Page 1

TITANZX4820andZX5420Zero-Turn-RadiusRiding

Mower

ModelNo.74920—SerialNo.312000001andUp

ModelNo.74924—SerialNo.312000001andUp

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3372-849RevA

SetupInstructions

ProcedureDescription

1

2

3

4

Nopartsrequired

Nopartsrequired

Rollbar1

Rollbarsupport2

Pivotbracket4

Flatspacer4

Pivotpinwithhairpinandlanyard2

Reinforcingbracket

Largewasher4

Bolt(1/2x4–1/2inches)

Bolt(1/2x3–1/2inches)

Cylindricalspacer

Flatwasher(1/2inch)

Flangelocknut(1/2inch)

Hexlocknut(1/2inch)

Flangelocknut(5/16inch,maybe

pre-installed)

Conicalrubberbumper(maybe

pre-installed)

Smallrubberbumper(maybe

pre-installed)

Bolt(5/16x3–3/4inch)

Flatwasher(5/16inch)

Flangelocknut(5/16inch)

Hosecoupling(notincludedwithCE

models)

Cutoffbafe(CEmodelsonly)

Bolt(5/16x5/8inch,54inchCEunits

only)

IgnitionKey1

Operator'sManual

EngineOperator'sManual

OperatorTrainingMaterial

Qty.

Use

–

–

2

2

8

2

4

8

2

2

2

2

2

2

2

1

1

2

1

1

1

Connectthebattery.

Setupthemotioncontrollevers.

InstalltheRollOverProtectionSystem

(ROPS).

