Toro 74901, 74901CP, 74902TE, 74903, 74903CP Service Manual

...

HY13-1521-M2/US

Parker Product

Effective: January, 2010

UHT

Product Series

Service Procedure

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS

DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized

distributors provide product and/or system options for further investigation by users having technical expertise. It

is important that you analyze all aspects of your application and review the information concerning the product or

system in the current product catalog. Due to the variety of operating conditions and applications for these

products or systems, the user, through its own analysis and testing, is solely responsible for making the final

selection of the products and systems and assuring that all performance, safety and warning requirements of the

application are met.

The products described herein, including without limitation, product features, specifications, designs, availability

and pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.

© Copyright 2009, Parker Hannifin Corporation, All Rights Reserved

2

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Section 1 General Information

Definitions/Disclaimer 4

Introduction/Design Features 5

Troubleshooting Guide 6

Troubleshooting Checklist 7

Tools & Materials Required for Servicing 8

Flow Test Instructions 9-10

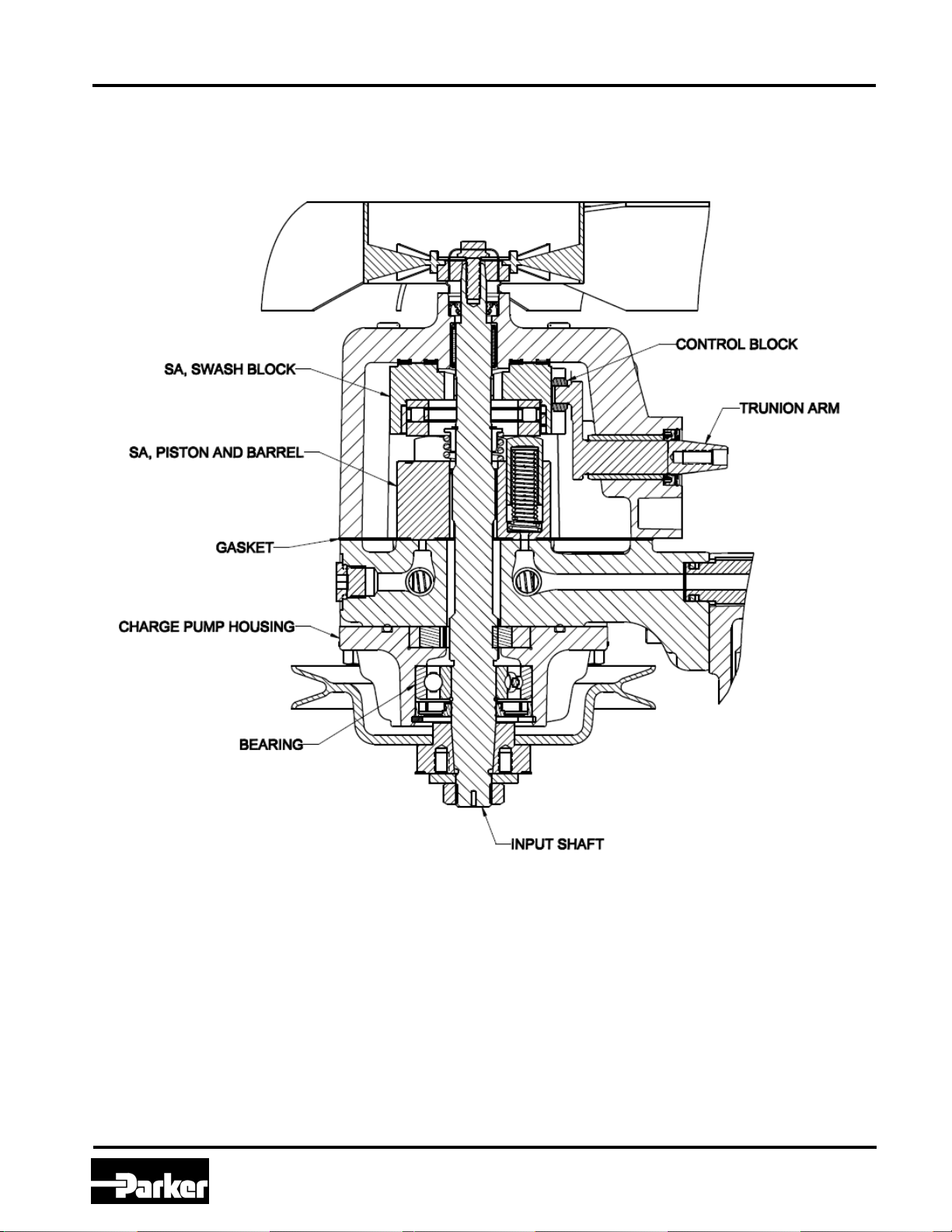

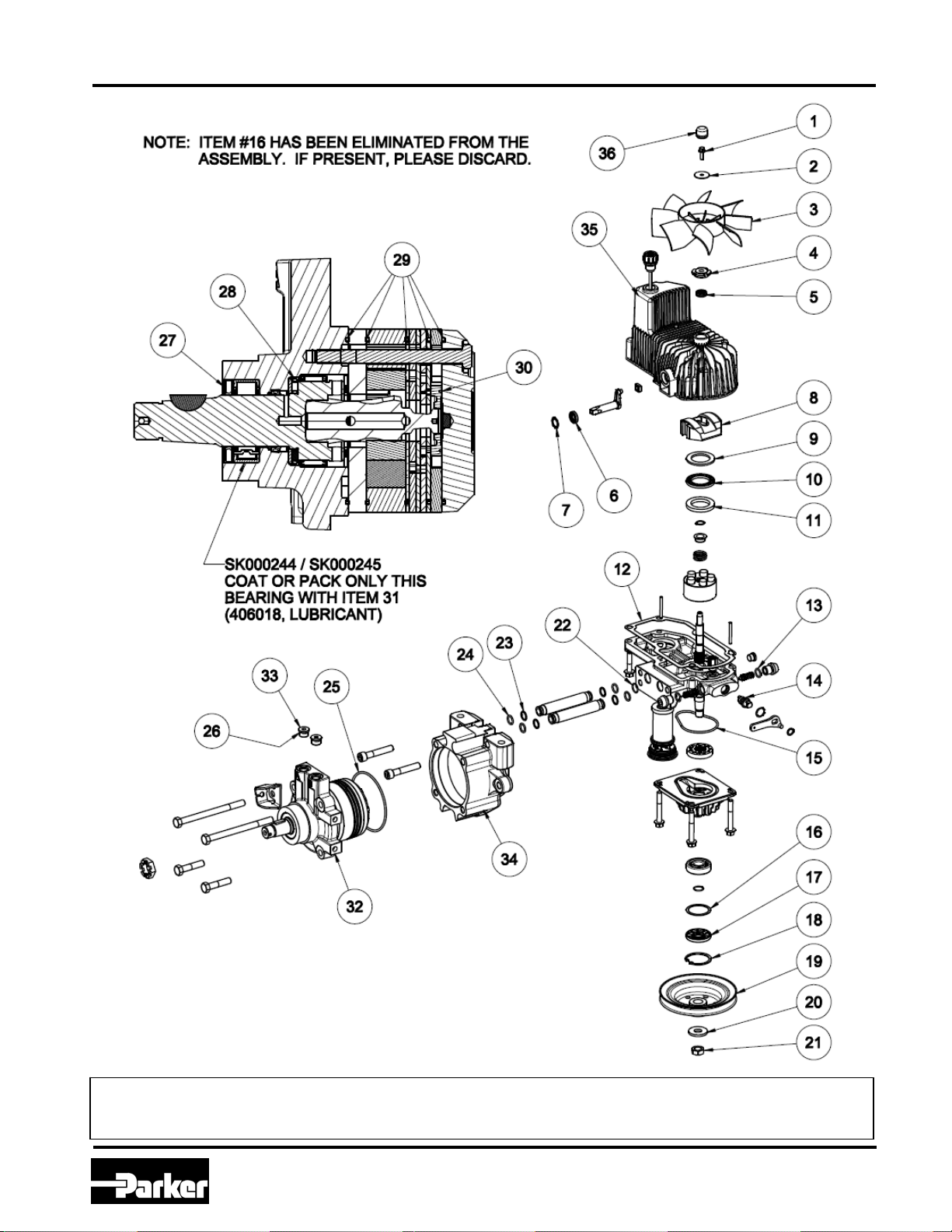

Exploded Views 11-20

Section 2 Reseal & Repair

Disassembly & Assembly - Fan Option 21

Disassembly 22-29

Assembly 30-38

Section 3 Maintenance

System Maintenance Tips 39

Hydraulic Fluids 39

Filtration 39

Oil Temperature 39

3

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

WARNING A warning describes hazards or unsafe practices which could result in severe

personal injury or death.

CAUTION

