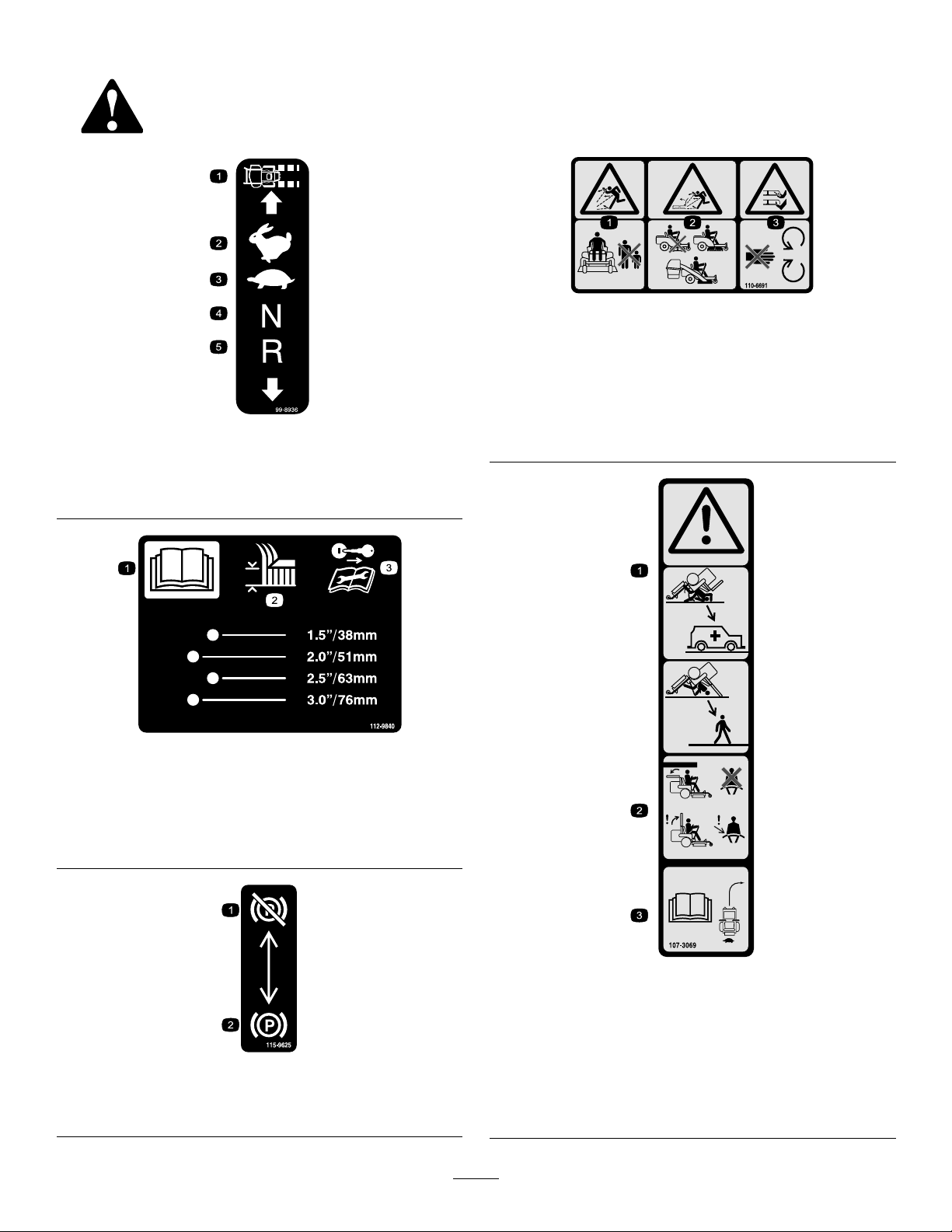

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

1.ReadtheOperator's

Manual.

2.Heightofcut

1.Parking

brake—disengaged

112-9840

3.Removetheignitionkey

andreadtheinstructions

beforeservicingor

performingmaintenance.

115-9625

2.Parkingbrake—engaged

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

8

Page 9

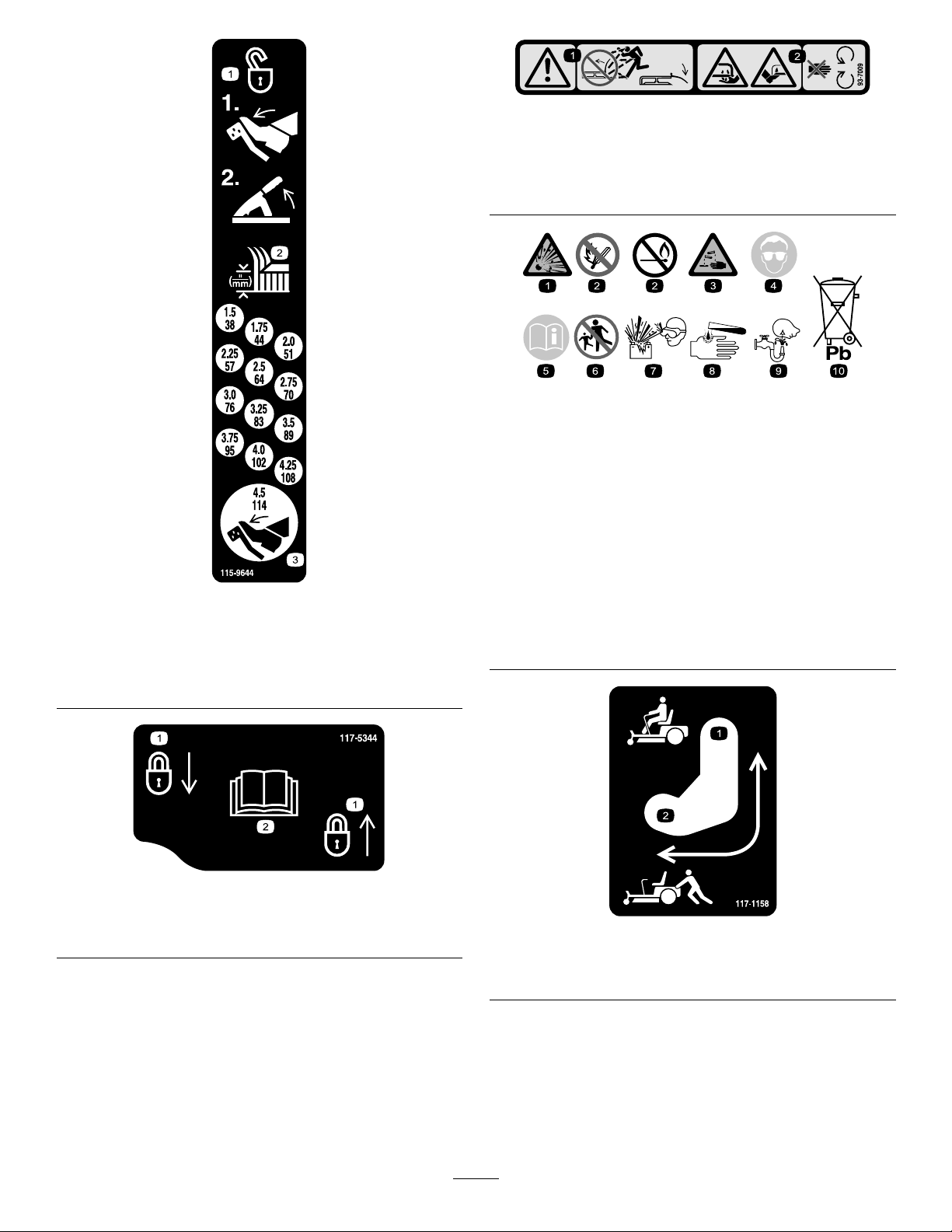

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

115-9644

1.Pressthepedalandlifttheheightofcutlevertounlockthe

deckposition.

