Page 1

FormNo.3380-815RevA

g019887

ZMaster

®

Professional6000

SeriesRidingMower

with48in,52in,60in,or72inTURBOFORCE

SideDischargeMower

ModelNo.74922—SerialNo.314000001andUp

ModelNo.74923—SerialNo.314000001andUp

ModelNo.74925—SerialNo.314000001andUp

ModelNo.74927—SerialNo.314000001andUp

ModelNo.78922—SerialNo.314000001andUp

ModelNo.78924—SerialNo.314000001andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3380-815*A

Page 2

WARNING

1

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedToroDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Note:ItisaviolationofCaliforniaPublicResource

CodeSection4442touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandwithout

asparkarrestermufermaintainedinworkingorder,or

theengineconstricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmayhave

similarlaws.

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

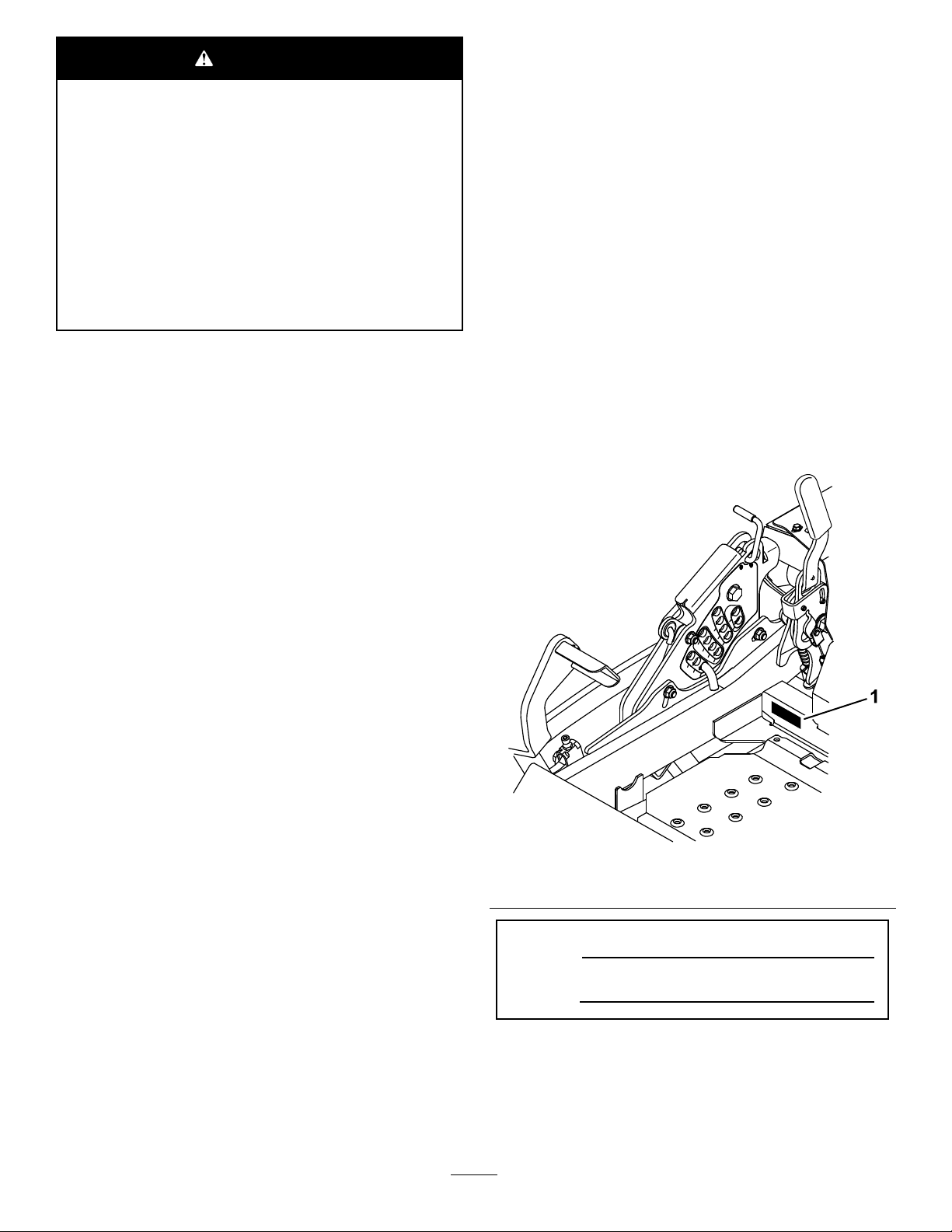

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorT oro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................15

Operation....................................................................16

AddingFuel...........................................................16

CheckingtheEngine-oilLevel..................................17

BreakingInaNewMachine.....................................17

UsingtheRolloverProtectionSystem(ROPS)............17

ThinkSafetyFirst...................................................18

OperatingtheParkingBrake....................................19

OperatingtheMowerBlade-controlSwitch

(PTO)...............................................................19

OperatingtheThrottle............................................20

OperatingtheChoke...............................................20

OperatingtheIgnitionSwitch..................................20

UsingtheFuelShutoffValve....................................20

StartingandStoppingtheEngine..............................21

UsingtheSafety-interlockSystem.............................22

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................24

AdjustingtheHeight-of-Cut....................................24

AdjustingtheAnti-scalpRollers................................25

AdjustingtheFlowBafeCamLocks........................26

PositioningtheFlowBafe......................................26

PositioningtheSeat................................................27

UnlatchingtheSeat.................................................27

ChangingtheSeatSuspension..................................27

UsingtheDrive-wheel-releaseValves........................27

UsingtheSideDischarge.........................................28

TransportingMachines............................................29

LoadingMachines..................................................29

OperatingTips......................................................31

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

Lubrication...............................................................33

AddingLightOilorSprayLubrication.......................33

GreasingtheMower...............................................33

LubricatingtheCaster-wheelHubs...........................34

EngineMaintenance..................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOil..........................................36

ServicingtheSparkPlug..........................................39

CheckingtheSparkArrester(ifequipped)..................40

FuelSystemMaintenance...........................................40

ReplacingtheFuelFilter..........................................40

ServicingtheFuelTank...........................................41

ElectricalSystemMaintenance....................................41

ServicingtheBattery...............................................41

ServicingtheFuses.................................................43

DriveSystemMaintenance.........................................43

3

Page 4

CheckingtheSeatBelt.............................................43

CheckingtheRolloverProtectionSystem(ROPS)

Knobs...............................................................43

AdjustingtheTracking............................................44

CheckingtheTirePressure......................................44

CheckingtheWheelLugNuts..................................45

CheckingtheWheelHubSlottedNut........................45

AdjustingtheCaster-pivotBearing............................45

UsingtheClutchShim............................................45

CoolingSystemMaintenance......................................47

CleaningtheEngineScreenandEngine-oil

Cooler...............................................................47

CleaningtheEngine-coolingFinsand

Shrouds.............................................................47

CheckingandCleaningtheHydraulic-unit

Shrouds.............................................................48

BrakeMaintenance....................................................49

AdjustingtheParkingBrake.....................................49

BeltMaintenance......................................................50

InspectingtheBelts................................................50

ReplacingtheMowerBelt........................................50

ReplacingtheHydraulicPump-driveBelt...................51

ControlsSystemMaintenance.....................................52

AdjustingtheControl-handlePosition.......................52

AdjustingtheMotion-controlLinkage.......................53

AdjustingtheMotion-controlDamper......................54

AdjustingtheMotionControlNeutral-lock

Pivot.................................................................54

HydraulicSystemMaintenance....................................55

ServicingtheHydraulicSystem.................................55

MowerDeckMaintenance...........................................57

LevelingtheMowerDeck........................................57

ServicingtheCuttingBlades.....................................59

RemovingtheMowerDeck.....................................61

ReplacingtheGrassDeector..................................63

Cleaning...................................................................63

CleaningundertheMower.......................................63

DisposingofWaste.................................................63

Storage........................................................................64

CleaningandStoringtheMachine.............................64

Troubleshooting...........................................................65

Schematics...................................................................67

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,W arning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthisOperator’s

Manual.Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorizedT oro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

4

Page 5

Preparation

•Keepyourhandsandfeetawayfromthecuttingunit.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.

Note:Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincluding:ahardhat,safety

glasses,andhearingprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentisused,andremove

allobjectsthatcanbethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Onlystartthe

enginefromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

5

Page 6

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeet,and

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass,or,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

•Donotstorefuelnearamesordrainindoors.

•Donotallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

GeneralOperation

•Besurethattheareaisclearofbystandersbeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartstocool

beforeattemptingtomaintain,adjust,orservicethe

machine.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithanyunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires,etc.)beforeoperatingunder

anyobjects,anddonotcontactthem.

•Slowdownbeforemakingturnsanduseextracaution.