A caution describes hazards or unsafe practices which could result in personal injury or

product or property damage.

NOTE A note gives key information to make fo

llowing a procedure easier or quicker.

Disclaimer

This Service Manual has been prepared by Parker Hannifin Corporation for reference and u se by mechanics

who have been trained to repair and service hydraulic pumps on commercial and non-commercial equipment

applications. Parker Hannifin Corporation has exercised reasonable care and diligence to present accurate, clear

and complete information and instructions regarding the techniques and tools required for maintaining, repairing

and servicing the Parker UHT Series. Since this is a general Service Manual, the photographs and illustrations

may not look exactly like the UHT being serviced. The procedures, therefore, must be carefully read and

understood before servicing.

If inspection or testing reveals evidence of abnormal wear or damage to the UHT or if you encounter

circumstances not covered in the Manual, STOP - CONSULT THE EQUIPMENT MANUFACTURER’S SERVICE

MANUAL AND WARRANTY. DO NOT TRY TO REPAIR OR SERVICE A UHT Series WHICH HAS BEEN

DAMAGED OR INCLUDES ANY PART THAT SHOWS EXCESSIVE WEAR UNLESS THE DAMAGED AND

WORN PARTS ARE REPLACED WITH ORIGINAL PARKER REPLACEMENT AND SERVICE PARTS AND

THE UNIT IS RESTORED TO PARKER SPECIFICATIONS FOR THE UHT Series.

It is the responsibility of the mechanic performing the maintenance, repairs or service on a particular UHT Series

to (a) inspect the unit for abnormal wear and damage, (b) choose a repair procedure which will not endanger

his/her safety, the safety of others, the equipment or the safe operation of the UHT Series, and (c) fully inspect

and test the UHT Series and the hydraulic system to ensure that the repair or service of the UHT Series has

been properly performed and that the UHT Series and hydraulic system will function properly.