2.Heightofcut

3.Pressthepedaltomovethedecktothetransportposition

117-5344

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.Lock

2.ReadtheOperator'sManual

1.Bypassleverpositionfor

operatingthemachine.

9

117–1158

2.Bypassleverpositionfor

pushingthemachine.

Page 10

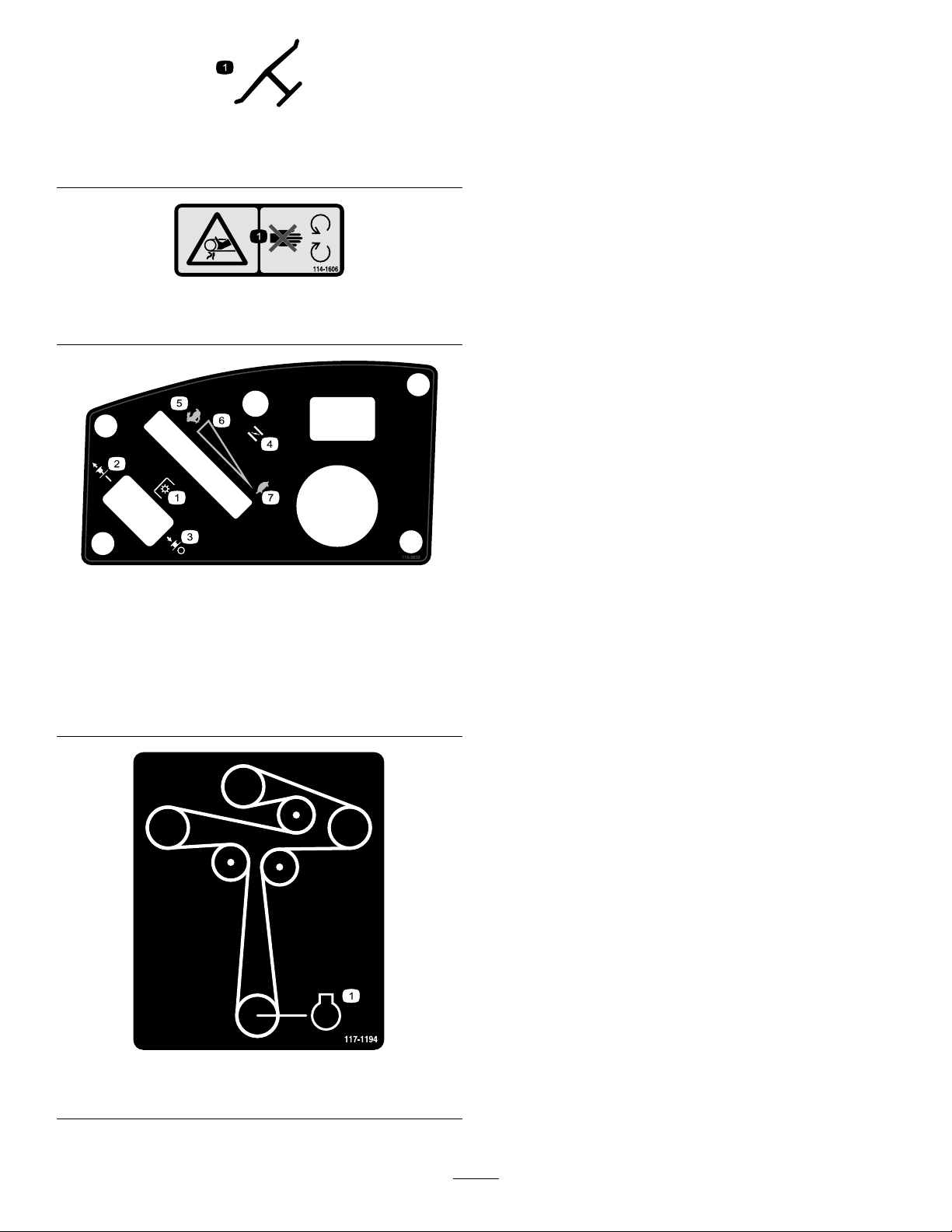

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

115-9632

1.Powertake-off(PTO),

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

setting

117-1194

1.Engine

10

Page 11

120-5466

1.Warning—readtheOperator'sManual.5.Lossoftraction/controlhazard,slopes—lossoftraction/control

2.Warning—readtheinstructionsbeforeservicingorperforming

maintenance;movethemotioncontrolleverstothepark

(brake)position,removetheignitionkeyanddisconnectthe

sparkplugwire.

3.Cutting/dismembermenthazard,mowerblade;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

4.Warning—donotusesplitramps,useafullrampswhen

transportingmachine.

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly .

6.Crushing/dismembermenthazardofbystanders,

reversing—donotcarrypassengers,lookbehindanddown

whenreversing.

7.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,keepdeector

inplace.

8.Tippinghazard—donotturnathighspeeds,donotoperate

neardrop-offsonslopesgreaterthan15degrees,donotmow

slopesgreaterthan15degrees,avoidsuddenandsharp

turnswhileonslopes.