Completethesetup.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

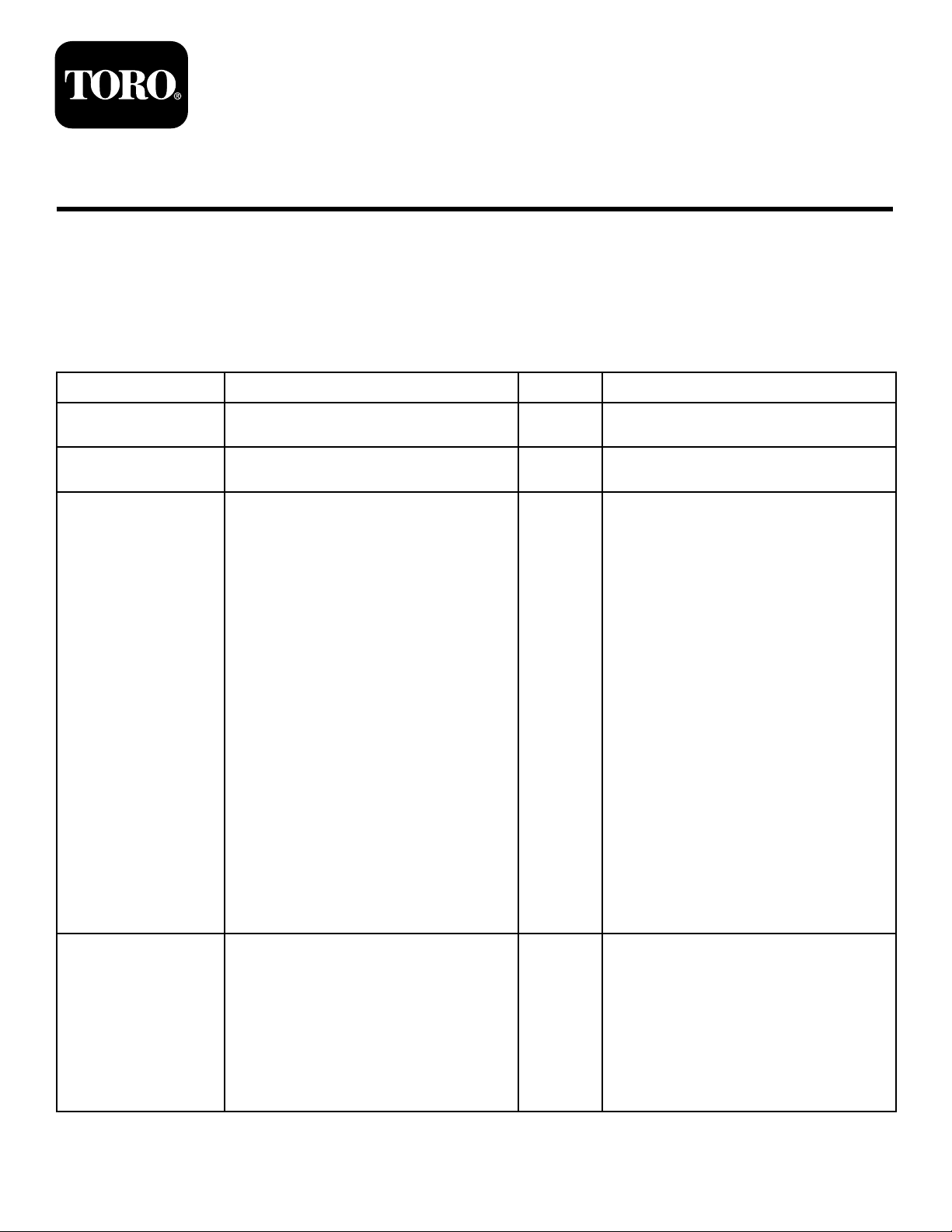

G010257

1

2

3

5

4

1

ConnectingtheBattery

NoPartsRequired

Procedure

1.Locatethebatteryandnegativebatterycableinthe

centerofthemachine.

2.Removetheblackplasticcapfromthenegative

batterypost.Removethefastenersfromthenegative

batterycableandusethemtosecurethenegative

batterycabletothenegativebatterypost(

Figure1).

1.Bolt4.Negativebatterypost

2.Washer5.Nut

3.Negativebatterycable

Figure1

2

SettingUptheMotionControlLeversandtheSeat

NoPartsRequired

Procedure

1.Locatethemotioncontrolleversattachedbutfoldeddownonthemachine.

2.Removetheupperbolt(3/8x1inch)andwasher;loosenthelowerbolt(3/8x1inch).Raisethemotioncontrol

leverstotheuprightposition.

3.Aligntheholesinthemotioncontrolleverwiththeholesinthecontrolarmshaftandinstalltheboltandwasher

removedpreviously.Handtightenallfasteners.Repeatthisforbothcontrolslevers.

4.Setuptheseatasfollows(

Figure2):