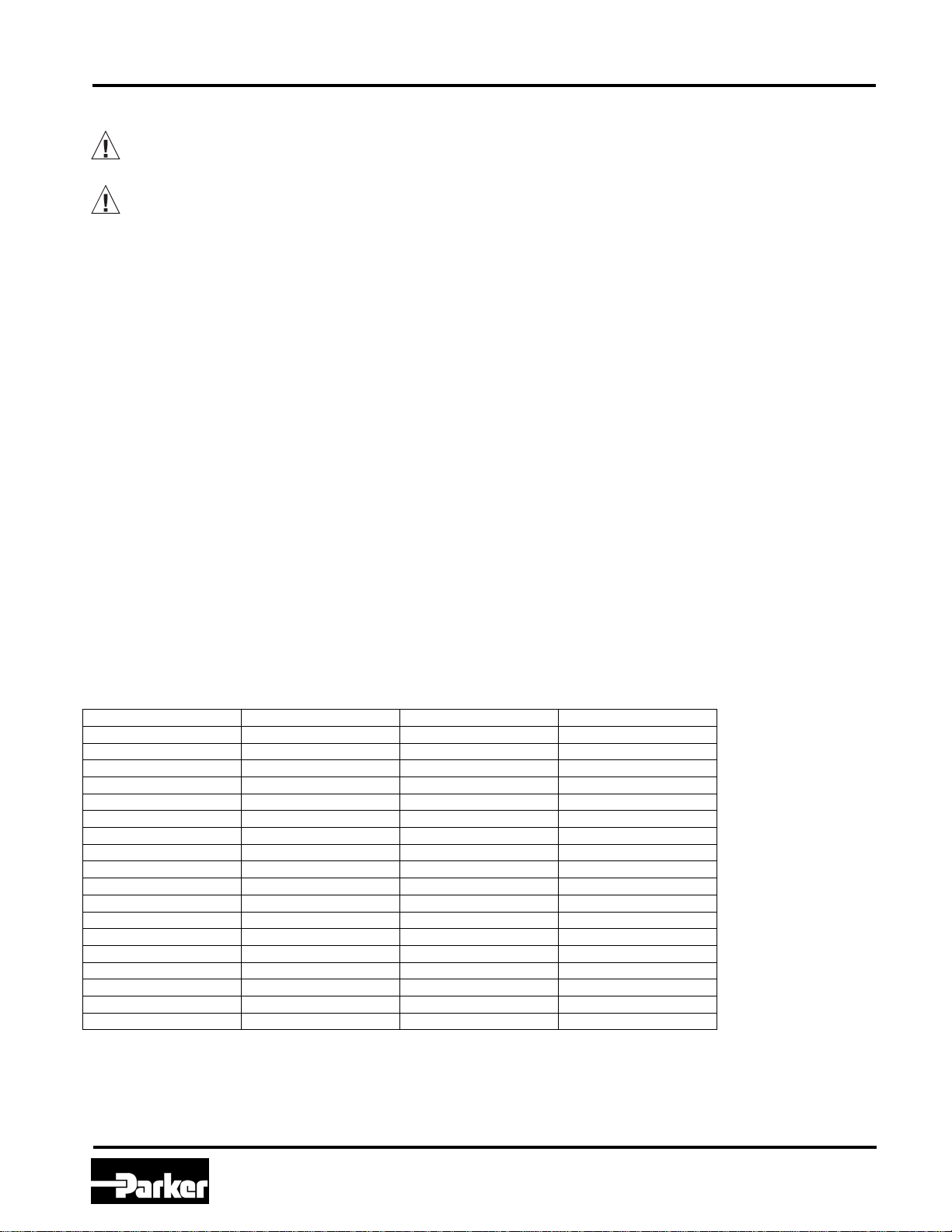

Conversions

Inches Mm Inches mm

.020 .511 1.060 26.92

.021 .531 1.295 32.89

.029 .741 1.297 32.94

.030 .760 1.396 35.46

.111 2.81 1.398 35.51

.119 3.02 1.620 41.15

.152 3.86 1.622 41.20

.160 4.06 1.983 50.37

.296 7.52 1.985 50.42

.304 7.72 2.120 53.85

.460 11.68 2.122 53.90

.470 11.94 2.233 56.72

.500 12.70 2.235 56.77

.585 14.86 2.483 63.07

.595 15.11 2.485 63.12

.660 16.76 2.500 63.5

.675 17.15 2.88 73.2

1.058 26.87

4

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Introduction

The three-column format used in this Service Manual will help make it easy for you to service a UHT. Column 1

illustrates the procedure with photographs, Column 2 gives a brief key for each step, and Column 3 explains in

detail the procedure you should follow. Pay special attention to the notes, cautions, and warnings.

This manual contains troubleshooting information and checklists. With them you can diagn ose a hydraulic

system problem without removing the entire assembly the checklists will help you to determine where the

problem may be.

Item numbers on the exploded view correspond with item numbers used throughout the Service Manual.

As you gain experience in servicing UHT Series, you may find that some information in this Service Manual

could be clearer and more complete. If so, let us know about it. Don’t try to second-guess the Service Manual; if

problems occur that you cannot solve, please contact your local OEM approved distributor. Servicing UHT Series

should be safe and productive.

DESIGN FEATURES

UHT

Large area cooling fins result in a cooler running system

Top housing and charge pump cover are sturdy, lightweight aluminum, excellent at

dispersing heat, resulting in an overall cooler system

Forged trunnion shaft increases shaft strength and lengthens pump life

Double caged thrust bearing improve lubrication and vibration absorption, thus

lengthening life of pump

Torqmotor

Roller vane to reduce friction and internal leakage and to maintain efficiency

A patented orbiting commutator system for less wear and longer life

A unique high-pressure shaft seal that eliminates the need for case drain

Manifold designed to improve operating efficiency

Roller vane and sealed commutation assure high volumetric efficiency and smooth low

speed operation

5

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Troubleshooting Guide

NOTE

Before troubleshooting any system problem, check

service literature published by the equipment and/or

component manufacturers. Follow their instructions, if

given, for checking any component other than the

transmission.

Preparation

Make your troubleshooting easier by preparing as

follows:

• work in a clean, well-lighted place

• have proper tools and materials nearby

• have an air pressure source.

WARNING

Since solvents are flammable, be extremely careful

when using any solvent. Even a small explosion could

cause injury or death.

WARNING

Wear eye protection and be sure to comply with

OSHA and other maximum air pressure

requirements.

Preliminary Checks

Hydraulic systems are often trouble-free. Hence, the

problem an operator complains of could be caused by

something other than the hydraulic components.

Thus, once you have determined that a problem

exists, start with the easy-to-check items, such as:

• Parts damaged from impact that were not properly

repaired, or that should have been replaced

• Improper replacement parts used in previous

servicing

• Mechanical linkage problems such as binding,

broken or loose parts, or slipping belts

Hydraulic Components

If you think the problem is caused by a hydraulic

component, start by checking the easy-to-reach

items.

Check all belts for cracks, hardening or other signs of

wear. Check all pulleys, fans and bolts to make sure

they are tightened to specified torque value. Look for

leaks, especially at coupling shaft, plugs and fittings.

