Page 1

FormNo.3362-716RevD

ZMaster

®

G3Mowers

forInternationalZMaster

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Nopartsrequired

Rearwheels2Installthedrivewheels.

RolloverProtectionSystemKit(ROPS)

Seat

Seatplate

Flangenuts(3/8inch)

Spacers(3/8inch)

Seat

Flangenuts(3/8inch)

Longspacers(deluxeseatsonly)

Shortspacers(deluxeseatsonly)

®

G3Mowers

SetupInstructions

Qty.

–

–

1

1

1

8

4

1

4

2

4

Removepartsfromthecrate.

Checkthetirepressure.

InstalltheRolloverProtectionSystem

(ROPS).

Installtheseat(Modelsthathaveaxed

ornonipupseat).

Installtheseat(Modelsthathavea

TiltingorFlipUpSeat).

Use

7

8

9

10

11

12

13

14

15

Nopartsrequired

Rightcontrollever1

Leftcontrollever

Bolt(3/8x1inch)(2areassembled)

Nut(3/8inch)(2areassembled)

Carriagebolt(3/8x1-1/2inches)

Flangelocknut(3/8inch)

Aircleanercap1

Hoseclamp1

Clamp

Wingnut(1/4inch)

Batteryholddown2

Nopartsrequired

Nopartsrequired

Nopartsrequired

Number2generalpurposelithiumbase

ormolybdenumbasegrease.(Purchase

separately.)

–

1

4

4

1

1

1

2

–

–

–

1tube

Checktheseatbelt.

Installthemotioncontrollevers.

Installtheliftassistpedal.

Installtheaircleanercap.

InstallaBattery(Modelnumbersthat

endwithCPonly)

Chargethebattery.

Checktheengineoillevel.

Addfueltothemachine.

Checkthemachineforgrease.

16

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Registeratwww.T oro.com.

–

Preparethesidedischargechute.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

ProcedureDescription

Qty.

Use

17

18

Nopartsrequired

Operator’sManual

EngineOwner’sManual

Operatortrainingmaterial

Key2

1

RemovingPartsfromtheCrate

NoPartsRequired

Procedure

Removethetires,theseatandtheRolloverProtection

System(ROPS)Kitfromtheshippingcrate.

–

1

1

1

Checkthemachinebeforedeliveryto

thecustomer.

Deliveringthemachinetothecustomer.