•Usecautionwhenridingtheplatformovercurbs,rocks,

roots,orotherobstructions.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.Useextracarewhenoperatinginreverse.

•Donotjerkthecontrols;useasteadymotion.

•Whenloadingorunloadingthemachine,useone

full-widthrampthatiswideenoughtoextendbeyond

thewidthofthemachine.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.

Note:Tallgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Note:Themachinecouldsuddenlyturnoverifawheel

goesovertheedgeofaclifforditch,orifanedgecavesin.

•Useextracarewithgrasscatchersorotherattachments.

Note:Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedordirection.

6

Page 7

•Mowslopessidetoside.

Service

•Donotmowslopesgreaterthan15degrees.

UsingtheRolloverProtectionSystem

(ROPS)

•TheROPSisanintegralandeffectivesafetydevice.Keep

theROPSintheraisedandlockedpositionandusethe

seatbeltwhenoperatingthemachine.

•LowertheROPStemporarilyonlywhenabsolutely

necessary.DonotweartheseatbeltwhentheROPSis

foldeddown.

•BeawarethereisnorolloverprotectionwhentheROPS

isinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddownthe

ROPSinareaswherethereareslopes,dropoffsorwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverinterferewiththeintendedfunctionofasafety

deviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onT orogenuineparts.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

7

Page 8

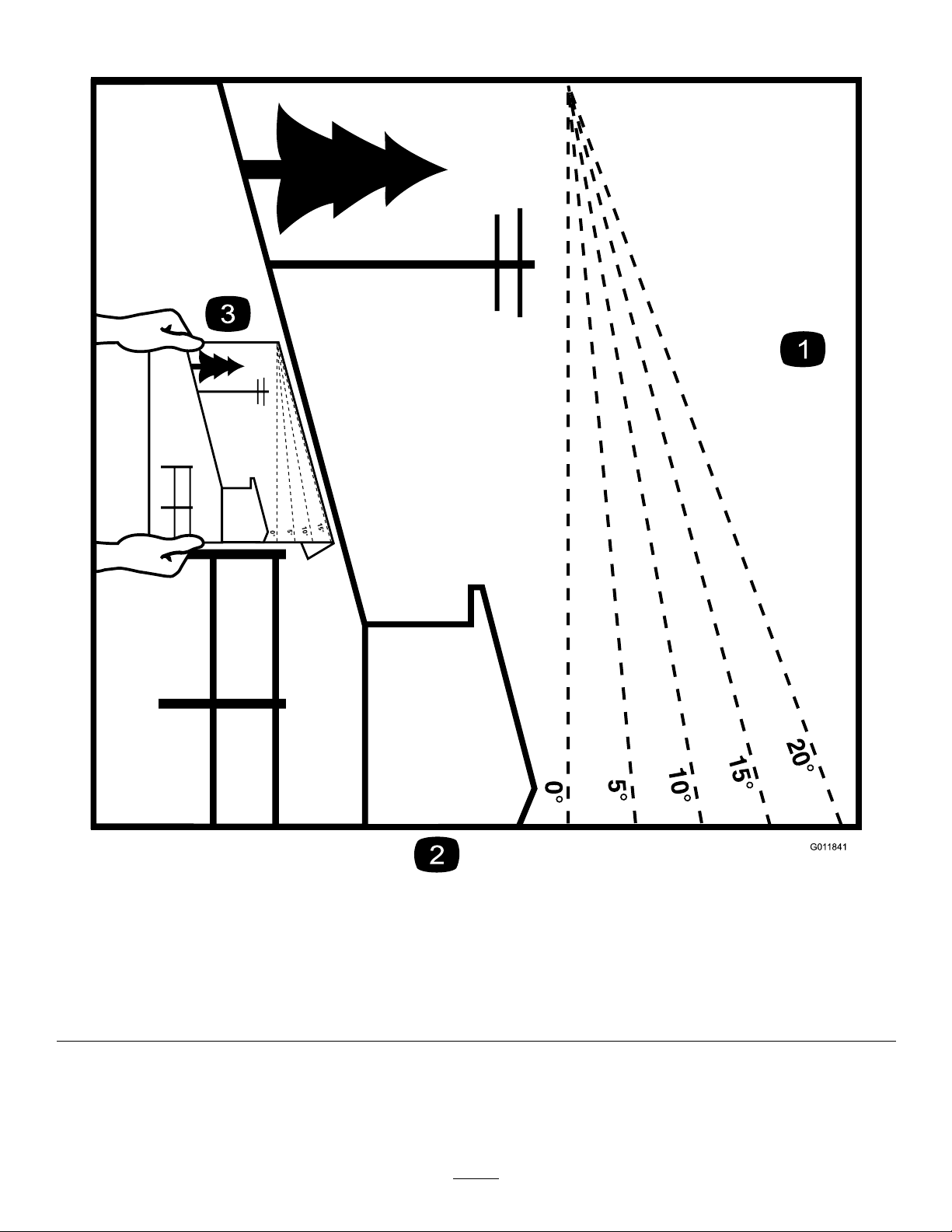

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

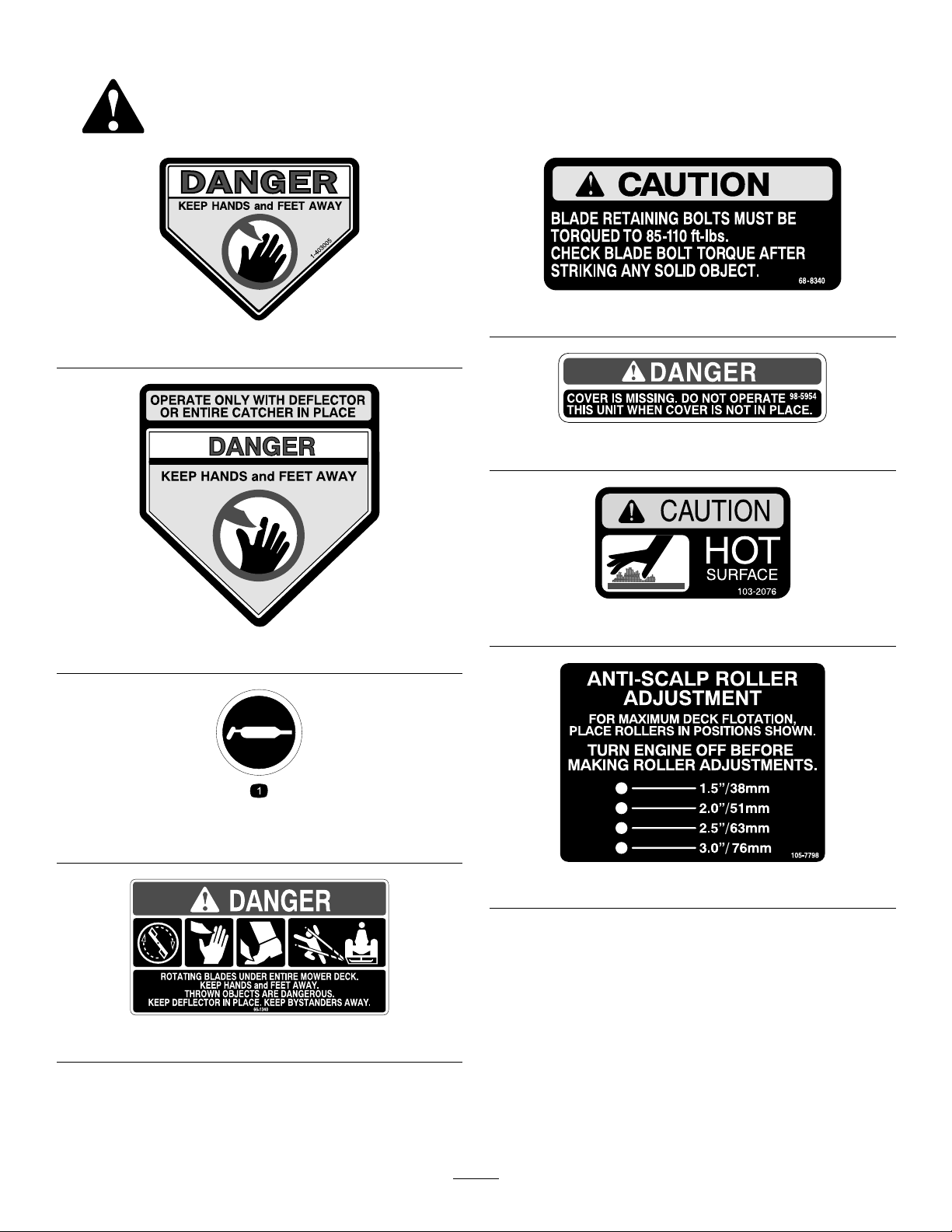

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-403005

68-8340

98-5954

103-2076

54-9220

58-6520

1.Grease

105-7798

66-1340

9

Page 10

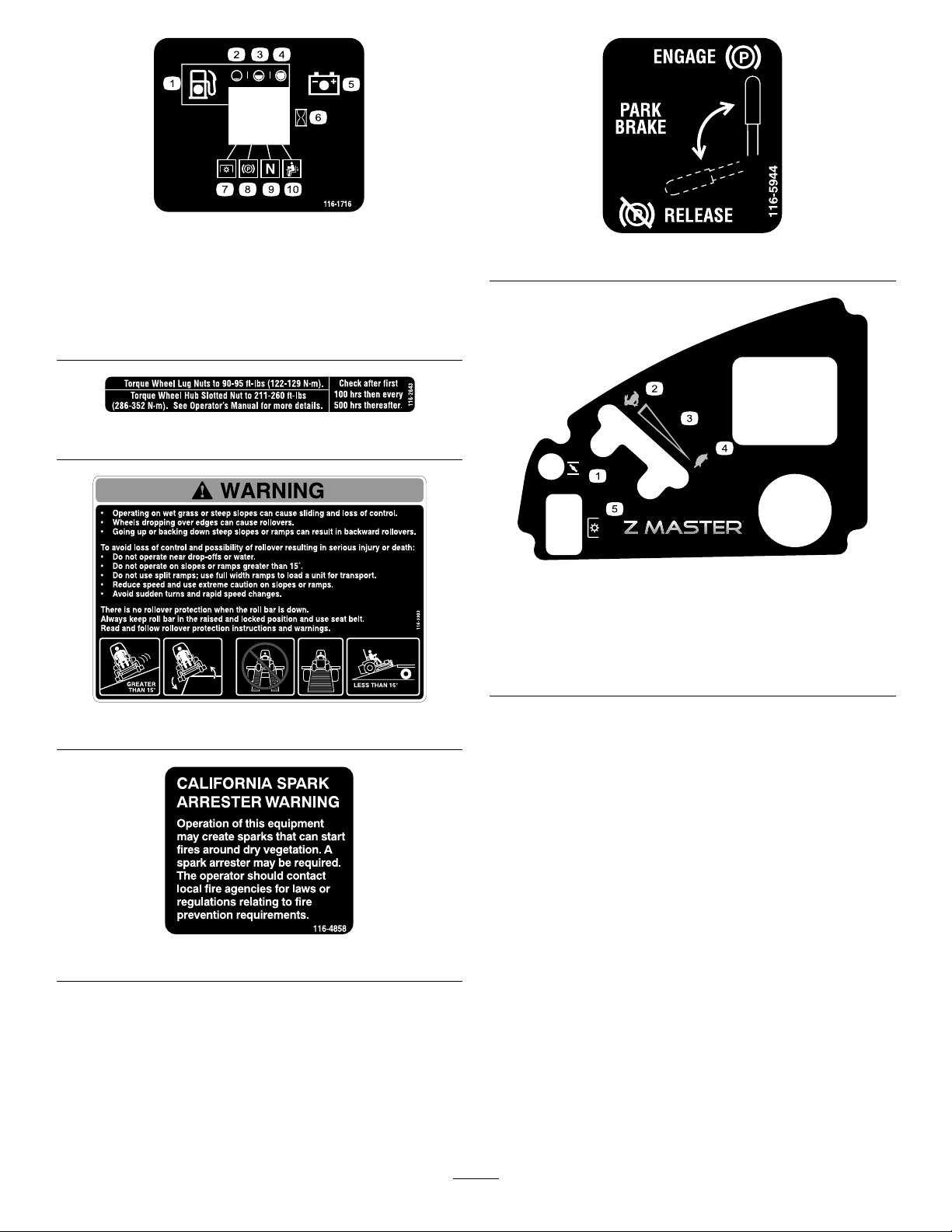

110-2067

110-2068

1.ReadtheOperator'sManual.