Next, go to the reservoir and filters. Check fluid level

and look for air bubbles. Check external filter(s). A

filter with a maximum of 25 - 30 micron filtration is

recommended for the UHT system.

Visually check other components to see if they are

loosely mounted, show signs of leaks, or other

damage or wear.

Excessive heat in a hydraulic system can create

problems that can easily be overlooked. Every

system has its limitation for the maximum amount of

temperature. After the temperature is attained and

passed, the following can occur:

• oil seal leaks

• pump loss of efficiency (resulting in lower

transmission speeds)

• pump failure

• belts become hard and brittle

• pulley lose

A normal temperature range means an efficient

hydraulic system. Consult the manuals published by

equipment and/or component manufacturers for

maximum allowable temperatures and hydraulic tests

that may be necessary to run on the performance of

the hydraulic components. The UHT is not

recommended for hydraulic systems with maximum

temperatures above 280

o

F (137o C).

6

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

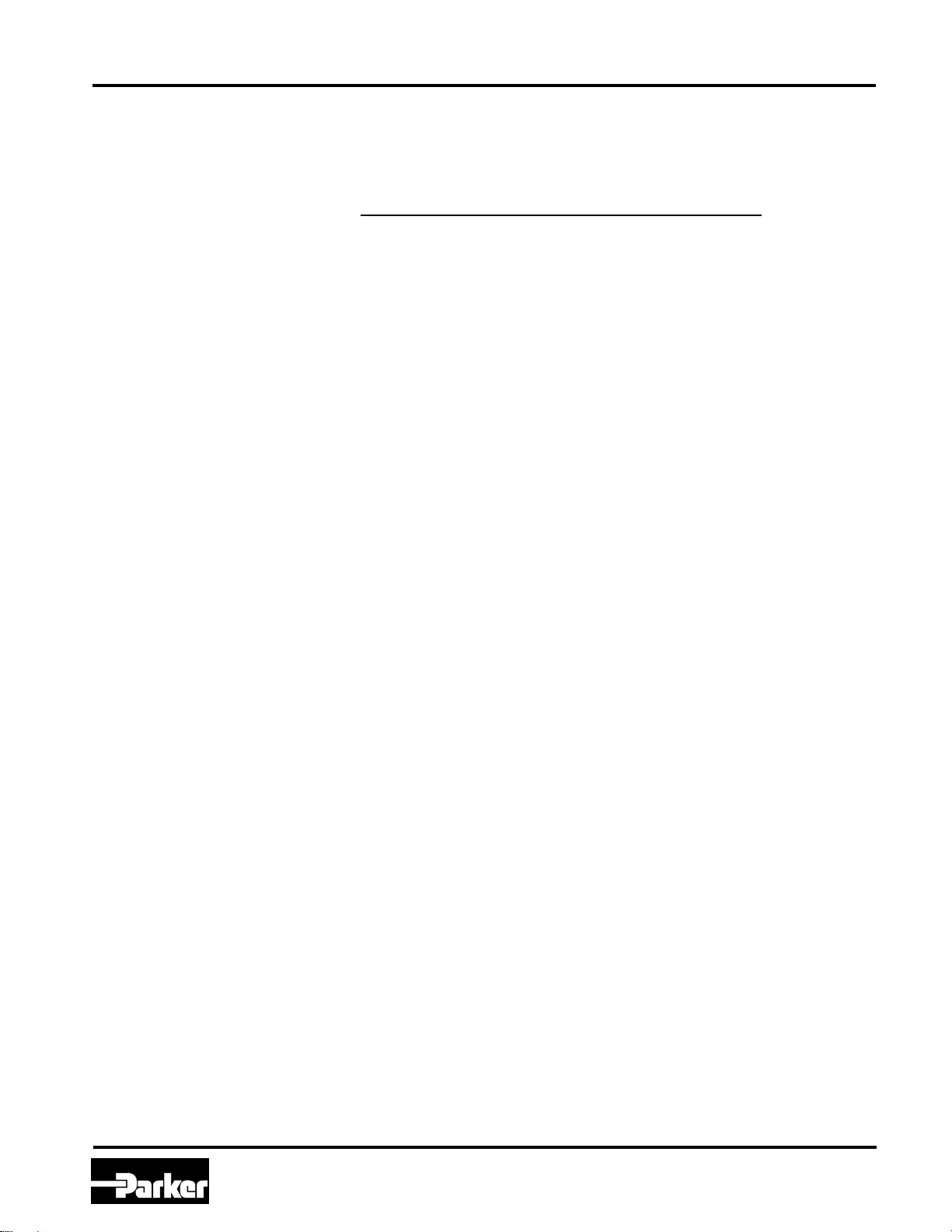

Troubleshooting Checklist

Trouble Cause Remedy

Oil Leakage

Operates Hot

1. Fitting loose, worn or

damaged.

2. Oil seals deteriorated

by excess heat.

1. Debris buildup Remove debris

2. Cooling fan damaged Replace fan

Check & replace damaged fittings or

“O” rings. Torque to manufacturers

specifications.

Replace oil seals by disassembling

unit.

No/Low Power

3. Oil level low or

Fill or change filter

contaminated

4. Excessive loading Reduce vehicle load

5. Air trapped in system

Run vehicle slowly forward and then

reverse several times

6. Mowing conditions Heavy grass or embankments

1. Engine speed low Adjust setting

2. Oil level low or

Fill or change filter

contaminated

3. Bypass turned Turn to closed (horizontal) position

4. Excessive loading Reduce vehicle load

5. Air trapped in system Purge per instructions

6. Suspect internal Disassemble and inspect

7. Pulley or belt loose

Tighten to specifications

Noisy Unit

1. Excessive speed input Adjust input speed above 1800 rpm

and below 3600 rpm

2. Oil level low or

Fill or change filter

contaminated

3. Excessive loading Reduce vehicle load

4. Air trapped in system Run vehicle slowly forward and then

reverse several times

5. Bypass valve open

Turn to closed (horizontal) position

7

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Tools and Materials Required for Servicing