3

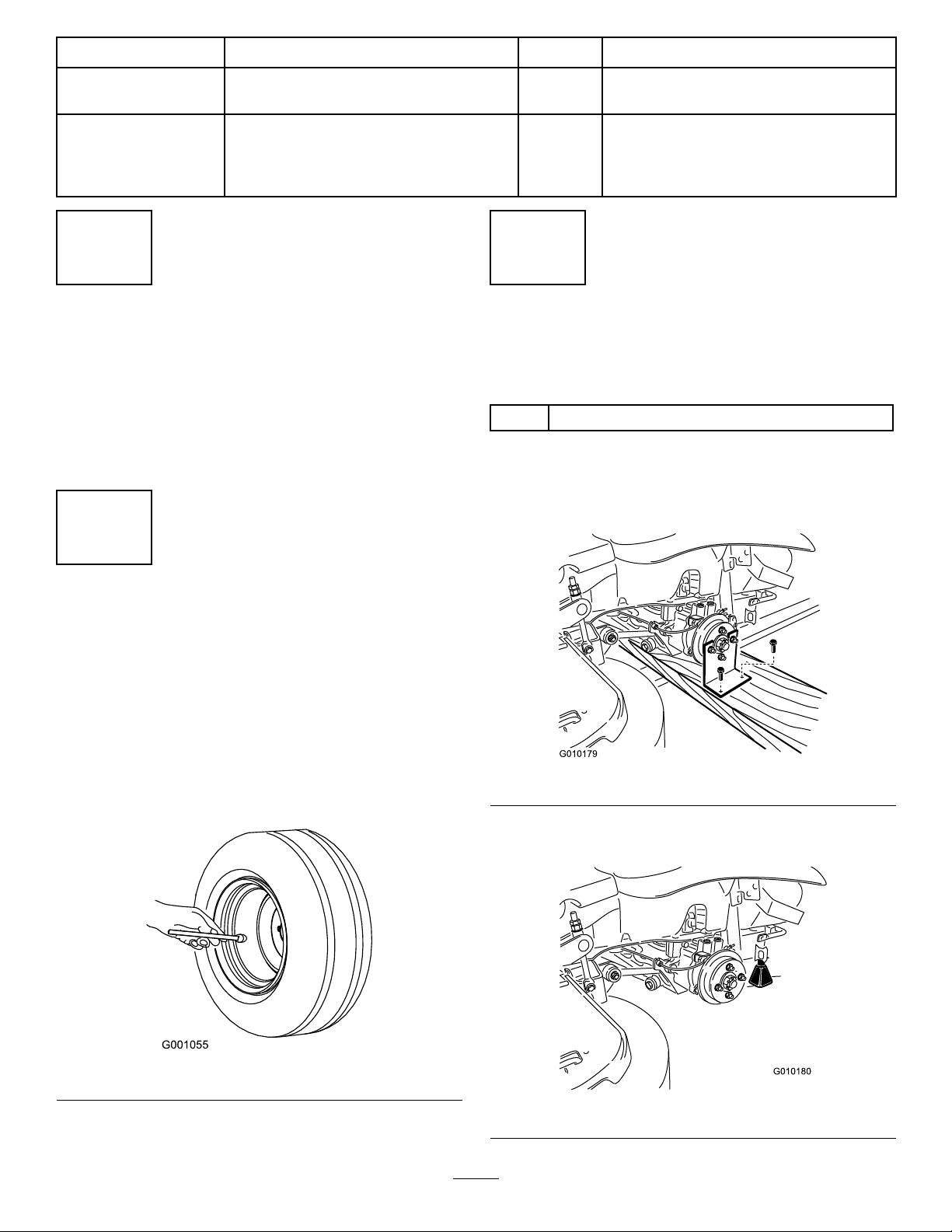

RaisingtheMachineUpand

InstallingtheDriveWheels

Partsneededforthisprocedure:

2Rearwheels

Procedure

1.Removethescrewsholdingtherightangleretaining

platetothecrate.

2

CheckingtheTirePressure

NoPartsRequired

Procedure

Pressure:13psi(90kPa)

Note:Thefrontcasterwheelisasemi-pneumatictire

anddoesnotneedtobechecked.

Checktheairpressureinthedrivetires.

Figure2

2.Raisethebackofthemachineupandsupportitwith

jack-stands.

Figure1

Figure3

2

Page 3

3.Removethewheelnutsfrombothsidesofthe

vehicleandremovetherightangleretainingplate.

Discardthescrewsandretainingplate.

4.Mountthewheelswiththevalvestemtotheoutside

andsecurethemwiththewheelnutspreviously

removed.

5.Torquethewheelnutsto95ft-lb(128N·m).

6.Removethejack-stands.