107-2102

114-4466

109-7232

1.Fast3.Neutral

2.Slow

1.Main,25A

2.PTO,10A

4.Reverse

3.Charge,25A

4.Auxiliary,15A

10

Page 11

116-0205

115-7445

1.Greasepulleysandspindles

2.Maintenanceinterval—50hours

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

116-0090

116-0752

116-0157

1.Onlyuserecommendedhydrooil

1.Locked2.Unlocked

116-1654

11

Page 12

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

116-2643

116-5944

120-5897

1.Choke4.Slow

2.Fast

3.Continuousvariable

setting

5.Powertake-off(PTO),

Bladecontrolswitch

116-3303

116-4858

12

Page 13

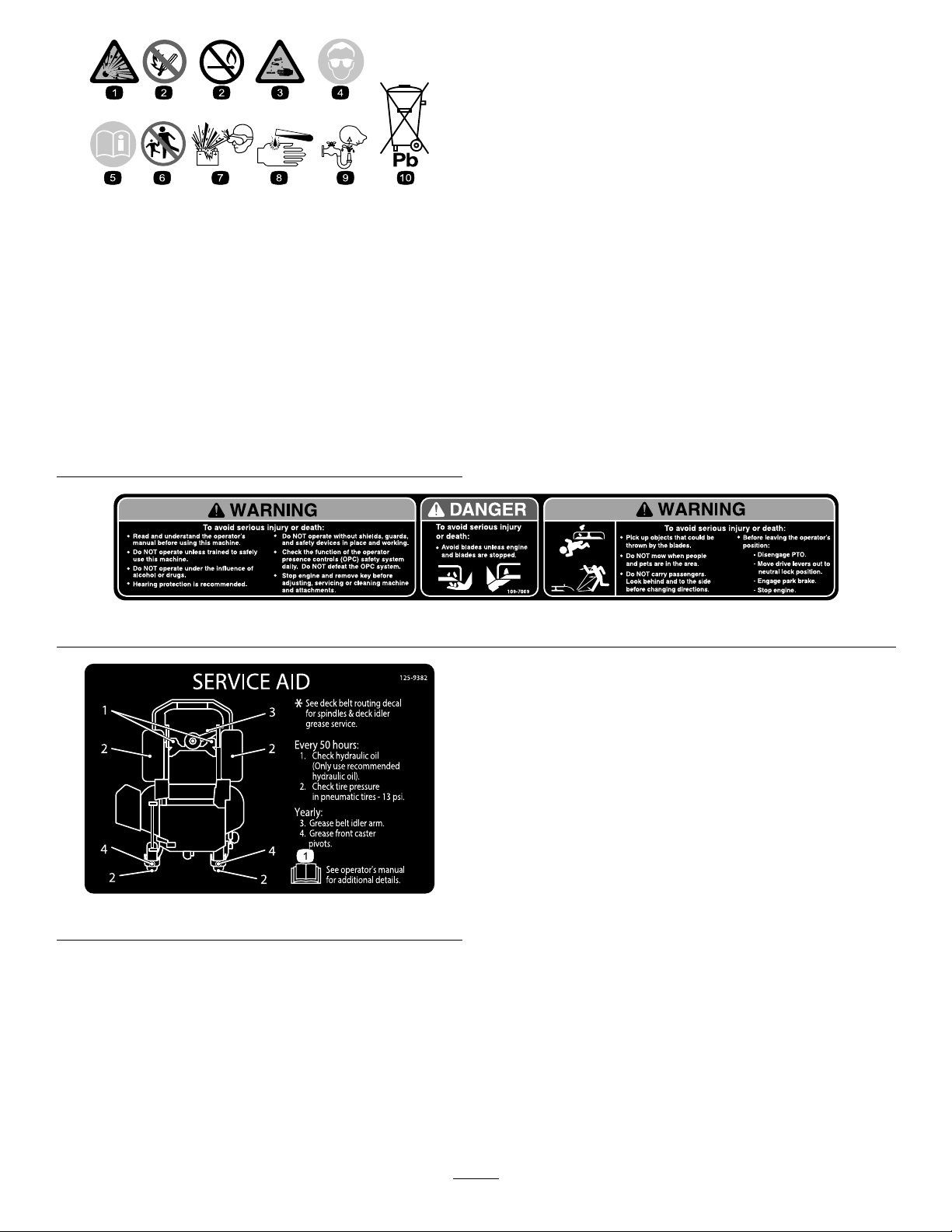

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

109-7069

125–9382

13

Page 14

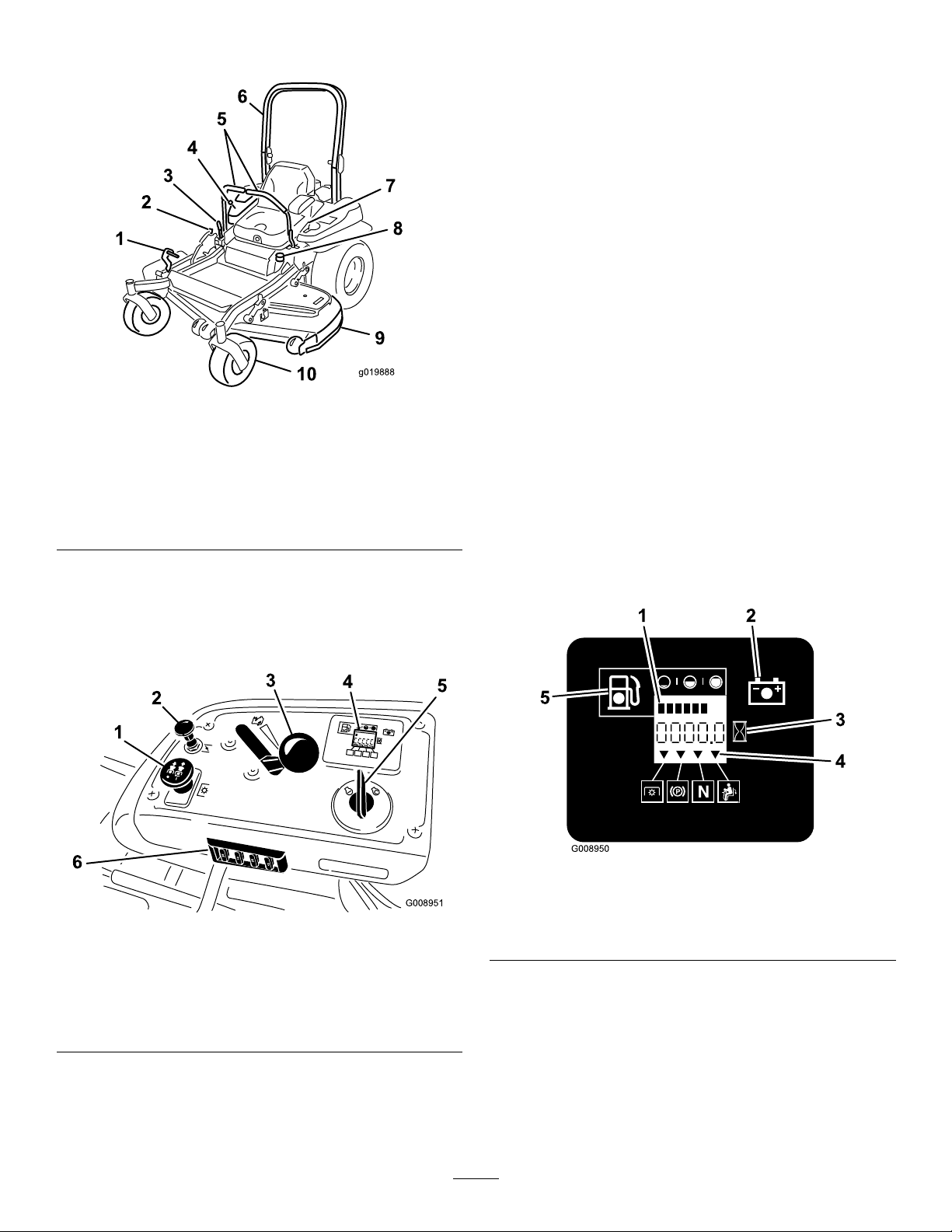

ProductOverview

g019888

25

25

10

15

G008951

1

2

3

4

5

6

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure6).

FuelGauge

Thefuelgaugeislocatedwiththehourmeter,andthebars

lightupwhentheignitionswitchisintheOnposition(Figure

6).

Theindicatorlightappearswhenthefuellevelislow

(approximatelyonegallonremaininginthefueltank).

Safety-interlockIndicators

Therearesymbolsonthehourmeter,andtheindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

Figure4

position(Figure6).

1.Height-of-cutdeck-lift

pedal

2.Transportlock

3.Parking-brakelever8.Fuelcap

4.Controls

5.Motion-controllevers

6.Rollbar

7.Seatbelt

9.Mowerdeck

10.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

Battery-indicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(

6).

Figure6

Figure

1.Fuelgauge(bars)4.Safety-interlocksymbols

Figure5

1.PTOSwitch

2.Choke

3.Throttlecontrol6.Fuses

4.Hour

5.Ignitionswitch

2.Batterylight

3.Hourmeter

meter/Safety-interlock

display

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

5.Lowfuel-indicatorlight

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.

14

Page 15