• Clean, petroleum-based solvent

• Emery paper

• Vise with soft jaws

• Air-pressure source

• Arbor press

• Flat screwdriver

• Grease pencil or paint pen

• Wheel puller

• 1/4" torque wrench : 155-190 in-lbs, 282-342 in-lbs, 90-110 in-lbs, 160-200 in-lbs

• Sockets: 3/8" drive ratchet, 5/16" hex, 1/4” hex, 3/8” hex, 10mm, 14mm, 16mm

• Allen wrenches: 5mm, 6mm, 1/4" and 3/8”

• Combination wrenches:

• Locking pliers

• Internal & external snap ring pliers

• Loctite ™ 242

• Grease – Mobil Mobilith SHC PM 460

• Oil – Recommended OEM Type Oil

• Four inch adjustable spanner wrench (Armstrong 34-157) or three inch fixed spanner (Armstrong 34-

124)

CAUTION

Mixing greases that have different bases can be detrimental to bearing and seal life.

8

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

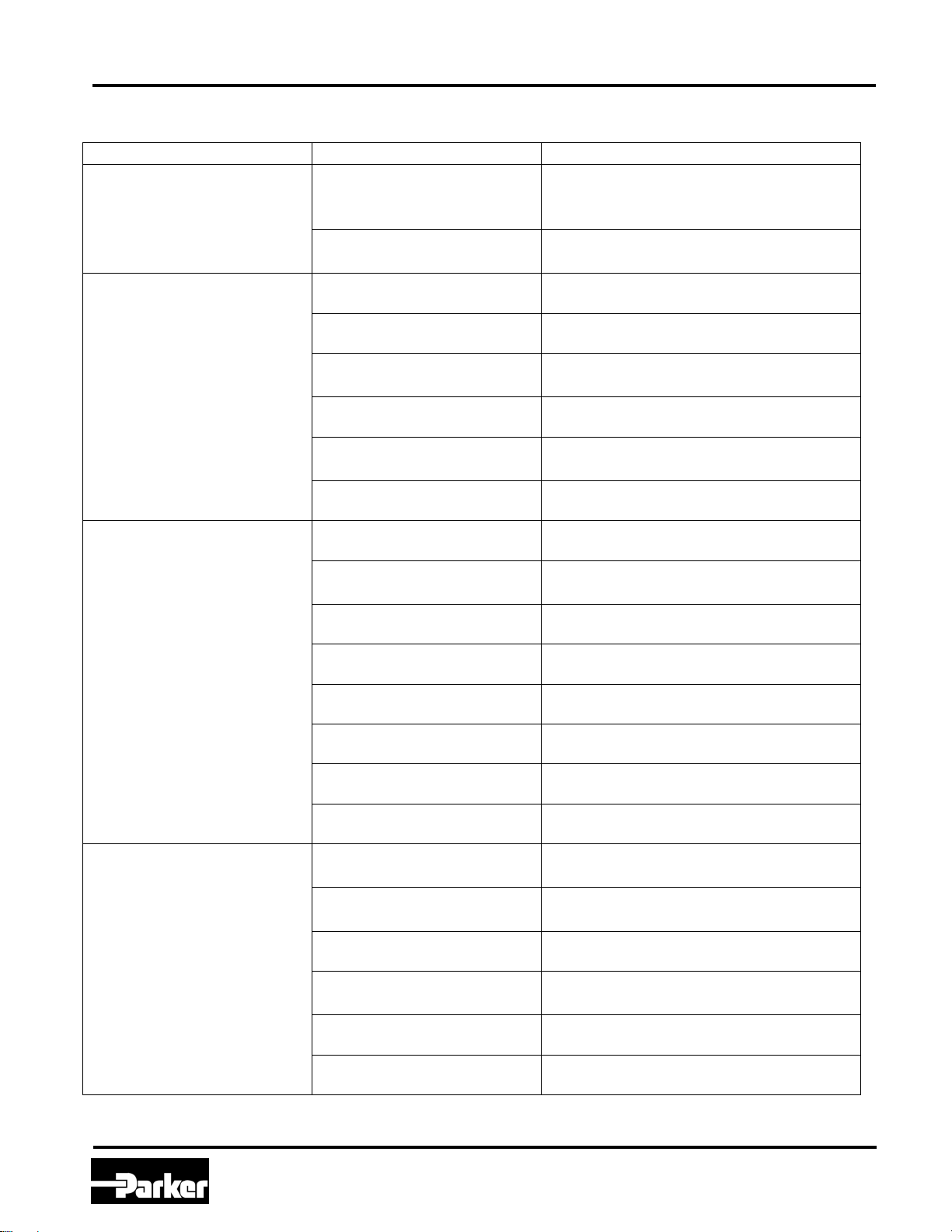