Figure4

5

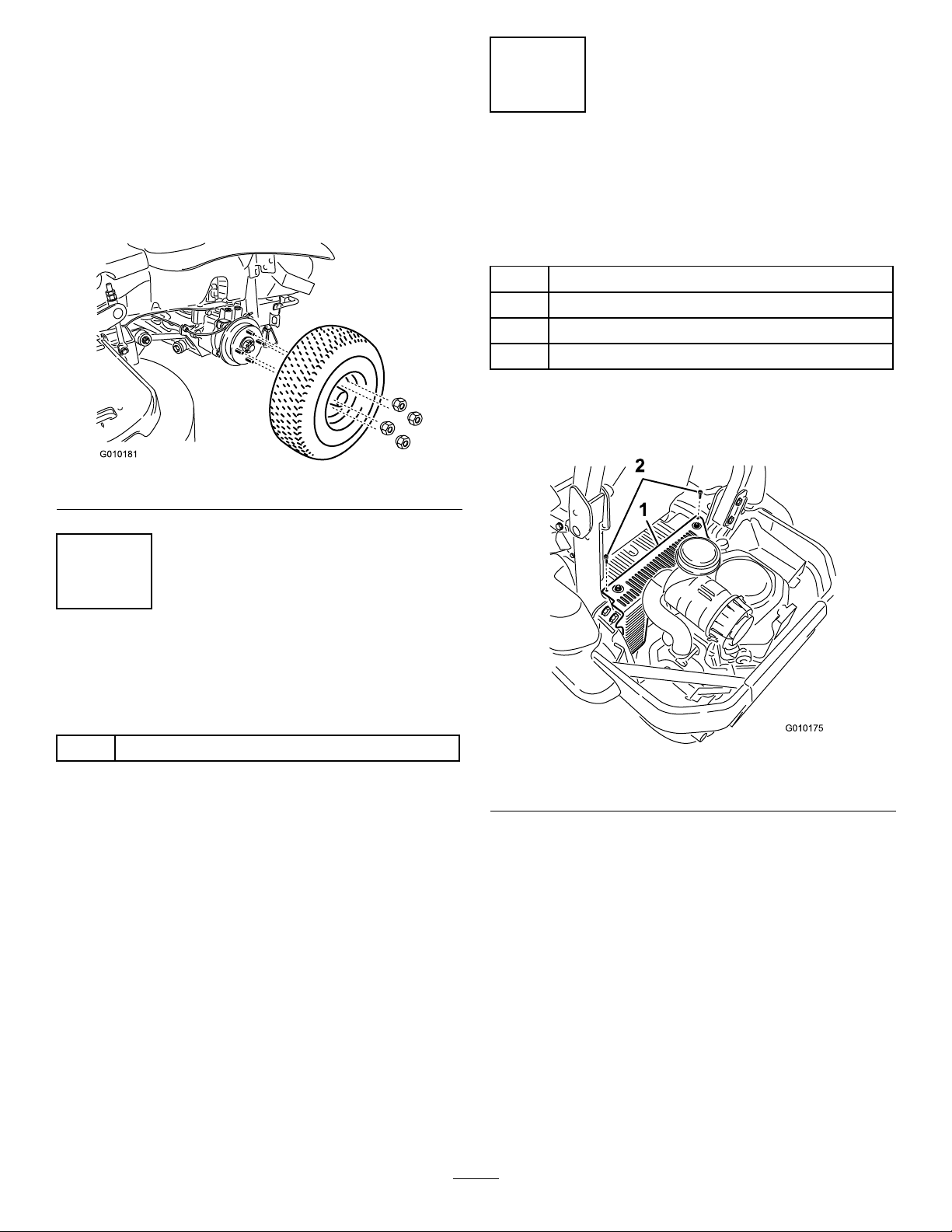

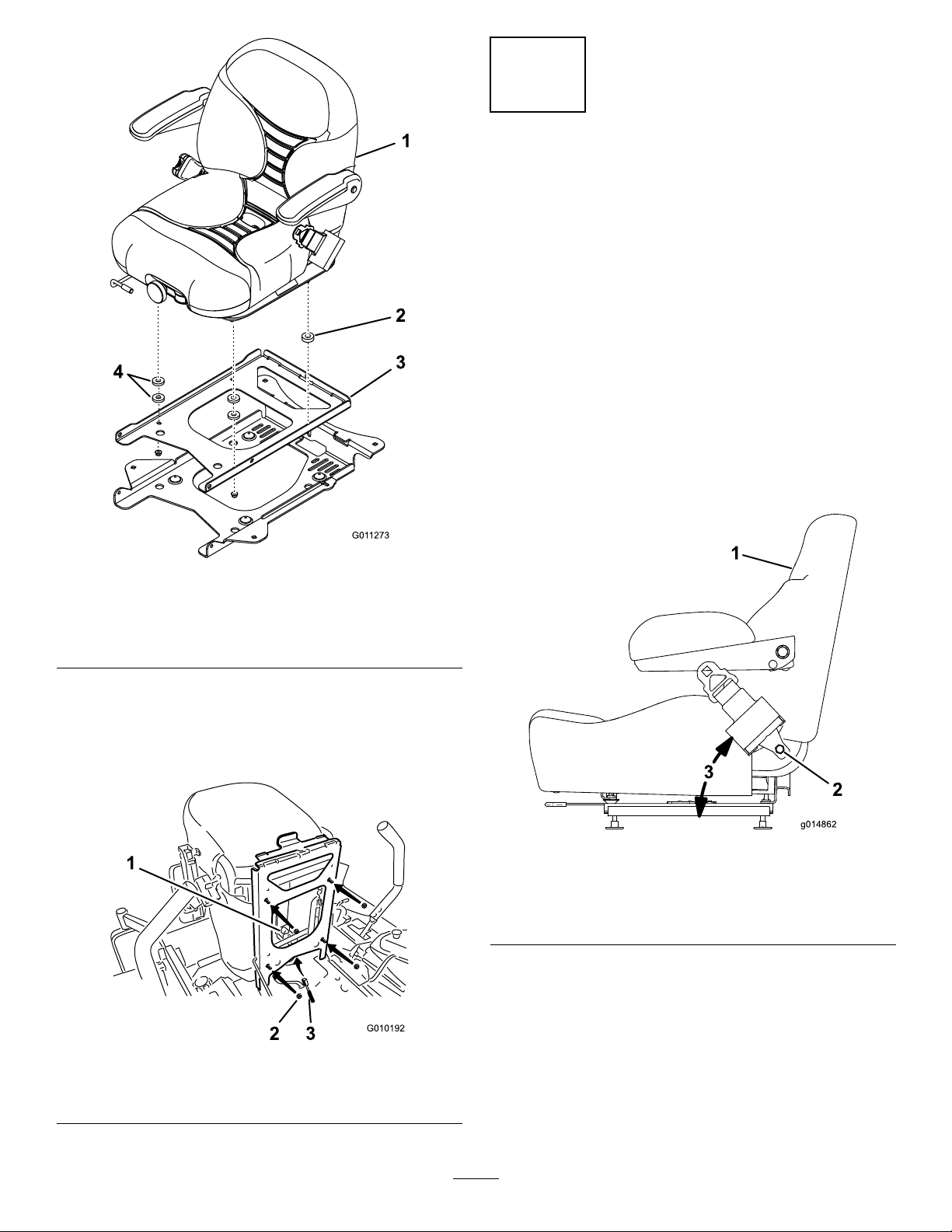

InstallingtheSeat(Models

thathaveaxedornonipup

seat)

Partsneededforthisprocedure:

1

Seat

1

Seatplate

8

Flangenuts(3/8inch)

4

Spacers(3/8inch)

Procedure

1.Removethehydraulicunitshroudfromthemachine.

4

InstallingtheRollOver

ProtectionSystem

Partsneededforthisprocedure:

1

RolloverProtectionSystemKit(ROPS)

Procedure

InstalltheRolloverProtectionSystemKit.Followthe

instructionsincludedwiththeROPSKit.

Figure5

1.Hydraulicunitshroud2.Bolts

2.Removethe4nutsholdingtheseatplatetothe

machine.Discardthesenuts,theyareusedfor

shippingonly.

3

Page 4

Figure6

3.Securetheseatplatetotheseatwith4spacersand

4angenuts(3/8inch).

Figure7

4.Plugtheharnessconnectorintotheseatswitch

locatedundertheseattowardsthefront.

5.Installtheseattothemachineframewith4ange

nuts(3/8inch).