11

Page 12

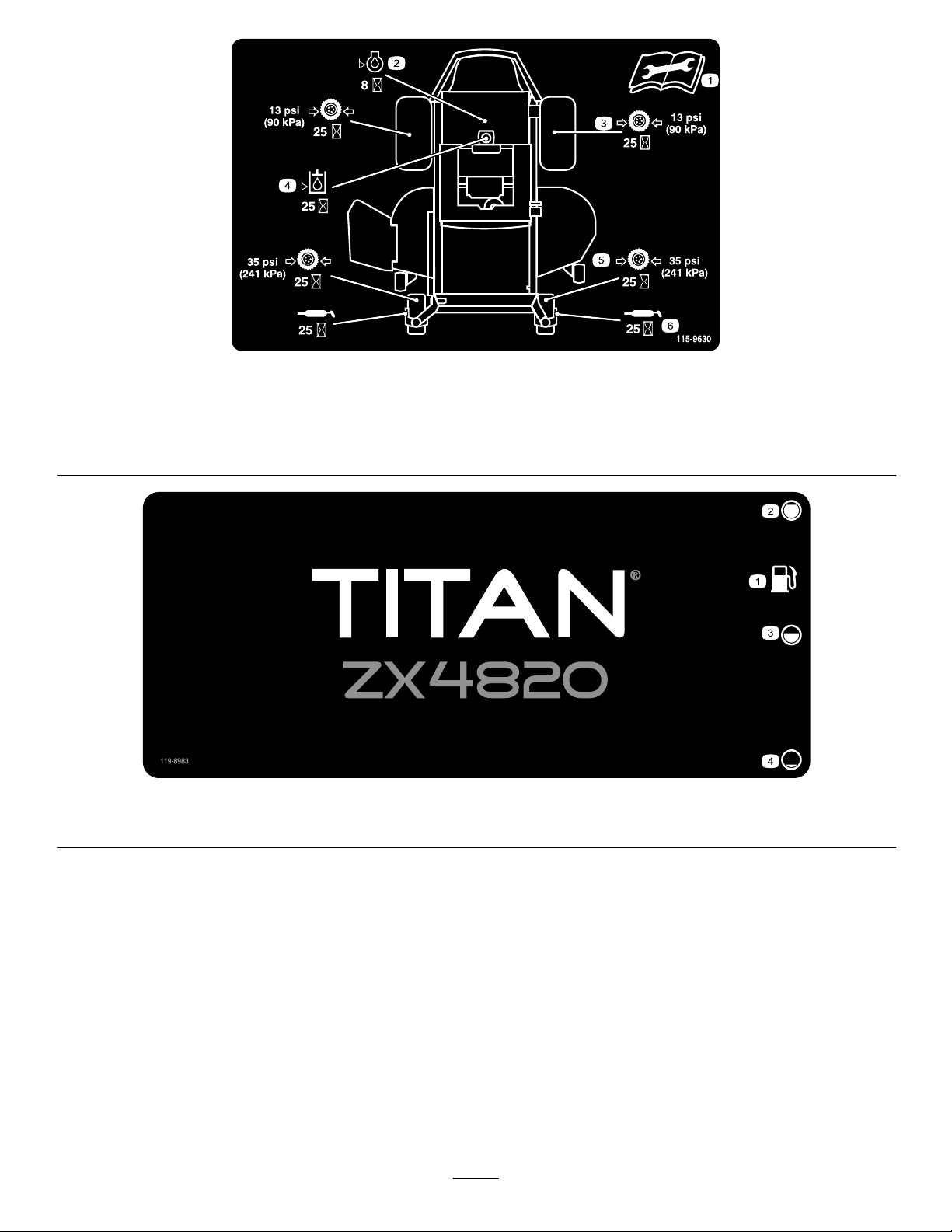

115-9630

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

119-8983

1.Fuel2.Full

3.Half

4.Empty

12

Page 13

119-8986

1.Fuel2.Full

3.Half

4.Empty

13

Page 14

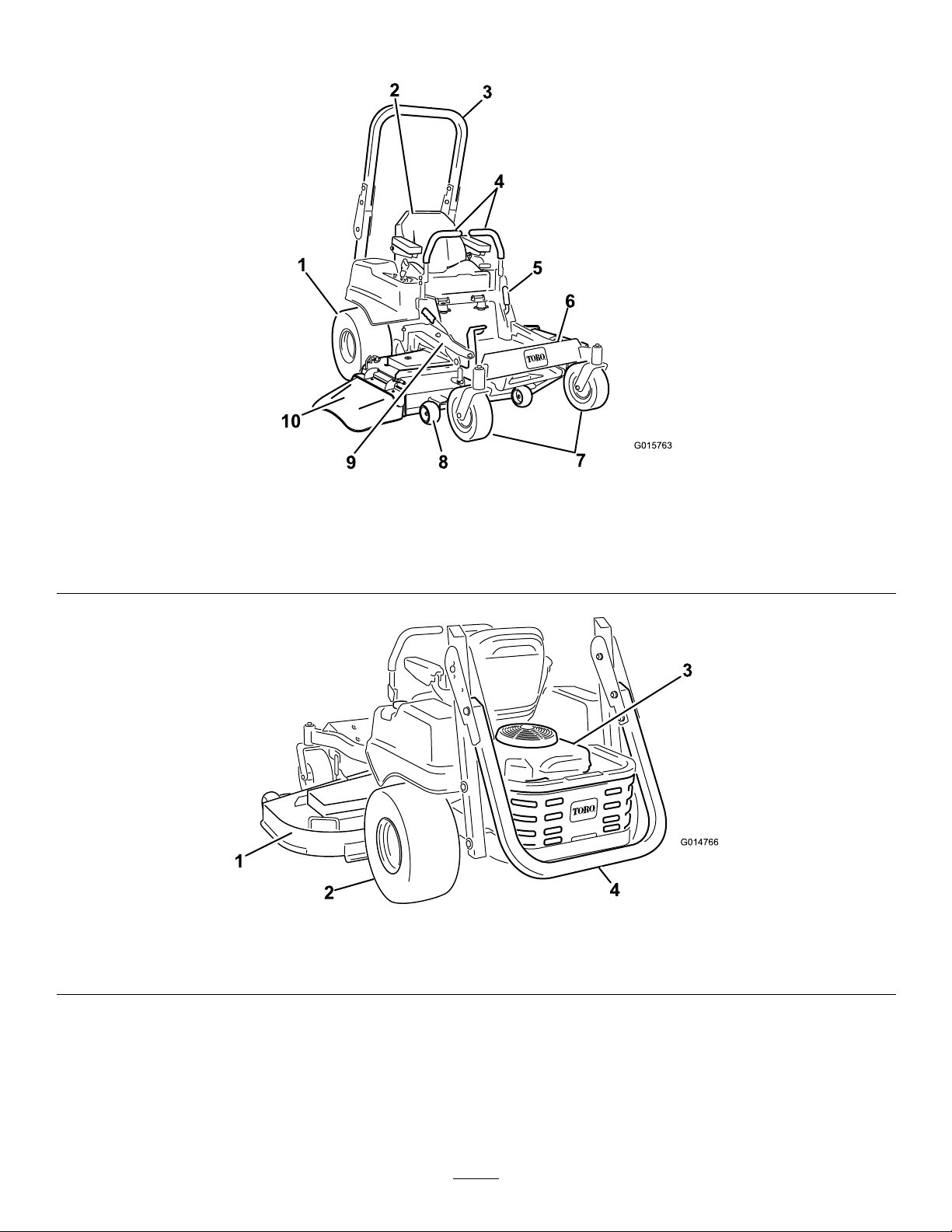

ProductOverview

G015763

1

2

3

4

5

6

7

8

9

10

G014766

1

2

3

4

Figure4

1.Drivewheel4.Motioncontrollevers7.Frontcasterwheel

2.Operatorseat

3.Rolloverprotectionsystem

(ROPS)