UHT Flow Test Kit Instructions

SK000251

Parts List

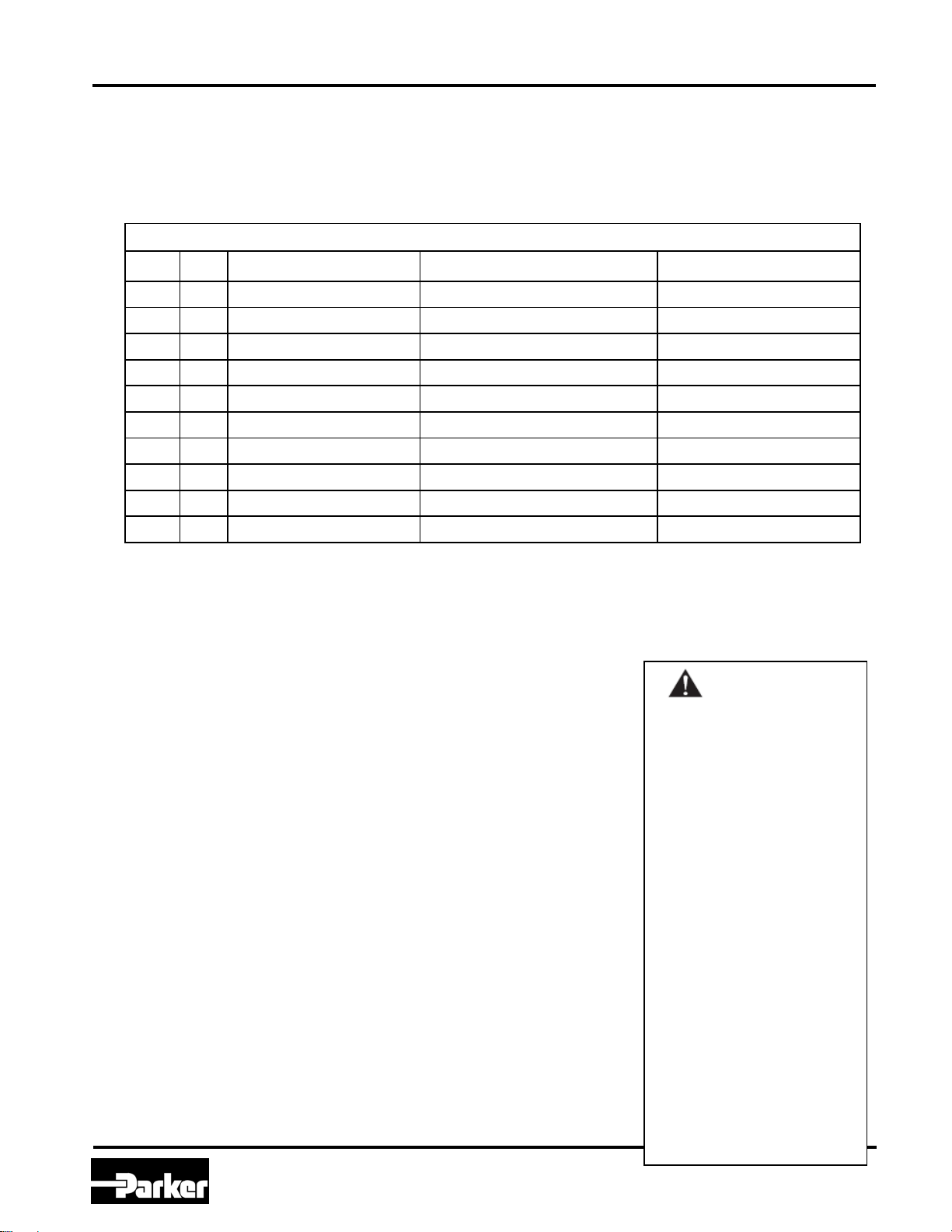

Item Qty Part Number

1

2 1 411102 Needle Valve 525 in lbs.

3 2 414003 Gauge Fitting “T” 165-525 in lbs.

4 2 411103 3000 PSI Pressure Gauge 165 in lbs.

5 2 411104 Hose Assembly 525 in lbs.

6 2 414005 Reducer Fitting 525-950 in lbs.

7 1 411105 20 GPM Flow Meter 525 in lbs.

8 1 409350 Diagnostic Plug 525 in lbs.

9 1 SAE-J514-8-8-070120CF Straight Thread Fitting 525 in lbs.

- 1 SK000251 Service Bulletin N/A

1 414002 SAE Swivel Fitting 525 in lbs.

Description

Torque

Overview:

The Flow Test Kit allows the dealer to easily determine if UHT pump is faulty by isolating the

pump section from the wheel motor. The following information describes how to test the pump

by installing the Flow Test Kit and simulating a wheel motor load.

Procedure:

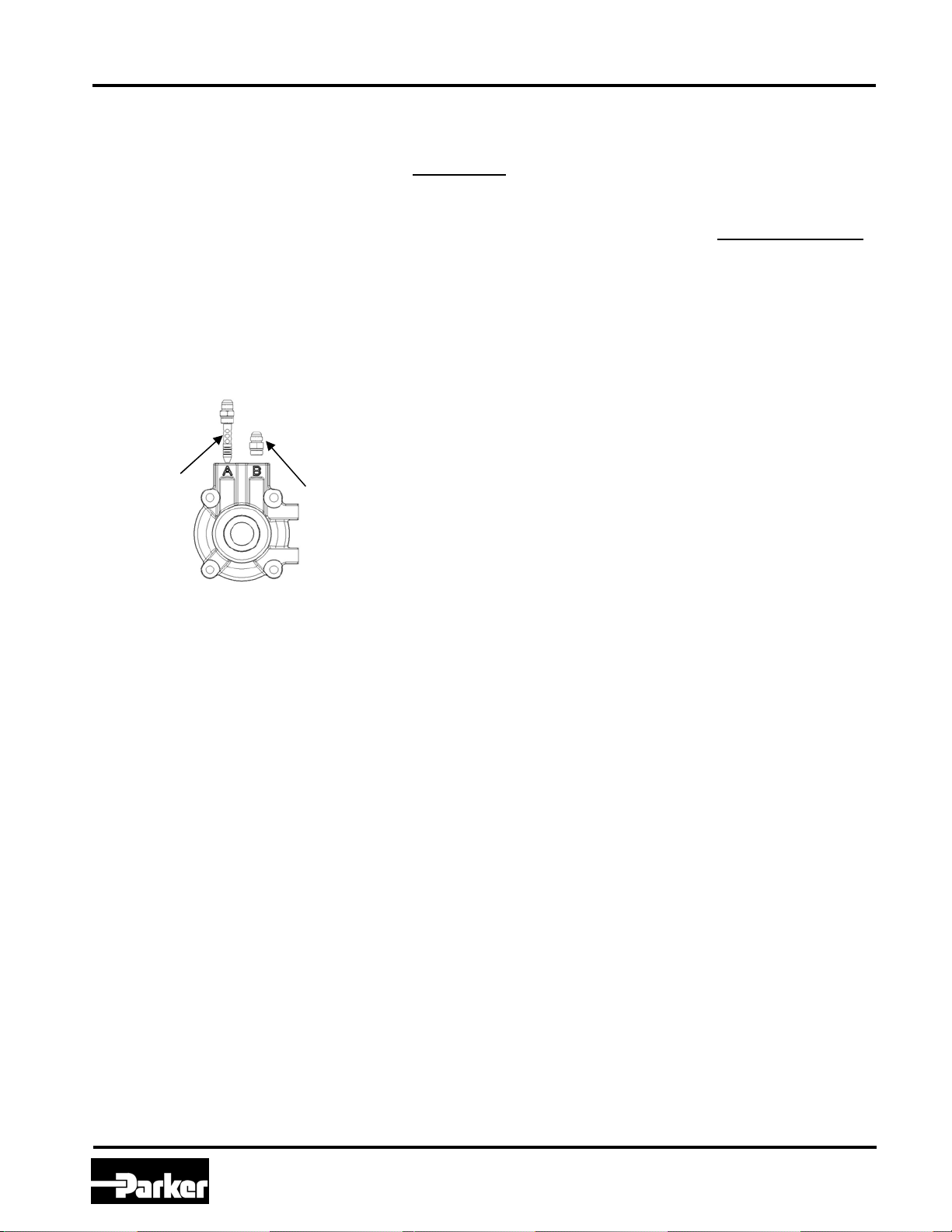

1. Raise the drive tires off the ground and block the remaining

tires to prevent movement of the vehicle during testing.

2. Remove wheel from the hub to gain access to motor.

3. Ensure the pump bypass lever is in the “Closed” position

(horizontal).

4. Isolate the pump from the wheel motor by removing the two

plugs from the top of the wheel motor assembly and installing

the Flow Test Kit. Install the Diagnostic Plug in port “A”, and the

Straight Thread Fitting in port “B”. Take precautions to ensure

no debris gets into the wheel motor system ports.

There is no need to determine the direction of flow with the

Parker flow tester. The flow meter may be connected in either

direction into the high pressure system lines.

9

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

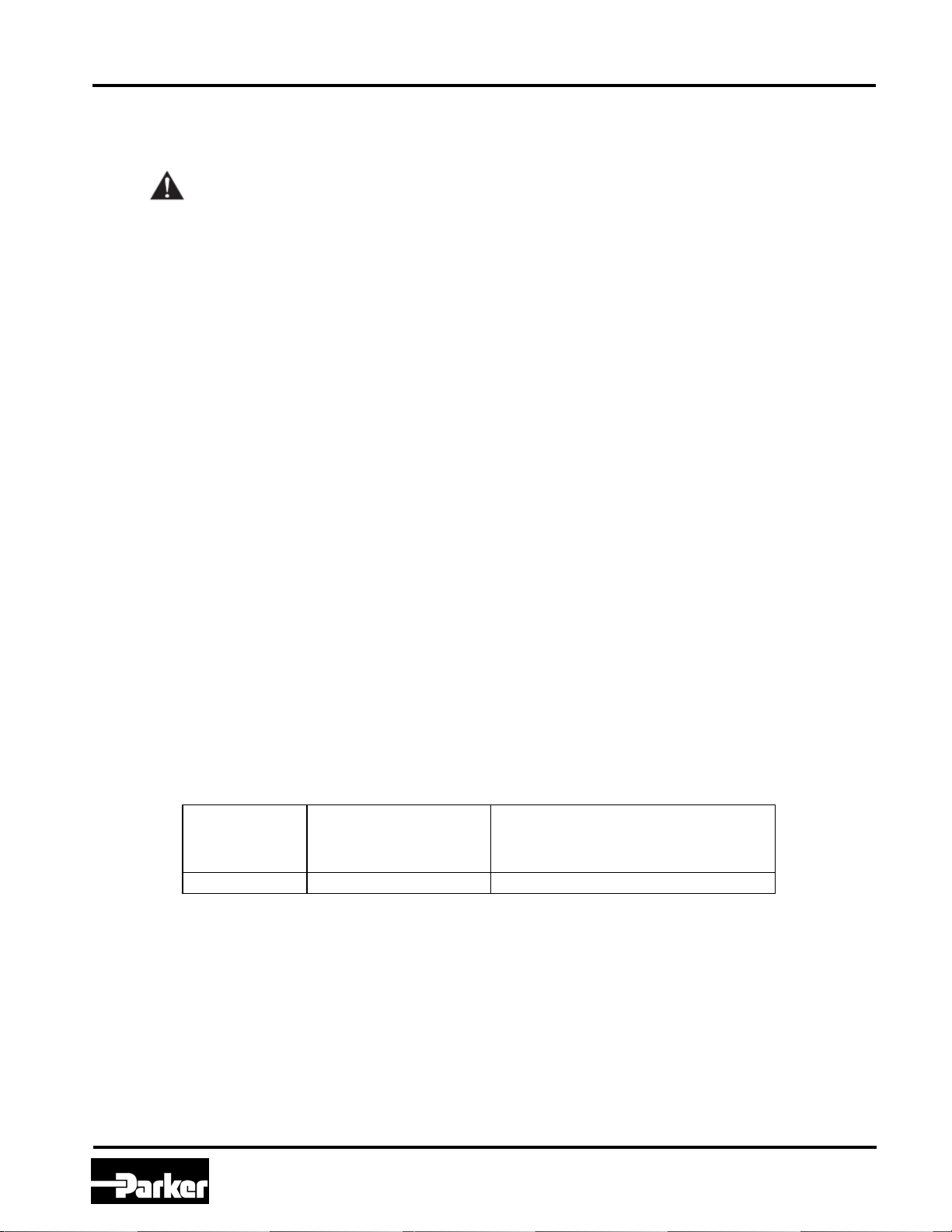

WARNINGS

Portions of this procedure

require testing while the

vehicle is operated in an

elevated position.

Ensure vehicle is properly

secured to prevent injury

to the service technician

or bystanders.

Do not attempt any adjustments with the engine

running. When working

around vehicle linkages,

use extreme caution.

High temperatures can be

generated.