Blade-controlSwitch(PTO)

Neutral-lockPosition

Theblade-controlswitch(PTO)isusedtoengagetheelectric

clutchanddrivethemowerblades.Pulltheswitchupto

Theneutral-lockpositionisusedwiththesafety-interlock

systemtoengageandtodeterminetheneutralposition.

engagethebladesandrelease.Todisengagetheblades,

pushtheblade-controlswitch(PTO)downormovea

motion-controlleverintotheneutral-lockposition.

FuelShut-offValve

Closethefuelshut-offvalve(undertheseat)when

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas3

positions:Start,RunandOff.

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

Motion-controlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width:

48-inchDeck52-inchDeck60-inchDeck70-inchDeck

WithoutDeck

DeectorUp137.2cm(54inches)146cm(57.5inches)156.8cm(61.7inches)187cm(73.6inches)

DeectorDown161.4cm(63.6inches)171.8cm(67.6inches)192.2cm(75.7inches)222.4cm(87.6inches)

116.1cm(45.7inches)116.1cm(45.7inches)134.6cm(53inches)150.1cm(59.1inches)

Length:

48-inchDeck52-inchDeck60-inchDeck70-inchDeck

RollBar-Up

RollBar-Down

201.2cm(79.2inches)201.2cm(79.2inches)211.1cm(83.1inches)218.7cm(86.1inches)

205.5cm(80.9inches)205.5cm(80.9inches)215.4cm(84.8inches)223cm(87.8inches)

Height:

RollBar-UpRollBar-Down

179.1cm(70.5inches)118.9cm(46.8inches)

Weight:

ModelWeight

74922

74923

74925

74927

78922

78924

520kg(1147lbs)

547kg(1206lbs)

569kg(1254lbs)

605kg(1334lbs)

520kg(1147lbs)

520kg(1147lbs)

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethechance

16

Page 17

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

G008942

1

2

4

3

atalltimes.

UsingtheRolloverProtection System(ROPS)

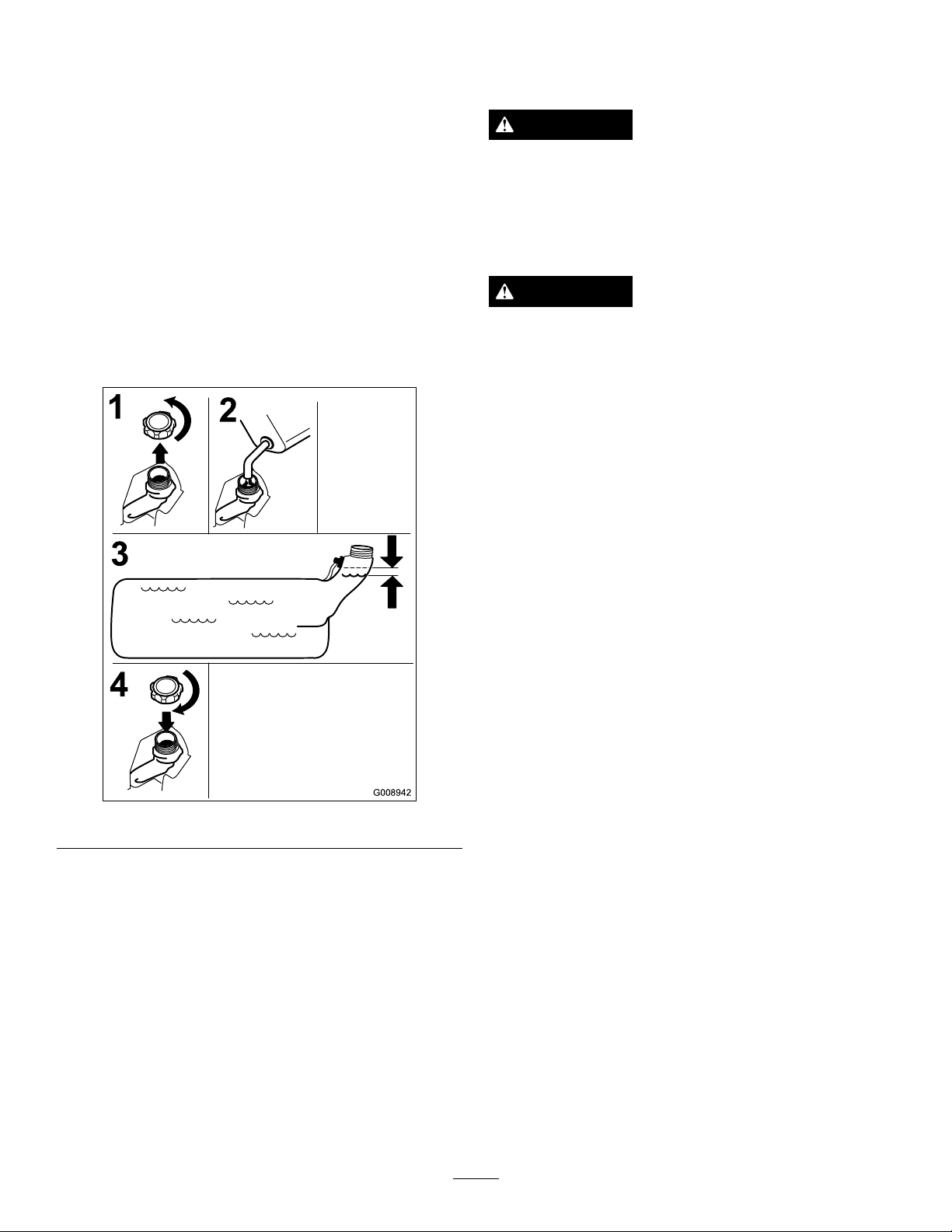

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthefuel

tanktothebottomofthellerneck.Theemptyspaceinthe

tankallowsthegasolinetoexpand.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck(

7).