1.MowerDeck3.Engine

2.Drivewheel

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

height-of-cut

Figure5

4.Rolloverprotectionsystem(ROPS),foldeddown

10.Deector

14

Page 15

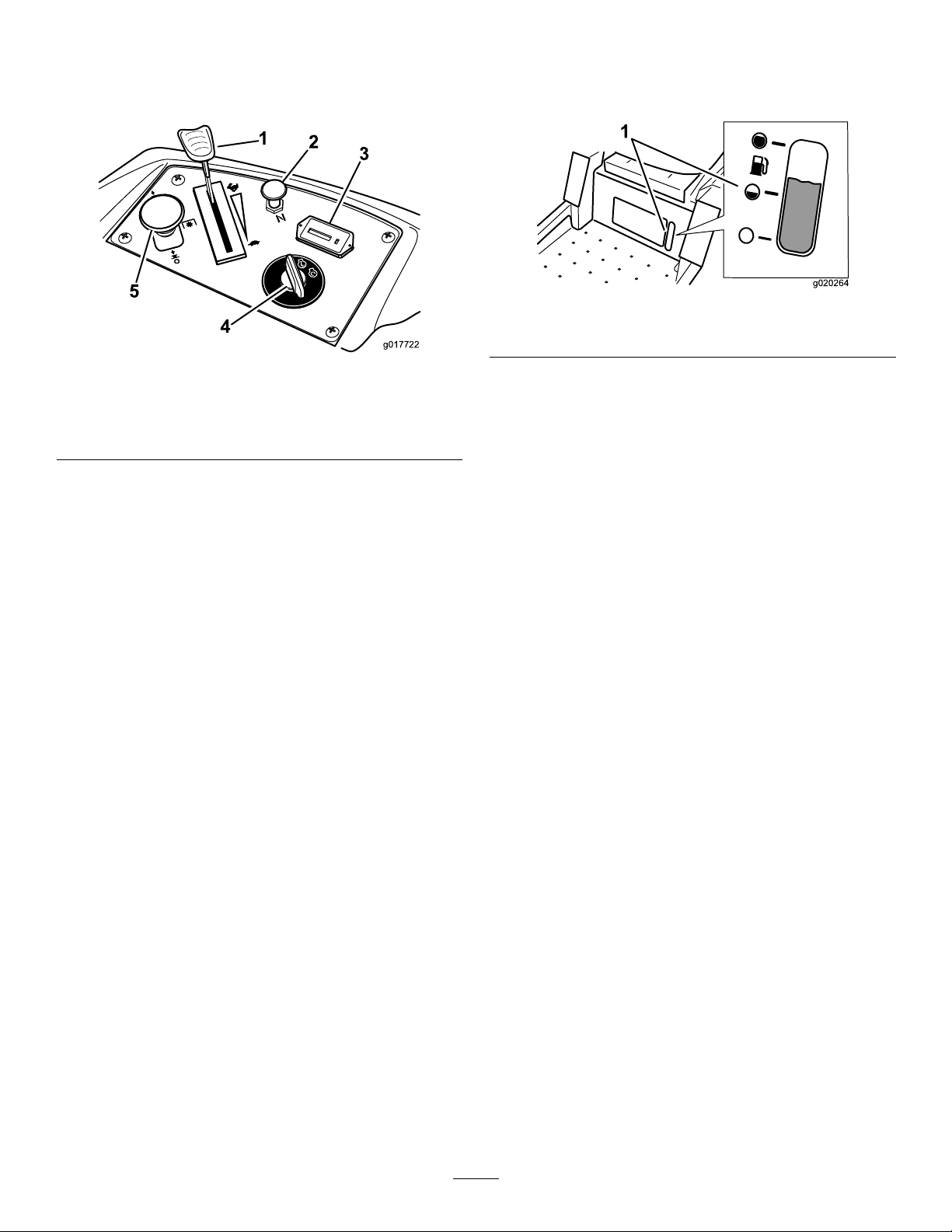

Controls

g017722

1

2

3

4

5

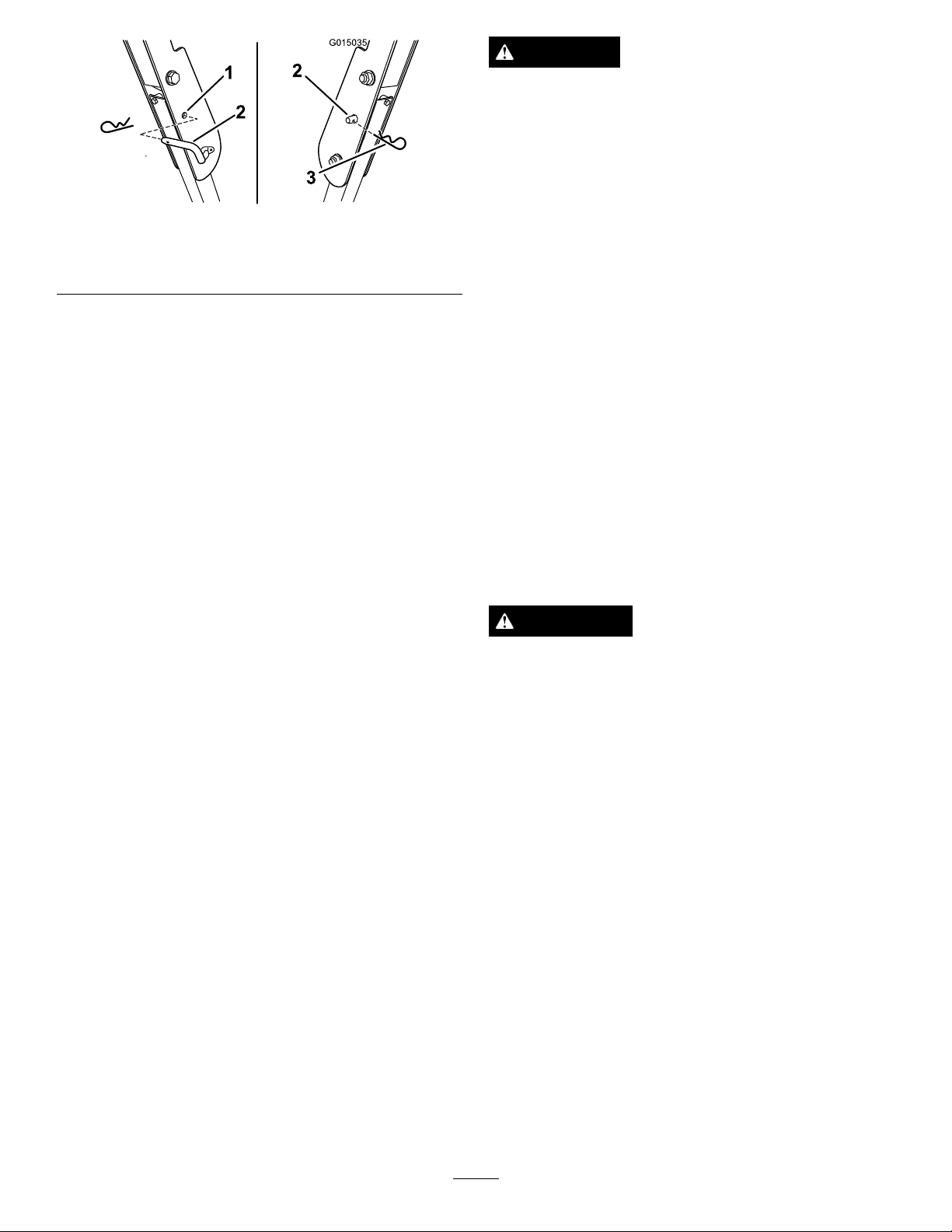

g020264

1

FuelGauge

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure6).

Figure6

1.Throttlecontrol4.Ignitionswitch

2.Choke5.Bladecontrolswitch(PTO)

3.Hourmeter

IgnitionSwitch

Theignitionswitchhasthreepositions:Start,RunandOff.

ThekeywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachineto

preventtheenginefromaccidentallystarting(Figure6).

Thefuelwindowlocatedbelowtheoperatorpositioncanbe

usedtoverifythelevelofgasolineinthetank(Figure7).

Figure7

1.Fuelgaugewindow

MotionControlLevers

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

totheneutrallockpositionandexitthemachine(Figure4).

Alwayspositionthemotioncontrolleversintotheneutrallock

positionwhenyoustopthemachineorleaveitunattended.