Figure8

1.Harnessconnector2.Flangenuts

6

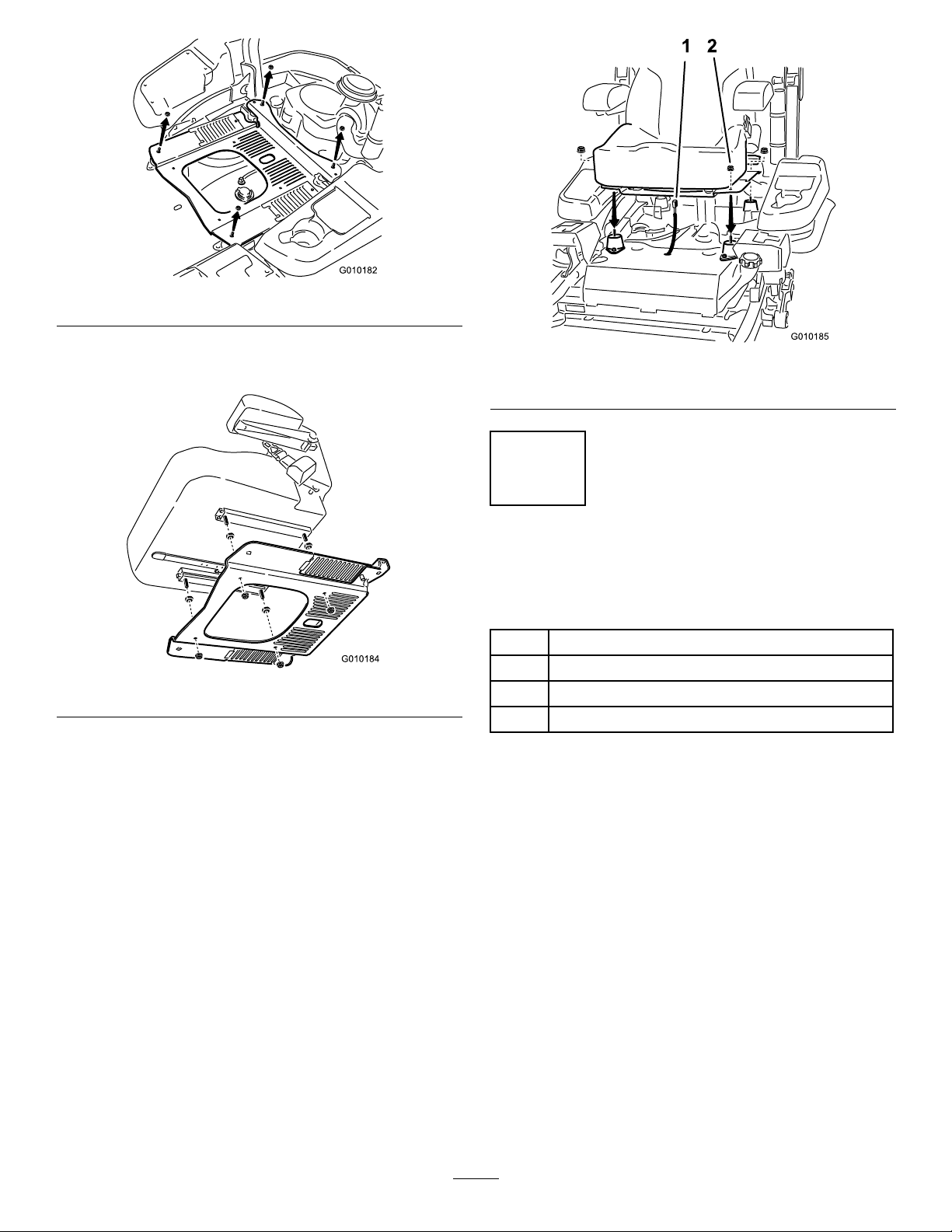

InstallingtheSeat(Modelsthat

haveatiltingoripupseat)

Partsneededforthisprocedure:

1

Seat

4

Flangenuts(3/8inch)

2

Longspacers(deluxeseatsonly)

4

Shortspacers(deluxeseatsonly)

Procedure

1.Tilttheseatframeup.

2.Fordeluxeseatsonly,installthespacersasshown

inFigure9.

4

Page 5

7

3

2

1

g014862

CheckingtheSeatBelt

NoPartsRequired

Procedure

Important:Ensurethebolttorqueissetbetween

49to61ft-lb(67to83N-m).

Theseatbeltangleandtheseatbeltbolttorqueneedto

becheckedbeforeoperating.

1.Checktheangleoftheseatbeltcomparedtothe

bottomoftheseat.Theangleneedstobe47

degrees.See(Figure11)

2.Ifneeded,settheseatbelttothecorrectangle.

3.Checkandsetthebolttorquebetween49to61ft-lb

(67to83N-m).

Figure9

Formowerswithadeluxeseatonly

1.Deluxeseat

2.Longspacer

3.Seatframe

4.Shortspacers

3.Installtheseattotheseatframewith4angenuts

(3/8inch)(Figure10).

4.Plugtheharnessconnectorintotheseatswitch

locatedundertheseattowardsthefront.