Note:Ensurethatthereisemptyspaceinthetankto

allowthegasolinetoexpand

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

Figure

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Figure7

CheckingtheEngine-oilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine-oil

Level(page36).

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew ,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

Important:Lowertherollbaronlywhenabsolutely

necessary.

Important:Ensuretheseatissecuredtothemachine.

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sotheyare

notengaged(Figure8).

3.Lowertherollbartothedownposition(Figure8).

17

Page 18

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure8

1.ROPSknob

2.PullROPSknoboutand

rotate90degrees

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssothattheymovepartially

intothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnapinto

positionwhentheholesalignwiththepins(Figure8).

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

6.Pushontherollbarandensurethatbothpinsare

engaged.

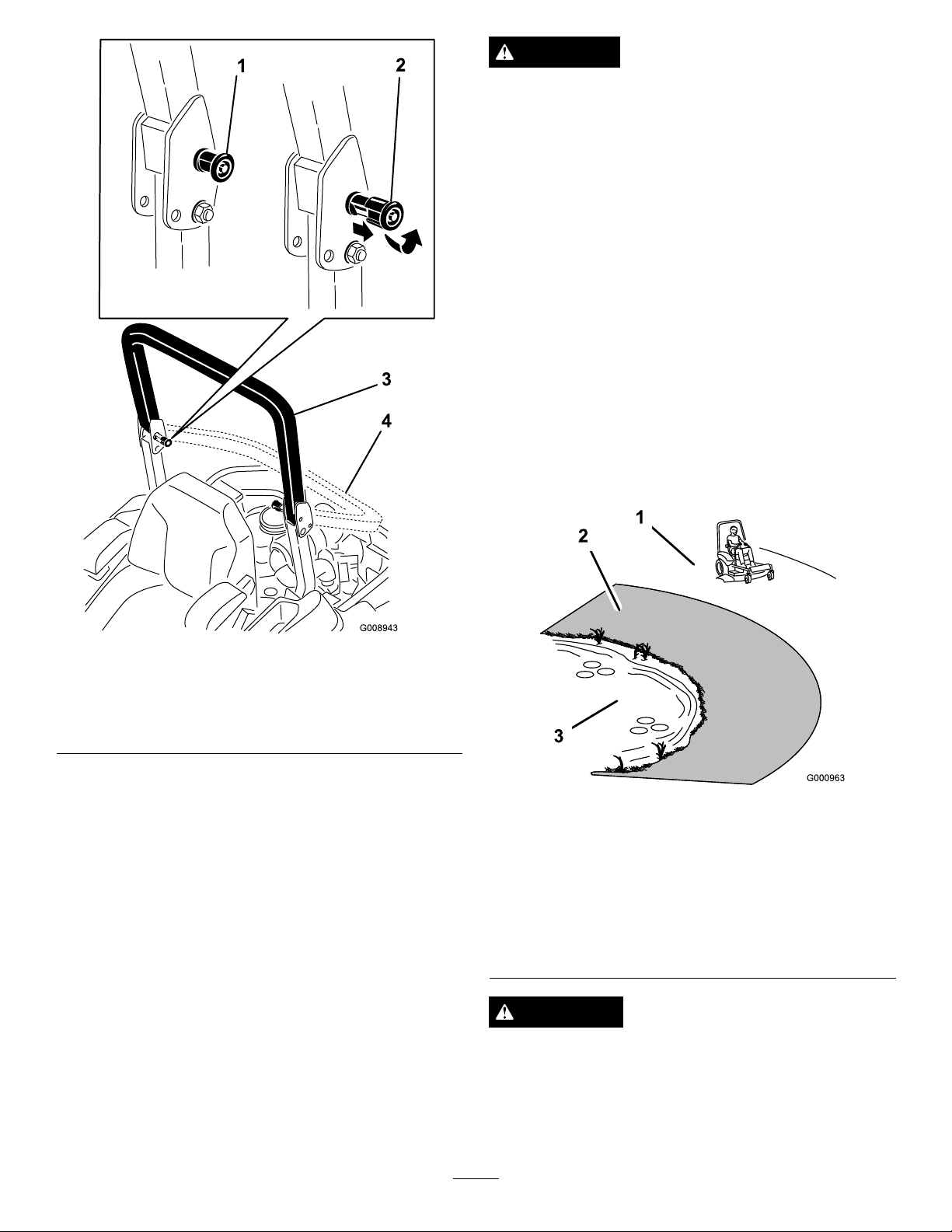

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

Figure9

1.SafeZone—usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

18

Page 19

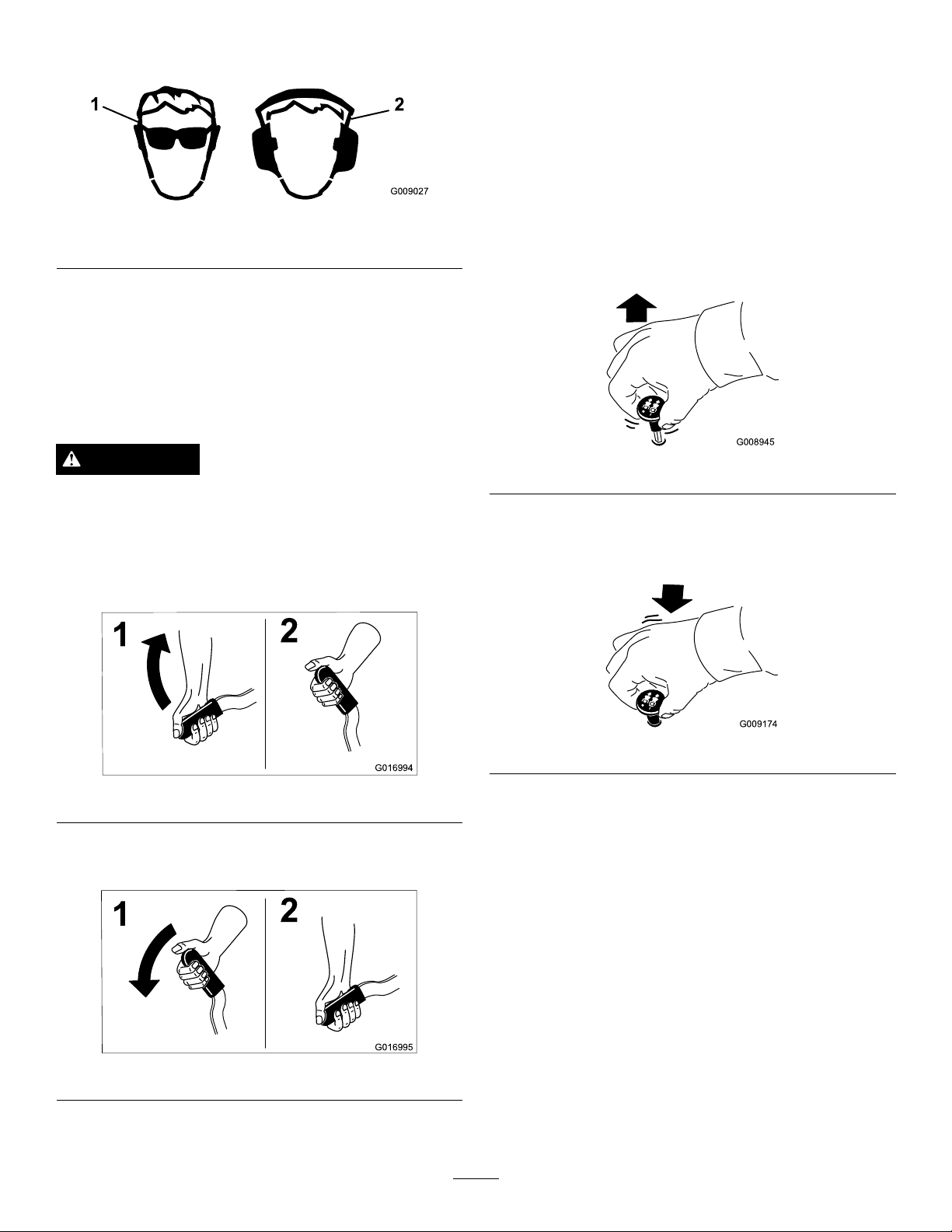

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

G009027

1

2

G016994

1

2

G016995

1

2

G008945

G009174

isrecommended.