Follow all safety procedures in the vehicle owner’s manual.

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

CAUTION: All fittings and hoses must be securely attached. The test is

accomplished using the vehicle’s high pressure system lines. Failure to secure

connections could result in bodily injury.

5. Completely open the restriction valve.

6. Start the engine and, if required, engage the drive pulley.

7. Slowly bring engine up to maximum operating speed.

8. Move the vehicle’s directional control lever on the pump being tested all the way into the

forward position. Lock the control arm into position to prevent false readings.

9. Continue to operate without any load to allow the system oil temperature to rise.

NOTE: Raising the temperature of the oil will make a difference in your readings. To complete

the test accurately, the oil temperature should fall between 110˚ and 140˚ F.

10. Tighten the restriction valve until the difference between the pressure gauge readings is

300 psi (21 bar). Record the flow reading from the bi-directional flow meter.

11. Tighten the restriction valve until the difference between the pressure gauge readings is

1000 psi (69 bar) and record the flow reading again.

12. The maximum allowable flow rate change is shown below. If the difference exceeds this

level, the pump is unacceptable.

13. When testing is complete, re-install the motor port plugs. Torque to 35 to 50 ft-lb.

Displacement

Series

cc/rev

(nominal)

UHT 12 to 16 1.0

* Max. Allowable Flow Rate Change is equal to the flow rate at 300 psi minus the flow rate at 1000 psi.

Max. Allowable Flow Rate

Change* (gpm)

10

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

EXAMPLE:

First Reading 300 psi (21 bar) 5 gpm (19 l/min)

Second Reading 1000 psi (69 bar) - 3 gpm (11 l/min)

Difference 2 gpm (8 l/min)

By subtracting the second reading from the first, a

defective pump can be identified. In the example

above, 2 gpm indicates a defective pump.

11

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

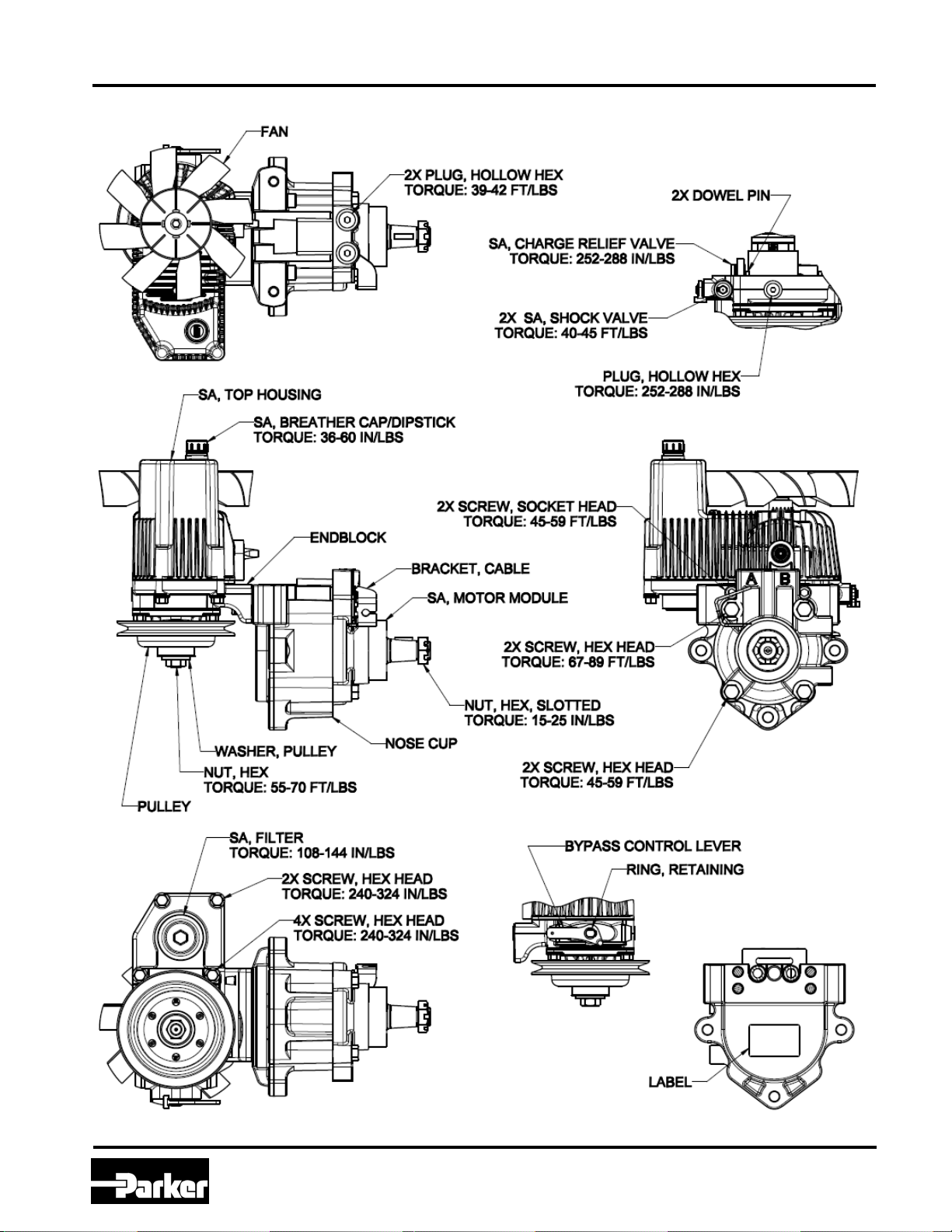

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

12

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

13

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

HY13-1521-M2/US Service Manual

General Information Series HB Hydrostatic Transmission

Note: When servicing UHT assemblies with a serial number code of 09256 or earlier, item 29 is not req uired.

When servicing UHT assemblies with a serial number code of 09257 or after, item 25 is not required. Though item 22 is

provided in the seal kit, it can be discarded if the endblock does not include a machined seal groove.

14

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, Tennessee USA

Loading...

Loading...