ParkingBrakeLever

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Movingthrottleleverforwardwillincreaseenginespeedand

movingthrottlelevertotherearwilldecreaseenginespeed.

Movingthethrottleforwardintothedetentisfullthrottle

(Figure6).

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.Pushdownonthechokeknobtodisengageit.

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(

HourMeter

Thehourmeterrecordsthenumberofhoursthebladeshave

operated.Itoperateswhenthebladecontrolswitch(PTO)is

engaged.Usethesetimesforschedulingregularmaintenance

(Figure6).

Figure6).

Locatedonleftsideoftheconsole(Figure4).Thebrakelever

engagesaparkingbrakeonthedrivewheels.Pulltheleverup

andrearwardtoengagethebrake.Pushtheleverforwardand

downtodisengagethebrake.

FootPedalDeckLiftSystem

Thefootpedaldeckliftsystemallowstheoperatortolower

andraisethedeckfromtheseatedposition.Theoperatorcan

usethefootpedaltoliftthedeckbrieytoavoidobstacles

orlockthedeckinthehighestheight-of-cutortransport

position(Figure4).

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedaltolockthe

deckinaspeciccuttingheight.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure4).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesare

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

15

Page 16

Operation

G015033

1

2

3

G015034

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

UsingtheRolloverProtection System(ROPS)

WARNING

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily,petsorbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

1.Toraisetherollbar,removethehaircotterpinand

removethelockingpins.

2.Raisetherollbartotheuprightposition(Figure9).

Figure8

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

16

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

3.Installthelockingpins.Securethepinsbyinstallingthe

haircotterpin(

Figure9

Figure10).

Page 17

G015035

1

2

3

2

Figure10

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

1.HoleinROPS

2.Lockingpin

4.Tolowertherollbar,removethehaircotterpinand

removethelockingpin.(Figure10).

5.Lowertherollbartothedownposition.

6.Usethetwolockingandcotterpinstosecurethebar.

3.Hairpincotter

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•DoNotaddoiltogasoline.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

17

Page 18

DANGER

g020264

1

G010475

1

2

4

3

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Figure11

1.Fuelgaugewindow

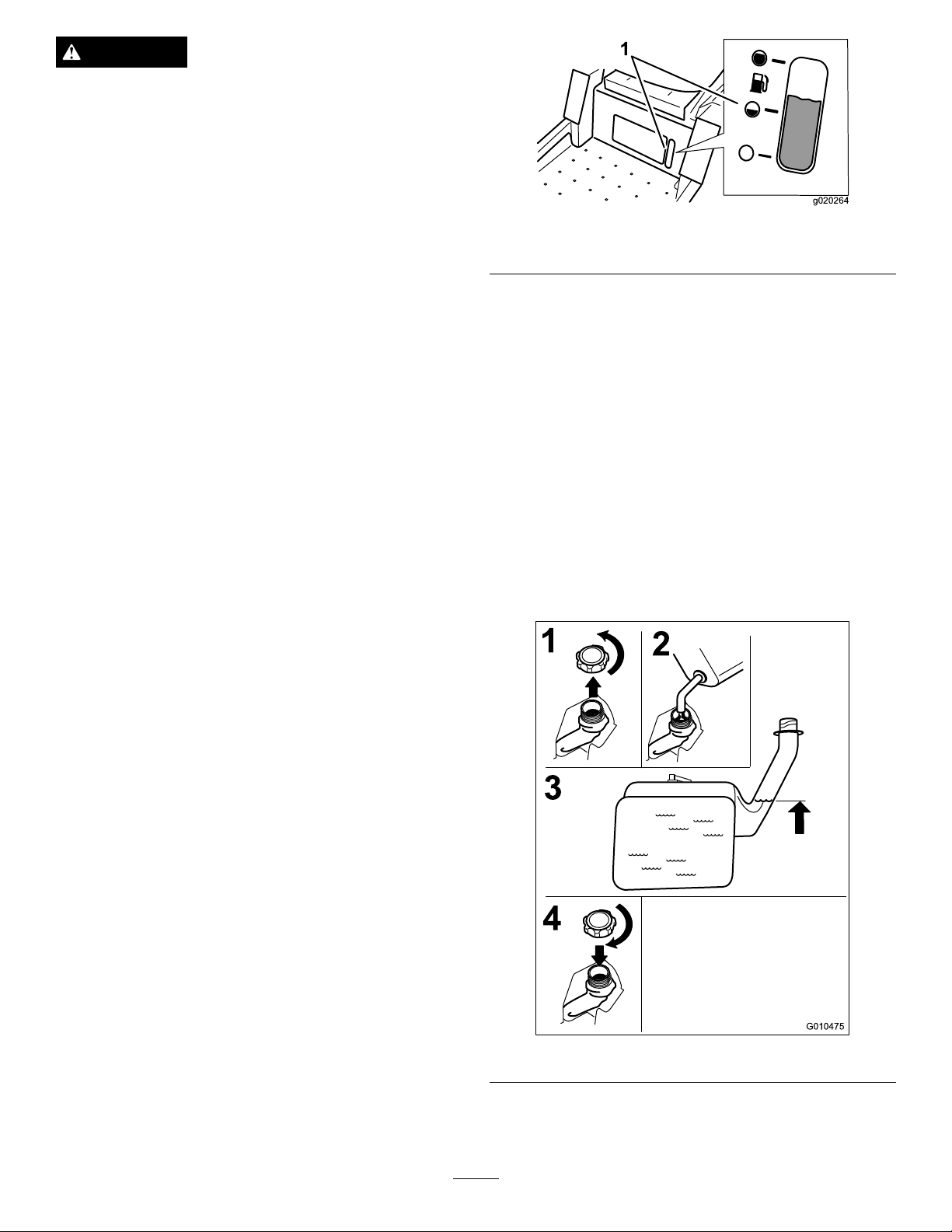

FillingtheFuelTank

Makesuretheengineisshutoffandthemotioncontrolsare

intheparkposition.

Important:DoNotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakageordamagetotheengineoremissionsystem.

1.Cleanaroundthefueltankcapandremovethecap.

Note:Youcanusethefuelwindowbelowthe

operatingpositionverifythepresenceofgasoline

beforellingthetank(

Figure11).

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.T ominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FuelGauge

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneck

Figure12.

Usethefuelwindowbelowtheoperatortoverifythelevelof

gasolinebeforellingthetank(Figure11).

Figure12

3.Installthefueltankcapsecurelyandtightenuntilit

“clicks”.Wipeupanygasolinethatmayhavespilled.

18

Page 19

CheckingtheEngineOilLevel

G010078

1

2

G010079

1

2

G008946

G008959

1

2

OperatingtheChoke

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine

OilLevel.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

Figure13

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(

3.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(Figure16).

Figure16).

ReleasingtheParkingBrake

Figure16

1.On2.Off

OperatingtheIgnitionSwitch

Figure14

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure15).

Alwaysusethefastpositionwhenturningonthemowerdeck

withthebladecontrolswitch(PTO).

1.TurntheignitionkeytotheStartposition(Figure17).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure15

19

Page 20

START

RUN

STOP

G008947

G010080

2

3

4

5

1

START

RUN

STOP

G008947

Figure17

2.Turntheignitionkeytostoptostoptheengine.

StartingandStoppingthe Engine

StartingtheEngine

1.Sitdownontheseat(Figure18)andfastentheseatbelt.