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

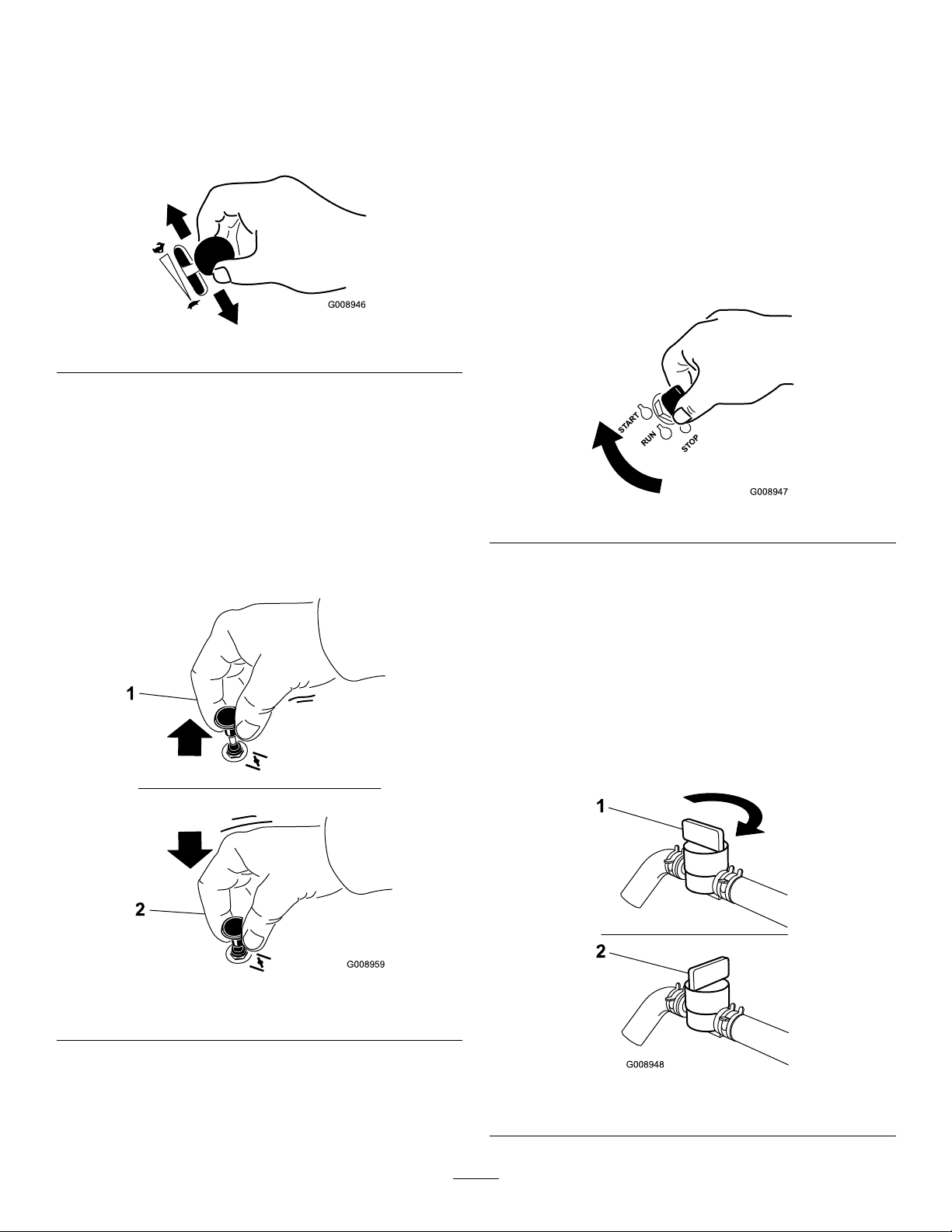

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

OperatingtheMower Blade-controlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-controlSwitch

(PTO)

Note:Engagingtheblade-controlswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

WARNING

Parkingbrakemaynotholdmachineparkedona

slopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlesswheelsarechocked

orblocked

Figure11

ReleasingtheParkingBrake

Figure13

DisengagingtheBlade-controlSwitch

(PTO)

Figure14

Figure12

19

Page 20

OperatingtheThrottle

G008946

G008959

1

2

START

RUN

STOP

G008947

G008948

1

2

OperatingtheIgnitionSwitch

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure15).

AlwaysusetheFastpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

Figure15

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure16).

1.TurntheignitionkeytotheStartposition(Figure17).

Note:Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure17

3.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(

Figure16).

2.Turntheignitionkeytostoptostoptheengine.

UsingtheFuelShutoffValve

Thefuelshut-offvalveislocatedundertheseat.Movethe

seatforwardtoaccessit.

Closethefuelshut-offvalvefortransport,maintenance,and

storage.

Ensurethefuelshut-offvalveisopenwhenstartingthe

engine.

Figure16

1.Onposition2.Offposition

Figure18

1.Onposition2.Offposition

20

Page 21

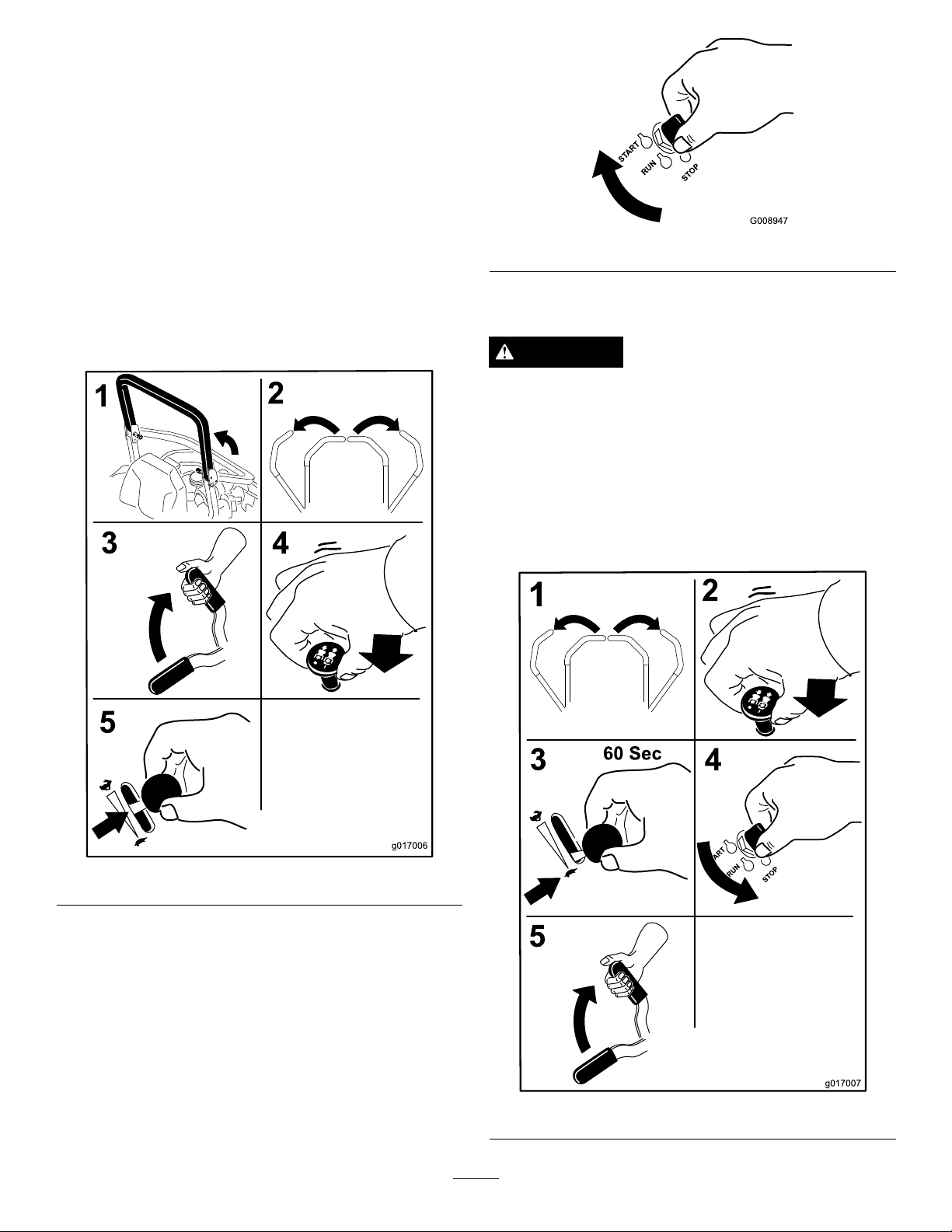

StartingandStoppingthe

g017006

START

RUN

STOP

G008947

g017007

Engine

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitontheseat,

andfastentheseatbelt.