2

Page 3

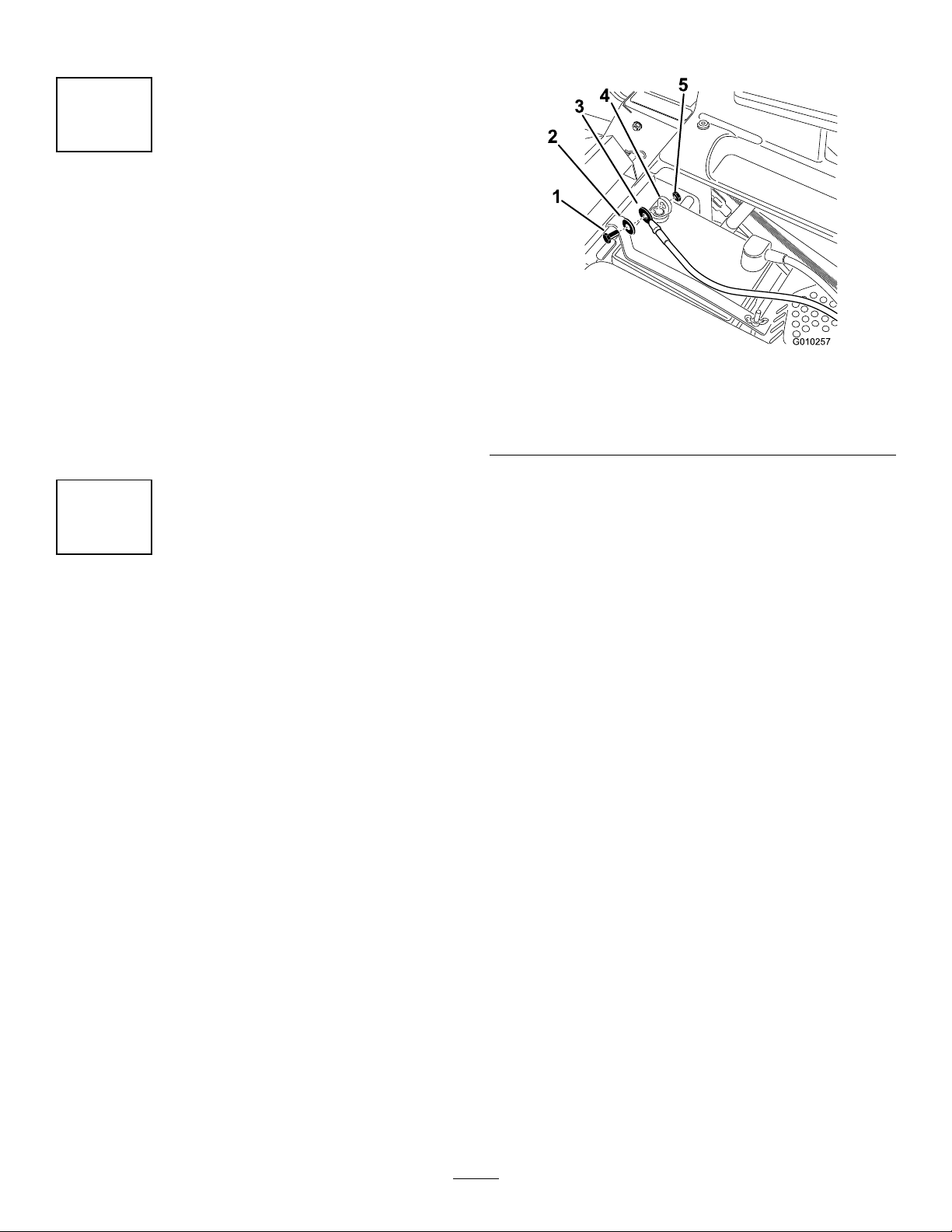

G010258

A B C

DC C

Figure2

A.Withthemotioncontrolleversintheoutward,neutrallockposition,removethehairpincottersontheseat

rodsecuringtheseattothemachine.

B.Slidetheseatrodoutfromthebracketsandseatframe.

C.Rotatetheseat180degreesandinstallitintothebracketyouremoveditfrom,usingtherodandhairpin

cottersremovedpreviously .

D.Connecttheinterlockswitchcabletotheseat.

E.Lowertheseatintotheoperatingposition.

5.Movethecontrolleversbacktothecenterposition(neutral).

6.Verifythemotioncontrolleversareproperlyaligned.Adjustasnecessary.Tightenallfasteners.

3

Page 4

3

13

14

15

g017895

16

InstallingtheRollOver

ProtectionSystem(ROPS)

Partsneededforthisprocedure:

1Rollbar

2Rollbarsupport

4Pivotbracket

4Flatspacer

2Pivotpinwithhairpinandlanyard

2

Reinforcingbracket

4Largewasher

2

Bolt(1/2x4–1/2inches)

8

Bolt(1/2x3–1/2inches)

2

Cylindricalspacer

4

Flatwasher(1/2inch)

8

Flangelocknut(1/2inch)

2

Hexlocknut(1/2inch)

2

Flangelocknut(5/16inch,maybepre-installed)

2

Conicalrubberbumper(maybepre-installed)

2

Smallrubberbumper(maybepre-installed)

2

Bolt(5/16x3–3/4inch)

2

Flatwasher(5/16inch)

2

Flangelocknut(5/16inch)

Figure4

1.Bolt(1/2x3–1/2inches)

(2)

2.Largewasher(4)10.Flangelocknut(1/2inch)

3.Rollbarsupport

4.Cutoutfacestherear12.Bolt(1/2x4–1/2inch)(2)

5.Brace,existing

6.Bolt(1/2x1–1/4inch)and

locknut(1/2inch),existing

7.Seatbeltassembly,

existing

8.Smallrubberbumper(2)

9.Hexlocknut(1/2inch)(2)

(2)

11.Reinforcingbracket(2)

13.Bolt(5/16x3–3/4inch)(2)

14.Flatwasher(5/16inch)(2)

15.Flangelocknut(5/16inch)

(2)

16.Engineguard

2.Loosenthelocknutthatsecuresthebracetothe

frame.Stopwhenthebraceswingsfreely(Figure4).

InstallingtheRollbarSupports

Completethefollowingstepsforbothleftandright

rollbarsupports.

1.Locatethefactoryinstalledbraceattachedtothe

framebetweentheengineandtherearwheel(see

Figure3andFigure4).

Note:Ifpreferred,therearwheelsmayberemoved

foreasieraccesstothebrace.

Figure3

Locationofthebraces

3.Attachtherollbarsupporttotheframeandthebrace

totherollbarsupportasshowninFigure4.Leave

theboltslooseenoughthatthepartsarefreetoshift

around.

Note:Ensurethatthecutoutatthetopofthe

supporttubefacestherearofthemachine.

Note:Notetheorientationofthereinforcing

bracket.

4.Attachtherollbarsupporttotheengineguardas

showninFigure4.

AttachingthePivotBrackets

Assemblethepivotbracketstotherollbarasshownin

Figure5.Leavetheboltslooseenoughthatthepartsare

freetoshiftaround.

Note:Ensurethatthelocknutsareontheinsideofthe

supporttube.

4

Page 5

Figure5

2

g017920

Note:Ensurethatthetabtowhichthelanyardis

attachedisangledawayfromthesurfaceofthepivot

bracket.

1.Bolt(1/2x3–1/2inches)

(4)

2.Flatwasher(4)5.Flangelocknut(4)

3.Pivotbracket,notchfacing

up(4)

4.Flatspacer(4)

6.Rollbar,cutoutfacing

down

AttachingtheRollbar

1.Insertthecylindricalspacerinthepivotholesinboth

rollbarsupports(Figure6).