2.Movethemotioncontrolsoutwardtotheneutrallock

position(Figure18).

3.Settheparkingbrake(

ParkingBrake.

4.Movethebladecontrolswitch(PTO)totheOff

position(Figure18).

5.MovethethrottlelevertoFast.

6.EngagethechokeasdescribedinOperatingtheChoke.

Note:Awarmorhotenginemaynotrequirechoking.

Inthiscase,rsttrystartingtheenginewithoutusing

thechoke.

Figure18);refertoSettingthe

Figure18

7.TurntheignitionkeytotheStartposition(Figure17).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure19

1.Off3.Start

2.Run

20

Page 21

StoppingtheEngine

S

T

A

R

T

R

U

N

S

T

O

P

G017771

2

3

4

5

1

G008945

G009174

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Note:Engagingthebladecontrolswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

Figure21

DisengagingtheBladeControlSwitch

(PTO)

Figure20

OperatingtheMowerBlade ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Engagethebladecontrolswitch(PTO)withthethrottle

positionatFast.

Figure22

TheSafetyInterlockSystem

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutrallockposition.

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

whenthecontrolleversareoutoftheneutrallockposition

21

Page 22

withtheparkingbrakeonorifyourisefromtheseatwhen

thebladesareengaged.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitchtoOn.Trystartingthe

engine;theengineshouldnotcrank.

2.Whilesittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitchtoOff.Moveeither

motioncontrollever(forwardorreverse).Trystarting

theengine;theengineshouldnotcrank.Repeatwith

theothermotioncontrollever.

3.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,releasetheparkingbrake,

engagethebladecontrolswitch,andriseslightlyfrom

theseat;theengineshouldstop.

UsingtheMotionControlLevers

4.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,centerthemotion

controls;theengineshouldstop.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Figure23

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetractioncontrolleversare

movedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrollevers

forward(Figure24).

22

Page 23

G008952

G008953

StoppingtheMachine

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheparkposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Tostopthemachine,movethetractioncontrolleversto

neutralandmovetolockedposition,disengagetheblade

controlswitch(PTO),andturntheignitionkeytooff.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake.Remembertoremovethekeyfrom

theignitionswitch.

Figure24

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrollevers

rearward(

Figure25).

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldeckliftsystem.

Theoperatorcanusethefootpedaltoliftthedeckbrieyto

avoidobstaclesorlockthedeckinthehighestheight-of-cut

ortransportposition.Theoperatorcanusetheheightof

cutleverwiththefootpedaltolockthedeckinaspecic

cuttingheight.

UsingtheFootPedalDeckLiftSystem

Pressthepedaldowntoraisethedeck;continuetopress

thepedaluntilthedeckislockedinthetransportposition

Figure26.Pushonthedeckliftpedalwithyourfootandraise

theheight-of-cutleverslightlytodisengagethetransportlock.

Figure25

23

Page 24

G010219

G010236

1

2

3

4

5

Figure27

Figure26

TransportLockPosition

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom1-1/2to4-1/2inch

(38to114mm)in1/4inch(6mm)incrementsbyrelocating

theheight-of-cutpinintodifferentholelocations.

1.Pushonthedeckliftpedalwithyourfootand

raisethemowerdecktothetransportposition(also

the4-1/2inch(114mm)cuttingheightposition)

(Figure27).

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure27).

3.Selectaholeintheheight-of-cutsystemcorresponding

totheheight-of-cutdesiredand,insertthepin

(Figure27).

1.Deckliftpedal

2.Cutheightpin

3.Height-of-cutpositions

4.Lockposition.lowest

height-of-cut(useonlyfor

deckremoval)

5.Lockposition.transport

position

UsingtheLockPositions

Thedeckcanbelockedinthehighestheight-of-cutor

transportpositionorthelowestheight-of-cutposition.

Tolockthedeckinthetransportposition:

1.Pushonthedeckliftpedalwithyourfootandraisethe

mowerdecktothetransportposition(alsothe4.5inch

(114mm)cuttingheightposition)(Figure27).

2.Removethepinfromtheheight-of-cutbracket

(Figure27).

3.Selectthelowerholeonthelockdecalandinsertthe

pin(Figure27).

Tolockthedeckinthelowestheight-of-cutposition:

4.Pushonthedeckliftpedalwithyourfootandraisethe

height-of-cutleverslightlytodisengagethetransport

lock.Lowerthedeckslowlyuntilthepinmakescontact

withthelever.

1.Pushonthedeckliftpedalwithyourfootandraisethe

mowerdecktothetransportposition(alsothe4.5inch

(114mm)cuttingheightposition)(Figure27).

2.Removethepinfromtheheight-of-cutbracket

(Figure27).

3.Pushonthedeckliftpedalwithyourfootandlower

themowerdecktothelowestposition.

4.Selecttheupperholeonthelockdecalandinsertthe

pin(

Figure27).

24

Page 25

AdjustingtheAnti-Scalp

G010233

1

2

3

4

G010232

1

4

1

2

G015764

3

5

AdjustingtheMotionControl

Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollersasshownin

matchtheclosestheight-of-cutposition.

Figure28

Figure28to

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort.

1.Removethe2boltsand2washersholdingthecontrol

levertothecontrolarmshaft(Figure30).

2.Movethecontrollevertothenextsetofholes.Secure

theleverwiththe2boltsand2washers(Figure30).

Figure30

1.Controlarmshaft

2.Controllever

3.Slotted,upperhole

4.Washer

5.Bolt

1.Anti-scalproller3.FlangeNut

2.Bolt4.Holespacing

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Whilesittingintheoperator'sposition,raisetheseat

adjustmentleverslightlyandmovetheseatforwardor

backwardtothedesiredposition(Figure29).

1.Adjustmentlever

Figure29

3.Repeattheadjustmentfortheoppositecontrollever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

controlarmshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforeoraft.Tightenbothboltstosecurethe

controlinthenewposition.

3.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausedamagemayoccur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtoneutrallock

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.Makesuretheparkingbrakeisdisengaged.

3.Locatethebypassleversattherearofthemachine,on

theleftandrightsideoftheframe.

25

Page 26

4.Movethebypassleversrearwardandthendowntolock

G012087

2

3

4

1

1

1

2

3

G012841

theminplaceasshowninFigure31todisengagethe

wheelmotors.Repeatthisoneachsideofthemachine.

Themachineisnowabletobepushedbyhand.

Figure31

2.Movethemotioncontrolleversoutwardtotheneutral

lockposition,settheparkingbrake,stoptheengine,

removethekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.RemovethemowerasdescribedintheRemovingthe

MowerprocedureintheMaintenancesectionformore

information.

4.Turnthemowerupsidedown.

5.Removetheexistingmowerbladesinstalledonyour

deck.RefertotheRemovingtheBladesprocedurein

theMaintenancesectionformoreinformation.

6.Removethetwolocknuts(5/16inch)securedto

theweldedpostsoftheleftbafeonthetopofthe

mowerdeckatthecenterandleftofcenterpositions

Figure32).Removethecarriageboltandlocknuton

(

thesidewallofthemowerdecksecuringtheleftbafe

tothedeck.

ToOperatetheMachine

Movethebypasstothepositionforoperatingthemachine

Figure31)toengagethewheelmotors.

(

Convertingthe48inchMower toSideDischarge

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandsidedischarge

performance.