1.Sideofseat

2.Seatbeltbolt,Settorque

between49to61ft-lb(67

to83N-m)

Figure11

3.47degrees

1.Seatswitch

2.Flangenuts

Figure10

3.Harnessconnector

5

Page 6

8

InstallingtheMotionControl

Levers

Partsneededforthisprocedure:

1Rightcontrollever

1

Leftcontrollever

4

Bolt(3/8x1inch)(2areassembled)

4

Nut(3/8inch)(2areassembled)

Procedure

1.Rotatethemotioncontrolleverstotheupright

position.

Figure13

2.Looselyinstallthecontrolleversontheoutsideof

theposts,using4boltsand4nuts.

Note:Installthecontrolleversinthetopand

middleholesforthehighpositionorthemiddleand

bottomholesforthelowposition,asdesired.

Figure12

1.Bolt(3/8x1inch)3.Controllever

2.Handle

4.Nut(3/8inch)

Note:Ifthemachineisnotproperlytracking,refer

toAdjustingtheTrackinginyourOperator’sManual.

9

InstallingtheLiftAssistPedal

Partsneededforthisprocedure:

1

Carriagebolt(3/8x1-1/2inches)

1

Flangelocknut(3/8inch)

Procedure

1.Ifneeded,loosentheexistingboltandnutforthe

liftassistpedal.

2.Rotatetheliftassistpedaltothecorrectposition

andinstallthecarriagebolt(3/8x1-1/2inches)and

locknut(3/8inch)(Figure14).Tightenbothbolts.

3.Raisetheleversandalignthemtogetherinthe

neutralpositionandtightenthebolts.

6

Page 7

1 2

3

g016346

Figure14

1.Liftassistpedal3.Carriagebolt(3/8x1-1/2

inches)

2.Flangelocknut(3/8inch)

10

Figure15

2.Removetheaircleanercapfromthemachine.

3.Installthehoseclampontotheaircleanercap.

Figure16

InstallingtheAirCleanerCap

Partsneededforthisprocedure:

1Aircleanercap

1Hoseclamp

Procedure

Note:Notallunitscomewithaheavydutyaircleaner.

Thisprocedureonlyappliestomodelsthathaveaheavy

dutyaircleaner.

1.Removetheplasticplugortapecoveringtheair

cleaner.

4.Installtheaircleanercapontotheaircleanerand

secureitwiththehoseclamp.

Figure17

7

Page 8

11

InstallingaBattery(Model

numbersthatendwithCP

only)

Partsneededforthisprocedure:

1

Clamp

2

Wingnut(1/4inch)

2Batteryholddown

Procedure

1.Purchasea12Vbattery.

Chargethebattery.RefertotheOperator’sManualfor

instructions.

Figure18

Modelswitha29hpengineandbelowrequirea

batterywithaminimumof260CCA.

Modelswitha30hpengineandhigherrequirea

batterywithaminimumof340CCA.

2.Locatethebatterymountinghardwareandinstallit

intothemachine.RefertoInstallingtheBatteryin

theOperator’sManual.

12

ChargingtheBattery

NoPartsRequired

Procedure

Chargingthebatteryproducesgassesthatcan

explodeandcauseseriousinjury.

•Keepcigarettes,sparksandamesaway

fromthebattery.

13

CheckingtheEngineOilLevel

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoServicing

theEngineOilLevelinOperator’sManual.

14

AddingFueltotheMachine

NoPartsRequired

Procedure

Addgasolinetothemachinebeforestartingit.Refer

toyourOperator’ sManual.forthecorrectfueland

procedure.

•Makesuretheignitionswitchisoff.

•Ventilatewhenchargingorusingthebattery

inanenclosedspace.

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemayoccur

totheengine.

8

Page 9

G008942

1

2

4

3

Figure19

Figure20

2.Checkthegreaseforthepumpdrivebeltidlerarm.

15

CheckingtheMachinefor

Grease

Partsneededforthisprocedure:

1tube

Procedure

1.Checkthegreaseforthethreespindlebearingsand

Number2generalpurposelithiumbaseor

molybdenumbasegrease.(Purchaseseparately.)

theidlerpulley.Ifneeded,addgreaseuntilitcomes

outofthelowerseals.

Figure21

9

Page 10

16

g015594

1

6 2

4

7

3

5

CheckingtheSideDischarge

Chute

NoPartsRequired

Procedure

Ifthereareplastictiesholdingthesidedischargechute

up,removethemandlowerthechuteintoplace.