2.Movethemotioncontrolstoneutral-lockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake(page19).

4.Movetheblade-controlswitch(PTO)totheOff

position(Figure19).

5.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

Figure20

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

Figure19

6.TurntheignitionkeytotheStartposition(Figure20).

Note:Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15-secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure21

21

Page 22

Important:Makesurethatthefuelshut-offvalveis

G009181

1

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

UsingtheSafety-interlock System

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-interlock

System

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheneutral-locked

position.

Thesafety-interlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

TestingtheSafety-interlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately .

1.Sittingontheseat,engagetheparkingbrakeandmove

theblade-controlswitch(PTO)totheOnposition.

Trystartingtheengine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

theblade-controlswitch(PTO)totheOffposition.

Moveeithermotion-controllever(outofneutrallocked

position).Trystartingtheengine;theengineshould

notcrank.Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,releasetheparkingbrake,engagethe

blade-controlswitch(PTO)andriseslightlyfromthe

seat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,centereithermotioncontrolandmove

(forwardorreverse);theengineshouldstop.Repeat

forothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Trystartingtheengine;theengineshould

notcrank.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllightup

inthecorrespondingsquare.

Figure22

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

22

Page 23

UsingtheMotion-controlLevers

G008952

G008953

Figure24

Figure23

1.Motion-control

lever—neutral-lock

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetraction-controlleversare

movedwiththeparkingbrakeengaged.

Tostop,pullthemotion-controlleverstotheneutralposition.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page19)

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotion-controllevers

forward(Figure24).

.

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(

Figure25).

Figure25

23

Page 24

StoppingtheMachine

Tostopthemachine,movethetraction-controlleversto

neutral,andthenmovethemtothelockedposition,disengage

thepowertakeoff(blade-controlswitch(PTO),andturnthe

ignitionkeytotheOffposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page19).Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeight-of-Cut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwiththe

deck-liftpedal.Thereisalockpositionandaunlockposition

forthetransportposition.Thetransportlockisusedwith

thedeck-liftpedal(Figure26).

Figure26

Transport-LockPositions

1.Transportlock3.Unlockposition—doesnot

2.Lockposition—mower

deckwilllockintotransport

position

24

lockthemowerdeckinto

transportposition

Page 25

AdjustingtheHeight-of-CutPin

1

3

2

G017027

Theheight-of-cutisadjustedfrom25to140mm(1to

5-1/2inches)in6mm(1/4inch)incrementsbyrelocating

theclevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeck-liftpedalwithyourfoot,andraisethe

mowerdecktothetransportposition(alsothe140mm

(5-1/2inches)cuttingheightposition)asshownin

Figure27.

3.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket(Figure27).

4.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,andinsertthepin(

27).

5.Pushonthedecklift,pullbackonthetransportlock,

andslowlylowerthemowerdeck.

Figure28

Figure

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

Figure27

1.Deck-liftpedal

2.Cut-of-heightpin

AdjustingtheAnti-scalp Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Transportlock

Figure29

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

Figure30

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

3.Adjusttheanti-scalprollersasshownin

,,and.

25

Page 26

AdjustingtheFlowBafeCam

G008961

1

2

3

4

Locks

Thisprocedureisapplicableonlytomachineswiththe

ow-bafelocks.Certainmodelswillhavenutsandboltsin

placeoftheow-bafelocksandcanbeadjustedthesame.

Themower-dischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlocksandbafeto

givethebestqualityofcut.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthecamlocks,swingtheleveruptoloosen

thecamlock(Figure31).

PositionA

Thisisthefullrearposition.Thesuggesteduseforthis

positionisafollows:

•Short,lightgrassmowingconditions

•Dryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthemower

4.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow.

5.Swingtheleverbackovertotightenthebafeandcam

Figure31).

locks(

6.Ifthecamlocksdonotlockthebafeintoplaceoritis

tootight,loosentheleverandthenrotatethecamlock.

Note:Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Figure31

1.Unlocklever

2.Rotatethecamlockto

increaseordecrease

lockingpressure

3.Positionthebafe

4.Locklever

Figure32

PositionB

Usethispositionwhenbagging.Alwaysalignitwiththe

bloweropening.

Figure33

PositionC

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

theheightofthegrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows:

•Tall,densegrassmowingconditions

•Wetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

•ThispositionissimilartothebenetsoftheToroSFS

mower

26

Page 27

Figure34

g019754

g019755

g019768

1

ChangingtheSeatSuspension

Theseatadjuststoprovideasmoothandcomfortableride.

Positiontheseatwhereyouaremostcomfortable.

Toadjust,turntheknobinfronteitherdirectiontoprovide

thebestcomfort(Figure37).

PositioningtheSeat

Theseatmovesforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlocktheseat(

35).

Figure35

UnlatchingtheSeat

Figure37

1.Seat-suspensionknob

Figure

UsingtheDrive-wheel-release Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey ,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscanbecome

veryhot.Touchingahotengineorhydraulic-drive

unitscancausesevereburns.

Figure36

1.Seatlatch2.Seat

Allowtheengineandhydraulic-driveunitstocool

completelybeforeaccessingthedrive-wheel-release

valves.

Thedrive-wheel-releasevalvesarelocatedinthebackofeach

hydraulic-driveunit,undertheseat.

Note:Makesurethereleasevalvesareinthefullyhorizontal

positionwhenoperatingthemachineorseveredamagetothe

hydraulicsystemcanoccur.

1.DisengagethePTO(blade-controlswitch)andturn

theignitionkeytotheOffposition,movetheleversto

neutral-lockedposition,applytheparkingbrake,and

removethekey.

27

Page 28

2.Rotatetherelease-valveleversverticallytopushthe

machine(Figure38).

Note:Thisallowshydraulicoiltobypassthepump

enablingthewheelstoturn.

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

3.Disengagetheparkingbrakebeforepushingthe

machine.

Figure38

1.Verticaltopushthe

machine

2.Horizontaltorunthe

machine

DANGER

Withoutagrassdeector,dischargecover,ora

completegrass-catcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(blade-controlswitch(PTO)totheOffposition,

rotatetheignitionkeytotheOffposition,and

removethekey.

•Makesurethegrassdeectorisinthedown

position.

4.Rotatetherelease-valvelevershorizontallytorunthe

machine(Figure38).

28

Page 29

TransportingMachines

LoadingMachines

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallthenecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,petsorbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle,and

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure39).

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefull-widthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(Figure40).Thelower,rearsectionof

themachineframeextendsbackbetweentherearwheels,and

servesasastopfortippingbackward.Havingafull-width

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

full-widthramp,useenoughindividualrampstosimulatea

full-widthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

mowercomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

Figure40).Asteeperanglemaycause

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

1.Tractionunittie-downloops

Figure39

•Useextremecautionwhenoperatingauniton

aramp.

•EnsuretheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsuretheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15-degreeanglebetweenramp

andgroundorbetweentherampandtraileror

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

29

Page 30

Figure40

1.Trailer3.Notgreaterthan

2.Full-widthramp4.Full-widthramp—side

15degrees

view

30

Page 31

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cutting1/3oftheGrassBlade

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Stopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly .

AlternatingtheMowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

AdjustingtheCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

MaintainingtheBlade

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

31

Page 32

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheellug-nuttorque.

•Checkthewheelhubslotted-nuttorque.

•Checktheparking-brakeadjustment.

•Changethehydraulicltersandhydraulicoilwhenusinganytypeofoil.

•Checkthesafetysystem.

•Checktheengine-oillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulic-unitshrouds.

•Inspecttheblades.

•Cleanthemowerdeck.

•Greasethemower-deckspindlesandtheidlerarm.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicoillevel.

•Lubricatethemower-deck-liftpivots.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Check,cleanandregapthesparkplug.

•Checkandcleanengine-coolingnsandshrouds.

Every200hours

Every250hours

Every500hours

Monthly

Yearly

Yearlyorbeforestorage

•Changetheengine-oillter.

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

•ChangethehydraulicltersandhydraulicoilwhenusingMobil®1oil(moreoftenin

dirtyordustyconditions).