Installthefastenersintothesameholesinthedecktheywere

originallyremovedfrom.Thisensurenoholesareleftopen

whenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouandothersto

throwndebris.Debristhrownoutofholesinthe

mowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

•Installhardwareinmountingholeswhenthe

bafeisremoved.

Figure32

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

7.Removetheleftbafefromthemowerdeckasshown

inFigure32.

8.Removethecarriagebolt(5/16x3/4inch)andlocknut

(5/16inch)ontherearwallofthemowerdecksecuring

thebafetothedeck(Figure33).

RemovingtheMulchBafe

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

26

Page 27

G012806

1

2

3

4

3

2

1

2

3

G012805

G012800

1

2

3

4

Figure35

Figure33

1.Bafeguard3.Carriagebolt(5/16x3/4

2.Locknut(5/16inch)4.Rightbafe

inch)

9.Locatethebafeguardatthefrontedgeoftheside

dischargeopening.Removethefastenerssecuringthe

bafeguardandtherightbafetothemowerdeck

asshownin

Figure33.Removethebafeguardand

retainallfasteners.

10.Removethetwolocknuts(5/16inch)tosecuringthe

weldedpostsoftherightbafetothetopofthemower

deckatcenterandrightofcenterpositions(

Figure34).

Removetherightbafefromthemowerdeck.

1.Carriagebolt,existing3.Cutoffbafe,shipped

2.Rearholesinthe

dischargeplate

loose

4.Locknut,existing

12.Usethefastenersremovedtosecurethecutoffbafe

tothedeck.

13.Installthebladestothedeck.RefertotheInstalling

theBladesprocedureintheMaintenancesectionfor

moreinformation.

14.InstallthemowerasdescribedintheInstallingthe

MowerprocedureintheMaintenancesectionformore

information.

Convertingthe54inchMower toSideDischarge

Themowerdeckandmowerbladesshippedwiththis

machineweredesignedforoptimummulchingperformance.

Sidedischargeperformancecanbeimprovedbyreplacingthe

mulchingbladeswithstandardcuttingbladesobtainedfrom

yourlocalauthorizedT orodealer.Tomaintainoptimum

mulchingperformance,alwaysinstallthemulchingbladesthat

areshippedwiththisunitwhenchangingbacktomulching

operation.

Figure34

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe

11.Locatethecutoffbafeintheloosepartsbag.Remove

thefastenersattherearholesofthedischargeplate.

Installthebafeatthesidedischargeopeningonthe

mowerdeck(

Figure35).

Installthefastenersintothesameholesinthedecktheywere

originallyremovedfrom.Thisensurenoholesareleftopen

whenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouandothersto

throwndebris.Debristhrownoutofholesinthe

mowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

•Installhardwareinmountingholeswhenthe

bafeisremoved.

27

Page 28

RemovingtheMulchBafe

G011149

1

1

2

3

4

G010712

1

2

4

3

5

6

7

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtotheneutral

lockposition,settheparkingbrake,stoptheengine,

removethekey,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.RemovethemowerasdescribedintheRemovingthe

MowerprocedureintheMaintenancesectionformore

information.

4.Turnthemowerupsidedown.

5.Removetheexistingmowerbladesinstalledonyour

deck.RefertotheRemovingtheBladesprocedurein

theMaintenancesectionformoreinformation.

6.Removethethreelocknuts(5/16inch)securedtothe

weldedpostsoftheleftbafeonthetopofthemower

deckatthecenter,leftofcenterandleftpositions

(Figure36).Removethecarriageboltandlocknuton

thesidewallofthemowerdecksecuringtheleftbafe

tothedeck.

9.Removethecarriagebolt(5/16x3/4inch)andlocknut

(5/16inch)ontherearwallofthemowerdecksecuring

thebafetothedeck(Figure37).

Figure37

Figure36

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

4.Installfastenershere

7.Removetheleftbafefromthemowerdeckasshown

inFigure36.

8.Locatethetwoboltsinloosepartsandusetheexisting

locknuts.Installthesefastenersintotheholesshownin

Figure36onthemowerdecktopreventyingdebris.

Installtheboltup,throughtheundersideofthedeck

anduseanexistinglocknuttosecurefromthetopside.

1.Carriagebolt(5/16x3/4

inch)

2.Locknuts,frontof

dischargeplate(reinstall

afterbafeisremoved)

3.Locknut,forwardholein

deck(reinstallafterbafe

isremoved)

4.Bafeguard,54inch

decks

5.Hexheadbolt,forward

holeindeck(reinstallafter

bafeisremoved)

6.Carriagebolts,frontof

dischargeplate(reinstall

afterbafeisremoved)

7.Locknut(5/16inch)

10.Locatethebafeguardatthefrontedgeoftheside

dischargeopening.Removethefastenerssecuringthe

bafeguardandtherightbafetothemowerdeck

asshowninFigure37.Removethebafeguardand

retainallfasteners.

11.Removethetwolocknuts(5/16inch)securingthe

weldedpostsoftherightbafetothetopofthemower

deckatcenterandrightofcenterpositions(Figure38).

12.Removethecarriageboltandlocknutsecuringtheright

bafetothetopofthemowerdeck.Removetheright

bafefromthemowerdeck(Figure38).

WARNING

Openholesinthemowerexposeyouand

otherstothrowndebriswhichcancause

severeinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemowerhousing.

•Installthehardwareinthemountingholes

whenyouremovethemulchingbafe.

28

Page 29

G010704

1

2

3

Figure38

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe4.Carriagebolt

13.Installthefastenersremovedpreviouslyatthefront

holesinthedischargeplateandforwardholeinthe

deck(Figure37).

17.InstallthemowerasdescribedintheInstallingthe

MowerprocedureintheMaintenancesectionformore

information.

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

14.Locatethecutoffbafeintheloosepartsbag.Remove

thefastenersattherearholesofthedischargeplate.

Installthebafeatthesidedischargeopeningonthe

mowerdeck(Figure39).

Figure39

1.Carriagebolt3.Cutoffbafe

2.Rearholesinthe

dischargeplate

4.Locknut

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethebladecontrolswitch

(PTO)totheoffposition,rotatetheignitionkey

tooffandremovethekey.

•Makesurethegrassdeectorisinthedown

position.

15.Usethefastenersremovedtosecurethecutoffbafe

tothedeck.

16.Installthebladestothedeck.RefertotheInstalling

theBladesprocedureintheMaintenancesectionfor

moreinformation.

29

Page 30

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethecutting

heightofthemowerdoesnotscalpanyunevenground.

However,thecuttingheightusedinthepastisgenerallythe

bestonetouse.Whencuttinggrasslongerthansixinchestall,

youmaywanttocutthelawntwicetoensureanacceptable

qualityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

30

Page 31

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlterandoil.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulicoillevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Servicethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenindusty,dirtyconditions).

•Checkthesparkplug(s).

•Replacethefuellters(moreoftenunderdusty,dirtyconditions).

•Replacethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheoillter.(moreoftenindusty,dirtyconditions)

•Changethehydraulicsystemlterandoil.

Monthly

Yearlyorbeforestorage

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug .

31

Page 32

Figure40

Locatedontheseatpanunderside

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

4.Checkthehydraulicoilevery25hours

6.Lubricatethecasterwheelevery25hours

32

Page 33

Premaintenance

G009949

1

Lubrication

Procedures

GreasingtheBearings

RaisingtheSeat

Makesurethemotioncontrolleversarelockedintheneutral

lockposition.Lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Servicedecal

•Fuses

•Batteryandcables

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2GeneralPurposeLithiumBaseGrease

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtotheneutral

lockposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure41andFigure40)with

arag.Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

Figure41

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure40and

Figure41).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

33

Page 34

EngineMaintenance

G015155

1

2

3

SAEV iscosityGrades

SAE40

SAE30

SAE10W– 30/ SAE10W– 30

-2002032406080100

-30-20-10010203040

°F

°C

STARTING TEMPERA TURERANGE ANTICIPATEDBEFORENEXT OIL CHANGE

SAE5W– 20

G010686

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

CleaningtheElement

ServiceInterval:Every100hours—Servicethepaper

element(moreoftenindusty ,dirty

conditions).

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement(moreoftenin

dusty,dirtyconditions).

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrol(PTO).

2.Movethemotioncontrolleverstotheneutrallock

position,settheparkingbrake,stoptheengine,remove

thekey,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanaroundtheaircleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.Liftthe

coverandremovethehoseclampsecuringtheair

cleanerassemblytotheengine(

4.Loosenthehoseclampandremovethepaperelement

(Figure42).

Figure42).

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orSL)

CrankcaseCapacity:61ounces(1.8l),[whenoillteris

removed:70ounces(2.1l)]

Viscosity:Seethetablebelow.

Figure42

1.Cover

2.Paperelement

3.Hoseclamp

Figure43

Note:Usingmultigradeoils(5W -20,10W-30,and10W -40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

34

Page 35

enginewithoilbelowthelowmarkbecausetheengine

G008792

1

2

5

6

7

3

9

10

4

8

G012153

1

2

3

4

5 6

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure44).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensuretheoildrains

completely.

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure45).

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changetheengine

Every100hours—Changetheengineoil(moreoften

industy,dirtyconditions).

Figure45

4.Slowlypourapproximately80%ofthespeciedoil

Figure44

oil.

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure46).

35

Page 36

G008796

2

3

4

5

6

1

Figure46

G008748

3/4

1

2

3

4

5

6

ChangingtheEngineOilFilter

ServiceInterval:Every200hours—Changetheoillter.

(moreoftenindusty ,dirtyconditions)

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(Figure47).

Figure47

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:NGKBPR4ES(orequivalent)

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

36

Page 37

Figure48

G008794

1

2

16ft-lb

22N-m

G010687

Note:Duetothedeeprecessaroundthesparkplug,

blowingoutthecavitywithcompressedairisusually

themosteffectivemethodforcleaning.Thesparkplug

ismostaccessiblewhentheblowerhousingisremoved

forcleaning.

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure50

CleaningtheCoolingSystem

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

Figure49

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft-lb(22N-m).

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagethebladecontrolswitchandmovethe

controlleverstotheneutrallockedpositionandapply

theparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,andfan

housing.

37

Page 38

FuelSystem

g017723

1

2

3

4

5

G008963

12

3

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)(moreoftenunderdusty,dirty

conditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,and

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Raisetheseatandlocatethefuelltersasshownin

Figure51.

Figure52

1.Fuellter

2.Hoseclamp

6.Removethelterfromthefuellines.

7.Installanewlterwiththeowdirectionarrowcoming

fromthefueltankandpointingtotheengine.Move

thehoseclampsclosetothelter(

itinplace.

3.Fuelline

Figure51)tosecure

Figure51

1.Fuellinefromtank

2.In-lineFuellter

3.Flowdirectionarrow

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure52).

4.Fuellinetoengine

5.Hoseclamp

38

Page 39

ElectricalSystem

G010240

1

2

3

4

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

Figure53

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

4.Removetheclamp(Figure53).

5.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(

6.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

Figure53).

(

7.Removethebattery.

3.Removethepositive

batterycable

4.Removebattery

Figure53).

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthefueltank(

2.First,installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Theninstallthenegativebatterycabletothenegative

(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

Figure53).

(

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure53).

Figure53).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethewingnutsecuringthebatteryclamp

(

Figure53).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

39

Page 40

Important:Alwayskeepthebatteryfullycharged.This

30

25

1 2

3

G015037

4

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure54).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure55

Figure54

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

Fuses:

•Main,30amp,blade-type

1.30amp

2.25amp4.Fuseblock

3.Openaccessoryslot

•Engine,20amp,blade-type

1.Thefusesarelocatedonrighthandconsolenextto

theseat(Figure55).

2.Toreplacethefuses,pulloutonthefusetoremoveit.

3.Installanewfuseofthesameamperageremoved

(Figure55).

40

Page 41

DriveSystem

G010253

1

2

3

HydraulicSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure56).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto13psi(90kPa).

Figure56

Maintenance

HydraulicSystemOilSpecication

OilType:ToroHYPR-OIL®500or20w-50motoroil.

SystemCapacity:approximately4.495liter(152oz)witha

lterchange.

Important:Useoilspeciedorequivalent.Otheruids

couldcausesystemdamage.

CheckingtheHydraulicOil Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryaddoiltothe

FULLCOLDline.

1.Valvestem

Figure57

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic SystemFilterandOil

Thelterandoilarechangedatthesametime.DoNotreuse

oil.Oncethenewlterisinstalledandoilisaddedanyairin

thesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheoilremainsatthe

FULLCOLDlineinthereservoirafterpurging.Failureto

properlyperformthisprocedurecanresultinirreparable

damagetothetransaxledrivesystem.

41

Page 42

RemovingHydraulicSystemFilters

G010254

1

2

3

4

5

G008748

3/4

1

2

3

4

5

6

Important:Whenthehydraulicoillterisremoved,all

ofthehydraulicoilineachtransaxlewilldrainout.Use

acontainerthatwillhandle4.495liters(152oz)orlarger.

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removethekeyandengagethe

parkingbrake.

2.Locatethelterandguardsoneachtransaxledrive

system(

lterguardandguard.

Figure58).Removethreescrewssecuringthe

Figure58

Rightsideshown

1.Transaxledrive

2.Oillter

3.Filterguard

3.Carefullycleantheareaaroundthelters.Itis

importantthatnodirtorcontaminationenterthe

hydraulicsystem.

4.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterandventplugsareremoved.

5.Locateandremovetheventplugoneachtransmission

6.Unscrewtheltertoremoveandallowoiltodrain

fromthedrivesystem.

Repeatthisprocedureforbothlters.

4.Screws

5.Ventplug

InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

Figure59

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4to

1fullturn.Repeatfortheotherlter

3.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

4.Verifytheventplugsareremovedbeforeaddingtheoil.

5.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.Stopandinstallthatventplug.Torquetheplug

to180in-lb(20.3N-m).

6.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.Stopandinstallthatvent

plug.T orquetheplugto180in-lb(20.3N-m).

7.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineontheexpansion

reservoir.ProceedtotheBleedingtheHydraulic

Systemsection.

Important:Failuretoperformthe

the Hy draulic System

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

42

Page 43

BleedingtheHydraulicSystem

G010333

1

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

Figure60

1.Jackingpoints

2.Entertheoperator'sposition.Startengineand

movethrottlecontrolaheadto1/2throttleposition.

Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.Withthe