Figure7

1.Bolt(1/2x3–1/2inch)(2)3.Flangelocknut(2)

2.Pivotpinwithhairpinand

lanyard(2)

4.Raisetherollbarintotheuprightpositionandlockit

inplacewithbothpivotpinsasshownin

Figure8.

Figure6

1.Cylindricalspacer

2.Largepivothole

2.Lifttherollbarwiththecutoutsinendsofthe

tubefacingupandalignthepivotholeswiththe

cylindricalspacersintherollbarsupports.

Note:Asecondpersontoperformthenextstep

willbehelpful.

3.Attachtherollbartotherollbarsupportsasshownin

Figure7.Leavetheboltsjustlooseenoughtoallow

therollbartofreelypivot.

Figure8

1.Rollbar3.Hairpin

2.Pivotpin4.Rollbar,uprightandlocked

MakingFinalAdjustments

1.Tightenthefastenersintheorderspeciedinthe

followingtable.Figure4andFigure5willhelp

identifytheparts.

5

Page 6

Sequence

1Threeboltsoneach

2Twoboltsoneach

3

4

DescriptionTorque

sideattachingthe

pivotbracketstothe

rollbarandrollbar

support.Ensure

thatthetabto

whichthelanyardis

attachedispointed

upward.

sideattachingthe

rollbarsupportto

theframeandthe

rollbarsupportto

thebrace.

Oneboltoneach

sideattaching

thebracestothe

machineframe.

Oneboltoneach

sideattachingthe

rollbartotheengine

guard.

400±40in-lbs

(45±.4N-m)

300±30in-lbs

(34±3N-m)

75±8ft-lbs

(102±11N-m)

60to80in-lbs.

(.4to.6N-m)

Note:Donotexceedtorquespecications.Doing

somaycausestructuraldamagetotheROPSorthe

frameofthemachine.

2.Ifnecessary,installbothsmallrubberbumpers.

Pressthesmallangeonthebackofeachintothe

holesonthebackoftherollbarsupports(

Figure4).

3.Removethepivotpinsandensurethattherollbar

pivotsfreelyupanddown.Ifitdoesnot,remove

therollbarandverifythatthecylindricalspacers

arecorrectlyinstalledaspreviouslydescribedin

AttachingtheRollbar.

Figure9

1.Conicalrubberbumper2.Flangenut(5/16inch)

5.Locktherollbarintheuprightpositionwiththe

pivotpins.Usethehairpinsattheendofeach

lanyardtosecurethepivotpins(Figure8).

Important:Thehairpinsattheendofboth

lanyardsmustbeinsertedintotheholesonthe

straightendofeachpivotpinuntiltheylockin

place.

4.Iftheconicalrubberbumpersarenotpre-installed,

unlocktherollbarandputitinthedownposition.

Installtheconicalrubberbumpersinsidethecutout

atthetopoftherollbarsupportsasshownin

Figure9.Securethemusingthe5/16inchange

nuts.

4

CompletingtheSetup

Partsneededforthisprocedure:

1

Hosecoupling(notincludedwithCEmodels)

1

Cutoffbafe(CEmodelsonly)

2

Bolt(5/16x5/8inch,54inchCEunitsonly)

1IgnitionKey

1

Operator'sManual

1

EngineOperator'sManual

1

OperatorTrainingMaterial

Procedure

6

Page 7

CheckingtheTirePressure

Checkthefrontandreartiresforproperination.Refer

toCheckingtheTirePressureintheOperator'sManual

fortherecommendedinationpressure.

CheckingtheSideDischargeChute

Removethepackingrestraintholdingthesidedischarge

chuteupandlowerthechuteintoplace.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theOilLevelintheOperator'sManual.

CheckingtheHydraulicOilLevel

Beforeyoustarttheengineandusethemachine,check

thehydraulicoillevelinthereservoirbehindtheseat;

refertoCheckingtheOilLevelintheOperator'sManual.

CheckingtheMowerAdjustment

Themowerdeckwasleveledatthefactory.Ifthemower

isnotcuttinglevel,adjusttheside-to-sidelevelandthe

front-to-rearbladeslope.SeetheOperator'sManualfor

theproperprocedure.

ReviewtheRemainingParts

Keepallthefollowingitemswiththemachine:

•IgnitionKey

•HoseCoupling(notincludedonCEmodels)

•Cutoffbafe(CEmodelsonly)

•5/16inchbolts(54inchCEunitsonly)

•Operator'sManual

•EngineOperator'sManual

•ViewtheOperatortrainingmaterial.

7

Page 8

Loading...

Loading...