•Replacethesecondaryairlter .

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Checkthewheellug-nuttorque.

•Checkthewheelhubslotted-nuttorque.

•Adjustthecaster-pivotbearing.

•Checktheparking-brakeadjustment.

•ChangethehydraulicltersandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil(moreoftenindirtyordustyconditions).

•Checkthebatterycharge.

•Greasethepump-belt-idlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcaster-wheelbearings(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

32

Page 33

CAUTION

G017028

G009029

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy.

GreaseType:No.2generalpurposelithiumbaseor

molybdenumbasegrease

1.Disengagethebladecontrolswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

6.Wipeupanyexcessgrease.

AddingLightOilorSpray

GreasingtheMower

ServiceInterval:Every50hours—Greasethemower-deck

spindlesandtheidlerarm.

Yearly—Greasethepump-belt-idlerarm.

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Yearly—Repackthefrontcaster-wheelbearings(more

oftenindirtyordustyconditions).

Important:Makesurecuttingunitspindlesarefullof

greaseweekly.

1.Disengagethebladecontrolswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Greasethemowerdeckidler-pulleypivotuntilgrease

comeoutthebottom(

4.Greasethe3spindlebearingsuntilgreasecomesout

(Figure42).

Figure42).

Lubrication

ServiceInterval:Every100hours

Lubricatethedeck-liftpivots.

Figure41

Figure42

5.Greasethedrive-belt-idlerarm(Figure43).

33

Page 34

Figure43

6.Removethedustcapandadjustthecasterpivots.

Note:Keepthedustcapoffuntilgreasingisdone;

refertoAdjustingtheCaster-pivotBearing(page45).

7.Removethehexplug.

8.Threadagreasettingintothehole.

9.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

10.Removethegreasettinginthehole.

11.Installthehexpluganddustcap(

Figure44).

LubricatingtheCaster-wheel Hubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

Figure45

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethemowerforaccess.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

5.Removeoneofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.

Figure44

12.Greasethecaster-wheelbearings(Figure44).

6.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

7.Pryoutsealsandinspectbearingsforwearordamage

andreplaceifnecessary.

8.Packthebearingswithageneral-purposegrease.

9.Insert1bearingand1newsealintothewheel.

Note:Thesealsmustbereplaced.

10.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto1

spacernut,andthreaditontotheaxlewiththewrench

atsfacingoutward.

Note:Donotthreadthespacernutalloftheway

ontotheendoftheaxle.Leaveapproximately3mm

(1/8inch)fromtheoutersurfaceofthespacernutto

theendoftheaxleinsidethenut.

11.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

12.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

13.Insertthesecondbearingandnewsealintothewheel.

34

Page 35

14.Applyathread-lockingadhesivetothesecondspacer

nut,andthreaditontotheaxlewiththewrenchats

facingoutward.

15.Torquethenutto8to9N-m(75to80in-lb),loosen,

thentorqueto2to3N-m(20to25in-lb).

Note:Makesureaxledoesnotextendbeyondeither

nut.

16.Installthesealguardsoverthewheelhub,andinsert

wheelintothecasterfork.

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawaythemuferandotherhotsurfaces.

17.Installthecasterboltandtightenthenutfully .

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay.Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applyanotherlayerofthread-lockingadhesive.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacetheprimaryair

lter.

Every250hours—Checkthesecondaryairlter.

Every500hours—Replacethesecondaryairlter.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pushdowntoreleasetheretainingclampsontheair

cleaner,andpulltheair-cleanercoverofftheair-cleaner

Figure46).

body(

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure46).Avoidknockingthelterintothe

sideofthebody.

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

Note:Holesinthelterwillappearasbrightspots.

Note:Ifthelterisdamageddiscardit.

35

Page 36

Figure46

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,orhigher)

OilCapacityfor74923,74925,and74927engines:witha

lterchange,2.3L(77oz);withnolterchange,2.1L(70oz)

OilCapacityfor74922,78922,and78924engines:witha

lterchange,2.1L(71oz);withnolterchange,1.8L(61oz)

Viscosity:Seethetablebelow.

1.Aircleanerclamps

2.Aircleanercover

3.Primaryairlter

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure46).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Donotattempttocleanthesecondarylter.

Ifthesecondarylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,alwaysoperate

theenginewithbothairltersandthecoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.

Note:Donotuseadamagedlter.

Figure47

Note:Useofmulti-gradeoils(5W -20,10W-30,or10W-40)

willincreaseoilconsumption.Checktheoillevelmore

frequentlywhenusingthem.

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawayfromthemuferandotherhotsurfaces.

2.Ifthesecondarylterisbeingreplaced,carefullyslide

itintothelterbody(

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure46).

4.Ensurethatitisfullyseatedbypushingontheouter

rimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

5.Installtheair-cleanercoverwiththebreathercapdown,

androtatesothattheretainingclampslockthecover

inplace(

Figure46).

Figure46).

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowtheLowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

36

Figure48).

Page 37

G008804

G008792

1

2

5

6

7

3

9

10

4

8

ChangingtheEngineOil

G008804

G008793

1

2

3

4

4

5

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachinesothattherearisslightlylowerthan

thefronttoensurethattheoildrainscompletely.

3.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure49).

Figure48

Figure49

37

Page 38

5.Slowlypourapproximately80%ofthespeciedoil

G008796

2

3

4

5

6

1

G008804

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure50).

ChangingtheEngine-oilFilter

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page37).

Figure50

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

2.Changetheengine-oillter(

Figure51).

Figure51

Note:Ensuretheoil-ltergaskettouchestheengine,

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

to

ChangingtheEngineOil(page37).

38

Page 39

ServicingtheSparkPlug

G008803

G008794

1

2

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:Champion

AirGap:0.76mm(0.03inches)

RemovingtheSparkPlug

1.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

2.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

3.Removethelefthandhydraulic-unitshroudinthe

orderlistedin

Note:Thisgivesyouaccesstothefrontsparkplug.

®

RC12YCorequivalent

Figure52.

4.Removethesparkplug.

Figure53

5.Installthelefthandhydraulic-unitshroud(Figure52).

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.76mm(0.03inches).

Figure54

1.Pullthistabouttothe

sideinthedirectionofthe

arrow

2.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

Figure52

3.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

4.Shroud

39

Page 40

InstallingtheSparkPlug

G008963

12

3

Tightenthesparkplug(s)to24.4to29.8N-m(18to22ft-lb).

Figure55

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

CheckingtheSparkArrester (ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotfuelorrunengineunlesssparkarresteris

installed.

1.Stopengine,waitforallmovingpartstostop,remove

thekey,andengagetheparkingbrake.

2.Waitformufertocool.

3.Ifthereareanybreaksinthescreenorweldsare

observed,replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester,

andcleanscreenitwithawirebrush(soakinsolvent

ifnecessary).

5.Installarresteronexhaustoutlet.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

5.Closethefuel-shutoffvalveundertheseat(

Figure56

1.Fuellter3.Fuel-shutoffvalve

2.Hoseclamp

Figure56).

6.Squeezetheendsofthehoseclampstogetherandslide

40

themawayfromthelter(Figure56).

7.Removethelterfromthefuellines.

8.Installanewlterandmovethehoseclampscloseto

thelter(Figure56).

9.Openthefuel-shutoffvalve.

Note:Itisimportanttoinstallthefuellinehosesandsecure

withplastictiesthesameastheywereoriginallyinstalledat

thefactorytokeepthefuellineawayfromcomponentsthat

cancausefuellinedamage.

Page 41

ServicingtheFuelTank

ElectricalSystem

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankandservices

anycomponentsofthefuelsystem.

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing .Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysreconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

41

Page 42

1.Disengagetheblade-controlswitch(PTO),movethe

G008804

+

-

+

-

+

-

G008964

1

2

3

4

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthenegativebatterycable(black)fromthe

negative(-)batteryterminal(Figure57).

4.Slidetheredterminalbootoffthepositive(red)battery

terminal,andremovethepositive(+)batterycable

Figure57).

(

5.Removethewingnutsecuringthebatteryclamp

(Figure57).

6.Removetheclamp(Figure57).

7.Removethebattery.

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure57).

2.Installthepositive(red)batterycabletopositive(+)

batteryterminal.

3.Installthenegative(black)batterycableandground

wiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

Figure57).

(

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(Figure

57).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

0°C(32°F).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure58).

3.Installthebatteryinthemachineandconnectthe

batterycables;refertoInstallingtheBattery(page42).

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure57

3.Removethepositive

batterycable

4.Removethebattery

42

Page 43

DriveSystem

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproperoperation

ofretractorandbuckle.Replacebeforeoperatingifdamaged.

CheckingtheRollover

Figure58

1.Positivebatterypost

2.Negativebatterypost