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresultin

seriousinjuryordeath.Also,contactwiththe

bladecouldoccur.

Neveroperatethelawnmowerwiththegrass

deectorremovedunlessyouinstallacover

plate,amulchplate,oragrasschuteand

catcher.

1.MakesureoneJendofthespringisinstalledbehind

thedeckedgebeforeinstallingtheboltasshownin

Figure22.

2.PlaceoneJhookendofthespringaroundthegrass

deector(Figure22).

Important:Thegrassdeectormustbefreeto

rotatewithdownwardtension.Liftthedeector

uptothefullopenpositionandensurethatit

rotatesfreely,withoutbindingintothefulldown

position.

Figure22

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring

5.Springinstalled(around

thegrassdeectorand

behindthedeckedge)

7.Jhookendofspring

10

Page 11

17

CheckingtheMachineBeforeDeliverytotheCustomer

NoPartsRequired

Procedure

Beforedeliveringthemachinetothecustomer,ensurethatyouperformorhaveperformedtheprocedureslistedin

thefollowingtableandinitialeachwhennished.RefertotheOperator’sManualforinstructionsonperforming

theseprocedures.

Initial

Checkthetirepressure.

Checkthelevelofthemower.

Checkthatallmowerspindlesaregreased.

Checktheengineoillevel.

Checkthehydraulicuidlevel.

CheckROPSissecure.

Onliquidcooledmachines,checkthelevelofthecoolantintheradiatorandoverowbottle.

Checktheadjustmentoftheparkingbrake.

Ensurethatthemachinetrackscorrectly;refertotheOperator’sManualfortheadjustmentprocedure.

Checkthesafetyinterlocksystem;refertotheOperator’sManual.

EnsurethatthePTOworks.

Checkallfastenersyouinstalledtoensurethattheyaretight.

CheckProcedure

Whenyounishsettingupthemachine,signanddateinthespaceprovidedbelow:

Signature:Date:

11

Page 12

18

DeliveringtheMachinetotheCustomer

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOwner’sManual

1

Operatortrainingmaterial

2Key

Procedure

Atdelivery,Fillinthemodelandserialnumberandcompletetheitemslistedinthefollowingtableandinitial

eachwhennished.

ModelNo.SerialNo.

12

Page 13

DealerInitial

CustomerInitialCheckProcedure

Showthecustomerwherethefollowingfeaturesarelocatedandhowtheyfunction:

•

Hourmeter/SafetyInterlockSymbols/BatteryIndicator/FuelGauge

•

Fueltankcap(s)

•

Oilllcap/Oildipstick

•

Sparkplug(s)

•

Engineoillter

•

Engineoildrain

•

Fuellter(s)

•

Airlter

•

Radiatorcoolant(ifapplicable)

•

Hydraulicuidreservoir

•

Hydrauliclter

•

Battery

•

Ignitionswitch

•

Throttlelever

•

Choke(ifapplicable)

•

Powertakeoffswitch(PTO)

•

Motioncontrollevers

•

Parkingbrake

•

Mowerheight-of-cut

•

Height-of-cutdeckliftpedal/TransportLock

•

ZStand®(ifapplicable)

•

Adjustableseat

•

Hydraulicbypassvalves

•

RolloverProtectionSystem(ROPS)

•

Mowerdeckowbafe

RefertotheOperator’sManualtopointoutsafetyprocedures,operation,and

maintenanceprocedures.

ReviewthewarrantystatementasshownintheOperator’sManual.

Describethepostsaleserviceproceduresforyourstore.

Assistthecustomerinllingoutandmailingtheregistrationcardorregisteronlineat

www.T oro.com

MakesurethatthecustomerreceivestheOperator’sManual,EngineOwner’sManual,

SetUpInstructions,andoperatortrainingmaterial.

MakesurethecustomerknowsthePartsCatalogisavailableatwww.Toro.com.

Assistthecustomerinloadingthemower.

Note:Whenyou,thedealerrepresentative,havenisheddeliveringthemachinetothecustomer,signanddatein

thespaceprovidebelowandkeepacopyofthispagefordealerrecords.

Signature:

Signature:Date:

Date:

13

Page 14

Notes:

14

Page 15

Notes:

15

Page 16

Loading...

Loading...